Phase-Separated Structure of NBR/PVC Blends with Different Acrylonitrile Contents Investigated Using STEM–EDS Mapping Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. DMA Measurement

2.4. STEM Observation

3. Results and Discussion

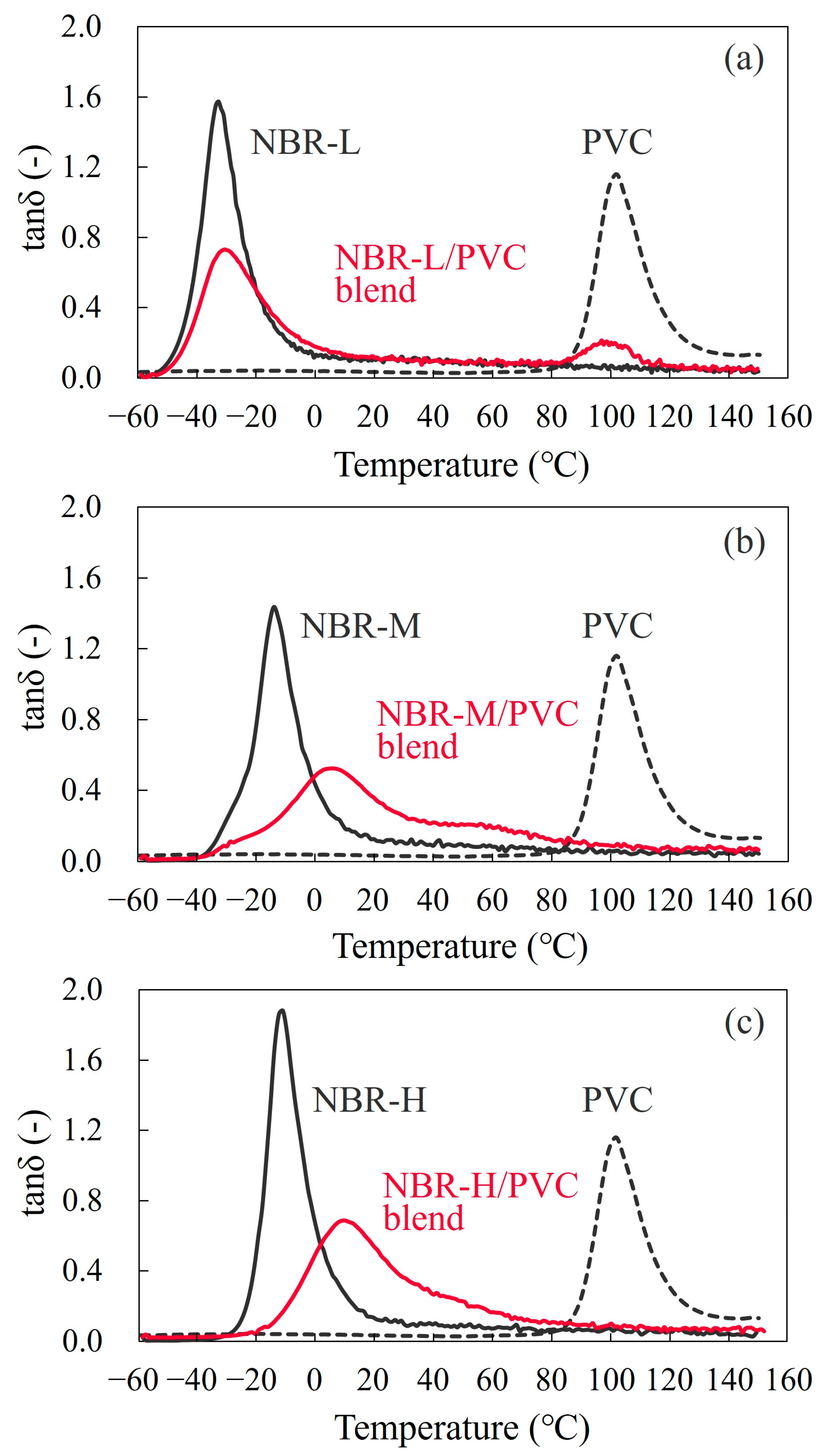

3.1. Glass Transition

3.2. Solubility Parameter

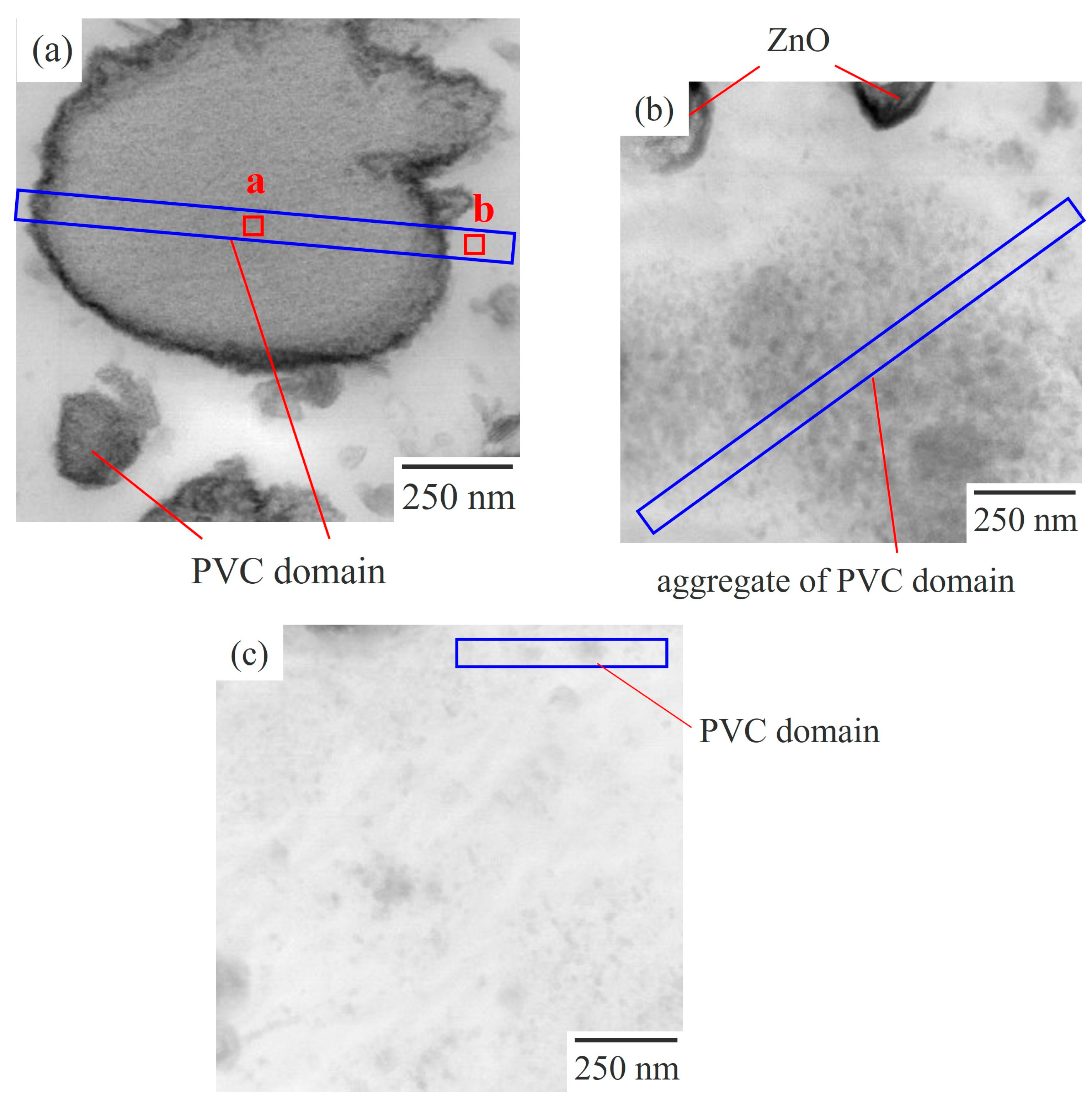

3.3. Two-Phase Morphology

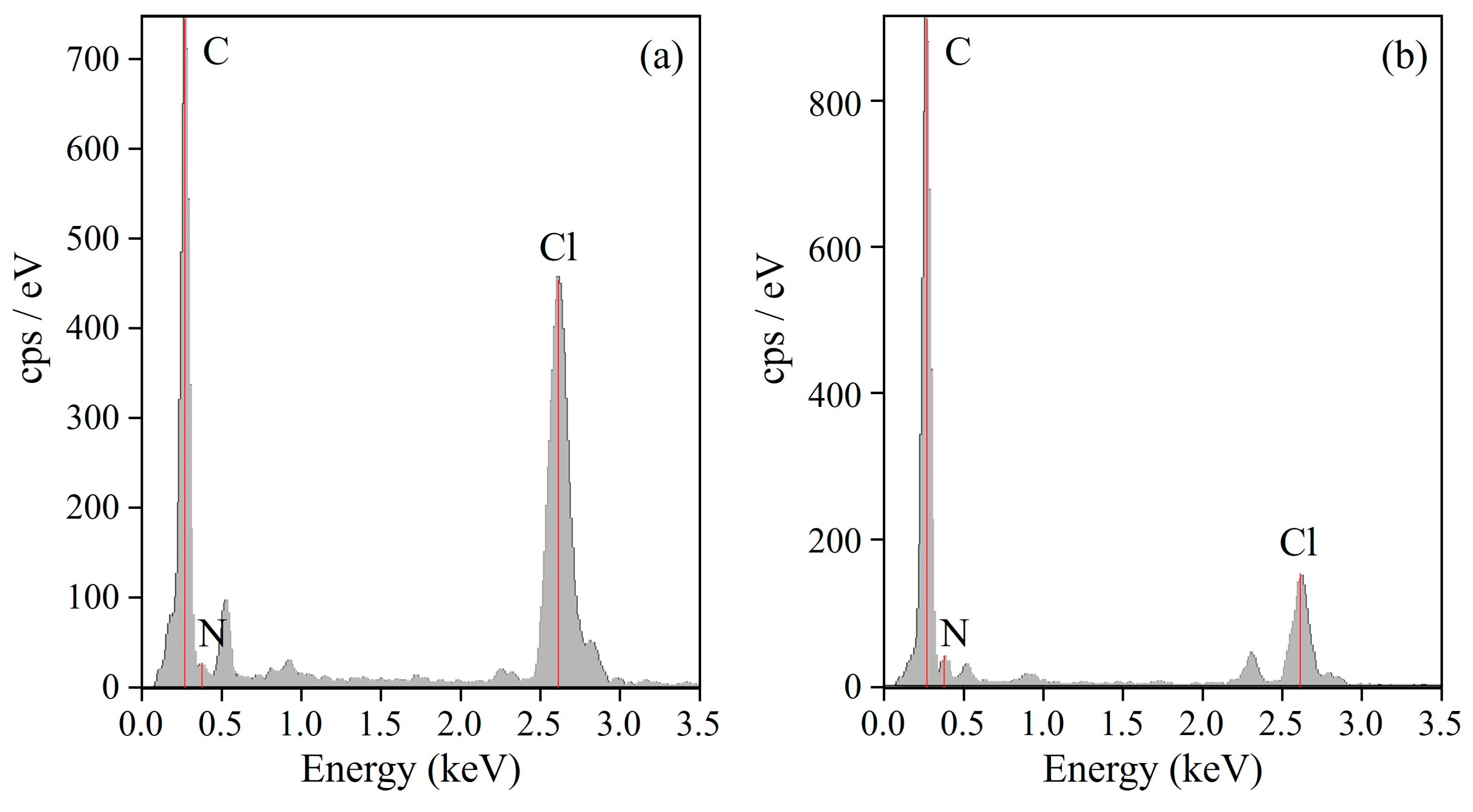

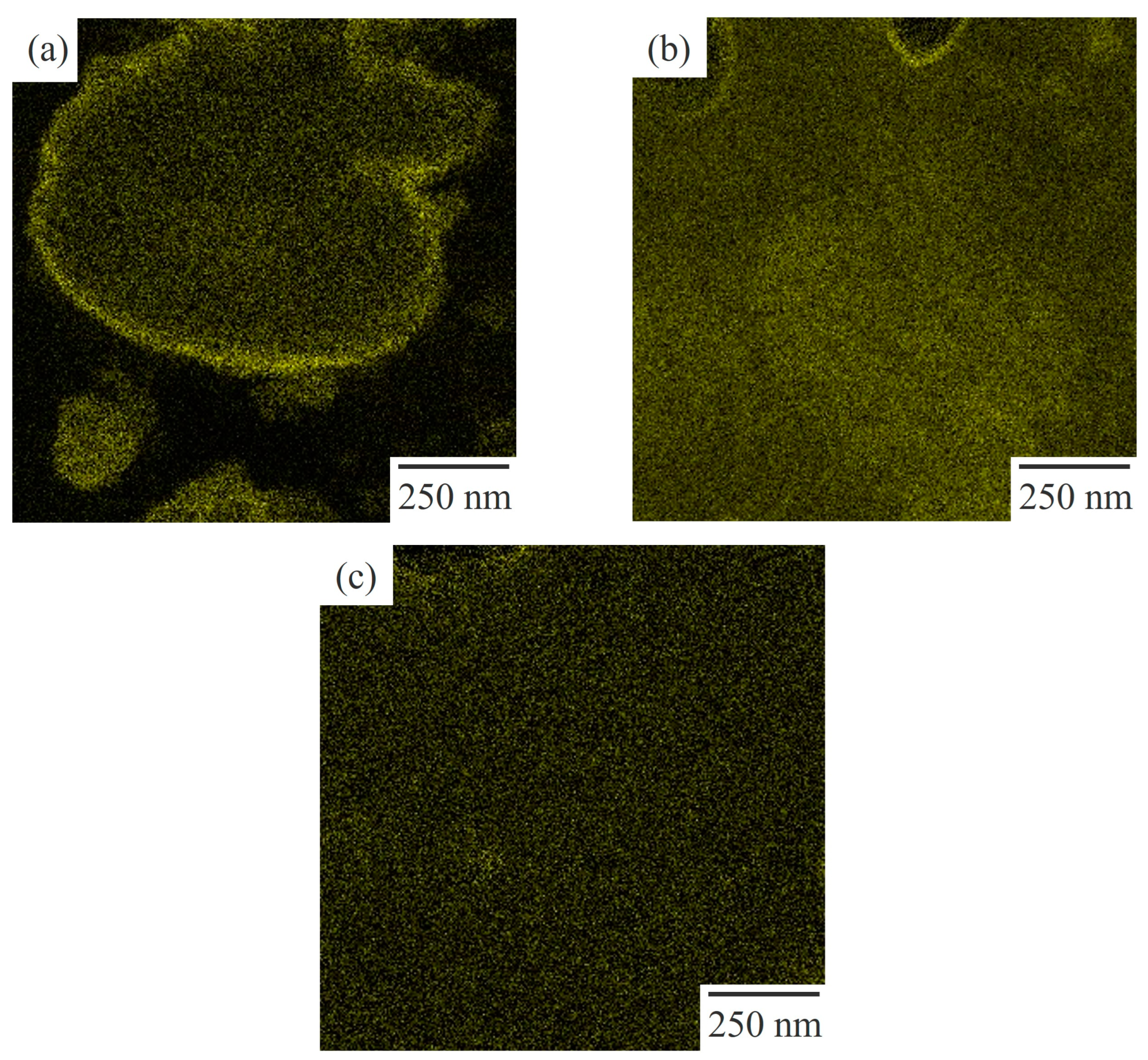

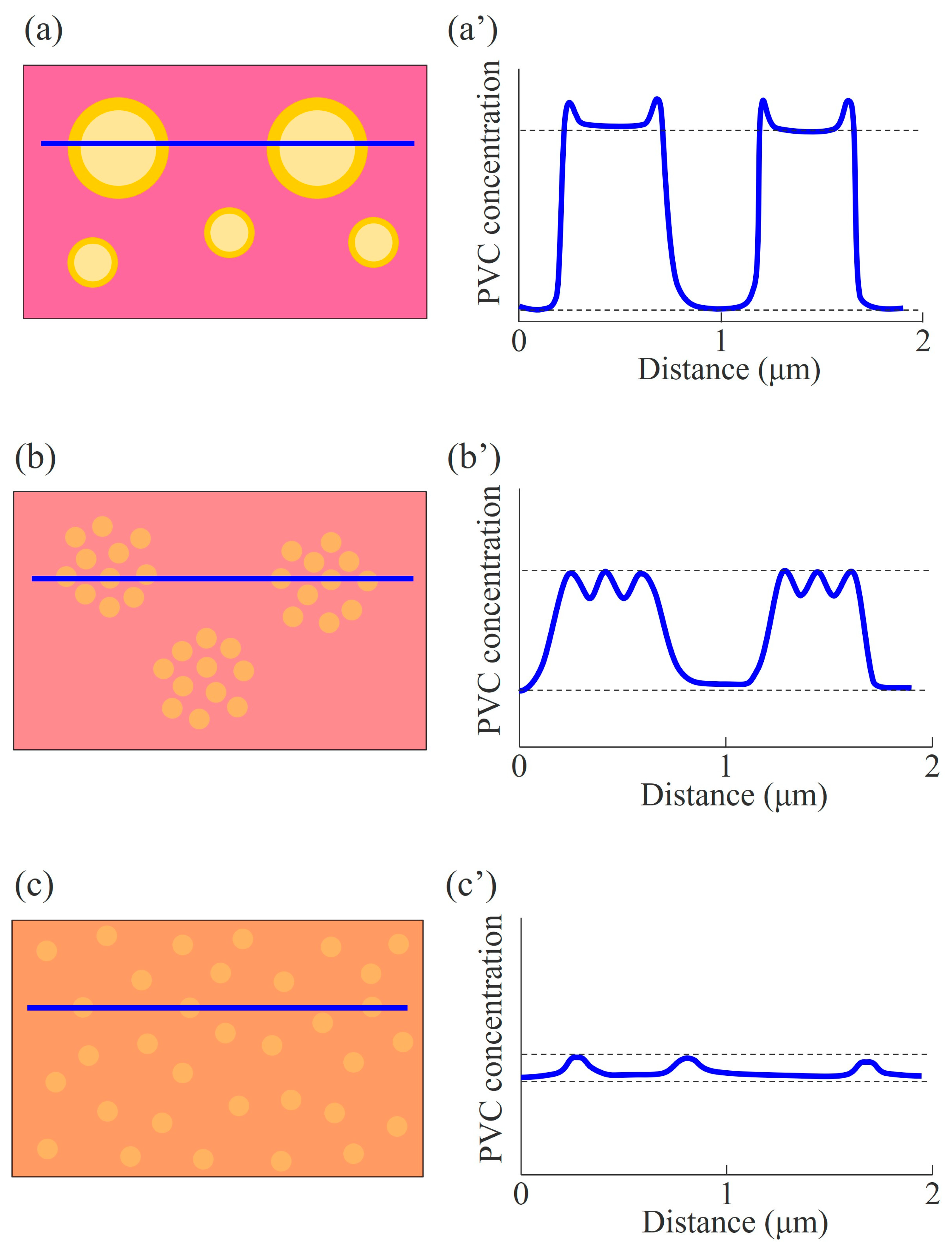

3.4. Concentration Distribution

3.5. Phase-Separated Structure of NBR/PVC Blends

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Olabis, O. Polymer-Polymer Miscibility; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Paul, D.R. Polymer Blends Volume 1; Elsevier: Amsterdam, The Netherlands, 2012; Volume 1. [Google Scholar]

- Utracki, L.A.; Wilkie, C.A. Polymer Blends Handbook; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002; Volume 1. [Google Scholar]

- Thomas, S.; Grohens, Y.; Jyotishkumar, P. Characterization of Polymer Blends: Miscibility, Morphology and Interfaces; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Kader, M.; Kim, W.; Kaang, S.; Nah, C. Morphology and dynamic mechanical properties of natural rubber/nitrile rubber blends containing trans-polyoctylene rubber as a compatibilizer. Polym. Int. 2005, 54, 120–129. [Google Scholar] [CrossRef]

- Samsudin, S.A.; Kelly, C.A.; Kukureka, S.N.; Jenkins, M.J. Development of partial miscibility in polycarbonate/polypropylene blends via annealing. J. Polym. Eng. 2017, 37, 707–714. [Google Scholar] [CrossRef]

- Takamatsu, K.; Suzuki, S.; Nishimura, Y.; Saito, H. Reduction of birefringence by dynamic asymmetry in miscible blends of dissimilar polycarbonates. Polymer 2021, 222, 123632. [Google Scholar] [CrossRef]

- Nair, T.M.; Kumaran, M.; Unnikrishnan, G.; Pillai, V. Dynamic mechanical analysis of ethylene–propylene–diene monomer rubber and styrene–butadiene rubber blends. J. Appl. Polym. Sci. 2009, 112, 72–81. [Google Scholar] [CrossRef]

- Ziquinatti, F.; Hugen, R.G.; Oliveira, C.M.; Coelho, L.A.; Pezzin, S.H. Miscibility and mechanical behavior of SAN/NBR blends. Macromol. Symp. 2005, 229, 276–280. [Google Scholar] [CrossRef]

- Nara, S.; Sagawa, H.; Saito, H.; Oyama, H.T. Synergetic toughening of poly (phenylene sulfide) by poly (phenylsulfone) and poly (ethylene-ran-methacrylate-ran-glycidyl methacrylate). J. Appl. Polym. Sci. 2021, 138, 49994. [Google Scholar] [CrossRef]

- Sun, H.; Yu, B.; Sheng, J. Phase morphology and miscibility of iPP/PcBR blends. Polym.-Plast. Technol. Eng. 2010, 49, 414–417. [Google Scholar] [CrossRef]

- Wu, C.; Akiyama, S. Dynamic mechanical and adhesive properties of acrylate rubber/chlorinated polypropylene blends compatibilized with a hindered phenol compound. Polym. J. 2001, 33, 955–958. [Google Scholar] [CrossRef]

- Komori, Y.; Taniguchi, A.; Shibata, H.; Goto, S.; Saito, H. Partial miscibility and concentration distribution of two-phase blends of crosslinked NBR and PVC. Polymers 2023, 15, 1383. [Google Scholar] [CrossRef]

- Shi, X.; Li, Q.; Fu, G.; Jia, L. The effects of a polyol on the damping properties of EVM/PLA blends. Polym. Test. 2014, 33, 1–6. [Google Scholar] [CrossRef]

- Liu, B.; Gao, X.; Zhao, Y.; Dai, L.; Xie, Z.; Zhang, Z. 9, 10-Dihydro-9-oxa-10-phosphaphenanthrene 10-oxide-based oligosiloxane as a promising damping additive for methyl vinyl silicone rubber (VMQ). J. Mater. Sci. 2017, 52, 8603–8617. [Google Scholar] [CrossRef]

- Liu, C.; Fan, J.; Chen, Y. Design of regulable chlorobutyl rubber damping materials with high-damping value for a wide temperature range. Polym. Test. 2019, 79, 106003. [Google Scholar] [CrossRef]

- Li, Z.; Lu, X.; Tao, G.; Guo, J.; Jiang, H. Damping elastomer with broad temperature range based on irregular networks formed by end-linking of hydroxyl-terminated poly (dimethylsiloxane). Polym. Eng. Sci. 2016, 56, 97–102. [Google Scholar] [CrossRef]

- Lu, X.; Yang, Y.; Cheng, B.; Li, T. High damping epoxized natural rubber/diallyl adiallyl phthalate prepolymer (ENR/DAP-A) blends engineered by interphase crosslinking. J. Appl. Polym. Sci. 2018, 135, 46300. [Google Scholar] [CrossRef]

- Li, J.-X.; Chan, C.-M. Effect of the size of the dispersed NBR phase in PVC/NBR blends on the stability of PVC to electron irradiation. Polymer 2001, 42, 6833–6839. [Google Scholar] [CrossRef]

- Slater, T.J.; Janssen, A.; Camargo, P.H.; Burke, M.G.; Zaluzec, N.J.; Haigh, S.J. STEM-EDX tomography of bimetallic nanoparticles: A methodological investigation. Ultramicroscopy 2016, 162, 61–73. [Google Scholar] [CrossRef]

- Kraxner, J.; Schäfer, M.; Röschel, O.; Kothleitner, G.; Haberfehlner, G.; Paller, M.; Grogger, W. Quantitative EDXS: Influence of geometry on a four detector system. Ultramicroscopy 2017, 172, 30–39. [Google Scholar] [CrossRef] [PubMed]

- Bender, H.; Richard, O.; Kundu, P.; Favia, P.; Zhong, Z.; Palenstijn, W.J.; Batenburg, K.J.; Wirix, M.; Kohr, H.; Schoenmakers, R. Combined STEM-EDS tomography of nanowire structures. Semicond. Sci. Technol. 2019, 34, 114002. [Google Scholar] [CrossRef]

- Stockdale, M.K. Thermoplastic elastomers from NBR and polyvinyl chloride. J. Vinyl Technol. 1990, 12, 235–244. [Google Scholar] [CrossRef]

- Mousa, A.; Ishiaku, U.; Mohd Ishak, Z. Oil resistance of dynamically vulcanized poly (vinyl chloride)/nitrile butadiene rubber thermoplastic elastomers. Polym. Bull. 2005, 53, 203–212. [Google Scholar] [CrossRef]

- Gheno, S.; Passador, F.; Pessan, L. Investigation of the phase morphology of dynamically vulcanized PVC/NBR blends using atomic force microscopy. J. Appl. Polym. Sci. 2010, 117, 3211–3219. [Google Scholar] [CrossRef]

- Sen, A.; Mukherjee, G. Studies on the thermodynamic compatibility of blends of poly (vinyl chloride) and nitrile rubber. Polymer 1993, 34, 2386–2391. [Google Scholar] [CrossRef]

- Liu, Z.; Zhu, X.; Wu, L.; Li, Y.; Qi, Z.; Choy, C.; Wang, F. Effects of interfacial adhesion on the rubber toughening of poly (vinyl chloride) Part 1. Impact tests. Polymer 2001, 42, 737–746. [Google Scholar] [CrossRef]

- George, K.; Joseph, R.; Francis, D.J. Studies on NBR/PVC blends. J. Appl. Polym. Sci. 1986, 32, 2867–2873. [Google Scholar] [CrossRef]

- Fukumori, K.; Sato, N.; Kurauchi, T. Pulsed NMR-study of motional heterogeneity in acrylonitrile butadiene poly(vinyl chloride) blends. Rubber Chem. Technol. 1991, 64, 522–533. [Google Scholar] [CrossRef]

- Zakrzewski, G. Investigation of the compatibility of butadiene—Acrylonitrile copolymers with poly (vinyl chloride). Polymer 1973, 14, 347–351. [Google Scholar] [CrossRef]

- Perera, M.S.; Ishiaku, U.; Ishak, Z.M. Characterisation of PVC/NBR and PVC/ENR50 binary blends and PVC/ENR50/NBR ternary blends by DMA and solid state NMR. Eur. Polym. J. 2001, 37, 167–178. [Google Scholar] [CrossRef]

- Pena, J.; Hidalgo, M.; Mijangos, C. Plastification of poly (vinyl chloride) by polymer blending. J. Appl. Polym. Sci. 2000, 75, 1303–1312. [Google Scholar] [CrossRef]

- Kwak, S.-Y.; Nakajima, N. Monitoring of homogenization and analysis of nanoscale structure in a butadiene−acrylonitrile copolymer/poly (vinyl chloride) blend. Macromolecules 1996, 29, 5446–5452. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, X.; Liu, S.; Gui, H.; Lai, J.; Liu, Y.; Gao, J.; Huang, F.; Song, Z.; Tan, B. Ultrafine full-vulcanized powdered rubbers/PVC compounds with higher toughness and higher heat resistance. Polymer 2005, 46, 10614–10617. [Google Scholar] [CrossRef]

- Cliff, G.; Lorimer, G.W. The quantitative analysis of thin specimens. J. Microsc. 1975, 103, 203–207. [Google Scholar] [CrossRef]

- Fedors, R.F. A method for estimating both the solubility parameters and molar volumes of liquids. Polym. Eng. Sci. 1974, 14, 147–154. [Google Scholar] [CrossRef]

- Araki, Y.; Shimizu, D.; Hori, Y.; Nakatani, K.; Saito, H. Mechanical properties and microphase structure of hydrogenated S-SB-S triblock copolymers. Polym. J. 2013, 45, 1140–1145. [Google Scholar] [CrossRef]

- Esmizadeh, E.; Naderi, G.; Ghoreishy, M.H.R. Modification of theoretical models to predict mechanical behavior of PVC/NBR/organoclay nanocomposites. J. Appl. Polym. Sci. 2013, 130, 3229–3239. [Google Scholar] [CrossRef]

- Zhang, S.; Zhai, Y.; Zhang, Y. Microwave-absorbing performance and mechanical properties of poly (vinyl chloride)/acrylonitrile–butadiene rubber thermoplastic elastomers filled with multiwalled carbon nanotubes and silicon carbide. J. Appl. Polym. Sci. 2013, 130, 345–351. [Google Scholar] [CrossRef]

- Lai, S.; Cheng, C.; Liao, Y.; Su, X.; Tan, Q.; Yang, S.; Bai, S. The structure and properties of mechanochemically modified acrylonitrile butadiene rubber (NBR)/poly (vinyl chloride)(PVC) scraps and fresh NBR composites. Waste Manag. 2023, 159, 93–101. [Google Scholar] [CrossRef]

| Material | Grade | Supplier | Additive Amount (g) |

|---|---|---|---|

| stabilizer for PVC | ADK STAB | Adeka Corp., Tokyo, Japan | 0.01 |

| SC-308E | |||

| cross-linking agent | colloidal | Hosoi Chemical Industry Co., Ltd., Tokyo, Japan | 0.018 |

| sulfur | |||

| zinc oxide | JIS-certified | Hakusui Tech Co., Ltd., Osaka, Japan | 0.036 |

| (ZnO) | Class 2 *2 | ||

| stearic acid | stearic acid | NOF Corp., Tokyo, Japan | 0.012 |

| N-cyclohexyl-2- | Nocceler CZ | Ouchi Shinko Chemical Industrial Co., Ltd., Tokyo, Japan | 0.018 |

| benzothiazolyl | |||

| sulfenamide (CZ) | |||

| tetramethylthiuram disulfide (TT) | Nocceler TT | Ouchi Shinko Chemical Industrial Co., Ltd., Tokyo, Japan | 0.002 |

| Polymer | AN (%) | EC (J/mol) | V (cm3/mol) | δi ((MPa)1/2) | Δδ (=δPVC − δNBR) ((MPa)1/2) |

|---|---|---|---|---|---|

| NBR-L | 18.0 | 21,272 | 55.6 | 19.6 | 3.0 |

| NBR-M | 29.0 | 22,966 | 53.4 | 20.7 | 1.9 |

| NBR-H | 33.5 | 23,659 | 52.5 | 21.2 | 1.4 |

| PVC | - | 19,920 | 39.1 | 22.6 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Komori, Y.; Taniguchi, A.; Shibata, H.; Goto, S.; Saito, H. Phase-Separated Structure of NBR/PVC Blends with Different Acrylonitrile Contents Investigated Using STEM–EDS Mapping Analysis. Polymers 2023, 15, 3343. https://doi.org/10.3390/polym15163343

Komori Y, Taniguchi A, Shibata H, Goto S, Saito H. Phase-Separated Structure of NBR/PVC Blends with Different Acrylonitrile Contents Investigated Using STEM–EDS Mapping Analysis. Polymers. 2023; 15(16):3343. https://doi.org/10.3390/polym15163343

Chicago/Turabian StyleKomori, Yuka, Aoi Taniguchi, Haruhisa Shibata, Shinya Goto, and Hiromu Saito. 2023. "Phase-Separated Structure of NBR/PVC Blends with Different Acrylonitrile Contents Investigated Using STEM–EDS Mapping Analysis" Polymers 15, no. 16: 3343. https://doi.org/10.3390/polym15163343

APA StyleKomori, Y., Taniguchi, A., Shibata, H., Goto, S., & Saito, H. (2023). Phase-Separated Structure of NBR/PVC Blends with Different Acrylonitrile Contents Investigated Using STEM–EDS Mapping Analysis. Polymers, 15(16), 3343. https://doi.org/10.3390/polym15163343