Plasticized Mechanical Recycled PLA Films Reinforced with Microbial Cellulose Particles Obtained from Kombucha Fermented in Yerba Mate Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

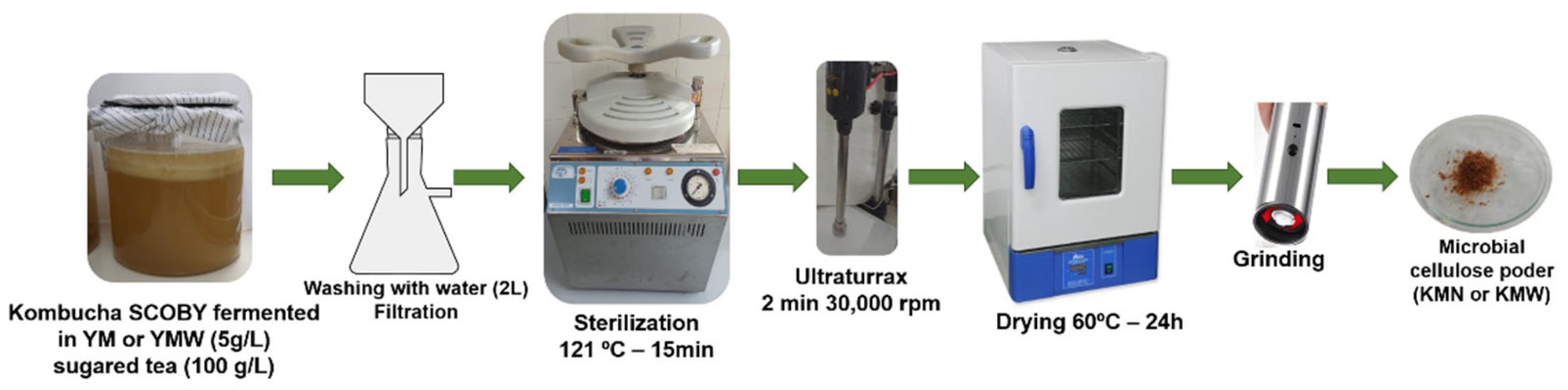

2.2. Processing of Kombucha to Obtain Cellulosic Particles from Yerba Mate Waste

2.3. Processing and Reprocessing of PLA

2.4. Films Preparation

2.5. Characterization of the Films

2.5.1. UV-Visible Measurements

2.5.2. Scanning Electron Microscopy

2.5.3. Differential Scanning Calorimetry

2.5.4. Thermogravimetric Analysis

2.5.5. Tensile Test Measurements

2.5.6. Static Contact Angle Measurements

2.5.7. Water Vapor Transmission Rate

2.5.8. Specific Migration Test and Antioxidant Activity

3. Results

3.1. Reprocessed PLA Characterization

3.2. UV-Visible Measurements

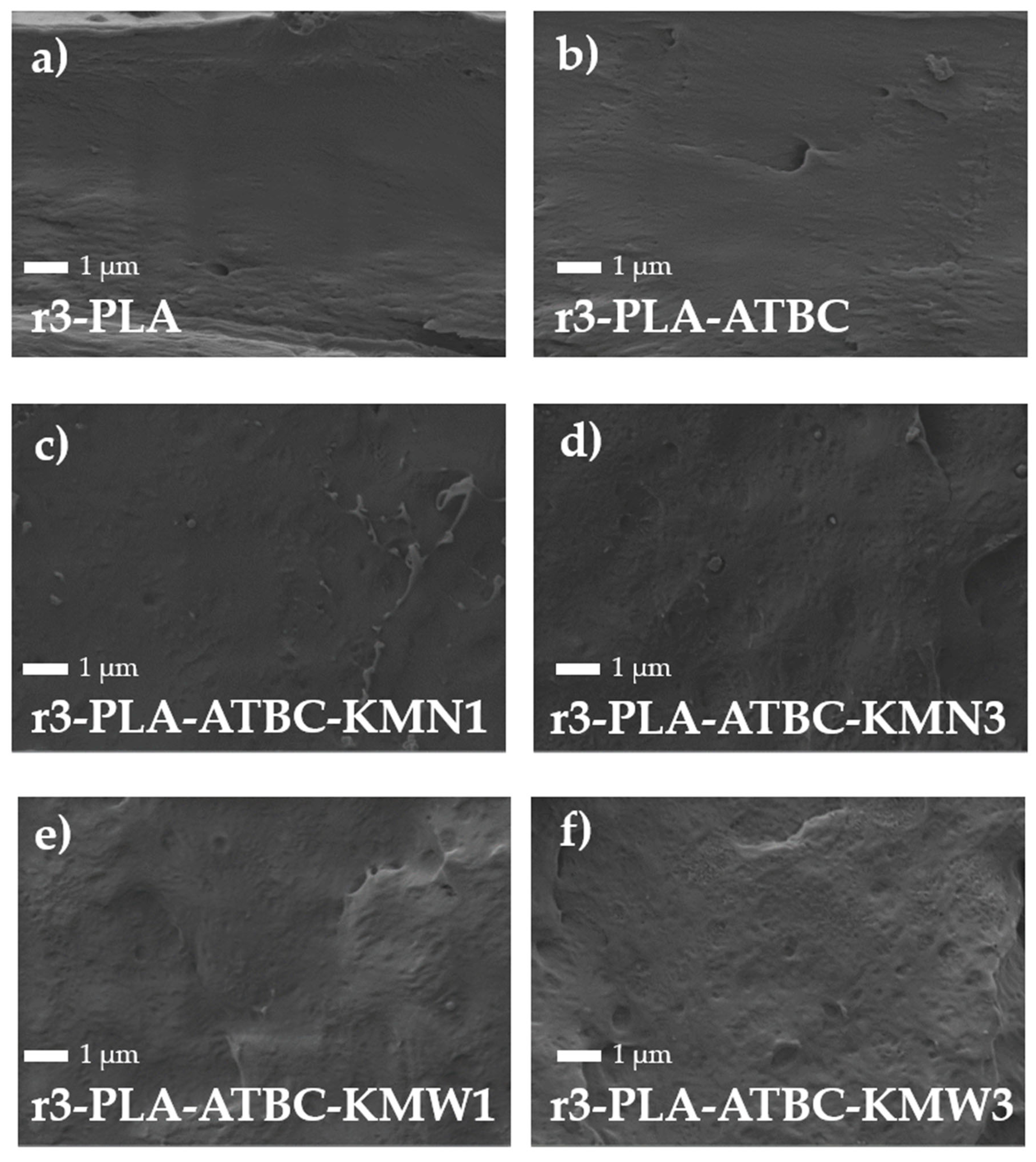

3.3. Scanning Electron Microscopy

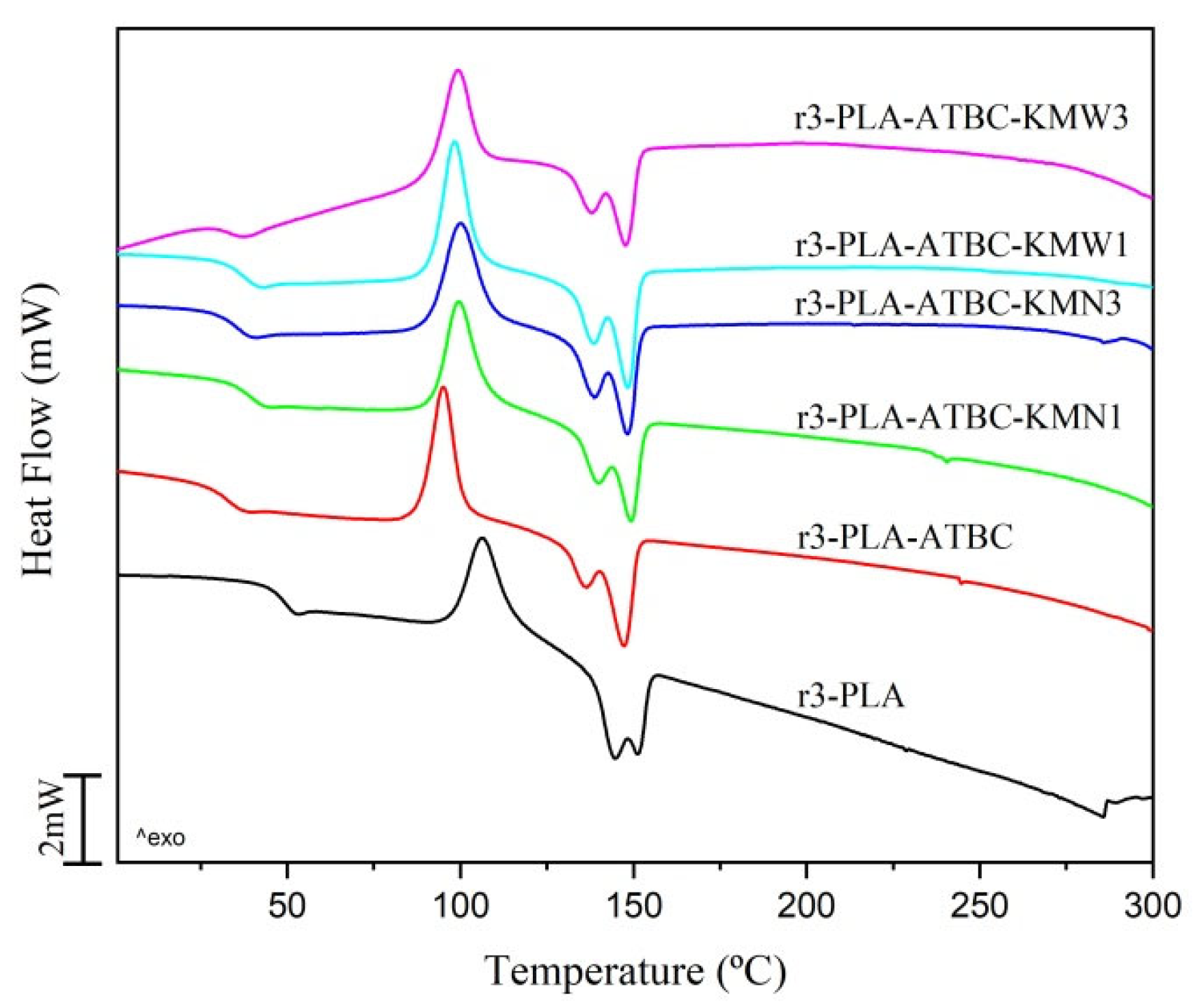

3.4. Differential Scanning Calorimetry

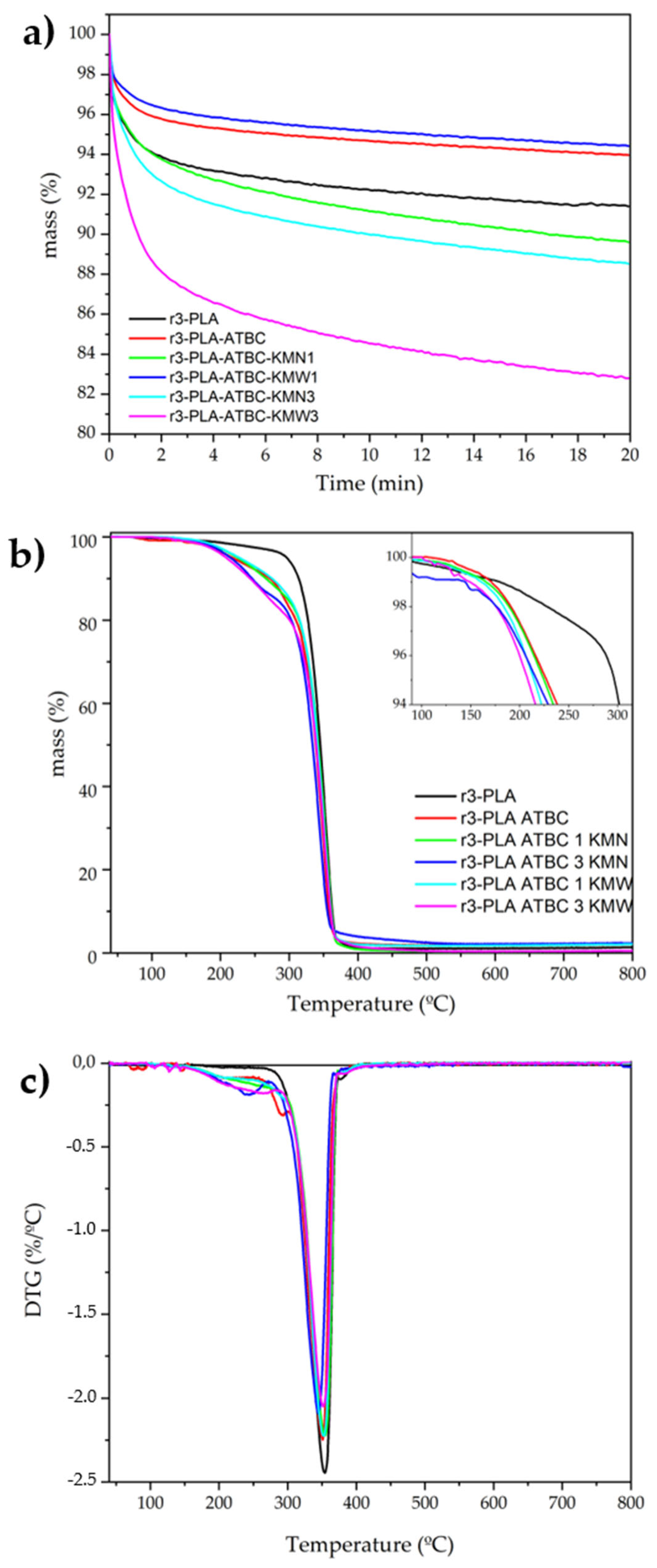

3.5. Thermogravimetric Analysis

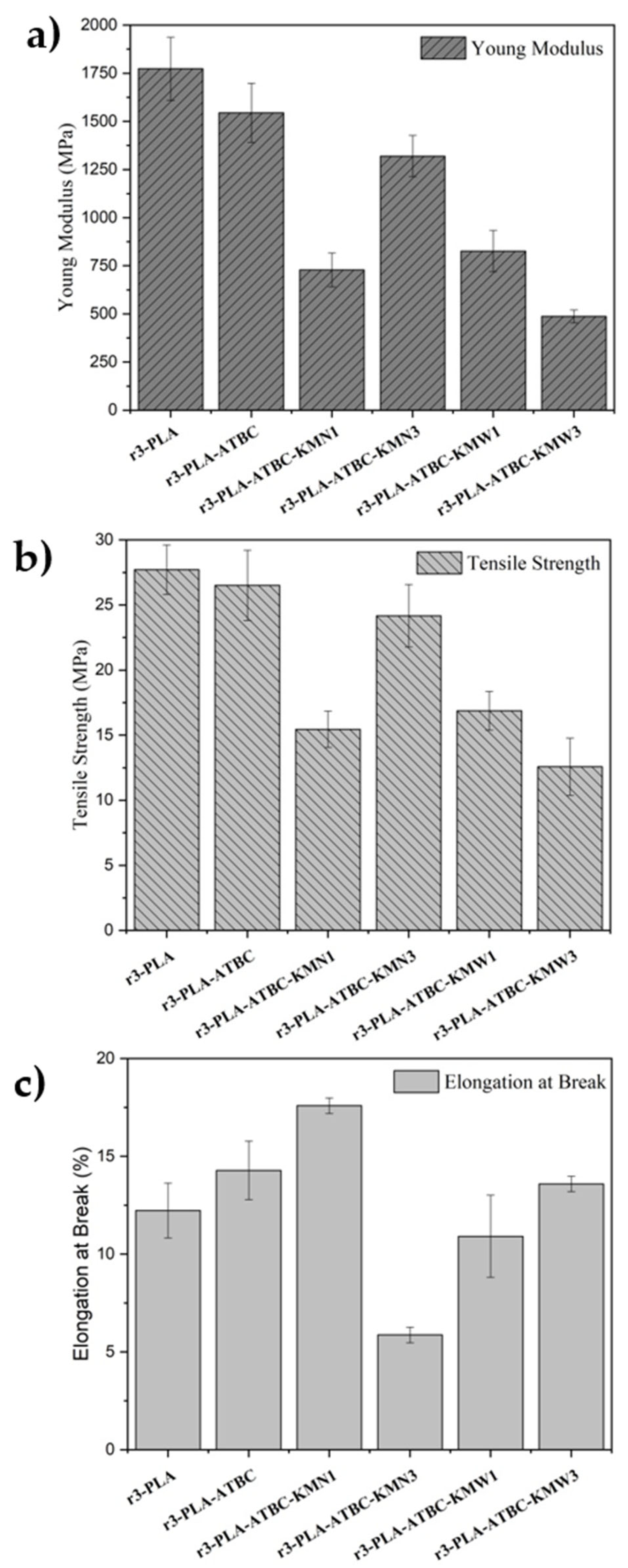

3.6. Tensile Test

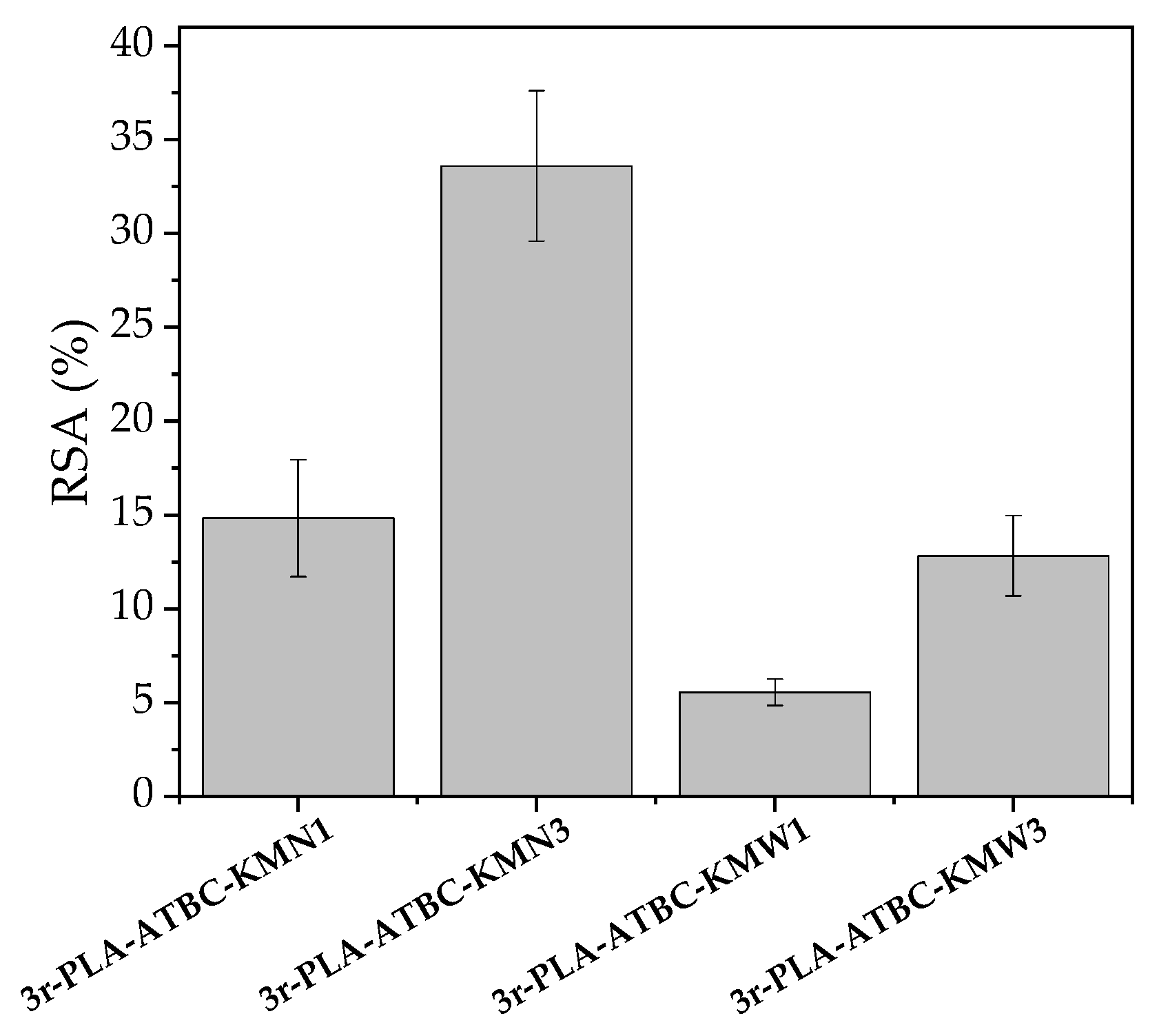

3.7. Release Studies and Antioxidant Ability

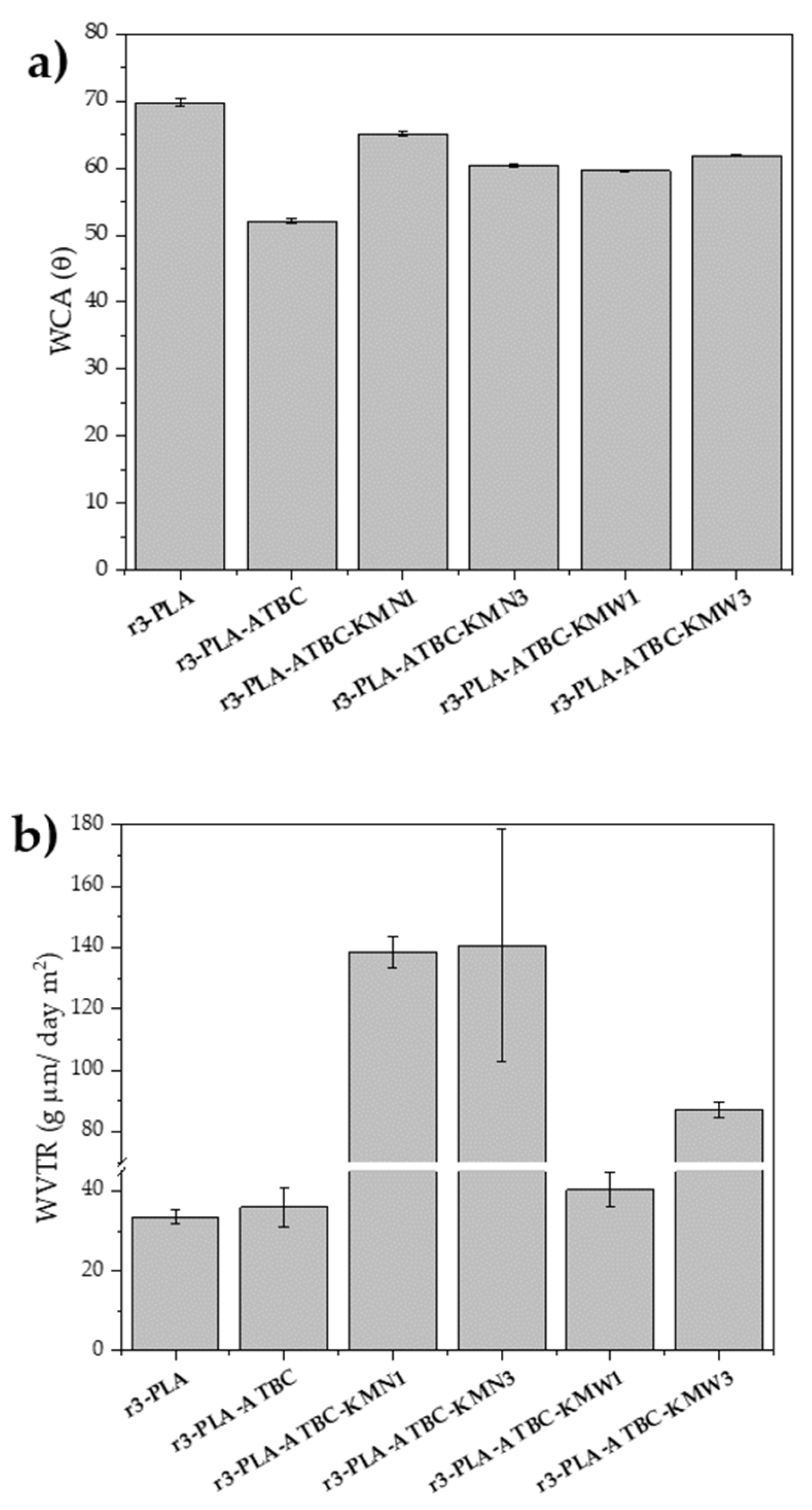

3.8. Water Contact Angle and Water Vapor Transmission Rate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Garcia-Garcia, D.; Carbonell-Verdu, A.; Arrieta, M.P.; López-Martínez, J.; Samper, M. Improvement of PLA film ductility by plasticization with epoxidized karanja oil. Polym. Degrad. Stab. 2020, 179, 109259. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An Overview of Polylactides as Packaging Materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef] [PubMed]

- Hernández-García, E.; Vargas, M.; Chiralt, A. Effect of active phenolic acids on properties of PLA-PHBV blend films. Food Packag. Shelf Life 2022, 33, 100894. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; López, J. On the Use of PLA-PHB Blends for Sustainable Food Packaging Applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef]

- Arrieta, M.P. Influence of plasticizers on the compostability of polylactic acid. J. Appl. Res. Technol. Eng. 2021, 2, 1–9. [Google Scholar] [CrossRef]

- Gil Muñoz, V.; Muneta, L.M.; Carrasco-Gallego, R.; de Juanes Marquez, J.; Hidalgo-Carvajal, D. Evaluation of the Circularity of Recycled Pla Filaments for 3d Printers. Appl. Sci. 2020, 10, 8967. [Google Scholar] [CrossRef]

- Beltrán, F.; Arrieta, M.; Antón, D.E.; Lozano-Pérez, A.; Cenis, J.; Gaspar, G.; de la Orden, M.; Urreaga, J.M. Effect of Yerba Mate and Silk Fibroin Nanoparticles on the Migration Properties in Ethanolic Food Simulants and Composting Disintegrability of Recycled PLA Nanocomposites. Polymers 2021, 13, 1925. [Google Scholar] [CrossRef]

- de Andrade, C.M.; Souza, F.P.; Cavalett, O.; Morales, A.R. Life Cycle Assessment of Poly(Lactic Acid)(PLA): Com-parison between Chemical Recycling, Mechanical Recycling and Composting. J. Polym. Environ. 2016, 24, 372–384. [Google Scholar] [CrossRef]

- Samper, M.D.; Arrieta, M.P.; Ferrandiz, S.; López, J. Influence of Biodegradable Materials in the Recycled Polystyrene. J. Appl. Polym. Sci. 2014, 131, 41161. [Google Scholar] [CrossRef]

- Samper, M.D.; Bertomeu, D.; Arrieta, M.P.; Ferri, J.M.; López-Martínez, J. Interference of Biodegradable Plastics in the Polypropylene Recycling Process. Materials 2018, 11, 1886. [Google Scholar] [CrossRef]

- Aldas, M.; Pavon, C.; De La Rosa-Ramírez, H.; Ferri, J.M.; Bertomeu, D.; Samper, M.D.; López-Martínez, J. The Impact of Biodegradable Plastics in the Properties of Recycled Polyethylene Terephthalate. J. Polym. Environ. 2021, 29, 2686–2700. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (Eu) 2022/1616 of 15 September 2022 on Recycled Plastic Materials and Articles Intended to Come into Contact with Foods, and Repealing Regulation (Ec) No 282/2008 (Text with Eea Relevance); European Commission: Brussels, Belgium, 2022. [Google Scholar]

- Agüero, A.; Morcillo, M.d.C.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Lascano, D.; Torres-Giner, S.; Fenollar, O. Study of the Influence of the Reprocessing Cycles on the Final Properties of Polylactide Pieces Obtained by Injection Molding. Polymers 2019, 11, 1908. [Google Scholar] [CrossRef] [PubMed]

- Chariyachotilert, C.; Joshi, S.; Selke, S.; Auras, R. Assessment of the properties of poly(L-lactic acid) sheets produced with differing amounts of postconsumer recycled poly(L-lactic acid). J. Plast. Film Sheeting 2012, 28, 314–335. [Google Scholar] [CrossRef]

- Arrieta, M.; Peponi, L.; López, D.; Fernández-García, M. Recovery of yerba mate (Ilex paraguariensis) residue for the development of PLA-based bionanocomposite films. Ind. Crop. Prod. 2018, 111, 317–328. [Google Scholar] [CrossRef]

- Tapias, Y.A.R.; Di Monte, M.V.; Peltzer, M.A.; Salvay, A.G. Bacterial cellulose films production by Kombucha symbiotic community cultured on different herbal infusions. Food Chem. 2021, 372, 131346. [Google Scholar] [CrossRef] [PubMed]

- Ashrafi, A.; Jokar, M.; Nafchi, A.M. Preparation and characterization of biocomposite film based on chitosan and kombucha tea as active food packaging. Int. J. Biol. Macromol. 2018, 108, 444–454. [Google Scholar] [CrossRef] [PubMed]

- Tapias, Y.A.R.; Peltzer, M.A.; Delgado, J.F.; Salvay, A.G. Kombucha Tea By-product as Source of Novel Materials: Formulation and Characterization of Films. Food Bioprocess Technol. 2020, 13, 1166–1180. [Google Scholar] [CrossRef]

- Deladino, L.; Teixeira, A.; Navarro, A.; Alvarez, I.; Molina-García, A.; Martino, M. Corn starch systems as carriers for yerba mate (Ilex paraguariensis) antioxidants. Food Bioprod. Process. 2015, 94, 463–472. [Google Scholar] [CrossRef]

- INYM—Instituto Nacional de la Yerba Mate. 2022. Available online: https://Inym.Org.Ar/Noticias/Estadisticas/79445-En-2020-El-Consumo-De-Yerba-Mate-Totalizo-311-7-Millones-De-Kilos (accessed on 9 October 2022).

- EFSA Panel of Food Contact Materials; Enzymes and Processing Aids. Scientific Opinion on Flavouring Group Evaluation 10, Revision 3 (Fge. 10rev3): Aliphatic Primary and Secondary Saturated and Unsaturated Alcohols, Aldehydes, Acetals, Carboxylic Acids and Esters Containing an Additional Oxygenated Functional Group and Lactones from Chemical Groups 9, 13 and 30. EFSA J. 2012, 10, 2563. [Google Scholar]

- Arrieta, M.P.; Samper, M.D.; Lopez, J.; Jiménez, A. Combined Effect of Poly(hydroxybutyrate) and Plasticizers on Polylactic acid Properties for Film Intended for Food Packaging. J. Polym. Environ. 2014, 22, 460–470. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; López, D.; Kenny, J.M.; Peponi, L. Development of Flexible Materials Based on Plasticized Electrospun PLA–PHB Blends: Structural, Thermal, Mechanical and Disintegration Properties. Eur. Polym. J. 2015, 73, 433–446. [Google Scholar] [CrossRef]

- Van den Oever, M.J.A.; Beck, B.; Müssig, J. Agrofibre Reinforced Poly (Lactic Acid) Composites: Effect of Moisture on Degradation and Mechanical Properties. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1628–1635. [Google Scholar] [CrossRef]

- Arrieta, M.; Fortunati, E.; Dominici, F.; López, J.; Kenny, J. Bionanocomposite films based on plasticized PLA–PHB/cellulose nanocrystal blends. Carbohydr. Polym. 2015, 121, 265–275. [Google Scholar] [CrossRef] [PubMed]

- Turner, J.F.; Riga, A.; O’Connor, A.; Zhang, J.; Collis, J. Characterization of drawn and undrawn poly-L-lactide films by differential scanning calorimetry. J. Therm. Anal. 2004, 75, 257–268. [Google Scholar] [CrossRef]

- Trifol, J.; Quintero, D.C.M.; Moriana, R. Pine Cone Biorefinery: Integral Valorization of Residual Biomass into Lignocellulose Nanofibrils (LCNF)-Reinforced Composites for Packaging. ACS Sustain. Chem. Eng. 2021, 9, 2180–2190. [Google Scholar] [CrossRef]

- European Commission. No. 10, 2011 of 14, on Plastic Materials and Articles Intended to Come into Contact with Food. Off. J. Eur. Union 2011, L12, 1–89. [Google Scholar]

- Beltrán, F.R.; Arrieta, M.P.; Gaspar, G.; de la Orden, M.U.; Martínez Urreaga, J. Effect of Iignocellulosic Nanoparticles Extracted from Yerba Mate (Ilex Paraguariensis) on the Structural, Thermal, Optical and Barrier Properties of Mechanically Recycled Poly(Lactic Acid). Polymers 2020, 12, 1690. [Google Scholar] [CrossRef]

- García-Arroyo, P.; Arrieta, M.P.; Garcia-Garcia, D.; Cuervo-Rodríguez, R.; Fombuena, V.; Mancheño, M.J.; Segura, J.L. Plasticized Poly(Lactic Acid) Reinforced with Antioxidant Covalent Organic Frameworks (COFs) as Novel Nanofillers De-signed for Non-Migrating Active Packaging Applications. Polymer 2020, 196, 122466. [Google Scholar] [CrossRef]

- Molinaro, S.; Cruz-Romero, M.; Boaro, M.; Sensidoni, A.; Lagazio, C.; Morris, M.; Kerry, J. Effect of nanoclay-type and PLA optical purity on the characteristics of PLA-based nanocomposite films. J. Food Eng. 2013, 117, 113–123. [Google Scholar] [CrossRef]

- Armentano, I.; Fortunati, E.; Burgos, N.; Dominici, F.; Luzi, F.; Fiori, S.; Jiménez, A.; Yoon, K.; Ahn, J.; Kang, S.; et al. Processing and Characterization of Plasticized Pla/Phb Blends for Biodegradable Mul-tiphase Systems. Express Polym. Lett. 2015, 9, 583–596. [Google Scholar] [CrossRef]

- Yang, W.; Fortunati, E.; Dominici, F.; Kenny, J.; Puglia, D. Effect of processing conditions and lignin content on thermal, mechanical and degradative behavior of lignin nanoparticles/polylactic (acid) bionanocomposites prepared by melt extrusion and solvent casting. Eur. Polym. J. 2015, 71, 126–139. [Google Scholar] [CrossRef]

- Burgos, N.; Martino, V.P.; Jiménez, A. Characterization and ageing study of poly(lactic acid) films plasticized with oligomeric lactic acid. Polym. Degrad. Stab. 2013, 98, 651–658. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Perdiguero, M.; Fiori, S.; Kenny, J.M.; Peponi, L. Biodegradable electrospun PLA-PHB fibers plasticized with oligomeric lactic acid. Polym. Degrad. Stab. 2020, 179, 109226. [Google Scholar] [CrossRef]

- Labrecque, L.V.; Kumar, R.A.; Gross, R.A.; McCarthy, S.P. Citrate esters as plasticizers for poly(lactic acid). J. Appl. Polym. Sci. 1997, 66, 1507–1513. [Google Scholar] [CrossRef]

- Courgneau, C.; Ducruet, V.; Avérous, L.; Grenet, J.; Domenek, S. Nonisothermal Crystallization Kinetics of Poly (Lac-tide)—Effect of Plasticizers and Nucleating Agent. Polym. Eng. Sci. 2013, 53, 1085–1098. [Google Scholar] [CrossRef]

- Beltrán, F.; Lorenzo, V.; Acosta, J.; de la Orden, M.; Urreaga, J.M. Effect of simulated mechanical recycling processes on the structure and properties of poly(lactic acid). J. Environ. Manag. 2018, 216, 25–31. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Beltran, F.; Abarca de las Muelas, S.S.; Gaspar, G.; Sanchez Hernandez, R.; de la Orden, M.U.; Martinez Urreaga, J. Development of Tri-Layer Antioxidant Packaging Systems Based on Recycled PLA/Sodium Caseinate/Recycled PLA Rein-forced with Lignocellulosic Nanoparticles Extracted from Yerba Mate Waste. Express Polym. Lett. 2022, 16, 881–900. [Google Scholar] [CrossRef]

- Zhang, J.; Tashiro, K.; Tsuji, H.; Domb, A.J. Disorder-to-Order Phase Transition and Multiple Melting Behavior of Poly(l-lactide) Investigated by Simultaneous Measurements of WAXD and DSC. Macromolecules 2008, 41, 1352–1357. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Castro-Lopez, M.M.; Rayón, E.; Barral-Losada, L.F.; López-Vilariño, J.M.; López, J.; Gon-zález-Rodríguez, M.V. Plasticized Poly(Lactic Acid)–Poly (Hydroxybutyrate)(PLA-PHB) Blends Incorporated with Catechin In-tended for Active Food-Packaging Applications. J. Agric. Food Chem. 2014, 62, 10170–10180. [Google Scholar] [CrossRef]

- Tee, Y.B.; Talib, R.A.; Abdan, K.; Chin, N.L.; Basha, R.K.; Md Yunos, K.F. Comparative Study of Chemical, Mechanical, Thermal, and Barrier Properties of Poly (Lactic Acid) Plasticized with Epoxidized Soybean Oil and Epoxidized Palm Oil. BioResources 2016, 11, 1518–1540. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; Ferrándiz, S.; Peltzer, M.A. Characterization of PLA-Limonene Blends for Food Packaging Applications. Polym. Test. 2013, 32, 760–768. [Google Scholar] [CrossRef]

- Threepopnatkul, P.; Sittattrakul, A.; Supawititpattana, K.; Jittiarpon, P.; Raksawat, P.; Kulsetthanchalee, C. Effect of bacterial cellulose on properties of poly(lactic acid). Mater. Today: Proc. 2017, 4, 6605–6614. [Google Scholar] [CrossRef]

- Maiza, M.; Benaniba, M.T.; Quintard, G.; Massardier-Nageotte, V. Biobased additive plasticizing Polylactic acid (PLA). Polimeros 2015, 25, 581–590. [Google Scholar] [CrossRef]

- Geng, S.; Wei, J.; Aitomäki, Y.; Noël, M.; Oksman, K. Well-dispersed cellulose nanocrystals in hydrophobic polymers by in situ polymerization for synthesizing highly reinforced bio-nanocomposites. Nanoscale 2018, 10, 11797–11807. [Google Scholar] [CrossRef]

- Iwatake, A.; Nogi, M.; Yano, H. Cellulose nanofiber-reinforced polylactic acid. Compos. Sci. Technol. 2008, 68, 2103–2106. [Google Scholar] [CrossRef]

- Luzi, F.; Torre, L.; Kenny, J.M.; Puglia, D. Bio- and Fossil-Based Polymeric Blends and Nanocomposites for Packaging: Structure–Property Relationship. Materials 2019, 12, 471. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U. Novel biopolymer-based sustainable composites for food packaging applications: A narrative review. Food Packag. Shelf Life 2022, 33, 100892. [Google Scholar] [CrossRef]

- Hambleton, A.; Fabra, M.J.; Debeaufort, F.; Dury-Brun, C.; Voilley, A. Interface and Aroma Barrier Properties of Io-ta-Carrageenan Emulsion–Based Films Used for Encapsulation of Active Food Compounds. J. Food Eng. 2009, 93, 80–88. [Google Scholar] [CrossRef]

| Sample | r3-PLA (wt.%) | ATBC (wt.%) | KMN (wt.%) | KMW (wt.%) |

|---|---|---|---|---|

| r3-PLA | 100 | - | - | - |

| r3-PLA-ATBC | 85 | 15 | - | - |

| r3-PLA-ATBC-KMN1 | 84.15 | 14.85 | 1 | - |

| r3-PLA-ATBC-KMN3 | 82.45 | 14.55 | 3 | - |

| r3-PLA-ATBC-KMW1 | 84.15 | 14.85 | - | 1 |

| r3-PLA-ATBC-KMW3 | 82.45 | 14.55 | - | 3 |

| Sample | Tg (°C) | Tcc (°C) | ΔHcc (J g−1) | TmI (°C) | TmII (°C) | ΔHm (J g−1) | χc (%) |

|---|---|---|---|---|---|---|---|

| r3-PLA | 49.1 | 106.1 | 20.0 | 144.4 | 151.3 | 23.2 | 3.4 |

| r3-PLA-ATBC | 32.1 | 95.0 | 21.2 | 135.6 | 146.8 | 23.4 | 2.8 |

| r3-PLA-ATBC-KMN1 | 39.1 | 99.5 | 19.2 | 139.7 | 148.9 | 19.8 | 0.7 |

| r3-PLA-ATBC-KMN3 | 36.8 | 99.9 | 19.5 | 138.3 | 148.2 | 20.2 | 1.0 |

| r3-PLA-ATBC-KMW1 | 37.3 | 98.4 | 20.3 | 137.7 | 148.1 | 22.8 | 3.1 |

| r3-PLA-ATBC-KMW3 | 33.5 | 99.3 | 19.0 | 138.3 | 147.8 | 21.5 | 3.2 |

| Sample | T5% (°C) | T10%(°C) | Tmax (°C) | Residual Mass (%) |

|---|---|---|---|---|

| r3-PLA | 296.1 | 313.52 | 354.4 | 0.4 |

| r3-PLA-ATBC | 217.4 | 272.28 | 351.1 | 0.8 |

| r3-PLA-ATBC-KMN1 | 224.8 | 266.74 | 354.1 | 0.5 |

| r3-PLA-ATBC-KMN3 | 214.7 | 246.21 | 344.7 | 0.7 |

| r3-PLA-ATBC-KMW1 | 227.2 | 274.62 | 352.4 | 0.5 |

| r3-PLA-ATBC-KMW3 | 208.1 | 243.19 | 351.8 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agüero, Á.; Corral Perianes, E.; Abarca de las Muelas, S.S.; Lascano, D.; de la Fuente García-Soto, M.d.M.; Peltzer, M.A.; Balart, R.; Arrieta, M.P. Plasticized Mechanical Recycled PLA Films Reinforced with Microbial Cellulose Particles Obtained from Kombucha Fermented in Yerba Mate Waste. Polymers 2023, 15, 285. https://doi.org/10.3390/polym15020285

Agüero Á, Corral Perianes E, Abarca de las Muelas SS, Lascano D, de la Fuente García-Soto MdM, Peltzer MA, Balart R, Arrieta MP. Plasticized Mechanical Recycled PLA Films Reinforced with Microbial Cellulose Particles Obtained from Kombucha Fermented in Yerba Mate Waste. Polymers. 2023; 15(2):285. https://doi.org/10.3390/polym15020285

Chicago/Turabian StyleAgüero, Ángel, Esther Corral Perianes, Sara Soledad Abarca de las Muelas, Diego Lascano, María del Mar de la Fuente García-Soto, Mercedes Ana Peltzer, Rafael Balart, and Marina Patricia Arrieta. 2023. "Plasticized Mechanical Recycled PLA Films Reinforced with Microbial Cellulose Particles Obtained from Kombucha Fermented in Yerba Mate Waste" Polymers 15, no. 2: 285. https://doi.org/10.3390/polym15020285

APA StyleAgüero, Á., Corral Perianes, E., Abarca de las Muelas, S. S., Lascano, D., de la Fuente García-Soto, M. d. M., Peltzer, M. A., Balart, R., & Arrieta, M. P. (2023). Plasticized Mechanical Recycled PLA Films Reinforced with Microbial Cellulose Particles Obtained from Kombucha Fermented in Yerba Mate Waste. Polymers, 15(2), 285. https://doi.org/10.3390/polym15020285