Cellulose-Based Intelligent Responsive Materials: A Review

Abstract

:1. Introduction

2. Preparation of Cellulose-Based Responsive Materials

2.1. Single-Layer Structure

2.2. Double-Layer/Multi-Layer Structure

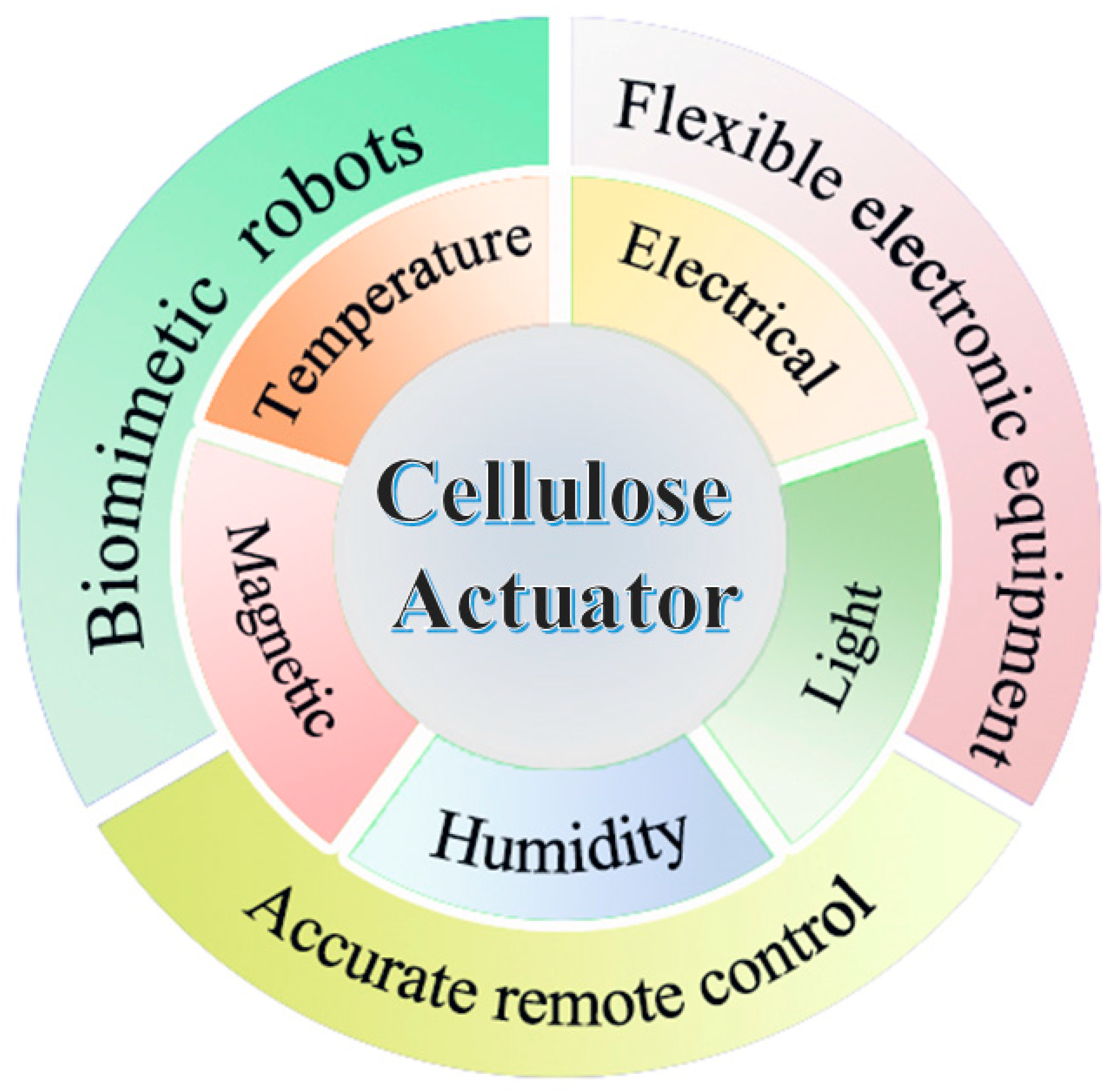

3. Response Mechanism of Actuators

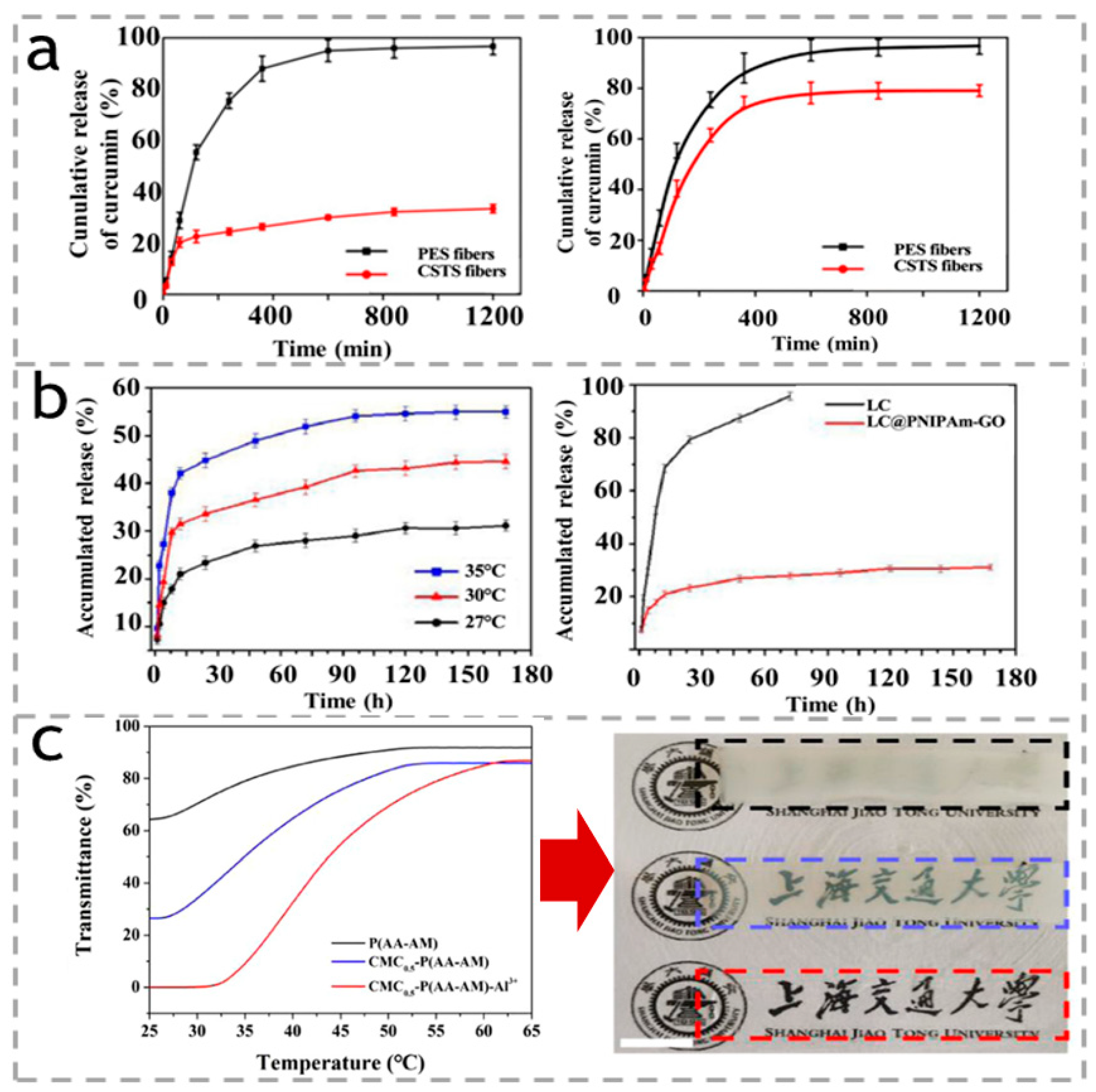

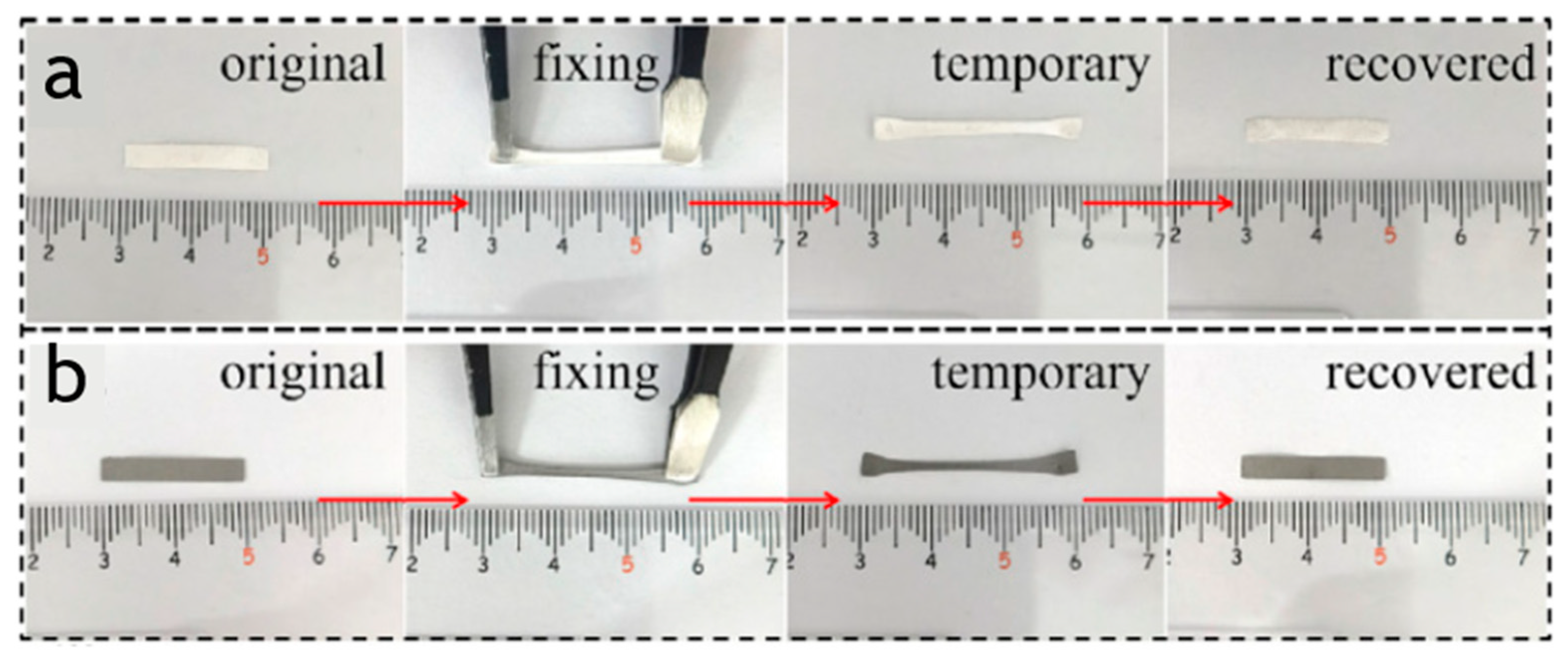

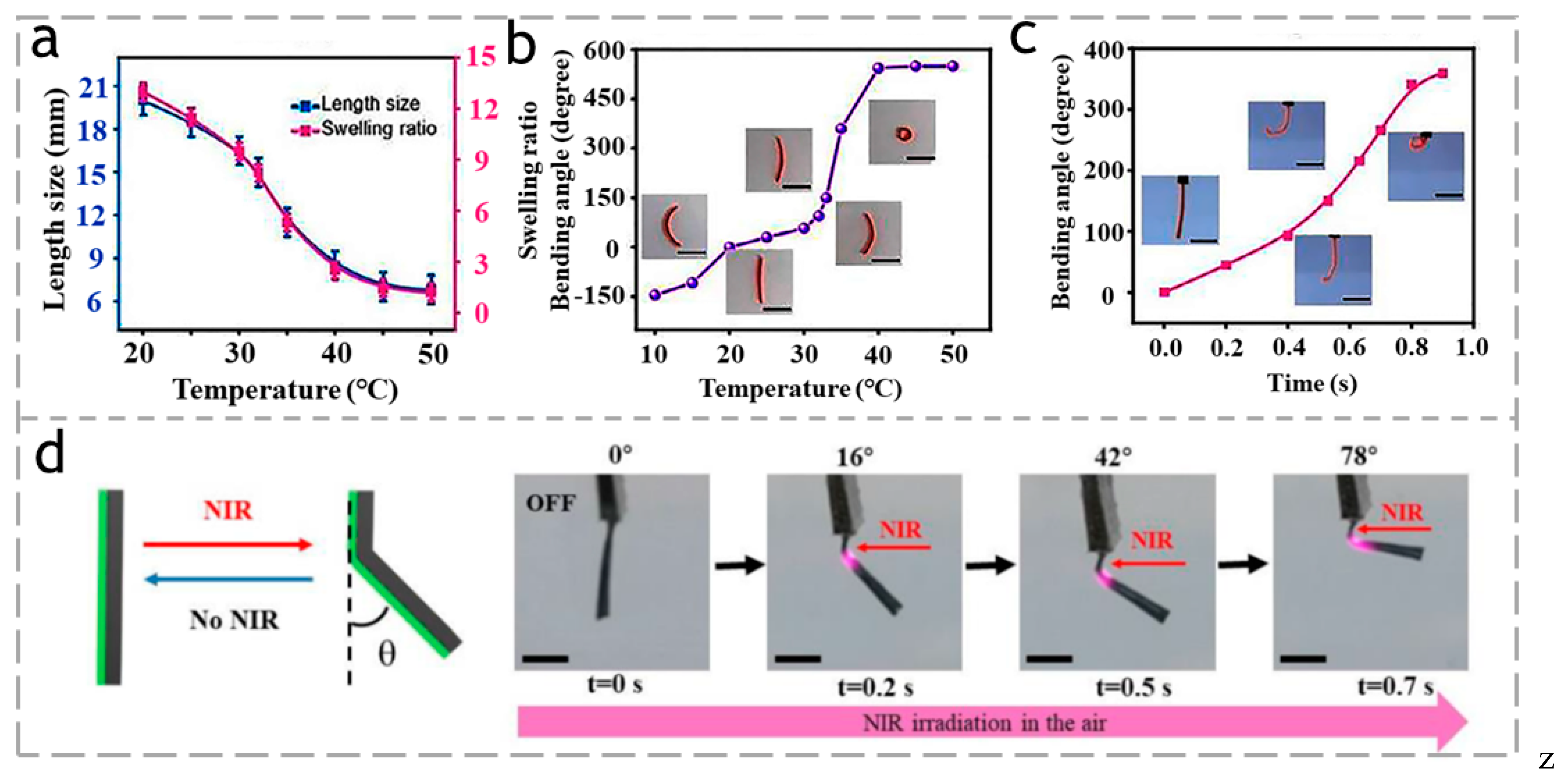

3.1. Temperature Response Mechanism

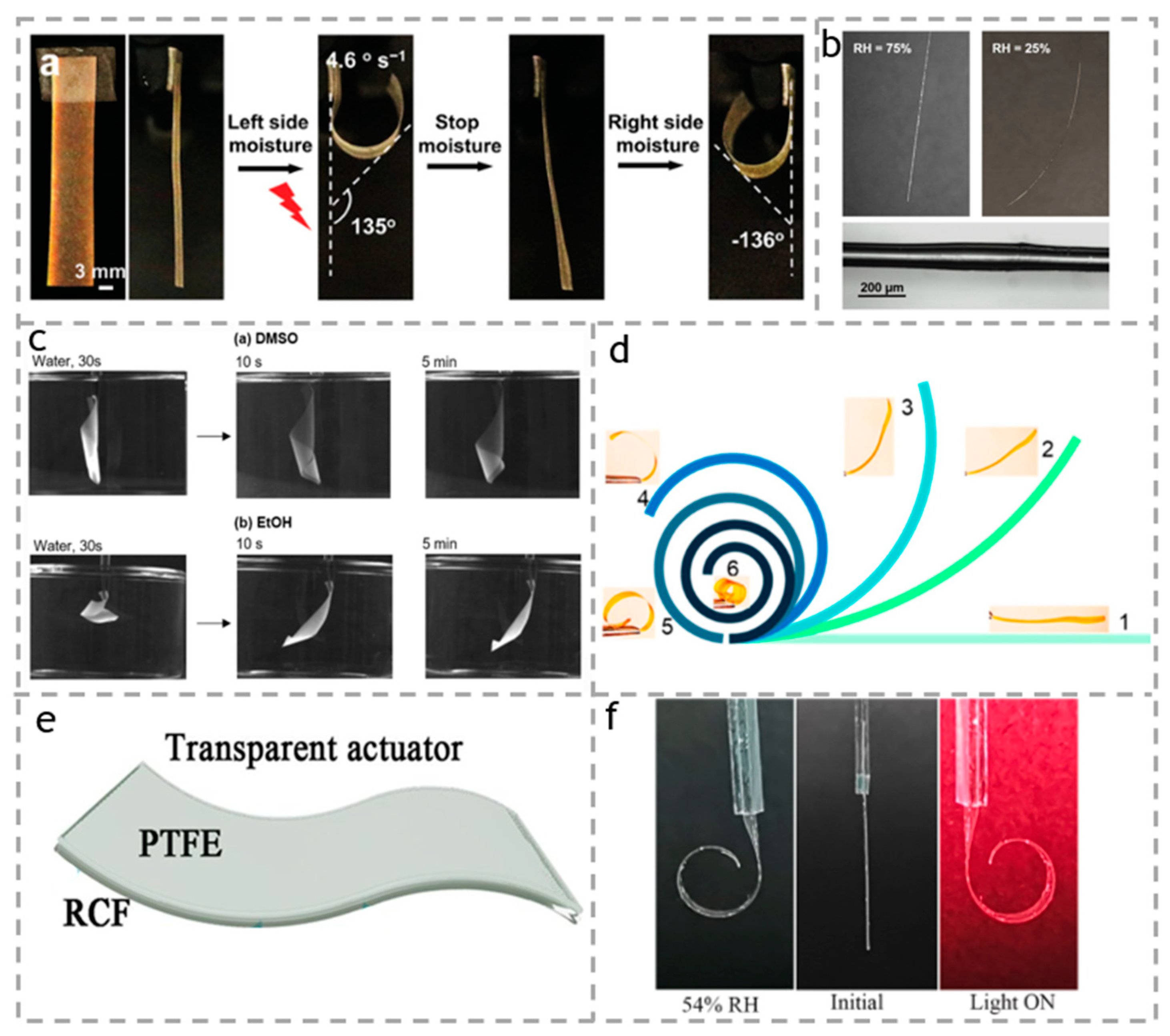

3.2. Light Response Mechanism

3.3. Electrical Response Mechanism

3.4. Magnetic Response Mechanism

3.5. Humidity Response Mechanism

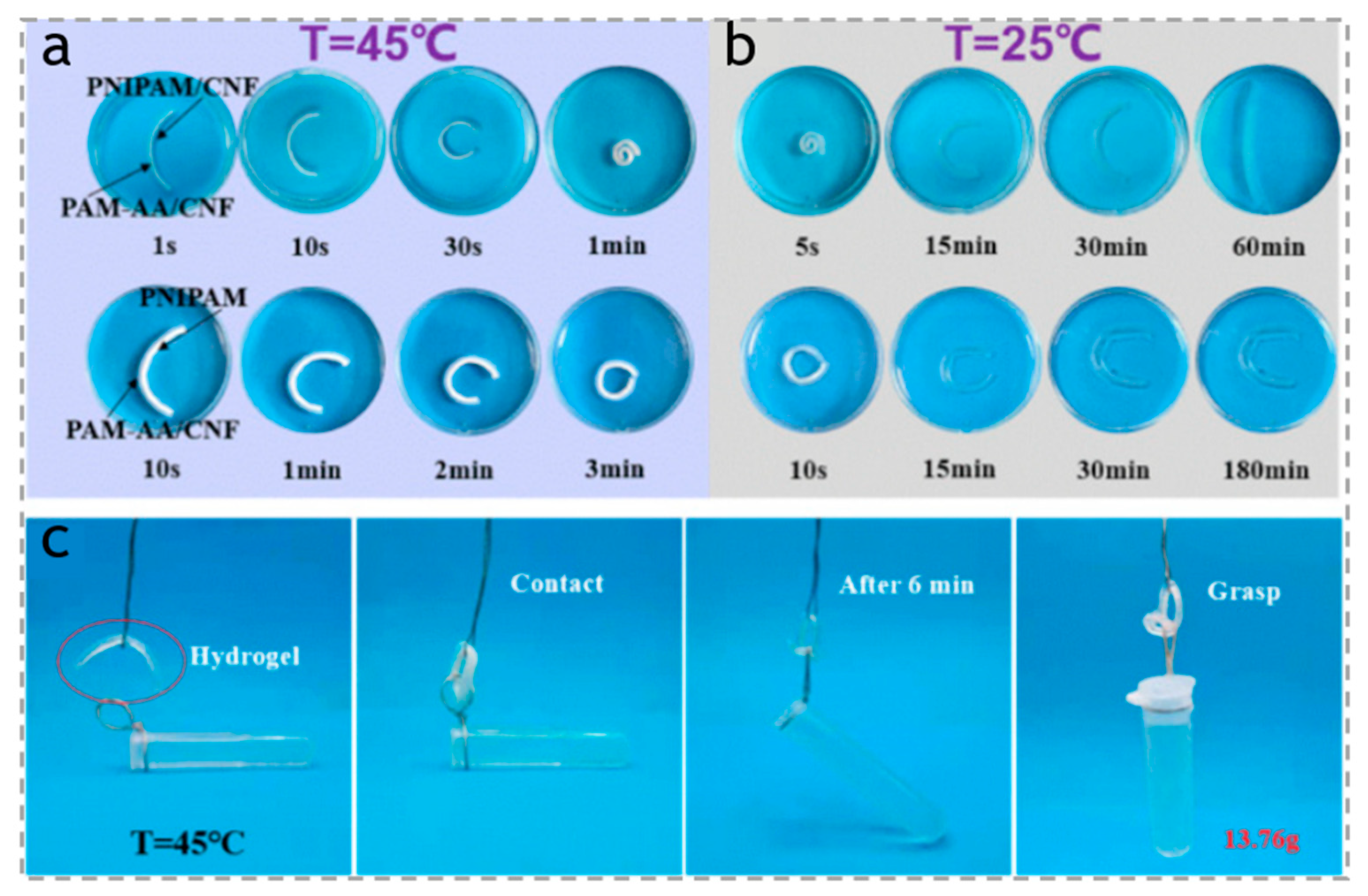

4. Cellulose-Based Temperature-Responsive Actuators

5. Cellulose-Based Light-Responsive Actuators

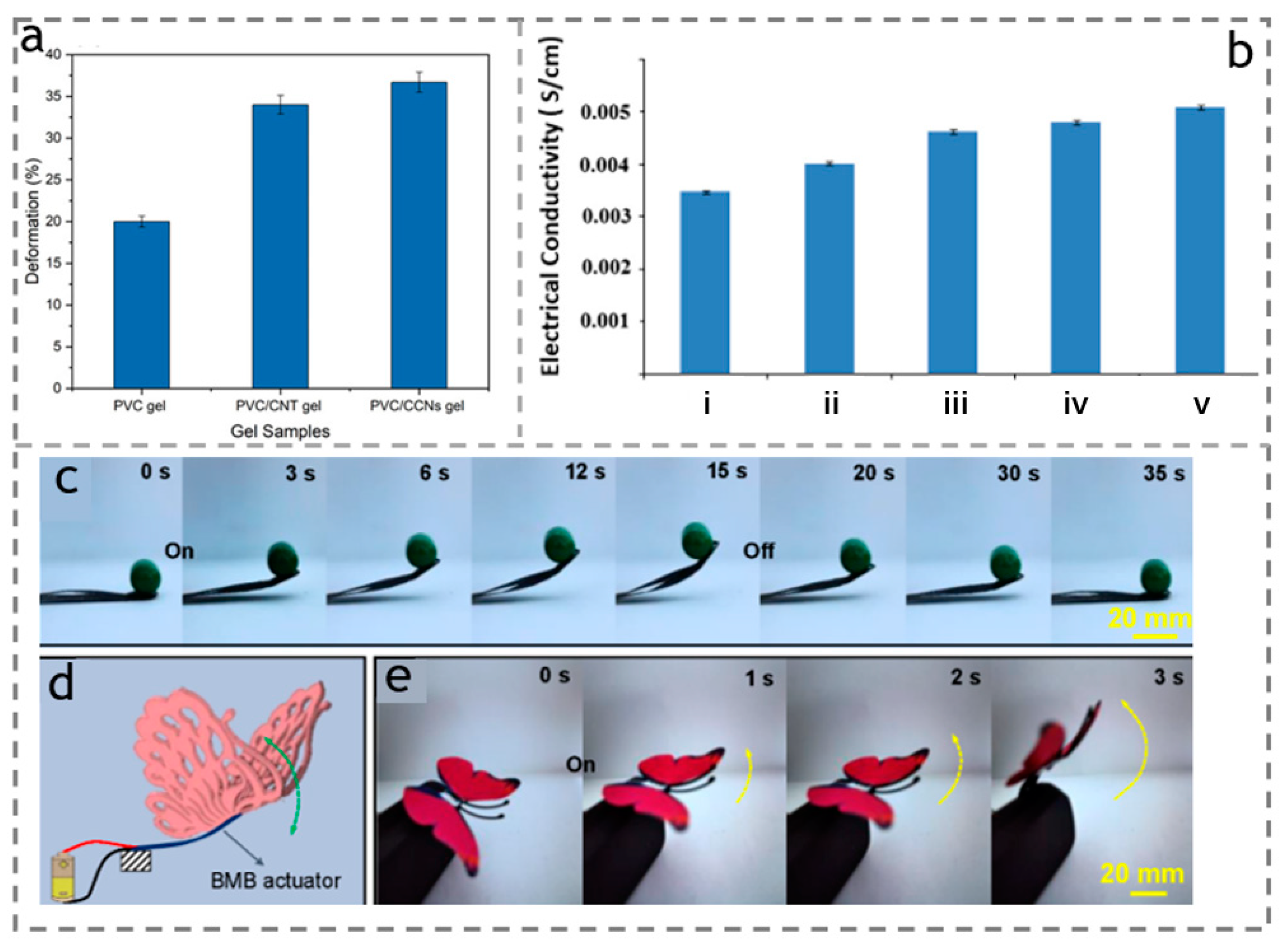

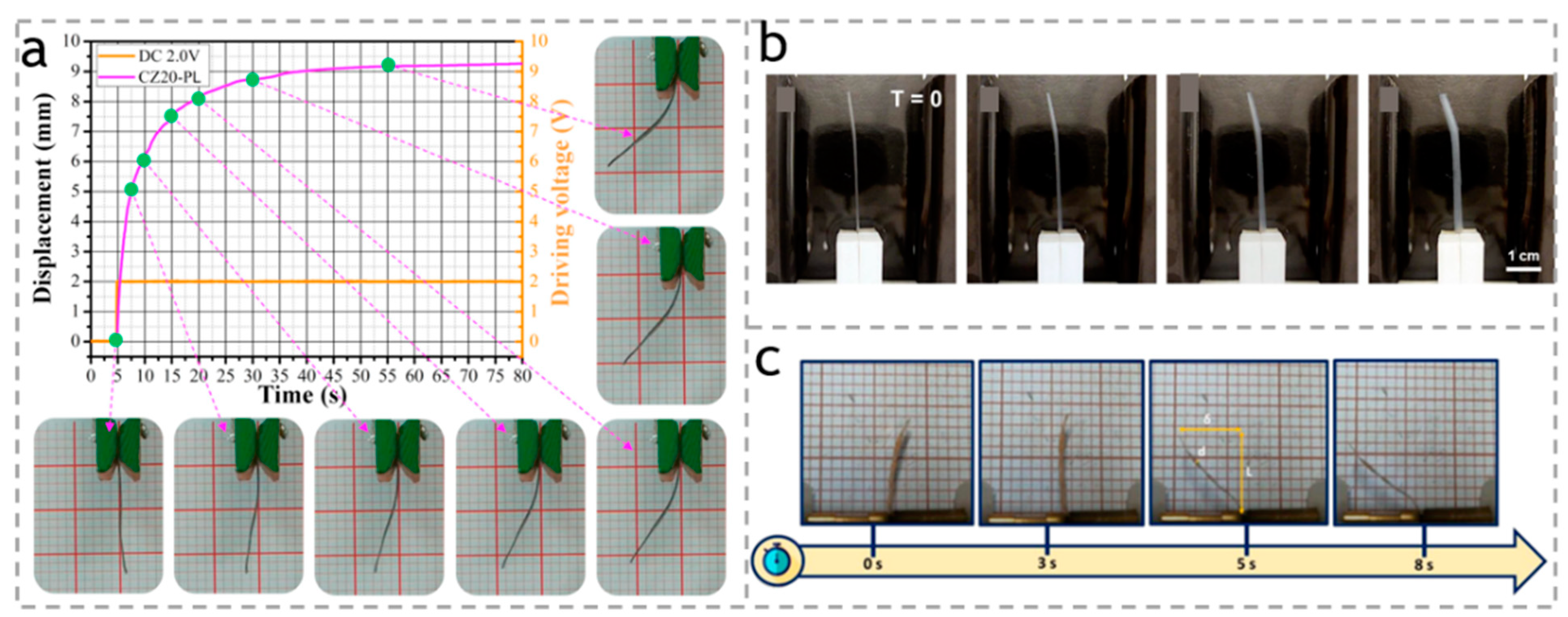

6. Cellulose-Based Electrically Responsive Actuators

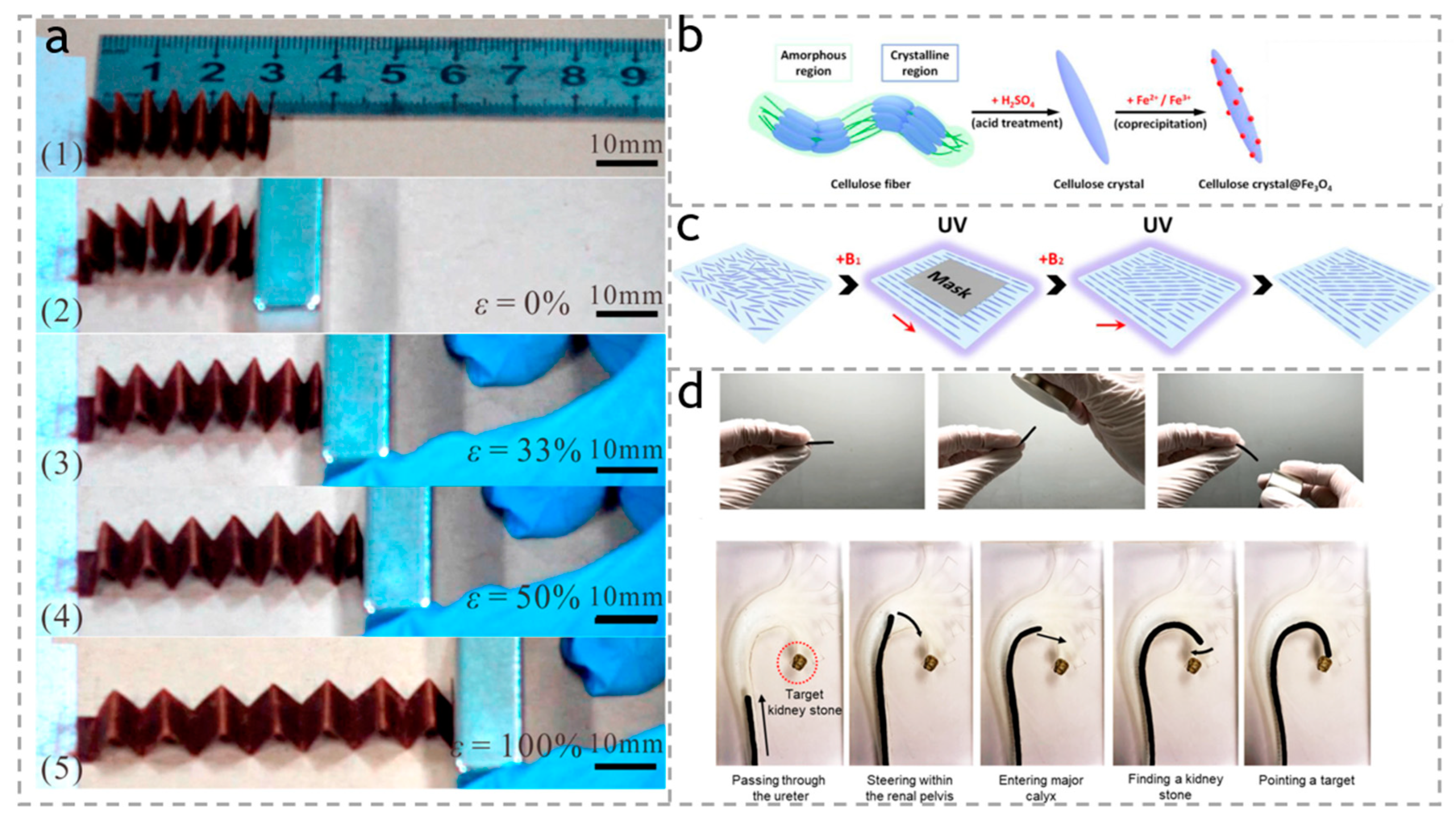

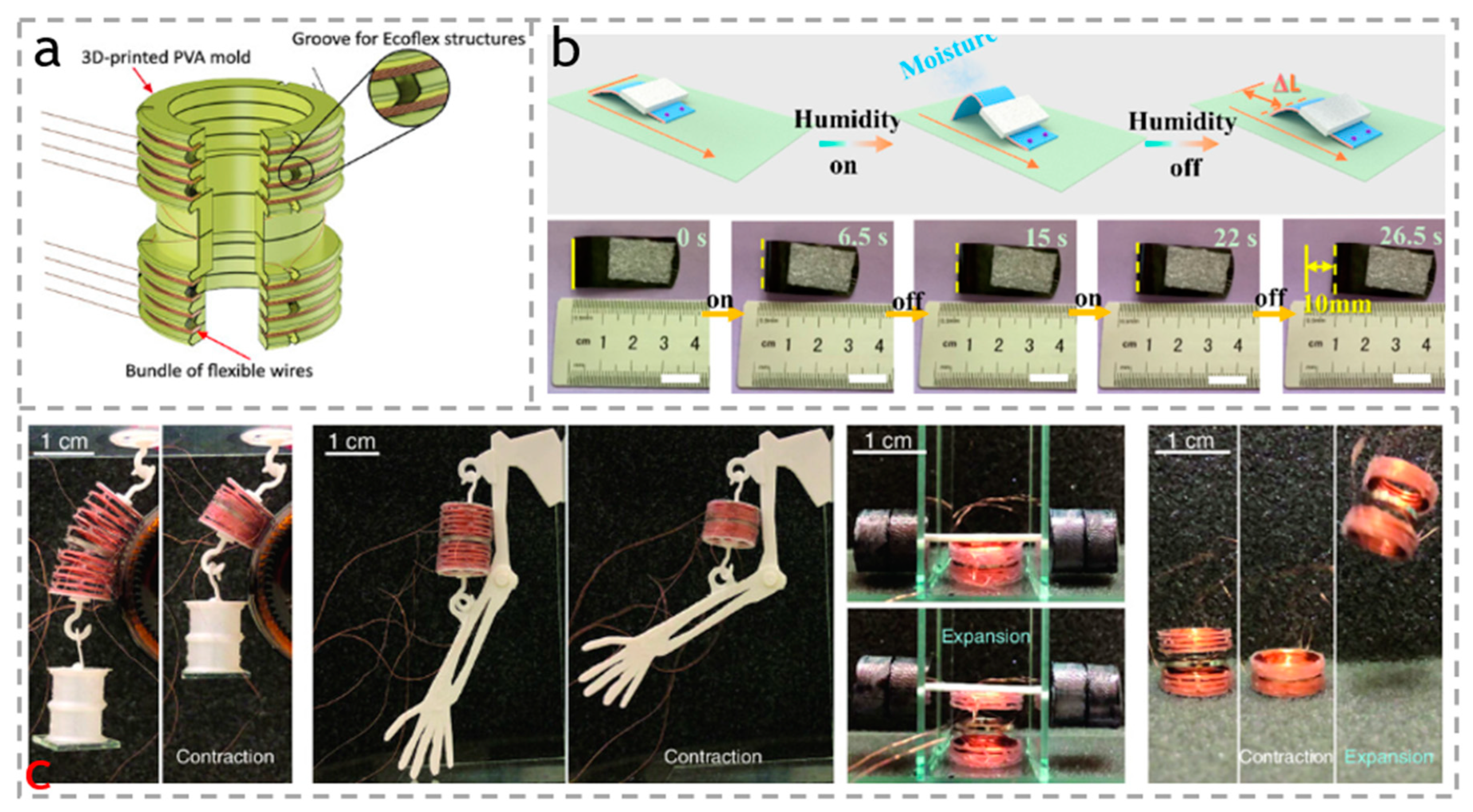

7. Cellulose-Based Magnetic-Responsive Actuators

8. Cellulose-Based Humidity-Responsive Actuators

9. Application of Cellulose-Based Actuators

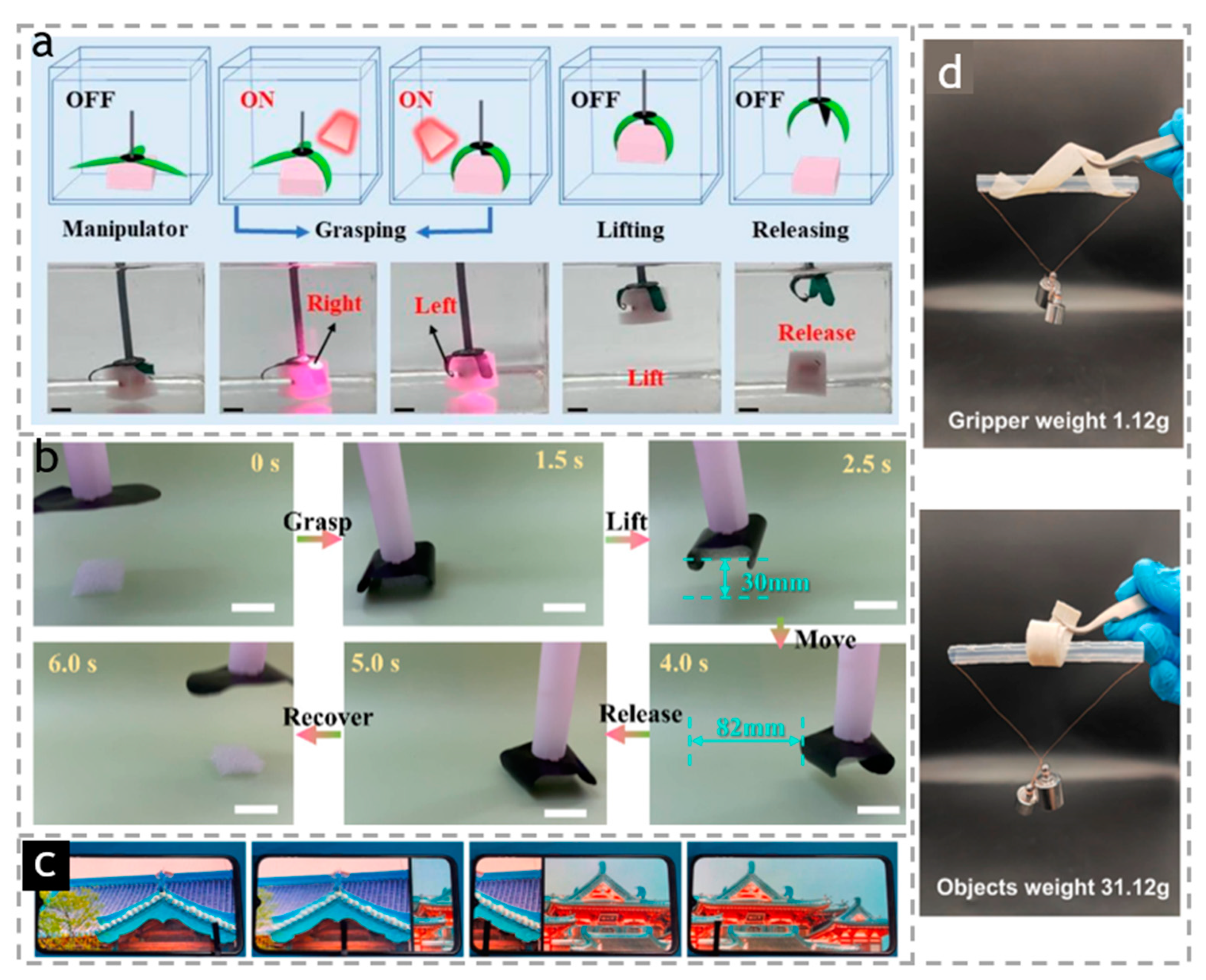

9.1. Biomimetic Robots

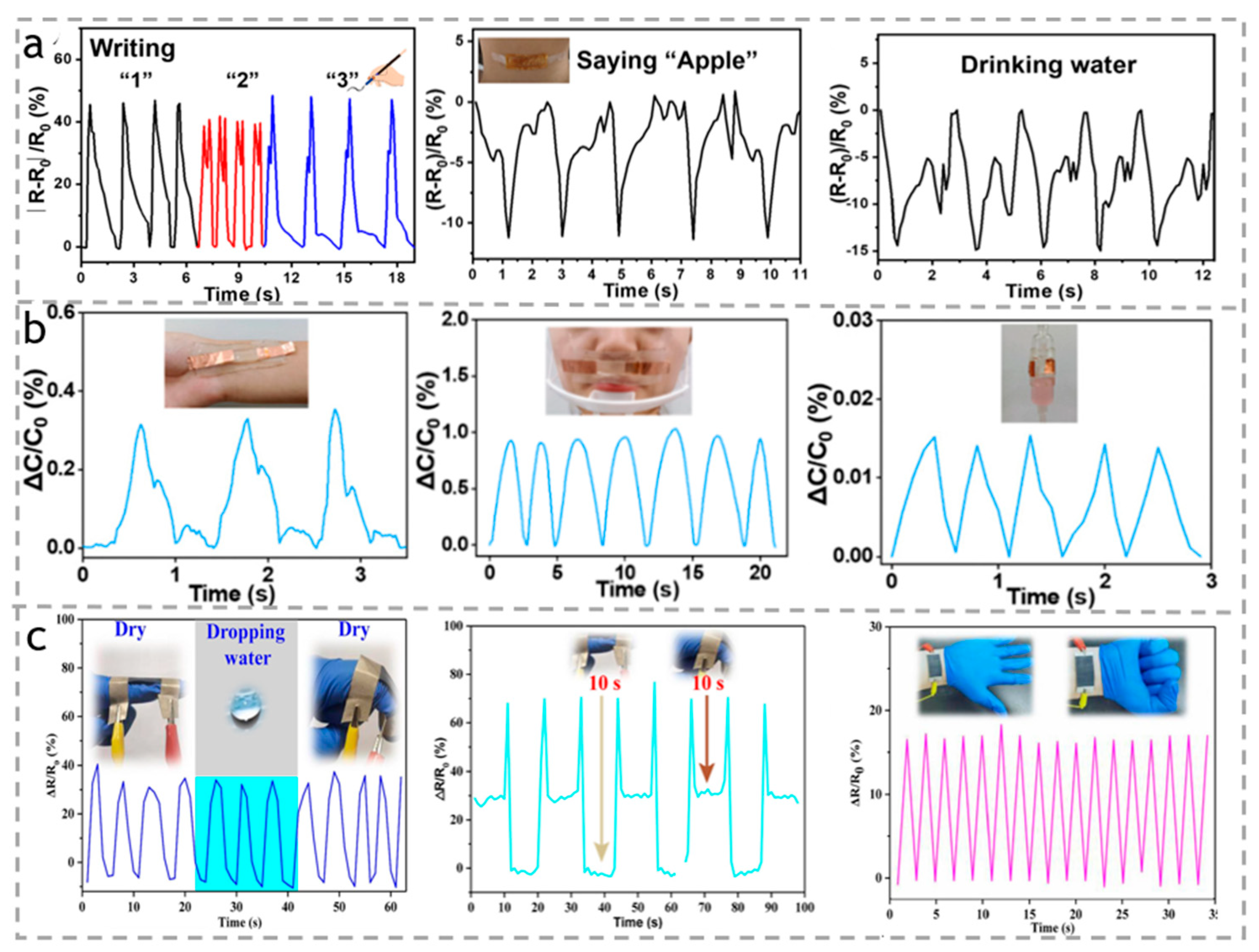

9.2. Flexible Electronic Equipment

9.3. Accurate Remote Control

10. Conclusions and Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, Y.; Li, Y.; Tao, Y.; Sun, L.; Yu, C. Recent advances in the material design for intelligent wearable devices. Mater. Chem. Front. 2023, 7, 3278–3297. [Google Scholar] [CrossRef]

- Wang, J.; Li, S.; Gao, D.; Xiong, J.; Lee, P.S. Reconfigurable and programmable origami dielectric elastomer actuators with 3D shape morphing and emissive architectures. NPG Asia Mater. 2019, 11, 71. [Google Scholar] [CrossRef]

- Wang, F.; Wang, L.; Wang, Y.; Wang, D. Highly bendable ionic electroactive polymer actuator based on carboxylated bacterial cellulose by doping with MWCNT. Appl. Phys. A 2022, 128, 911. [Google Scholar] [CrossRef]

- Nevstrueva, D.; Murashko, K.; Vunder, V.; Aabloo, A.; Pihlajamäki, A.; Mänttäri, M.; Pyrhönen, J.; Koiranen, T.; Torop, J. Natural cellulose ionogels for soft artificial muscles. Colloids Surf. B Biointerfaces 2018, 161, 244–251. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Sun, B.; Biehl, P.; Zhang, K. Cellulose-Based Soft Actuators. Macromol. Mater. Eng. 2022, 307, 2200072. [Google Scholar] [CrossRef]

- Constantinos, M.; Pfeiffer, C.; Mosley, M. Conventional actuators, shape memory alloys and electrorheological fluids. Autom. Miniat. Robot. Sens. Non-Destr. Test. Eval. 1999, 1, 26. [Google Scholar]

- Al-Khalili, J. The birth of the electric machines: A commentary on Faraday (1832) ‘Experimental researches in electricity’. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2015, 373, 20140208. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, J.; Han, X.; Yang, S.; An, G.; Lu, C. Fiber-Shaped Soft Actuators: Fabrication, Actuation Mechanism and Application. Adv. Fiber Mater. 2023, 5, 868–895. [Google Scholar] [CrossRef]

- Kim, H.; Lee, J.A.; Ambulo, C.P.; Lee, H.B.; Kim, S.H.; Naik, V.V.; Haines, C.S.; Aliev, A.E.; Ovalle-Robles, R.; Baughman, R.H.; et al. Intelligently Actuating Liquid Crystal Elastomer-Carbon Nanotube Composites. Adv. Funct. Mater. 2019, 29, 1905063. [Google Scholar] [CrossRef]

- Hwang, I.; Kim, H.J.; Mun, S.; Yun, S.; Kang, T.J. A Light-Driven Vibrotactile Actuator with a Polymer Bimorph Film for Localized Haptic Rendering. ACS Appl. Mater. Interfaces 2021, 13, 6597–6605. [Google Scholar] [CrossRef]

- Xiong, R.; Sauvage, F.; Fraire, J.C.; Huang, C.; De Smedt, S.C.; Braeckmans, K. Photothermal Nanomaterial-Mediated Photoporation. Acc. Chem. Res. 2023, 56, 631–643. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Weng, M.; Huang, F.; Zhang, W. Light- and humidity-driven actuators with programmable complex shape-deformations. Sens. Actuators B Chem. 2019, 282, 384–390. [Google Scholar] [CrossRef]

- Bhatti, M.R.A.; Bilotti, E.; Zhang, H.; Varghese, S.; Verpaalen, R.C.P.; Schenning, A.; Bastiaansen, C.W.M.; Peijs, T. Ultra-High Actuation Stress Polymer Actuators as Light-Driven Artificial Muscles. ACS Appl. Mater. Interfaces 2020, 12, 33210–33218. [Google Scholar] [CrossRef] [PubMed]

- Han, D.D.; Zhang, Y.L.; Ma, J.N.; Liu, Y.Q.; Han, B.; Sun, H.B. Light-Mediated Manufacture and Manipulation of Actuators. Adv. Mater. 2016, 28, 8328–8343. [Google Scholar] [CrossRef] [PubMed]

- Quashie, D., Jr.; Benhal, P.; Chen, Z.; Wang, Z.; Mu, X.; Song, X.; Jiang, T.; Zhong, Y.; Cheang, U.K.; Ali, J. Magnetic bio-hybrid micro actuators. Nanoscale 2022, 14, 4364–4379. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Xu, X.; Xu, J.; Dai, S.; Dong, X.; Han, F.; Yuan, N.; Ding, J. An ultra-large deformation bidirectional actuator based on a carbon nanotube/PDMS composite and a chitosan film. J. Mater. Chem. B 2019, 7, 7558–7565. [Google Scholar] [CrossRef]

- Miriyev, A.; Stack, K.; Lipson, H. Soft material for soft actuators. Nat Commun 2017, 8, 596. [Google Scholar] [CrossRef]

- Yang, H.; Leow, W.R.; Wang, T.; Wang, J.; Yu, J.; He, K.; Qi, D.; Wan, C.; Chen, X. 3D Printed Photoresponsive Devices Based on Shape Memory Composites. Adv. Mater. 2017, 29, 1701627. [Google Scholar] [CrossRef]

- Zhao, P.; Xu, B.; Zhang, Y.; Li, B.; Chen, H. Study on the Twisted and Coiled Polymer Actuator with Strain Self-Sensing Ability. ACS Appl. Mater. Interfaces 2020, 12, 15716–15725. [Google Scholar] [CrossRef]

- Liu, W.; Cheng, Y.; Liu, N.; Yue, Y.; Lei, D.; Su, T.; Zhu, M.; Zhang, Z.; Zeng, W.; Guo, H.; et al. Bionic MXene actuator with multiresponsive modes. Chem. Eng. J. 2021, 417, 129288. [Google Scholar] [CrossRef]

- Melling, D.; Martinez, J.G.; Jager, E.W.H. Conjugated Polymer Actuators and Devices: Progress and Opportunities. Adv. Mater. 2019, 31, 1808210. [Google Scholar] [CrossRef]

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 2016, 536, 451–455. [Google Scholar] [CrossRef] [PubMed]

- Basu, S.; Omadjela, O.; Gaddes, D.; Tadigadapa, S.; Zimmer, J.; Catchmark, J.M. Cellulose Microfibril Formation by Surface-Tethered Cellulose Synthase Enzymes. ACS Nano 2016, 10, 1896–1907. [Google Scholar] [CrossRef] [PubMed]

- Sinha, A.K.; Bhattacharya, S.; Narang, H.K. Abaca fibre reinforced polymer composites: A review. J. Mater. Sci. 2020, 56, 4569–4587. [Google Scholar] [CrossRef]

- Turner, S.; Kumar, M. Cellulose synthase complex organization and cellulose microfibril structure. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2018, 376, 20170048. [Google Scholar] [CrossRef]

- Che, X.; Wu, M.; Yu, G.; Liu, C.; Xu, H.; Li, B.; Li, C. Bio-inspired water resistant and fast multi-responsive Janus actuator assembled by cellulose nanopaper and graphene with lignin adhesion. Chem. Eng. J. 2022, 433, 133672. [Google Scholar] [CrossRef]

- Zhang, D.; Jian, J.; Xie, Y.; Gao, S.; Ling, Z.; Lai, C.; Wang, J.; Wang, C.; Chu, F.; Dumont, M.-J. Mimicking skin cellulose hydrogels for sensor applications. Chem. Eng. J. 2022, 427, 130921. [Google Scholar] [CrossRef]

- Yang, B.; Bi, W.; Zhong, C.a.; Huang, M.; Ni, Y.; He, L.; Wu, C. Moisture-triggered actuator and detector with high-performance: Interface engineering of graphene oxide/ethyl cellulose. Sci. China Mater. 2018, 61, 1291–1296. [Google Scholar] [CrossRef]

- Lin, F.; Wang, Z.; Shen, Y.; Tang, L.; Zhang, P.; Wang, Y.; Chen, Y.; Huang, B.; Lu, B. Natural skin-inspired versatile cellulose biomimetic hydrogels. J. Mater. Chem. A 2019, 7, 26442–26455. [Google Scholar] [CrossRef]

- Khan, A.; Khan, F.R.; Kim, H.S. Electro-Active Paper as a Flexible Mechanical Sensor, Actuator and Energy Harvesting Transducer: A Review. Sensors 2018, 18, 3474. [Google Scholar] [CrossRef]

- Lee, S.-W.; Kim, J.-H.; Kim, J.; Kim, H.S. Characterization and sensor application of cellulose electro-active paper (EAPap). Chin. Sci. Bull. 2009, 54, 2703–2707. [Google Scholar] [CrossRef]

- Yang, H.; Wu, F.; Zhu, G.; Li, H.; Jiang, S. Recent progress of modification and industrialization for nanocellulose towards green building materials. J. For. Eng. 2023, 8, 11–20. [Google Scholar] [CrossRef]

- Liang, X.; Chen, G.; Lin, S.; Zhang, J.; Wang, L.; Zhang, P.; Lan, Y.; Liu, J. Bioinspired 2D Isotropically Fatigue-Resistant Hydrogels. Adv. Mater. 2022, 34, 2107106. [Google Scholar] [CrossRef] [PubMed]

- Sano, K.; Ishida, Y.; Aida, T. Synthesis of Anisotropic Hydrogels and Their Applications. Angew. Chem. Int. Ed. 2018, 57, 2532–2543. [Google Scholar] [CrossRef]

- Roopsung, N.; Sugawara, A.; Hsu, Y.I.; Asoh, T.A.; Uyama, H. Cellulose Nanocrystal-Based Gradient Hydrogel Actuators with Controllable Bending Properties. Macromol. Rapid Commun. 2023, 16, 2300205. [Google Scholar] [CrossRef]

- Schafer, J.L.; Meckel, T.; Poppinga, S.; Biesalski, M. Chemical Gradients in Polymer-Modified Paper Sheets-Towards Single-Layer Biomimetic Soft Robots. Biomimetics 2023, 8, 43. [Google Scholar] [CrossRef]

- Wang, X.; Han, B.; Yu, R.-P.; Li, F.-C.; Zhao, Z.-Y.; Zhang, Q.-C.; Lu, T.J. Magnetic-responsive Fe3O4 nanoparticle-impregnated cellulose paper actuators. Extrem. Mech. Lett. 2018, 25, 53–89. [Google Scholar] [CrossRef]

- Lopes da Costa, L.; Moreau, C.; Lourdin, D.; Cathala, B.; Villares, A. Shape-recovery in organic solvents of water-responsive cellulose nanofiber actuators. Cellulose 2023, 30, 5811–5824. [Google Scholar] [CrossRef]

- Maki, Y. Poly(N,N-dimethylacrylamide)-clay nanocomposite hydrogels with patterned mechanical properties. Colloid Polym. Sci. 2019, 297, 587–594. [Google Scholar] [CrossRef]

- Zhang, E.; Wang, T.; Hong, W.; Sun, W.; Liu, X.; Tong, Z. Infrared-driving actuation based on bilayer graphene oxide-poly(N-isopropylacrylamide) nanocomposite hydrogels. J. Mater. Chem. A 2014, 2, 15633–15639. [Google Scholar] [CrossRef]

- Liu, L.; Jiang, S.; Sun, Y.; Agarwal, S. Giving Direction to Motion and Surface with Ultra-Fast Speed Using Oriented Hydrogel Fibers. Adv. Funct. Mater. 2015, 26, 1021–1027. [Google Scholar] [CrossRef]

- Ma, C.; Li, T.; Zhao, Q.; Yang, X.; Wu, J.; Luo, Y.; Xie, T. Supramolecular Lego Assembly Towards Three-Dimensional Multi-Responsive Hydrogels. Adv. Mater. 2014, 26, 5665–5669. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Ma, C.; Chen, L.; Sun, Y.; Wei, X.; Ma, C.; Zhao, H.; Yang, X.; Ma, X.; Zhang, C.; et al. A Tissue Paper/Hydrogel Composite Light-Responsive Biomimetic Actuator Fabricated by In Situ Polymerization. Polymers 2022, 14, 5454. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Zhang, K.; Ahn, J.; Wang, F.; Sun, Y.; Lee, J.; Young Cheong, J.; Ma, C.; Zhao, H.; Duan, G.; et al. Morph-genetic bamboo-reinforced hydrogel complex for bio-mimetic actuator. Chem. Eng. J. 2023, 463, 142391. [Google Scholar] [CrossRef]

- Huang, B.; Lin, F.; Tang, L.; Lu, Q.; Lu, B. Research advances of functional cellulose-based hydrogels and its applications. J. For. Eng. 2022, 7, 1–13. [Google Scholar] [CrossRef]

- Wu, Y.; Minamikawa, H.; Nakazumi, T.; Hara, Y. Actuation Properties of Paper Actuators Fabricated Using PEDOT/PSS Electrode Films. J. Oleo. Sci. 2020, 69, 1331–1337. [Google Scholar] [CrossRef]

- Terasawa, N. High-performance TEMPO-oxidised cellulose nanofibre/PEDOT:PSS/ionic liquid gel actuators. Sens. Actuators B Chem. 2021, 343, 130105. [Google Scholar] [CrossRef]

- Chen, Y.; Kuang, P.; Shen, X.; Lv, X.; Wang, Y.; Yin, W.; Zou, T.; Wang, B.; Liu, Y.; Fan, Q. Lignin precipitation-driven fabrication of gradient porous hydrogel actuator with temperature response. Smart Mater. Struct. 2023, 32, 035037. [Google Scholar] [CrossRef]

- Gao, S.; Zhou, A.; Cao, B.; Wang, J.; Li, F.; Tang, G.; Jiang, Z.; Yang, A.; Xiong, R.; Lei, J.; et al. A tunable temperature-responsive and tough platform for controlled drug delivery. New J. Chem. 2021, 45, 13056–13063. [Google Scholar] [CrossRef]

- Ghosh, R.; Misra, A. Carbon Nanotube-Based Hierarchical Paper Structure for Ultra-high Electrothermal Actuation in a Wide Humidity Range. ACS Appl. Electron. Mater. 2021, 3, 1260–1267. [Google Scholar] [CrossRef]

- Wei, Y.; Huo, H.; Huang, C.; Zhang, Q.; Hoogenboom, R.; Liu, F. Supramolecular control over self-assembly and double thermoresponsive behavior of an amphiphilic block copolymer. Eur. Polym. J. 2020, 125, 109537. [Google Scholar] [CrossRef]

- Toron, B.; Szperlich, P.; Koziol, M. SbSI Composites Based on Epoxy Resin and Cellulose for Energy Harvesting and Sensors-The Influence of SBSI Nanowires Conglomeration on Piezoelectric Properties. Materials 2020, 13, 902. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Yu, B.; Wang, S.; Shen, Y.; Cong, H. Preparation, surface functionalization and application of Fe(3)O(4) magnetic nanoparticles. Adv. Colloid Interface Sci. 2020, 281, 102165. [Google Scholar] [CrossRef] [PubMed]

- Vivekananthan, V.; Chandrasekhar, A.; Alluri, N.R.; Purusothaman, Y.; Khandelwal, G.; Pandey, R.; Kim, S.-J. Fe2O3 magnetic particles derived triboelectric-electromagnetic hybrid generator for zero-power consuming seismic detection. Nano Energy 2019, 64, 103926. [Google Scholar] [CrossRef]

- Xu, W.; Zheng, X.; Shangguan, Z.; Qu, J.; Zhang, W. A low-cost magnetic catalyst (MnFe2O4) for ciprofloxacin degradation via periodate activation: The synergistic effect of Mn and Fe. Chem. Eng. J. 2023, 464, 142562. [Google Scholar] [CrossRef]

- Erdem, D.; Bingham, N.S.; Heiligtag, F.J.; Pilet, N.; Warnicke, P.; Heyderman, L.J.; Niederberger, M. CoFe2O4and CoFe2O4-SiO2Nanoparticle Thin Films with Perpendicular Magnetic Anisotropy for Magnetic and Magneto-Optical Applications. Adv. Funct. Mater. 2016, 26, 1954–1963. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Xu, Y.; Shen, M.; Duan, C.; Dai, L.; Ni, Y. Green and sustainable cellulose-derived humidity sensors: A review. Carbohydr. Polym. 2021, 270, 118385. [Google Scholar] [CrossRef]

- Zhou, S.; Kong, X.; Strømme, M.; Xu, C. Efficient Solar Thermal Energy Conversion and Utilization by a Film of Conductive Metal–Organic Framework Layered on Nanocellulose. ACS Mater. Lett. 2022, 4, 1058–1064. [Google Scholar] [CrossRef]

- Tian, Y.; Liu, Y.; Ju, B.; Ren, X.; Dai, M. Thermoresponsive 2-hydroxy-3-isopropoxypropyl hydroxyethyl cellulose with tunable LCST for drug delivery. RSC Adv. 2019, 9, 2268–2276. [Google Scholar] [CrossRef]

- Mo, K.; He, M.; Cao, X.; Chang, C. Direct current electric field induced gradient hydrogel actuators with rapid thermo-responsive performance as soft manipulators. J. Mater. Chem. C 2020, 8, 2756–2763. [Google Scholar] [CrossRef]

- Michalska-Walkowiak, J.; Forster, B.; Hauschild, S.; Forster, S. Bistability, Remanence, Read/Write-Memory, and Logic Gate Function via a Stimuli-Responsive Polymer. Adv. Mater. 2022, 34, 2108833. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Helfricht, N.; Papastavrou, G.; Greiner, A.; Agarwal, S. Low-Density Self-Assembled Poly(N-Isopropyl Acrylamide) Sponges with Ultrahigh and Extremely Fast Water Uptake and Release. Macromol. Rapid Commun. 2018, 39, 1700838. [Google Scholar] [CrossRef] [PubMed]

- Kajornprai, T.; Katesripongsa, P.; Nam, S.Y.; Hamid, Z.A.A.; Ruksakulpiwat, Y.; Suppakarn, N.; Trongsatitkul, T. Potential Applications of Thermoresponsive Poly(N-Isoproplacrylamide)-Grafted Nylon Membranes: Effect of Grafting Yield and Architecture on Gating Performance. Polymers 2023, 15, 497. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Geng, L.; Wu, J.; Huang, A.; Peng, X. Highly strong and sensitive bilayer hydrogel actuators enhanced by cross-oriented nanocellulose networks. Compos. Sci. Technol. 2022, 225, 109494. [Google Scholar] [CrossRef]

- Wei, Z.; Liu, Z.; Wang, X.; Long, S.; Yang, J. Smart carrier from electrospun core-shell thermo-sensitive ultrafine fibers for controlled drug release. Eur. Polym. J. 2019, 114, 1–10. [Google Scholar] [CrossRef]

- Wang, Y.; Song, S.; Chu, X.; Feng, W.; Li, J.; Huang, X.; Zhou, N.; Shen, J. A new temperature-responsive controlled-release pesticide formulation—Poly(N-isopropylacrylamide) modified graphene oxide as the nanocarrier for lambda-cyhalothrin delivery and their application in pesticide transportation. Colloids Surf. A Physicochem. Eng. Asp. 2021, 612, 125987. [Google Scholar] [CrossRef]

- Zhen, C.; Jing, L.; Yujie, C.; Xu, Z.; Hezhou, L.; Hua, L. Multiple-Stimuli-Responsive and Cellulose Conductive Ionic Hydrogel for Smart Wearable Devices and Thermal Actuators. ACS Appl. Mater. Interfaces 2020, 13, 1353–1366. [Google Scholar] [CrossRef]

- Zong, R.; Hu, X.; Shang, M.; Wu, C.; Shentu, B. Phase Morphology and Conductive Properties of PBT/POE-g-GMA/PP/CNT Nanocomposites with a Tri-Continuous Structure via Thermal Annealing. Ind. Eng. Chem. Res. 2023, 62, 8289–8296. [Google Scholar] [CrossRef]

- Mao, F.; Fan, X.; Long, L.; Li, Y.; Chen, H.; Zhou, W. Constructing 3D hierarchical CNTs/VO2 composite microspheres with superior electromagnetic absorption performance. Ceram. Int. 2023, 49, 16924–16931. [Google Scholar] [CrossRef]

- Ji, C.; Wang, Y.; Ye, Z.; Tan, L.; Mao, D.; Zhao, W.; Zeng, X.; Yan, C.; Sun, R.; Kang, D.J.; et al. Ice-Templated MXene/Ag-Epoxy Nanocomposites as High-Performance Thermal Management Materials. ACS Appl. Mater. Interfaces 2020, 12, 24298–24307. [Google Scholar] [CrossRef]

- Mao, F.; Long, L.; Pi, W.; Li, Y.; Zhou, W. X-band electromagnetic absorption and mechanical properties of mullite/Ti3AlC2 composites. Mater. Chem. Phys. 2022, 292, 126819. [Google Scholar] [CrossRef]

- Wei, J.; Jia, S.; Wei, J.; Ma, C.; Shao, Z. Tough and Multifunctional Composite Film Actuators Based on Cellulose Nanofibers toward Smart Wearables. ACS Appl. Mater. Interfaces 2021, 13, 38700–38711. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Zhou, Z.; Zhu, Q.; Lu, S.; Li, Y.; Ionov, L. Electrospun cellulose acetate nanofibrous composites for multi-responsive shape memory actuators and self-powered pressure sensors. Carbohydr. Polym. 2023, 313, 120868. [Google Scholar] [CrossRef] [PubMed]

- Almeida, A.P.C.; Canejo, J.P.; Almeida, P.L.; Godinho, M.H. Cholesteric-type cellulosic structures: From plants to applications. Liq. Cryst. 2019, 46, 1937–1949. [Google Scholar] [CrossRef]

- Chang, T.; Wang, B.; Yuan, D.; Wang, Y.; Smalyukh, I.; Zhou, G.; Zhang, Z. Cellulose nanocrystal chiral photonic micro-flakes for multilevel anti-counterfeiting and identification. Chem. Eng. J. 2022, 446, 136630. [Google Scholar] [CrossRef]

- Juanjuan, S.; Jiayin, L.; Weidong, Y.; Jialing, T.; Yunjie, Y.; Chaoxia, W. Chiral Nematic Solvent-Responsive Actuator Based on a Cellulose Nanocrystal Template. ACS Appl. Polym. Mater. 2022, 12, 8952–8961. [Google Scholar] [CrossRef]

- Li, X.; Liu, J.; Zhang, X. Pressure/Temperature Dual-Responsive Cellulose Nanocrystal Hydrogels for On-Demand Schemochrome Patterning. Adv. Funct. Mater. 2023, 33, 2306208. [Google Scholar] [CrossRef]

- Orelma, H.; Hokkanen, A.; Leppänen, I.; Kammiovirta, K.; Kapulainen, M.; Harlin, A. Optical cellulose fiber made from regenerated cellulose and cellulose acetate for water sensor applications. Cellulose 2019, 27, 1543–1553. [Google Scholar] [CrossRef]

- Ren, Y.; Fang, L.; Liu, Y.; Shen, C.; Wu, L.; Zheng, X.; Fang, K. Warming performance of far infrared lights electrogenerated by carbon nanotubes composite fabrics. Mater. Lett. 2022, 319, 132220. [Google Scholar] [CrossRef]

- Loeb, S.; Li, C.; Kim, J.H. Solar Photothermal Disinfection using Broadband-Light Absorbing Gold Nanoparticles and Carbon Black. Env. Sci. Technol. 2018, 52, 205–213. [Google Scholar] [CrossRef]

- Simayee, M.; Esfandiar, A. Synergistic effect of reduced graphene oxide and carbon black as hybrid light absorber for efficient and antifouling texture-based solar steam generator. Sol. Energy 2022, 238, 226–237. [Google Scholar] [CrossRef]

- Zhao, Q.; Liang, Y.; Ren, L.; Yu, Z.; Zhang, Z.; Qiu, F.; Ren, L. Design and fabrication of nanofibrillated cellulose-containing bilayer hydrogel actuators with temperature and near infrared laser responses. J. Mater. Chem. B 2018, 6, 1260–1271. [Google Scholar] [CrossRef] [PubMed]

- Xinkai, L.; Jize, L.; Dongdong, L.; Shaoquan, H.; Kai, H.; Xinxing, Z. Bioinspired Multi-Stimuli Responsive Actuators with Synergistic Color- and Morphing-Change Abilities. Adv. Sci. 2021, 8, 2101295. [Google Scholar] [CrossRef]

- Chen, L.; Wei, X.; Wang, F.; Jian, S.; Yang, W.; Ma, C.; Duan, G.; Jiang, S. In-situ polymerization for mechanical strong composite actuators based on anisotropic wood and thermoresponsive polymer. Chin. Chem. Lett. 2022, 33, 2635–2638. [Google Scholar] [CrossRef]

- Chen, L.; Wei, X.; Sun, Y.; Xue, Y.; Wang, J.; Wu, Q.; Ma, C.; Yang, X.; Duan, G.; Wang, F.; et al. A bamboo/PNIPAM composite hydrogel assembly for both programmable and remotely-controlled light-responsive biomimetic actuations. Chem. Eng. J. 2022, 446, 137072. [Google Scholar] [CrossRef]

- Wang, F.; Lee, J.; Chen, L.; Zhang, G.; He, S.; Han, J.; Ahn, J.; Cheong, J.Y.; Jiang, S.; Kim, I.-D. Inspired by Wood: Thick Electrodes for Supercapacitors. ACS Nano 2023, 17, 8866–8898. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, H.; Xiong, R.; Huang, C. Xylan-based ratiometric fluorescence carbon dots composite with delignified wood for highly efficient water purification and photothermal conversion. Sep. Purif. Technol. 2023, 324, 124513. [Google Scholar] [CrossRef]

- Qu, Q.; Zhang, J.; Chen, X.; Ravanbakhsh, H.; Tang, G.; Xiong, R.; Manshian, B.B.; Soenen, S.J.; Sauvage, F.; Braeckmans, K.; et al. Triggered Release from Cellulose Microparticles Inspired by Wood Degradation by Fungi. ACS Sustain. Chem. Eng. 2021, 9, 387–397. [Google Scholar] [CrossRef]

- Chen, L.; Sun, Y.; Wang, J.; Ma, C.; Peng, S.; Cao, X.; Yang, L.; Ma, C.; Duan, G.; Liu, Z. A wood-mimetic porous MXene/gelatin hydrogel for electric field/sunlight bi-enhanced uranium adsorption. e-Polymers 2022, 22, 468–477. [Google Scholar] [CrossRef]

- Yun, G.-Y.; Kim, J.-H.; Kim, J. Dielectric and polarization behaviour of cellulose electro-active paper (EAPap). J. Phys. D Appl. Phys. 2009, 42, 082003. [Google Scholar] [CrossRef]

- Irfan, M.; Ali, I.; Ali, A.; Ahmed, M.; Soomro, T.A.; Yang, W.; Rahman, S.; Faraj Mursal, S.N.; Jalalah, M.; Jazem Ghanim, A.A. Analysis of the Performance of a Gel Actuator Made of Plasticized Polyvinyl Chloride/Carboxylated Cellulose Nanocrystals. ACS Omega 2023, 8, 17976–17982. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Dai, W.; Wang, L.; Yao, C.; Wang, C.; Gu, B.; Li, D.; He, J. Electroactive Oxidized Alginate/Gelatin/MXene (Ti(3)C(2)T(x)) Composite Hydrogel with Improved Biocompatibility and Self-Healing Property. Polymers 2022, 14, 3908. [Google Scholar] [CrossRef] [PubMed]

- Deng, W.; Xu, Y.; Zhang, X.; Li, C.; Liu, Y.; Xiang, K.; Chen, H. (NH4)2Co2V10O28·16H2O/(NH4)2V10O25·8H2O heterostructure as cathode for high-performance aqueous Zn-ion batteries. J. Alloys Compd. 2022, 903, 163824. [Google Scholar] [CrossRef]

- Wu, M.-S.; Lyu, L.-J.; Syu, J.-H. Copper and nickel hexacyanoferrate nanostructures with graphene-coated stainless steel sheets for electrochemical supercapacitors. J. Power Sources 2015, 297, 75–82. [Google Scholar] [CrossRef]

- Sen, I.; Seki, Y.; Sarikanat, M.; Cetin, L.; Gurses, B.O.; Ozdemir, O.; Yilmaz, O.C.; Sever, K.; Akar, E.; Mermer, O. Electroactive behavior of graphene nanoplatelets loaded cellulose composite actuators. Compos. Part B Eng. 2015, 69, 369–377. [Google Scholar] [CrossRef]

- Tang, Z.H.; Zhu, W.B.; Mao, Y.Q.; Zhu, Z.C.; Li, Y.Q.; Huang, P.; Fu, S.Y. Multiresponsive Ti(3)C(2)T(x) MXene-Based Actuators Enabled by Dual-Mechanism Synergism for Soft Robotics. ACS Appl. Mater. Interfaces 2022, 14, 21474–21485. [Google Scholar] [CrossRef]

- Zhou, J.; Mulle, M.; Zhang, Y.; Xu, X.; Li, E.Q.; Han, F.; Thoroddsen, S.T.; Lubineau, G. High-ampacity conductive polymer microfibers as fast response wearable heaters and electromechanical actuators. J. Mater. Chem. C 2016, 4, 1238–1249. [Google Scholar] [CrossRef]

- Kayser, L.V.; Lipomi, D.J. Stretchable Conductive Polymers and Composites Based on PEDOT and PEDOT:PSS. Adv. Mater. 2019, 31, e1806133. [Google Scholar] [CrossRef]

- Najathulla, B.C.; Kumar, S.; Deshpande, A.S.; Khandelwal, M. PEDOT:PSS-bacterial cellulose bilayer actuators: From the movement of ions to deflection. Polym. Adv. Technol. 2023, 34, 2407–2413. [Google Scholar] [CrossRef]

- Terasawa, N.; Asaka, K. Self-standing cellulose nanofiber/poly(3,4-ethylenedioxythiophene):poly(4-styrenesulfonate)/ionic liquid actuators with superior performance. RSC Adv. 2018, 8, 33149–33155. [Google Scholar] [CrossRef]

- Wang, F.; Wang, L.; Wu, Z.; Wang, W. A low-voltage electro-ionic soft actuator based on graphene nanoplatelets-sulfonated cellulose nanowhisker combined with microfibrillated cellulose. J. Mater. Sci. 2023, 58, 466–477. [Google Scholar] [CrossRef]

- Wang, F.; Jin, Z.; Zheng, S.; Li, H.; Cho, S.; Kim, H.J.; Kim, S.-J.; Choi, E.; Park, J.-O.; Park, S. High-fidelity bioelectronic muscular actuator based on porous carboxylate bacterial cellulose membrane. Sens. Actuators B Chem. 2017, 250, 402–411. [Google Scholar] [CrossRef]

- Reid, L.; Hamad, W.Y. Electro-osmotic Actuators from Cellulose Nanocrystals and Nanocomposite Hydrogels. ACS Appl. Polym. Mater. 2021, 4, 598–606. [Google Scholar] [CrossRef]

- Correia, D.M.; Lizundia, E.; Meira, R.M.; Rincón-Iglesias, M.; Lanceros-Méndez, S. Cellulose Nanocrystal and Water-Soluble Cellulose Derivative Based Electromechanical Bending Actuators. Materials 2020, 13, 2294. [Google Scholar] [CrossRef]

- Chen, X.; Ye, Z.; Yang, F.; Feng, J.; Li, Z.; Huang, C.; Ke, Q.; Yin, Y. Magnetic cellulose microcrystals with tunable magneto-optical responses. Appl. Mater. Today 2020, 20, 100749. [Google Scholar] [CrossRef]

- Tomás, A.R.; Gonçalves, A.I.; Paz, E.; Freitas, P.; Domingues, R.M.A.; Gomes, M.E. Magneto-mechanical actuation of magnetic responsive fibrous scaffolds boosts tenogenesis of human adipose stem cells. Nanoscale 2019, 11, 18255–18271. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Hyun, J. Soft Magnetostrictive Actuator String with Cellulose Nanofiber Skin. ACS Appl. Mater. Interfaces 2021, 13, 43904–43913. [Google Scholar] [CrossRef]

- Ge, W.; Zhang, F.; Wang, D.; Wei, Q.; Li, Q.; Feng, Z.; Feng, S.; Xue, X.; Qing, G.; Liu, Y. Highly Tough, Stretchable, and Solvent-Resistant Cellulose Nanocrystal Photonic Films for Mechanochromism and Actuator Properties. Small 2022, 18, 2107105. [Google Scholar] [CrossRef]

- Hartings, M.; Douglass, K.O.; Neice, C.; Ahmed, Z. Humidity Responsive Photonic Sensor based on a Carboxymethyl Cellulose Mechanical Actuator. Sens. Actuators B Chem. 2018, 265, 335–338. [Google Scholar] [CrossRef]

- Kuang, Y.; Chen, C.; Cheng, J.; Pastel, G.; Li, T.; Song, J.; Jiang, F.; Li, Y.; Zhang, Y.; Jang, S.-H.; et al. Selectively aligned cellulose nanofibers towards high-performance soft actuators. Extrem. Mech. Lett. 2019, 29, 100463. [Google Scholar] [CrossRef]

- Yinan, L.; Jun, W.; Huixin, L.; Liulian, H.; Lihui, C.; Yonghao, N.; Qinghong, Z. Highly transparent RCF/PTFE humidity and IR light dual-driven actuator with high force density, sensitivity and stability. Appl. Surf. Sci. 2021, 572, 151502. [Google Scholar] [CrossRef]

- Cao, J.; Zhou, Z.; Song, Q.; Chen, K.; Su, G.; Zhou, T.; Zheng, Z.; Lu, C.; Zhang, X. Ultrarobust Ti(3)C(2)T(x) MXene-Based Soft Actuators via Bamboo-Inspired Mesoscale Assembly of Hybrid Nanostructures. ACS Nano 2020, 14, 7055–7065. [Google Scholar] [CrossRef] [PubMed]

- Jie, W.; Shuai, J.; Chao, M.; Jie, G.; Chunxia, Y.; Libin, Z.; Ziqiang, S. Nacre-inspired composite film with mechanical robustness for highly efficient actuator powered by humidity gradients. Chem. Eng. J. 2022, 451, 138565. [Google Scholar] [CrossRef]

- Yang, L.; Cui, J.; Zhang, L.; Xu, X.; Chen, X.; Sun, D. A Moisture-Driven Actuator Based on Polydopamine-Modified MXene/Bacterial Cellulose Nanofiber Composite Film. Adv. Funct. Mater. 2021, 31, 2101378. [Google Scholar] [CrossRef]

- Li, P.; Su, N.; Wang, Z.; Qiu, J. A Ti3C2Tx MXene-Based Energy-Harvesting Soft Actuator with Self-Powered Humidity Sensing and Real-Time Motion Tracking Capability. ACS Nano 2021, 15, 16811–16818. [Google Scholar] [CrossRef]

- Mohammadi, M.; Berggren, M.; Tybrandt, K. Versatile Ultrasoft Electromagnetic Actuators with Integrated Strain-Sensing Cellulose Nanofibril Foams. Adv. Intell. Syst. 2023, 5, 2200449. [Google Scholar] [CrossRef]

- Wei, J.; Jia, S.; Guan, J.; Ma, C.; Shao, Z. Robust and Highly Sensitive Cellulose Nanofiber-Based Humidity Actuators. ACS Appl. Mater. Interfaces 2021, 13, 54417–54427. [Google Scholar] [CrossRef]

- Yang, K.; Cai, W.; Lan, M.; Ye, Y.; Tang, Z.; Guo, Q.; Weng, M. Multi-responsive and programmable actuators made with nacre-inspired graphene oxide-bacterial cellulose film. Soft Matter 2022, 18, 9057–9068. [Google Scholar] [CrossRef]

- Wang, F.; Huang, D.; Li, Q.; Wu, Y.; Yan, B.; Wu, Z.; Park, S. Highly electro-responsive ionic soft actuator based on graphene nanoplatelets-mediated functional carboxylated cellulose nanofibers. Compos. Sci. Technol. 2023, 231, 109854. [Google Scholar] [CrossRef]

- Cai, G.; Ciou, J.H.; Liu, Y.; Jiang, Y.; Lee, P.S. Leaf-inspired multiresponsive MXene-based actuator for programmable smart devices. Sci. Adv. 2019, 5, 7956. [Google Scholar] [CrossRef]

- Rühlicke, S.; Zhang, K. Synthesis of novel cellulose mixesters for transparent responsive films with switchable mechanical properties. Mater. Today Commun. 2020, 24, 101015. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Guo, J.; Fu, C.; Huang, L.; Chen, L.; Ni, Y.; Zheng, Q. UV and IR dual light triggered cellulose-based invisible actuators with high sensitivity. Int. J. Biol. Macromol. 2023, 238, 124031. [Google Scholar] [CrossRef] [PubMed]

- Shu, L.; Zhang, X.F.; Wu, Y.; Wang, Z.; Yao, J. Facile fabrication of strong and conductive cellulose hydrogels with wide temperature tolerance for flexible sensors. Int. J. Biol. Macromol. 2023, 240, 124438. [Google Scholar] [CrossRef]

- Chen, M.; Wan, H.; Hu, Y.; Zhao, F.; An, X.; Lu, A. Rationally designed cellulose hydrogel for an ultrasensitive pressure sensor. Mater. Horiz. 2023, 8, 2618. [Google Scholar] [CrossRef] [PubMed]

- Yun, T.; Du, J.; Ji, X.; Tao, Y.; Cheng, Y.; Lv, Y.; Lu, J.; Wang, H. Waterproof and ultrasensitive paper-based wearable strain/pressure sensor from carbon black/multilayer graphene/carboxymethyl cellulose composite. Carbohydr. Polym. 2023, 313, 120898. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Li, F.; Wang, Y.; Zhang, Q.; Ma, W.; Huang, C. Electrospun nanofiber membranes for wastewater treatment applications. Sep. Purif. Technol. 2020, 250, 117116. [Google Scholar] [CrossRef]

- Deng, Y.; Lu, T.; Cui, J.; Keshari Samal, S.; Xiong, R.; Huang, C. Bio-based electrospun nanofiber as building blocks for a novel eco-friendly air filtration membrane: A review. Sep. Purif. Technol. 2021, 277, 119623. [Google Scholar] [CrossRef]

- Deng, Y.; Lu, T.; Zhang, X.; Zeng, Z.; Tao, R.; Qu, Q.; Zhang, Y.; Zhu, M.; Xiong, R.; Huang, C. Multi-hierarchical nanofiber membrane with typical curved-ribbon structure fabricated by green electrospinning for efficient, breathable and sustainable air filtration. J. Membr. Sci. 2022, 660, 120857. [Google Scholar] [CrossRef]

- Cui, J.; Lu, T.; Li, F.; Wang, Y.; Lei, J.; Ma, W.; Zou, Y.; Huang, C. Flexible and transparent composite nanofibre membrane that was fabricated via a “green” electrospinning method for efficient particulate matter 2.5 capture. J. Colloid Interface Sci. 2021, 582, 506–514. [Google Scholar] [CrossRef]

- Lu, T.; Cao, W.; Liang, H.; Deng, Y.; Zhang, Y.; Zhu, M.; Ma, W.; Xiong, R.; Huang, C. Blow-Spun Nanofibrous Membrane for Simultaneous Treatment of Emulsified Oil/Water Mixtures, Dyes, and Bacteria. Langmuir 2022, 38, 15729–15739. [Google Scholar] [CrossRef]

- Deng, Y.; Zhu, M.; Lu, T.; Fan, Q.; Ma, W.; Zhang, X.; Chen, L.; Min, H.; Xiong, R.; Huang, C. Hierarchical fiber with granular-convex structure for highly efficient PM2.5 capture. Sep. Purif. Technol. 2023, 304, 122235. [Google Scholar] [CrossRef]

- Cui, J.; Wang, Y.; Lu, T.; Liu, K.; Huang, C. High performance, environmentally friendly and sustainable nanofiber membrane filter for removal of particulate matter 1.0. J. Colloid Interface Sci. 2021, 597, 48–55. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.; Ding, Y.; Li, Y.; Gao, S.; Jiang, Z.; Cui, J.; Huang, C.; Fu, G. Durable, self-healing superhydrophobic nanofibrous membrane with self-cleaning ability for highly-efficient oily wastewater purification. J. Membr. Sci. 2021, 634, 119402. [Google Scholar] [CrossRef]

- Deng, Y.; Lu, T.; Cui, J.; Ma, W.; Qu, Q.; Zhang, X.; Zhang, Y.; Zhu, M.; Xiong, R.; Huang, C. Morphology engineering processed nanofibrous membranes with secondary structure for high-performance air filtration. Sep. Purif. Technol. 2022, 294, 121093. [Google Scholar] [CrossRef]

- Wang, F.; Huang, D.; Wu, Y.; Wang, D. Ecofriendly low voltage high-performance ionic artificial muscles based on bacterial cellulose nanofibers reinforced with polyvinyl alcohol. J. Mater. Sci. Mater. Electron. 2023, 34, 123. [Google Scholar] [CrossRef]

- Gu, T.; Bi, H.; Sun, H.; Tang, J.; Ren, Z.; Zhou, X.; Xu, M. Design and development of 4D-printed cellulose nanofibers reinforced shape memory polymer composites: Application for self-deforming plant bionic soft grippers. Addit. Manuf. 2023, 70, 103544. [Google Scholar] [CrossRef]

- Wang, X.; Tang, S.; Wu, Z.; Fang, J.; Qin, X.; Wei, L. Research status of biomass-based composite films with high barrier properties. J. For. Eng. 2021, 6, 13–22. [Google Scholar] [CrossRef]

- Mao, F.; Long, L.; Zeng, G.; Chen, H.; Li, Y.; Zhou, W. Achieving excellent electromagnetic wave absorption property by constructing VO2 coated biomass carbon heterostructures. Diam. Relat. Mater. 2022, 130, 109422. [Google Scholar] [CrossRef]

- Xu, J.; Zhai, Q.; Long, F.; Jiang, X.; Han, S.; Jiang, J. Electrocatalytic oxidation and reduction of biomass-derived chemicals: A review. J. For. Eng. 2022, 7, 11–22. [Google Scholar] [CrossRef]

- Deng, W.-N.; Li, Y.-H.; Xu, D.-F.; Zhou, W.; Xiang, K.-X.; Chen, H. Three-dimensional hierarchically porous nitrogen-doped carbon from water hyacinth as selenium host for high-performance lithium–selenium batteries. Rare Met. 2022, 41, 3432–3445. [Google Scholar] [CrossRef]

- Guo, Z.; Han, X.; Zhang, C.; He, S.; Liu, K.; Hu, J.; Yang, W.; Jian, S.; Jiang, S.; Duan, G. Activation of biomass-derived porous carbon for supercapacitors: A review. Chin. Chem. Lett. 2023, in press. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, S.; Weng, Z.; Zhang, C.; Jiang, S.; Duan, G. Cellulose-Based Intelligent Responsive Materials: A Review. Polymers 2023, 15, 3905. https://doi.org/10.3390/polym15193905

Chang S, Weng Z, Zhang C, Jiang S, Duan G. Cellulose-Based Intelligent Responsive Materials: A Review. Polymers. 2023; 15(19):3905. https://doi.org/10.3390/polym15193905

Chicago/Turabian StyleChang, Sisi, Zhangzhao Weng, Chunmei Zhang, Shaohua Jiang, and Gaigai Duan. 2023. "Cellulose-Based Intelligent Responsive Materials: A Review" Polymers 15, no. 19: 3905. https://doi.org/10.3390/polym15193905

APA StyleChang, S., Weng, Z., Zhang, C., Jiang, S., & Duan, G. (2023). Cellulose-Based Intelligent Responsive Materials: A Review. Polymers, 15(19), 3905. https://doi.org/10.3390/polym15193905