Characterization of Thermo-Mechanical and Chemical Properties of Polypropylene/Hemp Fiber Biocomposites: Impact of Maleic Anhydride Compatibilizer and Fiber Content

Abstract

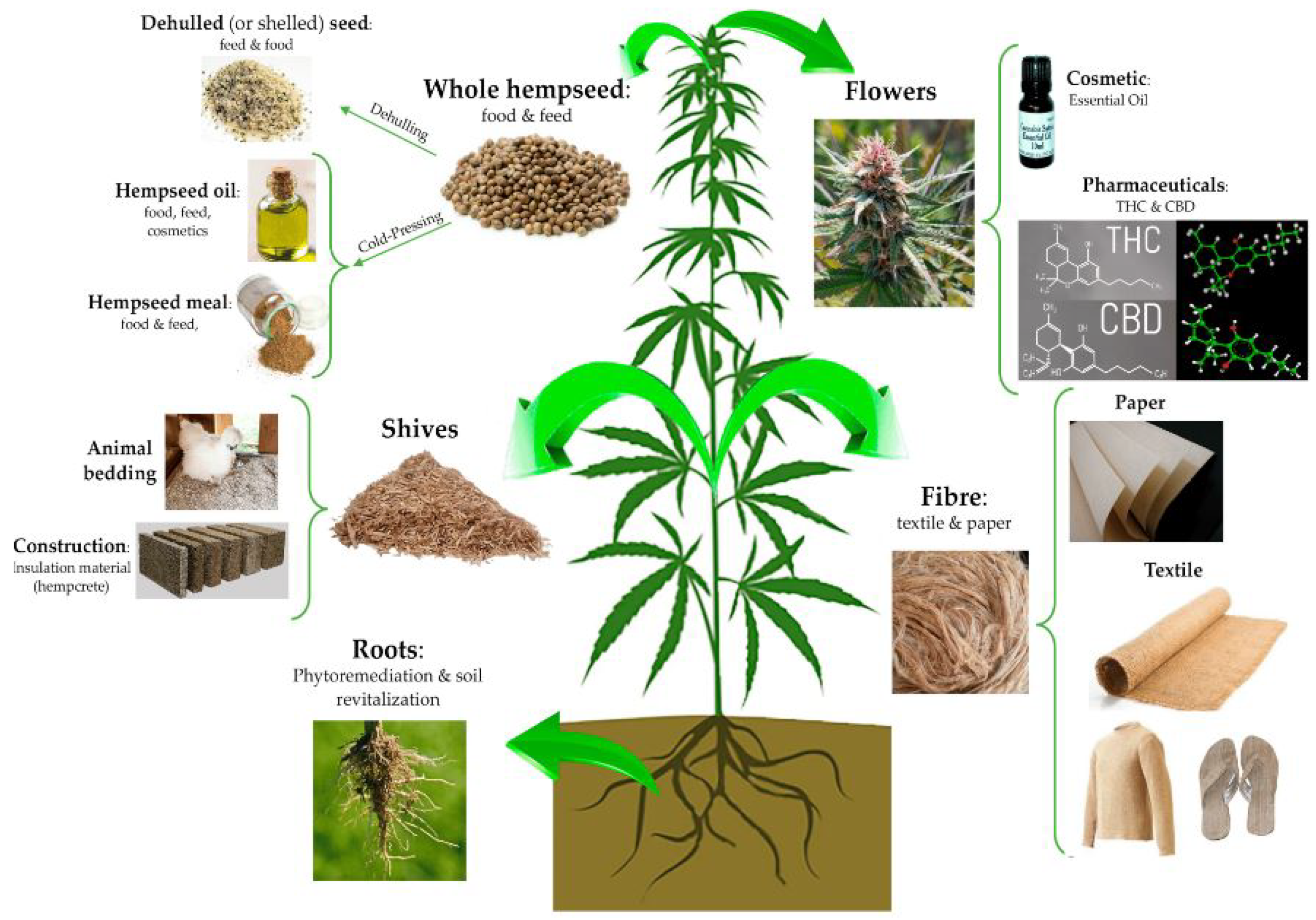

1. Introduction

2. Materials and Methods

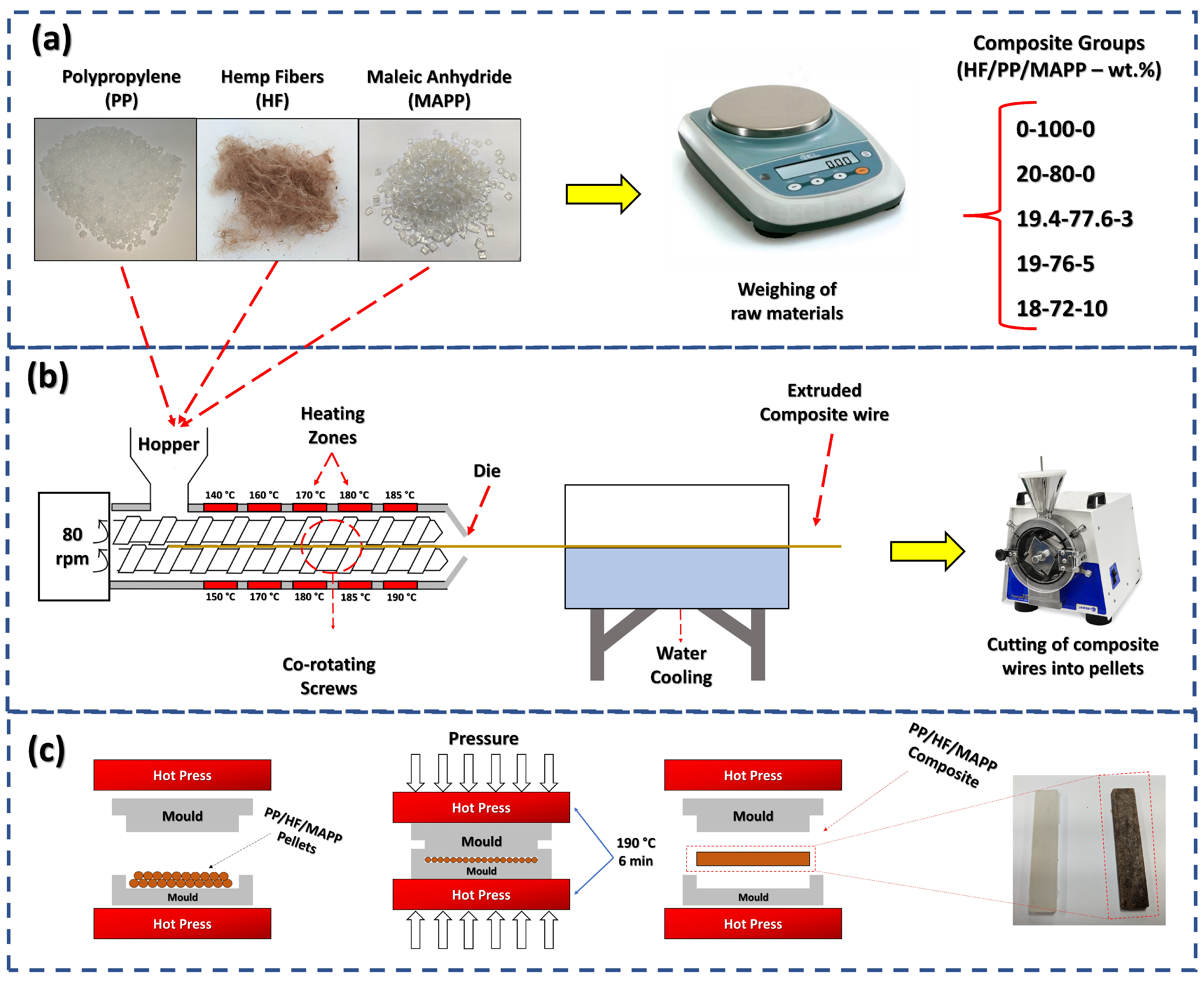

2.1. Raw Materials

2.2. Composite Processing

2.3. Characterization

2.3.1. X-ray Diffraction (XRD)

2.3.2. Fourier Transform Infrared Spectroscopy (FTIR)

2.3.3. Thermogravimetry/Derivative Thermogravimetry (TG/DTG)

2.3.4. Differential Scanning Calorimetry (DSC)

2.3.5. Shore-D Hardness

2.3.6. Izod Impact Test

2.3.7. Statistical Analysis

2.3.8. Scanning Electron Microscopy (SEM)

3. Results and Discussion

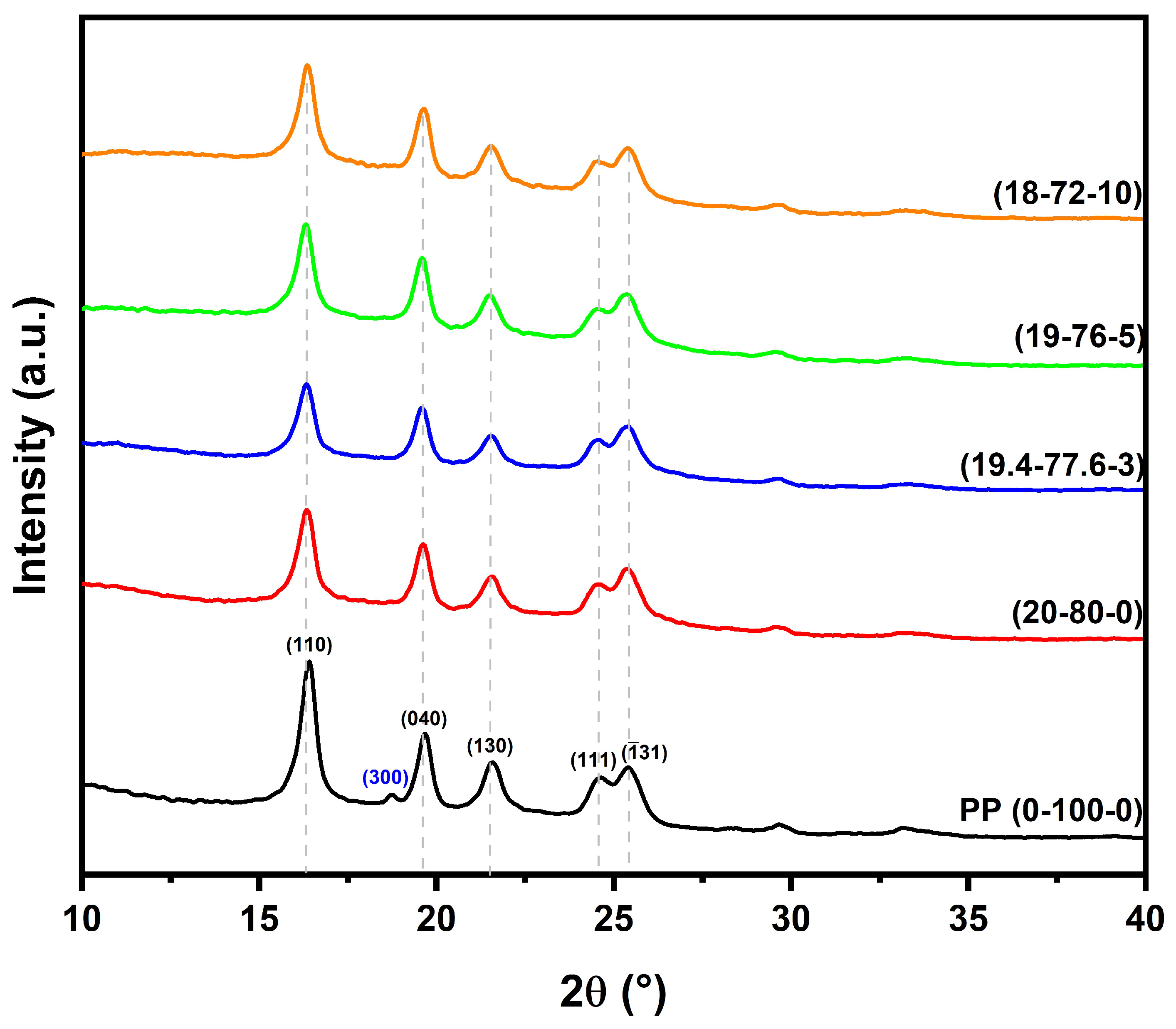

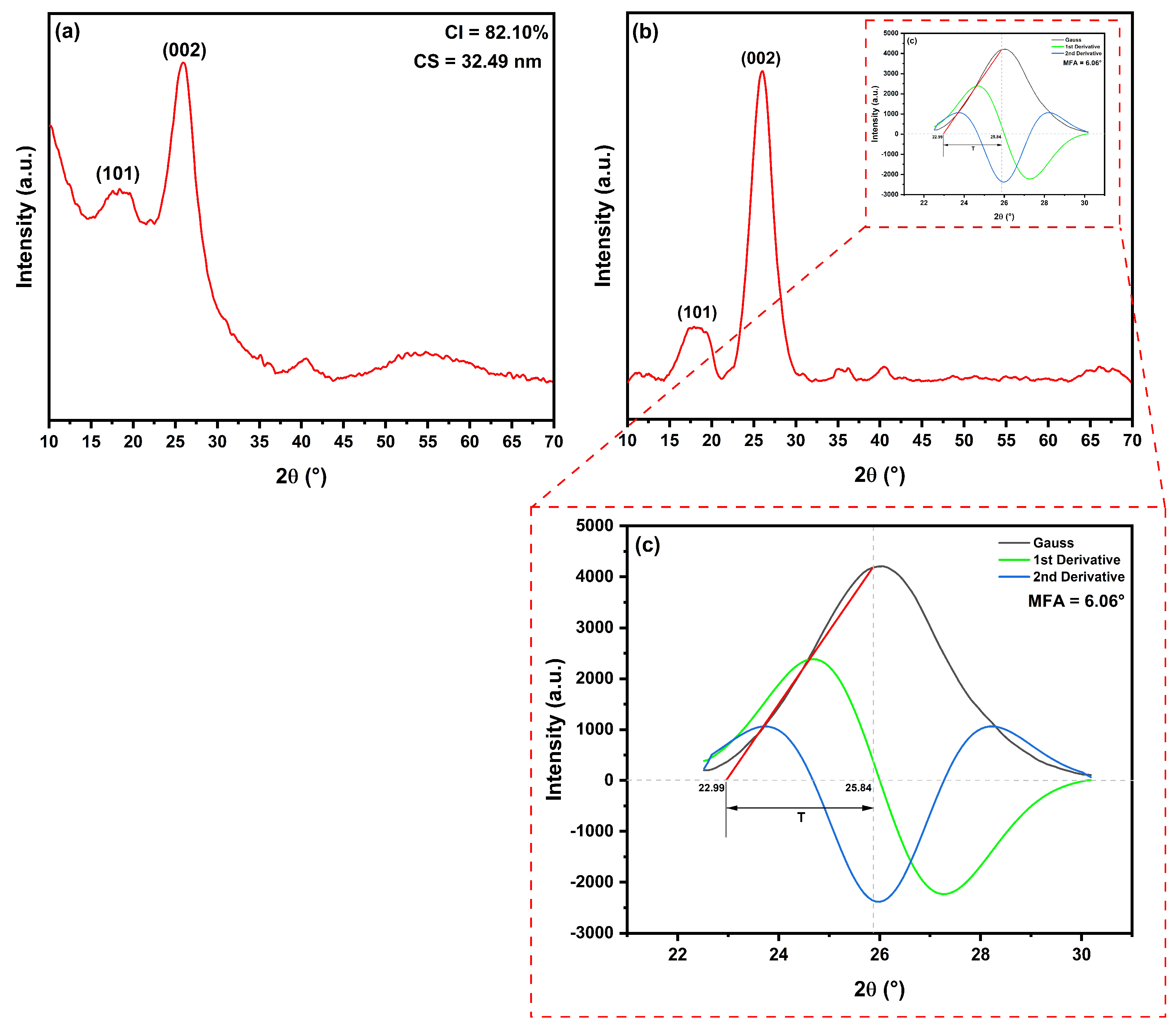

3.1. XRD Results

| Fiber | CI (%) | MFA (°) | CS (nm) |

|---|---|---|---|

| Hemp (Cannabis sativa L.) (PW*) | 82.10 | 6.06 | 32.49 |

| Seven-Islands-Sedge(Cyperus malaccensis) [58] | 62.47 | 7.36 | 2.56 |

| Carnauba (Copernicia prunifera) [74] | 86.90 | 7.48 | - |

| Ubim (Geonoma baculífera) [75] | 63–83 | 7.42 | - |

| Mendong Grass (Fimbristylis globulosa) [76] | 58.60 | 22.90 | 14.3 |

| Jack Tree Fiber [77] | 86.00 | 29.00 | 5.19 |

| Heteropogon contortus [78] | 54.10 | 14.53 | - |

| Nendran Banana Peduncle [79] | 53.30 | 9.45–13.87 | 4.72 |

| Cereus hildmannianus [80] | 40.19 | 1.38 | 28.27 |

| Aerial roots of banyan tree [81] | 72.47 | 10.88 | 6.28 |

| Prosopis juliflora bark [82] | 46.00 | 10.64 | 15.00 |

| Sida cordifolia stem [79] | 56.92 | 9.50 | 18.00 |

| Thespesia populnea [83] | 48.17 | 13.94 | 3.54 |

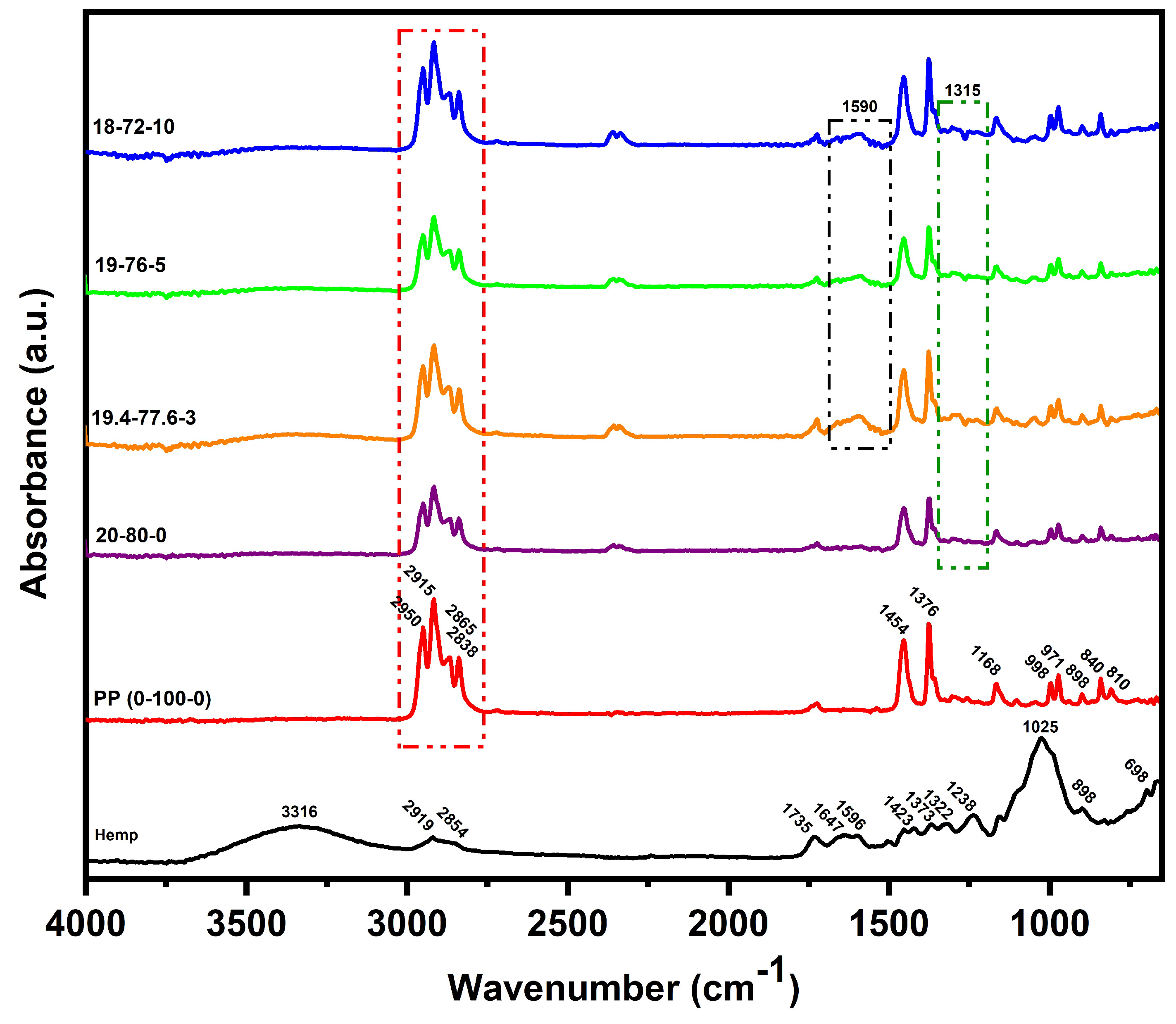

3.2. FTIR Results

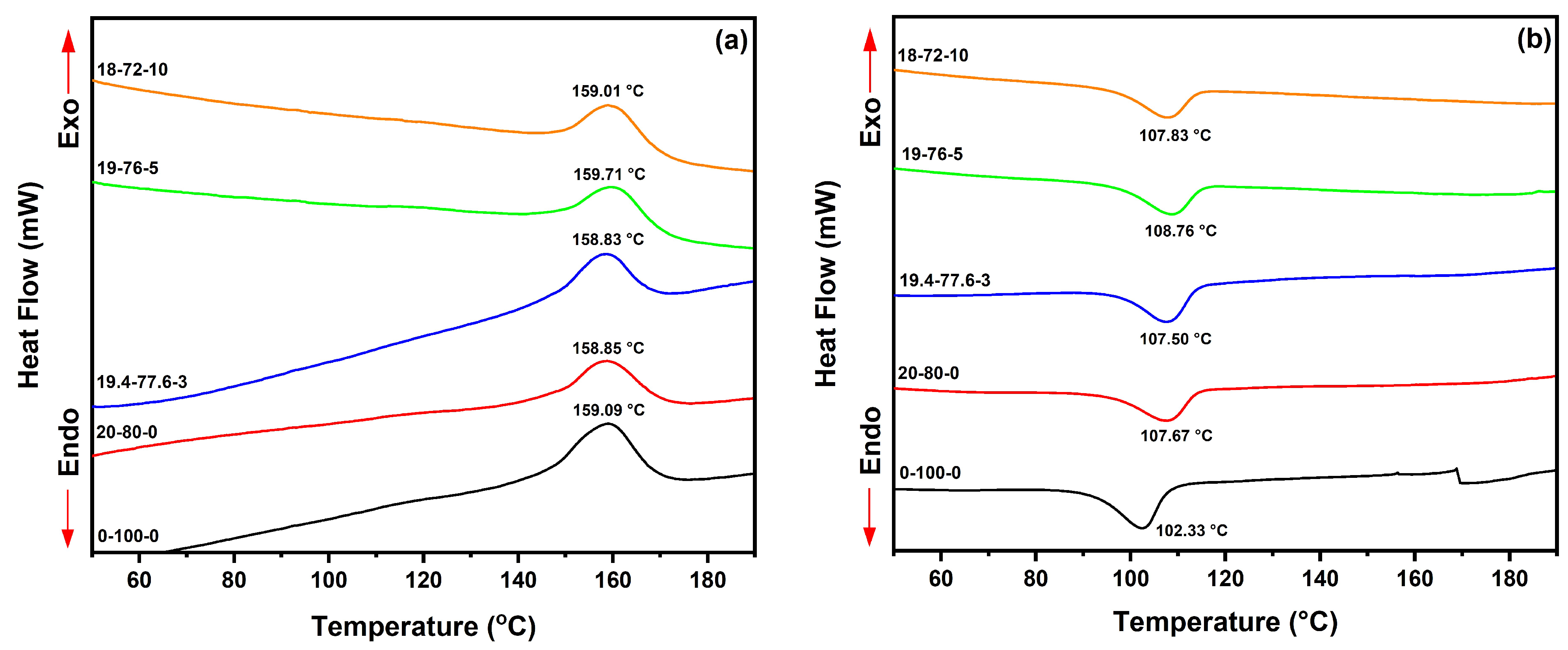

3.3. Thermal Analysis

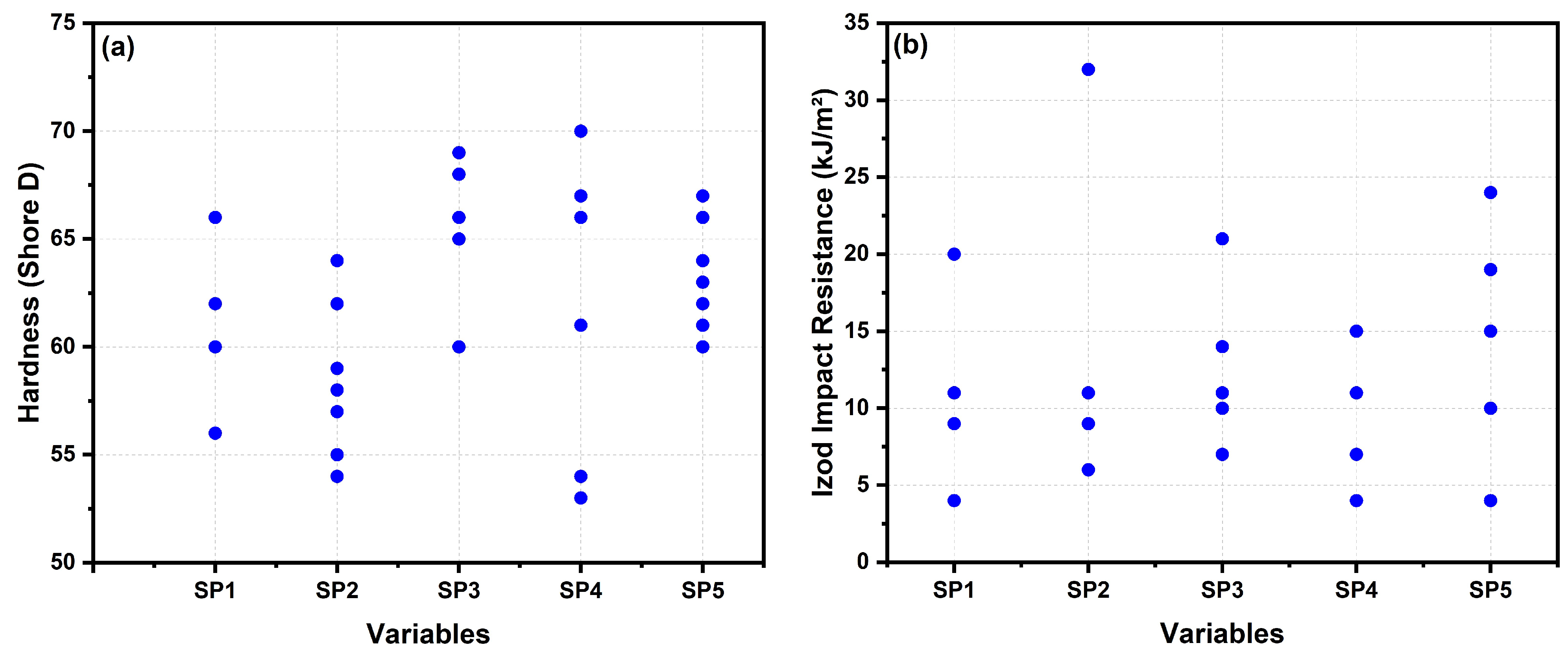

3.4. Mechanical Properties: Hardness and Impact Resistance

3.5. Statistical Analysis

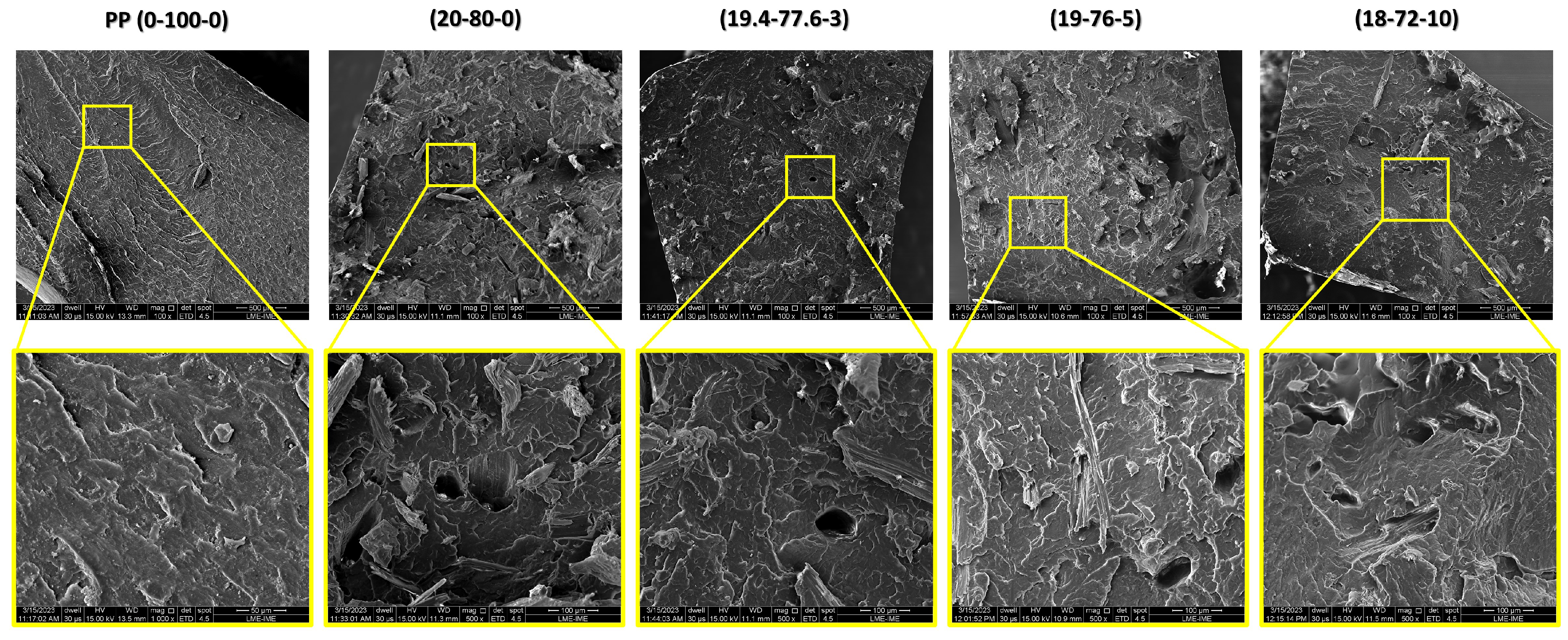

3.6. Microstructural Analysis

4. Summary and Conclusions

- XRD results indicated the presence of peaks corresponding to the beta phase in PP, which disappeared in the composites with the addition of HF and MAPP. The addition of HF and MAPP to the composites caused an increase in the average interplanar distance and crystallite size, as the hemp fiber’s crystallite size is larger than that of PP.

- HF exhibited a crystallinity index of 82.10%, significantly higher compared to other natural fibers. Moreover, the microfibril angle (MFA) of 6.06° makes the fiber an attractive material for engineering applications. The crystallite size was considered high, with a value of 32.49 nm.

- FTIR analyses revealed interactions between PP, HF, and MAPP, with noticeable peaks related to MAPP compatibilization increasing as the compatibilizer content increased.

- TGA tests demonstrated that the addition of 5 and 10 wt.% MAPP resulted in complete degradation of the composite, similar to PP. Despite the complete degradation of the composites with these MAPP concentrations, the Tonset, Tmax, and Tendset temperatures showed minimal variation, indicating similar thermal behavior of the HF-PP-MAPP composites.

- DSC analyses revealed a reduction in crystallinity (Xc) as a result of incorporating HF and MAPP. Similar to the TGA results where degradation temperatures remained mostly unchanged, DSC showed minimal variation in Tc temperatures, with the only significant variation observed from PP to the 20-80-0 composite. As for Tg, no variation occurred due to the addition of HF and MAPP.

- Shore D hardness tests indicated an increase in hardness with the addition of 5 wt.% of MAPP in the composite, but a sharp decrease in this property was observed with 10 wt.%.

- Izod impact tests showed that 3 and 5 wt.% fractions of MAPP in the composites improved impact resistance compared to composites without MAPP, while the addition of 10 wt.% MAPP critically reduced the composites’ impact strength.

- Variance analysis (ANOVA) was performed to verify the statistical reliability of the mechanical test results, subsequently indicating that the hardness test results are statistically similar, while the impact test results are statistically different.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chichane, A.; Boujmal, R.; El Barkany, A. Bio-composites and bio-hybrid composites reinforced with natural fibers. Mater. Today Proc. 2023, 72, 3471–3479. [Google Scholar] [CrossRef]

- Meliande, N.M.; Silveira, P.H.P.M.d.; Monteiro, S.N.; Nascimento, L.F.C. Tensile Properties of Curaua–Aramid Hybrid Laminated Composites for Ballistic Helmet. Polymers 2022, 14, 2588. [Google Scholar] [CrossRef]

- Patel, R.V.; Yadav, A.; Winczek, J. Physical, Mechanical, and Thermal Properties of Natural Fiber-Reinforced Epoxy Composites for Construction and Automotive Applications. Appl. Sci. 2023, 13, 5126. [Google Scholar] [CrossRef]

- Khatri, H.; Naveen, J.; Jawaid, M.; Jayakrishna, K.; Norrrahim, M.; Rashedi, A. Potential of natural fiber based polymeric composites for cleaner automotive component Production—A comprehensive review. J. Mater. Res. Technol. 2023, 25, 1086–1104. [Google Scholar]

- Hussain, M.; Levacher, D.; Leblanc, N.; Zmamou, H.; Djeran-Maigre, I.; Razakamanantsoa, A.; Saouti, L. Analysis of physical and mechanical characteristics of tropical natural fibers for their use in civil engineering applications. J. Nat. Fibers 2023, 20, 2164104. [Google Scholar]

- Abdollahiparsa, H.; Shahmirzaloo, A.; Teuffel, P.; Blok, R. A review of recent developments in structural applications of natural fiber-Reinforced composites (NFRCs). Compos. Adv. Mater. 2023, 32, 26349833221147540. [Google Scholar] [CrossRef]

- Doddamani, S.; Kulkarni, S.M.; Joladarashi, S.; TS, M.K.; Gurjar, A.K. Analysis of light weight natural fiber composites against ballistic impact: A review. Int. J. Lightweight Mater. Manuf. 2023, 6, 450–468. [Google Scholar] [CrossRef]

- Birniwa, A.H.; Abdullahi, S.S.; Ali, M.; Mohammad, R.E.A.; Jagaba, A.H.; Amran, M.; Avudaiappan, S.; Maureira-Carsalade, N.; Flores, E.I.S. Recent Trends in Treatment and Fabrication of Plant-Based Fiber-Reinforced Epoxy Composite: A Review. J. Compos. Sci. 2023, 7, 120. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Przyszczypkowski, P.; Szostak, M. Development and characterization of poly (ethylene terephthalate) based injection molded self-reinforced composites. Direct reinforcement by overmolding the composite inserts. Mater. Des. 2018, 153, 273–286. [Google Scholar]

- Ferreira, F.V.; Pinheiro, I.F.; de Souza, S.F.; Mei, L.H.; Lona, L.M. Polymer composites reinforced with natural fibers and nanocellulose in the automotive industry: A short review. J. Compos. Sci. 2019, 3, 51. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M. A review on thermomechanical properties of polymers and fibers reinforced polymer composites. J. Ind. Eng. Chem. 2018, 67, 1–11. [Google Scholar] [CrossRef]

- Mazur, K.; Jakubowska, P.; Romańska, P.; Kuciel, S. Green high density polyethylene (HDPE) reinforced with basalt fiber and agricultural fillers for technical applications. Compos. Part B Eng. 2020, 202, 108399. [Google Scholar]

- Omri, M.A.; Triki, A.; Ben Hassen, M.; Sanjay, M.R.; Arous, M.; Kallel, A. Effect of Alfa fiber mechanical separation on dielectric properties of hybrid unsaturated polyester composites. Polym. Compos. 2019, 40, 1774–1785. [Google Scholar]

- Srikavi, A.; Mekala, M. Characterization of Sunn hemp fibers as a substitute for synthetic fibers in composites and various applications. Ind. Crop. Prod. 2023, 192, 116135. [Google Scholar] [CrossRef]

- Fernandes, R.A.P.; Silveira, P.H.P.M.d.; Bastos, B.C.; Pereira, P.S.d.C.; Melo, V.A.d.; Monteiro, S.N.; Tapanes, N.d.L.C.O.; Bastos, D.C. Bio-Based Composites for Light Automotive Parts: Statistical Analysis of Mechanical Properties; Effect of Matrix and Alkali Treatment in Sisal Fibers. Polymers 2022, 14, 3566. [Google Scholar] [PubMed]

- Ariawan, D.; Akbar, H. Adhesion Energy and Roughness Observation on Alkali Treated Natural Fiber as Composites Reinforcement. In Proceedings of the Conference on Broad Exposure to Science and Technology 2021 (BEST 2021); Atlantis Press: Dordrecht, The Netherlands, 2022; pp. 464–469. [Google Scholar]

- Elaissi, A.; Alibi, H.; Ghith, A.; Legrand, X. The impact of chemical treatment of cellulosic fibers on surface properties and matrix/reinforcement interfacial adhesion. J. Nat. Fibers 2022, 19, 11560–11573. [Google Scholar] [CrossRef]

- Baiardo, M.; Zini, E.; Scandola, M. Flax fibre–polyester composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 703–710. [Google Scholar] [CrossRef]

- Gassan, J.; Bledzki, A.K. The influence of fiber-surface treatment on the mechanical properties of jute-polypropylene composites. Compos. Part A Appl. Sci. Manuf. 1997, 28, 1001–1005. [Google Scholar]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar]

- Plackett, D.; Andersen, T.L.; Pedersen, W.B.; Nielsen, L. Biodegradable composites based on L-polylactide and jute fibres. Compos. Sci. Technol. 2003, 63, 1287–1296. [Google Scholar] [CrossRef]

- Tserki, V.; Zafeiropoulos, N.; Simon, F.; Panayiotou, C. A study of the effect of acetylation and propionylation surface treatments on natural fibres. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1110–1118. [Google Scholar] [CrossRef]

- Li, Y.; Mai, Y.W.; Ye, L. Effects of fibre surface treatment on fracture-mechanical properties of sisal-fibre composites. Compos. Interfaces 2005, 12, 141–163. [Google Scholar] [CrossRef]

- Park, J.M.; Quang, S.T.; Hwang, B.S.; DeVries, K.L. Interfacial evaluation of modified Jute and Hemp fibers/polypropylene (PP)-maleic anhydride polypropylene copolymers (PP-MAPP) composites using micromechanical technique and nondestructive acoustic emission. Compos. Sci. Technol. 2006, 66, 2686–2699. [Google Scholar] [CrossRef]

- Arman Alim, A.A.; Baharum, A.; Mohammad Shirajuddin, S.S.; Anuar, F.H. Blending of Low-Density Polyethylene and Poly (Butylene Succinate)(LDPE/PBS) with Polyethylene–Graft–Maleic Anhydride (PE–g–MA) as a Compatibilizer on the Phase Morphology, Mechanical and Thermal Properties. Polymers 2023, 15, 261. [Google Scholar] [CrossRef]

- Turriziani, B.B.; Perez, M.Â.F.; Kiyataka, P.H.M.; Vieira, R.P.; Marangoni Júnior, L.; Alves, R.M.V. Effect of maleic anhydride-based compatibilizer incorporation on the properties of multilayer packaging films for meat products. J. Polym. Res. 2023, 30, 194. [Google Scholar]

- Keener, T.; Stuart, R.; Brown, T. Maleated coupling agents for natural fibre composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 357–362. [Google Scholar] [CrossRef]

- Sanadi, A.R.; Stelte, W. Effect of the Characteristics of Maleic Anhydride-Grafted Polypropylene (MAPP) Compatibilizer on the Properties of Highly Filled (85%) Kenaf-Polypropylene Composites. Mater. Res. 2023, 1–6. [Google Scholar] [CrossRef]

- Maou, S.; Meftah, Y.; Grohens, Y.; Kervoelen, A.; Magueresse, A. The effects of surface modified date-palm fiber fillers upon the thermo-physical performances of high density polyethylene-polyvinyl chloride blend with maleic anhydride as a grafting agent. J. Appl. Polym. Sci. 2023, 140, e53781. [Google Scholar] [CrossRef]

- Hammami, D.; Khlif, M.; Tounsi, F.; Bradai, C. Effect of maleic anhydride–grafted polypropylene coupling agent on mechanical properties of HDPE composites filled with grape leaves fiber. Biomass Convers. Biorefinery 2023, 1–13. [Google Scholar] [CrossRef]

- Venkatachalaiah, M.A.; Vasudeva Setty, R.N.; Johns, J. Effect of Compatibilizer on the Properties of Areca-Fiber Reinforced Polypropylene Composites. J. Nat. Fibers 2022, 19, 15261–15275. [Google Scholar] [CrossRef]

- Citti, C.; Linciano, P.; Panseri, S.; Vezzalini, F.; Forni, F.; Vandelli, M.A.; Cannazza, G. Cannabinoid profiling of hemp seed oil by liquid chromatography coupled to high-resolution mass spectrometry. Front. Plant Sci. 2019, 10, 120. [Google Scholar] [CrossRef]

- Christinat, N.; Savoy, M.C.; Mottier, P. Development, validation and application of a LC-MS/MS method for quantification of 15 cannabinoids in food. Food Chem. 2020, 318, 126469. [Google Scholar] [CrossRef] [PubMed]

- Fellermeier, M.; Zenk, M.H. Prenylation of olivetolate by a hemp transferase yields cannabigerolic acid, the precursor of tetrahydrocannabinol. FEBS Lett. 1998, 427, 283–285. [Google Scholar] [CrossRef] [PubMed]

- Panthapulakkal, S.; Sain, M. Injection-molded short hemp fiber/glass fiber-reinforced polypropylene hybrid composites—Mechanical, water absorption and thermal properties. J. Appl. Polym. Sci. 2007, 103, 2432–2441. [Google Scholar] [CrossRef]

- Gallos, A.; Lannoy, O.; Bellayer, S.; Fontaine, G.; Bourbigot, S.; Allais, F. Fire testing and mechanical properties of neat and elastomeric polylactic acid composites reinforced with raw and enzymatically treated hemp fibers. Green Chem. Lett. Rev. 2023, 16, 2164472. [Google Scholar] [CrossRef]

- Natrayan, L.; Bhaskar, A.; Patil, P.P.; Kaliappan, S.; Dineshkumar, M.; Esakkiraj, E. Optimization of filler content and size on mechanical performance of graphene/hemp/epoxy-based hybrid composites using taguchi with ANN technique. J. Nanomater. 2023, 2023, 8235077. [Google Scholar] [CrossRef]

- Small, E.; Pocock, T.; Cavers, P. The biology of Canadian weeds. 119. Cannabis sativa L. Can. J. Plant Sci. 2003, 83, 217–237. [Google Scholar] [CrossRef]

- Sen, T.; Reddy, H.J. Various industrial applications of hemp, kinaf, flax and ramie natural fibres. Int. J. Innov. Manag. Technol. 2011, 2, 192–198. [Google Scholar]

- Kaur, G.; Kander, R. The Sustainability of Industrial Hemp: A Literature Review of Its Economic, Environmental, and Social Sustainability. Sustainability 2023, 15, 6457. [Google Scholar] [CrossRef]

- Ribeiro, M.P.; de Mendonça Neuba, L.; da Silveira, P.H.P.M.; da Luz, F.S.; da Silva Figueiredo, A.B.H.; Monteiro, S.N.; Moreira, M.O. Mechanical, thermal and ballistic performance of epoxy composites reinforced with Cannabis sativa hemp fabric. J. Mater. Res. Technol. 2021, 12, 221–233. [Google Scholar] [CrossRef]

- Laverty, K.U.; Stout, J.M.; Sullivan, M.J.; Shah, H.; Gill, N.; Holbrook, L.; Deikus, G.; Sebra, R.; Hughes, T.R.; Page, J.E.; et al. A physical and genetic map of Cannabis sativa identifies extensive rearrangements at the THC/CBD acid synthase loci. Genome Res. 2019, 29, 146–156. [Google Scholar] [CrossRef]

- Small, E. Evolution and classification of Cannabis sativa (marijuana, hemp) in relation to human utilization. Bot. Rev. 2015, 81, 189–294. [Google Scholar] [CrossRef]

- Hamou, K.B.; Kaddami, H.; Elisabete, F.; Erchiqui, F. Synergistic association of wood/hemp fibers reinforcements on mechanical, physical and thermal properties of polypropylene-based hybrid composites. Ind. Crop. Prod. 2023, 192, 116052. [Google Scholar] [CrossRef]

- Lebrun, G.; Couture, A.; Laperrière, L. Tensile and impregnation behavior of unidirectional hemp/paper/epoxy and flax/paper/epoxy composites. Compos. Struct. 2013, 103, 151–160. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, H.; Lian, Z.; Tan, B.; Zheng, Y.; Erdun, E. Numerical simulation for porous hemp plastic composites sound absorption properties. J. Mater. Res. Technol. 2022, 19, 2458–2469. [Google Scholar] [CrossRef]

- Farinon, B.; Molinari, R.; Costantini, L.; Merendino, N. The seed of industrial hemp (Cannabis sativa L.): Nutritional quality and potential functionality for human health and nutrition. Nutrients 2020, 12, 1935. [Google Scholar] [CrossRef]

- Sullins, T.; Pillay, S.; Komus, A.; Ning, H. Hemp fiber reinforced polypropylene composites: The effects of material treatments. Compos. Part B Eng. 2017, 114, 15–22. [Google Scholar] [CrossRef]

- Merotte, J.; Le Duigou, A.; Kervoelen, A.; Bourmaud, A.; Behlouli, K.; Sire, O.; Baley, C. Flax and hemp nonwoven composites: The contribution of interfacial bonding to improving tensile properties. Polym. Test. 2018, 66, 303–311. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Vuluga, Z.; Frone, A.N.; Gabor, A.R.; Nicolae, C.A.; Uşurelu, C.D. Complex Effects of Hemp Fibers and Impact Modifiers in Multiphase Polypropylene Systems. Polymers 2023, 15, 409. [Google Scholar] [CrossRef]

- Talcott, S.; Uptmor, B.; McDonald, A.G. Evaluation of the Mechanical, Thermal and Rheological Properties of Hop, Hemp and Wood Fiber Plastic Composites. Materials 2023, 16, 4187. [Google Scholar] [CrossRef]

- Salehudiin, N.M.; Salim, N.; Roslan, R.; Bakar, N.H.A.; Sarmin, S.N. Improving the properties of kenaf reinforced polypropylene composite by alkaline treatment. Mater. Today Proc. 2023, 75, 156–162. [Google Scholar] [CrossRef]

- Gairola, S.; Naik, T.P.; Sinha, S.; Singh, I. Waste biomass and recycled polypropylene based jute hybrid composites for non-structural applications. J. Mater. Cycles Waste Manag. 2023, 25, 2063–2076. [Google Scholar] [CrossRef]

- Do Nascimento, E.P.; Luna, C.B.B.; Ferreira, E.d.S.B.; dos Santos Filho, E.A.; Siqueira, D.D.; Wellen, R.M.R.; Araújo, E.M. Extraction of natural fibers of Catole coconut (Syagrus cearensis): Application as reinforcing filler in polypropylene-based composites. Polym. Compos. 2023. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A., Jr.; Conrad, C. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Cave, I. Theory of X-ray measurement of microfibril angle in wood: Part 1. The condition for reflection X-ray diffraction by materials with fibre type symmetry. Wood Sci. Technol. 1997, 31, 143–152. [Google Scholar] [CrossRef]

- Cave, I. Theory of X-ray measurement of microfibril angle in wood: Part 2. The diffraction diagram X-ray diffraction by materials with fibre type symmetry. Wood Sci. Technol. 1997, 31, 225–234. [Google Scholar] [CrossRef]

- Neuba, L.d.M.; Junio, R.F.P.; Souza, A.T.; Ribeiro, M.P.; da Silveira, P.H.P.M.; da Silva, T.T.; Pereira, A.C.; Monteiro, S.N. Mechanical properties, critical length, and interfacial strength of seven-islands-sedge fibers (Cyperus malaccensis) for possible epoxy matrix reinforcement. Polymers 2022, 14, 3807. [Google Scholar] [CrossRef] [PubMed]

- Scherrer, P. Bestimmung der inneren Struktur und der Größe von Kolloidteilchen mittels Röntgenstrahlen; Springer: Berlin/Heidelberg, Germany, 1918; pp. 387–409. [Google Scholar]

- Tamanna, T.A.; Belal, S.A.; Shibly, M.A.H.; Khan, A.N. Characterization of a new natural fiber extracted from Corypha taliera fruit. Sci. Rep. 2021, 11, 7622. [Google Scholar] [CrossRef]

- Raju, J.S.N.; Depoures, M.V.; Kumaran, P. Comprehensive characterization of raw and alkali (NaOH) treated natural fibers from Symphirema involucratum stem. Int. J. Biol. Macromol. 2021, 186, 886–896. [Google Scholar] [CrossRef]

- Raju, J.S.N.; Depoures, M.V.; Shariff, J.; Chakravarthy, S. Characterization of natural cellulosic fibers from stem of Symphirema involucratum plant. J. Nat. Fibers 2022, 19, 5355–5370. [Google Scholar] [CrossRef]

- Burgada, F.; Fages, E.; Quiles-Carrillo, L.; Lascano, D.; Ivorra-Martinez, J.; Arrieta, M.P.; Fenollar, O. Upgrading recycled polypropylene from textile wastes in wood plastic composites with short hemp fiber. Polymers 2021, 13, 1248. [Google Scholar] [CrossRef] [PubMed]

- ASTM D2240; Standard Test Method for Rubber Property—Durometer Hardness. American Society For Testing Materials: West Conshohocken, PA, USA, 2021.

- ASTM D256; Izod Notched Impact Test on Plastics. American Society For Testing Materials: West Conshohocken, PA, USA, 2018.

- Wang, L.; Sheng, J. Preparation and properties of polypropylene/org-attapulgite nanocomposites. Polymer 2005, 46, 6243–6249. [Google Scholar] [CrossRef]

- Saujanya, C.; Radhakrishnan, S. Structure development and crystallization behaviour of PP/nanoparticulate composite. Polymer 2001, 42, 6723–6731. [Google Scholar]

- Cho, K.; Saheb, D.; Choi, J.; Yang, H. Real time in situ X-ray diffraction studies on the melting memory effect in the crystallization of β-isotactic polypropylene. Polymer 2002, 43, 1407–1416. [Google Scholar] [CrossRef]

- Liu, M.; Guo, B.; Du, M.; Chen, F.; Jia, D. Halloysite nanotubes as a novel β-nucleating agent for isotactic polypropylene. Polymer 2009, 50, 3022–3030. [Google Scholar]

- Lu, Y.; Weng, L.; Cao, X. Biocomposites of plasticized starch reinforced with cellulose crystallites from cottonseed linter. Macromol. Biosci. 2005, 5, 1101–1107. [Google Scholar]

- Venugopal, A.; Boominathan, S.K. Physico-chemical, thermal and tensile properties of alkali-treated acacia concinna fiber. J. Nat. Fibers 2022, 19, 3093–3108. [Google Scholar] [CrossRef]

- Kathirselvam, M.; Kumaravel, A.; Arthanarieswaran, V.; Saravanakumar, S. Characterization of cellulose fibers in Thespesia populnea barks: Influence of alkali treatment. Carbohydr. Polym. 2019, 217, 178–189. [Google Scholar] [CrossRef]

- Vijay, R.; Vinod, A.; Singaravelu, D.L.; Sanjay, M.; Siengchin, S. Characterization of chemical treated and untreated natural fibers from Pennisetum orientale grass—A potential reinforcement for lightweight polymeric applications. Int. J. Lightweight Mater. Manuf. 2021, 4, 43–49. [Google Scholar]

- Junio, R.F.P.; de Mendonça Neuba, L.; Souza, A.T.; Pereira, A.C.; Nascimento, L.F.C.; Monteiro, S.N. Thermochemical and structural characterization of promising carnauba novel leaf fiber (Copernicia prunifera). J. Mater. Res. Technol. 2022, 18, 4714–4723. [Google Scholar] [CrossRef]

- Marchi, B.Z.; Oliveira, M.S.; Bezerra, W.B.A.; de Sousa, T.G.; Candido, V.S.; da Silva, A.C.R.; Monteiro, S.N. Ubim fiber (Geonoma baculífera): A less known Brazilian amazon natural fiber for engineering applications. Sustainability 2021, 14, 421. [Google Scholar] [CrossRef]

- Suryanto, H.; Marsyahyo, E.; Irawan, Y.S.; Soenoko, R. Morphology, structure, and mechanical properties of natural cellulose fiber from mendong grass (Fimbristylis globulosa). J. Nat. Fibers 2014, 11, 333–351. [Google Scholar] [CrossRef]

- Hossain, S.; Jalil, M.A.; Islam, T.; Rahman, M.M. A low-density cellulose rich new natural fiber extracted from the bark of jack tree branches and its characterizations. Heliyon 2022, 8, e11667. [Google Scholar] [CrossRef]

- Hyness, N.R.J.; Vignesh, N.; Senthamaraikannan, P.; Saravanakumar, S.; Sanjay, M. Characterization of new natural cellulosic fiber from heteropogon contortus plant. J. Nat. Fibers 2018, 15, 146–153. [Google Scholar]

- Manimaran, P.; Prithiviraj, M.; Saravanakumar, S.; Arthanarieswaran, V.; Senthamaraikannan, P. Physicochemical, tensile, and thermal characterization of new natural cellulosic fibers from the stems of Sida cordifolia. J. Nat. Fibers 2018, 15, 860–869. [Google Scholar] [CrossRef]

- Subramanian, S.G.; Rajkumar, R.; Ramkumar, T. Characterization of natural cellulosic fiber from Cereus hildmannianus. J. Nat. Fibers 2021, 18, 343–354. [Google Scholar] [CrossRef]

- Ganapathy, T.; Sathiskumar, R.; Senthamaraikannan, P.; Saravanakumar, S.; Khan, A. Characterization of raw and alkali treated new natural cellulosic fibres extracted from the aerial roots of banyan tree. Int. J. Biol. Macromol. 2019, 138, 573–581. [Google Scholar] [CrossRef]

- Saravanakumar, S.; Kumaravel, A.; Nagarajan, T.; Sudhakar, P.; Baskaran, R. Characterization of a novel natural cellulosic fiber from Prosopis juliflora bark. Carbohydr. Polym. 2013, 92, 1928–1933. [Google Scholar] [CrossRef] [PubMed]

- Kathirselvam, M.; Kumaravel, A.; Arthanarieswaran, V.; Saravanakumar, S. Isolation and characterization of cellulose fibers from Thespesia populnea barks: A study on physicochemical and structural properties. Int. J. Biol. Macromol. 2019, 129, 396–406. [Google Scholar] [CrossRef] [PubMed]

- Donaldson, L. Microfibril angle: Measurement, variation and relationships—A review. Iawa J. 2008, 29, 345–386. [Google Scholar] [CrossRef]

- Gümüskaya, E.; Usta, M.; Kirci, H. The effects of various pulping conditions on crystalline structure of cellulose in cotton linters. Polym. Degrad. Stab. 2003, 81, 559–564. [Google Scholar] [CrossRef]

- Kim, U.J.; Eom, S.H.; Wada, M. Thermal decomposition of native cellulose: Influence on crystallite size. Polym. Degrad. Stab. 2010, 95, 778–781. [Google Scholar] [CrossRef]

- Khan, A.; Vijay, R.; Singaravelu, D.L.; Sanjay, M.; Siengchin, S.; Verpoort, F.; Alamry, K.A.; Asiri, A.M. Characterization of natural fibers from Cortaderia selloana grass (pampas) as reinforcement material for the production of the composites. J. Nat. Fibers 2021, 18, 1893–1901. [Google Scholar] [CrossRef]

- Khan, A.; Vijay, R.; Singaravelu, D.L.; Sanjay, M.; Siengchin, S.; Verpoort, F.; Alamry, K.A.; Asiri, A.M. Extraction and characterization of natural fiber from Eleusine indica grass as reinforcement of sustainable fiber reinforced polymer composites. J. Nat. Fibers 2021, 18, 1742–1750. [Google Scholar] [CrossRef]

- Jain, J.; Jain, S.; Sinha, S. Characterization and thermal kinetic analysis of pineapple leaf fibers and their reinforcement in epoxy. J. Elastomers Plast. 2019, 51, 224–243. [Google Scholar] [CrossRef]

- Rodríguez-Zúñiga, A.; Rodriguez-Solis, M.; Villalobos-Barquero, V.; Vega-Baudrit, J.; Moya-Roque, R.; Berrocal-Jiménez, A.; Starbird-Pérez, R. Biopulp from pineapple leaf fiber produced by colonization with two white-rot fungi: Trametes versicolor and Pleurotus ostreatus. BioRes 2016, 11, 8756–8776. [Google Scholar]

- Dayan, A.; Habib, M.; Kaysar, M.A.; Uddin, M. Study on the Physico-Mechanical Properties of Okra Fibre at Different Harvesting Time. Saudi J. Eng. Technol 2020, 5, 304–309. [Google Scholar] [CrossRef]

- Kalia, S.; Kumar, A.; Kaith, B. Sunn hemp cellulose graft copolymers polyhydroxybutyrate composites: Morphological and mechanical studies. Adv. Mater. Lett. 2012, 2, 17–25. [Google Scholar] [CrossRef]

- Vijay, R.; James Dhilip, J.D.; Gowtham, S.; Harikrishnan, S.; Chandru, B.; Amarnath, M.; Khan, A. Characterization of natural cellulose fiber from the barks of Vachellia farnesiana. J. Nat. Fibers 2022, 19, 1343–1352. [Google Scholar] [CrossRef]

- Da Silveira, P.H.P.; Ribeiro, M.P.; Silva, T.T.; Lima, A.M.; Lemos, M.F.; Oliveira, A.G.; Nascimento, L.F.C.; Gomes, A.V.; Monteiro, S.N. Effect of Alkaline Treatment and Graphene Oxide Coating on Thermal and Chemical Properties of Hemp (Cannabis sativa L.) Fibers. J. Nat. Fibers 2022, 19, 12168–12181. [Google Scholar] [CrossRef]

- Bakshi, P.; Pappu, A.; Bharti, D.K.; Patidar, R. Accelerated weathering performance of injection moulded PP and LDPE composites reinforced with calcium rich waste resources. Polym. Degrad. Stab. 2021, 192, 109694. [Google Scholar]

- Chagas, G.N.; Barros, M.M.; Leão, A.G.d.; Tapanes, N.d.L.C.O.; Ribeiro, R.C.d.C.; Bastos, D.C. A hybrid green composite for automotive industry. Polímeros 2022, 32. [Google Scholar]

- Stelea, L.; Filip, I.; Lisa, G.; Ichim, M.; Drobotă, M.; Sava, C.; Mureșan, A. Characterisation of hemp fibres reinforced composites using thermoplastic polymers as matrices. Polymers 2022, 14, 481. [Google Scholar] [PubMed]

- Tanjung, F.A.; Kuswardani, R.A.; Idumah, C.I.; Siregar, J.P.; Karim, A. Characterization of mechanical and thermal properties of esterified lignin modified polypropylene composites filled with chitosan fibers. Polym. Polym. Compos. 2022, 30, 09673911221082482. [Google Scholar]

- Salazar-Cruz, B.A.; Chávez-Cinco, M.Y.; Morales-Cepeda, A.B.; Ramos-Galván, C.E.; Rivera-Armenta, J.L. Evaluation of thermal properties of composites prepared from pistachio shell particles treated chemically and polypropylene. Molecules 2022, 27, 426. [Google Scholar]

- Coelho, K.V.; Líbano, E.; Ramos Filho, F.; Santos, S.F.; Pereira, P.S.; Bastos, D.C. Develpoment of wood plastic composite with reduced water absorption. Int. J. Dev. Res. 2021, 11, 44547–44551. [Google Scholar]

- Joseph, P.; Joseph, K.; Thomas, S.; Pillai, C.; Prasad, V.; Groeninckx, G.; Sarkissova, M. The thermal and crystallisation studies of short sisal fibre reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2003, 34, 253–266. [Google Scholar]

| Sample (HF-PP-MAPP) | Hemp Fiber (HF—wt.%) | Polypropylene (PP—wt.%) | Maleic Anhydride (MAPP—wt.%) |

|---|---|---|---|

| 0-100-0 | 0 | 100 | 0 |

| 20-80-0 | 20 | 80 | 0 |

| 19.4-77.6-3 | 19.4 | 77.6 | 3 |

| 19-76-5 | 19 | 76 | 5 |

| 18-72-10 | 18 | 72 | 10 |

| Sample | (1 1 0) | (0 4 0) | (1 3 0) | (1 1 1) | (31) | dhkl (Å) | CS (nm) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 (°) | I(1 1 0) | 2 (°) | I(0 4 0) | 2 (°) | I(1 3 0) | 2 (°) | I(1 1 1) | 2 (°) | I(31) | |||

| 0-100-0 | 16.42 | 8941 | 19.70 | 5923 | 21.60 | 4705 | 24.51 | 4073 | 25.42 | 4504 | 4.9094 ± 0.8869 | 23.35 ± 5.37 |

| 20-80-0 | 16.38 | 6939 | 19.64 | 5495 | 21.59 | 4145 | 24.46 | 3780 | 25.36 | 4456 | 4.9496 ± 0.8916 | 25.35 ± 5.38 |

| 19.4-77.6-3 | 16.35 | 5916 | 19.60 | 4909 | 21.59 | 3733 | 24.43 | 3576 | 25.43 | 4139 | 4.9227 ± 0.8977 | 24.25 ± 3.68 |

| 19-76-5 | 16.33 | 7449 | 19.62 | 6030 | 21.51 | 4465 | 24.51 | 3902 | 25.45 | 4499 | 4.9235 ± 0.9029 | 24.75 ± 5.69 |

| 18-72-10 | 16.37 | 7880 | 19.67 | 6047 | 21.55 | 4489 | 24.47 | 3830 | 25.46 | 4392 | 4.9168 ± 0.8951 | 23.66 ± 4.06 |

| Wavenumber (cm−1) | Functional Group | Compound |

|---|---|---|

| 2919 | Stretching vibration of CH | Cellulose |

| 2854 | Stretching vibration of CH2 | Hemicellulose |

| 1735 | C=O stretching vibration | Lignin and hemicellulose |

| 1647 | C=C stretching | Alkene group |

| 1373 | CH bending | Cellulose and hemicellulose |

| 1238 | C-O stretching vibration | Hemicellulose |

| 1025 | C-O stretching vibration | Lignin |

| 698 | C-OH out-of-plane | Cellulose |

| Sample (wt.%) HF-PP-MAPP | Mass Loss | Tonset (°C) | Tmax (°C) | Tendset (°C) | ||

|---|---|---|---|---|---|---|

| At 200 °C (%) | End of Second Stage (%) | At 600 °C (%) | ||||

| 0-100-0 | 0.27 | 98.91 | 100 | 413 | 455 | 473 |

| 20-80-0 | 0.00 | 90.75 | 90.90 | 425 | 456 | 474 |

| 19.4-77.6-3 | 1.51 | 96.01 | 97.65 | 424 | 455 | 474 |

| 19-76-5 | 1.49 | 100.00 | 100 | 423 | 457 | 474 |

| 18-72-10 | 2.03 | 99.02 | 100 | 423 | 456 | 472 |

| Sample (wt.%) HF-PP-MAPP | Tc (°C) | Tm (°C) | Hm (J/g) | Xc (%) |

|---|---|---|---|---|

| 0-100-0 | 102 | 159 | 70.77 | 42.89 |

| 20-80-0 | 107 | 158 | 52.66 | 39.89 |

| 19.4-77.6-3 | 107 | 158 | 44.78 | 34.97 |

| 19-76-5 | 108 | 159 | 48.61 | 38.76 |

| 18-72-10 | 107 | 159 | 28.36 | 23.87 |

| Sample (wt.%) HF-PP-MAPP | Hardness Shore D | Impact Strength (kJ/m2) |

|---|---|---|

| 0-100-0 | 62.80 ± 3.29 | 24.32 ± 5.61 |

| 20-80-0 | 62.70 ± 2.31 | 10.77 ± 0.86 |

| 19.4-77.6-3 | 61.20 ± 3.77 | 13.79 ± 3.43 |

| 19-76-5 | 66.50 ± 2.63 | 12.21 ± 2.78 |

| 18-72-10 | 58.40 ± 3.73 | 5.51 ± 1.32 |

| Source of Variation | Degree of Freedom (DF) | Sum of Squares (SQ) | Mean Squares (MQ) | F | Significance of F |

|---|---|---|---|---|---|

| Regression | 6 | 194,315 | 32,386 | 2366 | 1.7 × 10 |

| Residue | 46 | 944 | 20 | ||

| Total | 52 | 195,260 | |||

| Term | Coeficients | Standard Error | Stat t | Value-p | |

| PP | 0.6280 | 0.0143 | 43.8293 | 0.0000 | |

| HF | 0.0000 | 0.0000 | 65,535 | 0.5 | |

| MAPP | −10.9853 | 5.5895 | −1.9654 | 0.05 | |

| PP-HF | 0.0057 | 0.0011 | 5.0461 | 0.0000 | |

| PP-MAPP | 0.1660 | 0.0777 | 2.1369 | 0.0380 | |

| HF-MAPP | 0.0000 | 0.0000 | 65,535 | 0.5 | |

| S = 4.53 | |||||

| R-sq = 99.52% | |||||

| R-sq (adj) = 92.96% | |||||

| Source of Variation | Degree of Freedom (DF) | Sum of Squares (SQ) | Mean Squares (MQ) | F | Significance of F |

|---|---|---|---|---|---|

| Regression | 5 | 3957.975 | 791.595 | 21.9522 | 4.4 |

| Residue | 20 | 901.5002 | 45.075 | ||

| Total | 25 | 4859.475 | |||

| Term | Coeficients | Standard Error | Stat t | Value-p | |

| PP | 0.1155 | 0.0300 | 3.8475 | 0.0010 | |

| HF | 0.0000 | 0.0000 | 65535 | 0.5 | |

| MAPP | 20.8182 | 11.9918 | 1.7360 | 0.05 | |

| PP-HF | 0.0035 | 0.0024 | 1.4600 | 0.1598 | |

| PP-MAPP | −0.2836 | 0.1662 | −1.7061 | 0.1035 | |

| S = 6.71 | |||||

| R-sq = 81.45% | |||||

| R-sq (adj) = 68.66% | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silveira, P.H.P.M.; Santos, M.C.C.d.; Chaves, Y.S.; Ribeiro, M.P.; Marchi, B.Z.; Monteiro, S.N.; Gomes, A.V.; Tapanes, N.d.L.C.O.; Pereira, P.S.d.C.; Bastos, D.C. Characterization of Thermo-Mechanical and Chemical Properties of Polypropylene/Hemp Fiber Biocomposites: Impact of Maleic Anhydride Compatibilizer and Fiber Content. Polymers 2023, 15, 3271. https://doi.org/10.3390/polym15153271

da Silveira PHPM, Santos MCCd, Chaves YS, Ribeiro MP, Marchi BZ, Monteiro SN, Gomes AV, Tapanes NdLCO, Pereira PSdC, Bastos DC. Characterization of Thermo-Mechanical and Chemical Properties of Polypropylene/Hemp Fiber Biocomposites: Impact of Maleic Anhydride Compatibilizer and Fiber Content. Polymers. 2023; 15(15):3271. https://doi.org/10.3390/polym15153271

Chicago/Turabian Styleda Silveira, Pedro Henrique Poubel Mendonça, Mônica Cristina Celestino dos Santos, Yago Soares Chaves, Matheus Pereira Ribeiro, Belayne Zanini Marchi, Sergio Neves Monteiro, Alaelson Vieira Gomes, Neyda de La Caridad Om Tapanes, Patricia Soares da Costa Pereira, and Daniele Cruz Bastos. 2023. "Characterization of Thermo-Mechanical and Chemical Properties of Polypropylene/Hemp Fiber Biocomposites: Impact of Maleic Anhydride Compatibilizer and Fiber Content" Polymers 15, no. 15: 3271. https://doi.org/10.3390/polym15153271

APA Styleda Silveira, P. H. P. M., Santos, M. C. C. d., Chaves, Y. S., Ribeiro, M. P., Marchi, B. Z., Monteiro, S. N., Gomes, A. V., Tapanes, N. d. L. C. O., Pereira, P. S. d. C., & Bastos, D. C. (2023). Characterization of Thermo-Mechanical and Chemical Properties of Polypropylene/Hemp Fiber Biocomposites: Impact of Maleic Anhydride Compatibilizer and Fiber Content. Polymers, 15(15), 3271. https://doi.org/10.3390/polym15153271