Controlling Shear Rate for Designable Thermal Conductivity in Direct Ink Printing of Polydimethylsiloxane/Boron Nitride Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

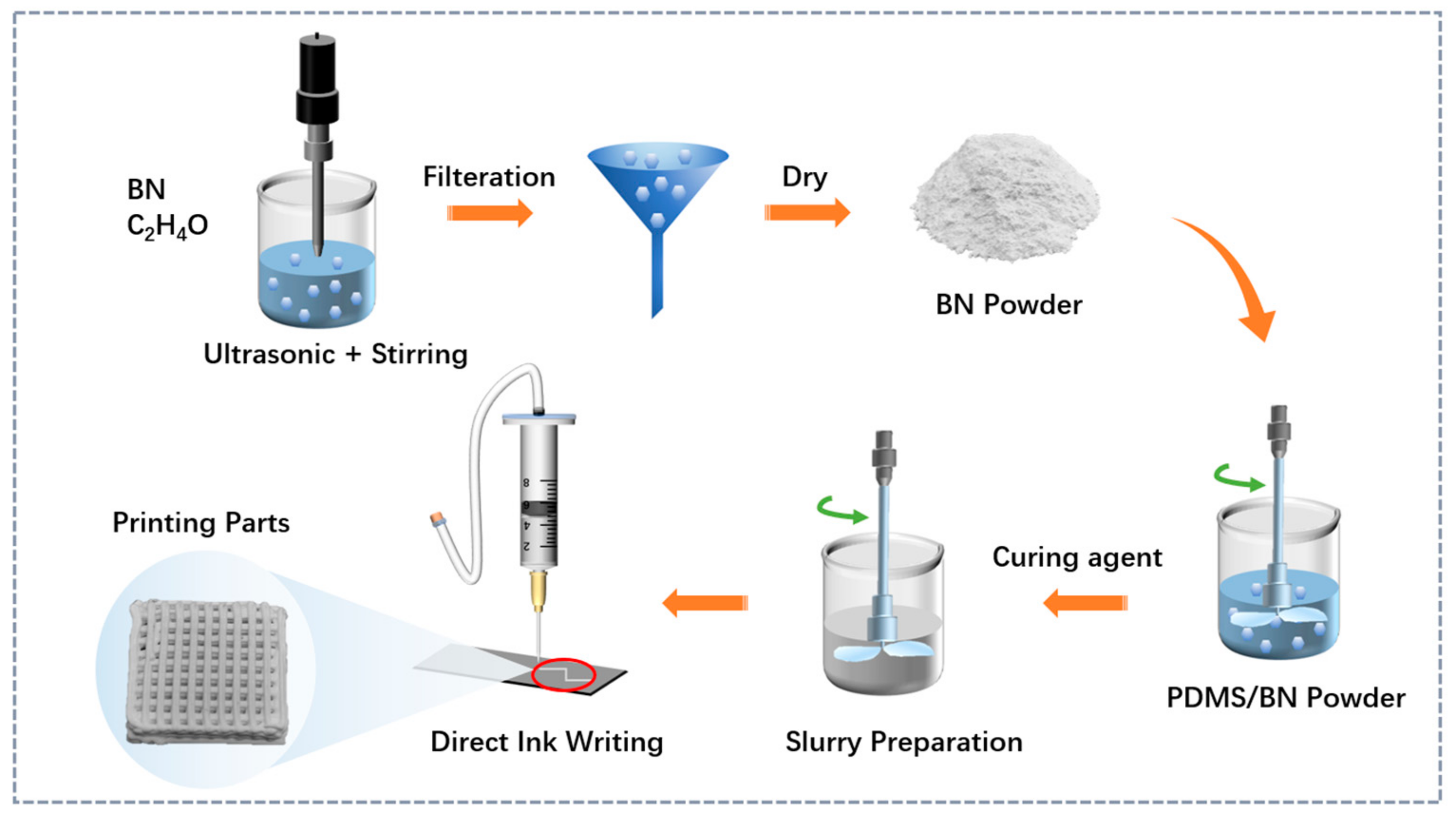

2.2. Preparation of PDMS/BN Composites

2.3. Characterizations

3. Results

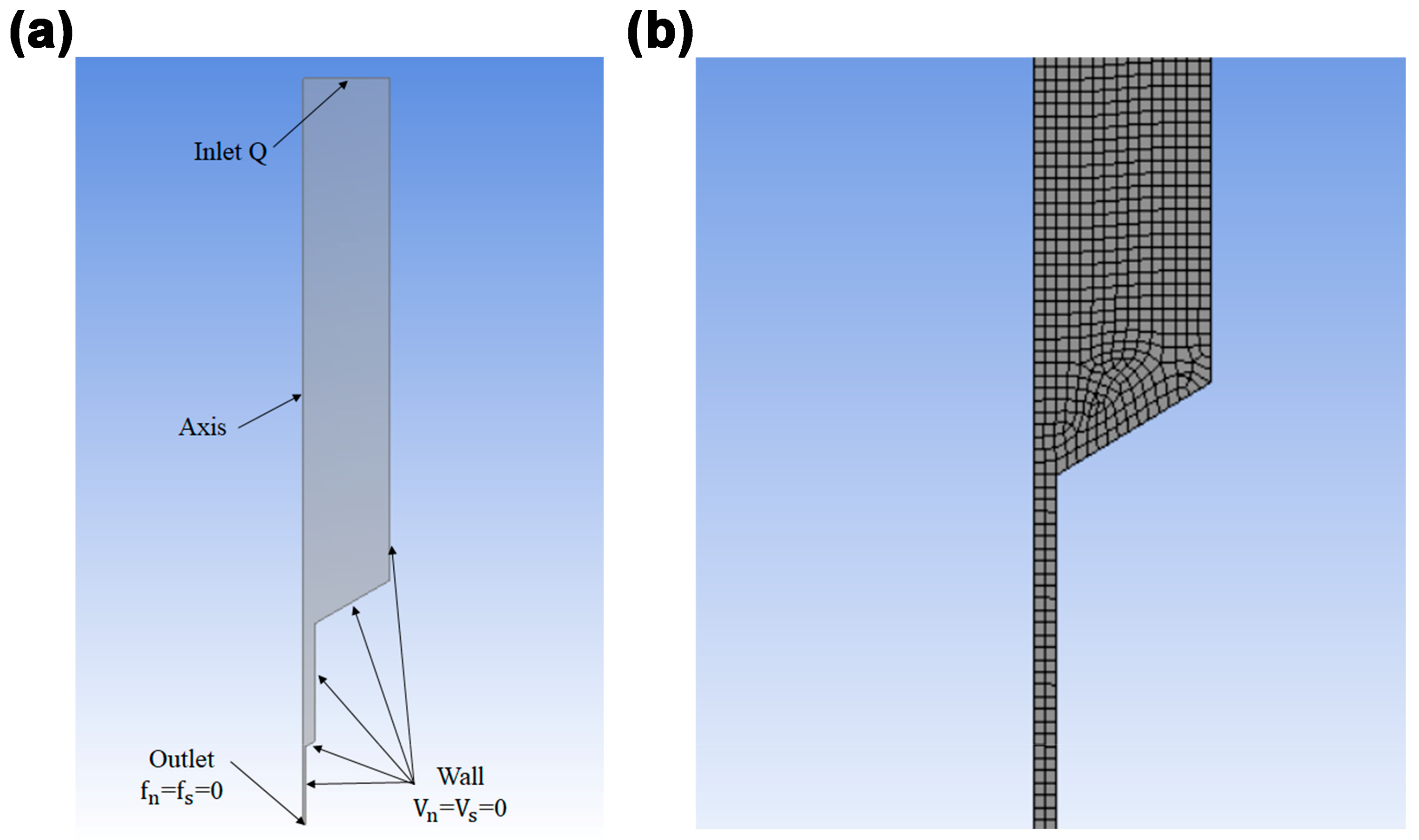

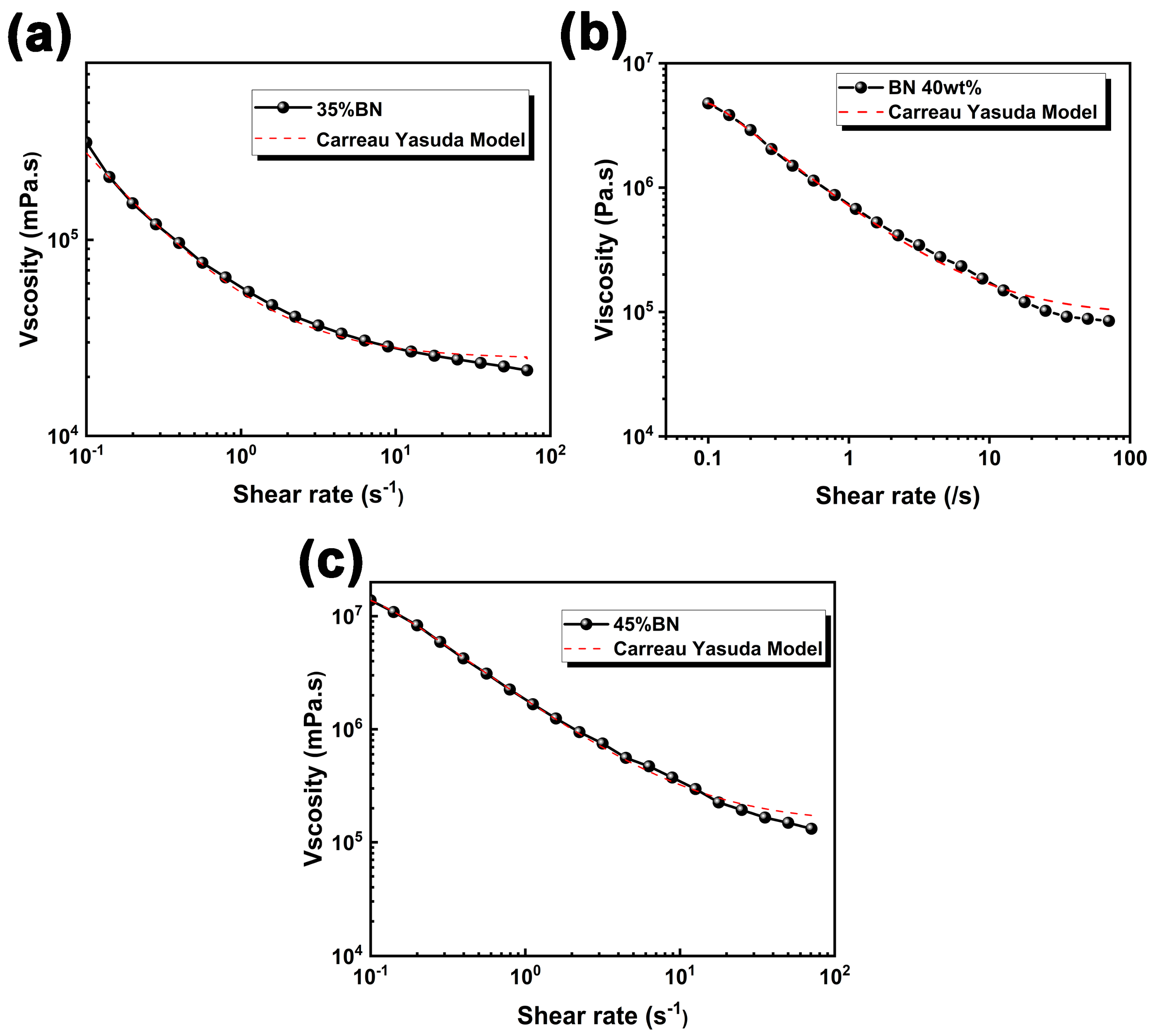

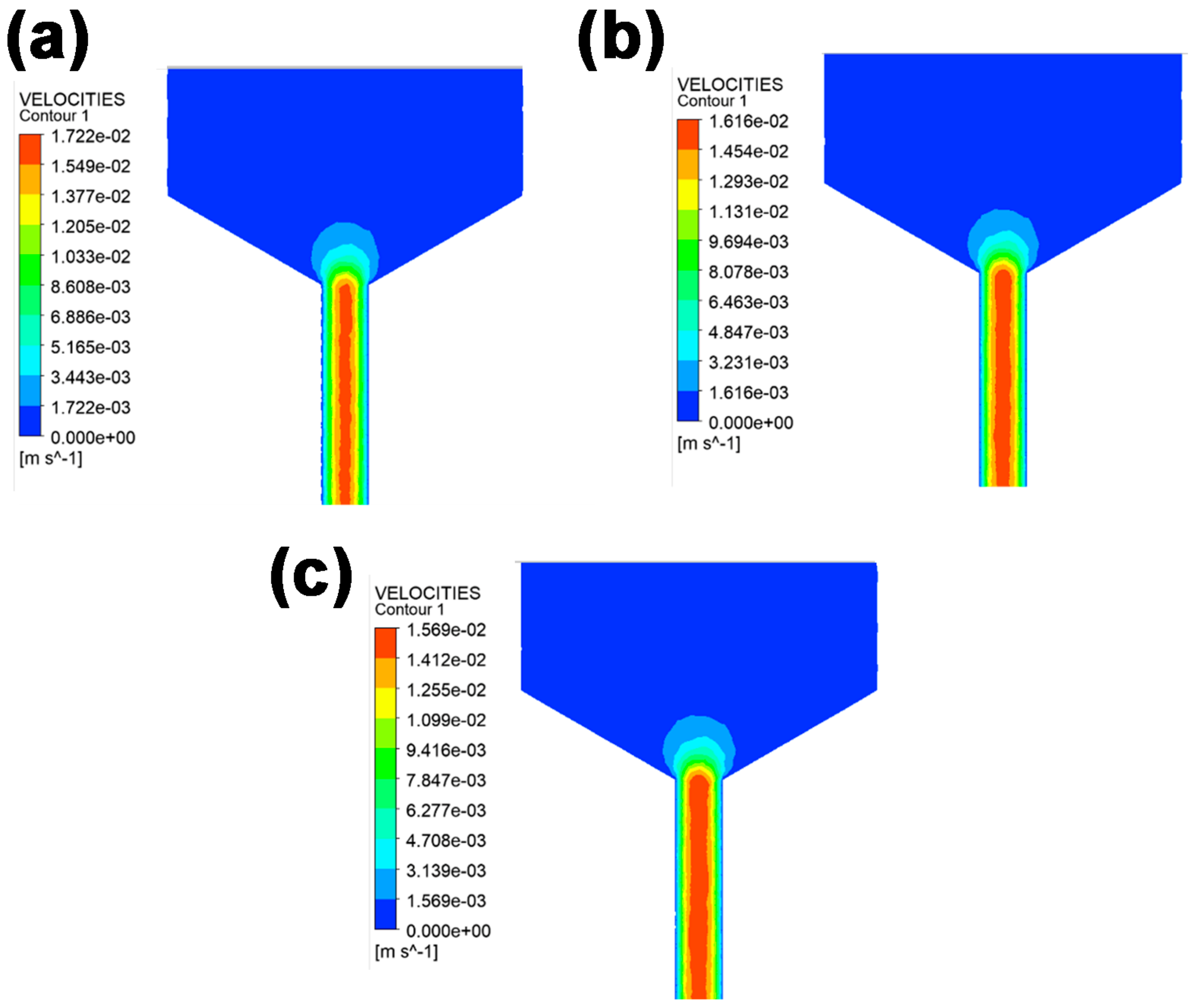

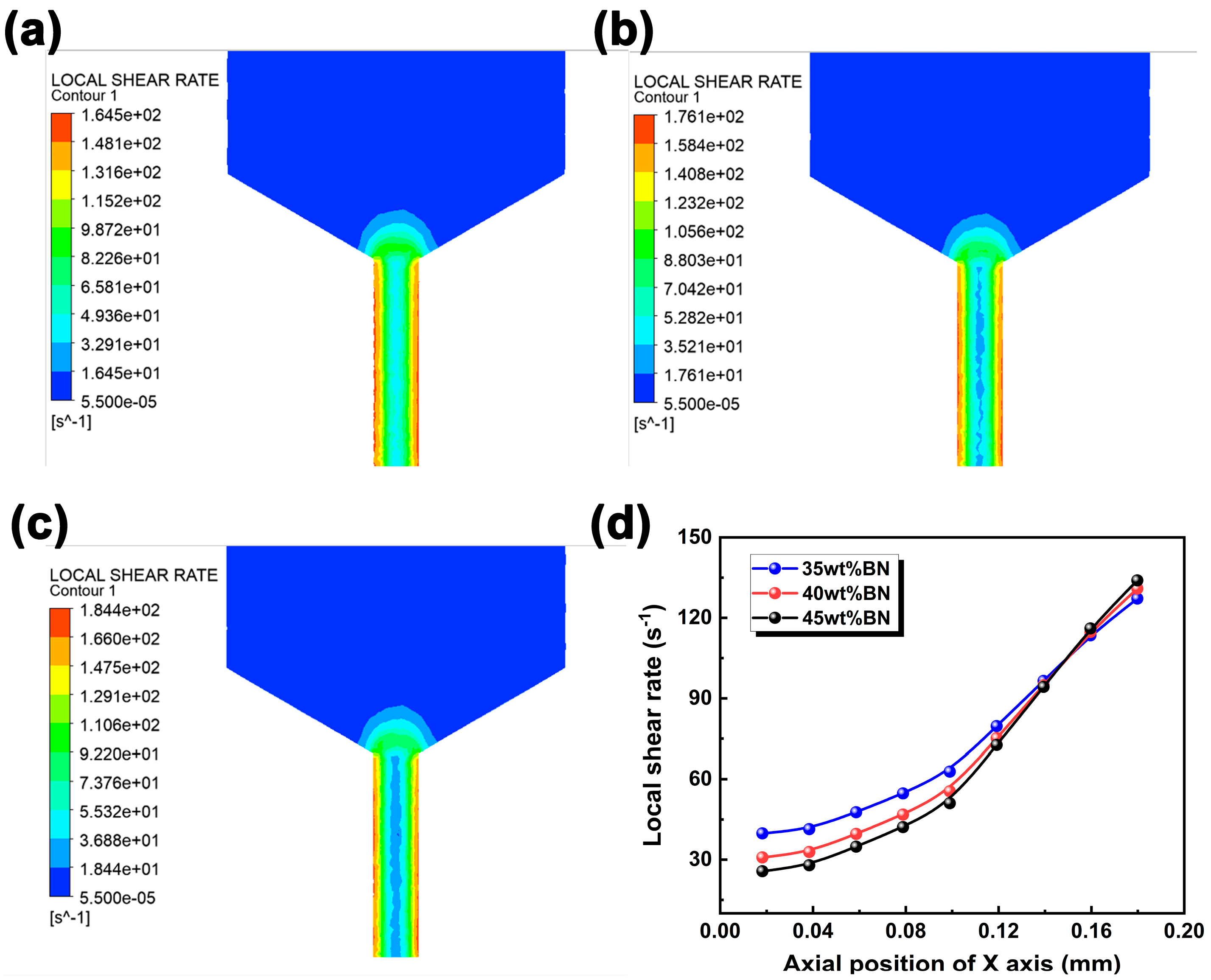

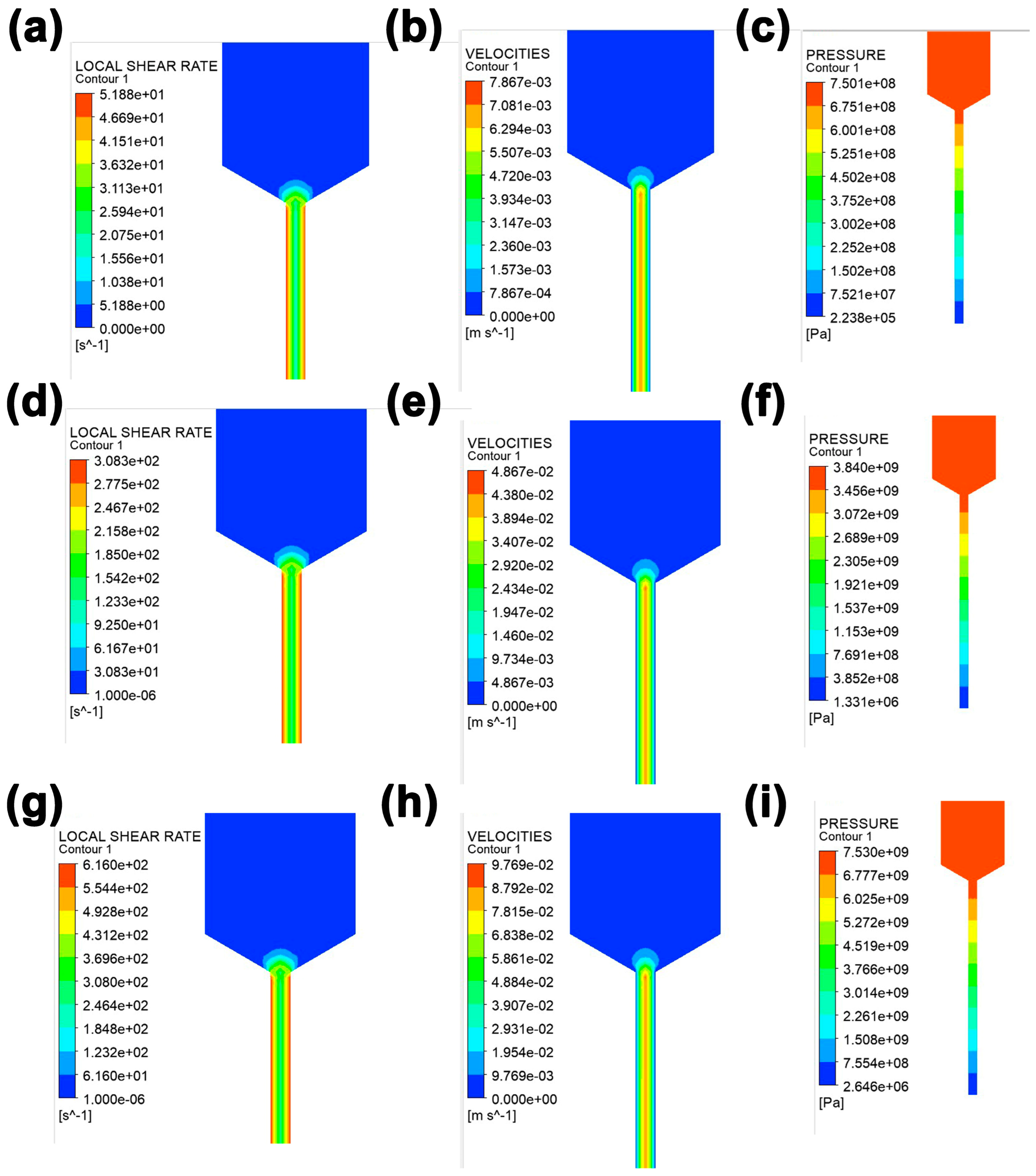

3.1. Evaluation of Rheological Behavior during DIW Printing

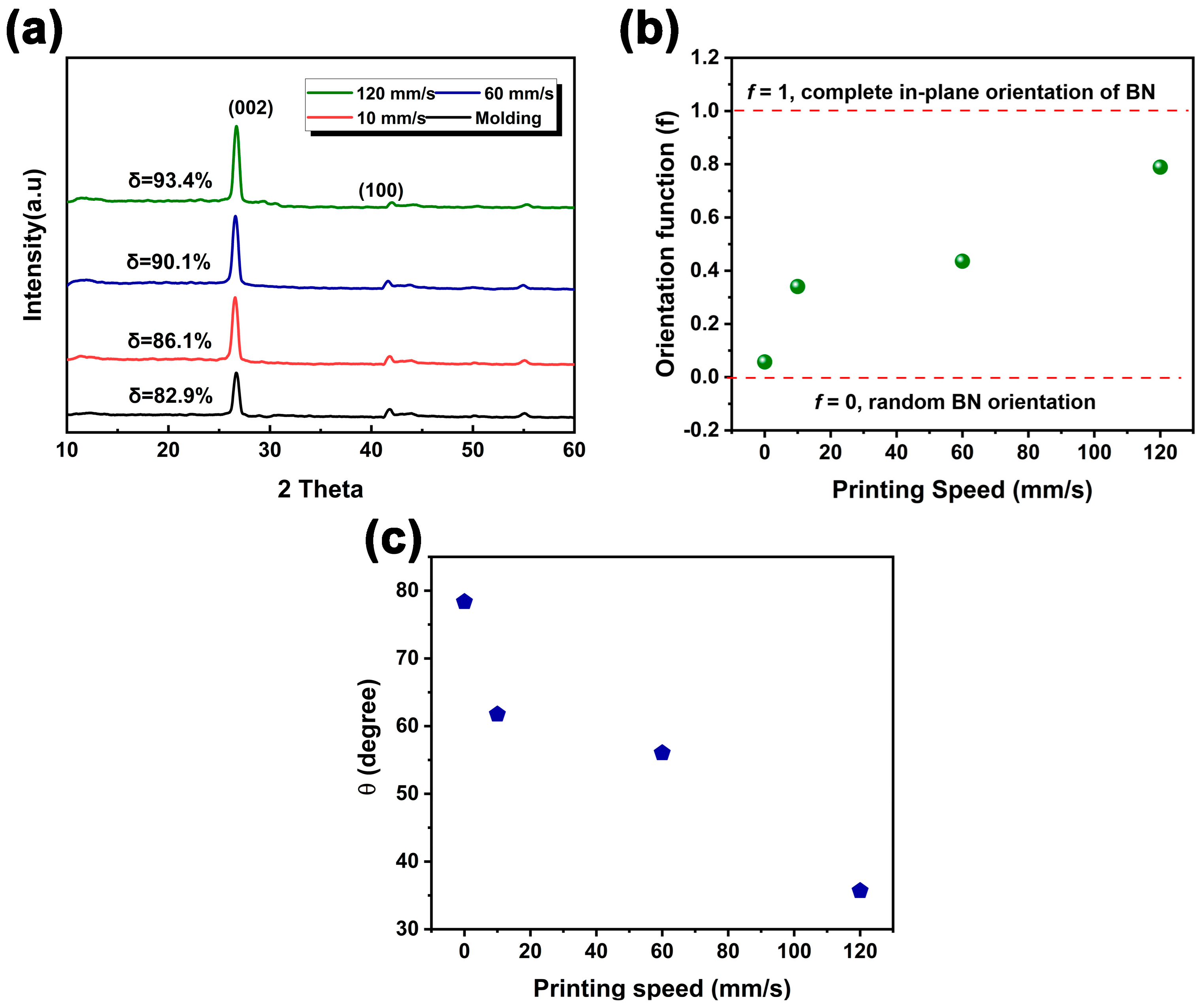

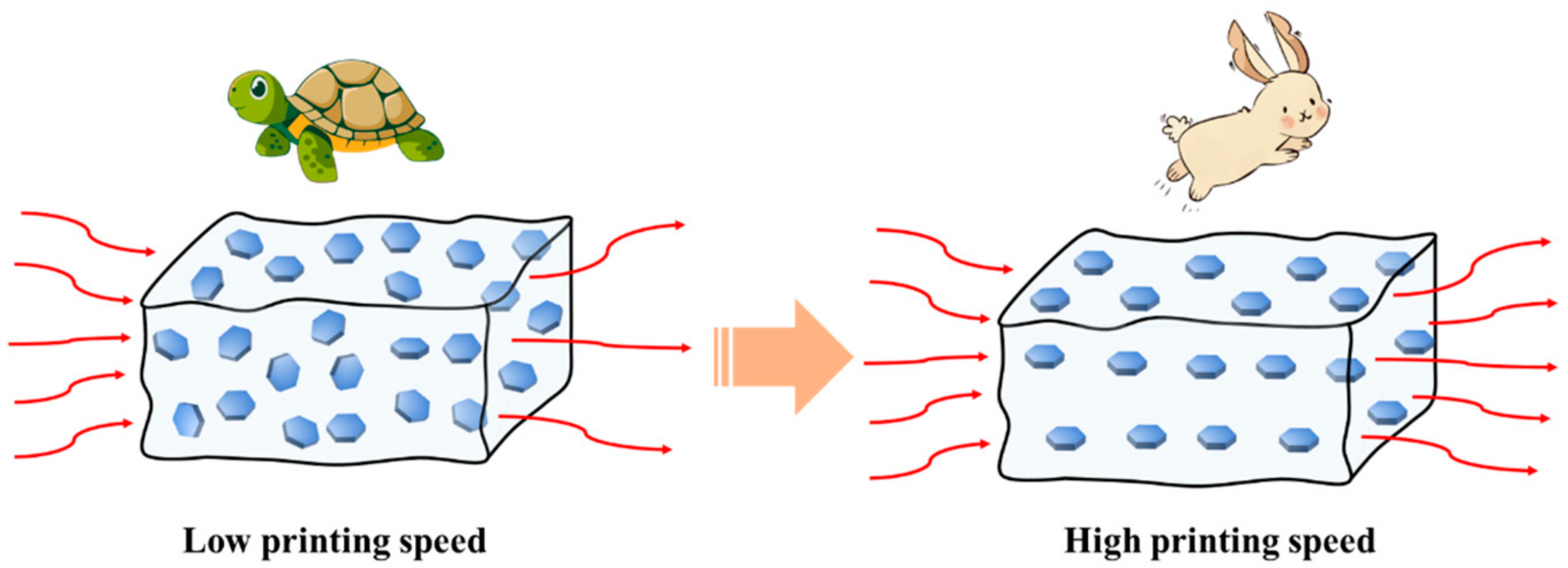

3.2. Effect of Printing Speed on the Orientation of BN Particles during DIW Printing

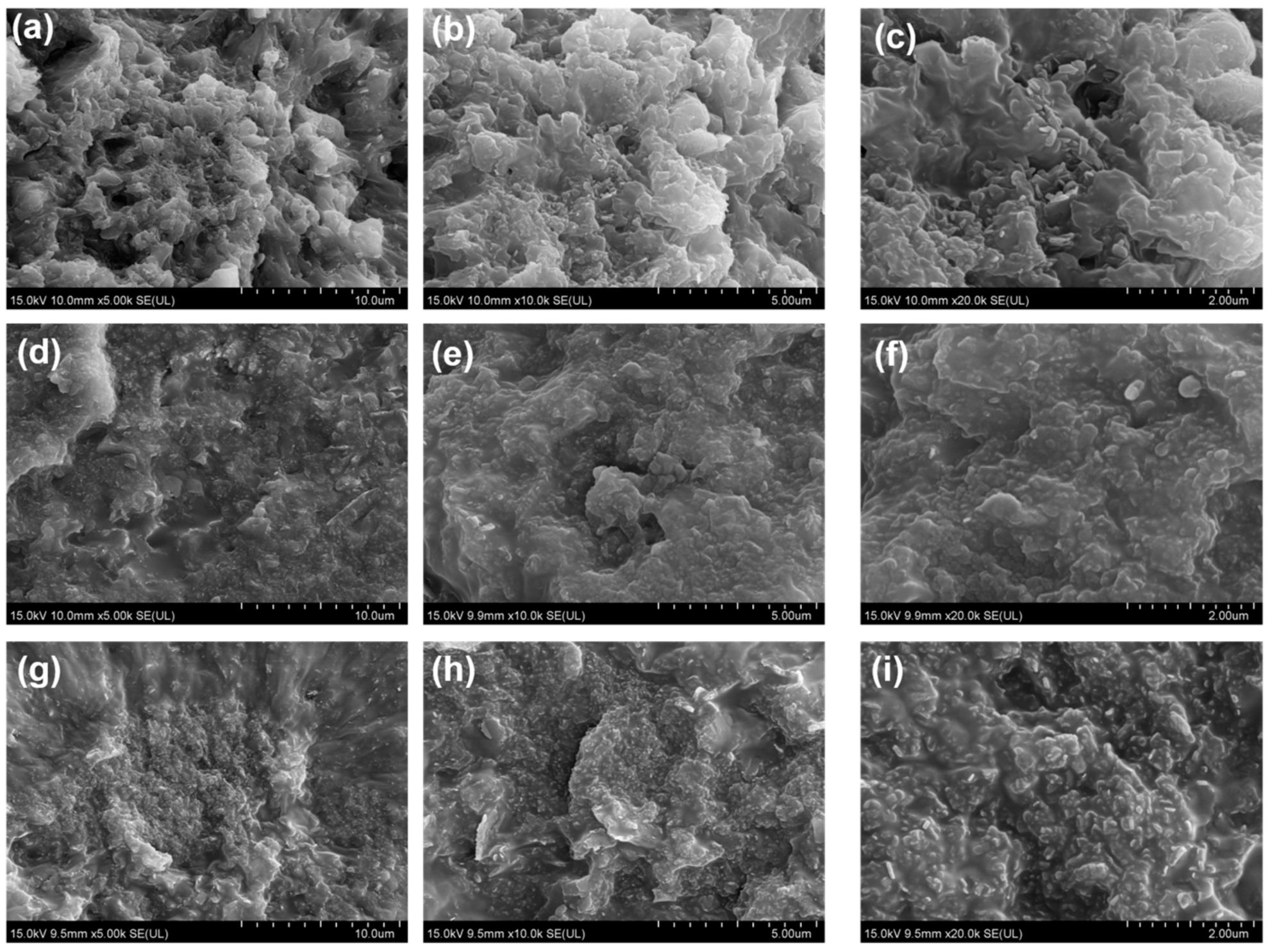

3.3. Morphologies Observation of the Printed PDMS/BN Composites

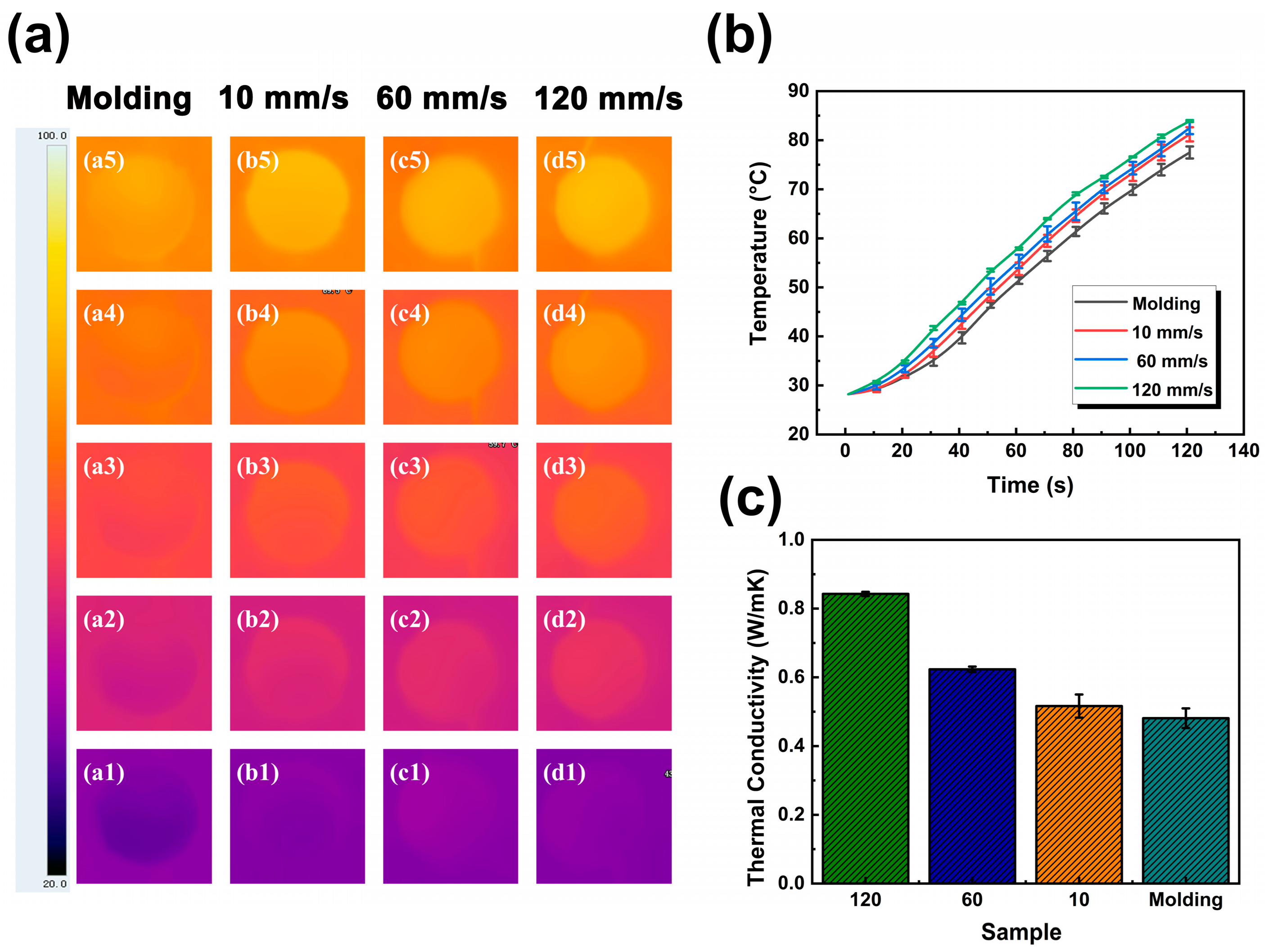

3.4. Thermal Conductivity Performance of the as-Printed PDMS/BN Composites

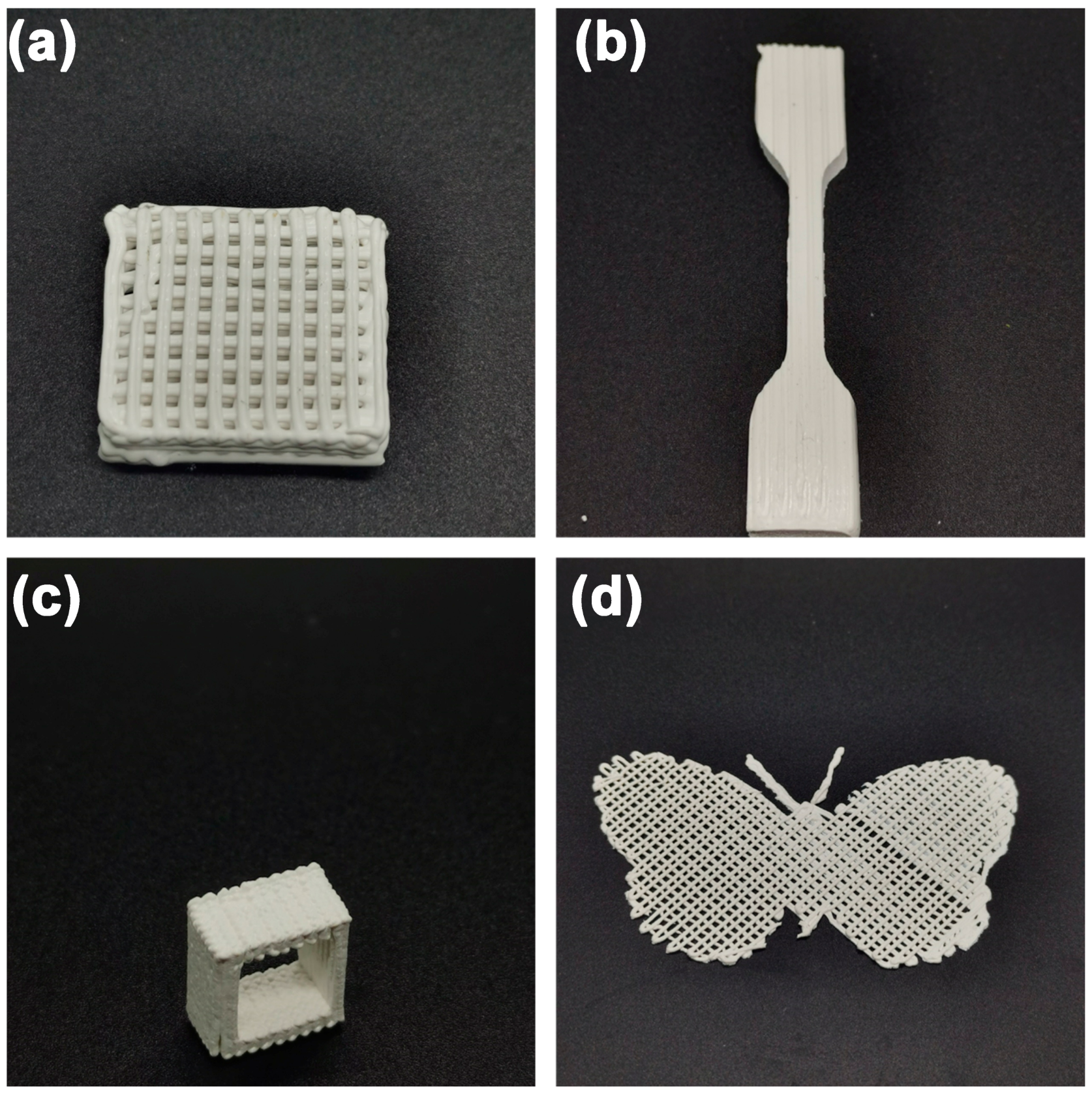

3.5. Preparation of Customizable Complex Heat-Conducting Parts Based on 3D Printing

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, C.; Lu, Q.; Liu, Y.; Huang, H.; Sun, J. Progressive review of heat transfer enhancement technologies in 2010–2020. Sustain. Energy Technol. Assess. 2023, 56, 103121. [Google Scholar] [CrossRef]

- Yi, P.; Awang, R.A.; Rowe, W.S.; Kalantar-zadeh, K.; Khoshmanesh, K. PDMS nanocomposites for heat transfer enhancement in microfluidic platforms. Lab Chip 2014, 14, 3419–3426. [Google Scholar] [CrossRef] [PubMed]

- Hu, R.; Liu, Y.; Shin, S.; Huang, S.; Ren, X.; Shu, W.; Cheng, J.; Tao, G.; Xu, W.; Chen, R. Emerging materials and strategies for personal thermal management. Adv. Energy Mater. 2020, 10, 1903921. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Z.; Luo, L.; Fan, Y.; Du, Z. A review on thermal management of lithium-ion batteries for electric vehicles. Energy 2022, 238, 121652. [Google Scholar] [CrossRef]

- He, Z.; Yan, Y.; Zhang, Z. Thermal management and temperature uniformity enhancement of electronic devices by micro heat sinks: A review. Energy 2021, 216, 119223. [Google Scholar] [CrossRef]

- Moore, A.L.; Shi, L. Emerging challenges and materials for thermal management of electronics. Mater. Today 2014, 17, 163–174. [Google Scholar] [CrossRef]

- Luedtke, A. Thermal management materials for high-performance applications. Adv. Eng. Mater. 2004, 6, 142–144. [Google Scholar] [CrossRef]

- Liang, L.; Xu, P.; Wang, Y.; Shang, Y.; Ma, J.; Su, F.; Feng, Y.; He, C.; Wang, Y.; Liu, C. Flexible polyvinylidene fluoride film with alternating oriented graphene/Ni nanochains for electromagnetic interference shielding and thermal management. Chem. Eng. J. 2020, 395, 125209. [Google Scholar] [CrossRef]

- Yao, B.; Xu, X.; Li, H.; Han, Z.; Hao, J.; Yang, G.; Xie, Z.; Chen, Y.; Liu, W.; Wang, Q. Soft liquid-metal/elastomer foam with compression adjustable thermal conductivity and electromagnetic interference shielding. Chem. Eng. J. 2021, 410, 128288. [Google Scholar] [CrossRef]

- Liang, C.; Hamidinejad, M.; Ma, L.; Wang, Z.; Park, C.B. Lightweight and flexible graphene/SiC-nanowires/poly (vinylidene fluoride) composites for electromagnetic interference shielding and thermal management. Carbon 2020, 156, 58–66. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Guo, Y.; Ruan, K.; Shi, X.; Yang, X.; Gu, J. Factors affecting thermal conductivities of the polymers and polymer composites: A review. Compos. Sci. Technol. 2020, 193, 108134. [Google Scholar] [CrossRef]

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Liu, B.; Li, Y.; Fei, T.; Han, S.; Xia, C.; Shan, Z.; Jiang, J. Highly thermally conductive polystyrene/polypropylene/boron nitride com posites with 3D segregated structure prepared by solution-mixing and hot-pressing method. Chem. Eng. J. 2020, 385, 123829. [Google Scholar] [CrossRef]

- Feng, C.; Ni, H.; Chen, J.; Yang, W. Facile method to fabricate highly thermally conductive graphite/PP composite with network structures. ACS Appl. Mater. Interfaces 2016, 8, 19732–19738. [Google Scholar] [CrossRef] [PubMed]

- Sohn, Y.; Han, T.; Han, J.H. Effects of shape and alignment of reinforcing graphite phases on the thermal conductivity and the coefficient of thermal expansion of graphite/copper composites. Carbon 2019, 149, 152–164. [Google Scholar] [CrossRef]

- Li, H.; Fu, C.; Chen, N.; Zhang, T.; Liu, J.; Du, G.; Ren, L.; Zeng, X.; Sun, R. Ice-templated assembly strategy to construct three-dimensional thermally conductive networks of BN nanosheets and silver nanowires in polymer composites. Compos. Commun. 2021, 25, 100601. [Google Scholar] [CrossRef]

- Zhang, R.-C.; Huang, Z.; Huang, Z.; Zhong, M.; Zang, D.; Lu, A.; Lin, Y.; Millar, B.; Garet, G. Turner Uniaxially stretched polyethylene/boron nitride nanocomposite films with metal-like thermal conductivity. Compos. Sci. Technol. 2020, 196, 108154. [Google Scholar] [CrossRef]

- Yuan, J.; Qian, X.; Meng, Z.; Yang, B.; Liu, Z.-Q. Highly thermally conducting polymer-based films with magnetic field-assisted vertically aligned hexagonal boron nitride for flexible electronic encapsulation. ACS Appl. Mater. Interfaces 2019, 11, 17915–17924. [Google Scholar] [CrossRef]

- Huang, Y.; Tian, X.; Zheng, Z.; Li, D.; Malakhov, A.V.; Polilov, A.N. Multiscale concurrent design and 3D printing of continuous fiber reinforced thermoplastic composites with optimized fiber trajectory and topological structure. Compos. Struct. 2022, 285, 115241. [Google Scholar] [CrossRef]

- Gadelmoula, A.; Aldahash, S.A. Effect of Reinforcement with Short Carbon Fibers on the Friction and Wear Resistance of Addi tively Manufactured PA12. Polymers 2023, 15, 3187. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Zhang, S.; Zhang, L.; Gao, Y.; Xuan, F. Strain sensing behavior of FDM 3D printed carbon black filled TPU with periodic configurations and flexible substrates. J. Manuf. Process. 2022, 74, 283–295. [Google Scholar] [CrossRef]

- Park, Y.G.; Yun, I.; Chung, W.G.; Park, W.; Lee, D.H.; Park, J.U. High-Resolution 3D Printing for Electronics. Adv. Sci. 2022, 9, 2104623. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Dou, T.; Wang, Y.; Zuo, H.; Chen, X.; Zhang, M.; Zou, L. Three-Dimensional-Printed Carbon Nanotube/Polylactic Acid composite for Efficient Electromagnetic Interference Shielding. Polymers 2023, 15, 3080. [Google Scholar] [CrossRef] [PubMed]

- De Pascali, C.; Naselli, G.A.; Palagi, S.; Scharff, R.B.; Mazzolai, B. 3D-printed biomimetic artificial muscles using soft actuators that contract and elongate. Sci. Robot. 2022, 7, eabn4155. [Google Scholar] [CrossRef]

- Shmueli, Y.; Lin, Y.-C.; Lee, S.; Zhernenkov, M.; Tannenbaum, R.; Marom, G.; Rafailovich, M.H. In situ time-resolved X-ray scattering study of isotactic polypropylene in additive manufacturing. ACS Appl. Mater. Interfaces 2019, 11, 37112–37120. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Wu, J.; Leng, J.; Cardon, L. Zhang Reinforced and toughened PP/PS composites prepared by Fused Filament Fabrication (FFF) with in-situ microfibril and shish-kebab structure. Polymer 2020, 186, 121971. [Google Scholar] [CrossRef]

- Han, R.; Yang, Q.; Wang, Z.; Cao, D.; Li, G.; Zheng, L.; Peng, B.; Gao, X.; Chen, G. 3D printing-enabled self-assembling β-nucleating agent alignment: Structural evolution and mechanical performances. Polymer 2022, 246, 124736. [Google Scholar] [CrossRef]

- Xu, W.; Jambhulkar, S.; Ravichandran, D.; Zhu, Y.; Kakarla, M.; Nian, Q.; Azeredo, B.; Chen, X.; Jin, K.; Vernon, B. 3D printing-enabled nanoparticle alignment: A review of mechanisms and applications. Small 2021, 17, 2100817. [Google Scholar] [CrossRef]

- Peng, Z.; Lv, Q.; Jing, J.; Pei, H.; Chen, Y.; Ivanov, E. FDM-3D printing LLDPE/BN@ GNPs composites with double network structures for high-efficiency thermal conductivity and electromagnetic interference shielding. Compos. Part B Eng. 2023, 251, 110491. [Google Scholar] [CrossRef]

- Liu, M.; Chiang, S.-W.; Chu, X.; Li, J.; Gan, L.; He, Y.; Li, B.; Kang, F. Du Polymer composites with enhanced thermal conductivity via oriented boron nitride and alumina hybrid fillers assisted by 3-D printing. Ceram. Int. 2020, 46, 20810–20818. [Google Scholar] [CrossRef]

- Del-Mazo-Barbara, L.; Ginebra, M.-P. Rheological characterisation of ceramic inks for 3D direct ink writing: A review. J. Eur. Ceram. Soc. 2021, 41, 18–33. [Google Scholar] [CrossRef]

- Hu, J.; Huang, Y.; Zeng, X.; Li, Q.; Ren, L.; Sun, R.; Xu, J.-B.; Wong, C.-P. Polymer composite with enhanced thermal conductivity and mechanical strength through orientation manipulating of BN. Compos. Sci. Technol. 2018, 160, 127–137. [Google Scholar] [CrossRef]

- Tanimoto, M.; Yamagata, T.; Miyata, K.; Ando, S. Anisotropic thermal diffusivity of hexagonal boron nitride-filled polyimide films: Effects of filler particle size, aggregation, orientation, and polymer chain rigidity. ACS Appl. Mater. Interfaces 2013, 5, 4374–4382. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Zhao, H.; Niu, H.; Ren, Y.; Fang, H.; Fang, X.; Lv, R.; Maqbool, M.; Bai, S. Highly thermally conductive 3D printed graphene filled polymer composites for scalable thermal management applications. ACS Nano 2021, 15, 6917–6928. [Google Scholar] [CrossRef] [PubMed]

- Kawamura, T.; Takami, H.; Kuwahara, K. Computation of high Reynolds number flow around a circular cylinder with surface roughness. Fluid Dyn. Res. 1986, 1, 145. [Google Scholar] [CrossRef]

- Hou, X.; Chen, Y.; Lv, L.; Dai, W.; Zhao, S.; Wang, Z.; Fu, L.; Lin, C.-T.; Jiang, N.; Yu, J. High-thermal-transport-channel construction within flexible composites via the welding of boron nitride nanosheets. ACS Appl. Nano Mater. 2019, 2, 360–368. [Google Scholar] [CrossRef]

- Agari, Y.; Uno, T. Estimation on thermal conductivities of filled polymers. J. Appl. Polym. Sci. 1986, 32, 5705–5712. [Google Scholar] [CrossRef]

- Pan, D.; Li, Q.; Zhang, W.; Dong, J.; Su, F.; Murugadoss, V.; Liu, Y.; Liu, C.; Naik, N.; Guo, Z. Highly thermal conductive epoxy nano composites filled with 3D BN/C spatial network prepared by salt template assisted method. Compos. Part B Eng. 2021, 209, 108609. [Google Scholar] [CrossRef]

- Dang, Z.M.; Yuan, J.K.; Yao, S.H.; Liao, R.J. Flexible nanodielectric materials with high permittivity for power energy storage. Adv. Mater. 2013, 25, 6334–6365. [Google Scholar] [CrossRef]

| BN Content | a | n | |||

|---|---|---|---|---|---|

| 35 wt% | 2.4 × 104 | 9.53 × 105 | 40.2 | 52.6 | 6.40 × 10−2 |

| 40 wt% | 9.27 × 104 | 5.0 × 106 | 9.4 | 7.96 | 5.61 × 10−2 |

| 45 wt% | 1.47 × 105 | 1.80 × 107 | 11.0 | 3.10 | 1.57 × 10−2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, B.; Zheng, X.; Zhao, Y.; Huang, B.; He, P.; Peng, B.; Chen, G. Controlling Shear Rate for Designable Thermal Conductivity in Direct Ink Printing of Polydimethylsiloxane/Boron Nitride Composites. Polymers 2023, 15, 3489. https://doi.org/10.3390/polym15163489

Xiao B, Zheng X, Zhao Y, Huang B, He P, Peng B, Chen G. Controlling Shear Rate for Designable Thermal Conductivity in Direct Ink Printing of Polydimethylsiloxane/Boron Nitride Composites. Polymers. 2023; 15(16):3489. https://doi.org/10.3390/polym15163489

Chicago/Turabian StyleXiao, Bing, Xinmei Zheng, Yang Zhao, Bingxue Huang, Pan He, Biyou Peng, and Gang Chen. 2023. "Controlling Shear Rate for Designable Thermal Conductivity in Direct Ink Printing of Polydimethylsiloxane/Boron Nitride Composites" Polymers 15, no. 16: 3489. https://doi.org/10.3390/polym15163489

APA StyleXiao, B., Zheng, X., Zhao, Y., Huang, B., He, P., Peng, B., & Chen, G. (2023). Controlling Shear Rate for Designable Thermal Conductivity in Direct Ink Printing of Polydimethylsiloxane/Boron Nitride Composites. Polymers, 15(16), 3489. https://doi.org/10.3390/polym15163489