A State-of-the-Art Review of Organic Polymer Modifiers for Slope Eco-Engineering

Abstract

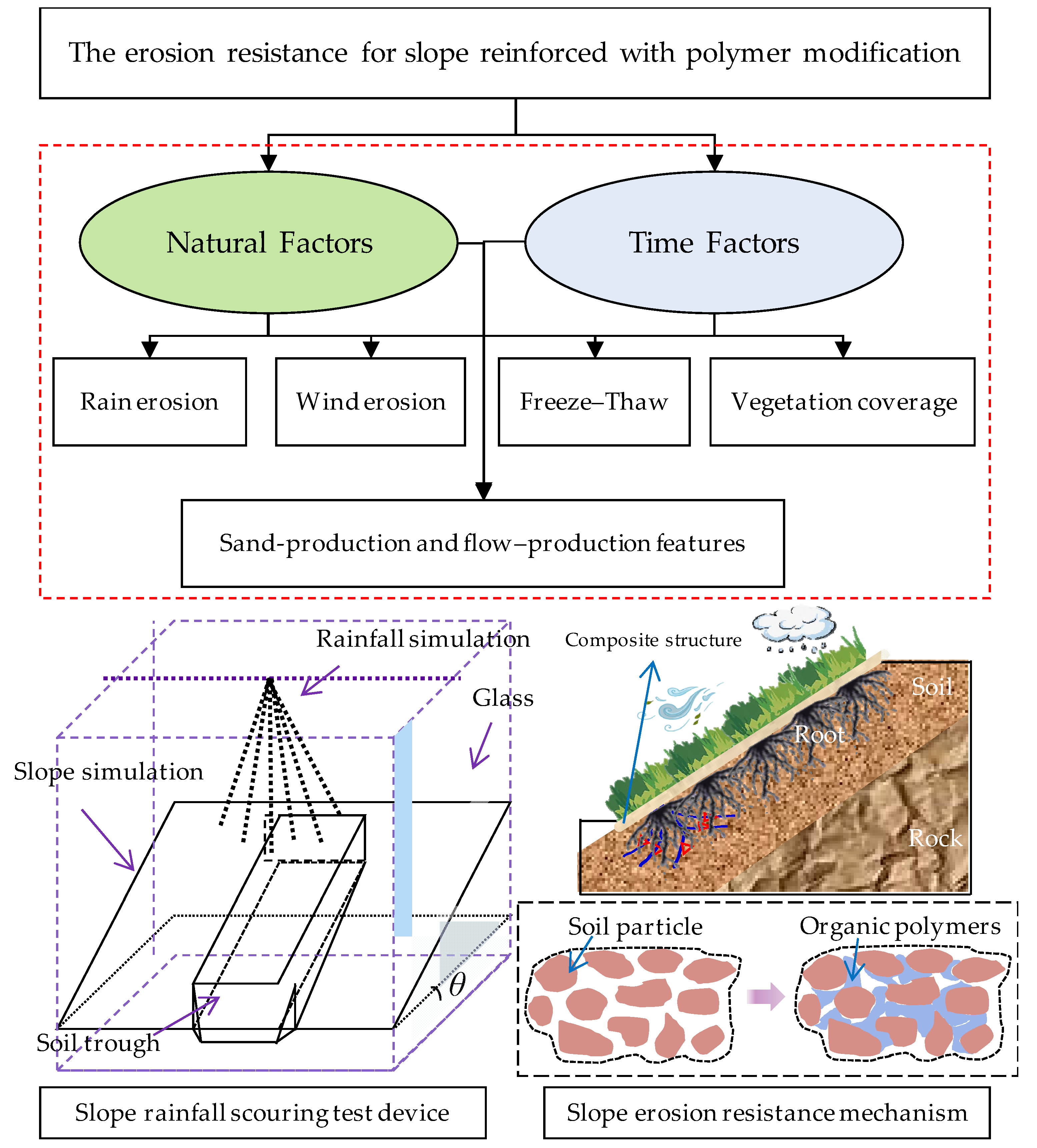

1. Introduction

2. The Technology of Ecological Slope Protection

3. Physicochemical Properties of Organic Polymer Modifiers

3.1. Synthetic Polymer Modifiers

3.2. Biopolymer Modifiers

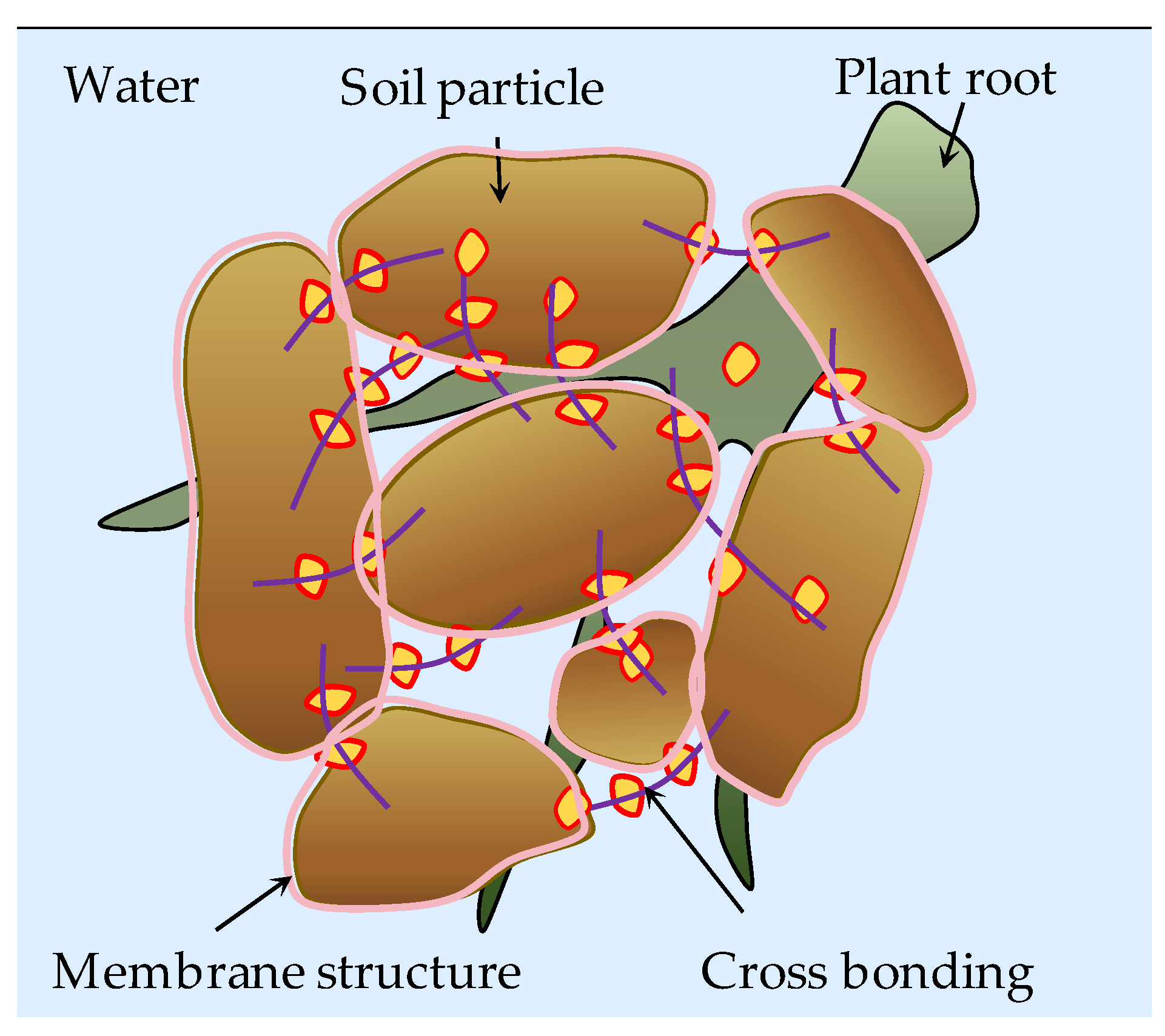

4. Interaction Mechanism between Polymer Modifiers and Soil

4.1. Interaction Mechanism between Synthetic Polymer Modifiers and Soil

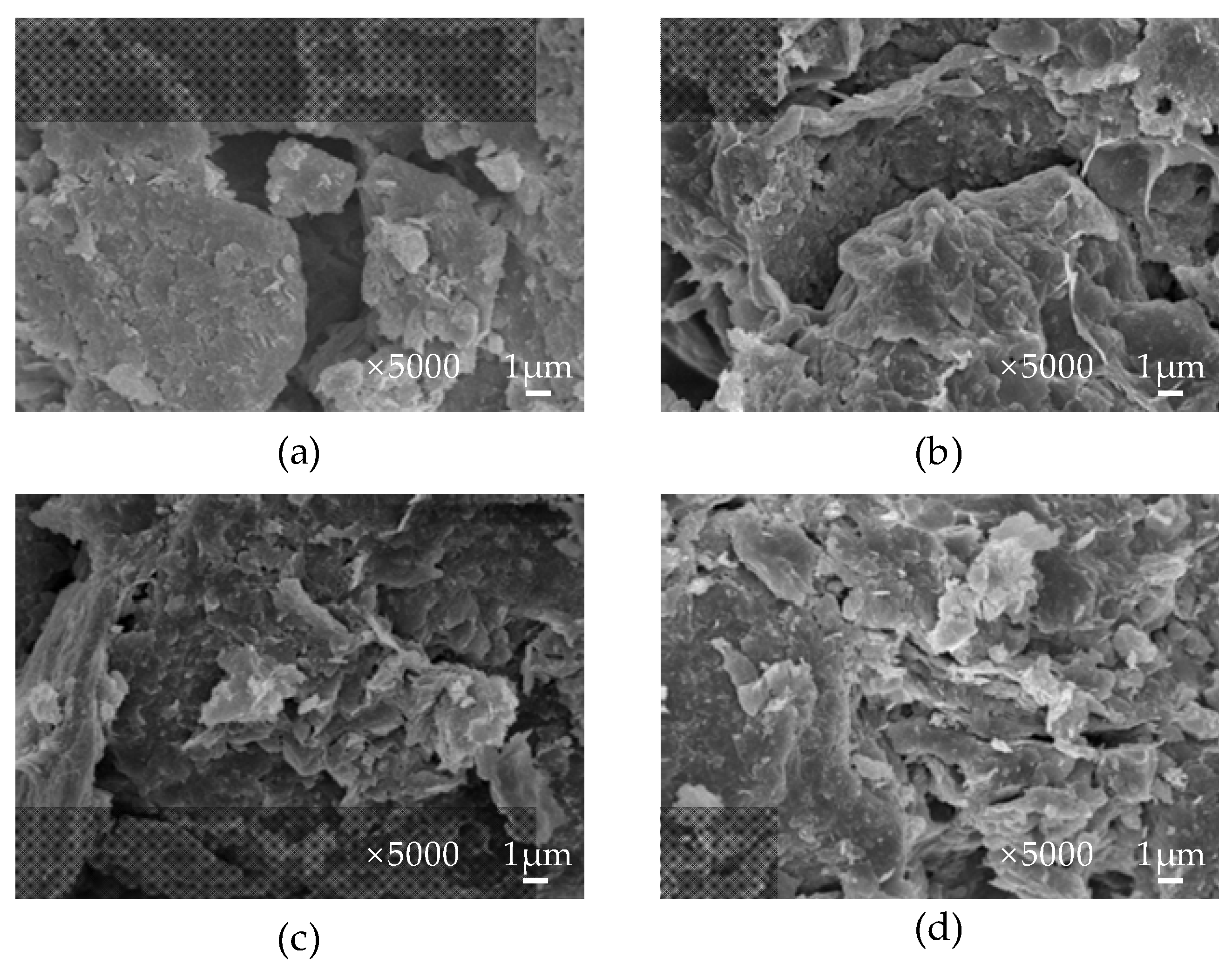

4.2. Interaction Mechanism between Biopolymer Modifiers and Soil

5. Engineering Properties of Polymer-Stabilized Slopes

5.1. Improvement of Mechanical Properties

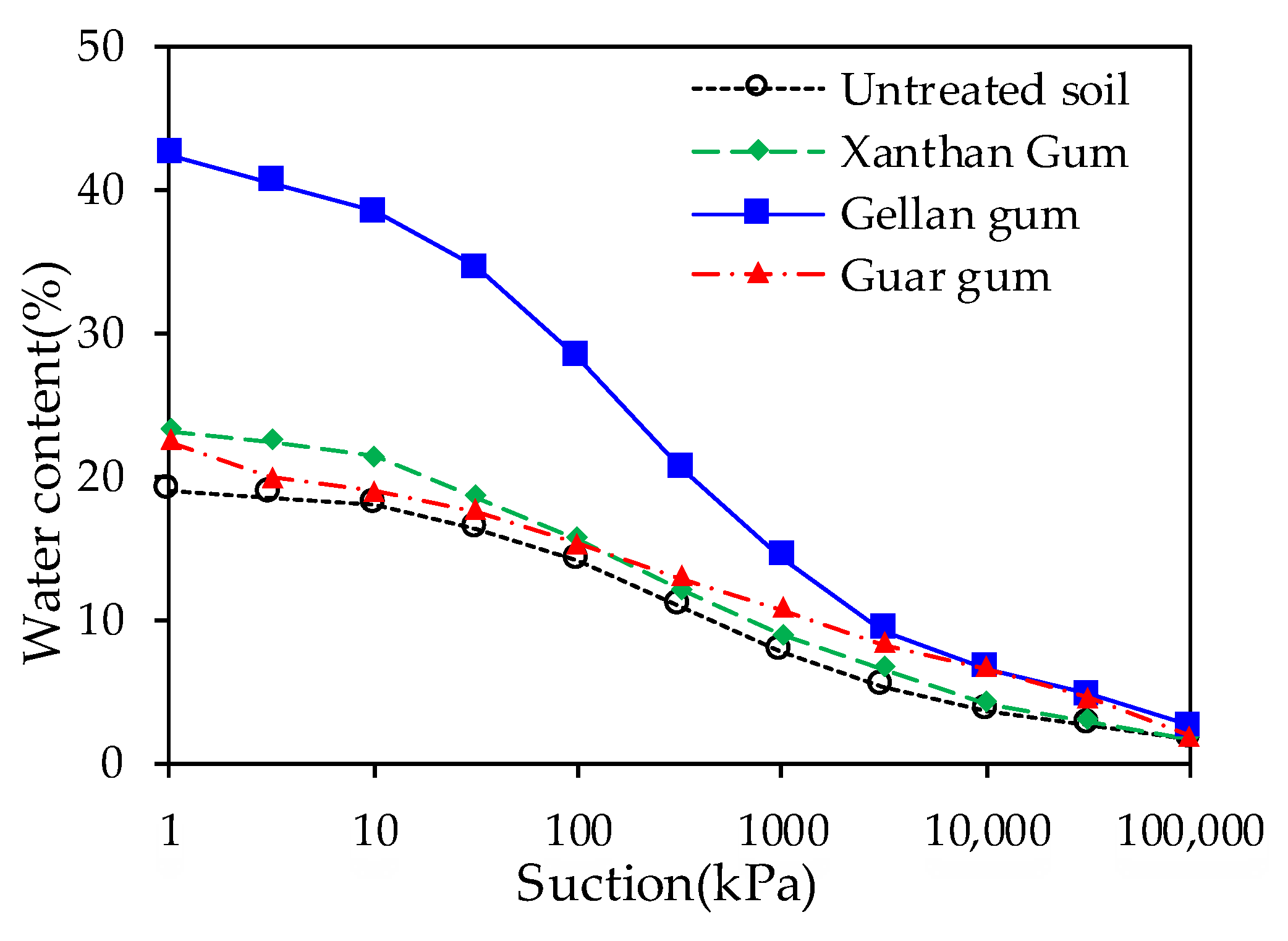

5.2. Improvement of Permeability

5.3. Improvement of Erosion Resistance

5.4. Promotion of Vegetation Growth

6. Challenges and Future Prospects

- Organic polymer materials have the potential to replace traditional technologies used to protect highway slopes due to their renewable and sustainable nature. The cost of biopolymers has decreased by over 80% between 1990 and 2014, making large-scale production and application more cost-effective. In addition, incorporating biopolymer modifiers with a mass fraction between 0.2% and 0.5% in soil reinforcement and vegetation growth promotion processes can significantly reduce material costs compared to synthetic organic polymers. Although the biopolymer industry is still in its developmental stage, its economic feasibility is expected to improve over time.

- The preparation of biopolymer modifiers presents a significant challenge, particularly given the high purity standards required for use in the food and medical sectors. As a result, production costs are currently high. However, if purity standards were relaxed, production expenses could be halved. While biopolymers are primarily used in the food and medical sectors, there is a growing demand for their use in slope engineering, where technical requirements are lower. This increased demand is expected to drive improvements in biopolymer synthesis technology.

- The use of biopolymer modifiers in ecological slope restoration is crucial for mitigating climate change and promoting ecological health. Biopolymers, in particular, offer superior environmental properties and benefits compared to traditional curing materials. By reducing CO2 emissions from synthetic sources, biopolymers can address the negative impact of cement production on the environment. Currently, cement is the most commonly used curing agent for reinforced soils, but it generates approximately 1 ton of CO2 per ton of cement produced. By adopting biopolymers as an alternative, it can significantly reduce this environmental impact.

- There is a lack of research on the carbon sequestration potential of vegetation on roadside slopes, and there is a need for systematic and quantitative estimation studies. However, the ecological engineering of roadside slope vegetation can effectively utilize plant photosynthesis to absorb CO2 emitted by vehicle exhausts. The decarbonization of organic polymers is currently a priority in ecology, and further research should be conducted to explore the potential of decarbonization in both organic polymers and vegetation.

- Most previous research is conducted through laboratory macro- and micro-experiments. Future research on organic synthetic and biopolymer modifiers should be performed in complex natural environments. It is necessary to carry out large-scale slope ecological protection and outdoor tests using organic polymers. This is a prerequisite for the extensive application of these modifiers.

- Considering the rainfall in natural environments, whether the organic polymer modifier can maintain its effect under dry–wet cycles and continuous rainfall needs further study. The durability of organic polymer modifiers in a natural environment still needs to be tested to ensure that the vegetation has been established on the slope. Under the initial protection of organic polymer modifiers, a “protective cover” is provided for vegetation growth, and the slope surface is reinforced. The durability improvement can be accomplished by combining various types of polymers or by designing new polymers.

- A wide variety of polymer modifiers can promote plant growth, but few studies have considered the toxicity of these polymers or composite polymers. It is not clear whether these polymers pollute the surface soil and slope groundwater. Therefore, it is necessary to monitor polymers and plants to evaluate their environmental performance. Additionally, the current research on promoting plant growth is mostly a short-term (about one month) observation, while slope vegetation protection is a long-term task. Therefore, the growth status of vegetation should be continuously tracked and monitored in the future.

- The soil erosion model can estimate runoff and erosion levels at different points in a slope watershed. It considers factors leading to erosion and sediment yield, including rainfall, interception, surface water flow, and sediment transport. The erosion degree of soil solidified by polymer modifiers is mainly evaluated based on runoff, and the erosion mitigation mechanism of polymer modifiers is ignored. Furthermore, the new soil erosion model after polymer modifier solidification needs further investigation for more effective soil erosion control by polymer modifiers.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gariano, S.L.; Guzzetti, F. Landslides in a changing climate. Earth-Sci. Rev. 2016, 162, 227–252. [Google Scholar] [CrossRef]

- Crozier, M.J. Deciphering the effect of climate change on landslide activity: A review. Geomorphology 2010, 124, 260–267. [Google Scholar] [CrossRef]

- Pan, Y.; Fang, H.; Li, B.; Wang, F. Stability analysis and full-scale test of a new recyclable supporting structure for underground ecological granaries. Eng. Struct. 2019, 192, 205–219. [Google Scholar] [CrossRef]

- Li, Z.; Ning, K.; Chen, J.; Liu, C.; Wang, D.; Nie, X.; Hu, X.; Wang, L.; Wang, T. Soil and water conservation effects driven by the implementation of ecological restoration projects: Evidence from the red soil hilly region of China in the last three decades. J. Clean. Prod. 2020, 260, 121109. [Google Scholar] [CrossRef]

- Yurui, L.; Xuanchang, Z.; Zhi, C.; Zhengjia, L.; Zhi, L.; Yansui, L. Towards the progress of ecological restoration and economic development in China’s Loess Plateau and strategy for more sustainable development. Sci. Total Environ. 2021, 756, 143676. [Google Scholar] [CrossRef] [PubMed]

- Rey, F.; Bifulco, C.; Bischetti, G.B.; Bourrier, F.; De Cesare, G.; Florineth, F.; Graf, F.; Marden, M.; Mickovski, S.B.; Phillips, C. Soil and water bioengineering: Practice and research needs for reconciling natural hazard control and ecological restoration. Sci. Total Environ. 2019, 648, 1210–1218. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Jia, Q.; Xu, X.; Yao, S.; Chen, H.; Hou, X.; Zhang, J.; Jin, G. Assessing the coordination of ecological and agricultural goals during ecological restoration efforts: A case study of Wuqi County, Northwest China. Land Use Policy 2019, 82, 550–562. [Google Scholar] [CrossRef]

- Lan, H.; Wang, D.; He, S.; Fang, Y.; Chen, W.; Zhao, P.; Qi, Y. Experimental study on the effects of tree planting on slope stability. Landslides 2020, 17, 1021–1035. [Google Scholar] [CrossRef]

- Li, Q.; Shi, X.; Wu, Q. Effects of protection and restoration on reducing ecological vulnerability. Sci. Total Environ. 2021, 761, 143180. [Google Scholar] [CrossRef]

- Muguda, S.; Hughes, P.N.; Augarde, C.E.; Perlot, C.; Walter Bruno, A.; Gallipoli, D. Cross-linking of biopolymers for stabilizing earthen construction materials. Build. Res. Inf. 2022, 50, 502–514. [Google Scholar] [CrossRef]

- Bai, Y.; Liu, J.; Xiao, H.; Song, Z.; Ma, K.; Deng, Y. Soil stabilization using synthetic polymer for soil slope ecological protection. Eng. Geol. 2023, 321, 107155. [Google Scholar] [CrossRef]

- Fu, H.; Zha, H.; Zeng, L.; Chen, C.; Jia, C.; Bian, H. Research progress on ecological protection technology of highway slope: Status and challenges. Transp. Saf. Environ. 2020, 2, 3–17. [Google Scholar] [CrossRef]

- Tang, W.; Mohseni, E.; Wang, Z. Development of vegetation concrete technology for slope protection and greening. Constr. Build. Mater. 2018, 179, 605–613. [Google Scholar] [CrossRef]

- Ramesh, B.; Menon, S.; Bawa, K.S. A vegetation based approach to biodiversity gap analysis in the Agastyamalai region, Western Ghats, India. Ambio 1997, 26, 529–536. [Google Scholar]

- Panova, I.; Drobyazko, A.; Spiridonov, V.; Sybachin, A.; Kydralieva, K.; Jorobekova, S.; Yaroslavov, A. Humics-based interpolyelectrolyte complexes for antierosion protection of soil: Model investigation. Land Degrad. Dev. 2019, 30, 337–347. [Google Scholar] [CrossRef]

- Liu, J.; Bai, Y.; Song, Z.; Kanungo, D.P.; Wang, Y.; Bu, F.; Chen, Z.; Shi, X. Stabilization of sand using different types of short fibers and organic polymer. Constr. Build. Mater. 2020, 253, 119164. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Shin, H.-D.; Cho, G.-C. Soil treatment using microbial biopolymers for anti-desertification purposes. Geoderma 2015, 253, 39–47. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.; Kanungo, D.P.; Song, Z.; Bai, Y.; Wang, Y.; Li, D.; Qian, W. Topsoil reinforcement of sandy slope for preventing erosion using water-based polyurethane soil stabilizer. Eng. Geol. 2019, 252, 125–135. [Google Scholar] [CrossRef]

- Löbmann, M.T.; Geitner, C.; Wellstein, C.; Zerbe, S. The influence of herbaceous vegetation on slope stability—A review. Earth-Sci. Rev. 2020, 209, 103328. [Google Scholar] [CrossRef]

- Li, L.; Chen, M.; Zhou, X.; Lu, L.; Wang, Y.; Cheng, X. Evaluation of the preparation and fertilizer release performance of planting concrete made with recycled-concrete aggregates from demolition. J. Clean. Prod. 2018, 200, 54–64. [Google Scholar] [CrossRef]

- Zimar, Z.; Robert, D.; Zhou, A.; Giustozzi, F.; Setunge, S.; Kodikara, J. Application of coal fly ash in pavement subgrade stabilisation: A review. J. Environ. Manag. 2022, 312, 114926. [Google Scholar] [CrossRef] [PubMed]

- Cristelo, N.; Glendinning, S.; Miranda, T.; Oliveira, D.; Silva, R. Soil stabilisation using alkaline activation of fly ash for self compacting rammed earth construction. Constr. Build. Mater. 2012, 36, 727–735. [Google Scholar] [CrossRef]

- Liu, Y.-J.; Wang, T.-W.; Cai, C.-F.; Li, Z.-X.; Cheng, D.-B. Effects of vegetation on runoff generation, sediment yield and soil shear strength on road-side slopes under a simulation rainfall test in the Three Gorges Reservoir Area, China. Sci. Total Environ. 2014, 485, 93–102. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Wu, P.; Zhao, X. Effects of rainfall intensity, underlying surface and slope gradient on soil infiltration under simulated rainfall experiments. Catena 2013, 104, 93–102. [Google Scholar] [CrossRef]

- Bordoloi, S.; Ng, C.W.W. The effects of vegetation traits and their stability functions in bio-engineered slopes: A perspective review. Eng. Geol. 2020, 275, 105742. [Google Scholar] [CrossRef]

- Lahalih, S.M.; Ahmed, N. Effect of new soil stabilizers on the compressive strength of dune sand. Constr. Build. Mater. 1998, 12, 321–328. [Google Scholar] [CrossRef]

- Krull, E.S.; Baldock, J.A.; Skjemstad, J.O. Importance of mechanisms and processes of the stabilisation of soil organic matter for modelling carbon turnover. Funct. Plant Biol. 2003, 30, 207–222. [Google Scholar] [CrossRef]

- Kang, X.; Xia, Z.; Chen, R.; Sun, H.; Yang, W. Effects of inorganic ions, organic polymers, and fly ashes on the sedimentation characteristics of kaolinite suspensions. Appl. Clay Sci. 2019, 181, 105220. [Google Scholar] [CrossRef]

- Yao, D.; Qian, G.; Yao, J.; Liu, J.; Yu, X. Polymer curing agent in ecological protection design weak rock slope engineering application. J. Perform. Constr. Facil. 2020, 34, 04019115. [Google Scholar] [CrossRef]

- Rivera-Gómez, C.; Galán-Marín, C.; Bradley, F. Analysis of the influence of the fiber type in polymer matrix/fiber bond using natural organic polymer stabilizer. Polymers 2014, 6, 977–994. [Google Scholar] [CrossRef]

- Kannan, G.; Sujatha, E.R. Crustacean polysaccharides for the geotechnical enhancement of organic silt: A clean and green alternative. Carbohydr. Polym. 2023, 299, 120227. [Google Scholar] [CrossRef]

- Liu, J.; Bu, F.; Bai, Y.; Chen, Z.; Kanungo, D.P.; Song, Z.; Wang, Y.; Qi, C.; Chen, J. Study on engineering properties of sand strengthened by mixed fibers and polyurethane organic polymer. Bull. Eng. Geol. Environ. 2020, 79, 3049–3062. [Google Scholar] [CrossRef]

- Duis, K.; Junker, T.; Coors, A. Environmental fate and effects of water-soluble synthetic organic polymers used in cosmetic products. Environ. Sci. Eur. 2021, 33, 21. [Google Scholar] [CrossRef]

- Karamanlioglu, M.; Preziosi, R.; Robson, G.D. Abiotic and biotic environmental degradation of the bioplastic polymer poly (lactic acid): A review. Polym. Degrad. Stab. 2017, 137, 122–130. [Google Scholar] [CrossRef]

- Ikeagwuani, C.C.; Nwonu, D.C. Emerging trends in expansive soil stabilisation: A review. J. Rock Mech. Geotech. Eng. 2019, 11, 423–440. [Google Scholar] [CrossRef]

- Heller, H.; Keren, R. Anionic polyacrylamide polymers effect on rheological behavior of sodium-montmorillonite suspensions. Soil Sci. Soc. Am. J. 2002, 66, 19–25. [Google Scholar] [CrossRef]

- Al-Atroush, M.; Sebaey, T. Stabilization of expansive soil using hydrophobic polyurethane foam: A review. Transp. Geotech. 2021, 27, 100494. [Google Scholar] [CrossRef]

- Kay-Shoemake, J.L.; Watwood, M.E.; Lentz, R.D.; Sojka, R.E. Polyacrylamide as an organic nitrogen source for soil microorganisms with potential effects on inorganic soil nitrogen in agricultural soil. Soil Biol. Biochem. 1998, 30, 1045–1052. [Google Scholar] [CrossRef]

- Zhang, B.; Jiang, W.; Xu, Q.; Yuan, D.; Shan, J.; Lu, R. Experimental feasibility study of ethylene-vinyl acetate copolymer (EVA) as cement stabilized soil curing agent. Road Mater. Pavement Des. 2022, 23, 617–638. [Google Scholar] [CrossRef]

- Rajabi, A.M.; Ghorashi, S.; Mahdavi, M. Effect of freezing soil temperatures on strength parameters of clayey sand soils stabilized by poly propylene and poly vinyl alcohol fibers. Cold Reg. Sci. Technol. 2023, 208, 103797. [Google Scholar] [CrossRef]

- Sendijarevic, V.; Sendijarevic, A.; Sendijarevic, I.; Bailey, R.E.; Pemberton, D.; Reimann, K.A. Hydrolytic stability of toluene diisocyanate and polymeric methylenediphenyl diisocyanate based polyureas under environmental conditions. Environ. Sci. Technol. 2004, 38, 1066–1072. [Google Scholar] [CrossRef]

- Brax, M.; Buchmann, C.; Schaumann, G.E. Biohydrogel induced soil-water interactions: How to untangle the gel effect? A review. J. Plant Nutr. Soil Sci. 2017, 180, 121–141. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Cho, G.-C. Introduction of microbial biopolymers in soil treatment for future environmentally-friendly and sustainable geotechnical engineering. Sustainability 2016, 8, 251. [Google Scholar] [CrossRef]

- Chang, I.; Cho, G.-C. Geotechnical behavior of a beta-1,3/1,6-glucan biopolymer-treated residual soil. Geomech. Eng 2014, 7, 633–647. [Google Scholar] [CrossRef]

- Chang, I.; Cho, G.-C. Strengthening of Korean residual soil with β-1, 3/1, 6-glucan biopolymer. Constr. Build. Mater. 2012, 30, 30–35. [Google Scholar] [CrossRef]

- Kwon, Y.-M.; Ham, S.-M.; Kwon, T.-H.; Cho, G.-C.; Chang, I. Surface-erosion behaviour of biopolymer-treated soils assessed by EFA. Géotechnique Lett. 2020, 10, 106–112. [Google Scholar] [CrossRef]

- Kwon, Y.-M.; Moon, J.-H.; Cho, G.-C.; Kim, Y.-U.; Chang, I. Xanthan gum biopolymer-based soil treatment as a construction material to mitigate internal erosion of earthen embankment: A field-scale. Constr. Build. Mater. 2023, 389, 131716. [Google Scholar] [CrossRef]

- Khatami, H.R.; O’Kelly, B.C. Improving mechanical properties of sand using biopolymers. J. Geotech. Geoenvironmental Eng. 2013, 139, 1402–1406. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Cho, G.-C. Soil strengthening using thermo-gelation biopolymers. Constr. Build. Mater. 2015, 77, 430–438. [Google Scholar] [CrossRef]

- Day, S.R.; O’Hannesin, S.F.; Marsden, L. Geotechnical techniques for the construction of reactive barriers. J. Hazard. Mater. 1999, 67, 285–297. [Google Scholar] [CrossRef]

- Bouazza, A.; Gates, W.P.; Ranjith, P.G. Hydraulic conductivity of biopolymer-treated silty sand. Géotechnique 2009, 59, 71–72. [Google Scholar] [CrossRef]

- Ghasemzadeh, H.; Modiri, F. Application of novel Persian gum hydrocolloid in soil stabilization. Carbohydr. Polym. 2020, 246, 116639. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, Y.-L.; Liu, S.-Y. Application of biomass by-product lignin stabilized soils as sustainable Geomaterials: A review. Sci. Total Environ. 2020, 728, 138830. [Google Scholar] [CrossRef]

- Orts, W.J.; Sojka, R.E.; Glenn, G.M. Biopolymer additives to reduce erosion-induced soil losses during irrigation. Ind. Crops Prod. 2000, 11, 19–29. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Lee, S.-W.; Cho, G.-C. Strength durability of gellan gum biopolymer-treated Korean sand with cyclic wetting and drying. Constr. Build. Mater. 2017, 143, 210–221. [Google Scholar] [CrossRef]

- Giavasis, I.; Harvey, L.M.; McNeil, B. Gellan gum. Crit. Rev. Biotechnol. 2000, 20, 177–211. [Google Scholar] [CrossRef] [PubMed]

- Naessens, M.; Cerdobbel, A.; Soetaert, W.; Vandamme, E.J. Leuconostoc dextransucrase and dextran: Production, properties and applications. J. Chem. Technol. Biotechnol. Int. Res. Process Environ. Clean Technol. 2005, 80, 845–860. [Google Scholar] [CrossRef]

- Harada, T.; Okuyama, K.; Konno, A.; Koreeda, A.; Harada, A. Effect of heating on formation of curdlan gels. Carbohydr. Polym. 1994, 24, 101–106. [Google Scholar] [CrossRef]

- Chenu, C. Clay—Or sand—Polysaccharide associations as models for the interface between micro-organisms and soil: Water related properties and microstructure. Geoderma 1993, 56, 143–156. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Chung, M.-K.; Cho, G.-C. Bovine casein as a new soil strengthening binder from diary wastes. Constr. Build. Mater. 2018, 160, 1–9. [Google Scholar] [CrossRef]

- Youzhi, W.; Jincheng, W.; Shiqiang, S.; Pinhua, R.; Runkai, W.; Shihui, L.; Liqi, X.; Feng, Z. Preparation and application properties of sustainable gelatin/chitosan soil conditioner microspheres. Int. J. Biol. Macromol. 2020, 159, 685–695. [Google Scholar] [CrossRef] [PubMed]

- Martucci, J.F.; Ruseckaite, R.A. Tensile properties, barrier properties, and biodegradation in soil of compression—Molded gelatin-dialdehyde starch films. J. Appl. Polym. Sci. 2009, 112, 2166–2178. [Google Scholar] [CrossRef]

- Ni, H.; Shen, S.-Q.; Fu, X.-L.; Wang, C.-M.; Du, Y.-J. Assessment of membrane and diffusion behavior of soil-bentonite slurry trench wall backfill consisted of sand and Xanthan gum amended bentonite. J. Clean. Prod. 2022, 365, 132779. [Google Scholar] [CrossRef]

- Feng, D.; Liang, B.; He, X.; Yi, F.; Xue, J.; Wan, Y.; Xue, Q. Mechanical properties of dredged soil reinforced by xanthan gum and fibers. J. Rock Mech. Geotech. Eng. 2023, in press. [Google Scholar] [CrossRef]

- Kumar, S.A.; Sujatha, E.R. An appraisal of the hydro-mechanical behaviour of polysaccharides, xanthan gum, guar gum and β-glucan amended soil. Carbohydr. Polym. 2021, 265, 118083. [Google Scholar] [CrossRef] [PubMed]

- Mamedov, A.I.; Huang, C.H.; Aliev, F.A.; Levy, G.J. Aggregate stability and water retention near saturation characteristics as affected by soil texture, aggregate size and polyacrylamide application. Land Degrad. Dev. 2017, 28, 543–552. [Google Scholar] [CrossRef]

- Lee, S.; Gantzer, C.; Thompson, A.; Anderson, S. Polyacrylamide and gypsum amendments for erosion and runoff control on two soil series. J. Soil Water Conserv. 2010, 65, 233–242. [Google Scholar] [CrossRef]

- Kang, M.W.; Yibeltal, M.; Kim, Y.H.; Oh, S.J.; Lee, J.C.; Kwon, E.E.; Lee, S.S. Enhancement of soil physical properties and soil water retention with biochar-based soil amendments. Sci. Total Environ. 2022, 836, 155746. [Google Scholar] [CrossRef]

- Lv, B.; Zhao, Y.; Li, N.; Yu, Y.; Wu, Y.; Gu, M. Triaxial Mechanical Properties and Mechanism of Waterborne Polyurethane-Reinforced Road Demolition Waste as Road Bases. Polymers 2022, 14, 2725. [Google Scholar] [CrossRef]

- Che, W.; Liu, J.; Li, H.; He, C.; Bai, Y.; Song, Z.; Wang, Y.; Qian, W.; Chen, Z. Experimental investigation and discrete element method simulation on mechanical properties and failure mechanism of polymer-stabilized sand. Bull. Eng. Geol. Environ. 2022, 81, 22. [Google Scholar] [CrossRef]

- Ghasemzadeh, H.; Mehrpajouh, A.; Pishvaei, M. Laboratory analyses of Kaolinite stabilized by vinyl polymers with different monomer types. Eng. Geol. 2021, 280, 105938. [Google Scholar] [CrossRef]

- Bu, F.; Liu, J.; Bai, Y.; Prasanna Kanungo, D.; Song, Z.; Kong, F.; Pan, C. Effects of the preparation conditions and reinforcement mechanism of polyvinyl acetate soil stabilizer. Polymers 2019, 11, 506. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Dixon, J.B.; White, G.N.; Loeppert, R.H.; Juo, A.S. Bonding between polyacrylamide and smectite. Colloids Surf. A Physicochem. Eng. Asp. 2006, 281, 82–91. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; Soltani, A.; Khayat, N. Stabilization of soft clay using short fibers and poly vinyl alcohol. Geotext. Geomembr. 2018, 46, 646–655. [Google Scholar] [CrossRef]

- Dubey, A.A.; Ravi, K.; Shahin, M.A.; Dhami, N.K.; Mukherjee, A. Bio-composites treatment for mitigation of current-induced riverbank soil erosion. Sci. Total Environ. 2021, 800, 149513. [Google Scholar] [CrossRef] [PubMed]

- Ao, C.; Yang, P.; Zeng, W.; Chen, W.; Xu, Y.; Xu, H.; Zha, Y.; Wu, J.; Huang, J. Impact of raindrop diameter and polyacrylamide application on runoff, soil and nitrogen loss via raindrop splashing. Geoderma 2019, 353, 372–381. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, J.; Lin, C.; Ma, X.-F.; Song, Z.-Z.; Chen, Z.-H.; Jiang, C.-H.; Qi, C.-Q. Polyvinyl acetate-based soil stabilization for rock slope ecological restoration. J. Environ. Manag. 2022, 324, 116209. [Google Scholar] [CrossRef]

- Rezaeimalek, S.; Huang, J.; Bin-Shafique, S. Evaluation of curing method and mix design of a moisture activated polymer for sand stabilization. Constr. Build. Mater. 2017, 146, 210–220. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Atchaya, S.; Sivasaran, A.; Keerdthe, R. Enhancing the geotechnical properties of soil using xanthan gum—An eco-friendly alternative to traditional stabilizers. Bull. Eng. Geol. Environ. 2021, 80, 1157–1167. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; O’Kelly, B.C. Intermittent swelling and shrinkage of a highly expansive soil treated with polyacrylamide. J. Rock Mech. Geotech. Eng. 2022, 14, 252–261. [Google Scholar] [CrossRef]

- Korres, S.; Sorochynska, L.; Grishchuk, S.; Karger-Kocsis, J. Swelling, compression and tribological behaviors of bentonite-modified polyacrylate-type hydrogels. J. Appl. Polym. Sci. 2011, 119, 1122–1134. [Google Scholar] [CrossRef]

- Liu, J.; Shi, B.; Jiang, H.; Huang, H.; Wang, G.; Kamai, T. Research on the stabilization treatment of clay slope topsoil by organic polymer soil stabilizer. Eng. Geol. 2011, 117, 114–120. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, X.; Zhang, J.; Jiang, T.; Wang, S.; Zhao, J.; Meng, Z. Water retention characteristics and vegetation growth of biopolymer-treated silt soils. Soil Tillage Res. 2023, 225, 105544. [Google Scholar] [CrossRef]

- Rashid, A.S.A.; Tabatabaei, S.; Horpibulsuk, S.; Mohd Yunus, N.Z.; Hassan, W.H.W. Shear strength improvement of lateritic soil stabilized by biopolymer based stabilizer. Geotech. Geol. Eng. 2019, 37, 5533–5541. [Google Scholar] [CrossRef]

- Dehghan, H.; Tabarsa, A.; Latifi, N.; Bagheri, Y. Use of xanthan and guar gums in soil strengthening. Clean Technol. Environ. Policy 2019, 21, 155–165. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Sivaraman, S.; Subramani, A.K. Impact of hydration and gelling properties of guar gum on the mechanism of soil modification. Arab. J. Geosci. 2020, 13, 1278. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, Y.; Ceylan, H.; Kim, S.; Gopalakrishnan, K. Assessment of soils stabilized with lignin-based byproducts. Transp. Geotech. 2018, 17, 122–132. [Google Scholar] [CrossRef]

- Zhang, T.; Cai, G.; Liu, S. Application of lignin-stabilized silty soil in highway subgrade: A macroscale laboratory study. J. Mater. Civ. Eng. 2018, 30, 04018034. [Google Scholar] [CrossRef]

- Hamidi, S.; Marandi, S.M. Clay concrete and effect of clay minerals types on stabilized soft clay soils by epoxy resin. Appl. Clay Sci. 2018, 151, 92–101. [Google Scholar] [CrossRef]

- Ma, G.; Ran, F.; Feng, E.; Dong, Z.; Lei, Z. Effectiveness of an eco-friendly polymer composite sand-fixing agent on sand fixation. Water Air Soil Pollut. 2015, 226, 221. [Google Scholar] [CrossRef]

- Buchmann, C.; Bentz, J.; Schaumann, G. Intrinsic and model polymer hydrogel-induced soil structural stability of a silty sand soil as affected by soil moisture dynamics. Soil Tillage Res. 2015, 154, 22–33. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.; Zeng, Z.; Kanungo, D.P.; Bu, F.; Bai, Y.; Qi, C.; Qian, W. Influence of polyurethane polymer on the strength and mechanical behavior of sand-root composite. Fibers Polym. 2020, 21, 829–839. [Google Scholar] [CrossRef]

- Huang, W.; Du, J.; Lai, H.; Zhang, Q.; Zhou, C.; Liu, Z. Mechanical properties and mechanism of soil treated with nano-aqueous adhesive (NAA). Sci. Rep. 2022, 12, 14711. [Google Scholar] [CrossRef]

- Sauceda, M.; Johnson, D.W.; Huang, J.; Bin-Shafique, S.; Sponsel, V.M.; Appleford, M. Soil-strength enhancements from polymer-infused roots. J. Geotech. Geoenvironmental Eng. 2014, 140, 04013004. [Google Scholar] [CrossRef]

- Bian, X.; Zhang, W.; Li, X.; Shi, X.; Deng, Y.; Peng, J. Changes in strength, hydraulic conductivity and microstructure of superabsorbent polymer stabilized soil subjected to wetting–drying cycles. Acta Geotech. 2022, 17, 5043–5057. [Google Scholar] [CrossRef]

- Xia, W.; Wang, Q.; Yu, Q.; Yao, M.; Sun, D.; Liu, J.; Wang, Z. Experimental investigation of the mechanical properties of hydrophobic polymer-modified soil subjected to freeze–thaw cycles. Acta Geotech. 2023, 1–20. [Google Scholar] [CrossRef]

- Bozyigit, I.; Zingil, H.O.; Altun, S. Performance of eco-friendly polymers for soil stabilization and their resistance to freeze–thaw action. Constr. Build. Mater. 2023, 379, 131133. [Google Scholar] [CrossRef]

- Seo, S.; Lee, M.; Im, J.; Kwon, Y.-M.; Chung, M.-K.; Cho, G.-C.; Chang, I. Site application of biopolymer-based soil treatment (BPST) for slope surface protection: In-situ wet-spraying method and strengthening effect verification. Constr. Build. Mater. 2021, 307, 124983. [Google Scholar] [CrossRef]

- Caballero, S.; Acharya, R.; Banerjee, A.; Bheemasetti, T.V.; Puppala, A.; Patil, U. Sustainable slope stabilization using biopolymer-reinforced soil. In Geo-Chicago 2016; ASCE Library: Reston, VA, USA, 2016; pp. 116–126. [Google Scholar]

- Acharya, R.; Pedarla, A.; Bheemasetti, T.V.; Puppala, A.J. Assessment of guar gum biopolymer treatment toward mitigation of desiccation cracking on slopes built with expansive soils. Transp. Res. Rec. 2017, 2657, 78–88. [Google Scholar] [CrossRef]

- Fatehi, H.; Abtahi, S.M.; Hashemolhosseini, H.; Hejazi, S.M. A novel study on using protein based biopolymers in soil strengthening. Constr. Build. Mater. 2018, 167, 813–821. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.-C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Wang, G.; Kong, X.; Zhang, Y.; Zhao, Q.; Feng, X. Stability and Micro-mechanisms of Lignin-Improved Soil in a Drying-Wetting Environment. KSCE J. Civ. Eng. 2022, 26, 3314–3324. [Google Scholar] [CrossRef]

- Ojuri, O.O.; Ramdas, V.; Aderibigbe, E.A.; Williams, C.G.; Ramchuran, S.; Al-Nageim, H. Improving strength and hydraulic characteristics of regional clayey soils using biopolymers. Case Stud. Constr. Mater. 2022, 17, e01319. [Google Scholar] [CrossRef]

- Ceylan, H.; Kim, S.; Uzer, A.U.; Yang, B. Strength performance of Iowa soils stabilized with biofuel industry co-product. Procedia Eng. 2015, 125, 317–323. [Google Scholar] [CrossRef]

- Chen, C.; Wu, L.; Harbottle, M. Exploring the effect of biopolymers in near-surface soils using xanthan gum-modified sand under shear. Can. Geotech. J. 2020, 57, 1109–1118. [Google Scholar] [CrossRef]

- Smitha, S.; Sachan, A. Use of agar biopolymer to improve the shear strength behavior of sabarmati sand. Int. J. Geotech. Eng. 2016, 10, 387–400. [Google Scholar] [CrossRef]

- Zhang, J.; Meng, Z.; Jiang, T.; Wang, S.; Zhao, J.; Zhao, X. Experimental Study on the Shear Strength of Silt Treated by Xanthan Gum during the Wetting Process. Appl. Sci. 2022, 12, 6053. [Google Scholar] [CrossRef]

- Sepaskhah, A.; Shahabizad, V. Effects of water quality and PAM application rate on the control of soil erosion, water infiltration and runoff for different soil textures measured in a rainfall simulator. Biosyst. Eng. 2010, 106, 513–520. [Google Scholar] [CrossRef]

- Dearfield, K.L.; Abernathy, C.O.; Ottley, M.S.; Brantner, J.H.; Hayes, P.F. Acrylamide: Its metabolism, developmental and reproductive effects, genotoxicity, and carcinogenicity. Mutat. Res. Rev. Genet. Toxicol. 1988, 195, 45–77. [Google Scholar] [CrossRef]

- Li, S.; Xu, H.; Ao, C. Polyacrylamide and rill flow rate effects on erosion and ammonium nitrogen losses. Water Air Soil Pollut. 2019, 230, 11. [Google Scholar] [CrossRef]

- Ma, L.; Hu, T.; Liu, Y.; Liu, J.; Wang, Y.; Wang, P.; Zhou, J.; Chen, M.; Yang, B.; Li, L. Combination of biochar and immobilized bacteria accelerates polyacrylamide biodegradation in soil by both bio-augmentation and bio-stimulation strategies. J. Hazard. Mater. 2021, 405, 124086. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Shi, J.; Dang, P.; Mamedov, A.; Shainberg, I.; Levy, G. Soil and polymer properties affecting water retention by superabsorbent polymers under drying conditions. Soil Sci. Soc. Am. J. 2012, 76, 1758–1767. [Google Scholar] [CrossRef]

- Misiewicz, J.; Datta, S.S.; Lejcuś, K.; Marczak, D. The Characteristics of Time-Dependent Changes of Coefficient of Permeability for Superabsorbent Polymer-Soil Mixtures. Materials 2022, 15, 4465. [Google Scholar] [CrossRef]

- Huang, W.; Liu, Z.; Zhou, C.; Yang, X. Enhancement of soil ecological self-repair using a polymer composite material. Catena 2020, 188, 104443. [Google Scholar] [CrossRef]

- Chang, I.; Cho, G.-C.; Tran, T.P.A. Water retention properties of xanthan-gum-biopolymer-treated soils. Environ. Geotech. 2023, 1–11. [Google Scholar] [CrossRef]

- Biju, M.; Arnepalli, D. Effect of biopolymers on permeability of sand-bentonite mixtures. J. Rock Mech. Geotech. Eng. 2020, 12, 1093–1102. [Google Scholar] [CrossRef]

- Konrad, J.-M.; Lebeau, M. Capillary-based effective stress formulation for predicting shear strength of unsaturated soils. Can. Geotech. J. 2015, 52, 2067–2076. [Google Scholar] [CrossRef]

- Gao, Y.; Sun, D.; Zhou, A.; Li, J. Effect of stress state on soil–water retention and its application on the strength prediction. Géotechnique Lett. 2018, 8, 324–329. [Google Scholar] [CrossRef]

- Rosenzweig, R.; Shavit, U.; Furman, A. Water retention curves of biofilm-affected soils using xanthan as an analogue. Soil Sci. Soc. Am. J. 2012, 76, 61–69. [Google Scholar] [CrossRef]

- Michel, B.E. Evaluation of the water potentials of solutions of polyethylene glycol 8000 both in the absence and presence of other solutes. Plant Physiol. 1983, 72, 66–70. [Google Scholar] [CrossRef]

- Zhou, C.; So, P.S.; Chen, X. A water retention model considering biopolymer-soil interactions. J. Hydrol. 2020, 586, 124874. [Google Scholar] [CrossRef]

- Hataf, N.; Ghadir, P.; Ranjbar, N. Investigation of soil stabilization using chitosan biopolymer. J. Clean. Prod. 2018, 170, 1493–1500. [Google Scholar] [CrossRef]

- Losini, A.E.; Grillet, A.; Bellotto, M.; Woloszyn, M.; Dotelli, G. Natural additives and biopolymers for raw earth construction stabilization—A review. Constr. Build. Mater. 2021, 304, 124507. [Google Scholar] [CrossRef]

- Armistead, S.J.; Smith, C.C.; Staniland, S.S. Sustainable biopolymer soil stabilisation: The effect of microscale chemical characteristics on macroscale mechanical properties. Acta Geotech. 2023, 18, 3213–3227. [Google Scholar] [CrossRef]

- Huang, W.; Du, J.; Sun, H.; Zhou, C.; Liu, Z.; Zhang, L. New polymer composites improve silty clay soil microstructure: An evaluation using NMR. Land Degrad. Dev. 2021, 32, 3272–3281. [Google Scholar] [CrossRef]

- Timms, W.; Crane, R.; Anderson, D.; Bouzalakos, S.; Whelan, M.; McGeeney, D.; Rahman, P.; Acworth, R. Accelerated gravity testing of aquitard core permeability and implications at formation and regional scale. Hydrol. Earth Syst. Sci. 2016, 20, 39–54. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, W.; Li, C.; Pu, Y.; Sun, H. Effects of polyacrylamide on soil erosion and nutrient losses from substrate material in steep rocky slope stabilization projects. Sci. Total Environ. 2016, 554, 26–33. [Google Scholar] [CrossRef] [PubMed]

- Levy, G.; Levin, J.; Shainberg, I. Polymer effects on runoff and soil erosion from sodic soils. Irrig. Sci. 1995, 16, 9–14. [Google Scholar] [CrossRef]

- Al-Abed, N.; Amayreh, J.; Shudifat, E.; Qaqish, L.; El-Mehaisin, G. Polyacrylamide (PAM) effect on irrigation induced soil erosion and infiltration. Arch. Agron. Soil Sci. 2003, 49, 301–308. [Google Scholar] [CrossRef]

- Inbar, A.; Ben-Hur, M.; Sternberg, M.; Lado, M. Using polyacrylamide to mitigate post-fire soil erosion. Geoderma 2015, 239, 107–114. [Google Scholar] [CrossRef]

- Lu, S.; Wang, Z.; Hu, Y.; Liu, B.; Liu, J.e. Effectiveness and durability of polyacrylamide (PAM) and polysaccharide (Jag C 162) in reducing soil erosion under simulated rainfalls. Water 2018, 10, 257. [Google Scholar] [CrossRef]

- Kavazanjian, E., Jr.; Iglesias, E.; Karatas, I. Biopolymer soil stabilization for wind erosion control. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering, Alexandria, Egypt, 5–9 October 2009; pp. 881–884. [Google Scholar]

- Chang, I.; Lee, M.; Tran, A.T.P.; Lee, S.; Kwon, Y.-M.; Im, J.; Cho, G.-C. Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Transp. Geotech. 2020, 24, 100385. [Google Scholar] [CrossRef]

- Ham, S.-M.; Chang, I.; Noh, D.-H.; Kwon, T.-H.; Muhunthan, B. Improvement of surface erosion resistance of sand by microbial biopolymer formation. J. Geotech. Geoenviron. Eng. 2018, 144, 06018004. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, B.; Guo, H.; Xiao, H.; Wei, T. The effect of super absorbent polymers on soil and water conservation on the terraces of the loess plateau. Ecol. Eng. 2017, 102, 270–279. [Google Scholar] [CrossRef]

- Yang, Q.-W.; Pei, X.-J.; Huang, R.-Q. Impact of polymer mixtures on the stabilization and erosion control of silty sand slope. J. Mt. Sci. 2019, 16, 470–485. [Google Scholar] [CrossRef]

- Liu, J.; Shi, B.; Jiang, H.; Bae, S.; Huang, H. Improvement of water-stability of clay aggregates admixed with aqueous polymer soil stabilizers. Catena 2009, 77, 175–179. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Chen, R.; Wang, H.; Xia, J. Surface rainfall erosion resistance and freeze-thaw durability of bio-cemented and polymer-modified loess slopes. J. Environ. Manag. 2022, 301, 113883. [Google Scholar] [CrossRef]

- Zhao, Z.; Hamdan, N.; Shen, L.; Nan, H.; Almajed, A.; Kavazanjian, E.; He, X. Biomimetic hydrogel composites for soil stabilization and contaminant mitigation. Environ. Sci. Technol. 2016, 50, 12401–12410. [Google Scholar] [CrossRef]

- Kebede, B.; Tsunekawa, A.; Haregeweyn, N.; Tsubo, M.; Mulualem, T.; Mamedov, A.I.; Meshesha, D.T.; Adgo, E.; Fenta, A.A.; Ebabu, K. Effect of Polyacrylamide integrated with other soil amendments on runoff and soil loss: Case study from northwest Ethiopia. Int. Soil Water Conserv. Res. 2022, 10, 487–496. [Google Scholar] [CrossRef]

- Biju, M.; Arnepalli, D. Biopolymer-modified soil: Prospects of a promising green technology. In Geotechnical Characterisation and Geoenvironmental Engineering; Lecture Notes in Civil Engineering; Stalin, V., Muttharam, M., Eds.; Springer: Singapore, 2018; Volume 16. [Google Scholar] [CrossRef]

- Sadeghi, S.H.; Kiani-Harchegani, M.; Hazbavi, Z.; Sadeghi, P.; Angulo-Jaramillo, R.; Lassabatere, L.; Younesi, H. Field measurement of effects of individual and combined application of biochar and polyacrylamide on erosion variables in loess and marl soils. Sci. Total Environ. 2020, 728, 138866. [Google Scholar] [CrossRef]

- Zezin, A.; Mikheikin, S.; Rogacheva, V.; Zansokhova, M.; Sybachin, A.; Yaroslavov, A. Polymeric stabilizers for protection of soil and ground against wind and water erosion. Adv. Colloid Interface Sci. 2015, 226, 17–23. [Google Scholar] [CrossRef] [PubMed]

- Su, L.-Q.; Li, J.-G.; Xue, H.; Wang, X.-F. Super absorbent polymer seed coatings promote seed germination and seedling growth of Caragana korshinskii in drought. J. Zhejiang Univ. -SCIENCE B 2017, 18, 696–706. [Google Scholar] [CrossRef]

- Chirino, E.; Vilagrosa, A.; Vallejo, V.R. Using hydrogel and clay to improve the water status of seedlings for dryland restoration. Plant Soil 2011, 344, 99–110. [Google Scholar] [CrossRef]

- Huang, W.; Zhou, C.; Liu, Z. Model Test Study on the Enhancement of Ecological Self-Repairing Ability of Surface Slope Soil by New Polymer Composites. Int. J. Environ. Res. Public Health 2022, 19, 9933. [Google Scholar] [CrossRef]

- Tran, A.T.P.; Chang, I.; Cho, G.-C. Soil water retention and vegetation survivability improvement using microbial biopolymers in drylands. Geomech. Eng. 2019, 17, 475–483. [Google Scholar]

- Yang, Q.; Pei, X.; Fu, C. Effect of Polymer Mixtures on Physical-Chemical Properties of Sandy Soil and Plant Growth. Front. Ecol. Evol. 2022, 10, 889357. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, K.; Tang, Z. Effect of fly ash-and polyacrylamide-consolidated soil layer on A. splendens growth in a desert in North China. Catena 2022, 210, 105935. [Google Scholar] [CrossRef]

- Fernández, P.L.; Behrends Kraemer, F.; Sabatté, L.; Guiroy, J.; Gutierrez Boem, F. Superabsorbent polyacrylamide effects on hydrophysical soil properties and plant biomass in a sandy loam soil. Commun. Soil Sci. Plant Anal. 2022, 53, 2892–2906. [Google Scholar] [CrossRef]

- Huang, W.; Zhou, C.; Liu, Z.; Sun, H.; Du, J.; Zhang, L. Improving soil-water characteristics and pore structure of silty soil using nano-aqueous polymer stabilisers. KSCE J. Civ. Eng. 2021, 25, 3298–3305. [Google Scholar] [CrossRef]

- Zhou, C.; Huang, W.; Qiu, S.; Liu, Z. A quantitative study on the amount of water-retaining agent based on adhesive-modified red bed weathered soil. Bull. Eng. Geol. Environ. 2021, 80, 3139–3150. [Google Scholar] [CrossRef]

- Anandha Kumar, S.; Sujatha, E.R.; Pugazhendi, A.; Jamal, M.T. Guar gum-stabilized soil: A clean, sustainable and economic alternative liner material for landfills. Clean Technol. Environ. Policy 2023, 25, 323–341. [Google Scholar] [CrossRef]

- Tian, X.; Wang, K.; Fan, H.; Wang, J.; Wang, L. Effects of polymer materials on the transformation and utilization of soil nitrogen and yield of wheat under drip irrigation. Soil Use Manag. 2021, 37, 712–722. [Google Scholar] [CrossRef]

- Li, T.; Dai, F.; He, Y.; Xu, D.; Wang, R. An Eco-Friendly Polymer Composite Fertilizer for Soil Fixation, Slope Stability, and Erosion Control. Polymers 2022, 14, 1461. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Du, J.; Lai, H.; Lin, K.; Zhou, C.; Liu, Z.; Zhang, L. Soil and water conservation and ecological restoration on the slopes treated with new polymer composite materials. Environ. Earth Sci. 2022, 81, 448. [Google Scholar] [CrossRef]

- Zhang, J.-f.; Zhao, T.-n.; Sun, B.-p.; Song, S.-s.; Guo, H.-b.; Shen, H.-j.; Wu, Y. Effects of biofertilizers and super absorbent polymers on plant growth and soil fertility in the arid mining area of Inner Mongolia, China. J. Mt. Sci. 2018, 15, 1920–1935. [Google Scholar] [CrossRef]

- Yang, L.; Yang, Y.; Chen, Z.; Guo, C.; Li, S. Influence of super absorbent polymer on soil water retention, seed germination and plant survivals for rocky slopes eco-engineering. Ecol. Eng. 2014, 62, 27–32. [Google Scholar] [CrossRef]

- Głąb, T.; Palmowska, J.; Zaleski, T.; Gondek, K. Effect of biochar application on soil hydrological properties and physical quality of sandy soil. Geoderma 2016, 281, 11–20. [Google Scholar] [CrossRef]

- Wang, C.; Walter, M.; Parlange, J.-Y. Modeling simple experiments of biochar erosion from soil. J. Hydrol. 2013, 499, 140–145. [Google Scholar] [CrossRef]

- Laird, D.A.; Fleming, P.; Davis, D.D.; Horton, R.; Wang, B.; Karlen, D.L. Impact of biochar amendments on the quality of a typical Midwestern agricultural soil. Geoderma 2010, 158, 443–449. [Google Scholar] [CrossRef]

- Graber, E.R.; Meller Harel, Y.; Kolton, M.; Cytryn, E.; Silber, A.; Rav David, D.; Tsechansky, L.; Borenshtein, M.; Elad, Y. Biochar impact on development and productivity of pepper and tomato grown in fertigated soilless media. Plant Soil 2010, 337, 481–496. [Google Scholar] [CrossRef]

- Gholami, L.; Karimi, N.; Kavian, A. Soil and water conservation using biochar and various soil moisture in laboratory conditions. Catena 2019, 182, 104151. [Google Scholar] [CrossRef]

- Sadeghi, S.H.; Hazbavi, Z.; Harchegani, M.K. Controllability of runoff and soil loss from small plots treated by vinasse-produced biochar. Sci. Total Environ. 2016, 541, 483–490. [Google Scholar] [CrossRef] [PubMed]

- Bolan, N.; Hoang, S.A.; Beiyuan, J.; Gupta, S.; Hou, D.; Karakoti, A.; Joseph, S.; Jung, S.; Kim, K.-H.; Kirkham, M. Multifunctional applications of biochar beyond carbon storage. Int. Mater. Rev. 2022, 67, 150–200. [Google Scholar] [CrossRef]

| Polymer Modifier Types | Composition | Basic Features | Reference |

|---|---|---|---|

| PAM | Synthesized from acrylamide subunits with straight chain or cross-linked conformation. | Cross-linked PAMs are water-absorbent and insoluble, but linear-chained PAMs are water-soluble. | [36] |

| Linear-chained PAMs are suitable for soil reinforcement. | |||

| PU | Composed of macromolecular polyols, polyisocyanates, etc. | The reaction products are stable, with good adhesion, heat resistance, and elasticity and short gelation time. | [37] |

| Polyacrylate | Consists of monomers of acrylic acid and esters. | Easily polymerizes with other functional groups to form different polymers. | [38] |

| Good hydrophilicity and high reactivity with vinyl and carboxyl groups. | |||

| PVAc | Synthesis from vinyl acetate monomer. | Insoluble in water but soluble in benzene, acetone, etc. | [39] |

| Good adhesion. | |||

| PVA | Prepared by alcoholysis of poly (vinyl ester). | It has water solubility and is highly polar. | [40] |

| MDI | Condensation of aniline with formaldehyde, followed by reaction with phosgene. | Its NCO group reacts easily with OH groups in water to form a mixture of diisocyanates and amines, and the solid mixture binds the soil particles together. | [41] |

| Polymer Modifier Types | Source | Basic Features | Reference |

|---|---|---|---|

| Agar Gum | Rhodophyta (Red algae). | Belongs to reversible gels, i.e., it can be dissolved in boiling water and forms a gel after cooling at about 35 °C. | [48,49] |

| Agar gels have rheological properties, hydrophilic. | |||

| Guar Gum | Cyamopsis tetragonoloba (Leguminous shrub). | Rapid hydration in cold water, high-viscosity solutions can be formed even at low concentrations. | [50,51] |

| Natural decomposition to monosaccharides and water by the action of microorganisms or enzymes, extreme pH, and temperature degradation. | |||

| Persian gum | The trunk and branches of wild almond trees of Zagros forests in Iran. | Anionic polysaccharide, a plant exudate gel. | [52] |

| Lignin | Vascular plant and algae. | Rich diversity of types and sources; it is a cross-linked complex phenolic polymer, soluble in strong alkaline and sulfite solutions. | [53] |

| Starch | Seeds, grains, and roots of plants. | It can be used as a thickening agent, stabilizer, disintegrant, binder, etc. | [54] |

| Xanthan Gum | Xanthomonas campestris (Bacteria). | High stability over a wide range of temperatures, pH, and electrolyte concentrations. | [51] |

| Better viscosity for use in gels and suspensions. | |||

| Gellan Gum | Sphingomonas elodea (Microbial fermentation). | Double helical chain form at low temperatures, presenting single helical chains at high temperatures. | [49,55,56] |

| Temperature-dependent structure and viscosity transformation properties, i.e., thermal gelation. | |||

| Good durability in dry and wet cycles. | |||

| Dextran | Leuconostoc mesenteroides and Streptococcus mutans (Lactic acid bacteria). | A flexible biopolymer that forms a high density and low permeability in aqueous media. | [57] |

| β-glucan | Cellulose, bran, and the cell walls of yeasts, fungi, and bacteria. | Water solubility, dispersibility, viscosity, and gelation properties. | [45] |

| The natural β-glucan is electrostatically neutral and negatively charged when modified by hydroxyl groups (−OH). | |||

| Curdlan | Agrobacterium biovars and Alcaligenes faecalis (Pathogenic bacteria). | Elastic but irreversible when heated. | [58] |

| Being used as a water reducer in concrete mixtures to prevent the separation of cement aggregates. | |||

| Scleroglucan | Sclerotium rolfsii (Fungus). | It has good water retention and thickening properties. | [59] |

| Casein | Animal proteins. | Hydrophobic, capable of coagulating and forming suspended colloids. | [60] |

| Gelatin | Animal bones, skin, and tendons. | Soluble in hot water, used as a gelling agent, stabilizer, emulsifier, and thickening agent. | [61,62] |

| Polymer Modifier Types | Soil Types | Research Methods | Mechanism of Action | Reference |

|---|---|---|---|---|

| PAM | Expansive soil and clay | SEM | The gel structure is thin and lean, adhering to the surface of soil particles. | [80] |

| Polyacrylate | Clay | SEM | Polymer functional groups with the −OH groups of the clay platelets via H-bonding. | [81] |

| PVAc | Clay | SEM | Filling of voids. | [82] |

| Long-chain macromolecules wrap around the surface of the aggregates and interconnect to form elastic and adhesive membrane structures. | ||||

| PVA | Soft clay | SEM | Fill in the pores and form larger aggregates. | [74] |

| PU | Sandy soil | SEM | Sand particles are tightly wrapped by a thin and tough polymer film, which forms a three-dimensional cross-linked network structure among the particles and plays a cementing role. | [18] |

| MDI | Sand | SEM | Wrap the soil particles and fill the pores. | [78] |

| Xanthan gum | Silt | SEM | Form sticky hydrogels to coat the soil particles and fill the pores. | [83] |

| Form xanthan chains and a “honeycomb”-shaped pore structure. | ||||

| Laterite | FESEM | The gel wraps the soil and forms an interlocking structure with the soil. | [84] | |

| Gellan gum | Silt | SEM | Forming biofilms that produce network structures and gellan micelles that fill soil pores. | [83] |

| Guar gum | Clay | SEM | Chemical bonding and wrapping bypass. | [85,86] |

| Lignin | Silt and sandy soil | SEM, XRD, FTIR, and MIP | A flocculent soil structure is produced, and porosity is reduced. | [87,88] |

| Cementing material covers the soil and binds and fills the pores | ||||

| Persian gum | Kaolinite soil | SEM, SZM, BET, TGA, and PSA | Fill pores, compact structure; reacts with charged clay surfaces through hydrogen bonding and ion interactions. | [52] |

| The carboxyl group crosslinks with the negatively charged surface of clay. | ||||

| Forming sticky gels to aggregate soil particles. | ||||

| Epoxy resin and aminoamide-based hardener mixtures | Kaolinite clay, bentonite, and cement | SEM and XRD | Epoxy resin provides a gel layer on top of the soil particles, and kaolinite clay does not react in any way with epoxy resin. | [89] |

| XG-g-PAA | Laterite | FTIR, XRD, TGA, and SEM | The laterite nanoflakes flocculate and disperse homogeneously in the polymer matrix, forming a homogeneous composition. | [90] |

| Solid sand specimens containing CSFA show dense contacts in the sand–sand grain transition region, where sand grains bond to each other through CSFA to form a bonding layer. | ||||

| NaA is attached to the XG chain, and the -OH group of the laterite is involved in the polymerization reaction. | ||||

| PAA hydrogel | Silty sand | 1H NMR relaxometry | Releasing gradually into the pores of the soil, the elastomeric gum acts as an adhesive agent. | [91] |

| In arid environments, the cementation and friction among soil particles are intensified, thereby enhancing the overall structural stability of the soil. |

| Polymer Modifier–Soil Interaction Patterns | Synthetic Polymer Modifiers | Biopolymer Modifiers |

|---|---|---|

| Filling and adsorption | Hydrophilic functional groups undergo ion-exchange reactions with soil particles, establishing hydrogen bonds and van der Waals forces. The surface layer of these aggregates is coated with long-chain macromolecules. | Modifiers present in the soil matrix undergo gelation, leading to encapsulation, adhesion, and pore-filling effects. Additionally, they exhibit electrostatic interactions that enable adsorption of soil particles. |

| Pore structure | The formation of a three-dimensional adhesive network structure results in the flocculation of soil particles. | Refining the formation of biological chains and “honeycomb” pore structures within the soil. |

| Membrane structure | The physical–chemical bond is established, and the modifier is linked to soil particles via chemical bonding, resulting in the formation of an elastic membrane structure. | The colloid–polymer bond is activated, resulting in the formation of a three-dimensional polymer membrane structure and stiffened polymer chains. |

| Penetrating quality | The enhancement of bonding and reduction in particle spacing is contingent upon the uniform permeability of the modifier solution within the soil. | The infiltration of soil pores is restricted by high viscosity, cohesion, and surface tension. Moreover, the curing effect is significantly influenced by soil particle size. |

| Polymer Modifier Types | Polymer Modifier Dosage | Soil Types | Plant Types | Vegetation Growth Properties | Reference |

|---|---|---|---|---|---|

| Acrylamide and potassium acrylate copolymer | 10% | Clay | Caragana korshinskii | Seed germination rate increased by approximately 244%. | [145] |

| Hydrogel mixed with a peat-based | 1.5% | Clay | Quercus suber L. | Survival rate increased by over 20%. | [146] |

| NBA mixed with SAR (ADNB) | NBA10 g/m2 and SAR60 g/m2 | Silty clay | Crotalaria pallida | Plant germination rate increased by 40%, plant height increased by 32.73%, and coverage rate increased by 553.85%. | [147] |

| Xanthan gum | 0.5% | Silt | Ryegrass | 28% increase in height. | [83] |

| Gellan gum | 0.5% | Silt | Ryegrass | 8% increase in height. | |

| Guar gum | 0.5% | Silt | Ryegrass | 4% increase in height. | |

| Starch | 0.5% | In situ soil (Seosan, Korea) and jumunjin sand | Ryegrass | The germination rate increases by about 5%, and the average root length after treatment increases. | [148] |

| β-glucan | 0.5% | Korean red yellow soil | Oats | Increase seed germination rate by 6.6–10.8%. | [17] |

| Xanthan gum | 0.5% | Korean red yellow soil | Oats | Increase seed germination rate by 1.9% to 5.5%. | |

| M-CMC | 1.1% | Sand soil | Elymus | Plant biomass increased by 59.65%, plant lodging rate decreased by more than 60%, and drought resistance survival rate increased by more than 80%. | [149] |

| FA and PAM | 10%FA and 0.1%PAM | Sand soil | A. splendens | The average height of plants increased by 145%, and the tillers number increased by 2.3 times. | [150] |

| Potassium polyacrylate polymer | 0.08% | Sand soil | Festuca arundinacea ssp. | Aerial vegetation biomass doubled in size. | [151] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Yao, Y.; Li, J.; Liu, K.; Wu, F. A State-of-the-Art Review of Organic Polymer Modifiers for Slope Eco-Engineering. Polymers 2023, 15, 2878. https://doi.org/10.3390/polym15132878

Wang L, Yao Y, Li J, Liu K, Wu F. A State-of-the-Art Review of Organic Polymer Modifiers for Slope Eco-Engineering. Polymers. 2023; 15(13):2878. https://doi.org/10.3390/polym15132878

Chicago/Turabian StyleWang, Lei, Yongsheng Yao, Jue Li, Kefei Liu, and Fei Wu. 2023. "A State-of-the-Art Review of Organic Polymer Modifiers for Slope Eco-Engineering" Polymers 15, no. 13: 2878. https://doi.org/10.3390/polym15132878

APA StyleWang, L., Yao, Y., Li, J., Liu, K., & Wu, F. (2023). A State-of-the-Art Review of Organic Polymer Modifiers for Slope Eco-Engineering. Polymers, 15(13), 2878. https://doi.org/10.3390/polym15132878