Updates on Biomaterials Used in Total Hip Arthroplasty (THA)

Abstract

1. Introduction

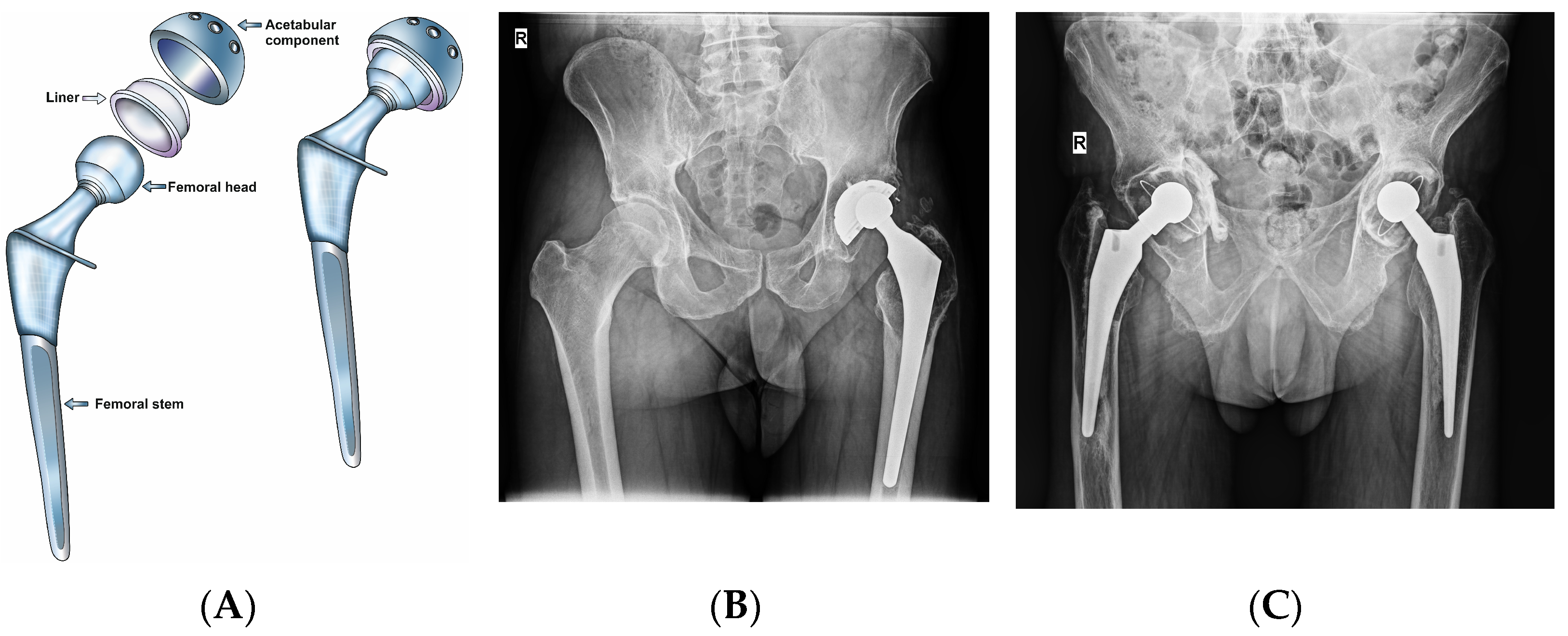

2. Background

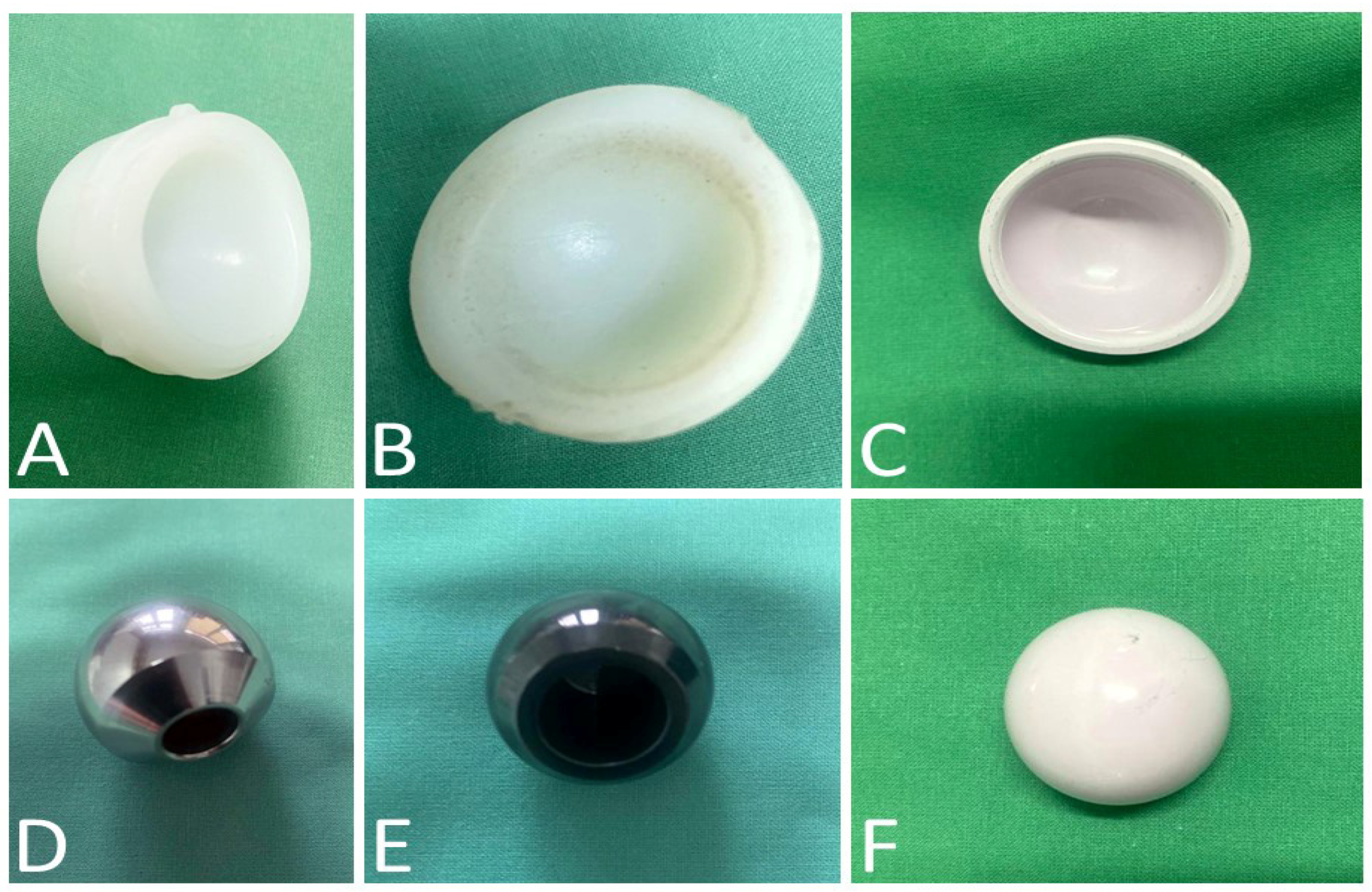

3. Bearing Surfaces and Biomaterials Used in Primary Total Hip Arthroplasties

3.1. Polymers

3.2. Metals

3.3. Ceramic Materials

4. The Choices of the Bearing Surfaces

4.1. Metal-on-Polyethylene (MoP)

4.2. Metal-on-Metal (MoM)

4.3. Ceramic-on-Polyethylene (CoP)

4.4. Ceramic-on-Ceramic (CoC)

5. Brief Requirements for THA’s Materials

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Bernasek, T.L.; Gill, M.; Herekar, R.; Lyons, S.T. Total Joint Replacement, Contemporary Concepts. In Managing Cardiovascular Risk in Elective Total Joint Arthroplasty; Harrison, E.E., Ho, N.H., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 7–22. ISBN 978-3-031-26414-6. [Google Scholar]

- Hussein, I.H.; Zalikha, A.K.; Tuluca, A.; Crespi, Z.; El-Othmani, M.M. Epidemiology of Obese Patients Undergoing Revision Total Knee Arthroplasty: Understanding Demographics, Comorbidities, and Propensity Weighted Analysis of Inpatient Outcomes. JAAOS Glob. Res. Rev. 2022, 6, e21.00263. [Google Scholar] [CrossRef] [PubMed]

- Allen, Q.; Raeymaekers, B. Surface Texturing of Prosthetic Hip Implant Bearing Surfaces: A Review. J. Tribol. 2020, 143, 040801. [Google Scholar] [CrossRef] [PubMed]

- Maradit Kremers, H.; Larson, D.R.; Crowson, C.S.; Kremers, W.K.; Washington, R.E.; Steiner, C.A.; Jiranek, W.A.; Berry, D.J. Prevalence of Total Hip and Knee Replacement in the United States. J. Bone Jt. Surg. Am. 2015, 97, 1386–1397. [Google Scholar] [CrossRef] [PubMed]

- Patel, I.; Nham, F.; Zalikha, A.K.; El-Othmani, M.M. Epidemiology of Total Hip Arthroplasty: Demographics, Comorbidities and Outcomes. Arthroplasty 2023, 5, 2. [Google Scholar] [CrossRef]

- Arshi, A.; Hughes, A.J.; Robin, J.X.; Parvizi, J.; Fillingham, Y.A. Return to Sport After Hip and Knee Arthroplasty: Counseling the Patient on Resuming an Active Lifestyle. Curr. Rev. Musculoskelet. Med. 2023, 16, 329–337. [Google Scholar] [CrossRef]

- Pivec, R.; Johnson, A.J.; Mears, S.C.; Mont, M.A. Hip Arthroplasty. Lancet 2012, 380, 1768–1777. [Google Scholar] [CrossRef]

- Kurtz, S.; Ong, K.; Lau, E.; Mowat, F.; Halpern, M. Projections of Primary and Revision Hip and Knee Arthroplasty in the United States from 2005 to 2030. J. Bone Jt. Surg. 2007, 89, 780–785. [Google Scholar] [CrossRef]

- Ashkenazi, I.; Christensen, T.; Oakley, C.; Bosco, J.; Lajam, C.; Slover, J.; Schwarzkopf, R. Trends in Revision Total Hip Arthroplasty Cost, Revenue, and Contribution Margin 2011 to 2021. J. Arthroplast. 2023, 38, S34–S38. [Google Scholar] [CrossRef]

- Pabinger, C.; Lothaller, H.; Portner, N.; Geissler, A. Projections of Hip Arthroplasty in OECD Countries up to 2050. HIP Int. 2018, 28, 498–506. [Google Scholar] [CrossRef]

- Reyes Rojas, A.; Aguilar Elguezabal, A.; Porporati, A.A.; Bocanegra Bernal, M.; Esparza Ponce, H.E. Performance of Metals and Ceramics in Total Hip Arthroplasty; Synthesis Lectures on Biomedical Engineering; Springer Nature: Cham, Switzerland, 2023; ISBN 978-3-031-25419-2. [Google Scholar]

- Chen, X.; Xiong, J.; Wang, P.; Zhu, S.; Qi, W.; Peng, H.; Yu, L.; Qian, W. Robotic-Assisted Compared with Conventional Total Hip Arthroplasty: Systematic Review and Meta-Analysis. Postgrad. Med. J. 2018, 94, 335–341. [Google Scholar] [CrossRef]

- Le Ferrand, H.; Athanasiou, C.E. A Materials Perspective on the Design of Damage-Resilient Bone Implants Through Additive/Advanced Manufacturing. JOM 2020, 72, 1195–1210. [Google Scholar] [CrossRef]

- Paione, C.M.; Baino, F. Non-Oxide Ceramics for Bone Implant Application: State-of-the-Art Overview with an Emphasis on the Acetabular Cup of Hip Joint Prosthesis. Ceramics 2023, 6, 994–1016. [Google Scholar] [CrossRef]

- Liu, A.; Richards, L.; Bladen, C.L.; Ingham, E.; Fisher, J.; Tipper, J.L. The Biological Response to Nanometre-Sized Polymer Particles. Acta Biomater. 2015, 23, 38–51. [Google Scholar] [CrossRef]

- Schwartz, A.M.; Farley, K.X.; Guild, G.N.; Bradbury, T.L. Projections and Epidemiology of Revision Hip and Knee Arthroplasty in the United States to 2030. J. Arthroplast. 2020, 35, S79–S85. [Google Scholar] [CrossRef] [PubMed]

- Evans, J.T.; Evans, J.P.; Walker, R.W.; Blom, A.W.; Whitehouse, M.R.; Sayers, A. How Long Does a Hip Replacement Last? A Systematic Review and Meta-Analysis of Case Series and National Registry Reports with More than 15 Years of Follow-Up. Lancet 2019, 393, 647–654. [Google Scholar] [CrossRef]

- Rajaee, S.S.; Campbell, J.C.; Mirocha, J.; Paiement, G.D. Increasing Burden of Total Hip Arthroplasty Revisions in Patients Between 45 and 64 Years of Age. JBJS 2018, 100, 449. [Google Scholar] [CrossRef]

- Kenney, C.; Dick, S.; Lea, J.; Liu, J.; Ebraheim, N.A. A Systematic Review of the Causes of Failure of Revision Total Hip Arthroplasty. J. Orthop. 2019, 16, 393–395. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Ruggiero, A.; Merola, M. Advanced Biomaterials in Hip Joint Arthroplasty. A Review on Polymer and Ceramics Composites as Alternative Bearings. Compos. Part B Eng. 2015, 83, 276–283. [Google Scholar] [CrossRef]

- Donaruma, L.G. Definitions in Biomaterials, D.F. Williams, Ed., Elsevier, Amsterdam, 1987, 72 pp. J. Polym. Sci. B Polym. Lett. Ed. 1988, 26, 414. [Google Scholar] [CrossRef]

- Bota, N.C.; Nistor, D.-V.; Caterev, S.; Todor, A. Historical Overview of Hip Arthroplasty: From Humble Beginnings to a High-Tech Future. Orthop. Rev. 2021, 13, 8773. [Google Scholar] [CrossRef]

- Trinkaus, E. Pathology and the Posture of the La Chapelle-Aux-Saints Neandertal. Am. J. Phys. Anthropol. 1985, 67, 19–41. [Google Scholar] [CrossRef] [PubMed]

- Gomez, P.F.; Morcuende, J.A. Early Attempts at Hip Arthroplasty. Iowa Orthop. J. 2005, 25, 25–29. [Google Scholar] [PubMed]

- Thould, A.K.; Thould, B.T. Arthritis in Roman Britain. Br. Med. J. (Clin. Res. Ed.) 1983, 287, 1909–1911. [Google Scholar] [CrossRef] [PubMed]

- Thomas, H.O. Diseases of the Hip, Knee, and Ankle Joints and Their Treatment: By a New and Efficient Method; Forgotten Books: London, UK, 2018; ISBN 978-1-331-21369-7. [Google Scholar]

- Barton, J.R. On the Treatment of Anchylosis, by the Formation of Artificial Joints. Lond. Med. Phys. J. 1827, 3, 138–150. [Google Scholar] [CrossRef]

- Henneguy, L.F. Recherches sur Le Développement des Poissons Osseux: Embryogénie de La Truite; F. Alcan: Ancienne Librairie Germer Bailliere C Felix Alcan, Editeur 108; F. Alcan: Paris, France, 1889. [Google Scholar]

- Smith-Petersen, M.N. Evolution of Mould Arthroplasty of the Hip Joint. J. Bone Jt. Surg. Br. Vol. 1948, 30-B, 59–75. [Google Scholar] [CrossRef]

- Wiles, P. The Surgery of the Osteo-Arthritic Hip. Br. J. Surg. 1958, 45, 488–497. [Google Scholar] [CrossRef]

- Moore, A.T.; Bohlman, H.R. THE CLASSIC: Metal Hip Joint: A Case Report. Clin. Orthop. Relat. Res. 2006, 453, 22. [Google Scholar] [CrossRef]

- Charnley, J. 2 Total Hip Replacement by Low-Friction Arthroplasty. Clin. Orthop. Relat. Res. (1976–2007) 1970, 72, 7. [Google Scholar] [CrossRef]

- Learmonth, I.D.; Young, C.; Rorabeck, C. The Operation of the Century: Total Hip Replacement. Lancet 2007, 370, 1508–1519. [Google Scholar] [CrossRef]

- Ring, P.A. 17 Total Replacement of the Hip. Clin. Orthop. Relat. Res. 1970, 72, 161. [Google Scholar] [CrossRef]

- Boutin, P. Total Arthroplasty of the Hip by Fritted Aluminum Prosthesis. Experimental Study and 1st Clinical Applications. Rev. Chir. Orthop. Reparatrice L’appareil Mot. 1972, 58, 229–246. [Google Scholar]

- Laurent, M.P.; Johnson, T.S.; Crowninshield, R.D.; Blanchard, C.R.; Bhambri, S.K.; Yao, J.Q. Characterization of a Highly Cross-Linked Ultrahigh Molecular-Weight Polyethylene in Clinical Use in Total Hip Arthroplasty. J. Arthroplast. 2008, 23, 751–761. [Google Scholar] [CrossRef]

- Jacobs, J.J. The UHMWPE Handbook. Ultra-High Molecular Weight Polyethylene in Total Joint Replacement. JBJS 2005, 87, 1906. [Google Scholar] [CrossRef][Green Version]

- Lerf, R.; Zurbrügg, D.; Delfosse, D. Use of Vitamin E to Protect Cross-Linked UHMWPE from Oxidation. Biomaterials 2010, 31, 3643–3648. [Google Scholar] [CrossRef]

- Haider, H.; Weisenburger, J.N.; Kurtz, S.M.; Rimnac, C.M.; Freedman, J.; Schroeder, D.W.; Garvin, K.L. Does Vitamin E–Stabilized Ultrahigh-Molecular-Weight Polyethylene Address Concerns of Cross-Linked Polyethylene in Total Knee Arthroplasty? J. Arthroplast. 2012, 27, 461–469. [Google Scholar] [CrossRef]

- Rowell, S.L.; Muratoglu, O.K. Investigation of Surgically Retrieved, Vitamin E-Stabilized, Crosslinked UHMWPE Implants after Short-Term In Vivo Service. J. Biomed. Mater. Res. Part B Appl. Biomater. 2016, 104, 1132–1140. [Google Scholar] [CrossRef] [PubMed]

- Brizuela, M.; Garcia-Luis, A.; Viviente, J.L.; Braceras, I.; Oñate, J.I. Tribological Study of Lubricious DLC Biocompatible Coatings. J. Mater. Sci. Mater. Med. 2002, 13, 1129–1133. [Google Scholar] [CrossRef] [PubMed]

- Balagna, C.; Faga, M.G.; Spriano, S. Tantalum-Based Multilayer Coating on Cobalt Alloys in Total Hip and Knee Replacement. Mater. Sci. Eng. C 2012, 32, 887–895. [Google Scholar] [CrossRef][Green Version]

- Ching, H.A.; Choudhury, D.; Nine, M.J.; Osman, N.A.A. Effects of Surface Coating on Reducing Friction and Wear of Orthopaedic Implants. Sci. Technol. Adv. Mater. 2014, 15, 014402. [Google Scholar] [CrossRef]

- Rahaman, M.N.; Yao, A.; Bal, B.S.; Garino, J.P.; Ries, M.D. Ceramics for Prosthetic Hip and Knee Joint Replacement. J. Am. Ceram. Soc. 2007, 90, 1965–1988. [Google Scholar] [CrossRef]

- Thejeel, B.; Endo, Y. Imaging of Total Hip Arthroplasty: Part I—Implant Design, Imaging Techniques, and Imaging of Component Wear and Fracture. Clin. Imaging 2023, 98, 74–85. [Google Scholar] [CrossRef]

- Lachiewicz, P.F.; Kleeman, L.T.; Seyler, T. Bearing Surfaces for Total Hip Arthroplasty. JAAOS-J. Am. Acad. Orthop. Surg. 2018, 26, 45–57. [Google Scholar] [CrossRef] [PubMed]

- Gu, J. Bearing Surfaces for Total Hip Arthroplasty. In Principles of Primary Total Hip Arthroplasty; Zhou, Y., Tang, J., Shao, H., Eds.; Springer Nature: Singapore, 2022; pp. 21–27. ISBN 978-981-19360-5-0. [Google Scholar]

- Charnley, J. Anchorage of the Femoral Head Prosthesis to the Shaft of the Femur. J. Bone Jt. Surg. Br. Vol. 1960, 42, 28–30. [Google Scholar] [CrossRef] [PubMed]

- Charnley, J. The Bonding of Prostheses to Bone by Cement. J. Bone Jt. Surg. Br. Vol. 1964, 46, 518–529. [Google Scholar] [CrossRef]

- Charnley, J. A Biomechanical Analysis of the Use of Cement to Anchor the Femoral Head Prosthesis. J. Bone Jt. Surg. Br. Vol. 1965, 47, 354–363. [Google Scholar] [CrossRef]

- Britton, A.; Murray, D.; Bulstrode, C.; McPherson, K.; Denham, R. Long-Term Comparison of Charnley and Stanmore Design Total Hip Replacements. J. Bone Jt. Surg. Br. Vol. 1996, 78, 802–808. [Google Scholar] [CrossRef]

- Abdel-Kader, K.F.M.; Allcock, S.; Walker, D.I.; Chaudhry, S.B. Boneloc Bone–Cement. J. Arthroplast. 2001, 16, 811–819. [Google Scholar] [CrossRef]

- Waugh, T.R. Polytetrafluoroethylene (Teflon) Tools for Total Arthroplasty of the Hip. Clin. Orthop. Relat. Res. 1972, 85, 155. [Google Scholar] [CrossRef] [PubMed]

- Khalifa, A.A.; Bakr, H.M. Updates in Biomaterials of Bearing Surfaces in Total Hip Arthroplasty. Arthroplasty 2021, 3, 32. [Google Scholar] [CrossRef]

- Feder, O.; Lawrence, K.W.; Driesman, A.; Ran Schwarzkopf, M.; Aggarwal, V.; Rozell, J. Ortho Plastics: The Adoption and Evolution of Polyethylene in Orthopedic Surgery. Bull. NYU Hosp. Jt. Dis. 2023, 81, 78–83. [Google Scholar]

- Slouf, M.; Gajdosova, V.; Dybal, J.; Sticha, R.; Fulin, P.; Pokorny, D.; Mateo, J.; Panisello, J.J.; Canales, V.; Medel, F.; et al. European Database of Explanted UHMWPE Liners from Total Joint Replacements: Correlations among Polymer Modifications, Structure, Oxidation, Mechanical Properties and Lifetime In Vivo. Polymers 2023, 15, 568. [Google Scholar] [CrossRef]

- Ruggiero, A.; D’Amato, R.; Gómez, E.; Merola, M. Experimental Comparison on Tribological Pairs UHMWPE/TIAL6V4 Alloy, UHMWPE/AISI316L Austenitic Stainless and UHMWPE/AL2O3 Ceramic, under Dry and Lubricated Conditions. Tribol. Int. 2016, 96, 349–360. [Google Scholar] [CrossRef]

- Brach del Prever, E.M.; Bistolfi, A.; Bracco, P.; Costa, L. UHMWPE for Arthroplasty: Past or Future? J. Orthop. Traumatol. 2009, 10, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Hasegawa, M.; Tone, S.; Naito, Y.; Sudo, A. Ultra-High-Molecular-Weight Polyethylene in Hip and Knee Arthroplasties. Materials 2023, 16, 2140. [Google Scholar] [CrossRef] [PubMed]

- Sobieraj, M.C.; Rimnac, C.M. Ultra High Molecular Weight Polyethylene: Mechanics, Morphology, and Clinical Behavior. J. Mech. Behav. Biomed. Mater. 2009, 2, 433–443. [Google Scholar] [CrossRef]

- Bistolfi, A.; Giustra, F.; Bosco, F.; Sabatini, L.; Aprato, A.; Bracco, P.; Bellare, A. Ultra-High Molecular Weight Polyethylene (UHMWPE) for Hip and Knee Arthroplasty: The Present and the Future. J. Orthop. 2021, 25, 98–106. [Google Scholar] [CrossRef]

- Zeman, J.; Ranuša, M.; Vrbka, M.; Gallo, J.; Křupka, I.; Hartl, M. UHMWPE Acetabular Cup Creep Deformation during the Run-in Phase of THA’s Life Cycle. J. Mech. Behav. Biomed. Mater. 2018, 87, 30–39. [Google Scholar] [CrossRef]

- Zhou, J.; Chakravartula, A.; Pruitt, L.; Komvopoulos, K. Tribological and Nanomechanical Properties of Unmodified and Crosslinked Ultra-High Molecular Weight Polyethylene for Total Joint Replacements. J. Tribol. 2004, 126, 386–394. [Google Scholar] [CrossRef]

- Sethi, R.K.; Neavyn, M.J.; Rubash, H.E.; Shanbhag, A.S. Macrophage Response to Cross-Linked and Conventional UHMWPE. Biomaterials 2003, 24, 2561–2573. [Google Scholar] [CrossRef]

- Eddoumy, F.; Addiego, F.; Celis, J.P.; Buchheit, O.; Berradja, A.; Muller, R.; Toniazzo, V.; Ruch, D. Reciprocating Sliding of Uniaxially-Stretched Ultra-High Molecular Weight Polyethylene for Medical Device Applications. Wear 2011, 272, 50–61. [Google Scholar] [CrossRef]

- Ishida, T.; Tateiwa, T.; Takahashi, Y.; Masaoka, T.; Shishido, T.; Yamamoto, K. Do Polyethylene Wear Particles Affect the Development of Pseudotumor in Total Hip Arthroplasty? A Minimum 15-Year Follow-Up. J. Orthop. Surg. Res. 2023, 18, 147. [Google Scholar] [CrossRef] [PubMed]

- Takakubo, Y.; Berce, A.; Trebše, R.; Tamaki, Y.; Milošev, I.; Al-Samadi, A.; Tiainen, V.-M.; Orton; Konttinen, Y.T. Wear and Corrosion in the Loosening of Total Joint Replacements (TJRs). In Bio-Tribocorrosion in Biomaterials and Medical Implants; Yan, Y., Ed.; Woodhead Publishing Series in Biomaterials; Woodhead Publishing: Cambridge, UK, 2013; pp. 74–110. ISBN 978-0-85709-540-4. [Google Scholar]

- Merola, M.; Affatato, S. Materials for Hip Prostheses: A Review of Wear and Loading Considerations. Materials 2019, 12, 495. [Google Scholar] [CrossRef] [PubMed]

- Baker, D.A.; Hastings, R.S.; Pruitt, L. Study of Fatigue Resistance of Chemical and Radiation Crosslinked Medical Grade Ultrahigh Molecular Weight Polyethylene. J. Biomed. Mater. Res. 1999, 46, 573–581. [Google Scholar] [CrossRef]

- Fransen, B.L.; Bengoa, F.J.; Neufeld, M.E.; Sheridan, G.A.; Garbuz, D.S.; Howard, L.C. Thin Highly Cross-Linked Polyethylene Liners Combined with Large Femoral Heads in Primary Total Hip Arthroplasty Show Excellent Survival and Low Wear Rates at a Mean Follow-Up of 12.8 Years. Bone Jt. J. 2023, 105-B, 29–34. [Google Scholar] [CrossRef]

- Ast, M.P.; John, T.K.; Labbisiere, A.; Robador, N.; Della Valle, A.G. Fractures of a Single Design of Highly Cross-Linked Polyethylene Acetabular Liners: An Analysis of Voluntary Reports to the United States Food and Drug Administration. J. Arthroplast. 2014, 29, 1231–1235. [Google Scholar] [CrossRef]

- Oral, E.; Muratoglu, O.K. Radiation Cross-Linking in Ultra-High Molecular Weight Polyethylene for Orthopaedic Applications. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2007, 265, 18–22. [Google Scholar] [CrossRef]

- Bracco, P.; Brunella, V.; Luda, M.P.; Zanetti, M.; Costa, L. Radiation-Induced Crosslinking of UHMWPE in the Presence of Co-Agents: Chemical and Mechanical Characterisation. Polymer 2005, 46, 10648–10657. [Google Scholar] [CrossRef]

- Costa, L.; Luda, M.P.; Trossarelli, L.; Brach del Prever, E.M.; Crova, M.; Gallinaro, P. Oxidation in Orthopaedic UHMWPE Sterilized by Gamma-Radiation and Ethylene Oxide. Biomaterials 1998, 19, 659–668. [Google Scholar] [CrossRef]

- Bhaskar, B.; Arun, S.; Sreekanth, P.; Kanagaraj, S. Biomaterials in Total Hip Joint Replacements: The Evolution of Basic Concepts, Trends, and Current Limitations—A Review. Trends Biomater. 2016, 5, 175. [Google Scholar]

- Pruitt, L.; Koo, J.; Rimnac, C.M.; Suresh, S.; Wright, T.M. Cyclic Compressive Loading Results in Fatigue Cracks in Ultra High Molecular Weight Polyethylene. J. Orthop. Res. 1995, 13, 143–146. [Google Scholar] [CrossRef]

- Moro, T.; Takatori, Y.; Tanaka, S.; Ishihara, K.; Oda, H.; Kim, Y.T.; Umeyama, T.; Fukatani, E.; Ito, H.; Kyomoto, M. Clinical Safety and Wear Resistance of the Phospholipid Polymer-grafted Highly Cross-linked Polyethylene Liner. J. Orthop. Res. 2017, 35, 2007–2016. [Google Scholar] [CrossRef]

- Devane, P.A.; Horne, J.G.; Ashmore, A.; Mutimer, J.; Kim, W.; Stanley, J. Highly Cross-Linked Polyethylene Reduces Wear and Revision Rates in Total Hip Arthroplasty: A 10-Year Double-Blinded Randomized Controlled Trial. JBJS 2017, 99, 1703. [Google Scholar] [CrossRef] [PubMed]

- Wegrzyn, J.; Antoniadis, A.; Sarshari, E.; Boubat, M.; Terrier, A. Polyethylene Wear of Dual Mobility Cups: A Comparative Analysis Based on Patient-Specific Finite Element Modeling. Int. Orthop. (SICOT) 2022, 46, 779–787. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.-H.; Park, J.-W.; Kim, J.-S. Alumina Delta-on-Highly Crosslinked-Remelted Polyethylene Bearing in Cementless Total Hip Arthroplasty in Patients Younger than 50 Years. J. Arthroplast. 2016, 31, 2800–2804. [Google Scholar] [CrossRef] [PubMed]

- Callaghan, J.J.; Cuckler, J.M.; Huddleston, J.I.; Galante, J.O. How Have Alternative Bearings (Such as Metal-on-Metal, Highly Cross-Linked Polyethylene, and Ceramic-on-Ceramic) Affected the Prevention and Treatment of Osteolysis? J. Am. Acad. Orthop. Surg. 2008, 16, S33–S38. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Bracco, P.; Costa, L.; Oral, E.; Muratoglu, O.K. Vitamin E-Blended UHMWPE Biomaterials. In UHMWPE Biomaterials Handbook, 3rd ed.; Kurtz, S.M., Ed.; William Andrew Publishing: Oxford, UK, 2016; pp. 293–306. ISBN 978-0-323-35401-1. [Google Scholar]

- Affatato, S.; De Mattia, J.S.; Bracco, P.; Pavoni, E.; Taddei, P. Wear Performance of Neat and Vitamin E Blended Highly Cross-Linked PE under Severe Conditions: The Combined Effect of Accelerated Ageing and Third Body Particles during Wear Test. J. Mech. Behav. Biomed. Mater. 2016, 64, 240–252. [Google Scholar] [CrossRef]

- Spece, H.; Yarbrough, R.V.; Kurtz, S.M. In Vivo Performance of Vitamin E Stabilized Polyethylene Implants for Total Hip Arthroplasty: A Review. J. Arthroplast. 2023, 38, 970–979. [Google Scholar] [CrossRef]

- Wolf, C.; Krivec, T.; Blassnig, J.; Lederer, K.; Schneider, W. Examination of the Suitability of α-Tocopherol as a Stabilizer for Ultra-High Molecular Weight Polyethylene Used for Articulating Surfaces in Joint Endoprostheses. J. Mater. Sci. Mater. Med. 2002, 13, 185–189. [Google Scholar] [CrossRef]

- Takahashi, Y.; Yamamoto, K.; Pezzotti, G. Effects of Vitamin E Blending on Plastic Deformation Mechanisms of Highly Crosslinked Ultrahigh Molecular Weight Polyethylene (HXL-UHMWPE) in Total Hip Arthroplasty. Acta Biomater. 2015, 15, 227–236. [Google Scholar] [CrossRef]

- Oral, E.; Muratoglu, O.K. Vitamin E Diffused, Highly Crosslinked UHMWPE: A Review. Int. Orthop. (SICOT) 2011, 35, 215–223. [Google Scholar] [CrossRef]

- Galea, V.P.; Connelly, J.W.; Shareghi, B.; Kärrholm, J.; Sköldenberg, O.; Salemyr, M.; Laursen, M.B.; Muratoglu, O.; Bragdon, C.; Malchau, H. Evaluation of In Vivo Wear of Vitamin E-Diffused Highly Crosslinked Polyethylene at Five Years: A Multicentre Radiostereometric Analysis Study. Bone Jt. J. 2018, 100-B, 1592–1599. [Google Scholar] [CrossRef]

- Kjærgaard, K.; Ding, M.; Jensen, C.; Bragdon, C.; Malchau, H.; Andreasen, C.M.; Ovesen, O.; Hofbauer, C.; Overgaard, S. Vitamin E-Doped Total Hip Arthroplasty Liners Show Similar Head Penetration to Highly Cross-Linked Polyethylene at Five Years: A Multi-Arm Randomized Controlled Trial. Bone Jt. J. 2020, 102, 1303–1310. [Google Scholar] [CrossRef] [PubMed]

- Mbogori, M.; Vaish, A.; Vaishya, R.; Haleem, A.; Javaid, M. Poly-Ether-Ether-Ketone (PEEK) in Orthopaedic Practice- A Current Concept Review. J. Orthop. Rep. 2022, 1, 3–7. [Google Scholar] [CrossRef]

- Wang, A.; Lin, R.; Polineni, V.K.; Essner, A.; Stark, C.; Dumbleton, J.H. Carbon Fiber Reinforced Polyether Ether Ketone Composite as a Bearing Surface for Total Hip Replacement. Tribol. Int. 1998, 31, 661–667. [Google Scholar] [CrossRef]

- Ma, H.; Suonan, A.; Zhou, J.; Yuan, Q.; Liu, L.; Zhao, X.; Lou, X.; Yang, C.; Li, D.; Zhang, Y. PEEK (Polyether-Ether-Ketone) and Its Composite Materials in Orthopedic Implantation. Arab. J. Chem. 2021, 14, 102977. [Google Scholar] [CrossRef]

- Ishihara, K. Highly Lubricated Polymer Interfaces for Advanced Artificial Hip Joints through Biomimetic Design. Polym. J. 2015, 47, 585–597. [Google Scholar] [CrossRef]

- Moroni, A.; Hoque, M.; Micera, G.; Sinapi, F.; Giannini, S. S-34 Clinical Outcomes of Metal–Polyurethane Bearings in Hip Arthroplasty. J. Biomech. 2010, 43 (Suppl. S1), S43. [Google Scholar] [CrossRef]

- El-Desouky, I.I.; Helal, A.H.; Mansour, A.M.R. Ten-Year Survival of Ceramic-on-Ceramic Total Hip Arthroplasty in Patients Younger than 60 Years: A Systematic Review and Meta-Analysis. J. Orthop. Surg. Res. 2021, 16, 679. [Google Scholar] [CrossRef] [PubMed]

- Peterson, S.M.; O’Byrne, T.J.; Brennan, P.C.; Jannetto, P.J.; Pavelko, K.D.; Lewallen, D.G.; Vassilaki, M.; Maradit Kremers, H. Cross-Sectional Association between Systemic Metal Concentrations and Immune Markers in Patients with Total Joint Arthroplasty. Front. Immunol. 2023, 14, 1130209. [Google Scholar] [CrossRef] [PubMed]

- Silverman, E.J.; Ashley, B.; Sheth, N.P. Metal-on-Metal Total Hip Arthroplasty: Is There Still a Role in 2016? Curr. Rev. Musculoskelet. Med. 2016, 9, 93–96. [Google Scholar] [CrossRef]

- Hu, C.Y.; Yoon, T.-R. Recent Updates for Biomaterials Used in Total Hip Arthroplasty. Biomater. Res. 2018, 22, 33. [Google Scholar] [CrossRef] [PubMed]

- Ezzet, K.A.; Hermida, J.C.; Colwell, C.W.J.; D’Lima, D.D. Oxidized Zirconium Femoral Components Reduce Polyethylene Wear in a Knee Wear Simulator. Clin. Orthop. Relat. Res. (1976–2007) 2004, 428, 120–124. [Google Scholar] [CrossRef]

- Ezzet, K.A.; Hermida, J.C.; Steklov, N.; D’Lima, D.D. Wear of Polyethylene Against Oxidized Zirconium Femoral Components: Effect of Aggressive Kinematic Conditions and Malalignment in Total Knee Arthroplasty. J. Arthroplast. 2012, 27, 116–121. [Google Scholar] [CrossRef] [PubMed]

- Good, V.; Ries, M.; Barrack, R.L.; Widding, K.; Hunter, G.; Heuer, D. Reduced Wear with Oxidized Zirconium Femoral Heads. JBJS 2003, 85, 105. [Google Scholar] [CrossRef] [PubMed]

- Patel, A.M.; Spector, M. Tribological Evaluation of Oxidized Zirconium Using an Articular Cartilage Counterface: A Novel Material for Potential Use in Hemiarthroplasty. Biomaterials 1997, 18, 441–447. [Google Scholar] [CrossRef]

- Hunter, G.; Dickinson, J.; Herb, B.; Graham, R. Creation of Oxidized Zirconium Orthopaedic Implants. J. ASTM Int. 2005, 2, JAI12775. [Google Scholar] [CrossRef]

- Clarke, I.C.; Lazennec, J.Y.; Smith, E.J.; Sugano, N.; McEntire, B.J.; Pezzotti, G. Ceramic-on-Ceramic Bearings: Simulator Wear Compared to Clinical Retrieval Data. In Material for Total Joint Arthroplasty: Biotribology of Potential Bearings; Sonntag, R., Kretzer, J.P., Eds.; Imperial College Press: London, UK, 2015; pp. 85–131. [Google Scholar]

- Malahias, M.-A.; Atrey, A.; Gu, A.; Chytas, D.; Nikolaou, V.S.; Waddell, J.P. Is Oxidized Zirconium Femoral Head Superior to Other Bearing Types in Total Hip Arthroplasty? A Systematic Review and Meta-Analysis. J. Arthroplast. 2019, 34, 1844–1852. [Google Scholar] [CrossRef]

- Łapaj, Ł.; Wendland, J.; Markuszewski, J.; Mróz, A.; Wiśniewski, T. Retrieval Analysis of Titanium Nitride (TiN) Coated Prosthetic Femoral Heads Articulating with Polyethylene. J. Mech. Behav. Biomed. Mater. 2016, 55, 127–139. [Google Scholar] [CrossRef]

- Yorifuji, M.; Affatato, S.; Tateiwa, T.; Takahashi, Y.; Shishido, T.; Marin, E.; Zanocco, M.; Zhu, W.; Pezzotti, G.; Yamamoto, K. Wear Simulation of Ceramic-on-Crosslinked Polyethylene Hip Prostheses: A New Non-Oxide Silicon Nitride versus the Gold Standard Composite Oxide Ceramic Femoral Heads. Materials 2020, 13, 2917. [Google Scholar] [CrossRef]

- Choudhury, D.; Lackner, J.; Fleming, R.A.; Goss, J.; Chen, J.; Zou, M. Diamond-like Carbon Coatings with Zirconium-Containing Interlayers for Orthopedic Implants. J. Mech. Behav. Biomed. Mater. 2017, 68, 51–61. [Google Scholar] [CrossRef]

- Khanna, R.; Kokubo, T.; Matsushita, T.; Nomura, Y.; Nose, N.; Oomori, Y.; Yoshida, T.; Wakita, K.; Takadama, H. Novel Artificial Hip Joint: A Layer of Alumina on Ti–6Al–4V Alloy Formed by Micro-Arc Oxidation. Mater. Sci. Eng. C 2015, 55, 393–400. [Google Scholar] [CrossRef] [PubMed]

- Maru, M.M.; Amaral, M.; Rodrigues, S.P.; Santos, R.; Gouvea, C.P.; Archanjo, B.S.; Trommer, R.M.; Oliveira, F.J.; Silva, R.F.; Achete, C.A. The High Performance of Nanocrystalline CVD Diamond Coated Hip Joints in Wear Simulator Test. J. Mech. Behav. Biomed. Mater. 2015, 49, 175–185. [Google Scholar] [CrossRef]

- Ammarullah, M.I.; Hartono, R.; Supriyono, T.; Santoso, G.; Sugiharto, S.; Permana, M.S. Polycrystalline Diamond as a Potential Material for the Hard-on-Hard Bearing of Total Hip Prosthesis: Von Mises Stress Analysis. Biomedicines 2023, 11, 951. [Google Scholar] [CrossRef] [PubMed]

- Shankar, S.; Nithyaprakash, R.; Abbas, G.; Naveenkumar, R.; Prakash, C.; Pramanik, A.; Basak, A.K. Tribological Behavior of AZ31 Alloy Against Si3N4 Using In-Vitro and In-Silico Submodeling Approach for Human Hip Prosthesis. Silicon 2023, 15, 983–991. [Google Scholar] [CrossRef]

- Ying, J.; Cheng, L.; Li, J.; Wu, B.; Qiu, X.; Zhang, T.; Wang, F.; Liu, B.; Yang, L.; Pokharel, D.B.; et al. Treatment of Acetabular Bone Defect in Revision of Total Hip Arthroplasty Using 3D Printed Tantalum Acetabular Augment. Orthop. Surg. 2023, 15, 1264–1271. [Google Scholar] [CrossRef] [PubMed]

- Viamont-Guerra, M.-R.; Ramos-Pascual, S.; Saffarini, M.; Sales, J.; Laude, F. Effect of Femoral Stem Surface Coating on Clinical and Radiographic Outcomes of Cementless Primary Total Hip Arthroplasty: A Patient-Matched Retrospective Study. Int. Orthop. (SICOT) 2023, 47, 165–174. [Google Scholar] [CrossRef]

- Smith, A.J.; Dieppe, P.; Vernon, K.; Porter, M.; Blom, A.W. Failure Rates of Stemmed Metal-on-Metal Hip Replacements: Analysis of Data from the National Joint Registry of England and Wales. Lancet 2012, 379, 1199–1204. [Google Scholar] [CrossRef]

- Filip, N.; Radu, I.; Veliceasa, B.; Filip, C.; Pertea, M.; Clim, A.; Pinzariu, A.C.; Drochioi, I.C.; Hilitanu, R.L.; Serban, I.L. Biomaterials in Orthopedic Devices: Current Issues and Future Perspectives. Coatings 2022, 12, 1544. [Google Scholar] [CrossRef]

- Grigoriev, S.; Sotova, C.; Vereschaka, A.; Uglov, V.; Cherenda, N. Modifying Coatings for Medical Implants Made of Titanium Alloys. Metals 2023, 13, 718. [Google Scholar] [CrossRef]

- Martelli, A.; Erani, P.; Pazzagli, N.; Cannillo, V.; Baleani, M. Surface Analysis of Ti-Alloy Micro-Grooved 12/14 Tapers Assembled to Non-Sleeved and Sleeved Ceramic Heads: A Comparative Study of Retrieved Hip Prostheses. Materials 2023, 16, 1067. [Google Scholar] [CrossRef] [PubMed]

- Morita, A.; Kobayashi, N.; Choe, H.; Tezuka, T.; Misumi, T.; Inaba, Y. Effect of Implant Composition on Periprosthetic Bone Mineral Density after Total Hip Arthroplasty. Arch. Orthop. Trauma Surg. 2022, 143, 2763–2771. [Google Scholar] [CrossRef] [PubMed]

- Frye, B.M.; Laughery, K.R.; Klein, A.E. The Oxinium Arthrogram: A Sign of Oxidized Zirconium Implant Failure. Arthroplast. Today 2021, 8, 103–109. [Google Scholar] [CrossRef] [PubMed]

- Zhao, K.; Zhao, J.; Wei, X.; Guan, X.; Deng, C.; Dai, B.; Zhu, J. Bottom-Up Cu Filling of High-Aspect-Ratio through-Diamond Vias for 3D Integration in Thermal Management. Micromachines 2023, 14, 290. [Google Scholar] [CrossRef] [PubMed]

- Guignard, J.; Prakasam, M.; Largeteau, A. A Review of Binderless Polycrystalline Diamonds: Focus on the High-Pressure–High-Temperature Sintering Process. Materials 2022, 15, 2198. [Google Scholar] [CrossRef]

- Yan, X.; Dong, S.; Li, X.; Zhao, Z.; Dong, S.; An, L. Optimization of Machining Parameters for Milling Zirconia Ceramics by Polycrystalline Diamond Tool. Materials 2022, 15, 208. [Google Scholar] [CrossRef]

- Zhan, G.D.; Xu, J.; He, D. Applications of Polycrystalline Diamond (PCD) Materials in Oil and Gas Industry. In Applications and Use of Diamond; IntechOpen: Rijeka, Croatia, 2022; ISBN 1-80356-318-4. [Google Scholar]

- Ramírez, G.; Gonzalez Castro, J.M.; Orrit-Prat, J.; Bonet, R.; Cuadrado, N.; Vilaseca, M.; Carreras, L.; Caro, J. Super-Hard DLC Coatings as an Alternative to Polycrystalline Diamond for Cutting Tools: Predictive Analysis of Aluminium Alloy Surface Quality. Lubricants 2022, 10, 135. [Google Scholar] [CrossRef]

- Li, Q.; Zhan, G.; Li, D.; He, D.; Moellendick, T.E.; Gooneratne, C.P.; Alalsayednassir, A.G. Ultrastrong Catalyst-Free Polycrystalline Diamond. Sci. Rep. 2020, 10, 22020. [Google Scholar] [CrossRef]

- Hannouche, D.; Zingg, M.; Miozzari, H.; Nizard, R.; Lübbeke, A. Third-Generation Pure Alumina and Alumina Matrix Composites in Total Hip Arthroplasty. EFORT Open Rev. 2018, 3, 7–14. [Google Scholar] [CrossRef]

- Piconi, C. Ceramics for Joint Replacement: Design and Application of Commercial Bearings. In Advances in Ceramic Biomaterials; Palmero, P., Cambier, F., De Barra, E., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 129–179. ISBN 978-0-08-100881-2. [Google Scholar]

- Van Loon, J.; Sierevelt, I.N.; Spekenbrink-Spooren, A.; Opdam, K.T.; Poolman, R.W.; Kerkhoffs, G.M.; Haverkamp, D. Higher Risk of 2-Year Cup Revision of Ceramic-on-Ceramic versus Ceramic-on-Polyethylene Bearing: Analysis of 33,454 Primary Press-Fit Total Hip Arthroplasties Registered in the Dutch Arthroplasty Register (LROI). HIP Int. 2023, 33, 280–287. [Google Scholar] [CrossRef]

- Lee, Y.-K.; Ha, Y.-C.; Won, S.J.; Kim, J.-H.; Park, J.-W.; Koo, K.-H. Mid-Term Results of Revision Total Hip Arthroplasty Using Delta Ceramic-on-Ceramic Bearing. Clin. Orthop. Surg. 2023, 15, 20. [Google Scholar] [CrossRef]

- Macdonald, N.; Bankes, M. Ceramic on Ceramic Hip Prostheses: A Review of Past and Modern Materials. Arch. Orthop. Trauma Surg. 2014, 134, 1325–1333. [Google Scholar] [CrossRef]

- Affatato, S.; Jaber, S.A.; Taddei, P. Ceramics for Hip Joint Replacement. In Biomaterials in Clinical Practice: Advances in Clinical Research and Medical Devices; Zivic, F., Affatato, S., Trajanovic, M., Schnabelrauch, M., Grujovic, N., Choy, K.L., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 167–181. ISBN 978-3-319-68025-5. [Google Scholar]

- Xu, J.; Oni, T.; Shen, D.; Chai, Y.; Walter, W.K.; Walter, W.L. Long-Term Results of Alumina Ceramic-On-Ceramic Bearings in Cementless Total Hip Arthroplasty: A 20-Year Minimum Follow-Up. J. Arthroplast. 2022, 37, 549–553. [Google Scholar] [CrossRef]

- McEntire, B.J.; Bal, B.S.; Rahaman, M.N.; Chevalier, J.; Pezzotti, G. Ceramics and Ceramic Coatings in Orthopaedics. J. Eur. Ceram. Soc. 2015, 35, 4327–4369. [Google Scholar] [CrossRef]

- Lim, S.-J.; Kim, S.-M.; Kim, D.-W.; Moon, Y.-W.; Park, Y.-S. Cementless Total HIP Arthroplasty Using Biolox®Delta Ceramic-on-Ceramic Bearing in Patients with Osteonecrosis of the Femoral Head. HIP Int. 2016, 26, 144–148. [Google Scholar] [CrossRef] [PubMed]

- Massin, P.; Lopes, R.; Masson, B.; Mainard, D. Does Biolox® Delta Ceramic Reduce the Rate of Component Fractures in Total Hip Replacement? Orthop. Traumatol. Surg. Res. 2014, 100, S317–S321. [Google Scholar] [CrossRef] [PubMed]

- Karidakis, G.K.; Karachalios, T. Oxidized Zirconium Head on Crosslinked Polyethylene Liner in Total Hip Arthroplasty: A 7- to 12-Year In Vivo Comparative Wear Study. Clin. Orthop. Relat. Res. 2015, 473, 3836–3845. [Google Scholar] [CrossRef]

- Mamalis, A.G.; Ramsden, J.J.; Grabchenko, A.I.; Lytvynov, L.A.; Filipenko, V.A.; Lavrynenko, S.N. A Novel Concept for the Manufacture of Individual Sapphire-Metallic Hip Joint Endoprostheses. J. Biol. Phys. Chem. 2006, 6, 113–117. [Google Scholar] [CrossRef]

- Lim, S.-J.; Yeo, I.; Park, C.-W.; Lee, K.-J.; Min, B.-W.; Park, Y.-S. High Survivorship of Highly Cross-Linked Polyethylene in Revision Total Hip Arthroplasty: A Minimum 10-Year Follow-up Study. Arthroplasty 2019, 1, 16. [Google Scholar] [CrossRef] [PubMed]

- Almaawi, A.; Alzuhair, A.; AlHakbani, A.; Benfaris, D.; Al-Abdullatif, F.; Alabdulkarim, N.H.; Awwad, W.; Almaawi, A.; Alzuhair, A.; AlHakbani, A.; et al. Comparison of Ceramic-on-Ceramic and Ceramic-on-Highly-Crosslinked-Polyethylene in Primary Total Hip Arthroplasty: Findings of a Meta-Analysis. Cureus 2021, 13, e13304. [Google Scholar] [CrossRef] [PubMed]

- Oral, E.; Christensen, S.D.; Malhi, A.S.; Wannomae, K.K.; Muratoglu, O.K. Wear Resistance and Mechanical Properties of Highly Cross-Linked, Ultrahigh–Molecular Weight Polyethylene Doped with Vitamin E. J. Arthroplast. 2006, 21, 580–591. [Google Scholar] [CrossRef]

- Takahashi, Y.; Masaoka, T.; Yamamoto, K.; Shishido, T.; Tateiwa, T.; Kubo, K.; Pezzotti, G. Vitamin-E Blended and Infused Highly Cross-Linked Polyethylene for Total Hip Arthroplasty: A Comparison of Three-Dimensional Crystalline Morphology and Strain Recovery Behavior. J. Mech. Behav. Biomed. Mater. 2014, 36, 59–70. [Google Scholar] [CrossRef]

- Bracco, P.; Oral, E. Vitamin E-Stabilized UHMWPE for Total Joint Implants: A Review. Clin. Orthop. Relat. Res. 2011, 469, 2286–2293. [Google Scholar] [CrossRef] [PubMed]

- Scemama, C.; Anract, P.; Dumaine, V.; Babinet, A.; Courpied, J.P.; Hamadouche, M. Does Vitamin E-Blended Polyethylene Reduce Wear in Primary Total Hip Arthroplasty: A Blinded Randomised Clinical Trial. Int. Orthop. (SICOT) 2017, 41, 1113–1118. [Google Scholar] [CrossRef] [PubMed]

- Rochcongar, G.; Buia, G.; Bourroux, E.; Dunet, J.; Chapus, V.; Hulet, C. Creep and Wear in Vitamin E-Infused Highly Cross-Linked Polyethylene Cups for Total Hip Arthroplasty: A Prospective Randomized Controlled Trial. JBJS 2018, 100, 107. [Google Scholar] [CrossRef] [PubMed]

- Sköldenberg, O.G.; Rysinska, A.D.; Chammout, G.; Salemyr, M.; Mukka, S.S.; Bodén, H.; Eisler, T. A Randomized Double-Blind Noninferiority Trial, Evaluating Migration of a Cemented Vitamin E-Stabilized Highly Crosslinked Component Compared with a Standard Polyethylene Component in Reverse Hybrid Total Hip Arthroplasty. Bone Jt. J. 2019, 101-B, 1192–1198. [Google Scholar] [CrossRef] [PubMed]

- Elbardesy, H.; Yadav, H.; Rabea, M.; Guerin, S.; Harty, J. Femoral Head Penetration in Vitamin-E Polyethylene Liner versus Conventional Liners in Total Hip Arthroplasty: Systematic Review and Meta-Analysis of Randomised Control Trials. SICOT-J 2021, 7, 47. [Google Scholar] [CrossRef]

- Baghdadi, J.; Alkhateeb, S.; Roth, A.; Jäger, M.; Busch, A.; Alkhateeb, S.; Landgraeber, S.; Serong, S.; Haversath, M.; vonWasen, A.; et al. Cup Positioning and Its Effect on Polyethylene Wear of Vitamin E- and Non-Vitamin E-Supplemented Liners in Total Hip Arthroplasty: Radiographic Outcome at 5-Year Follow-Up. Arch. Orthop. Trauma Surg. 2023, 143, 1679–1688. [Google Scholar] [CrossRef]

- Nielson, T.; Owens, G.; Miller, B.; Meneghini, E.; Deckard, E.R.; Meneghini, R.M. Large Femoral Heads in Total Hip Arthroplasty with Vitamin E Highly Cross-Linked Polyethylene: Head Penetration Rates Compared to Highly Cross-Linked Polyethylene. J. Arthroplast. 2022, 37, S685–S691. [Google Scholar] [CrossRef]

- Kim, Y.-H. Comparison of Polyethylene Wear Associated with Cobalt-Chromium and Zirconia Heads After Total Hip Replacement: A Prospective, Randomized Study. JBJS 2005, 87, 1769. [Google Scholar] [CrossRef]

- Zaoui, A.; Hage, S.E.; Langlois, J.; Scemama, C.; Courpied, J.P.; Hamadouche, M. Do Oxidized Zirconium Femoral Heads Reduce Polyethylene Wear in Cemented THAs? A Blinded Randomized Clinical Trial. Clin. Orthop. Relat. Res. 2015, 473, 3822–3828. [Google Scholar] [CrossRef][Green Version]

- Jonsson, B.A.; Kadar, T.; Havelin, L.I.; Haugan, K.; Espehaug, B.; Indrekvam, K.; Furnes, O.; Hallan, G. Oxinium Modular Femoral Heads Do Not Reduce Polyethylene Wear in Cemented Total Hip Arthroplasty at Five Years: A Randomised Trial of 120 Hips Using Radiostereometric Analysis. Bone Jt. J. 2015, 97-B, 1463–1469. [Google Scholar] [CrossRef] [PubMed]

- Jassim, S.S.; Patel, S.; Wardle, N.; Tahmassebi, J.; Middleton, R.; Shardlow, D.L.; Stephen, A.; Hutchinson, J.; Haddad, F.S. Five-Year Comparison of Wear Using Oxidised Zirconium and Cobalt–Chrome Femoral Heads in Total Hip Arthroplasty: A Multicentre Randomised Controlled Trial. Bone Jt. J. 2015, 97-B, 883–889. [Google Scholar] [CrossRef] [PubMed]

- Bergvinsson, H.; Sundberg, M.; Flivik, G. Polyethylene Wear with Ceramic and Metal Femoral Heads at 5 Years: A Randomized Controlled Trial with Radiostereometric Analysis. J. Arthroplast. 2020, 35, 3769–3776. [Google Scholar] [CrossRef] [PubMed]

- Teeter, M.G.; MacLean, C.J.; Somerville, L.E.; Howard, J.L.; McCalden, R.W.; Lanting, B.A.; Vasarhelyi, E.M. Wear Performance of Cobalt Chromium, Ceramic, and Oxidized Zirconium on Highly Crosslinked Polyethylene at Mid-Term Follow-Up. J. Orthop. 2018, 15, 620–623. [Google Scholar] [CrossRef]

- Long, W.T. The Clinical Performance of Metal-on-Metal as an Articulation Surface in Total Hip Replacement. Iowa Orthop. J. 2005, 25, 10–16. [Google Scholar]

- Prime, M.S.; Palmer, J.; Khan, W.S.; Lindeque, B.G.P. The National Joint Registry of England and Wales. Orthopedics 2011, 34, 107–110. [Google Scholar] [CrossRef]

- Migaud, H.; Jobin, A.; Chantelot, C.; Giraud, F.; Laffargue, P.; Duquennoy, A. Cementless Metal-on-Metal Hip Arthroplasty in Patients Less than 50 Years of Age: Comparison with a Matched Control Group Using Ceramic-on-Polyethylene after a Minimum 5-Year Follow-Up. J. Arthroplast. 2004, 19, 23–28. [Google Scholar] [CrossRef]

- Dorr, L.D.; Wan, Z.; Longjohn, D.B.; Dubois, B.; Murken, R. Total Hip Arthroplasty with Use of the Metasul Metal-on-Metal Articulation: Four to Seven-Year Results. JBJS 2000, 82, 789. [Google Scholar] [CrossRef]

- Pandit, H.; Glyn-Jones, S.; McLardy-Smith, P.; Gundle, R.; Whitwell, D.; Gibbons, C.L.M.; Ostlere, S.; Athanasou, N.; Gill, H.S.; Murray, D.W. Pseudotumours Associated with Metal-on-Metal Hip Resurfacings. J. Bone Jt. Surg. Br. Vol. 2008, 90-B, 847–851. [Google Scholar] [CrossRef]

- Brodner, W.; Bitzan, P.; Meisinger, V.; Kaider, A.; Gottsauner-Wolf, F.; Kotz, R. Elevated Serum Cobalt with Metal-on-Metal Articulating Surfaces. J. Bone Jt. Surg. Br. Vol. 1997, 79-B, 316–321. [Google Scholar] [CrossRef]

- Urban, R.M.; Jacobs, J.J.; Tomlinson, M.J.; Gavrilovic, J.; Black, J.; Peoc’h, M. Dissemination of Wear Particles to the Liver, Spleen, and Abdominal Lymph Nodes of Patients with Hip or Knee Replacement. JBJS 2000, 82, 457. [Google Scholar] [CrossRef]

- Case, C. Chromosomal Changes after Surgery for Joint Replacement. J. Bone Jt. Surg. Br. Vol. 2001, 83, 1093–1095. [Google Scholar] [CrossRef]

- Smith, A.J.; Dieppe, P.; Porter, M.; Blom, A.W. Risk of Cancer in First Seven Years after Metal-on-Metal Hip Replacement Compared with Other Bearings and General Population: Linkage Study between the National Joint Registry of England and Wales and Hospital Episode Statistics. BMJ 2012, 344, e2383. [Google Scholar] [CrossRef] [PubMed]

- Skinner, J.; Kay, P. Commentary: Metal on Metal Hips. BMJ 2011, 342, d3009. [Google Scholar] [CrossRef]

- Kusaba, A.; Kuroki, Y.; Kondo, S.; Hirose, I.; Ito, Y.; Shirasaki, Y.; Tateishi, T.; Scholz, J. Frictional Torque and Wear of Retrieved Hip Prostheses: A Comparison Between Alumina/PE and Co-Cr/PE Prostheses. JLT 2002, 12, 10. [Google Scholar] [CrossRef]

- Urban, J.A.; Garvin, K.L.; Boese, C.K.; Bryson, L.; Pedersen, D.R.; Callaghan, J.J.; Miller, R.K. Ceramic-on-Polyethylene Bearing Surfaces in Total Hip Arthroplasty: Seventeen to Twenty-One-Year Results. JBJS 2001, 83, 1688. [Google Scholar] [CrossRef]

- Wroblewski, B.M.; Siney, P.D.; Fleming, P.A. Low-Friction Arthroplasty of the Hip Using Alumina Ceramic and Cross-Linked Polyethylene: A 17-YEAR FOLLOW-UP REPORT. J. Bone Jt. Surg. Br. Vol. 2005, 87-B, 1220–1221. [Google Scholar] [CrossRef] [PubMed]

- Sugano, N.; Nishii, T.; Nakata, K.; Masuhara, K.; Takaoka, K. Polyethylene Sockets and Alumina Ceramic Heads in Cemented Total Hip Arthroplasty. A Ten-Year Study. J. Bone Jt. Surg. Br. Vol. 1995, 77-B, 548–556. [Google Scholar] [CrossRef]

- Nakahara, I.; Nakamura, N.; Nishii, T.; Miki, H.; Sakai, T.; Sugano, N. Minimum Five-Year Follow-Up Wear Measurement of Longevity Highly Cross-Linked Polyethylene Cup against Cobalt-Chromium or Zirconia Heads. J. Arthroplast. 2010, 25, 1182–1187. [Google Scholar] [CrossRef]

- Sychterz, C.J.; Engh, C.A.; Young, A.M.; Hopper, R.H.; Engh, C.A. Comparison of In Vivo Wear between Polyethylene Liners Articulating with Ceramic and Cobalt-Chrome Femoral Heads. J. Bone Jt. Surg. Br. Vol. 2000, 82-B, 948–951. [Google Scholar] [CrossRef]

- Cohn, R.M.; González Della Valle, A.; Peterson, M.; Cornell, C.N. Similar Wear in Total Hip Arthroplasties with Metallic or Zirconia Femoral Heads. HSS J. 2008, 4, 107–111. [Google Scholar] [CrossRef]

- Ihle, M.; Mai, S.; Siebert, W. Ceramic Versus Metal Femoral Heads in Combination with Polyethylene Cups: Long-Term Wear Analysis at 20 Years. Semin. Arthroplast. 2011, 22, 218–224. [Google Scholar] [CrossRef]

- Raphael, I.J.; Parvizi, J.; Rothman, R.H. The Influence of Head Material on Polyethylene Wear. In Total Hip Arthroplasty: Tribological Considerations and Clinical Consequences; Knahr, K., Ed.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 97–104. ISBN 978-3-642-35653-7. [Google Scholar]

- Hernigou, P.; Zilber, S.; Filippini, P.; Poignard, A. Ceramic-Ceramic Bearing Decreases Osteolysis: A 20-Year Study versus Ceramic-Polyethylene on the Contralateral Hip. Clin. Orthop. Relat. Res. 2009, 467, 2274–2280. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Hernigou, P.; Roubineau, F.; Bouthors, C.; Flouzat-Lachaniette, C.-H. What Every Surgeon Should Know about Ceramic-on-Ceramic Bearings in Young Patients. EFORT Open Rev. 2016, 1, 107–111. [Google Scholar] [CrossRef] [PubMed]

- Chevillotte, C.; Trousdale, R.T.; Chen, Q.; Guyen, O.; An, K.-N. The 2009 Frank Stinchfield Award: “Hip Squeaking”: A Biomechanical Study of Ceramic-on-Ceramic Bearing Surfaces. Clin. Orthop. Relat. Res. 2010, 468, 345–350. [Google Scholar] [CrossRef]

- Morlock, M.; Nassutt, R.; Janssen, R.; Willmann, G.; Honl, M. Mismatched Wear Couple Zirconium Oxide and Aluminum Oxide in Total Hip Arthroplasty. J. Arthroplast. 2001, 16, 1071–1074. [Google Scholar] [CrossRef]

- Blakeney, W.G.; Beaulieu, Y.; Puliero, B.; Lavigne, M.; Roy, A.; Massé, V.; Vendittoli, P.-A. Excellent Results of Large-Diameter Ceramic-on-Ceramic Bearings in Total Hip Arthroplasty: Is Squeaking Related to Head Size. Bone Jt. J. 2018, 100-B, 1434–1441. [Google Scholar] [CrossRef]

- Henri Bauwens, P.; Fary, C.; Servien, E.; Lustig, S.; Batailler, C. Early Low Complication Rate of Ceramic-on-Ceramic Total Hip Arthroplasty by Direct Anterior Approach. SICOT-J 2020, 6, 30. [Google Scholar] [CrossRef]

- Bierbaum, B.E.; Nairus, J.; Kuesis, D.; Morrison, J.C.; Ward, D. Ceramic-on-Ceramic Bearings in Total Hip Arthroplasty. Clin. Orthop. Relat. Res. 2002, 405, 158. [Google Scholar] [CrossRef]

- Maher, S.A.; Lipman, J.D.; Curley, L.J.; Gilchrist, M.; Wright, T.M. Mechanical Performance of Ceramic Acetabular Liners under Impact Conditions. J. Arthroplast. 2003, 18, 936–941. [Google Scholar] [CrossRef]

- Yoo, J.J.; Kim, Y.-M.; Yoon, K.S.; Koo, K.-H.; Song, W.S.; Kim, H.J. Alumina-on-Alumina Total Hip Arthroplasty: A Five-Year Minimum Follow-up Study. JBJS 2005, 87, 530. [Google Scholar] [CrossRef] [PubMed]

- D’Antonio, J.; Capello, W.; Manley, M.; Bierbaum, B. New Experience with Alumina-on-Alumina Ceramic Bearings for Total Hip Arthroplasty. J. Arthroplast. 2002, 17, 390–397. [Google Scholar] [CrossRef] [PubMed]

- Garino, J.P. Modern Ceramic-on-Ceramic Total Hip Systems in the United States: Early Results. Clin. Orthop. Relat. Res. 2000, 379, 41. [Google Scholar] [CrossRef] [PubMed]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti Based Biomaterials, the Ultimate Choice for Orthopaedic Implants—A Review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Williams, D.F. Tissue-Biomaterial Interactions. J. Mater. Sci. 1987, 22, 3421–3445. [Google Scholar] [CrossRef]

- Aherwar, A.; Singh, A.K.; Patnaik, A. Current and Future Biocompatibility Aspects of Biomaterials for Hip Prosthesis. AIMS Bioeng. 2015, 3, 23–43. [Google Scholar] [CrossRef]

- Ou, K.-L.; Weng, C.-C.; Lin, Y.-H.; Huang, M.-S. A Promising of Alloying Modified Beta-Type Titanium-Niobium Implant for Biomedical Applications: Microstructural Characteristics, in Vitro Biocompatibility and Antibacterial Performance. J. Alloys Compd. 2017, 697, 231–238. [Google Scholar] [CrossRef]

- Miura, K.; Yamada, N.; Hanada, S.; Jung, T.-K.; Itoi, E. The Bone Tissue Compatibility of a New Ti–Nb–Sn Alloy with a Low Young’s Modulus. Acta Biomater. 2011, 7, 2320–2326. [Google Scholar] [CrossRef]

| Polymer | Advantages | Disadvantages | References |

|---|---|---|---|

| Polymethyl methacrylate | Long-term studies showed >90% survival at 10 years | The accelerator and the monomer are suspected to cause the loosening of the implant Stick the mobile components of the prosthesis | [48,49,50,51,52] |

| Polytetrafluoroethylene [PTFE] | - thermally stable | - very high wear rates | [20,32,53,54,55] |

| - hydrophobic | |||

| Ultra-high molecular weight polyethylene [UHMWPE] | - good wear resistance | - the release of polyethylene wear particles | [17,18,32,54,56,57,58,59,60,61,62,63,64,65,66] |

| - high strength | |||

| - biocompatibility | |||

| Highly cross-linked polyethylene [HXLPE] | - less release of free radicals | - compromising the mechanical properties of UHMWPE: hardness and rigidity | [20,36,37,45,54,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81] |

| - higher wear resistance | |||

| Vitamin E-blended polymers | - higher wear resistance than UHMWPE | - insufficient clinical studies | [38,39,40,54,59,82,83,84,85,86,87,88,89] |

| Polyether-ether-ketone [PEEK] | - decreases the production of wear particles | - insufficient clinical studies | [90,91,92] |

| - decreasing the stress shielding effect (in stems) | |||

| Poly 2-methacryloyloxyethyl phosphorylcholine [PMPC] | - decreases the production of wear particles and bone resorption responses | - insufficient clinical studies | [54,93] |

| Polycarbonate-urethane [PCU] | - biostability | - insufficient clinical studies | [28,54,94] |

| - hydrolysis resistance, oxidation, and calcification | |||

| - absent biodegradation | |||

| - low wear rate | |||

| - high resistance to corrosion |

| Metals | Advantages | Disadvantages | References |

|---|---|---|---|

| Stainless steel | - resistance to oxidation | - poor biocompatibility | [11,45,46,54,95,98] |

| - easy fabrication | - abrasive wear | ||

| Cobalt-chromium molybdenum [CoCrMo] alloys | - high corrosion resistance | - the particles released in the joint cause an inflammatory reaction and subsequently osteolysis | [54,83,116] |

| Titanium alloys [Ti-6Al-4 V] | - biocompatibility | - not for the femoral head - low wear resistance | [54,98,117,118,119] |

| - resistance to corrosion | |||

| - high values of mechanical strength | |||

| Zirconium alloy [Zr-2.5Nb] | - increased hardness and low roughness similar to ceramics | - insufficient clinical studies | [99,100,101,102,103,104,105,120] |

| - increased resistance to fatigue and breakage similar to metal | |||

| - the decrease in the release of particles in the joint compared to CoCrMo | |||

| Polycrystalline Diamond | - excellent hardness, extreme wear resistance, low coefficient of friction, superior toughness, and good biocompatibility, good dimensional stability and resistance to deformation and mechanical damage | - insufficient clinical studies | [111,121,122,123,124,125,126] |

| Magnesium alloy (AZ31-Si3N4 Alloy) | - excellent biocompatibility | - insufficient clinical studies | [112] |

| Ceramic | Advantages | Disadvantages | References |

|---|---|---|---|

| Alumina | - high wear resistance | - low mechanical strength with risk of breakage | [131,132,133] |

| - low coefficient of friction | - squeaking | ||

| Zirconia | - good mechanical proprieties | [54,134] | |

| - lower wear rate | |||

| - good resistance to breaking | |||

| Zirconia-toughened alumina [ZTA] | - good strength | - squeaking | [128,131,132,135,136,137] |

| - high wear resistance | |||

| Delta ceramic 82% alumina and 17% zirconia | Mid-term large cohort study of revision: - no ceramic fracture | - squeaking rate of 1.7% | [130] |

| - survival rate of 91.6% after 12 years | |||

| Sapphire | - high wear resistance | - insufficient clinical studies | [54,138] |

| - low coefficient of friction |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savin, L.; Pinteala, T.; Mihai, D.N.; Mihailescu, D.; Miu, S.S.; Sirbu, M.T.; Veliceasa, B.; Popescu, D.C.; Sirbu, P.D.; Forna, N. Updates on Biomaterials Used in Total Hip Arthroplasty (THA). Polymers 2023, 15, 3278. https://doi.org/10.3390/polym15153278

Savin L, Pinteala T, Mihai DN, Mihailescu D, Miu SS, Sirbu MT, Veliceasa B, Popescu DC, Sirbu PD, Forna N. Updates on Biomaterials Used in Total Hip Arthroplasty (THA). Polymers. 2023; 15(15):3278. https://doi.org/10.3390/polym15153278

Chicago/Turabian StyleSavin, Liliana, Tudor Pinteala, Dana Nicoleta Mihai, Dan Mihailescu, Smaranda Stefana Miu, Mihnea Theodor Sirbu, Bogdan Veliceasa, Dragos Cristian Popescu, Paul Dan Sirbu, and Norin Forna. 2023. "Updates on Biomaterials Used in Total Hip Arthroplasty (THA)" Polymers 15, no. 15: 3278. https://doi.org/10.3390/polym15153278

APA StyleSavin, L., Pinteala, T., Mihai, D. N., Mihailescu, D., Miu, S. S., Sirbu, M. T., Veliceasa, B., Popescu, D. C., Sirbu, P. D., & Forna, N. (2023). Updates on Biomaterials Used in Total Hip Arthroplasty (THA). Polymers, 15(15), 3278. https://doi.org/10.3390/polym15153278