Analysis of the Dynamic Cushioning Property of Expanded Polyethylene Based on the Stress–Energy Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

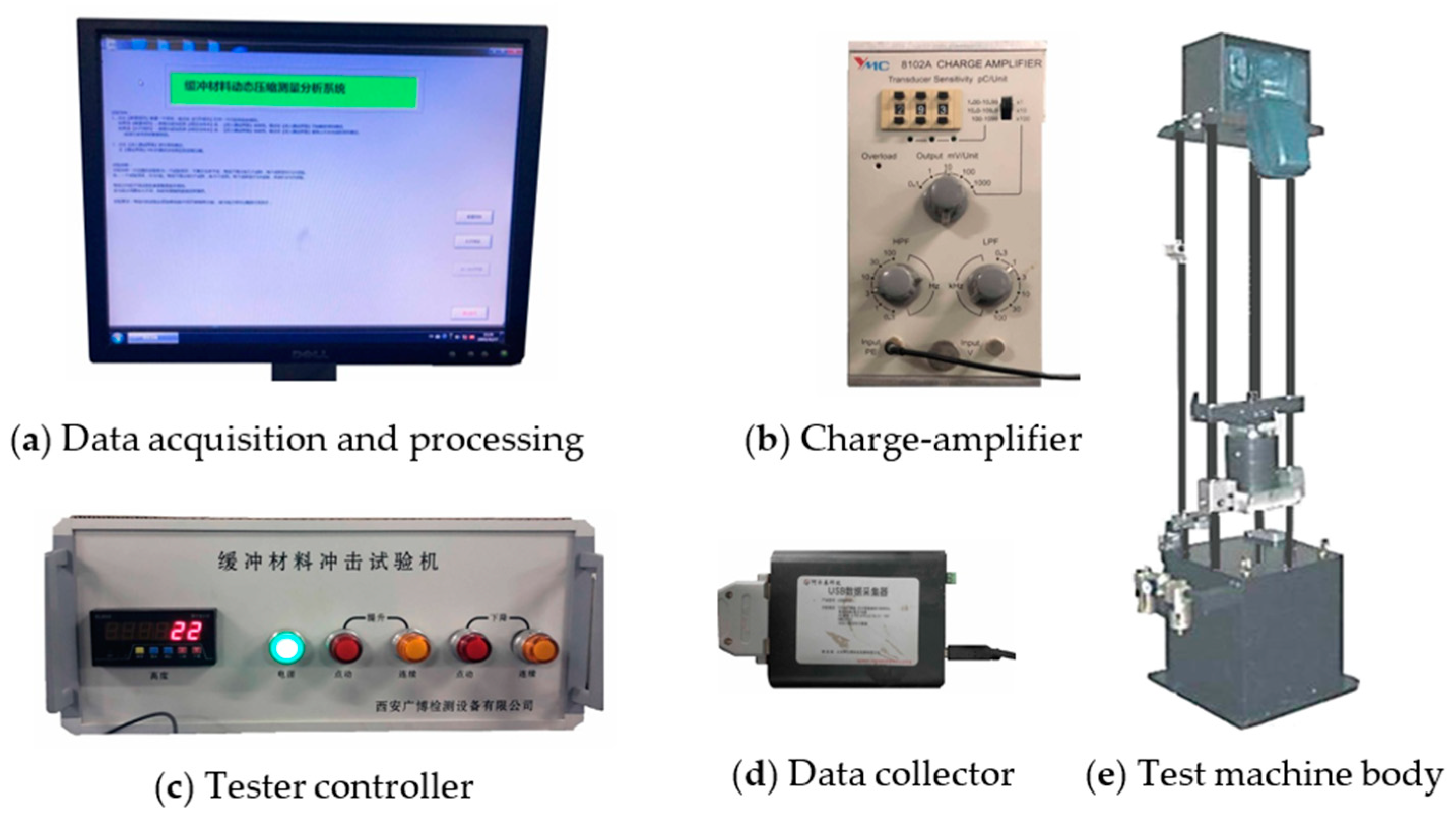

2.2. Impact Test Equipment and Method

2.3. Impact Compression Test Equipment

2.4. Impact Characteristic Criteria

3. Results

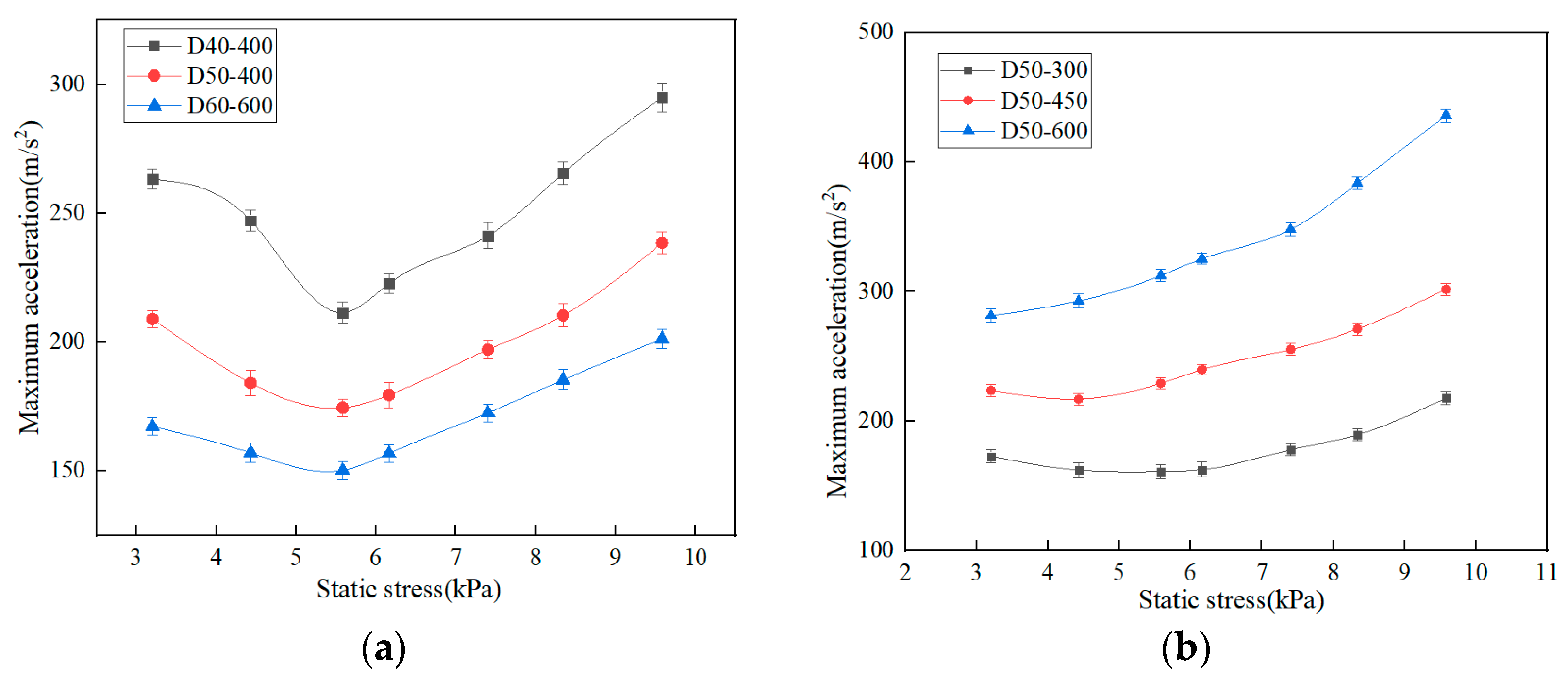

3.1. Traditional Dynamic Cushioning Curve Test

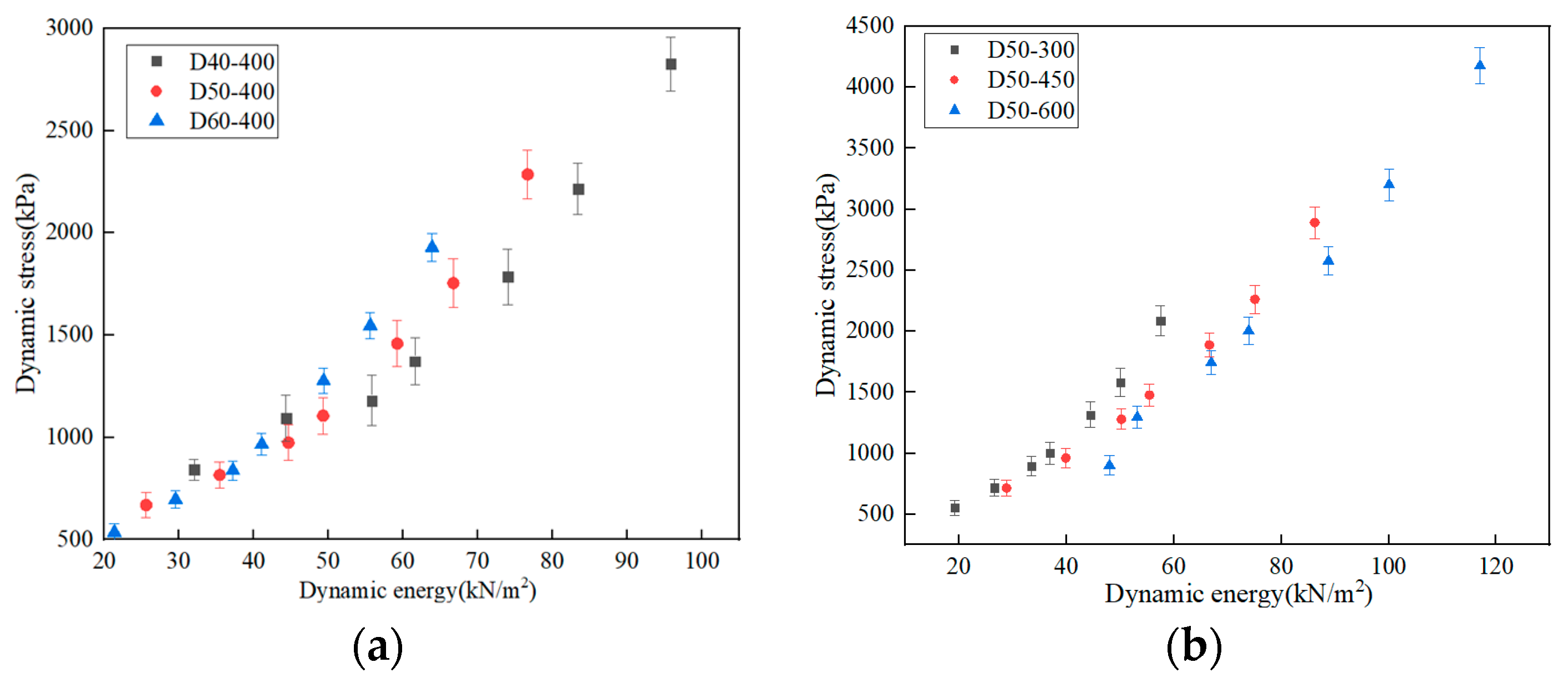

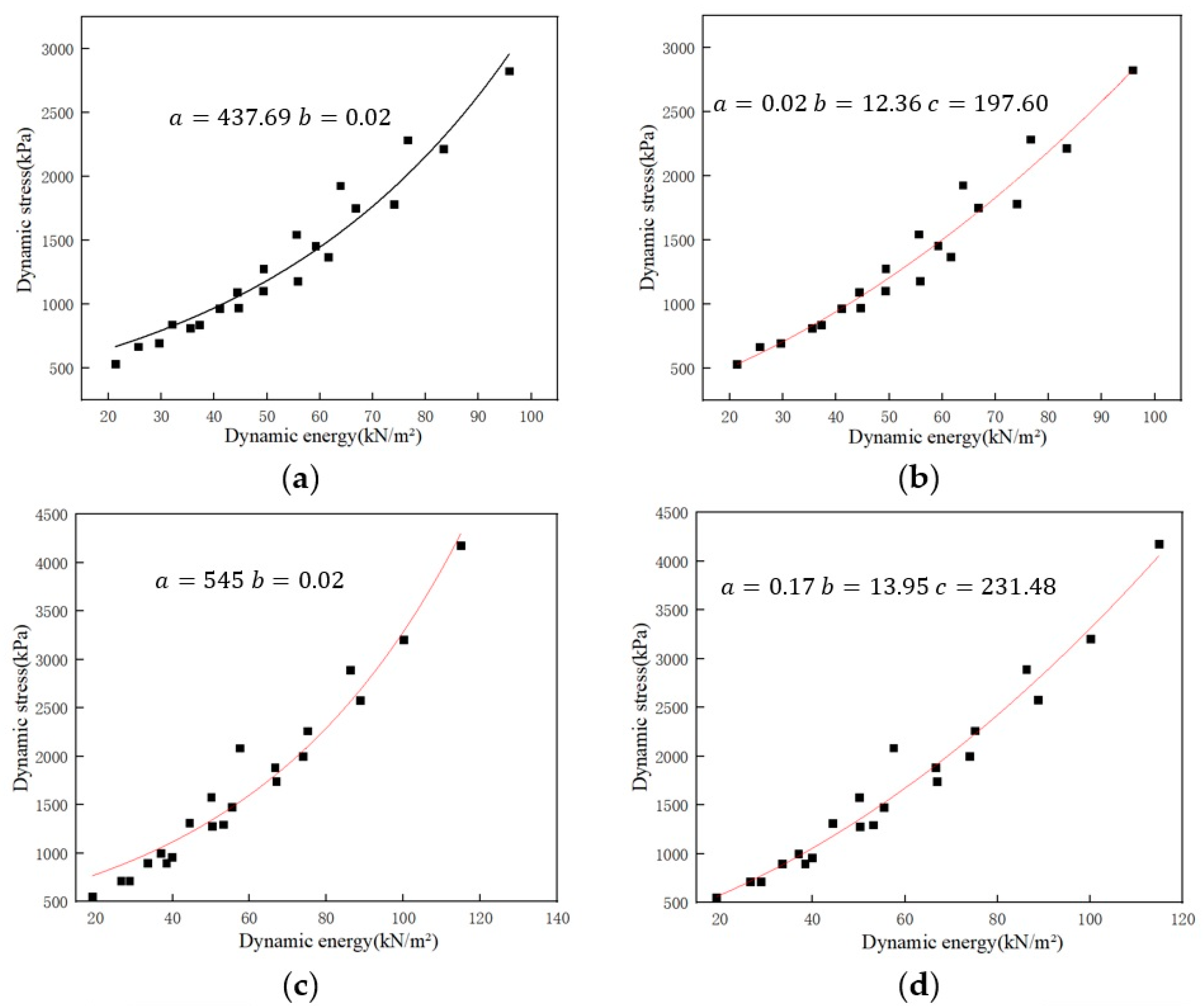

3.2. Stress–Energy Method

3.3. Equipartition Dynamic Energy Domain

4. Discussion

5. Conclusions

- (1)

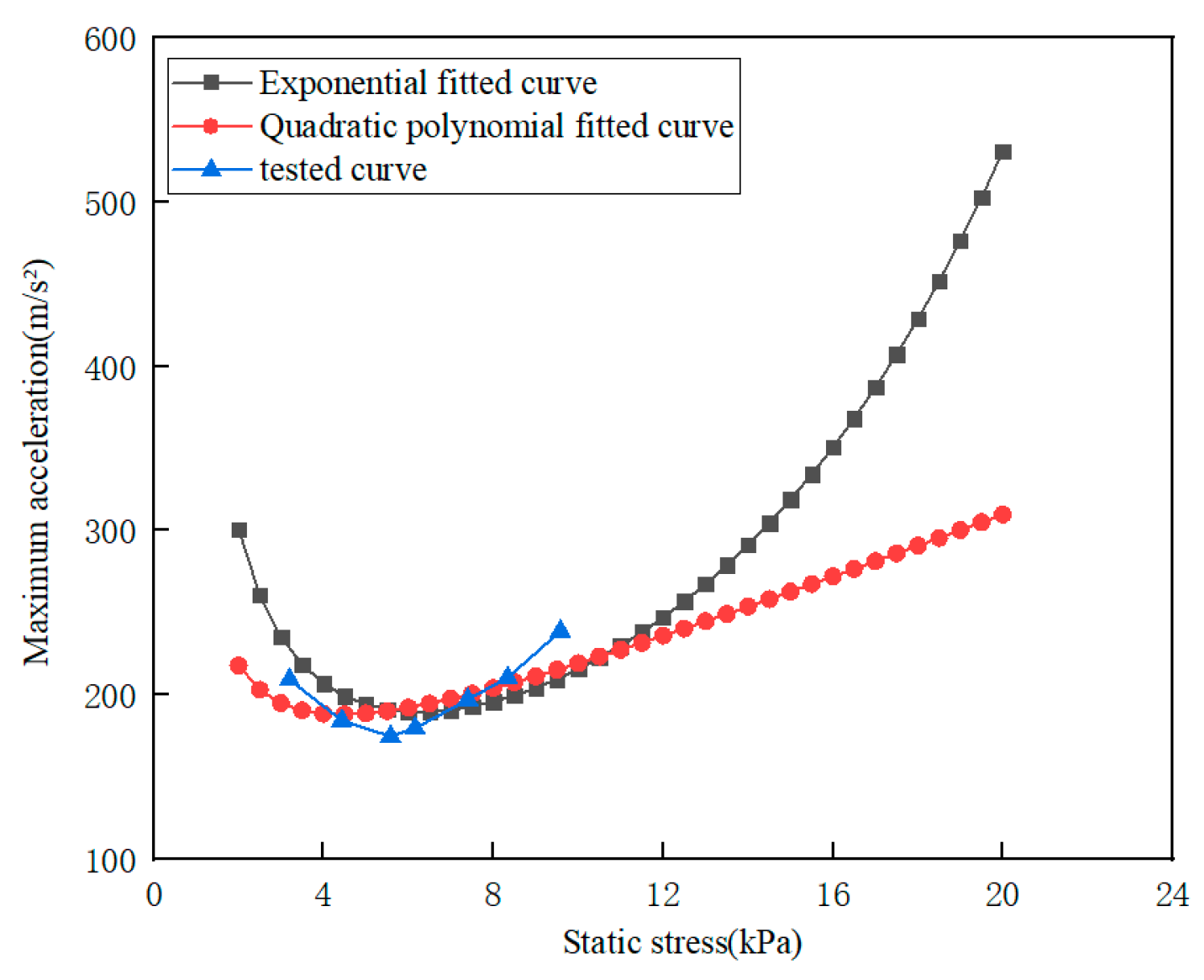

- Using a dynamic stress-dynamic energy curve to obtain the cushioning characteristics of EPE under any thickness and dropping heights will reduce the number of tests, avoid the system error caused by the test environment and equipment, and obtain stable data.By the equipartition dynamic energy domain method, it can be seen that the fitted curve and the tested curve coincide within a certain range of static stress. Therefore, the maximum acceleration-static stress curve of an EPE specimen of a certain density with any thickness and dropping height can be obtained by exponential fitting and polynomial fitting.

- (2)

- Due to the diversified processing methods of EPE for packaging, the density of EPE is unstable, resulting in different actual densities with different thickness specifications of the same theoretic density batch. Therefore, there is still a little difference between the fitted maximum acceleration and the actual maximum acceleration in the stress–energy method. In addition, because the test environment and equipment debugging for obtaining the actual acceleration are not suitable for control, too high dropping height, too light and too heavy static load will cause the actual acceleration to deviate from the fitted acceleration phenomenon; therefore, this part of the research needs to be further tested and discussed. The influence of EPE density and other factors on dynamic cushioning performance will be studied later.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Yan, S.H.I.; Guang, L.I. Research on Stress–energy Method for Determining Cushioning Curve. Packag. J. 2014, 6, 35–40. [Google Scholar]

- Yang, F.; Li, Z.; Liu, Z.; Zhuang, Z. Shock Loading Mitigation Performance and Mechanism of the PE/Wood/PU/Foam Structures. Int. J. Impact Eng. 2021, 155, 103904. [Google Scholar] [CrossRef]

- Feng, Y. Comparison and Analysis for Double Direction Performances of Cushioning Materials. China Packag. Ind. 2007, 10, 47–48. [Google Scholar]

- Zhang, Y.; Rodrigue, D.; Ait-Kadi, A. High density polyethylene foams. II. Elastic modulus. J. Appl. Polym. Sci. 2003, 90, 2120–2129. [Google Scholar] [CrossRef]

- Ramirez-Arreola, D.E.; Rosa, S.D.L.; Haro-Mares, N.B.; Ramírez-Morán, J.A.; Pérez-Fonseca, A.A.; Robledo-Ortíz, J.R. Compressive strength study of cement mortars lightened with foamed HDPE nanocomposites. Mater. Des. 2015, 74, 119–124. [Google Scholar] [CrossRef]

- Lu, B. Study on static compression buffer curve of foamed polyethylene buffer material. Packag. Eng. 2007, 28, 42–44. [Google Scholar]

- American Society of Testing Materials. ASTMD1596 Standard Test Method for Shock Absorbing Properties of Package Cushioning Materials. In Annual Book of ASTM Standards; ASTM International: Conshohocken, PA, USA, 2003. [Google Scholar]

- General Administration of Quality Supervision. Inspection and Quarantine of the Peoples Republic of China, Standardization Administration of the Peoples’ Republic of China; GB 8167-2008 Testing Method of Dynamic Compression for Packaging Cushioning Materials; Standards Press of China: Beijing, China, 2009; pp. 1–3. [Google Scholar]

- Navarro-Javierre, P.; Garcia-Romeu-Martinez, M.-A.; Cloquell-Ballester, V.-A.; de-la-Cruz-Navarro, E. Evaluation of Two Simplified Methods for Determining Cushion Curves of Closed Cell Foams. Packag. Technol. Sci. 2012, 25, 217–231. [Google Scholar] [CrossRef]

- Luo, L. Experimental Research on Dynamic Cushioning Performance of the Buffer Material. Packag. Eng. 1996, 17, 10–13. [Google Scholar]

- Wu, L.; Jiang, S. Experimental Research on Dynamic Cushioning Performance of the Three Kinds of Cushioning Materials. China Water Transp. 2006, 11, 62–64. [Google Scholar]

- Yang, S. Research on Cushioning Properties of EPE. Ph.D. Thesis, Tianjin University of Science and Technology, Tianjin, China, 2015. [Google Scholar]

- Deng, Z. Research on Performances of Molded Pulp Products under Dynamic Test. Ph.D. Thesis, Tianjin University of Science and Technology, Tianjin, China, 2011. [Google Scholar]

- Yan, L.; Xie, Y. Dynamic Cushioning Properties of Combination of Honeycomb Paperboard and EPE. Packag. Eng. 2010, 31, 13–16. [Google Scholar]

- Jin, Q.; Sun, D.; Li, G.; Xing, Y. Effect of density on dynamic impact properties of polypropylene foams. Packag. Eng. 2018, 39, 88–92. [Google Scholar]

- Koohbor, B.; Kidane, A. Design optimization of continuously and discretely graded foam materials for efficient energy absorption. Mater. Des. 2016, 102, 151–161. [Google Scholar] [CrossRef]

- E, Y.P.; Li, Y. Effect of density gradient change on mechanical properties of multilayer foamed polyethylene. Packag. J. 2016, 8, 30–35. [Google Scholar]

- Mcgee, S.D.; Batt, G.S.; Gibert, J.M.; Darby, D. Predicting the Effect of Temperature on the Shock Absorption Properties of Polyethylene Foam. Packag. Technol. Sci. 2017, 30, 477–494. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Ngamkhanong, C.; Papaelias, M.; Roberts, C. Wet/dry influence on behaviors of closed-cell polymeric cross-linked foams under static, dynamic and impact loads. Constr. Build Mater. 2018, 187, 1092–1102. [Google Scholar] [CrossRef]

- Daum, M. A Simplified Process for Determining Cushion Curves: The Stress–Energy Method; Hewlett-Packard Company: Palo Alto, CA, USA, 1999. [Google Scholar]

- Zhang, H.; Xie, Y.; Wang, J. Determination of Cushioning Performance of Foam Using Improved Stress–Energy Method. Packag. Eng. 2011, 32, 36–38. [Google Scholar]

- Ding, Y.; Chen, L.; Su, J. Discussion on measuring buffer curve of packaging materials based on energy method. Packag. Food Mach. 2011, 29, 66–69. [Google Scholar]

- Chen, M.; Liu, L. Study on Properties of buffer packaging materials based on stress–Energy method. Packag. Eng. 2018, 39, 44–47. [Google Scholar]

- Wang, J.; Liu, C. Study on function model for obtaining foam buffer curve by stress–Energy method. Packag. Eng. 2014, 35, 79–82. [Google Scholar]

- Daum, M. A New Method for Cushion Curves: The Stress–Energy Method. In Proceedings of the International Conference on Transport Packaging, San Antonio, TX, USA, 11–14 December 2006. [Google Scholar]

- Zhang, B. Application of stress–energy method in measurement of foam buffer curve. Packag. Eng. 2008, 29, 59–60, 65. [Google Scholar]

- Xing, Y.; Sun, D.; Zhang, M.; Shu, G. Crushing responses of expanded polypropylene foam. Polymers 2023, 15, 2059. [Google Scholar] [CrossRef] [PubMed]

- Xing, Y.; Guo, X.; Shu, G.; He, X. Dynamic Crushing Behavior of Ethylene Vinyl Acetate Copolymer Foam Based on Energy Method. Polymers 2023, 15, 3016. [Google Scholar] [CrossRef]

- Peng, G. Transportation Packaging Design; Printing Industry Press: Beijing, China, 1999. [Google Scholar]

- Chen, S. The Research Progress of Foaming Material Buffer Performance Characterization Methods. Print. Qual. Stand. 2013, 1, 25–27. [Google Scholar]

- Xu, W. Packaging Test Technology, 1st ed.; Printing Industry Press: Beijing, China, 1994. [Google Scholar]

- Yin, X.; Chen, Z.; Cui, J.; Zheng, Q. Dynamic Buffering Performance of EPE/Corrugated Board Used in Express Packaging. Packag. Eng. 2022, 43, 52–57. [Google Scholar]

- Sun, D.; Jin, Q.; Li, G. Analysis on Dynamic Cushioning Property of Expanded Polypropylene Materials. Packag. Eng. 2019, 40, 114–119. [Google Scholar]

| Specimens | Dynamic Energy (kN/m2) | Dynamic Stress (kPa) |

|---|---|---|

| D40-400 | 32 | 843 |

| 44 | 1095 | |

| 56 | 1180 | |

| 62 | 1372 | |

| 74 | 1786 | |

| 83 | 2215 | |

| 96 | 2826 | |

| D50-400 | 26 | 669 |

| 35 | 816 | |

| 45 | 974 | |

| 49 | 1106 | |

| 59 | 1459 | |

| 67 | 1755 | |

| 77 | 2286 | |

| D60-400 | 21 | 535 |

| 30 | 696 | |

| 37 | 839 | |

| 41 | 967 | |

| 49 | 1277 | |

| 56 | 1546 | |

| 64 | 1928 |

| Specimens | Dynamic Energy (kN/m2) | Dynamic Stress (kPa) |

|---|---|---|

| D50-300 | 19 | 553 |

| 27 | 718 | |

| 33 | 897 | |

| 37 | 1000 | |

| 44 | 1316 | |

| 50 | 1580 | |

| 57 | 2087 | |

| D50-450 | 29 | 716 |

| 40 | 961 | |

| 50 | 1279 | |

| 55 | 1477 | |

| 67 | 1888 | |

| 75 | 2263 | |

| 86 | 2891 | |

| D50-600 | 38 | 535 |

| 53 | 696 | |

| 67 | 839 | |

| 74 | 967 | |

| 89 | 1277 | |

| 100 | 1546 | |

| 115 | 1928 |

| Curve Types | Maximum Acceleration (m/s2) | Static Stress (kPa) | R2 |

|---|---|---|---|

| Exponential fitted curve | 187.7 | 6 | 0.9751 |

| Polynomial fitted curve | 188.9 | 4.5 | 0.9685 |

| Tested curve | 184.6 | 5.7 |

| Dynamic Energy (kN·m−2) | Static Stress (kPa) | Thickness (mm) | Dropping Height (mm) | Specimen (mm) |

|---|---|---|---|---|

| 25 | 3.2 | 40 | 313 | 200 × 200 |

| 25 | 3.2 | 50 | 391 | 200 × 200 |

| 25 | 3.2 | 60 | 469 | 200 × 200 |

| 50 | 5.69 | 40 | 351 | 150 × 150 |

| 50 | 5.69 | 50 | 439 | 150 × 150 |

| 50 | 5.69 | 60 | 527 | 150 × 150 |

| 75 | 5.69 | 40 | 527 | 150 × 150 |

| 75 | 5.69 | 50 | 659 | 150 × 150 |

| 75 | 5.69 | 60 | 791 | 150 × 150 |

| 100 | 12.8 | 40 | 313 | 100 × 100 |

| 100 | 12.8 | 50 | 391 | 100 × 100 |

| 100 | 12.8 | 60 | 469 | 100 × 100 |

| 125 | 17 | 40 | 294 | 100 × 100 |

| 125 | 17 | 50 | 368 | 100 × 100 |

| 125 | 17 | 60 | 441 | 100 × 100 |

| 150 | 17 | 40 | 353 | 100 × 100 |

| 150 | 17 | 50 | 441 | 100 × 100 |

| 150 | 17 | 60 | 529 | 100 × 100 |

| 175 | 17 | 40 | 412 | 100 × 100 |

| Dynamic Energy (kN·m−2) | Mean Dynamic Stress (kPa) |

|---|---|

| 25 | 62 |

| 50 | 110 |

| 75 | 158 |

| 100 | 235 |

| 125 | 379 |

| 150 | 488 |

| 175 | 605 |

| Dynamic Energy (kN·m−2) | Dynamic Stress (kPa) |

|---|---|

| 20 | 62 |

| 40 | 110 |

| 59 | 158 |

| 78 | 235 |

| 90 | 379 |

| 109 | 488 |

| 127 | 605 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, Y.; Sun, D.; Chen, G. Analysis of the Dynamic Cushioning Property of Expanded Polyethylene Based on the Stress–Energy Method. Polymers 2023, 15, 3603. https://doi.org/10.3390/polym15173603

Xing Y, Sun D, Chen G. Analysis of the Dynamic Cushioning Property of Expanded Polyethylene Based on the Stress–Energy Method. Polymers. 2023; 15(17):3603. https://doi.org/10.3390/polym15173603

Chicago/Turabian StyleXing, Yueqing, Deqiang Sun, and Guoliang Chen. 2023. "Analysis of the Dynamic Cushioning Property of Expanded Polyethylene Based on the Stress–Energy Method" Polymers 15, no. 17: 3603. https://doi.org/10.3390/polym15173603

APA StyleXing, Y., Sun, D., & Chen, G. (2023). Analysis of the Dynamic Cushioning Property of Expanded Polyethylene Based on the Stress–Energy Method. Polymers, 15(17), 3603. https://doi.org/10.3390/polym15173603