Evaluation and Correlation Analysis of the Rheological Properties of Ground Tire Rubber and Styrene Butadiene Styrene Compound-Modified Asphalt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Research Methods, Experimental Methods and Analytical Theories

2.2.1. Research Methods

- Implement penetration tests, cone penetration tests, ductility tests, softening point tests, and viscosity tests to analyze the conventional properties of GTRSA;

- Perform frequency sweep tests and MSCR tests to quantitatively analyze the viscoelastic characteristics of GTRSA according to rutting factor, fatigue factor, 2S2P1D model, elastic recovery rate, and unrecoverable creep compliance;

- Apply the Pearson correlation coefficient to compute the correlation between the conventional performance and the rheological performance of GTRSA and analyze the modification mechanisms of GTRSA based on the relevant results.

2.2.2. Experimental Methods and Analytical Theories

- Conventional performance tests

- Frequency sweep test

- MSCR test

3. Results and Discussion

3.1. Conventional Pavement Properties

3.1.1. Intermediate Temperature Performance

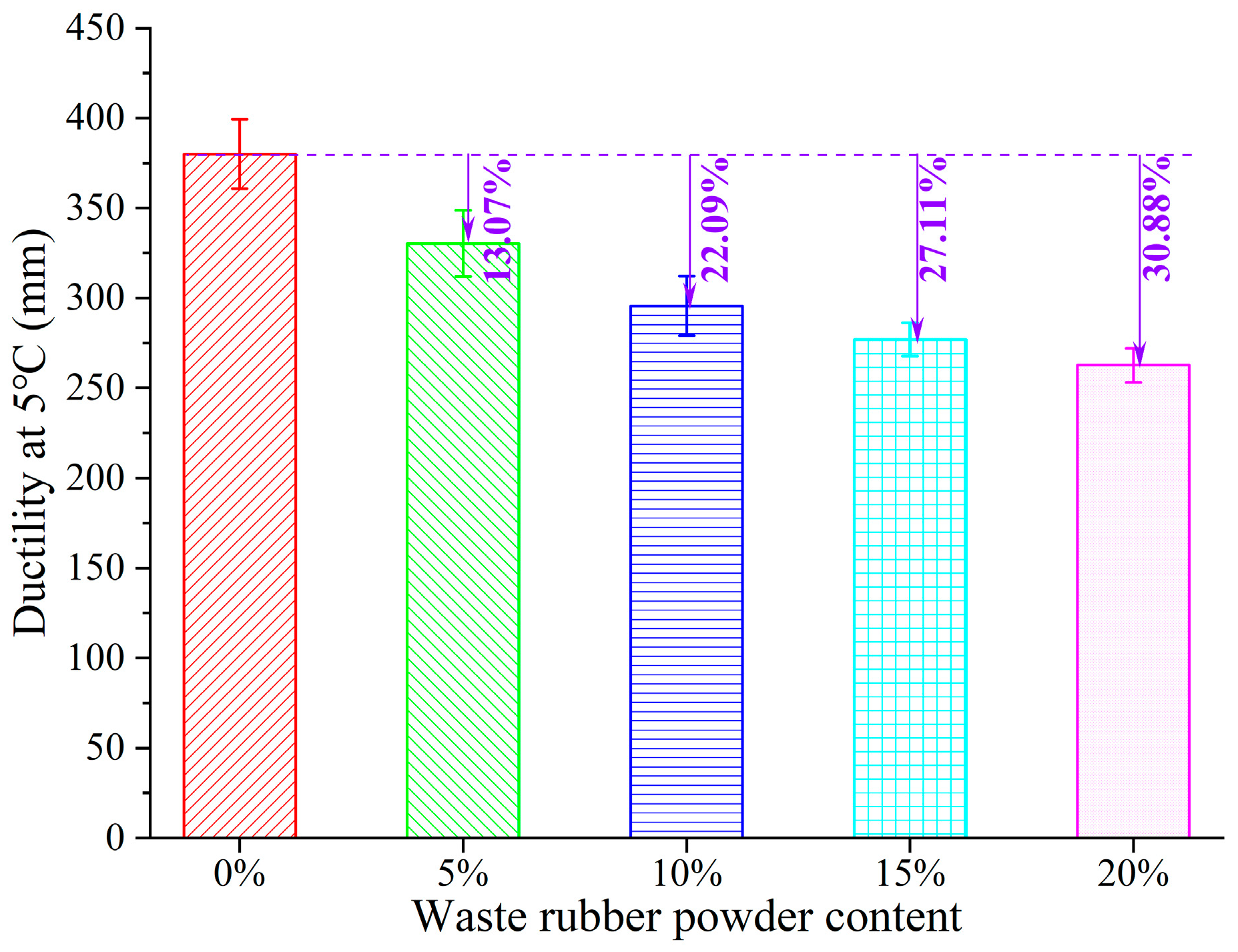

3.1.2. Performance at Low Temperatures

3.1.3. High-Temperature Performance

3.1.4. Workable Performance

3.2. Rheological Properties of GTRSA

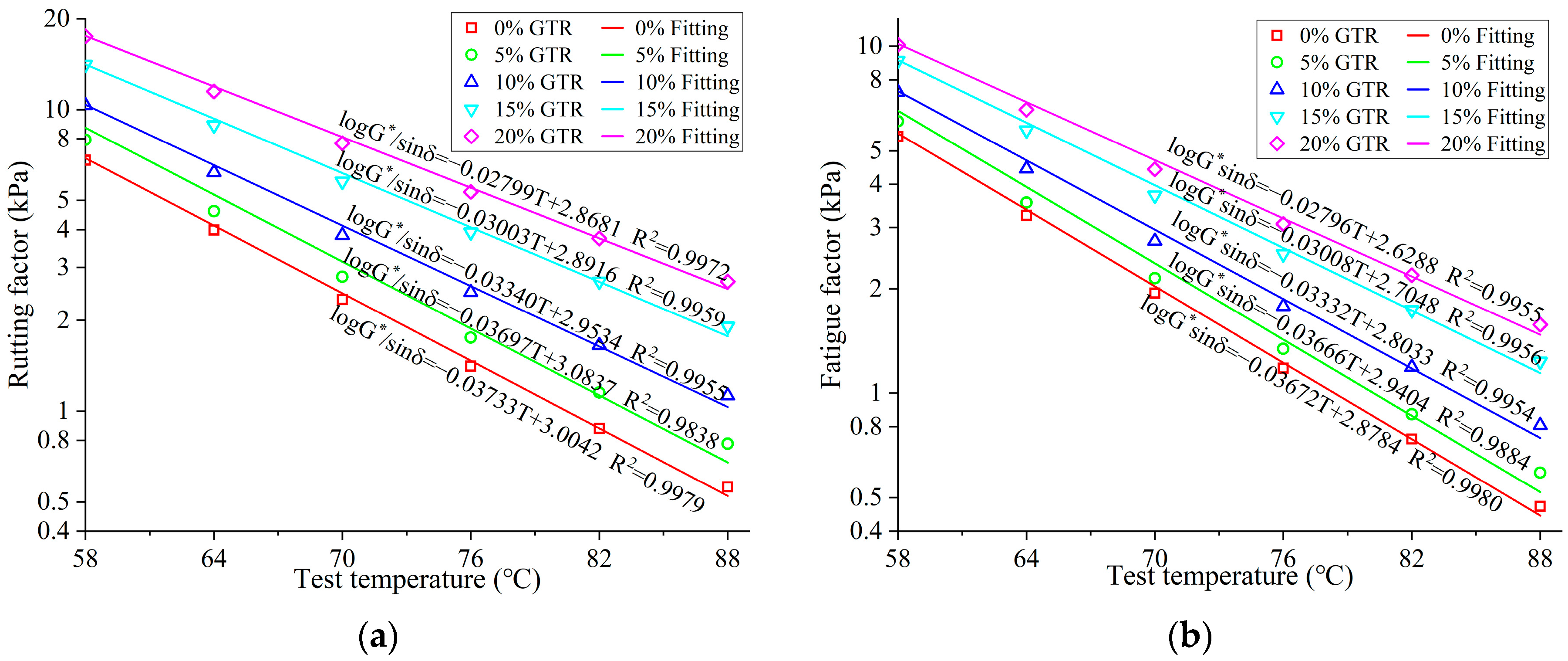

3.2.1. Impact of GTR Content on the Rheological Performance of Asphalt

3.2.2. Rheological Property Analysis Based on the 2S2P1D Model

3.3. GTRSA’s Creep Recovery Characteristics

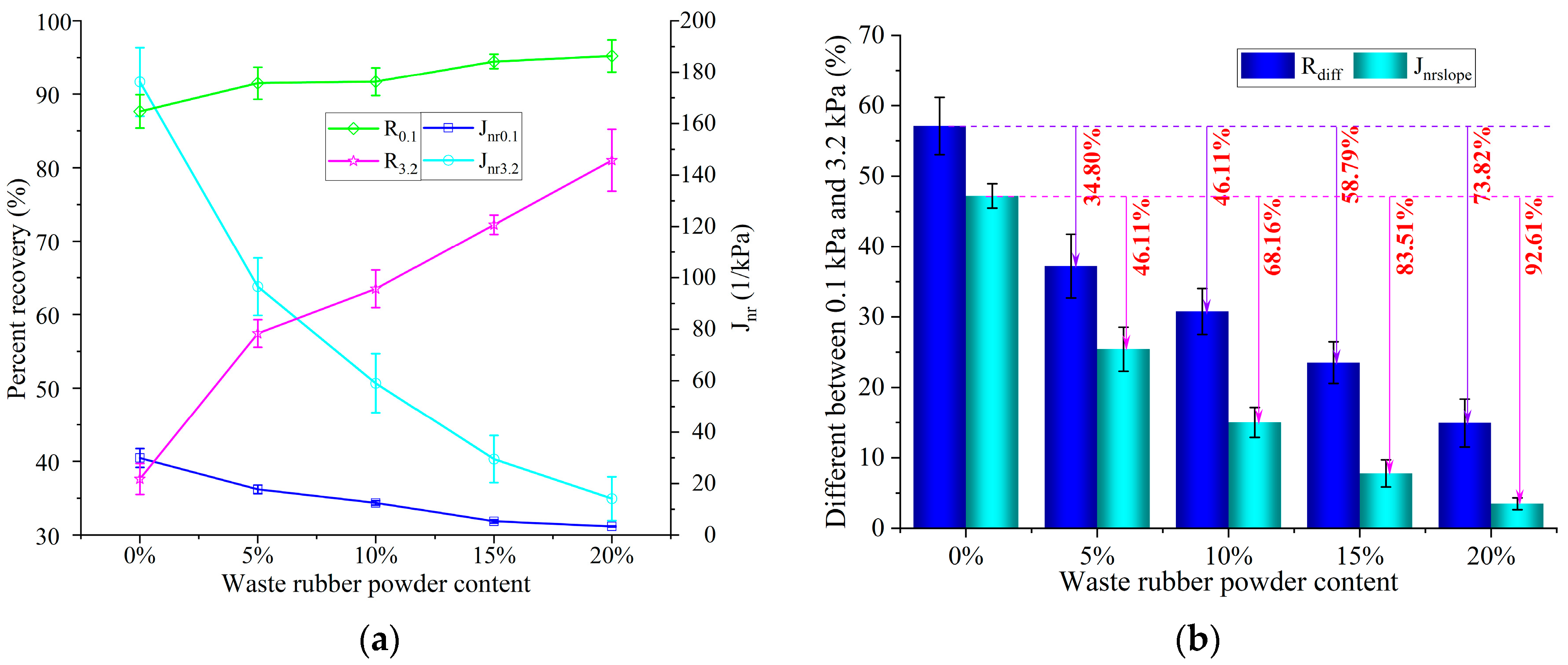

3.3.1. Results of MSCR Testing

3.3.2. Recovery from Creep and Resistance to Unrecoverable Creep Deformation

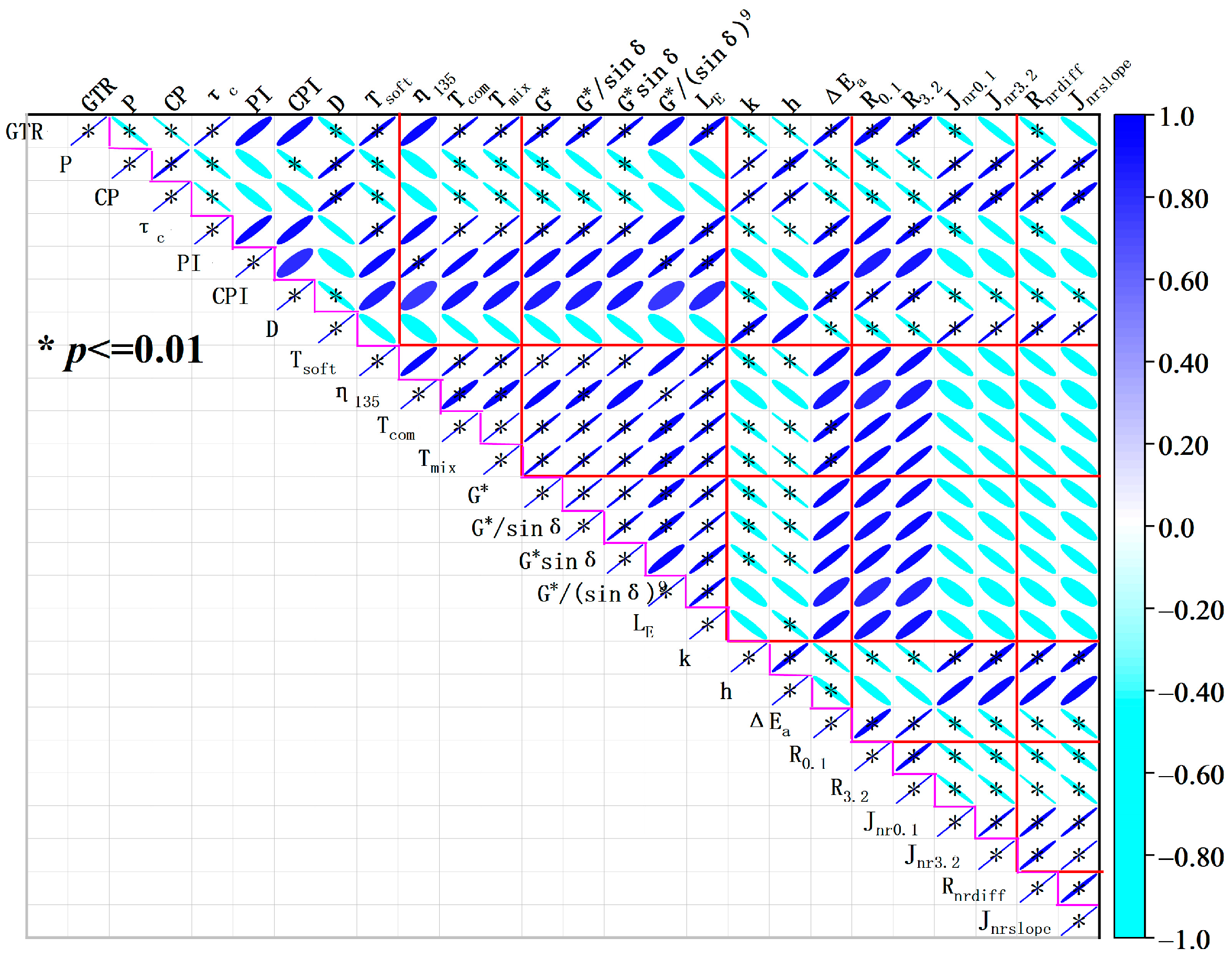

3.4. Modified Mechanism and Correlation Analysis of GTRSA

4. Conclusions

- Adding GTR can significantly improve the anti-rutting deformation and temperature sensitivity at high and intermediate temperatures. This is mainly attributed to the shear swelling and partial dissolution of rubber powder in SBS-modified asphalt, which adsorbs the lightweight components (aromatics and saturates) in the asphalt, resulting in an increase in the relative content of resin and asphaltene in the GTRSA and improving the asphalt’s shear deformation resistance. However, GTR can have a negative effect on low-temperature performance and workable performance. Considering the conventional performance of GTRSA, the additional content of GTR is recommended at 10~20%;

- The elasticity of SBS-modified asphalt can be enhanced by adopting GTR as a compound modifier according to the fitted results of fractional-order exponents k and h. Due to GTRSA’s high activation energy ΔEa, the inclusion of GTR helps to increase the substance’s ability to withstand shear deformation;

- An increase of 20% GTR was able to increase the creep recovery rate by 7.1 percentage points at low stress and by 49.9 percentage points at high stress, reaching 80.8%. Moreover, by including GTR, SBS-modified asphalt’s stress sensitivity significantly increased. The addition of 20% GTR was able to increase the stress sensitivity of GTRSA by 73.82% and 93.89% according to the results of Rnrdiff and Jnrslope, respectively. The partially undissolved rubber powder microparticle elastic core was widely dispersed in the asphalt medium, which cannot be ignored in improving the creep recovery ability of composite-modified asphalt;

- The frequency sweep test results were closely related to the softening point (Tsoft), viscosity (η135), mixing temperature (Tmix), and compaction temperature (Tcom) of GTRSA. The creep recovery and irrecoverable creep compliance of GTRSA were closely related to the indexes of the GTR content, penetration (P), cone penetration (CP), CPI, and ductility (D), as well as 2S2P1D model parameters (k). In contrast, the relationship between the frequency sweep test outcomes and the MSCR test outcomes showed a weak linear correlation;

- GTR has an obvious enhancement effect on SBS-modified asphalt, but the excessive mixing and compaction temperatures of GTRSA still need to be improved by adding some warm mixing agents and adopting other methods. In addition, it is advisable to further explore the modified mechanism of GTRSA by combining various analytical and experimental methods, as well as to establish the function model between these indicators. These things considered, it is recommended to further study the road performance of GTRSA mixtures, which can provide an idea for developing environmentally friendly long-life asphalt pavements and building a resource-recycling society.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Q.; Wang, N.; Tseng, M.; Huang, Y.; Li, N. Waste tire recycling assessment: Road application potential and carbon emissions reduction analysis of crumb rubber modified asphalt in China. J. Clean. Prod. 2020, 249, 119411. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Perram, D.; Hand, D.; Ahmed, Z.; Wei, W.; Luo, S. Emission analysis of recycled tire rubber modified asphalt in hot and warm mix conditions. J. Hazard. Mater. 2019, 365, 942–951. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Hong, L.; Wu, H.; Liu, H.; Jia, D. Grafting waste rubber powder and its application in asphalt. Constr. Build. Mater. 2021, 271, 121881. [Google Scholar] [CrossRef]

- Mazzotta, F.; Tataranni, P.; Simone, A.; Fornai, D.; Airey, G.; Sangiorgi, C. Multi-Scale Rheo-Mechanical Study of SMA Mixtures Containing Fine Crumb Rubber in a New Dry-Hybrid Technology. Appl. Sci. 2020, 10, 3887. [Google Scholar] [CrossRef]

- Zhang, W.; Luan, Y.; Ma, T.; Wang, S.; Chen, J.; Li, J.; Wu, M. Multilevel Analysis of the Aging Mechanisms and Performance Evolution of Rubber-Modified Asphalt. J. Mater. Civ. Eng. 2021, 33, 04021365. [Google Scholar] [CrossRef]

- Han, L.; Zheng, M.; Guo, H.; Wang, T.; Zhu, J.; Hajikarimi, P. Mechanism behind Time Dependent Elasticity of Crumb Rubber-Nano-Asphalt Hybrids Using Discrete Relaxation Spectrum. J. Renew. Mater. 2022, 10, 1727–1752. [Google Scholar] [CrossRef]

- Qian, G.; Yang, C.; Huang, H.; Gong, X.; Yu, H. Resistance to Ultraviolet Aging of Nano-SiO2 and Rubber Powder Compound Modified Asphalt. Materials 2020, 13, 5067. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Q.; Li, Z.; Ding, S. Rhysiological properties of graphene nanoplatelets/rubber crowd composite modified asphalt. Constr. Build. Mater. 2020, 261, 120505. [Google Scholar] [CrossRef]

- Abdelmagid, A.A.A.; Pei Feng, C. Evaluating the Effect of Rice-Husk Ash and Crumb-Rubber Powder on the High-Temperature Performance of Asphalt Binder. J. Mater. Civ. Eng. 2019, 31, 04019296. [Google Scholar] [CrossRef]

- Liu, H.B.; Fu, L.X.; Jiao, Y.B.; Tao, J.L.; Wang, X.Q. Short-Term Aging Effect on Properties of Sustainable Pavement Asphalts Modified by Waste Rubber and Diatomite. Sustainability 2017, 9, 996. [Google Scholar] [CrossRef] [Green Version]

- Ghasemi, M.; Marandi, S.M. Performance improvement of a crumb rubber modified bitumen using recycled glass powder. J. Zhejiang Univ. Sci. A 2013, 14, 805–814. [Google Scholar] [CrossRef] [Green Version]

- Ouyang, C.; Gao, Q.; Shi, Y.; Shan, X. Compatibilizer in waste tire powder and low-density polyethylene blends and the blends modified asphalt. J. Appl. Polym. Sci. 2012, 123, 485–492. [Google Scholar] [CrossRef]

- Gibreil, H.A.A.; Feng, C.P. Effects of high-density polyethylene and crumb rubber powder as modifiers on properties of hot mix asphalt. Constr. Build. Mater. 2017, 142, 101–108. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. The research for crumb rubber/waste plastic compound modified asphalt. J. Therm. Anal. Calorim. 2015, 124, 729–741. [Google Scholar] [CrossRef]

- Zhou, T.; Kabir, S.F.; Cao, L.; Luan, H.; Dong, Z.; Fini, E.H. Comparing effects of physisorption and chemisorption of bio-oil onto rubber particles in asphalt. J. Clean. Prod. 2020, 273, 123112. [Google Scholar] [CrossRef]

- Wang, H.; Jing, Y.; Zhang, J.; Cao, Y.; Lyu, L. Preparation and performance evaluation of swine manure bio-oil modified rubber asphalt binder. Constr. Build. Mater. 2021, 294, 123584. [Google Scholar] [CrossRef]

- Gong, M.; Yang, B.; Zhang, H.; Sun, Q. Comparative study on durability of different composite modified asphalt mixtures. Road Mater. Pavement 2019, 22, 1369–1388. [Google Scholar] [CrossRef]

- Zhu, X.; Lu, C.; Liang, M. Rheological Property of Bitumen Modified by the Mixture of the Mechanochemically Devulcanized Tire Rubber Powder and SBS. J. Mater. Civ. Eng. 2009, 21, 699–705. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Z.H.; Li, S. The Preparation Technology and Performance Study of SBS and Rubber Powder Composite Modified Asphalt. Appl. Mech. Mater. 2013, 361–363, 1617–1620. [Google Scholar] [CrossRef]

- Wang, L.; Hu, J.S.; Chen, G. Microstructure and Temperature Characterization of Compound Crumb Rubber Modified Asphalt. Adv. Mater. Res. 2014, 1052, 382–386. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, X.; Xu, G.; Fu, Q. Evaluation of low temperature performance for SBS/CR compound modified asphalt binders based on fractional viscoelastic model. Constr. Build. Mater. 2019, 214, 326–336. [Google Scholar] [CrossRef]

- Wu, S.; He, R.; Chen, H.; Li, W.; Li, G. Rheological Properties of SBS/CRP Composite Modified Asphalt under Different Aging Treatments. Materials 2020, 13, 4921. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Wang, L.; Bin, X.; Cao, D.; Li, J.; Zhao, K. Performance of SBS modifier-crumb rubber composite modified asphalt used as an anti-wear layer of perpetual pavement. Int. J. Pavement Eng. 2021, 23, 4097–4111. [Google Scholar] [CrossRef]

- Li, H.; Li, W.; Sheng, Y.; Lv, H. Influence of Compound Action of Rubber Powder and SBS on High-Temperature Performance of Asphalt Pavement Surface. J. Mater. Civ. Eng. 2021, 33, 04021126. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, L.; Zhang, Y.; Lv, Z.; Zhu, C. Quantitative Analysis of Effect and Interaction of Diatomite and Basalt Fiber on Asphalt Performance. J. Mater. Civ. Eng. 2019, 31, 04019306. [Google Scholar] [CrossRef]

- Li, L.; Wu, C.; Cheng, Y.; Wang, H.; Liang, J.; Zhao, W. Synergistic effect of waste rubber powder on low-temperature toughness and high-temperature rheological properties of SBS modified asphalt. Constr. Build. Mater. 2023, 365, 130112. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. MotoPro: Beijing, China, 2011.

- ASTM D7175; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). ASTM: West Conshohocken, PA, USA, 2015.

- ASTM D7405; Standard Test Method for Multiple Stress Creep and Recovery (MSCR) of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM: West Conshohocken, PA, USA, 2020.

- Veropalumbo, R.; Russo, F.; Viscione, N.; Biancardo, S.A.; Oreto, C. Investigating the rheological properties of hot bituminous mastics made up using plastic waste materials as filler. Constr. Build. Mater. 2020, 270, 121394. [Google Scholar] [CrossRef]

- Xiong, R.; Fang, J.; Xu, A.; Guan, B.; Liu, Z. Laboratory investigation on the brucite fiber reinforced asphalt binder and asphalt concrete. Constr. Build. Mater. 2015, 83, 44–52. [Google Scholar] [CrossRef]

- Meng, Y.; Yan, T.; Muhammad, Y.; Li, J.; Qin, P.; Ling, L.; Rong, H.; Yang, X. Study on the performance and sustainability of modified waste crumb rubber and steel slag powder/SBS composite modified asphalt mastic. J. Clean. Prod. 2022, 338, 130563. [Google Scholar] [CrossRef]

- Venudharan, V.; Biligiri, K.P. Effect of crumb rubber gradation on asphalt binder modification: Rheological evaluation, optimization and selection. Mater. Struct. 2017, 50, 129. [Google Scholar] [CrossRef]

- Li, L.D.; Wu, C.L.; Cheng, Y.C.; He, X.; Wang, H.T.; Liang, J.X. Laboratory investigation on viscoelastic and fatigue properties of diatomite modified asphalt based on dynamic shear rheometer. Constr. Build. Mater. 2022, 327, 126940. [Google Scholar] [CrossRef]

- Wang, D.; Cannone Falchetto, A.; Poulikakos, L.; Hofko, B.; Porot, L. RILEM TC 252-CMB report: Rheological modeling of asphalt binder under different short and long-term aging temperatures. Mater. Struct. 2019, 52, 73. [Google Scholar] [CrossRef]

- Miao, Y. Master Curve and Mesoscopic Simulation Experiment of Dynamic Modulus of Asphalt Mixture. Master’s Thesis, Hefei University of Technology, Hefei, China, 2021. [Google Scholar]

- Zhang, L.; Xing, C.; Gao, F.; Li, T.; Tan, Y. Using DSR and MSCR tests to characterize high temperature performance of different rubber modified asphalt. Constr. Build. Mater. 2016, 127, 466–474. [Google Scholar] [CrossRef]

- Zhao, Y.; Jiang, J.; Dai, Y.; Zhou, L.; Ni, F. Thermal Property Evaluation of Porous Asphalt Concrete Based on Heterogeneous Meso-Structure Finite Element Simulation. Appl. Sci. 2020, 10, 1671. [Google Scholar] [CrossRef] [Green Version]

| Test Items | Unit | Values | Standard Values | Specification |

|---|---|---|---|---|

| Penetration at 25 °C | 0.1 mm | 68 | 60~80 | T0604-2011 |

| Softening point TR&B | °C | 71 | ≥55 | T0606-2011 |

| Ductility at 5 °C and 5 cm/min | cm | 38 | ≥30 | T0605-2011 |

| Solubility | % | 99.4 | ≥99 | T0607-2011 |

| Storage stability | °C | 1.5 | ≤2.5 | T0661-2011 |

| Elasticity recovery at 25 °C | % | 87 | ≥65 | T0662-2000 |

| After rolling thin-film oven test (RTFOT), according to T0610-2011 | ||||

| Mass loss | % | 0.16 | ±1.0 | T0610-2011 |

| Residual penetration ratio at 25 °C | % | 72 | ≥60 | T0610-2011 |

| Ductility at 5 °C | cm | 27 | ≥20 | T0610-2011 and T0605-2011 |

| Test Items | Unit | Values | Standard Values |

|---|---|---|---|

| Density | g/cm3 | 1.18 | 1.1–1.3 |

| Metal content | % | 0.038 | <0.05 |

| Moisture content | % | 0.32 | <1 |

| Fiber content | % | 0.43 | <1 |

| Ash content | % | 4.5 | ≤8 |

| GTR Content | 2S2P1D Parameters’ Fitting Results | Arrhenius Equation ΔEa (kJ/mol) | ||||||

|---|---|---|---|---|---|---|---|---|

| k | h | μ | β | τ | G0 (kPa) | Gm (kPa) | ||

| 0% | 0.724 | 0.731 | 3.560 | 259.2 | 0.0006 | 0 | 1050 | 114.173 |

| 5% | 0.657 | 0.704 | 4.182 | 2472.3 | 0.0006 | 0 | 1050 | 115.981 |

| 10% | 0.631 | 0.666 | 3.589 | 2054.9 | 0.0006 | 0 | 1050 | 116.547 |

| 15% | 0.574 | 0.624 | 3.518 | 2042.8 | 0.0006 | 0 | 1050 | 116.612 |

| 20% | 0.538 | 0.585 | 3.591 | 2010.4 | 0.0006 | 0 | 1050 | 117.561 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.; Tan, X.; Li, L.; Liang, C.; Zhao, Y.; Li, H.; Wang, F.; Zhang, L. Evaluation and Correlation Analysis of the Rheological Properties of Ground Tire Rubber and Styrene Butadiene Styrene Compound-Modified Asphalt. Polymers 2023, 15, 3289. https://doi.org/10.3390/polym15153289

Wu C, Tan X, Li L, Liang C, Zhao Y, Li H, Wang F, Zhang L. Evaluation and Correlation Analysis of the Rheological Properties of Ground Tire Rubber and Styrene Butadiene Styrene Compound-Modified Asphalt. Polymers. 2023; 15(15):3289. https://doi.org/10.3390/polym15153289

Chicago/Turabian StyleWu, Chunli, Xiaoshu Tan, Liding Li, Chunyu Liang, Yongchao Zhao, Hanjun Li, Fuen Wang, and Long Zhang. 2023. "Evaluation and Correlation Analysis of the Rheological Properties of Ground Tire Rubber and Styrene Butadiene Styrene Compound-Modified Asphalt" Polymers 15, no. 15: 3289. https://doi.org/10.3390/polym15153289

APA StyleWu, C., Tan, X., Li, L., Liang, C., Zhao, Y., Li, H., Wang, F., & Zhang, L. (2023). Evaluation and Correlation Analysis of the Rheological Properties of Ground Tire Rubber and Styrene Butadiene Styrene Compound-Modified Asphalt. Polymers, 15(15), 3289. https://doi.org/10.3390/polym15153289