Abstract

Poly(L-lactide) (PLLA) is a promising candidate as a bioplastic because of its non-toxicity and biodegradability. However, the low flexibility of PLLA limits its use in many applications. Poly(L-lactide)-b-poly(ethylene glycol)-b-poly(L-lactide) (PLLA-b-PEG-b-PLLA) block copolymer is of interest for bioplastic applications due to its superior flexibility compared to PLLA. The aim of this work is to modify PLLA-b-PEG-b-PLLA using a low-cost calcium carbonate (CaCO3) filler to improve material properties compared to PLLA/CaCO3 composites. The addition of CaCO3 enhanced the crystallinity and thermal stability for the PLLA-b-PEG-b-PLLA matrix but not for the PLLA matrix, as determined by differential scanning calorimetry (DSC), X-ray diffractometry (XRD), and thermogravimetric analysis (TGA). Phase morphology investigation using scanning electron microscopy (SEM) revealed that the interfacial adhesion between PLLA-b-PEG-b-PLLA and CaCO3 was stronger than between PLLA and CaCO3. Additionally, tensile testing was carried out to determine the mechanical properties of the composites. With the addition of CaCO3, the tensile stress and Young’s modulus of the PLLA-b-PEG-b-PLLA matrix were increased, whereas these properties of the PLLA matrix were significantly decreased. Thus, CaCO3 shows great promise as an inexpensive filler that can induce nucleation and reinforcing effects for PLLA-b-PEG-b-PLLA bioplastics.

1. Introduction

Nowadays, bio-based polymers are gaining great interest for production of environmentally sustainable products due to their lower carbon footprint compared with petro-based polymers [1,2]. Among bio-based polymers, poly(L-lactic acid) or poly(L-lactide) (PLLA) has received the most attention because of its biodegradability, biocompatibility, processability, and possibilities for production scale-up [3,4,5]. PLLA has been extensively investigated for medical, pharmaceutical, packaging, agricultural, automotive, and electronic applications [1,2,5,6,7]. The main limitation in the use of PLLA is that it is less flexible [8]. High-molecular-weight PLLA-b-poly(ethylene glycol)-b-PLLA (PLLA-b-PEG-b-PLLA) block copolymers are more flexible than PLLA due to flexibility of the PEG middle-blocks [9,10].

PLLA composites have been prepared in combination with micro- and nano-fillers to improve some properties and/or to reduce the production cost of the products [1,11,12,13]. Many mineral fillers such as talc, calcium carbonate, kaolin, and silicon dioxide have been used for this purpose [1,14]. Calcium carbonate (CaCO3) is the cheapest mineral filler and is commonly available in the market. Unfortunately, weak interfacial adhesion with poor phase compatibility between PLLA matrix and CaCO3 filler was shown to be the main limitation for improving the properties of PLLA composites [15,16]. Modification of CaCO3 has been performed to make a hydrophobic surface to improve phase compatibility with the PLLA matrix [1,15,16,17,18,19]. The addition of surface-modified CaCO3 enhanced the thermal stability and the mechanical properties of the PLLA composites [1,15]. Therefore, improving phase compatibility between PLLA and CaCO3 remains a challenging area of research.

The hydrophilicity of the PLLA-b-PEG-b-PLLA was higher than that of the PLLA due to the hydrophilic PEG blocks [20]. The phase compatibility between the PLLA-b-PEG-b-PLLA matrix and hydrophilic thermoplastic starch (TPS) [20] was found to be better than that between the PLLA matrix and hydrophilic TPS. However, the combination of the PLLA-b-PEG-b-PLLA block copolymer with CaCO3 has not been reported so far. It could be conjectured that the hydrophilic PEG blocks could enhance the interfacial adhesion between the block copolymer and CaCO3. Thus, the aim of this research is to investigate the effect of the addition of a CaCO3 and CaCO3 ratio on thermal transition, thermal decomposition, and mechanical properties of the block copolymer-based composites. The composites were prepared by melt compounding block copolymer with CaCO3. The PLLA/CaCO3 composites were also prepared under the same condition for comparison.

2. Materials and Methods

2.1. Materials

PLLA-b-PEG-b-PLLA block copolymer was synthesized by ring-opening polymerization of L-lactide (LLA) monomer in the presence of a chain extender (2.0 parts per hundred of resin, phr) as described in our previous work [21]. The block copolymer was synthesized at 165 °C for 6 h under a nitrogen atmosphere using a stannous octoate/PEG mixture as the initiating system. The molecular weight of PEG was 20,000. Joncryl ADR 4368 (BASF, Bangkok, Thailand) was used as a chain extender. The number-averaged molecular weight (Mn) and dispersity (Đ) of the block copolymer were characterized using a gel permeation chromatography (GPC, Waters e2695 separations module, Waters Corporation, Midford, MA, USA) equipped with PLgel 10 μm mixed B 2 columns operating at 40 °C at a flow rate of 1.0 mL/min. A refractive index (RI) detector was employed. Tetrahydrofuran was used as the solvent. The GPC curve of the block copolymer is presented in Figure S1. The results of Mn and Đ were 108,500 and 2.2, respectively. The chemical composition of the block copolymer was determined as an LLA:ethylene oxide (LLA:EO) ratio using a 1H-NMR spectrometer (DPX 400, Bruker Advance, Karlsruhe, Germany) at 25 °C, as shown in Figure S2, from methine protons of LLA units (peak 1) and methylene protons of EO units (peak 14), repeating units of PLLA and PEG blocks, respectively [10]. CDCl3 was used as the solvent, and tetramethysilane was used as the internal standard. The resulting LLA:EO ratio was 60:40 mol%. Peaks 6–9 and 11–13 of a chain extender were also assigned [10].

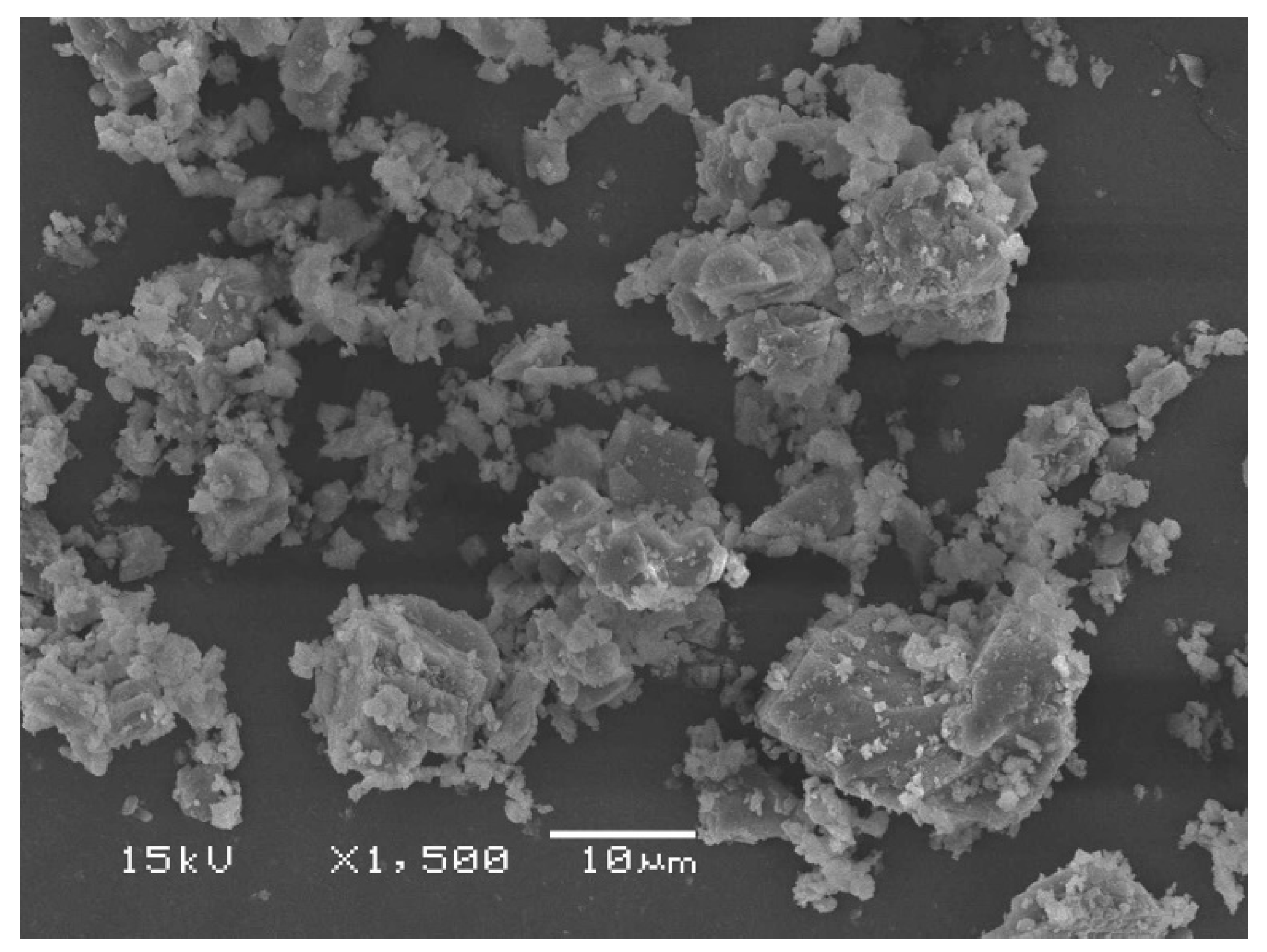

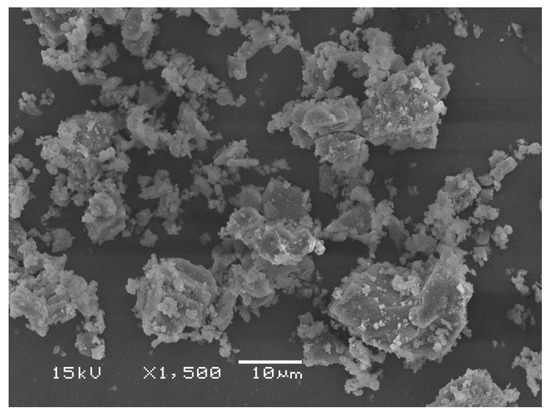

PLLA (3251D grade) was purchased from NatureWorks LLC (MA, USA). Its Mn and Đ were 56,200 and 1.6, respectively [22]. Melt flow indices (MFI) of PLLA and block copolymer determined at 190 °C under 2.16 kg load were 29 and 26 g/10 min, respectively. Calcium carbonate (CaCO3, 1250 grade) sieved with 1250 mesh was purchased from Thai Poly Chemicals Co., Ltd. (Samut Sakorn, Thailand). The SEM image of CaCO3 is shown in Figure 1.

Figure 1.

SEM image of CaCO3 powder.

2.2. Preparation of the Composites

Block copolymer and CaCO3 were dried in a vacuum oven at 50 °C for 24 h to remove moisture prior to melt compounding using a torque rheometer (HAAKETM Polylab OS Rheomix Thermo Scientific, Waltham, MA, USA) at 170 °C for 8 min with a rotor speed of 100 rpm. Block copolymer-based composites were prepared with 0%, 5%, 10%, 20%, and 30 %wt CaCO3. PLLA/CaCO3 composites were also prepared by the same conditions for comparison. All the obtained composites were dried in a vacuum oven at 50 °C for 24 h to remove moisture prior to processing into film (10 mm × 10 mm × 0.2 mm) using a hot-press machine (Carver Auto CH, Wabash, IN, USA). Each composite film was prepared by preheating at 170 °C for 4 min before hot pressing for 2 min under 5 MPa force. The resulting film was cooled with water-cooled plates for 1 min under 5 MPa force and was subsequently stored in a desiccator for at least 24 h before characterization.

2.3. Characterization of the Composites

The FTIR spectra of the samples were recorded using a FT-IR spectrophotometer (Invenio-S, Bruker, Karlsruhe, Germany) with the ATR accessory. A scan range of 4000 cm−1 to 500 cm−1 with a resolution of 4 cm−1 for 64 scans was used.

Thermal transition properties of the samples were studied using a differential scanning calorimeter (DSC, Pyris Diamond, PerkinElmer, Waltham, MA, USA). For DSC heating scans, the sample was first heated at 200 °C for 3 min to remove thermal history before fast quenching to 0 °C. Subsequently, the sample was scanned from 0 °C to 200 °C with a heating rate of 10 °C/min under a nitrogen gas flow. The degree of crystallinity from DSC (DSC − Xc) of the sample was calculated from the following equation.

where ∆Hm and ∆Hcc are melting and cold-crystallization enthalpies, respectively. The ΔHm value for 100%DSC − Xc PLLA is 93.6 J/g [20,23]. WPLLA is the PLLA weight-fraction.

DSC − Xc (%) = [(ΔHm − ΔHcc)/(93.6 × WPLLA)] × 100

For DSC cooling scans, the thermal history of the sample was first removed by complete melting at 200 °C for 3 min. After that, the sample was scanned from 200 °C to 0 °C at a cooling rate of 10 °C/min under a nitrogen gas flow.

The thermal decompositions of the samples were determined using a thermogravimetric analyzer (TGA, SDT Q600, TA Instruments, New Castle, DE, USA). The sample was heated from 50 °C to 600 °C at a rate of 20 °C/min under a nitrogen gas flow.

The crystalline structures of the film samples were investigated using a wide-angle X-ray diffractometer (XRD, D8 Advance, Bruker Corporation, Karlsruhe, Germany). A CuKα radiation at 40 kV and 40 mA and a scan speed was 3 °/min were employed. The degree of crystallinity from XRD (XRD − Xc) for PLLA crystallites was calculated with the following equation.

where Ac and Aa are the integrated peak areas for PLLA crystallites and the integrated halo area for the PLLA amorphous, respectively.

XRD − Xc (%) = [(Ac)/(Ac + Aa)] × 100

Phase morphology of the film cross-sections was investigated using a scanning electron microscope (SEM, JSM-6460LV, JEOL, Tokyo, Japan). The composite films were cryogenically fractured after immersing in liquid nitrogen. High-quality SEM images were obtained by sputter gold coating before SEM analysis at 15 kV.

The tensile properties of the film samples (80 mm × 10 mm) were measured using a tensile tester (LY-1066B, Dongguan Liyi Environmental Technology Co., Ltd., Guangdong, China) with a load cell of 100 kg according to the ASTM D638. The gauge length was 50 mm and tensile rate was 50 mm/min. The averaged tensile value was calculated from at least 10 specimens of each sample.

3. Results and Discussion

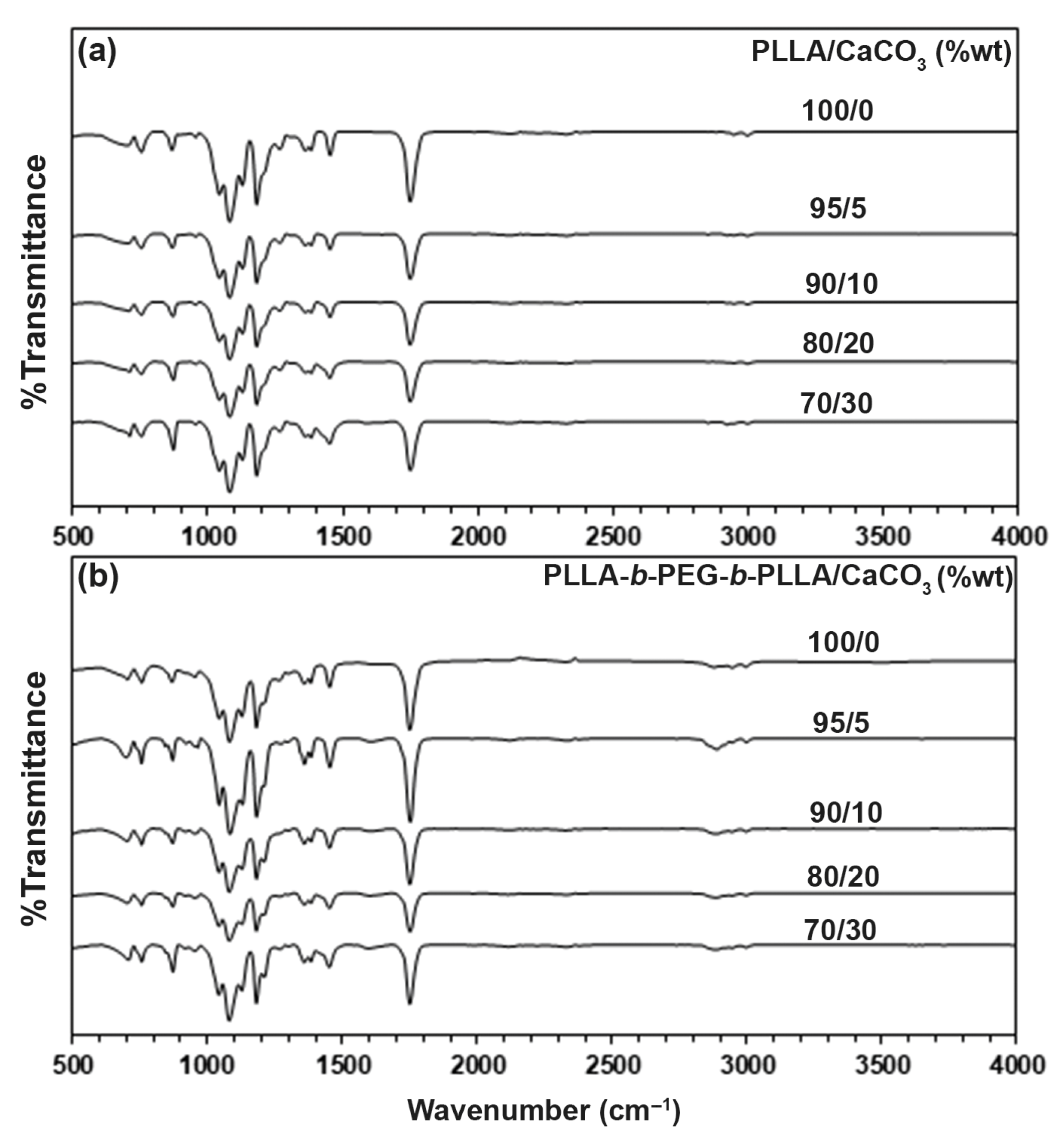

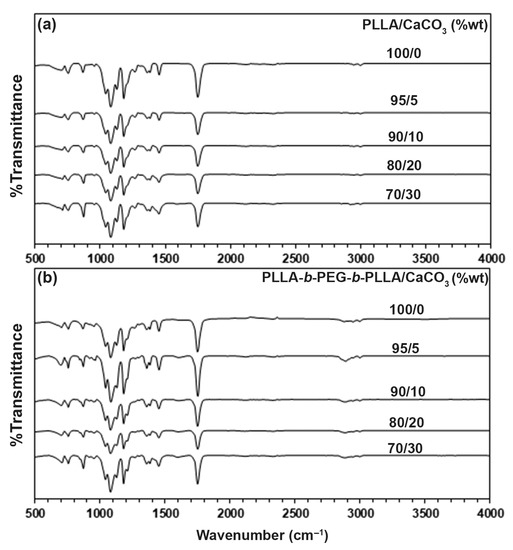

3.1. FTIR

The chemical functional groups of the composites were determined from the ATR-FTIR spectra, as shown in Figure 2. The pure PLLA in Figure 2a exhibited a peak at 1748 cm−1, which was attributed to the carbonyl (C=O) in ester groups. The peaks at 1181 cm−1, 1128 cm−1, and 1080 cm−1 were assigned to C-O-C in ester groups and three peaks at 2995 cm−1, 2944 cm−1, and 2879 cm−1 were attributed to C-H stretching groups, which indicates the PLLA functional groups [20,24]. The pure block copolymer in Figure 2b showed peaks that were similar the pure PLLA with the addition of a peak at 2877 cm−1, which was attributed to methylene (−CH2) in oxyethylene groups (repeating units of PEG blocks) and a broad peak at 3501 cm−1, which was assigned to hydroxyl (−OH) end-groups [20].

Figure 2.

ATR-FTIR spectra of (a) PLLA/CaCO3 and (b) PLLA-b-PEG-b-PLLA/CaCO3 composite films with various CaCO3 ratios.

The ATR-FTIR spectrum of CaCO3 is presented in Figure S3. There were three characteristic peaks of CaCO3 at 1398 cm−1, 873 cm−1, and 712 cm−1, which were attributed to the asymmetric stretching, in-plane bending, and out-of-plane bending modes of carbonate ions, respectively [17]. However, these peaks of CaCO3 were not clearly detected for the composites. This may be because they overlapped with the peaks from the PLLA and block copolymer matrices. From Figure S4, the −CH2 peak of block copolymer matrix at 2877 cm−1 shifted significantly to a higher wavenumber at 2886 cm−1 when the 5 %wt CaCO3 was initially loaded. However, this peak shifted to a lower wavenumber (2880–2881 cm−1) when the CaCO3 ratio was higher than the 5 %wt. On the other hand, the ATR-FTIR spectra of the PLLA-based composites did not change significantly with different CaCO3 ratios. This suggests the occurrence of interactions between the block copolymer and CaCO3 components. This assumption was clarified by SEM analysis.

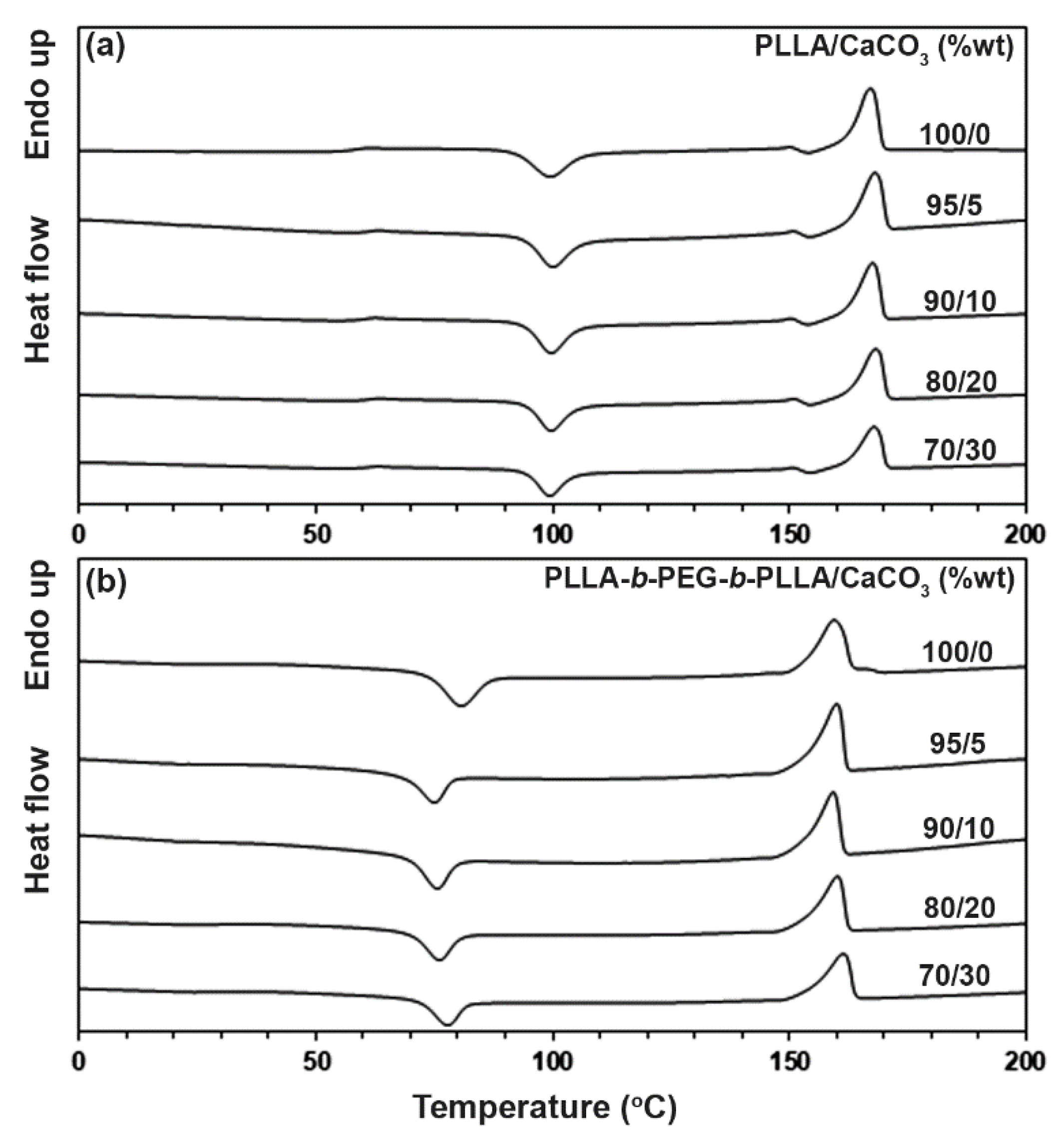

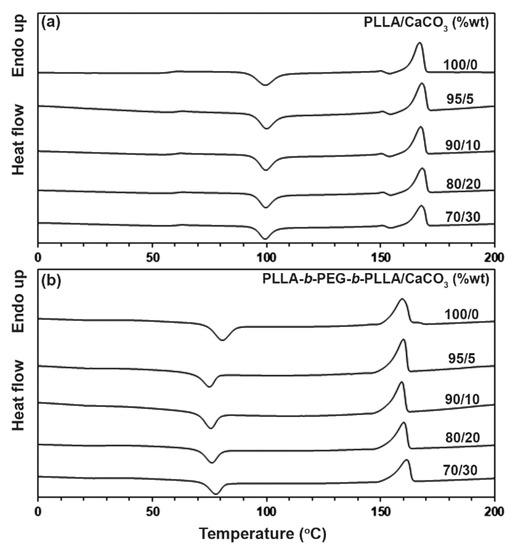

3.2. Thermal Transition Properties

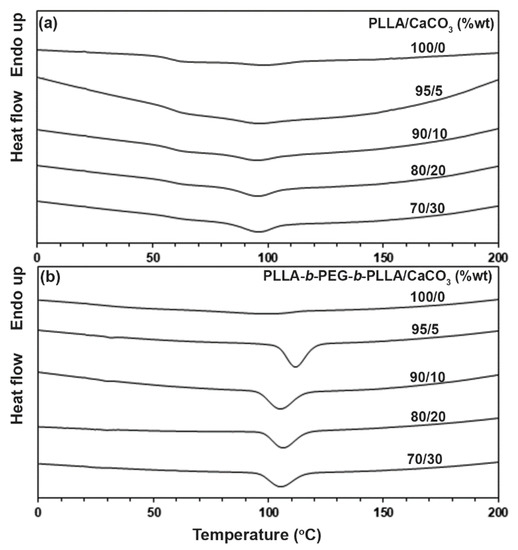

The thermal transition properties of the composites were determined by the DSC method. Figure 3 shows the DSC heating curves of the composites with and without CaCO3, and Table 1 sums up the DSC results from Figure 3. The Tg values of the PLLA-based and block copolymer-based composites were in the ranges of 58–60 °C and 30–32 °C, respectively. The Tcc, Tm, and DSC − Xc values of the PLLA-based composites did not change significantly as the CaCO3 ratio increased. For the block copolymer-based composites, it should be noted that the Tm peak of PEG with a molecular weight of 20,000 (about 68 °C) in the block copolymer was not detected [25]. This may be because the good miscibility between the PEG middle-blocks and the long PLLA end-blocks prevented the crystallization of PEG blocks [9,10]. When the 5 %wt CaCO3 was loaded, the Tcc peak of the block copolymer dramatically decreased from 81 °C to 75 °C and the DSC − Xc value increased from 13.9% to 18.4%. The shifting to lower temperature of the Tcc peak suggests CaCO3 acted as a heterogeneous nucleating agent for the block copolymer [26]. However, when the CaCO3 ratio was higher than 5 %wt, the Tcc peak of the block copolymer-based composites slightly shifted to a higher temperature and the DSC − Xc value slightly decreased. This may have been due to the reduced nucleation efficiency from the aggregation at high ratios of the CaCO3.

Figure 3.

DSC heating curves of (a) PLLA/CaCO3 and (b) PLLA-b-PEG-b-PLLA/CaCO3 composites with various CaCO3 ratios.

Table 1.

Thermal transition properties of the composites from Figure 3.

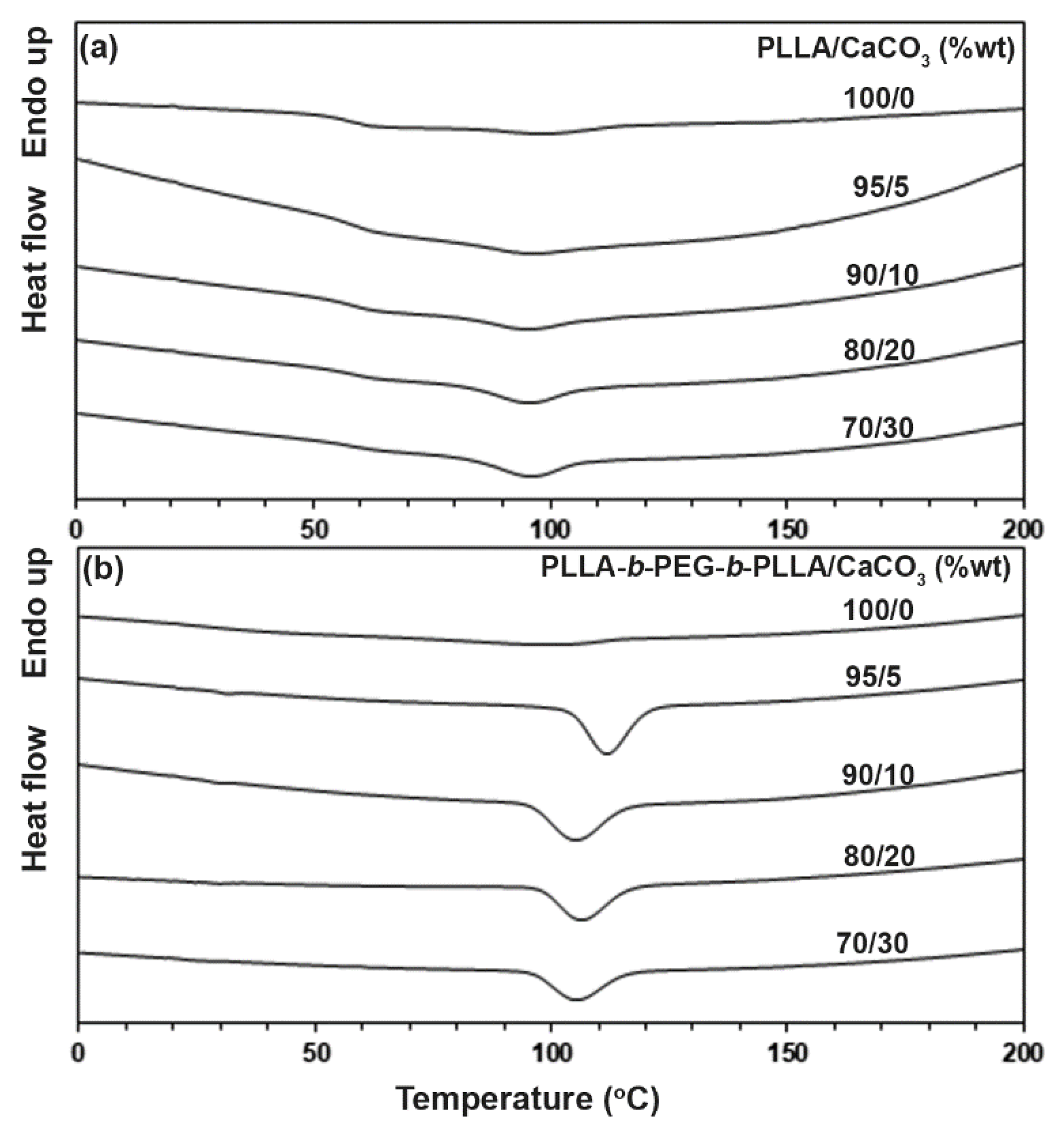

Figure 4 shows the DSC cooling curves of the composites. The DSC results from Figure 4 are summarized in Table 2. The Tc peaks (95–99 °C) and ΔHc values (5.5–6.1 J/g) of the PLLA-based composites did not change significantly as the CaCO3 ratio increased. The Tc peak of the block copolymer dramatically shifted from 99 °C to 112 °C and the ΔHc value greatly increased from 11.7% to 31.7% when the 5 %wt CaCO3 was loaded, indicating the nucleation efficiency of CaCO3 [23]. However, the Tc peak of the block copolymer-based composites shifted to a lower temperature and the ΔHc value decreased when the CaCO3 ratio was higher than the 5 %wt. The results confirmed that CaCO3 acted as a heterogeneous nucleating agent enhancing the crystallization of the block copolymer, consistent with the previous discussed results from the DSC heating curves.

Figure 4.

DSC cooling curves of (a) PLLA/CaCO3 and (b) PLLA-b-PEG-b-PLLA/CaCO3 composites with various CaCO3 ratios.

Table 2.

Thermal transition properties of the composites from Figure 4.

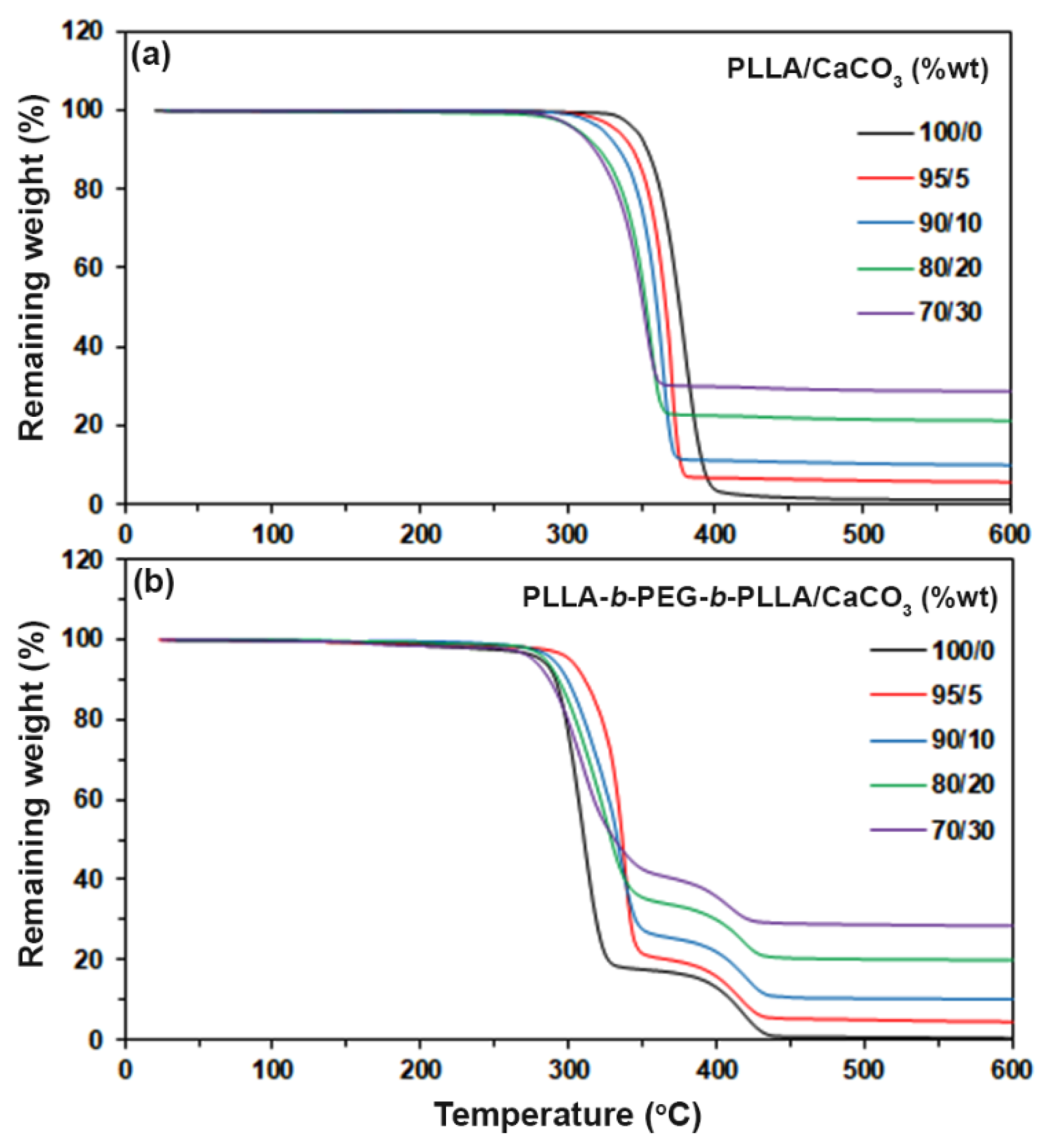

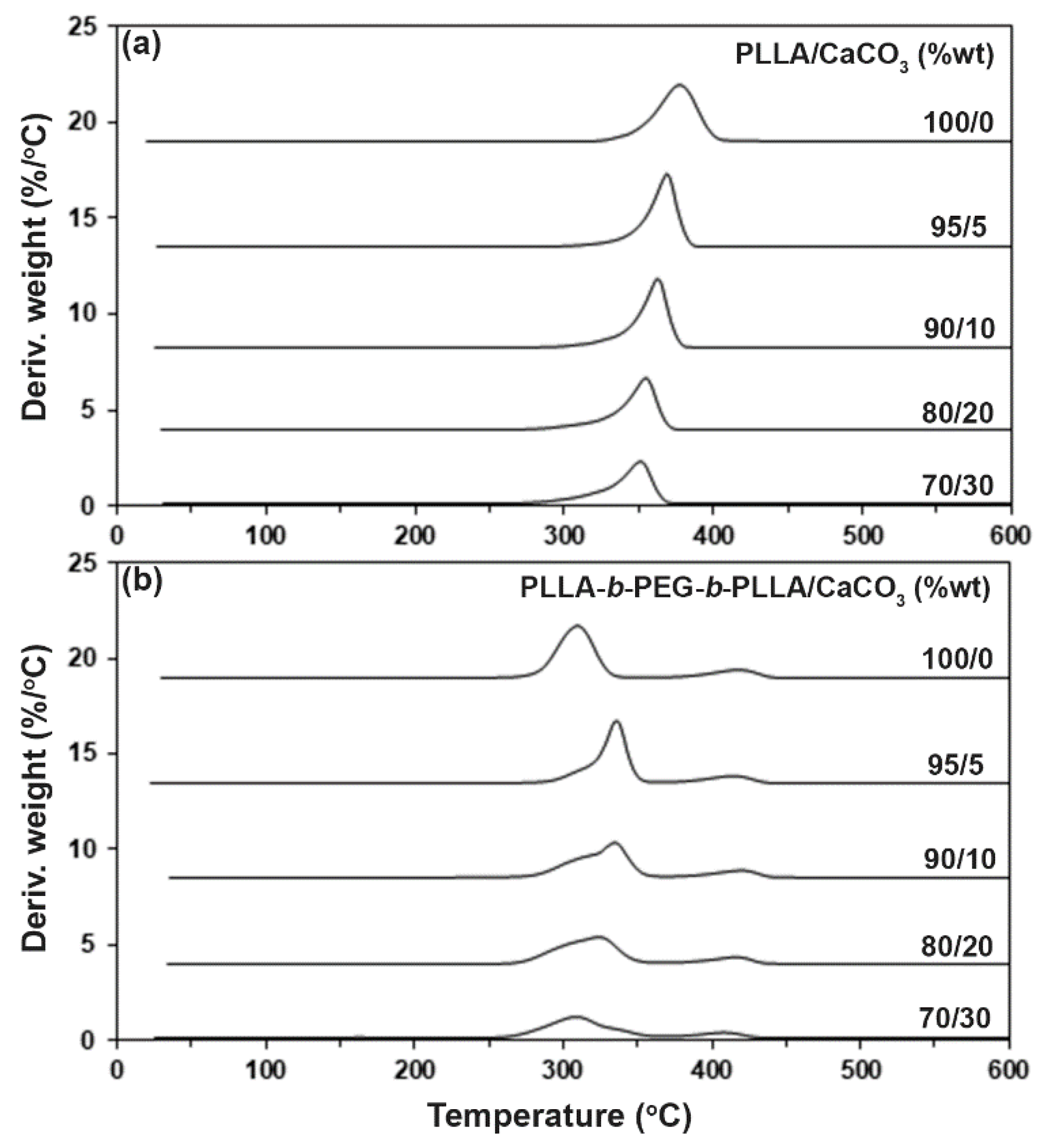

3.3. Thermal Decompositions

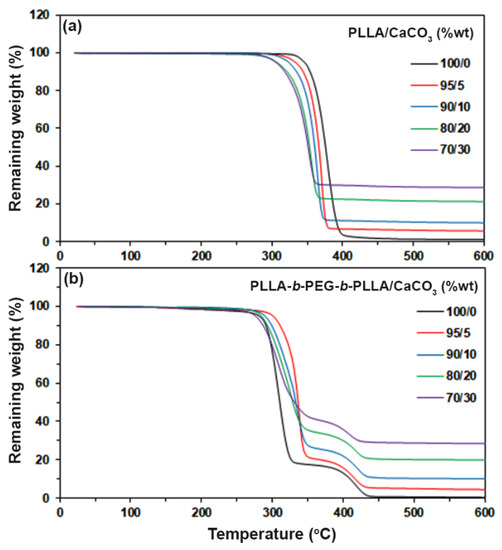

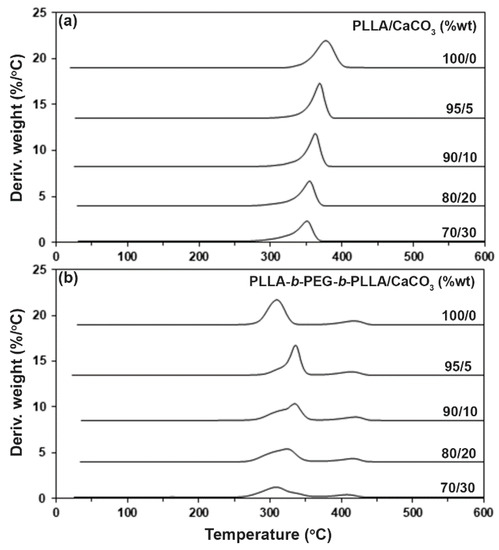

The thermal decomposition behaviors of the composites were determined by the TGA method. Figure 5 shows the TG thermograms of the composites, and Table 3 sums up the 5%–Td and residue ash at 600 °C values of the composites. Derivative TG (DTG) thermograms in Figure 6 were derived from Figure 5 to provide further details on the thermal decomposition behaviors. Each DTG peak was assigned to the Td,max peak of each thermal decomposition step, which is also reported in Table 3.

Figure 5.

TG thermograms of (a) PLLA/CaCO3 and (b) PLLA-b-PEG-b-PLLA/CaCO3 composites with various CaCO3 ratios.

Table 3.

Thermal decomposition properties of the composites.

Figure 6.

DTG thermograms of (a) PLLA/CaCO3 and (b) PLLA-b-PEG-b-PLLA/CaCO3 composites with various CaCO3 ratios.

The TG thermograms of the pure PLLA in Figure 5a showed a single decomposition step of PLLA in the range of 300–450 °C, whereas the pure block copolymer in Figure 5b exhibited two decomposition steps of PLLA and PEG blocks in ranges of 250–350 °C and 350–450 °C, respectively [20]. Increasing the CaCO3 ratio of the composites steadily decreased the 5%–Td value for the PLLA-based composites. It is interesting that the 5%–Td value of the block copolymer shifted dramatically from 282 °C to 302 °C when the 5 %wt CaCO3 was loaded, suggesting that the addition of CaCO3 significantly slowed down the thermal decomposition of the PLLA blocks in the block copolymer matrices. The 5%–Td value of the block copolymer decreased as the CaCO3 with higher 5 %wt was loaded. The residue weights at 600 °C of both the pure PLLA and the block copolymer were approximately zero (Table 3), indicating that they were completely thermally decomposed. The value of the residue weight at 600 °C of the composites steadily increased with the CaCO3 content because the CaCO3 did not decompose below 600 °C [15].

According to Table 3, the PLLA-based composites exhibited single PLLA–Td,max peaks, whereas the block copolymer-based composites showed the PLLA–Td,max and PEG–Td,max peaks. The PLLA–Td,max peak of the PLLA-based composites steadily shifted to a lower temperature as the CaCO3 ratio increased. The results of the 5%–Td from TG thermograms and the PLLA–Td,max from DTG thermograms indicated that the addition of CaCO3 decreased the thermal stability of the PLLA matrices. This may be explained by the CaCO3-catalyzed depolymerization of the PLLA by chain scission at the ester bonds [15].

The PLLA–Td,max peak of the block copolymer shifted dramatically from 309 °C to 338 °C when the 5 %wt CaCO3 was loaded. The increasing thermal stability of the block copolymer-based composites may have been due to the interactions between the components, as described in the FTIR analysis detailed above. However, the PLLA–Td,max peak of the block copolymer-based composites shifted to a lower temperature when the CaCO3 ratio was higher than 5 %wt. At these CaCO3 ratios, the effect of CaCO3 filler on the thermal stabilization of the block copolymer matrices could have decreased because of the aggregation of CaCO3 particles, which reduced the interactions between the components, as indicated by the previously described FTIR and DSC analyses. It should be noted that all the block copolymer-based composites still had the PLLA–Td,max at higher temperature than the pure block copolymer. The PEG–Td,max peak of the block copolymer-based composites shifted slightly to a lower temperature as the CaCO3 ratio increased. Overall, the TG and DTG results revealed that the addition of CaCO3 improved the thermal stability of the block copolymer matrices but did not improve that of the PLLA matrices.

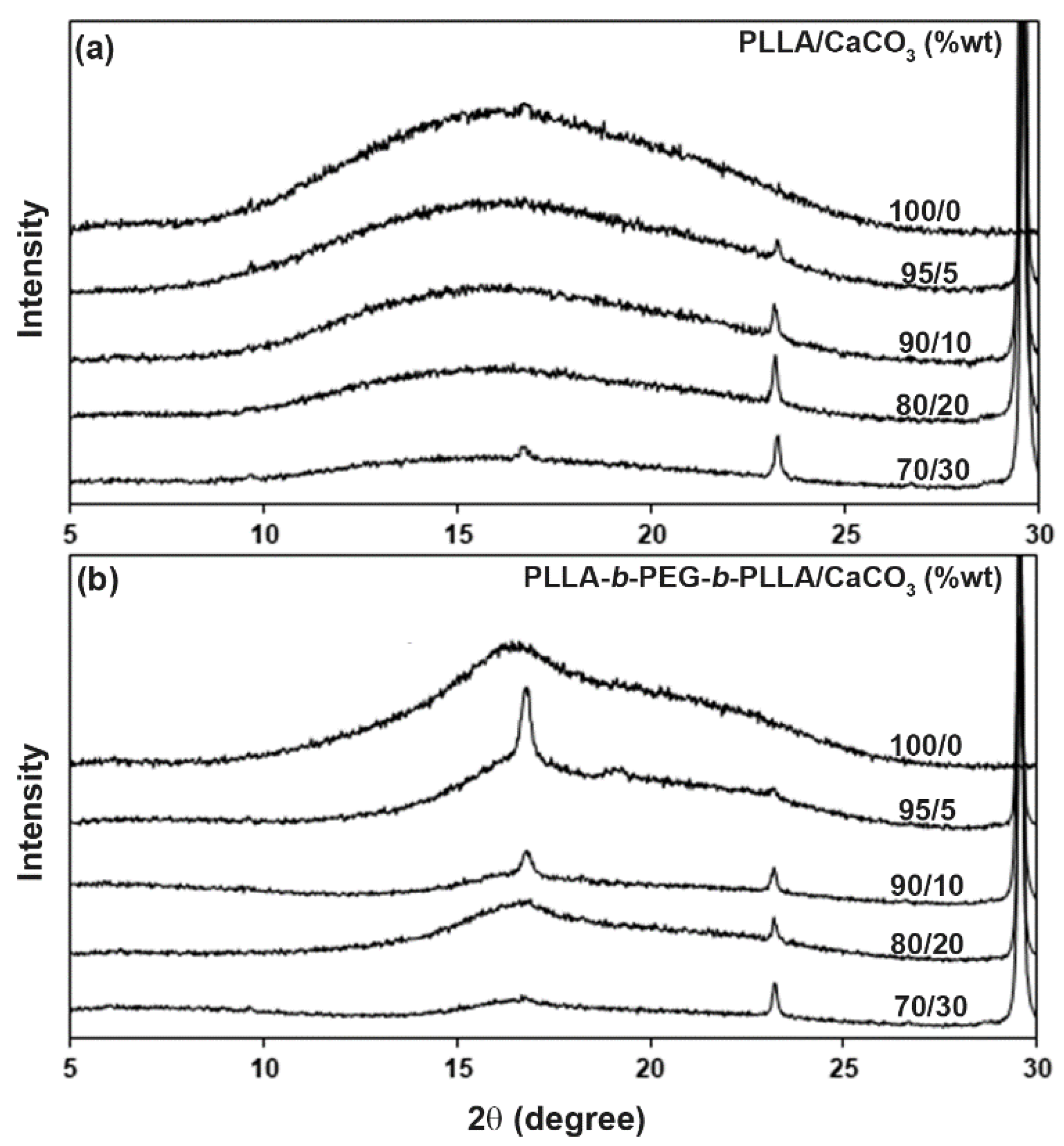

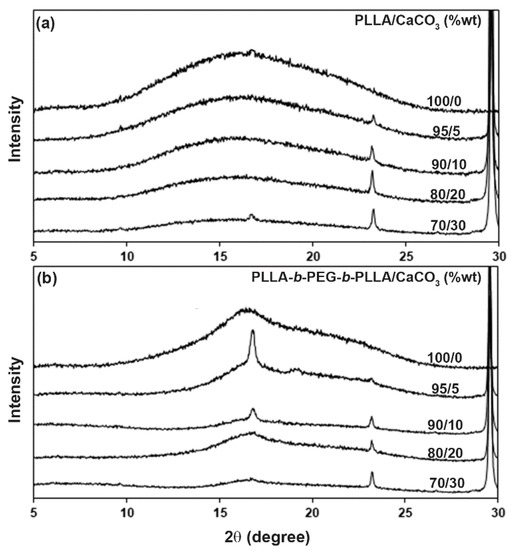

3.4. Crystalline Structures

XRD patterns were used to investigate the crystalline structures of the composite films, as shown in Figure S5. All the composites exhibited XRD peaks of CaCO3 at 2θ = 23.2°, 29.5°, 31.6°, 36.1°, 39.5°, 43.3°, 47.6°, and 48.6° [17]. The intensities of these peaks increased with the CaCO3 content. Figure 7 shows expanded XRD patterns in the range of 5–30° of the composite films. The pure PLLA film in Figure 7a had no XRD peaks of the PLLA crystallites, suggesting that it was completely amorphous. All the PLLA-based composite films were also completely amorphous except for the 70/30 PLLA/CaCO3 composite, which showed a small peak at 2θ = 16.5° of the PLLA crystallites [23].

Figure 7.

Expanded XRD patterns of (a) PLLA/CaCO3 and (b) PLLA-b-PEG-b-PLLA/CaCO3 composite films with various CaCO3 ratios.

The pure block copolymer in Figure 7b exhibited a broad peak at 2θ = 16.5° of the PLLA crystallites. This was due to the PEG middle-blocks enhancing the crystallization of the PLLA end-blocks [9,10]. The peak intensity of PLLA crystallites increased significantly when a 5 %wt CaCO3 ratio was added. However, the intensity of this peak decreased when the CaCO3 ratio was higher than the 5 %wt. The XRD − Xc values of the composites are summarized in Table 4. It was found that the XRD − Xc values of the block copolymer-based composites increased as the CaCO3 ratio increased, indicating that the added CaCO3 enhanced crystallization of PLLA end-blocks. Differences in the XRD − Xc and DSC − Xc values may be explained by different thermal history and shear force. The strain-induced nucleation influenced the crystallinity of the PLLA [26,27].

Table 4.

Crystallinity contents of the composite films from Figure 7.

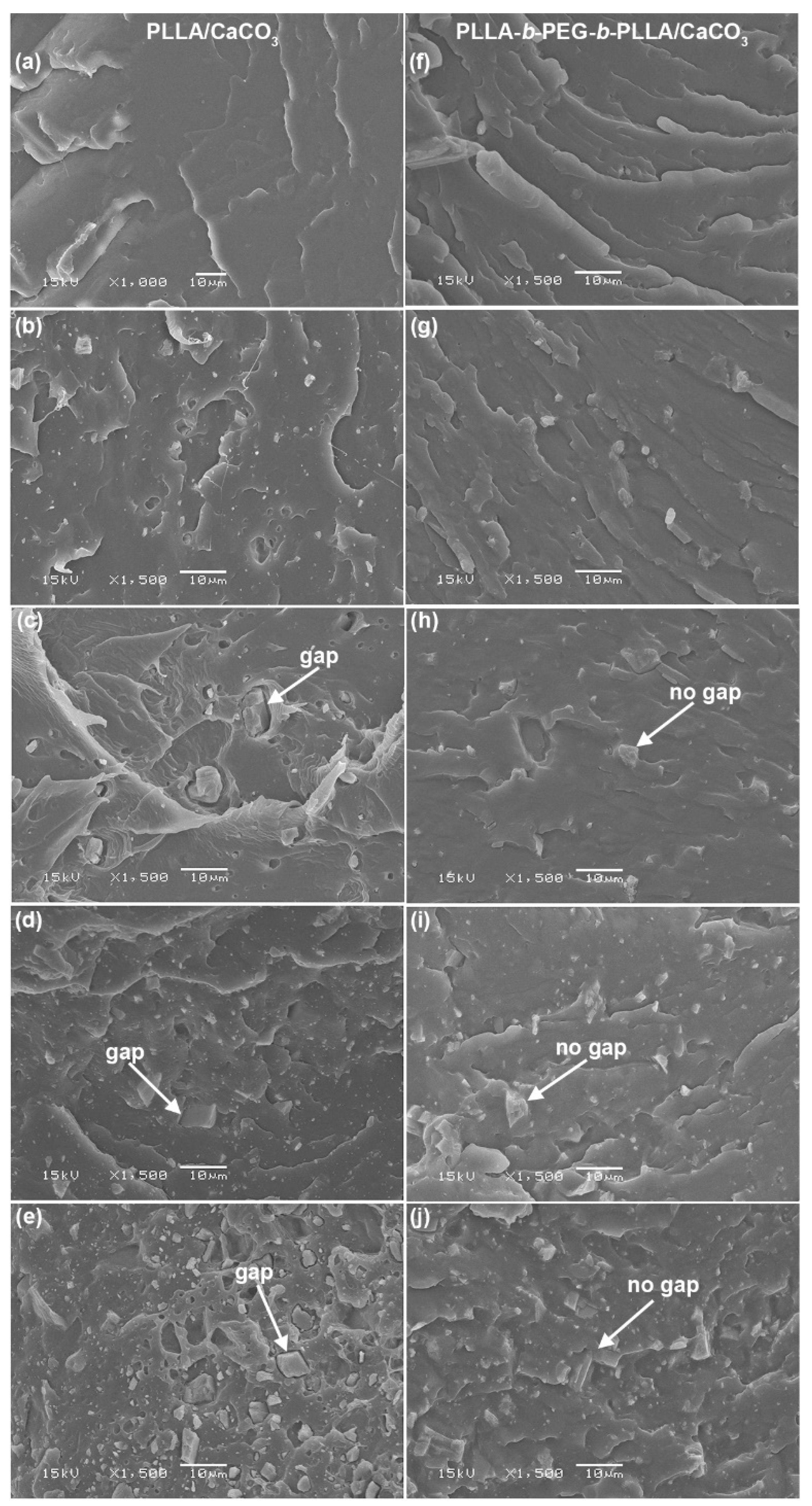

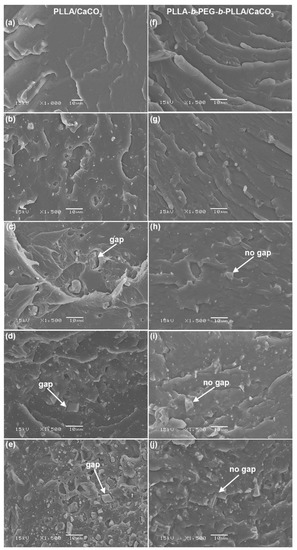

3.5. Phase Morphology

The phase morphology of the composites was analyzed from SEM images, as illustrated in Figure 8. Phase separation between dispersed CaCO3 and film matrices was clearly observed. The amount and aggregation of CaCO3 particles increased significantly as the CaCO3 ratio increased. The gaps between the CaCO3 surfaces and the PLLA matrices were clearly detected, especially for the larger CaCO3 particles, as indicated by the white arrows in Figure 8c–e. Some CaCO3 particles were detached from the PLLA matrices, which was attributed to the poor phase compatibility between the PLLA matrix and CaCO3. Consequently, empty holes were formed, as can be clearly observed in Figure 8e. This is due to the different hydrophilicity resulting in weak interfacial adhesion between the components [16,17]. CaCO3 has higher hydrophilicity than PLLA. Interestingly, the block copolymer-based composites had no gaps between the block copolymer matrix and CaCO3, indicating that they had good phase compatibility, as shown by the white arrows in Figure 8h–j. This suggests strong interfacial adhesion between components in the block copolymer-based composites compared to the PLLA-based composites. This can be explained by the block copolymer having higher hydrophilicity than the PLLA due to the high hydrophilicity of PEG blocks [20]. The SEM results supported the evidence of interactions between the block copolymer matrix and CaCO3 in the above FTIR results.

Figure 8.

SEM images of cryogenic film fractures with PLLA/CaCO3 ratios of (a) 100/0, (b) 95/5, (c) 90/10, (d) 80/20, and (e) 70/30 %wt, as well as with PLLA-b-PEG-b-PLLA/CaCO3 ratios of (f) 100/0, (g) 95/5, (h) 90/10, (i) 80/20, and (j) 70/30 %wt (all bar scales = 10 µm).

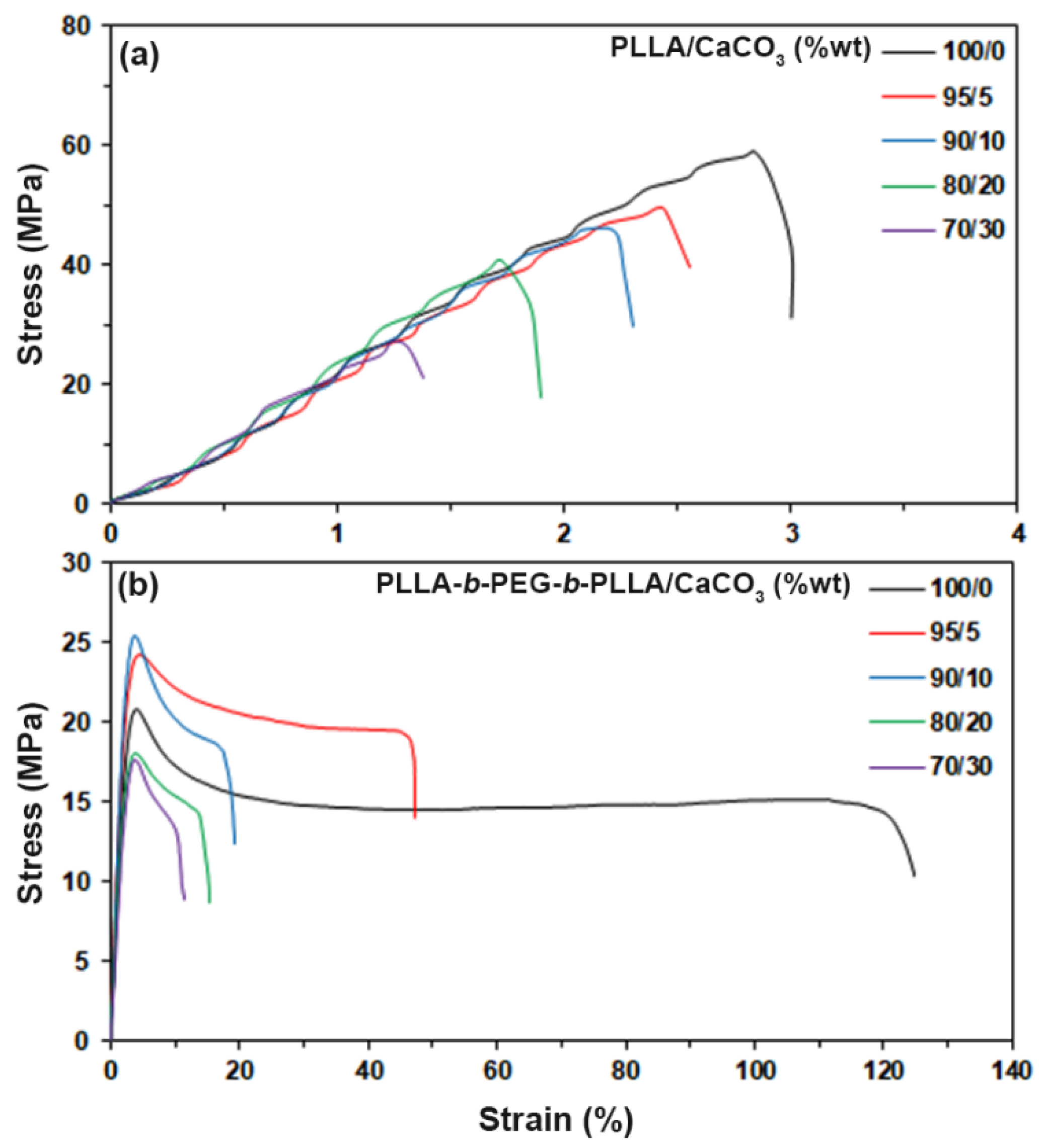

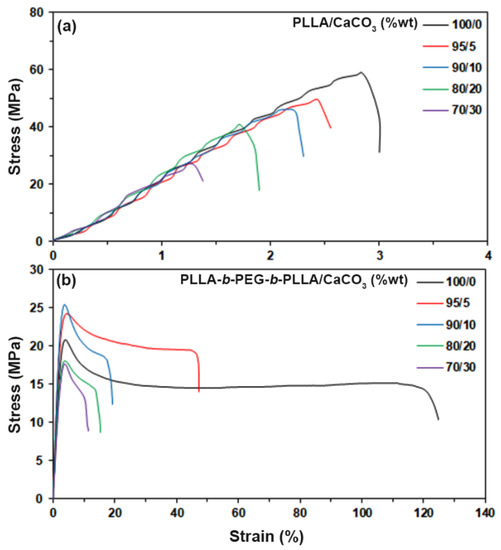

3.6. Tensile Properties

Tensile testing was used to study the mechanical properties of the composites. Figure 9 shows the stress–strain curves of all the film samples. Averaged tensile properties of the composites are summarized in Table 5. The stress at break, strain at break, and Young’s modulus of the PLLA-based composites decreased as the CaCO3 ratio increased, which implies that the addition of CaCO3 decreased the mechanical properties of the PLLA. This is because of the weak interfacial adhesion between the components [1], as described in the SEM analysis. The weak interfacial adhesion between the mineral fillers and matrix tends to decrease the tensile stress of the materials due to the fillers acting as the stress concentration points [1,28,29].

Figure 9.

Stress–strain curves of (a) PLLA/CaCO3 and (b) PLLA-b-PEG-b-PLLA/CaCO3 films with various CaCO3 ratios.

Table 5.

Averaged tensile properties of the composite films.

The pure block copolymer and its composites exhibited a yield point (Figure 9b), which implies that they were more flexible than the PLLA because the Tg of block copolymer matrix was lower than that of the PLLA matrix (see Table 1). As shown in Table 5, all the block copolymer-based composites showed lower stress at break, a lower Young’s modulus, and higher strain at break than those of the PLLA-based composites. This is due to the PEG middle-block acting as plasticizing sites that enhance the chain mobility of PLLA end-blocks [9,10]. However, it was seen that the stress at yield, stress at break, and Young’s modulus of the pure block copolymer increased and strain at break decreased when the 5 %wt CaCO3 was initially added. This indicates that there were effective interactions between the filler and matrix [30,31,32], as supported by the FTIR and SEM results. Therefore, the CaCO3 acted as a reinforcing filler for the block copolymer. It was further seen that the stress at yield, stress at break, and Young’s modulus of the block copolymer-based composites decreased as the CaCO3 ratio increased beyond 5 %wt. This may be due to the agglomeration of the CaCO3 at high ratios resulting in the reduction on the reinforcement of CaCO3 in the composites [32,33]. The strain at break of the block copolymer-based composites decreased steadily as the CaCO3 ratio increased because of the high rigidity of the CaCO3 mineral filler. However, these values were still higher than those of the pure PLLA (3.3%).

4. Conclusions

In this study, the PLLA-b-PEG-b-PLLA block copolymer-based composites were prepared by melt blending with CaCO3 and compared to the PLLA-based composites. The results indicated that the molecular interactions between the block copolymer matrix and the CaCO3 filler enhanced the PLLA crystallization properties and thermal stability. These properties decreased slightly as the CaCO3 contents increased beyond 5 %wt. The block copolymer matrix and CaCO3 showed good phase compatibility. The addition of CaCO3 at 5 %wt and 10 %wt resulted in the reinforcing effects that increased the tensile stress and Young’s modulus of the block copolymer-based composites. In contrast, CaCO3 did not improve these properties of the PLLA-based composites. In conclusion, CaCO3 showed great potential for use as a low-cost filler, a nucleating agent, and a reinforcing filler for the flexible PLLA-b-PEG-b-PLLA bioplastic. These biocomposites have a competitive production cost and can be used as flexible and biodegradable packaging materials.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/polym15020301/s1, Figure S1: GPC curve of a chain-extended PLLA-b-PEG-b-PLLA; Figure S2: 1H-NMR spectrum of a chain-extended PLLA-b-PEG-b-PLLA; Figure S3: FTIR spectrum of CaCO3 powder; Figure S4: Expanded ATR-FTIR spectra of PLLA-b-PEG-b-PLLA/CaCO3 composite films with various CaCO3 ratios; Figure S5: XRD patterns of (a) PLLA/CaCO3 and (b) PLLA-b-PEG-b-PLLA/CaCO3 films with various CaCO3 ratios.

Author Contributions

Conceptualization, Y.B. and P.S.; methodology, Y.B. and P.S.; investigation, Y.B. and P.S.; resources, Y.B.; visualization, Y.B. and P.S.; writing—original draft, Y.B., P.S. and W.T.; writing—review and editing, Y.B., P.S. and W.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research project was financially supported by Mahasarakham University. Y.B. is also grateful to the partial support provided by the Centre of Excellence for Innovation in Chemistry (PERCH-CIC), Office of the Higher Education Commission, Ministry of Education, Thailand.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Murariu, M.; Dubois, P. PLA composites: From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Tripathi, N.; Misra, M.; Amar, K.; Mohanty, A.K. Durable Polylactic Acid (PLA)-Based Sustainable Engineered Blends and Biocomposites: Recent Developments, Challenges, and Opportunities. ACS Eng. Au 2021, 1, 7–38. [Google Scholar] [CrossRef]

- da Silva, D.; Kaduri, M.; Poley, M.; Adir, O.; Krinsky, N.; Shainsky-Rotiman, J.; Schroeder, A. Biocompatibility, biodegradation and excretion of polylactic acid (PLA) in medical implants and theranostic systems. Chem. Eng. J. 2018, 340, 9–14. [Google Scholar] [CrossRef]

- Rezvani Ghomi, E.; Khosravi, F.; Saedi Ardahaei, A.; Dai, Y.; Neisiany, R.E.; Foroughi, F.; Wu, M.; Das, O.; Ramakrishna, S. The Life Cycle Assessment for Polylactic Acid (PLA) to Make It a Low-Carbon Material. Polymers 2021, 13, 1854. [Google Scholar] [CrossRef]

- Balla, E.; Daniilidis, V.; Karlioti, G.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Vlachopoulos, A.; Koumentakou, I.; Bikiaris, D.N. Poly(lactic Acid): A Versatile Biobased Polymer for the Future with Multifunctional Properties—From Monomer Synthesis, Polymerization Techniques and Molecular Weight Increase to PLA Applications. Polymers 2021, 13, 1822. [Google Scholar] [CrossRef]

- Rihayat, T.; Hadi, A.E.; Aidy, N.; Safitri, A.; Siregar, J.P.; Cionita, T.; Irawan, A.P.; Hamdan, M.H.M.; Fitriyana, D.F. Biodegradation of polylactic acid-based bio-composites reinforced with chitosan and essential oils as anti-microbial material for food packaging. Polymers 2021, 13, 4019. [Google Scholar] [CrossRef]

- Peng, K.; Mubarak, S.; Diao, X.; Cai, Z.; Zhang, C.; Wang, J.; Wu, L. Progress in the Preparation, Properties, and Applications of PLA and Its Composite Microporous Materials by Supercritical CO2: A Review from 2020 to 2022. Polymers 2022, 14, 4320. [Google Scholar] [CrossRef]

- Jin, F.L.; Hu, R.R.; Park, S.J. Improvement of thermal behaviors of biodegradable poly(lactic acid) polymer: A review. Compos. B Eng. 2019, 164, 287–296. [Google Scholar] [CrossRef]

- Yun, X.; Li, X.; Jin, Y.; Sun, W.; Dong, T. Fast crystallization and toughening of poly(L-lactic acid) by incorporating with poly(ethylene glycol) as a middle block chain. Polym. Sci.—Ser. A 2018, 60, 141–155. [Google Scholar] [CrossRef]

- Baimark, Y.; Rungseesantivanon, W.; Prakymorama, N. Improvement in melt flow property and flexibility of poly(L-lactide)-b-poly(ethylene glycol)-b-poly(L-lactide) by chain extension reaction for potential use as flexible bioplastics. Mater. Des. 2018, 154, 73–80. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; et al. Polylactic acid (PLA) biocomposite: Processing, additive manufacturing and advanced applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef]

- Stepanova, M.; Korzhikova-Vlakh, E. Modification of Cellulose Micro- and Nanomaterials to Improve Properties of Aliphatic Polyesters/Cellulose Composites: A Review. Polymers 2022, 14, 1477. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Rayung, M.; Abu, F.; Ahmad, S.; Fadil, F.; Karim, A.A.; Norizan, M.N.; Sarifuddin, N.; Mat Desa, M.S.Z.; Mohd Basri, M.S.; et al. A Review on Antimicrobial Packaging from Biodegradable Polymer Composites. Polymers 2022, 14, 174. [Google Scholar] [CrossRef]

- Barletta, M.; Puopolo, M. Thermoforming of compostable PLA/PBS blends reinforced with highly hygroscopic calcium carbonate. J. Manuf. Processes 2020, 56 Pt A, 1185–1192. [Google Scholar] [CrossRef]

- Kim, H.-S.; Park, B.H.; Choi, J.H.; Yoon, J.-S. Mechanical properties and thermal stability of poly(L-lactide)/calcium carbonate composites. J. Appl. Polym. Sci. 2008, 109, 3087–3092. [Google Scholar] [CrossRef]

- Piekarska, K.; Piorkowska, E.; Bojda, J. The influence of matrix crystallinity, filler grain size and modification on properties of PLA/calcium carbonate composites. Polym. Test. 2017, 62, 203–209. [Google Scholar] [CrossRef]

- Kumar, V.; Dev, A.; Gupta, A.P. Studies of poly(lactic acid) based calcium carbonate nanocomposites. Compos. B Eng. 2014, 56, 184–188. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, G.; Siligardi, C.; Ori, G.; Lazzeri, A. Comparison of precipitated calcium carbonate/polylactic acid and halloysite/polylactic acid nanocomposites. J. Nanomater. 2015, 16, 67. [Google Scholar] [CrossRef]

- Asadi, Z.; Javadi, A.; Mohammadzadeh, F.; Alavi, K. Investigation on the role of nanoclay and nanocalcium carbonate on morphology, rheology, crystallinity and mechanical properties of binary and ternary nanocomposites based on PLA. Int. J. Polym. Anal. Charact. 2021, 26, 1–16. [Google Scholar] [CrossRef]

- Srisuwan, Y.; Baimark, Y. Thermal, morphological and mechanical properties of flexible poly(l-lactide)-b-polyethylene glycol-b-poly(l-lactide)/thermoplastic starch blends. Carbohydr. Polym. 2022, 283, 119155. [Google Scholar] [CrossRef]

- Baimark, Y.; Rungseesantivanon, W.; Prakymoramas, N. Synthesis of flexible poly(L-lactide)-b-polyethylene glycol-b-poly(L-lactide) bioplastics by ring-opening polymerization in the presence of chain extender. e-Polymers 2020, 20, 423–429. [Google Scholar] [CrossRef]

- Volpe, V.; Filitto, M.; Klofacova, V.; Santis, F.; Roberto Pantani, R. Effect of mold opening on the properties of PLA samples obtained by foam injection molding. Polym. Eng. Sci. 2018, 58, 475–484. [Google Scholar] [CrossRef]

- Baimark, Y.; Srihanam, P.; Srisuwan, Y.; Phromsopha, T. Enhancement in Crystallizability of Poly(L-Lactide) Using Stereocomplex-Polylactide Powder as a Nucleating Agent. Polymers 2022, 14, 4092. [Google Scholar] [CrossRef]

- Cuevas-Carballo, Z.B.; Duarte-Aranda, S.; Canch’ e-Escamilla, G. Properties and biodegradation of thermoplastic starch obtained from grafted starches with poly(lactic acid). J. Polym. Environ. 2019, 27, 2607–2617. [Google Scholar] [CrossRef]

- Pielichowski, K.; Flejtuch, K. Differential scanning calorimetry studies on poly(ethylene glycol) with different molecular weights for thermal energy storage materials. Polym. Adv. Technol. 2002, 13, 690–696. [Google Scholar] [CrossRef]

- Saeidlou, S.; Huneault, M.A.; Li, H.; Park, C.B. Poly(lactic acid) crystallization. Prog. Polym. Sci. 2012, 37, 1657–1677. [Google Scholar] [CrossRef]

- Huang, S.; Li, H.; Jiang, S.; Chen, X.; An, L. Crystal structure and morphology influenced by shear effect of poly(l-lactide) and its melting behavior revealed by WAXD, DSC and in-situ POM. Polymer 2011, 52, 3478–3487. [Google Scholar] [CrossRef]

- Aliotta, L.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A. Rigid filler toughening in PLA-calcium carbonate composites: Effect of particle surface treatment and matrix plasticization. Eur. Polym. J. 2019, 113, 78–88. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Alba, J.; Tarrés, Q.; Espinach, F.X.; Mutjé, P.; Delgado-Aguilar, M. Characterization of CaCO3 filled poly(lactic) acid and bio polyethylene materials for building applications. Polymers 2021, 13, 3323. [Google Scholar] [CrossRef]

- Mohd Zain, A.H.; Kahar, A.W.M.; Hanafi, I. Solid-state photocross-linking of cassava starch: Improvement properties of thermoplastic starch. Polym. Bull. 2018, 75, 3341–3356. [Google Scholar] [CrossRef]

- Mohd Zain, A.H.; Kahar, A.W.M.; Hanafi, I. Effect of calcium carbonate incorporation on the properties of low linear density polyethylene/thermoplastic starch blends. J. Eng. Sci. 2019, 15, 97–108. [Google Scholar] [CrossRef]

- Bindhu, B.; Renisha, R.; Roberts, L.; Varghese, T.O. Boron nitride reinforced polylactic acid composites film for packaging: Preparation and properties. Polym. Test. 2018, 66, 172–177. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, C.; Luo, C.; Chen, Y.; Zhou, Y.; Yao, B.; Dong, L.; Du, X.; Ji, J. Effect of talc and diatomite on compatible, morphological, and mechanical behavior of PLA/PBAT blends. e-Polymers 2021, 21, 234–243. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).