Multi Scale Analysis of the Retting and Process Effect on the Properties of Flax Bio-Based Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation of Bio-Based Composites

2.3. Analysis Methods of Bio-Based Materials

2.3.1. Biochemical Analysis

2.3.2. Crystallinity Index

2.3.3. Density Analysis

2.3.4. Tensile Test for Technical Flax Fibers

2.3.5. Tensile Test for Scutched Flax Band

2.3.6. Tensile Test for Bio-Based Composite Materials

2.3.7. Dynamic Mechanical Analysis

2.3.8. SEM Analysis

3. Results and Discussions

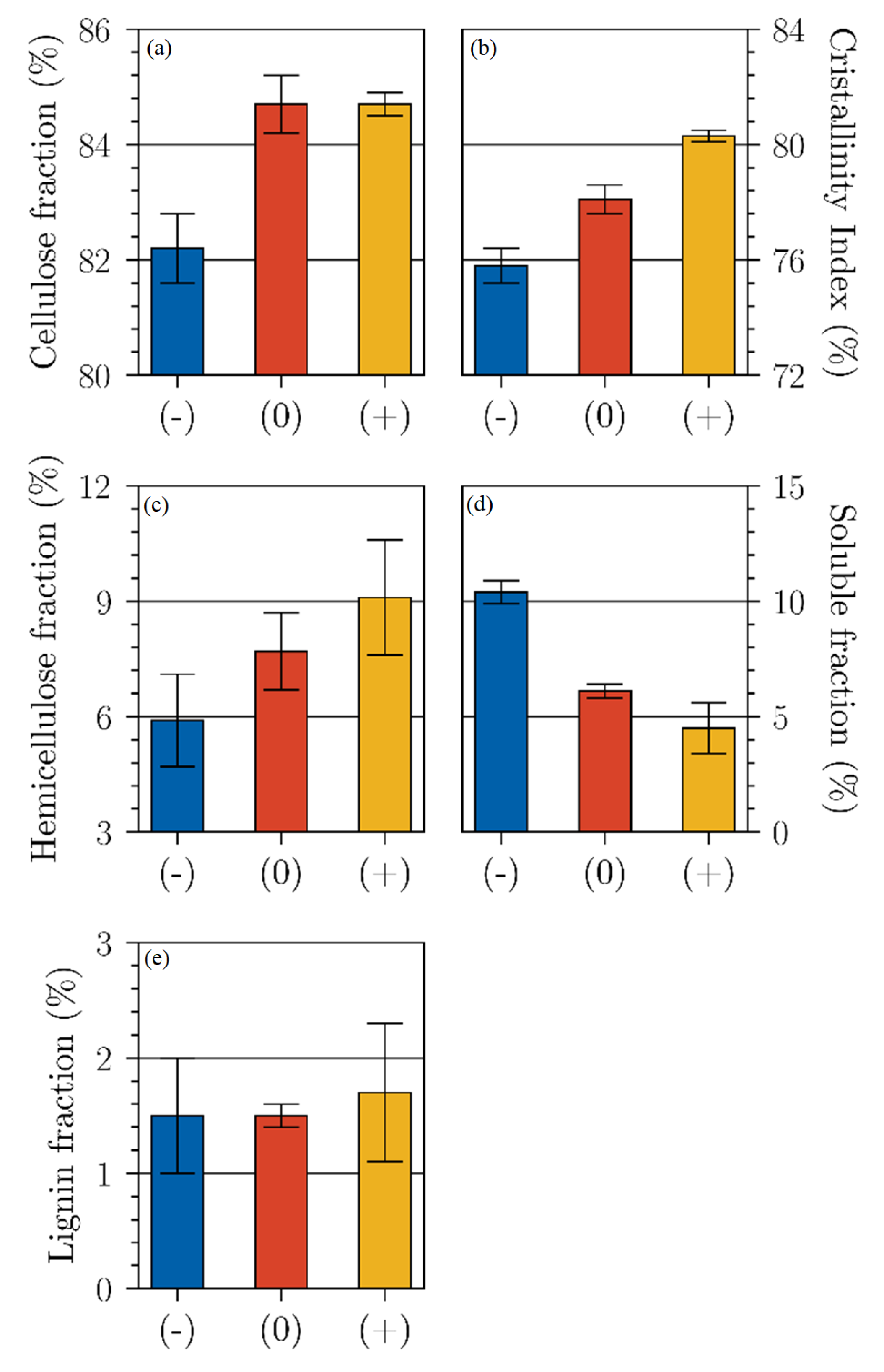

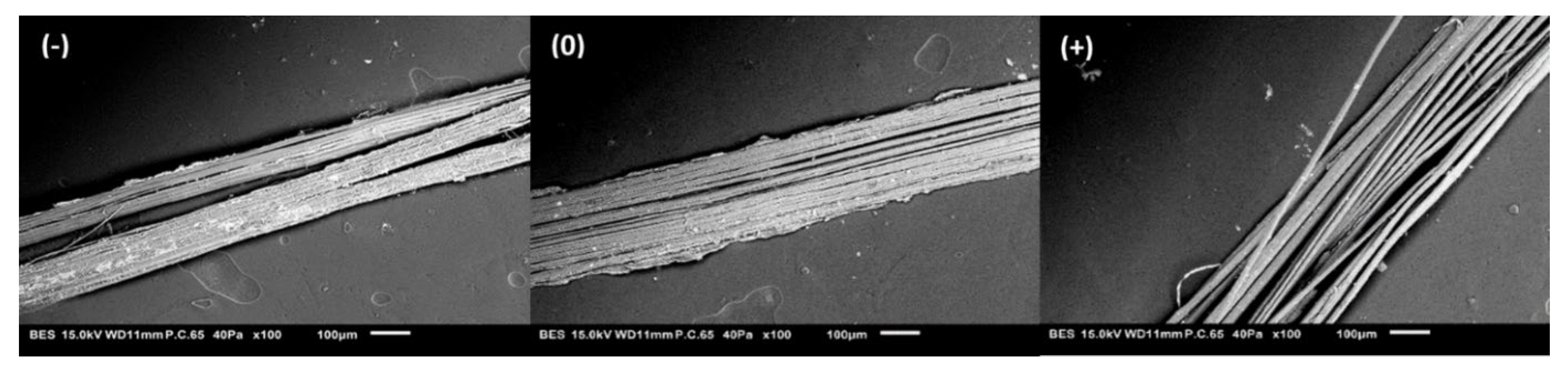

3.1. Biochemical and Microstructural Analysis of Flax Fiber

3.2. Mechanical Analysis of Flax Reinforcements

3.2.1. Technical Flax Reinforcements

- When the fiber length tends towards 0 mm, the specimen is close to huge continuous elementary fiber. Its mechanical behavior tends to that of elementary fiber.

- When the fiber length reaches 100 mm and over, its mechanical behavior is that of long technical fiber, i.e., a sum of bundles of elementary fibers mainly linked by pectins.

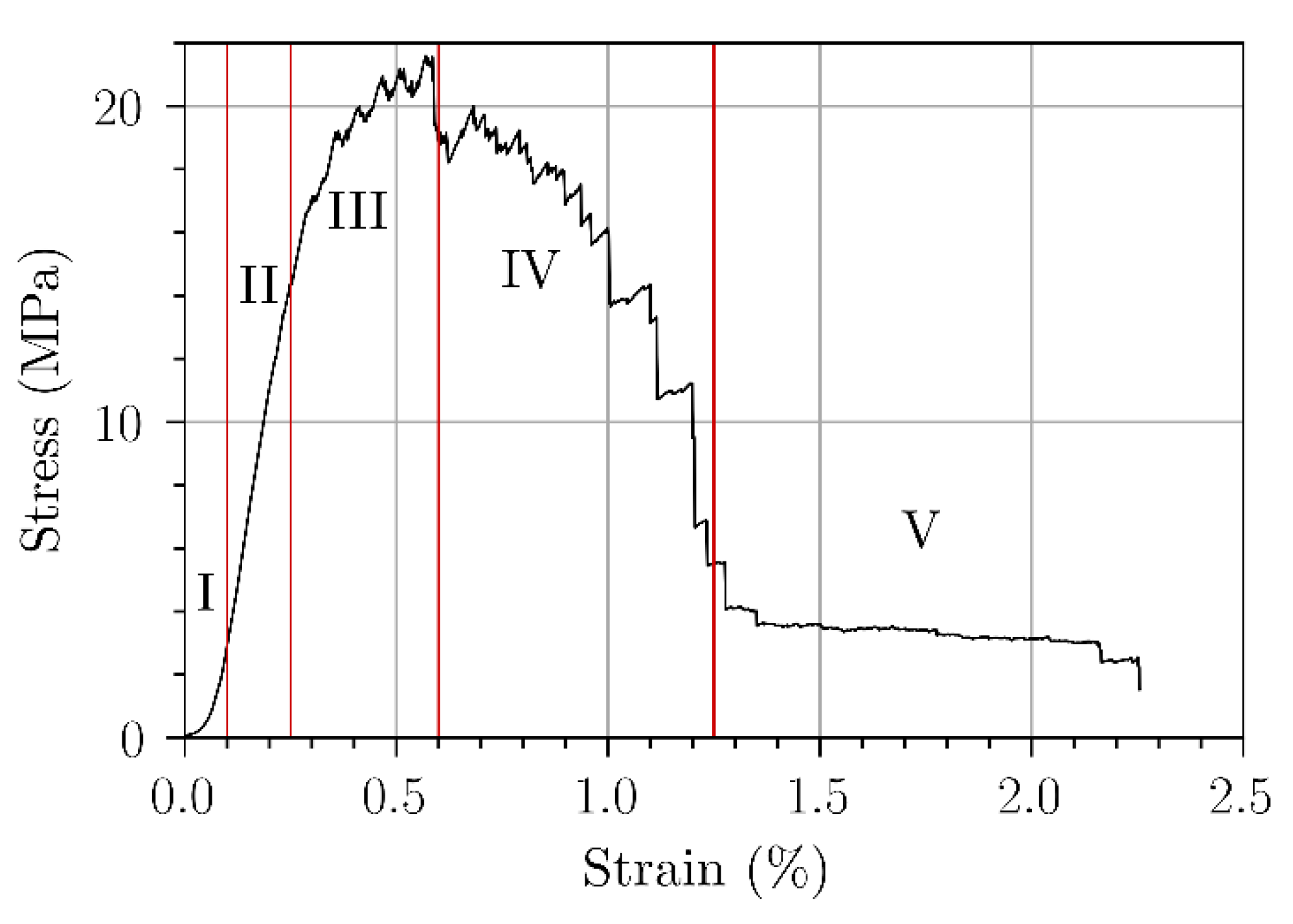

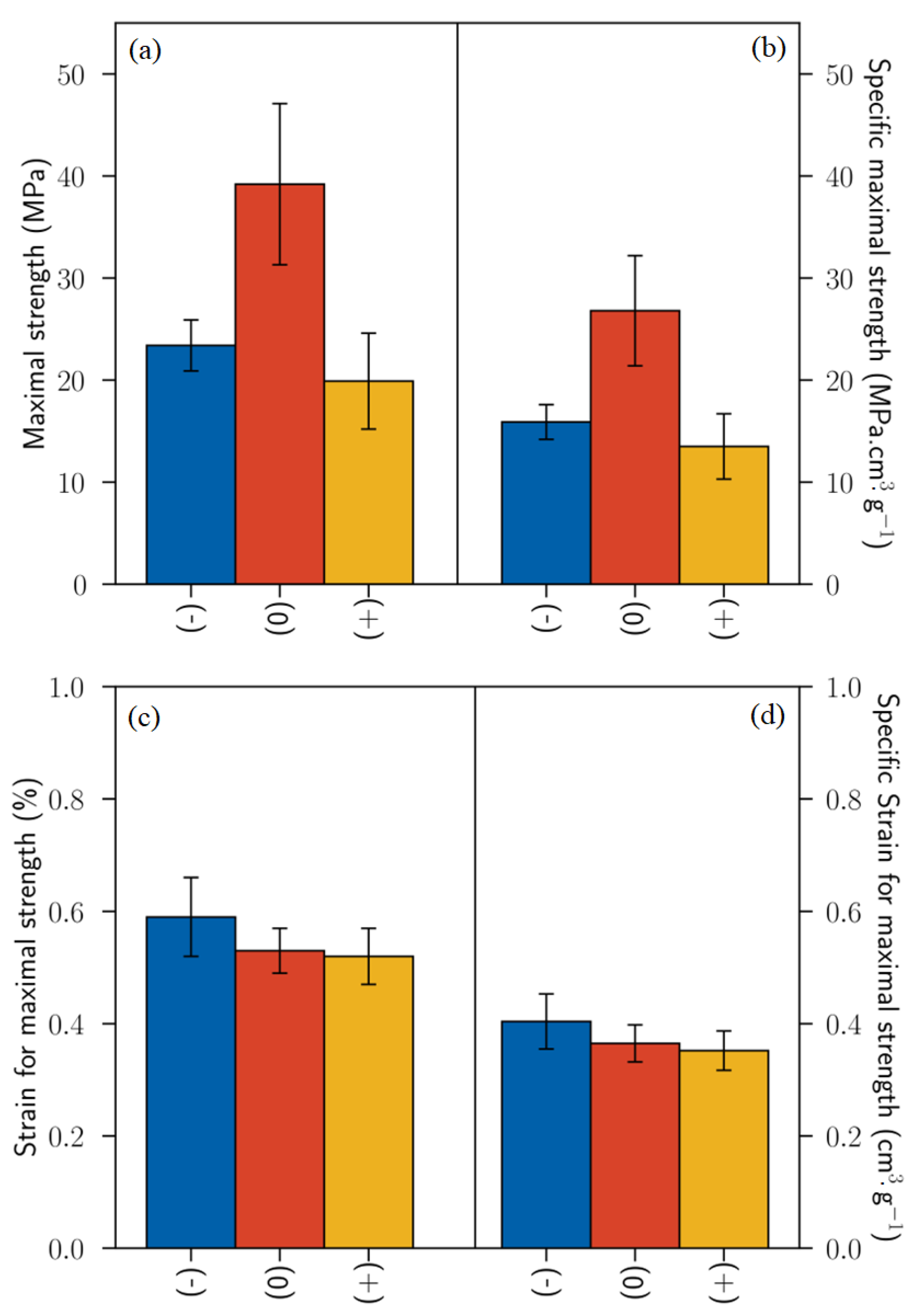

3.2.2. Flax Bands

- The 1st area (between 0 and 0.1% of elongation) consists of a non-linear stress rise corresponding to the mechanical tensioning of the flax band. The band flax fibers align themselves in the direction of the tension.

- The 2nd area (between 0.1 and 0.3% of elongation) corresponds to a quasi-linear progression of the elastic behavior.

- The 4th area is where the stress decreases due to decohesion phenomena.

- The 5th area of quasi-constant stress and a weak fibers friction.

3.2.3. Bio-Based Composites

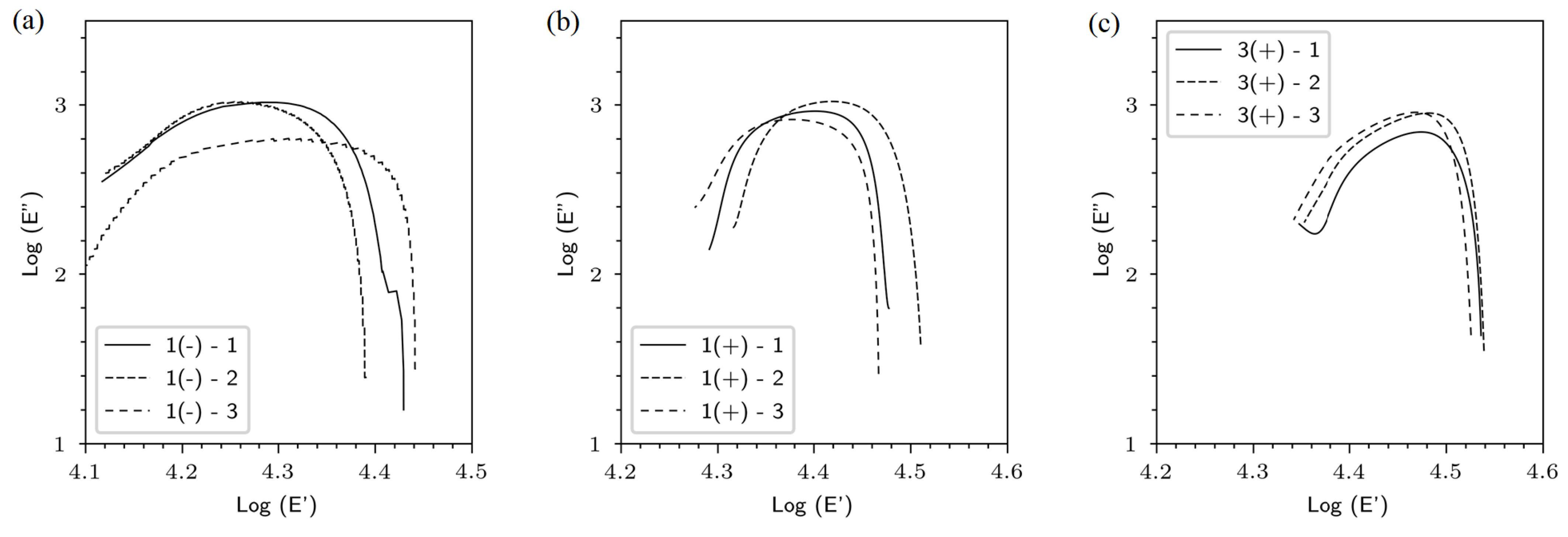

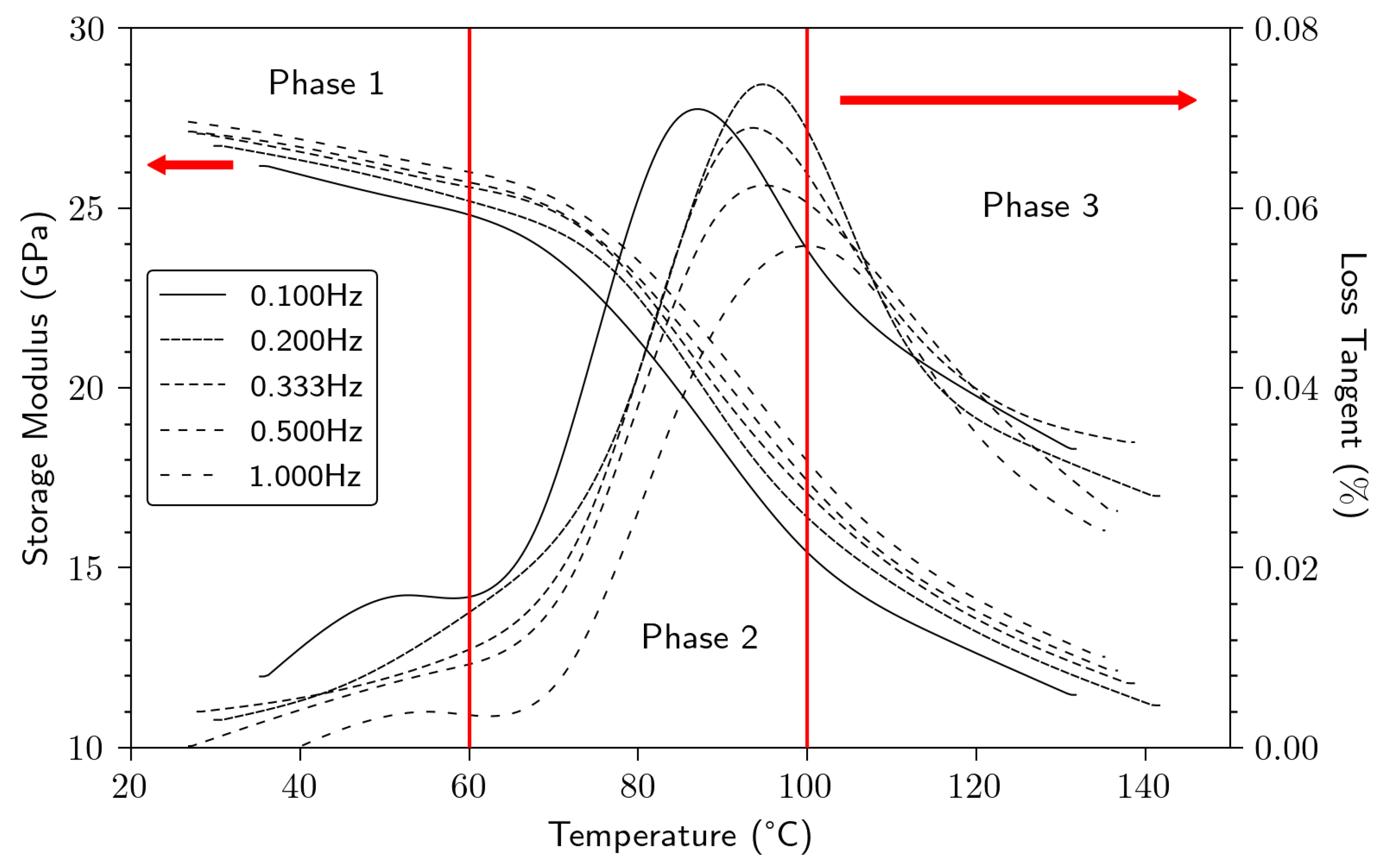

3.3. Dynamic Mechanical Analysis

- Phase 2, when 60 < T < 100 °C, was characterized by a sharp drop in the elastic behavior and a strong increase in the viscous part, attributed to a relaxation process, attributed to the glass relaxation of epoxy.

- Phase 3, when T > 100 °C, was characterized by a dominant viscous behavior (E″ > E′), a typical behavior of a thermoset composite in a rubbery state. Both moduli (E″ and E′) continued to decrease significantly.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bourmaud, A.; Shah, D.U.; Beaugrand, J.; Dhakal, H.N. Property Changes in Plant Fibres during the Processing of Bio-Based Composites. Ind. Crop. Prod. 2020, 154, 112705. [Google Scholar] [CrossRef]

- Jawaid, M.; Awad, S.; Fouad, H.; Asim, M.; Saba, N.; Dhakal, H.N. Improvements in the Thermal Behaviour of Date Palm/Bamboo Fibres Reinforced Epoxy Hybrid Composites. Compos. Struct. 2021, 277, 114644. [Google Scholar] [CrossRef]

- Mahmoud Zaghloul, M.Y.; Yousry Zaghloul, M.M.; Yousry Zaghloul, M.M. Developments in Polyester Composite Materials—An in-Depth Review on Natural Fibres and Nano Fillers. Compos. Struct. 2021, 278, 114698. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, H.; Njuguna, J.; Abhyankar, H. Recent Development of Flax Fibres and Their Reinforced Composites Based on Different Polymeric Matrices. Materials 2013, 6, 5171–5198. [Google Scholar] [CrossRef] [PubMed]

- Keryvin, V.; Lan, M.; Bourmaud, A.; Parenteau, T.; Charleux, L.; Baley, C. Analysis of Flax Fibres Viscoelastic Behaviour at Micro and Nano Scales. Compos. Part A Appl. Sci. Manuf. 2015, 68, 219–225. [Google Scholar] [CrossRef]

- De Prez, J.; Van Vuure, A.W.; Ivens, J.; Aerts, G.; Van de Voorde, I. Effect of Enzymatic Treatment of Flax on Chemical Composition and the Extent of Fiber Separation. BioResources 2019, 14, 3012–3030. [Google Scholar] [CrossRef]

- Dey, P.; Mahapatra, B.S.; Pramanick, B.; Kumar, A.; Negi, M.S.; Paul, J.; Shukla, D.K.; Singh, S.P. Quality Optimization of Flax Fibre through Durational Management of Water Retting Technology under Sub-Tropical Climate. Ind. Crop. Prod. 2021, 162, 113277. [Google Scholar] [CrossRef]

- Martin, N.; Mouret, N.; Davies, P.; Baley, C. Influence of the Degree of Retting of Flax Fibers on the Tensile Properties of Single Fibers and Short Fiber/Polypropylene Composites. Ind. Crop. Prod. 2013, 49, 755–767. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, G.; Wang, Y.; Han, B.; Wan, B.; Hao, Q.; Bai, Y. Tensile Strain and Damage Self-Sensing of Flax FRP Laminates Using Carbon Nanofiber Conductive Network Coupled with Acoustic Emission. Compos. Struct. 2022, 290, 115549. [Google Scholar] [CrossRef]

- Assarar, M.; Zouari, W.; Sabhi, H.; Ayad, R.; Berthelot, J.-M. Evaluation of the Damping of Hybrid Carbon–Flax Reinforced Composites. Compos. Struct. 2015, 132, 148–154. [Google Scholar] [CrossRef]

- Bourmaud, A.; Pinsard, L.; Guillou, E.; De Luycker, E.; Fazzini, M.; Perrin, J.; Weitkamp, T.; Ouagne, P. Elucidating the Formation of Structural Defects in Flax Fibres through Synchrotron X-ray Phase-Contrast Microtomography. Ind. Crop. Prod. 2022, 184, 115048. [Google Scholar] [CrossRef]

- Chabbert, B.; Padovani, J.; Djemiel, C.; Ossemond, J.; Lemaître, A.; Yoshinaga, A.; Hawkins, S.; Grec, S.; Beaugrand, J.; Kurek, B. Multimodal Assessment of Flax Dew Retting and Its Functional Impact on Fibers and Natural Fiber Composites. Ind. Crop. Prod. 2020, 148, 112255. [Google Scholar] [CrossRef]

- Lecoublet, M.; Khennache, M.; Leblanc, N.; Ragoubi, M.; Poilâne, C. Physico-Mechanical Performances of Flax Fiber Bio-based Composites: Retting and Process Effects. Ind. Crop. Prod. 2021, 173, 114110. [Google Scholar] [CrossRef]

- Khennache, M.; Mahieu, A.; Ragoubi, M.; Taibi, S.; Poilâne, C.; Leblanc, N. Physicochemical and Mechanical Performances of Technical Flax Fibers and Bio-based Composite Material: Effects of Flax Transformation Process. J. Mater. Res. 2019, 19, 821–838. [Google Scholar]

- Mazian, B.; Bergeret, A.; Benezet, J.-C.; Malhautier, L. Influence of Field Retting Duration on the Biochemical, Microstructural, Thermal and Mechanical Properties of Hemp Fibres Harvested at the Beginning of Flowering. Ind. Crop. Prod. 2018, 116, 170–181. [Google Scholar] [CrossRef]

- Akin, D.E.; Foulk, J.A.; Dodd, R.B. Influence on Flax Fibers of Components in Enzyme Retting Formulations. Text. Res. J. 2002, 72, 510–514. [Google Scholar] [CrossRef]

- Muneer Ahmed, M.; Dhakal, H.N.; Zhang, Z.Y.; Barouni, A.; Zahari, R. Enhancement of Impact Toughness and Damage Behaviour of Natural Fibre Reinforced Composites and Their Hybrids through Novel Improvement Techniques: A Critical Review. Compos. Struct. 2021, 259, 113496. [Google Scholar] [CrossRef]

- Malik, K.; Ahmad, F.; Gunister, E.; Nakato, T.; Mouri, E.; Muhammad, M.B.; Ali, S. A Review of Flax Fiber Reinforced Thermoset Polymer Composites: Structure and Mechanical Performance. J. Nat. Fibers 2022, 19, 9656–9680. [Google Scholar] [CrossRef]

- Malik, K.; Ahmad, F.; Yunus, N.A.; Gunister, E.; Nakato, T.; Mouri, E.; Ali, S. A Review of Flax Fiber Reinforced Thermoset Polymer Composites: Thermal-Physical Properties, Improvements and Application. J. Nat. Fibers 2022, 19, 10412–10430. [Google Scholar] [CrossRef]

- Deng, Y.; Tian, Y. Assessing the Environmental Impact of Flax Fibre Reinforced Polymer Composite from a Consequential Life Cycle Assessment Perspective. Sustainability 2015, 7, 11462–11483. [Google Scholar] [CrossRef]

- Granado, L.; Kempa, S.; Gregoriades, L.J.; Brüning, F.; Genix, A.-C.; Fréty, N.; Anglaret, E. Kinetic Regimes in the Curing Process of Epoxy-Phenol Composites. Thermochim. Acta 2018, 667, 185–192. [Google Scholar] [CrossRef]

- Boopathi, C.; Sundaram, S.K.; Jayabal, S.; Karthikeyan, S.; Scholar, P.G. Influence of Curing Temperature and Fiber Volume Fraction on the Mechanical Properties of Sisal Fiber Reinforced Polyester Composites. Int. J. Innov. Sci. Eng. Technol. 2007, 3, 14662–14667. [Google Scholar]

- Poilâne, C.; Cherif, Z.E.; Richard, F.; Vivet, A.; Ben Doudou, B.; Chen, J. Polymer Reinforced by Flax Fibres as a Viscoelastoplastic Material. Compos. Struct. 2014, 112, 100–112. [Google Scholar] [CrossRef]

- Dujardin, N.; Fois, M.; Grimau, M.; Poilâne, C. Soft Interface Dynamics in Flax-Fabrics/Epoxy Composites. Compos. Struct. 2018, 202, 389–396. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.-F. Natural Fibres as Reinforcement in Polylactic Acid (PLA) Composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Muralidhar, B.A. Study of Flax Hybrid Preforms Reinforced Epoxy Composites. Mater. Des. 2013, 52, 835–840. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Zafeiropoulos, N.E.; Baillie, C.A.; Matthews, F.L. A Study of Transcrystallinity and Its Effect on the Interface in Flax Fibre Reinforced Composite Materials. Compos. Part Appl. Sci. Manuf. 2001, 32, 525–543. [Google Scholar] [CrossRef]

- Kolasangiani, K.; Oguamanam, D.; Bougherara, H. Strain-Controlled Fatigue Life Prediction of Flax-Epoxy Laminates Using a Progressive Fatigue Damage Model. Compos. Struct. 2021, 266, 113797. [Google Scholar] [CrossRef]

- Morvan, C.; Andème-Onzighi, C.; Girault, R.; Himmelsbach, D.S.; Driouich, A.; Akin, D.E. Building Flax Fibres: More than One Brick in the Walls. Plant Physiol. Biochem. 2003, 41, 935–944. [Google Scholar] [CrossRef]

- Moothoo, J. A Study of the Tensile Behaviour of Flax Tows and Their Potential for Composite Processing. Mater. Des. 2014, 55, 672–764. [Google Scholar] [CrossRef]

- Réquilé, S.; Le Duigou, A.; Bourmaud, A.; Baley, C. Peeling Experiments for Hemp Retting Characterization Targeting Biocomposites. Ind. Crop. Prod. 2018, 123, 573–580. [Google Scholar] [CrossRef]

- Alix, S.; Lebrun, L.; Marais, S.; Philippe, E.; Bourmaud, A.; Baley, C.; Morvan, C. Pectinase Treatments on Technical Fibres of Flax: Effects on Water Sorption and Mechanical Properties. Carbohydr. Polym. 2012, 87, 177–185. [Google Scholar] [CrossRef] [PubMed]

- Khalfallah, M.; Abbès, B.; Abbès, F.; Guo, Y.Q.; Marcel, V.; Duval, A.; Vanfleteren, F.; Rousseau, F. Innovative Flax Tapes Reinforced Acrodur Biocomposites: A New Alternative for Automotive Applications. Mater. Des. 2014, 64, 116–126. [Google Scholar] [CrossRef]

- Hughes, M.; Carpenter, J.; Hill, C. Deformation and Fracture Behaviour of Flax Fibre Reinforced Thermosetting Polymer Matrix Composites. J. Mater. Sci. 2007, 42, 2499–2511. [Google Scholar] [CrossRef]

- Devi, L.U.; Bhagawan, S.S.; Thomas, S. Dynamic Mechanical Analysis of Pineapple Leaf/Glass Hybrid Fiber Reinforced Polyester Composites. Polym. Compos. 2010, 31, 956–965. [Google Scholar] [CrossRef]

- Asim, M.; Paridah, M.T.; Saba, N.; Jawaid, M.; Alothman, O.Y.; Nasir, M.; Almutairi, Z. Thermal, Physical Properties and Flammability of Silane Treated Kenaf/Pineapple Leaf Fibres Phenolic Hybrid Composites. Compos. Struct. 2018, 202, 1330–1338. [Google Scholar] [CrossRef]

- Duc, F.; Bourban, P.-E.; Månson, J.-A.E. Dynamic Mechanical Properties of Epoxy/Flax Fibre Composites. J. Reinf. Plast. Compos. 2014, 33, 1625–1633. [Google Scholar] [CrossRef]

- Qi, G.; Cui, Q.; Zhang, B.; Du, S. A Carbon Fiber Lamina Electrode Based on Macroporous Epoxy with Vertical Ion Channels for Structural Battery Composites. Compos. Struct. 2023, 304, 116425. [Google Scholar] [CrossRef]

- Lachaud, F.; Boutin, M.; Espinosa, C.; Hardy, D. Failure Prediction of a New Sandwich Panels Based on Flax Fibres Reinforced Epoxy Bio-Composites. Compos. Struct. 2021, 257, 113361. [Google Scholar] [CrossRef]

- Yang, B.; Nar, M.; Visi, D.K.; Allen, M.; Ayre, B.; Webber, C.L.; Lu, H.; D’Souza, N.A. Effects of Chemical versus Enzymatic Processing of Kenaf Fibers on Poly(Hydroxybutyrate-Co-Valerate)/Poly(Butylene Adipate-Co-Terephthalate) Composite Properties. Compos. Part B Eng. 2014, 56, 926–933. [Google Scholar] [CrossRef]

- Pillai, K.V.; Renneckar, S. Dynamic Mechanical Analysis of Layer-by-Layer Cellulose Nanocomposites. Ind. Crop. Prod. 2016, 93, 267–275. [Google Scholar] [CrossRef]

- Idicula, M.; Malhotra, S.K.; Joseph, K.; Thomas, S. Dynamic Mechanical Analysis of Randomly Oriented Intimately Mixed Short Banana/Sisal Hybrid Fibre Reinforced Polyester Composites. Compos. Sci. Technol. 2005, 65, 1077–1087. [Google Scholar] [CrossRef]

- Wu, F.; Zhou, X.; Yu, X. Reaction Mechanism, Cure Behavior and Properties of a Multifunctional Epoxy Resin, TGDDM, with Latent Curing Agent Dicyandiamide. RSC Adv. 2018, 8, 8248–8258. [Google Scholar] [CrossRef]

| Seeding | Harvesting | Winding (W) | Total Precipitation (mm) | |

|---|---|---|---|---|

| Under retted (−) | April 10th, 2017 | July 13th, 2017 | W1 = August 7th, 2017 | 17.2 |

| Nominally retted (0) | W2 = August 28th, 2017 | 66 | ||

| Over retted (+) | W3 = September 22nd, 2017 | 130 |

| Retting | t (min) | T (°C) | P (Bars) | |

|---|---|---|---|---|

| 1 | (−) | 370 | 140 | 50 |

| (0) | 370 | 140 | 50 | |

| (+) | 370 | 140 | 50 | |

| 2 | (−) | 175 | 140 | 25 |

| (0) | 175 | 140 | 25 | |

| (+) | 175 | 140 | 25 | |

| 3 | (−) | 130 | 160 | 50 |

| (0) | 130 | 160 | 50 | |

| (+) | 130 | 160 | 50 |

| Modalities | Ultimate Elastic Modulus (GPa·cm3·g−1) | Ultimate Tensile Strength (MPa·cm3·g−1) | Specific Ultimate Elastic Modulus (GPa·cm3·g−1) | Specific Ultimate Tensile Strength (MPa·cm3·g−1) | Density (g·cm−3) | Ultimate Failure Strain (%) | |

|---|---|---|---|---|---|---|---|

| Extrapolations to 0 mm length | (−) | 96.1 ± 2.6 | 927 ± 25 | 65.4 ± 1.8 | 631 ± 17 | 1.470 ± 0.04 | 0.84 |

| (0) | 85.8 ± 0.6 | 897 ± 6 | 58.4 ± 0.4 | 612 ± 4 | 1.464 ± 0.01 | 0.97 | |

| (+) | 60.1 ± 0.8 | 809 ± 11 | 41.0 ± 0.6 | 553 ± 8 | 1.463 ± 0.02 | 1.09 | |

| Extrapolations to 100 mm length | (−) | 69.9 ± 1.9 | 702 ± 18 | 47.5 ± 1.3 | 477 ± 12 | 1.470 ± 0.04 | 0.79 |

| (0) | 59.1 ± 0.4 | 513 ± 3 | 40.4 ± 0.3 | 350 ± 2 | 1.464 ± 0.01 | 0.75 | |

| (+) | 43.6 ± 0.6 | 328 ± 1 | 29.8 ± 0.4 | 224 ± 3 | 1.463 ± 0.02 | 0.69 | |

| Bio-Based Composites | E 1 (GPa) | E 2 (GPa) | σ (MPa) | ẟE (%) | Density (g·cm−3) |

|---|---|---|---|---|---|

| 1 (−) | 15 ± 1.91 | 12 ± 1.02 | 287 ± 25.3 | 20.17 ± 2.78 | 1.220 ± 0.015 |

| 1 (0) | 16 ± 0.98 | 12 ± 0.74 | 322 ± 23.1 | 23.59 ± 1.86 | 1.253 ± 0.010 |

| 1 (+) | 17 ± 0.96 | 12 ± 0.76 | 279 ± 17.9 | 27.58 ± 3.24 | 1.262 ± 0.009 |

| 2 (−) | 14 ± 0.58 | 11 ± 0.42 | 283 ± 14.5 | 22.25 ± 1.16 | 1.244 ± 0.006 |

| 2 (0) | 15 ± 1.69 | 11 ± 0.28 | 323 ± 33.9 | 21.21 ± 1.92 | 1.253 ± 0.010 |

| 2 (+) | 16 ± 1.46 | 11 ± 1.23 | 290 ± 36.1 | 27.78 ± 3.58 | 1.258 ± 0.009 |

| 3 (−) | 16 ± 0.83 | 12 ± 0.65 | 250 ± 16.2 | 25.28 ± 1.76 | 1.297 ± 0.004 |

| 3 (0) | 18 ± 0.57 | 14 ± 0.57 | 350 ± 17.4 | 23.98 ± 1.13 | 1.293 ± 0.018 |

| 3 (+) | 19 ± 0.91 | 13 ± 0.59 | 381 ± 32.1 | 31.11 ± 1.88 | 1.280 ± 0.016 |

| Bio-Based Composites | 0.1 H | 1 Hz | ||||

|---|---|---|---|---|---|---|

| E′ (40 °C) | E′ (30 °C) | Tg (Tan δ) | E′ (40 °C) | E′ (130 °C) | Tg (Tan δ) | |

| 1 (−) | 26.05 ± 0.90 | 11.53 ± 0.12 | 87.93 ± 4.47 | 26.94 ± 0.83 | 12.91 ± 0.29 | 100.60 ± 1.40 |

| 1 (0) | 26.30 ± 0.64 | 15.67 ± 0.13 | 81.93 ± 1.27 | 27.26 ± 0.67 | 17.09 ± 0.07 | 93.37 ± 3.45 |

| 1 (+) | 29.97 ± 1.61 | 18.26 ± 0.64 | 82.93 ± 5.05 | 31.71 ± 2.04 | 18.26 ± 0.64 | 82.93 ± 5.05 |

| 2 (+) | 29.04 ± 1.74 | 19.22 ± 0.20 | 86.20 ± 5.88 | 30.19 ± 1.98 | 20.60 ± 0.40 | 96.33 ± 4.57 |

| 3 (+) | 33.75 ± 0.49 | 21.33 ± 0.46 | 81.87 ± 1.51 | 34.99 ± 0.53 | 23.13 ± 0.34 | 89.37 ± 0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ragoubi, M.; Lecoublet, M.; Khennache, M.; Poilane, C.; Leblanc, N. Multi Scale Analysis of the Retting and Process Effect on the Properties of Flax Bio-Based Composites. Polymers 2023, 15, 2531. https://doi.org/10.3390/polym15112531

Ragoubi M, Lecoublet M, Khennache M, Poilane C, Leblanc N. Multi Scale Analysis of the Retting and Process Effect on the Properties of Flax Bio-Based Composites. Polymers. 2023; 15(11):2531. https://doi.org/10.3390/polym15112531

Chicago/Turabian StyleRagoubi, Mohamed, Morgan Lecoublet, Medhi Khennache, Christophe Poilane, and Nathalie Leblanc. 2023. "Multi Scale Analysis of the Retting and Process Effect on the Properties of Flax Bio-Based Composites" Polymers 15, no. 11: 2531. https://doi.org/10.3390/polym15112531

APA StyleRagoubi, M., Lecoublet, M., Khennache, M., Poilane, C., & Leblanc, N. (2023). Multi Scale Analysis of the Retting and Process Effect on the Properties of Flax Bio-Based Composites. Polymers, 15(11), 2531. https://doi.org/10.3390/polym15112531