Interactions, Structure and Properties of PLA/lignin/PBAT Hybrid Blends

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Characterization and Measurements

3. Results

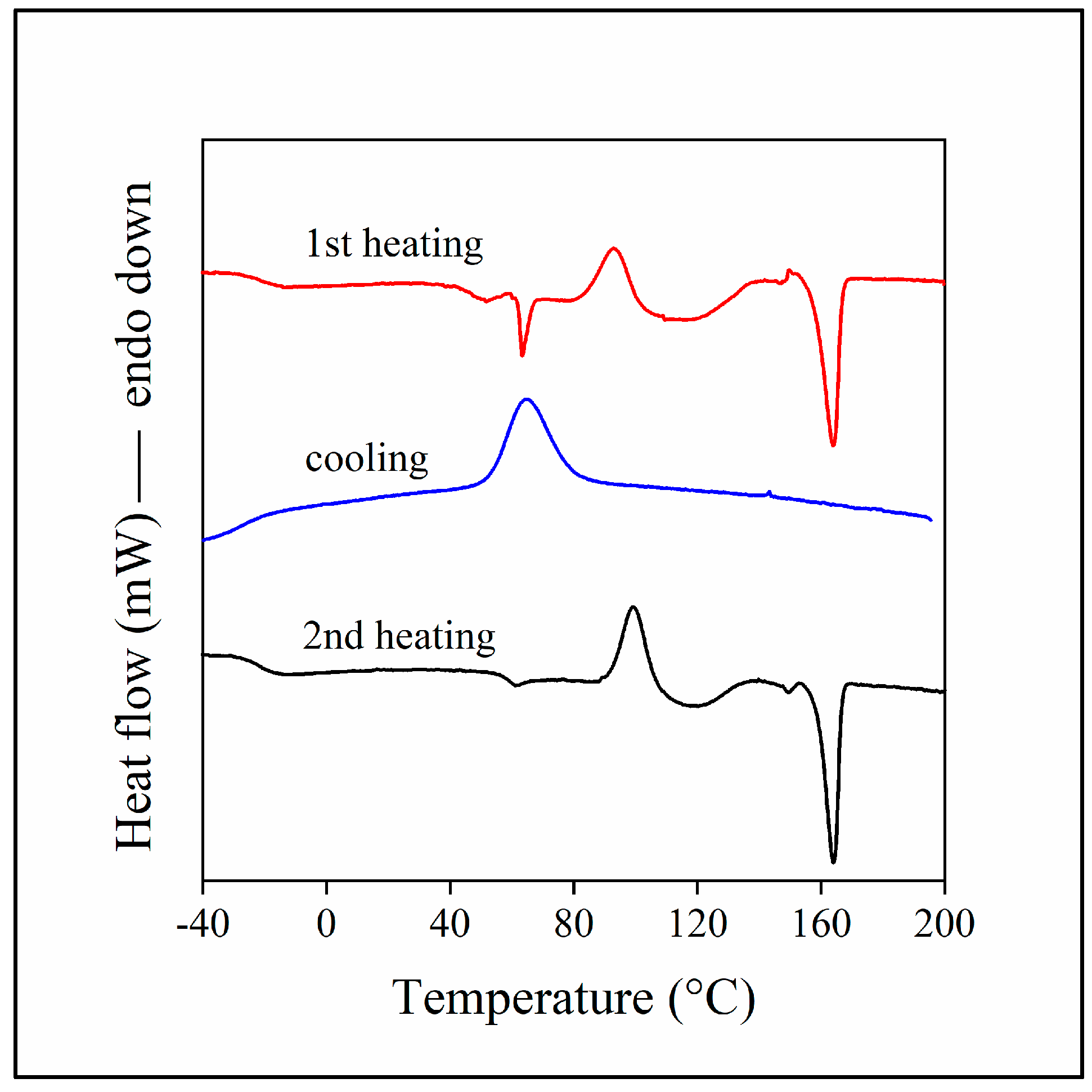

3.1. Interactions and Miscibility

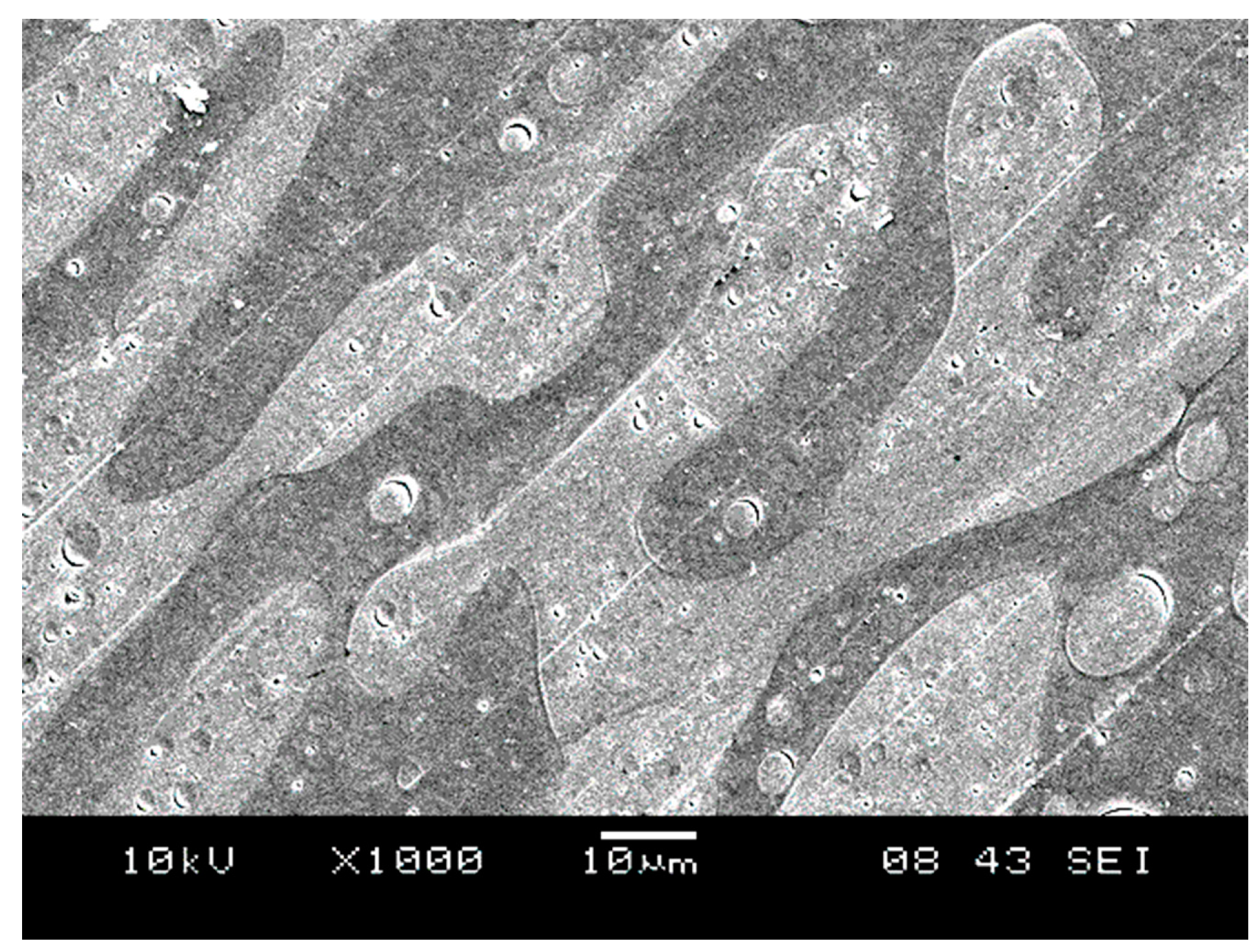

3.2. Structure

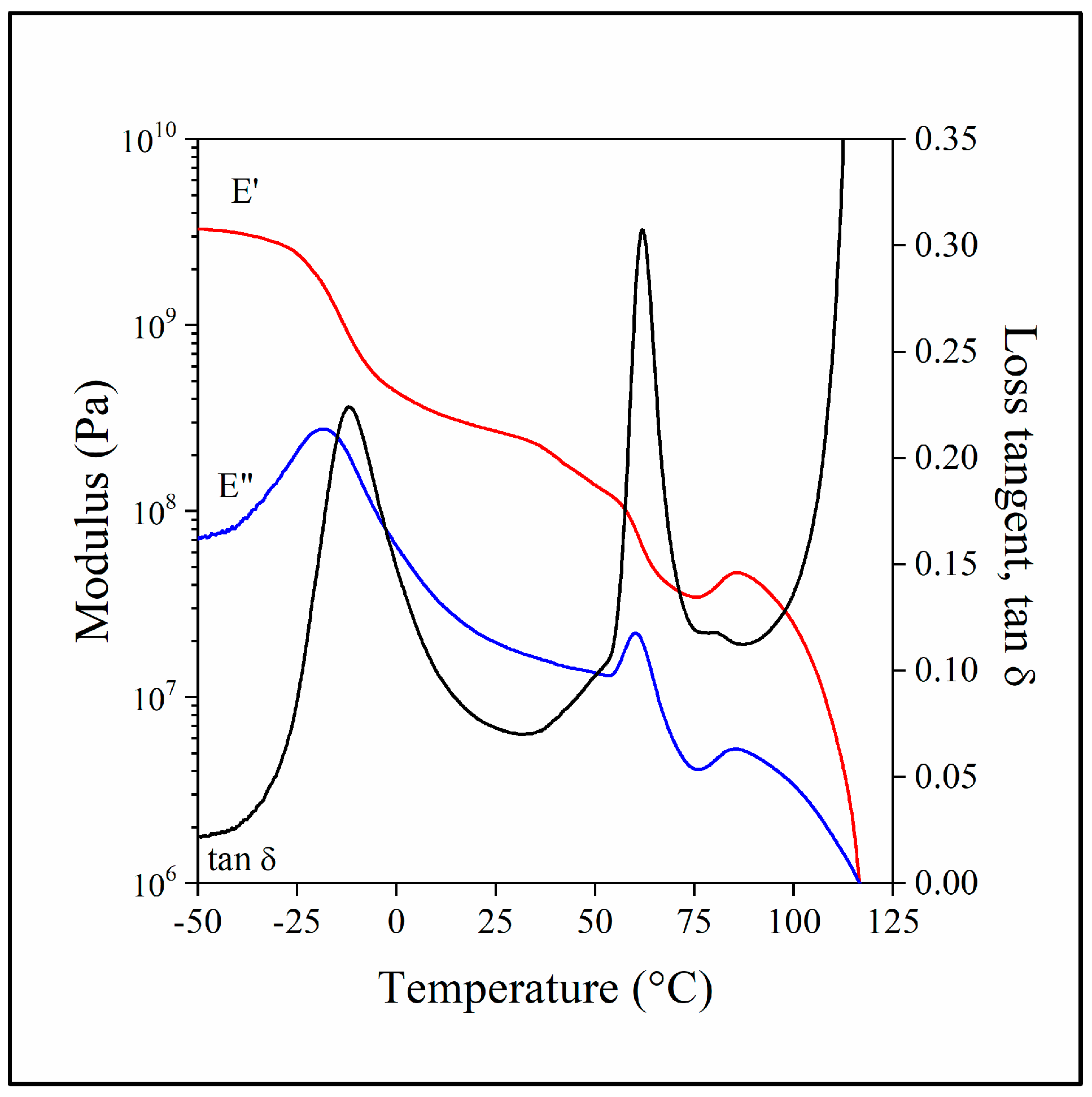

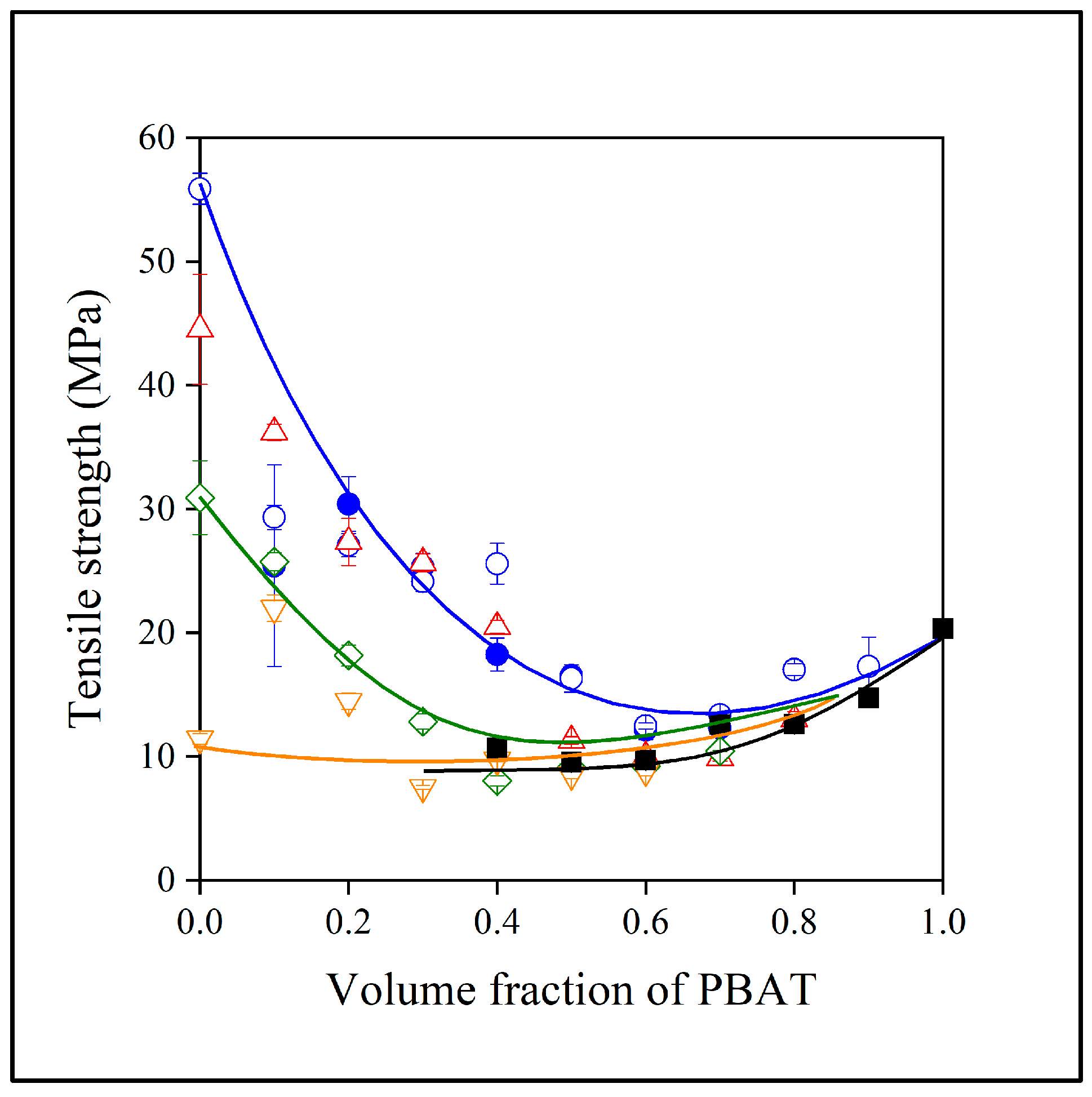

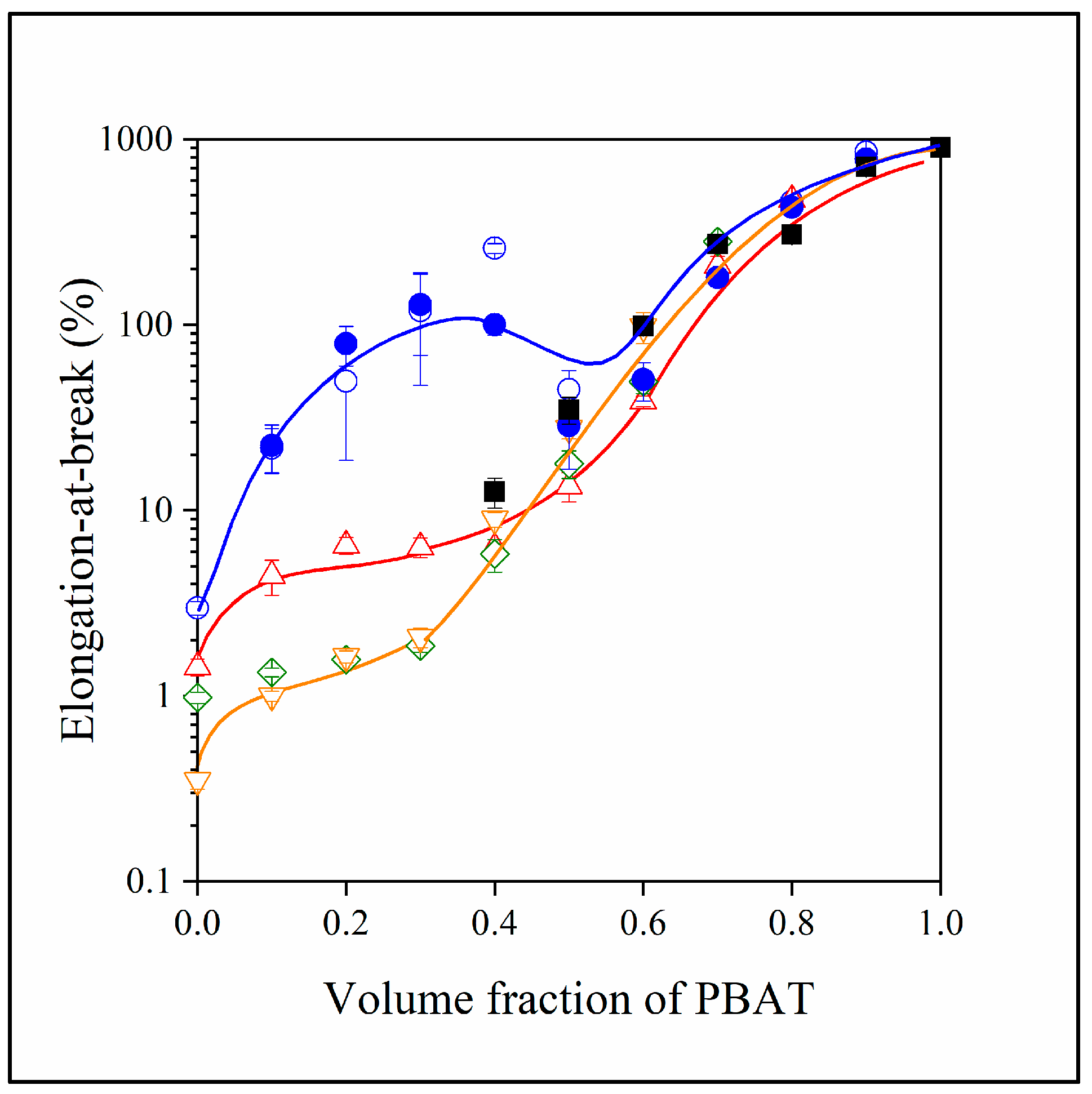

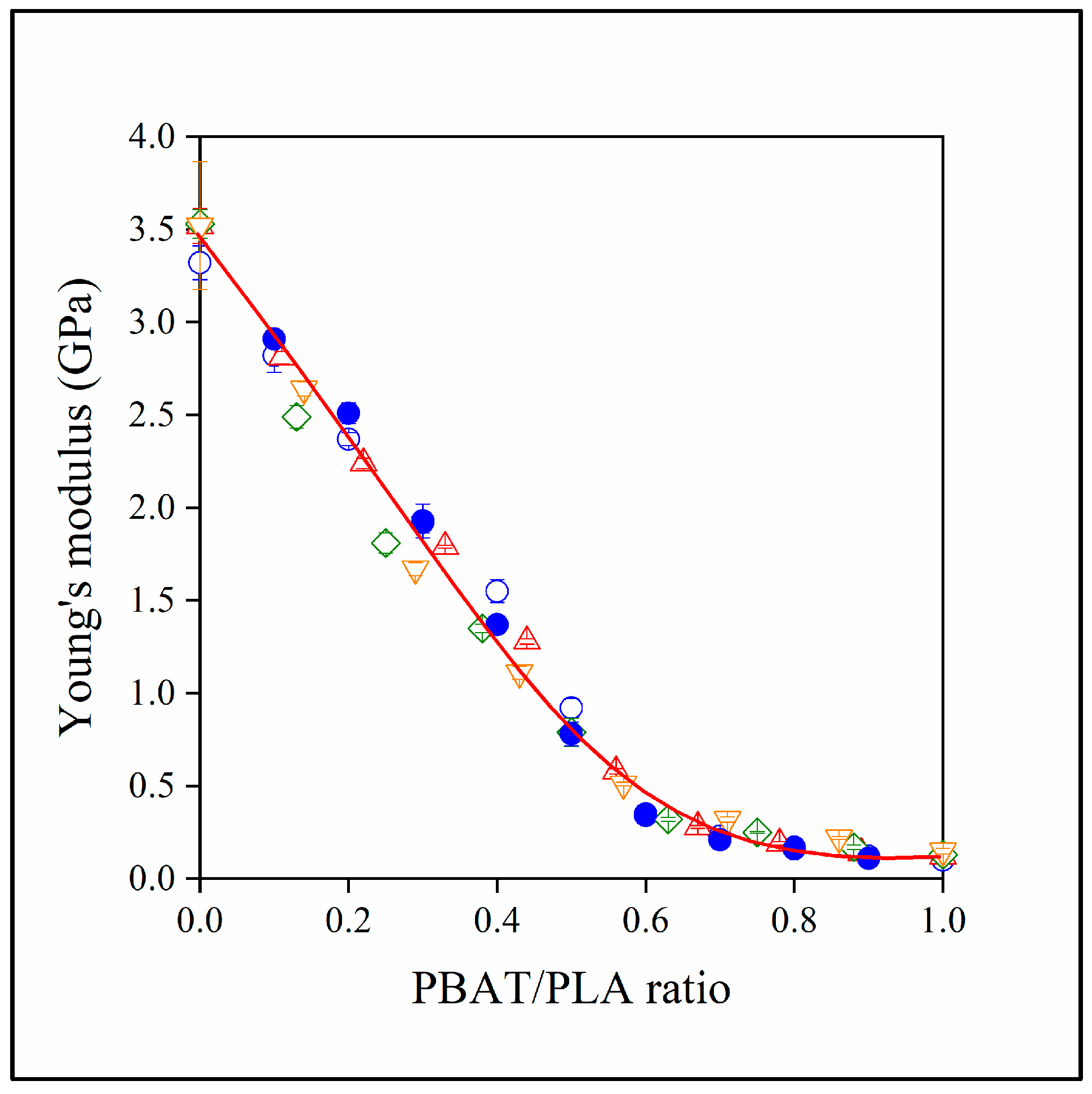

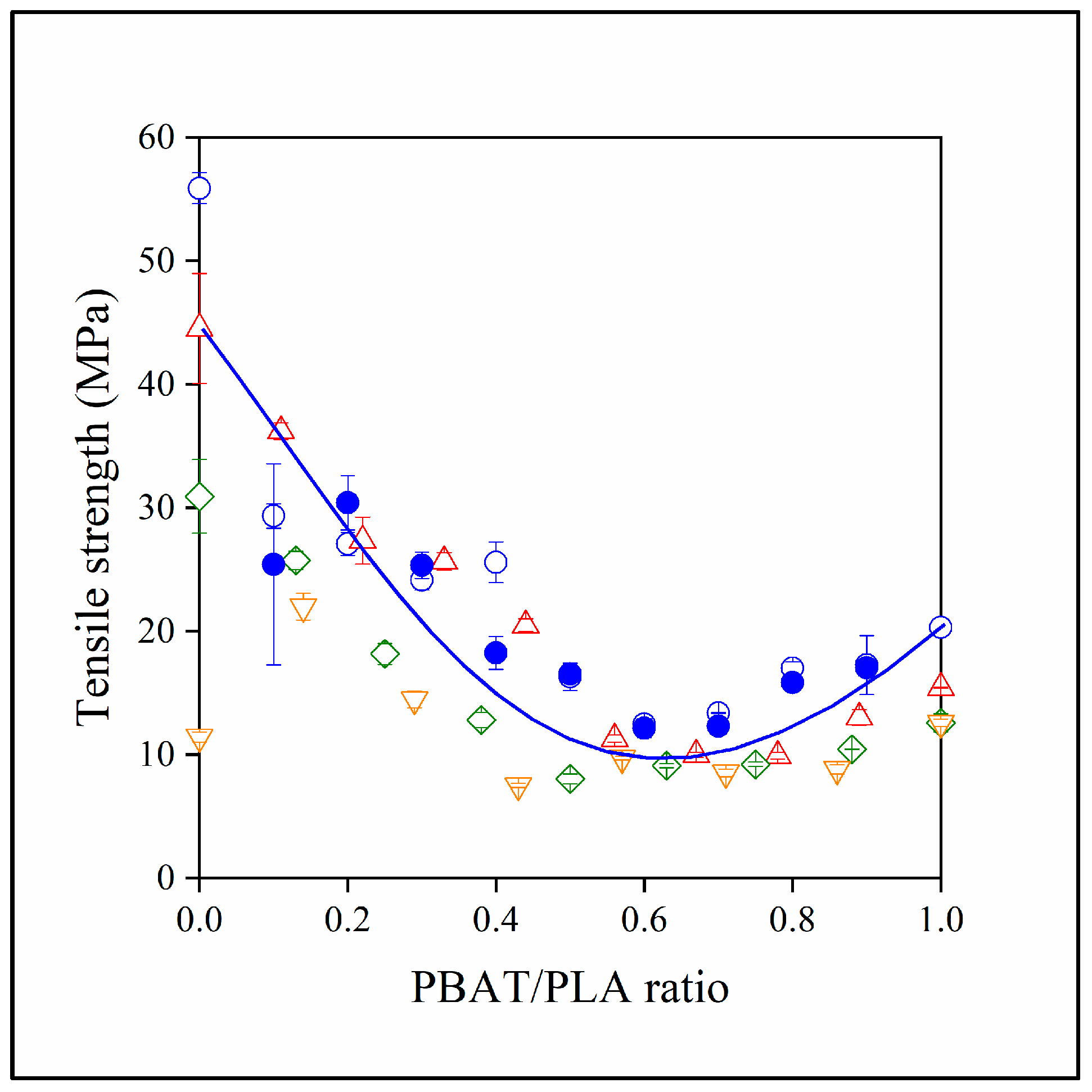

3.3. Properties

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kibria, M.G.; Masuk, N.I.; Safayet, R.; Nguyen, H.Q.; Mourshed, M. Plastic Waste: Challenges and Opportunities to Mitigate Pollution and Effective Management; Springer International Publishing: New York, NY, USA, 2023; Volume 17. [Google Scholar]

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a Circular Economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Xu, S.; Liu, B.; Wang, H.; Qiao, F.; Ren, X.; Wei, Q. PLA Bioplastic Production: From Monomer to the Polymer. Eur. Polym. J. 2023, 193, 112076. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. 4D Printing of PLA-TPU Blends: Effect of PLA Concentration, Loading Mode, and Programming Temperature on the Shape Memory Effect. J. Mater. Sci. 2023, 58, 7227–7243. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Aberoumand, M.; Soltanmohammadi, K.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. Toughening PVC with Biocompatible PCL Softeners for Supreme Mechanical Properties, Morphology, Shape Memory Effects, and FFF Printability. Macromol. Mater. Eng. 2023, 2300114. [Google Scholar] [CrossRef]

- Li, L.; Liu, W.; Wang, Y.; Zhao, Z. Mechanical Performance and Damage Monitoring of CFRP Thermoplastic Laminates with an Open Hole Repaired by 3D Printed Patches. Compos. Struct. 2023, 303, 116308. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and Mechanical Properties of PLA, and Their Functions in Widespread Applications—A Comprehensive Review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Sin, L.T.; Rahmat, A.R.; Rahman, W.A.W.A. Mechanical Properties of Poly(Lactic Acid). In Polylactic Acid; Elsevier: Oxford, UK, 2013; pp. 177–219. [Google Scholar]

- Lim, L.T.; Auras, R.; Rubino, M. Processing Technologies for Poly(Lactic Acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Cui, L.; Imre, B.; Tátraaljai, D.; Pukánszky, B. Physical Ageing of Poly(Lactic Acid): Factors and Consequences for Practice. Polymer 2020, 186, 122014. [Google Scholar] [CrossRef]

- Sin, L.T.; Rahmat, A.R.; Rahman, W.A.W.A. Thermal Properties of Poly(Lactic Acid). In Polylactic Acid; Elsevier: Oxford, UK, 2013; pp. 109–141. [Google Scholar]

- Foglia, F.; De Meo, A.; Iozzino, V.; Volpe, V.; Pantani, R. Isothermal Crystallization of PLA: Nucleation Density and Growth Rates of α and α’ Phases. Can. J. Chem. Eng. 2020, 98, 1998–2007. [Google Scholar] [CrossRef]

- Nofar, M.; Sacligil, D.; Carreau, P.J.; Kamal, M.R.; Heuzey, M.-C. Poly (Lactic Acid) Blends: Processing, Properties and Applications. Int. J. Biol. Macromol. 2019, 125, 307–360. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Ayyoob, M.; Joo, J.; Deri, F. Polylactic Acid Blends: The Future of Green, Light and Tough. Prog. Polym. Sci. 2018, 85, 83–127. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Geerinck, R.; Coltelli, M.-B.; Lazzeri, A. Micromechanical Analysis and Fracture Mechanics of Poly(Lactic Acid) (PLA)/Polycaprolactone (PCL) Binary Blends. Polym. Test. 2023, 121, 107984. [Google Scholar] [CrossRef]

- Farsetti, S.; Cioni, B.; Lazzeri, A. Physico-Mechanical Properties of Biodegradable Rubber Toughened Polymers. Macromol. Symp. 2011, 301, 82–89. [Google Scholar] [CrossRef]

- Ferdinánd, M.; Várdai, R.; Móczó, J.; Pukánszky, B. Poly(Lactic Acid) Reinforced with Synthetic Polymer Fibers: Interactions, Structure and Properties. Compos. Part A Appl. Sci. Manuf. 2023, 164, 107318. [Google Scholar] [CrossRef]

- Bartos, A.; Nagy, K.; Anggono, J.; Antoni; Purwaningsih, H.; Móczó, J.; Pukánszky, B. Biobased PLA/Sugarcane Bagasse Fiber Composites: Effect of Fiber Characteristics and Interfacial Adhesion on Properties. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106273. [Google Scholar] [CrossRef]

- Faludi, G.; Dora, G.; Imre, B.; Renner, K.; Móczó, J.; Pukánszky, B. PLA/Lignocellulosic Fiber Composites: Particle Characteristics, Interfacial Adhesion, and Failure Mechanism. J. Appl. Polym. Sci. 2014, 131, 39902. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A.; Seggiani, M. Thermo-Mechanical Properties of PLA/Short Flax Fiber Biocomposites. Appl. Sci. 2019, 9, 3797. [Google Scholar] [CrossRef]

- Murariu, M.; Dubois, P. PLA Composites: From Production to Properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Imre, B.; Pukánszky, B. Compatibilization in Bio-Based and Biodegradable Polymer Blends. Eur. Polym. J. 2013, 49, 1215–1233. [Google Scholar] [CrossRef]

- Lemmouchi, Y.; Murariu, M.; Dos Santos, A.M.; Amass, A.J.; Schacht, E.; Dubois, P. Plasticization of Poly(Lactide) with Blends of Tributyl Citrate and Low Molecular Weight Poly(d,l-Lactide)-b-Poly(Ethylene Glycol) Copolymers. Eur. Polym. J. 2009, 45, 2839–2848. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J. Research Progress in Toughening Modification of Poly(Lactic Acid). J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1051–1083. [Google Scholar] [CrossRef]

- Calvo-Flores, F.G. Structure and Physicochemical Properties. In Lignin and Lignans as Renewable Raw Materials; Calvo-Flores, F.G., Dobado, J.A., Isac-García, J., Martín-Martínez, F.J., Eds.; John Wiley & Sons, Ltd.: Chichester, UK, 2015; pp. 9–48. [Google Scholar]

- Kun, D.; Pukánszky, B. Polymer/Lignin Blends: Interactions, Properties, Applications. Eur. Polym. J. 2017, 93, 618–641. [Google Scholar] [CrossRef]

- Bozsódi, B.; Romhányi, V.; Pataki, P.; Kun, D.; Renner, K.; Pukánszky, B. Modification of Interactions in Polypropylene/Lignosulfonate Blends. Mater. Des. 2016, 103, 32–39. [Google Scholar] [CrossRef]

- Collins, M.N.; Nechifor, M.; Tanasă, F.; Zănoagă, M.; McLoughlin, A.; Stróżyk, M.A.; Culebras, M.; Teacă, C.-A. Valorization of Lignin in Polymer and Composite Systems for Advanced Engineering Applications–A Review. Int. J. Biol. Macromol. 2019, 131, 828–849. [Google Scholar] [CrossRef]

- Li, W.; Sun, H.; Wang, G.; Sui, W.; Dai, L.; Si, C. Lignin as a Green and Multifunctional Alternative to Phenol for Resin Synthesis. Green Chem. 2023, 25, 2241–2261. [Google Scholar] [CrossRef]

- Gong, X.; Meng, Y.; Lu, J.; Tao, Y.; Cheng, Y.; Wang, H. A Review on Lignin-Based Phenolic Resin Adhesive. Macromol. Chem. Phys. 2022, 223, 2100434. [Google Scholar] [CrossRef]

- Alinejad, M.; Nikafshar, S.; Gondaliya, A.; Bagheri, S.; Chen, N.; Singh, S.K.; Hodge, D.B.; Nejad, M. Lignin-Based Polyurethanes: Opportunities for Bio-Based Foams, Elastomers, Coatings and Adhesives. Polymers 2019, 11, 1202. [Google Scholar] [CrossRef]

- Li, H.; Liang, Y.; Li, P.; He, C. Conversion of Biomass Lignin to High-Value Polyurethane: A Review. J. Bioresour. Bioprod. 2020, 5, 163–179. [Google Scholar] [CrossRef]

- Vieira, F.R.; Magina, S.; Evtuguin, D.V.; Barros-Timmons, A. Lignin as a Renewable Building Block for Sustainable Polyurethanes. Materials 2022, 15, 6182. [Google Scholar] [CrossRef]

- Canetti, M.; Bertini, F.; De Chirico, A.; Audisio, G. Thermal Degradation Behaviour of Isotactic Polypropylene Blended with Lignin. Polym. Degrad. Stab. 2006, 91, 494–498. [Google Scholar] [CrossRef]

- Levon, K.; Huhtala, J.; Malm, B.; Lindberg, J.J. Improvement of the Thermal Stabilization of Polyethylene with Lignosulphonate. Polymer 1987, 28, 745–750. [Google Scholar] [CrossRef]

- Gregorova, A.; Košíková, B.; Staško, A. Radical Scavenging Capacity of Lignin and Its Effect on Processing Stabilization of Virgin and Recycled Polypropylene. J. Appl. Polym. Sci. 2007, 106, 1626–1631. [Google Scholar] [CrossRef]

- Romhányi, V.; Kun, D.; Pukánszky, B. Correlations among Miscibility, Structure, and Properties in Thermoplastic Polymer/Lignin Blends. ACS Sustain. Chem. Eng. 2018, 6, 14323–14331. [Google Scholar] [CrossRef]

- Gordobil, O.; Egüés, I.; Llano-Ponte, R.; Labidi, J. Physicochemical Properties of PLA Lignin Blends. Polym. Degrad. Stab. 2014, 108, 330–338. [Google Scholar] [CrossRef]

- Cicala, G.; Saccullo, G.; Blanco, I.; Samal, S.; Battiato, S.; Dattilo, S.; Saake, B. Polylactide/Lignin Blends. J. Therm. Anal. Calorim. 2017, 130, 515–524. [Google Scholar] [CrossRef]

- Ouyang, W.; Huang, Y.; Luo, H.; Wang, D. Poly(Lactic Acid) Blended with Cellulolytic Enzyme Lignin: Mechanical and Thermal Properties and Morphology Evaluation. J. Polym. Environ. 2012, 20, 1–9. [Google Scholar] [CrossRef]

- Zhao, G.; Gomes, F.P.C.; Marway, H.; Thompson, M.R.; Zhu, Z. Physical Aging as the Driving Force for Brittle–Ductile Transition of Polylactic Acid. Macromol. Chem. Phys. 2020, 221, 1900475. [Google Scholar] [CrossRef]

- Gigante, V.; Canesi, I.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A. Rubber Toughening of Polylactic Acid (PLA) with Poly(Butylene Adipate-Co-Terephthalate) (PBAT): Mechanical Properties, Fracture Mechanics and Analysis of Ductile-to-Brittle Behavior While Varying Temperature and Test Speed. Eur. Polym. J. 2019, 115, 125–137. [Google Scholar] [CrossRef]

- Gigante, V.; Bosi, L.; Parlanti, P.; Gemmi, M.; Aliotta, L.; Lazzeri, A. Analysis of the Damage Mechanism around the Crack Tip for Two Rubber-Toughened Pla-Based Blends. Polymers 2021, 13, 4053. [Google Scholar] [CrossRef]

- Jiang, L.; Wolcott, M.P.; Zhang, J. Study of Biodegradable Polylactide/Poly(Butylene Adipate- Co -Terephthalate) Blends. Biomacromolecules 2006, 7, 199–207. [Google Scholar] [CrossRef]

- Barbosa Camargo Lamparelli, R.d.C.; Montagna, L.S.; da Silva, A.P.B.; Do Amaral Montanheiro, T.L.; Lemes, A.P. Study of the Biodegradation of PLA/PBAT Films after Biodegradation Tests in Soil and the Aqueous Medium. Biointerface Res. Appl. Chem. 2022, 12, 833–846. [Google Scholar] [CrossRef]

- Weng, Y.-X.; Jin, Y.-J.; Meng, Q.-Y.; Wang, L.; Zhang, M.; Wang, Y.-Z. Biodegradation Behavior of Poly(Butylene Adipate-Co-Terephthalate) (PBAT), Poly(Lactic Acid) (PLA), and Their Blend under Soil Conditions. Polym. Test. 2013, 32, 918–926. [Google Scholar] [CrossRef]

- Arrigo, R.; D’Anna, A.; Frache, A. Fully Bio-Based Ternary Polymer Blends: Structural Characterization and Mechanical Behavior. Mater. Today Sustain. 2023, 21, 100314. [Google Scholar] [CrossRef]

- Nemirovski, N.; Siegmann, A.; Narkis, M. Morphology of Ternary Immiscible Polymer Blends. J. Macromol. Sci. Part B 1995, 34, 459–475. [Google Scholar] [CrossRef]

- Wang, D.; Li, Y.; Xie, X.-M.; Guo, B.-H. Compatibilization and Morphology Development of Immiscible Ternary Polymer Blends. Polymer 2011, 52, 191–200. [Google Scholar] [CrossRef]

- Abdelwahab, M.A.; Taylor, S.; Misra, M.; Mohanty, A.K. Thermo-Mechanical Characterization of Bioblends from Polylactide and Poly(Butylene Adipate-Co-Terephthalate) and Lignin. Macromol. Mater. Eng. 2015, 300, 299–311. [Google Scholar] [CrossRef]

- Chen, R.; Abdelwahab, M.A.; Misra, M.; Mohanty, A.K. Biobased Ternary Blends of Lignin, Poly(Lactic Acid), and Poly(Butylene Adipate-Co-Terephthalate): The Effect of Lignin Heterogeneity on Blend Morphology and Compatibility. J. Polym. Environ. 2014, 22, 439–448. [Google Scholar] [CrossRef]

- Barros, J.J.P.; Soares, C.P.; de Moura, E.A.B.; Wellen, R.M.R. Enhanced Miscibility of PBAT/PLA/Lignin upon γ-irradiation and Effects on the Non-isothermal Crystallization. J. Appl. Polym. Sci. 2022, 139, e53124. [Google Scholar] [CrossRef]

- Wu, W.; Huang, J.; Zhao, W.; Zhang, Q.; Cao, X.; Li, X.; Li, R.K.Y. Construction of Highly Ductile, UV-Shielding Polylactide/Poly(Butylene Adipate-Co-Terephthalate) Biocomposites with Hyperbranched Polysiloxane Functionalized Lignin as a Biocompatibilizer. Int. J. Biol. Macromol. 2023, 242, 124943. [Google Scholar] [CrossRef]

- Gigante, V.; Aliotta, L.; Canesi, I.; Sandroni, M.; Lazzeri, A.; Coltelli, M.-B.; Cinelli, P. Improvement of Interfacial Adhesion and Thermomechanical Properties of PLA Based Composites with Wheat/Rice Bran. Polymers 2022, 14, 3389. [Google Scholar] [CrossRef]

- Nunes, M.A.B.S.; de Matos, B.R.; Silva, G.G.; Ito, E.N.; de Melo, T.J.A.; Fechine, G.J.M. Hybrids Nanocomposites Based on a Polymer Blend (Linear Low-Density Polyethylene/Poly(Ethylene-Co-Methyl Acrylate) and Carbonaceous Fillers (Graphene and Carbon Nanotube). Polym. Compos. 2021, 42, 661–677. [Google Scholar] [CrossRef]

- Salehiyan, R.; Nofar, M.; Malkappa, K.; Ray, S.S. Effect of Nanofillers Characteristics and Their Selective Localization on Morphology Development and Rheological Properties of Melt-processed Polylactide/Poly(Butylene Adipate-co-terephthalate) Blend Composites. Polym. Eng. Sci. 2020, 60, 2749–2760. [Google Scholar] [CrossRef]

- Wu, W.; Wu, C.; Peng, H.; Sun, Q.; Zhou, L.; Zhuang, J.; Cao, X.; Roy, V.A.L.; Li, R.K.Y. Effect of Nitrogen-Doped Graphene on Morphology and Properties of Immiscible Poly(Butylene Succinate)/Polylactide Blends. Compos. Part B Eng. 2017, 113, 300–307. [Google Scholar] [CrossRef]

- Wu, C.M.; Lai, W.Y.; Wang, C.Y. Effects of Surface Modification on the Mechanical Properties of Flax/β-Polypropylene Composites. Materials 2016, 9, 314. [Google Scholar] [CrossRef] [PubMed]

- Gaduan, A.N.; Singkronart, K.; Bell, C.; Tierney, E.; Burgstaller, C.; Lee, K.Y. Mechanical Upcycling Immiscible Polyethylene Terephthalate-Polypropylene Blends with Carbon Fiber Reinforcement. ACS Appl. Polym. Mater. 2022, 4, 3294–3303. [Google Scholar] [CrossRef]

- Li, Y.; Shi, W.; Li, J.; Yang, C.; Xia, T.; Sheng, X.; Wang, X. Structure and Properties of Glass Fiber Reinforced Polypropylene/Liquid Crystal Polymer Blends. J. Macromol. Sci. Part B Phys. 2015, 54, 1144–1152. [Google Scholar] [CrossRef]

- Pregi, E.; Kun, D.; Faludi, G.; Móczó, J.; Pukánszky, B. Modeling the Mechanical Properties of Polypropylene/Lignin/Flax Hybrid Composites. Mater. Des. 2022, 220, 110833. [Google Scholar] [CrossRef]

- Várdai, R.; Lummerstorfer, T.; Pretschuh, C.; Jerabek, M.; Gahleitner, M.; Bartos, A.; Móczó, J.; Anggono, J.; Pukánszky, B. Improvement of the Impact Resistance of Natural Fiber–Reinforced Polypropylene Composites through Hybridization. Polym. Adv. Technol. 2021, 32, 2499–2507. [Google Scholar] [CrossRef]

- Hartikainen, J.; Hine, P.; Szabó, J.S.; Lindner, M.; Harmia, T.; Duckett, R.A.; Friedrich, K. Polypropylene Hybrid Composites Reinforced with Long Glass Fibres and Particulate Filler. Compos. Sci. Technol. 2005, 65, 257–267. [Google Scholar] [CrossRef]

- Aguilar, H.; Yazdani-Pedram, M.; Toro, P.; Quijada, R.; López-Manchado, M.Á. Synergic Effect of Two Inorganic Fillers on the Mechanical and Thermal Properties of Hybrid Polypropylene Composites. J. Chil. Chem. Soc. 2014, 59, 2468–2473. [Google Scholar] [CrossRef]

- Haneefa, A.; Bindu, P.; Aravind, I.; Thomas, S. Studies on Tensile and Flexural Properties of Short Banana/Glass Hybrid Fiber Reinforced Polystyrene Composites. J. Compos. Mater. 2008, 42, 1471–1489. [Google Scholar] [CrossRef]

- Premphet, K.; Horanont, P. Influence of Stearic Acid Treatment of Filler Particles on the Structure and Properties of Ternary-Phase Polypropylene Composites. J. Appl. Polym. Sci. 1999, 74, 3445–3454. [Google Scholar] [CrossRef]

- Hornsby, P.R.; Premphet, K. Influence of Phase Microstructure on the Mechanical Properties of Ternary Phase Polypropylene Composites. J. Appl. Polym. Sci. 1998, 70, 587–597. [Google Scholar] [CrossRef]

- Sudár, A.; Renner, K.; Móczó, J.; Lummerstorfer, T.; Burgstaller, C.; Jerabek, M.; Gahleitner, M.; Doshev, P.; Pukánszky, B. Fracture Resistance of Hybrid PP/Elastomer/Wood Composites. Compos. Struct. 2016, 141, 146–154. [Google Scholar] [CrossRef]

- Keledi, G.; Sudar, A.; Burgstaller, C.; Renner, K.; Moczo, J.; Pukanszky, B. Tensile and Impact Properties of Three-Component PP/Wood/Elastomer Composites. Express Polym. Lett. 2012, 6, 224–236. [Google Scholar] [CrossRef]

- Stamhuis, J.E. Mechanical Properties and Morphology of Polypropylene Composites. III. Short Glass Fiber Reinforced Elastomer Modified Polypropylene. Polym. Compos. 1988, 9, 280–284. [Google Scholar] [CrossRef]

- Stamhuis, J.E. Mechanical Properties and Morphology of Polypropylene Composites II. Effect of Polar Components in Talc-Filled Polypropylene. Polym. Compos. 1988, 9, 72–77. [Google Scholar] [CrossRef]

- Sameni, J.; Krigstin, S.; Sain, M. Characterization of Lignins Isolated from Industrial Residues and Their Beneficial Uses. BioResources 2016, 11, 8435–8456. [Google Scholar] [CrossRef]

- Rohde, V.; Böringer, S.; Tübke, B.; Adam, C.; Dahmen, N.; Schmiedl, D. Fractionation of Three Different Lignins by Thermal Separation Techniques-A Comparative Study. GCB Bioenergy 2019, 11, 206–217. [Google Scholar] [CrossRef]

- Hu, Z.; Du, X.; Liu, J.; Chang, H.M.; Jameel, H. Structural Characterization of Pine Kraft Lignin: BioChoice Lignin vs Indulin AT. J. Wood Chem. Technol. 2016, 36, 432–446. [Google Scholar] [CrossRef]

- Elhamnia, M.; Hashemi Motlagh, G. Predicting Droplet Size by Rheometry Analysis for PBAT/EVOH Blend. In Eco-Friendly and Smart Polymer Systems; Mirzadeh, H., Katbab, A.A., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 694–697. [Google Scholar]

- Siemann, U. The Solubility Parameter of Poly(Dl-Lactic Acid). Eur. Polym. J. 1992, 28, 293–297. [Google Scholar] [CrossRef]

- Su, S. Prediction of the Miscibility of Pbat/Pla Blends. Polymers 2021, 13, 2339. [Google Scholar] [CrossRef] [PubMed]

- Thielemans, W.; Wool, R.P. Lignin Esters for Use in Unsaturated Thermosets: Lignin Modification and Solubility Modeling. Biomacromolecules 2005, 6, 1895–1905. [Google Scholar] [CrossRef] [PubMed]

- Jalali Dil, E.; Carreau, P.J.; Favis, B.D. Morphology, Miscibility and Continuity Development in Poly(Lactic Acid)/Poly(Butylene Adipate-Co-Terephthalate) Blends. Polymer 2015, 68, 202–212. [Google Scholar] [CrossRef]

- Ding, Y.; Feng, W.; Huang, D.; Lu, B.; Wang, P.; Wang, G.; Ji, J. Compatibilization of Immiscible PLA-Based Biodegradable Polymer Blends Using Amphiphilic Di-Block Copolymers. Eur. Polym. J. 2019, 118, 45–52. [Google Scholar] [CrossRef]

- Sameni, J.; Krigstin, S.; Sain, M. Solubility of Lignin and Acetylated Lignin in Organic Solvents. BioResources 2017, 12, 1548–1565. [Google Scholar] [CrossRef]

- Yang, K.; Yazawa, K.; Tsuchiya, K.; Numata, K.; Guan, J. Molecular Interactions and Toughening Mechanisms in Silk Fibroin–Epoxy Resin Blend Films. Biomacromolecules 2019, 20, 2295–2304. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pregi, E.; Romsics, I.; Várdai, R.; Pukánszky, B. Interactions, Structure and Properties of PLA/lignin/PBAT Hybrid Blends. Polymers 2023, 15, 3237. https://doi.org/10.3390/polym15153237

Pregi E, Romsics I, Várdai R, Pukánszky B. Interactions, Structure and Properties of PLA/lignin/PBAT Hybrid Blends. Polymers. 2023; 15(15):3237. https://doi.org/10.3390/polym15153237

Chicago/Turabian StylePregi, Emese, Imre Romsics, Róbert Várdai, and Béla Pukánszky. 2023. "Interactions, Structure and Properties of PLA/lignin/PBAT Hybrid Blends" Polymers 15, no. 15: 3237. https://doi.org/10.3390/polym15153237

APA StylePregi, E., Romsics, I., Várdai, R., & Pukánszky, B. (2023). Interactions, Structure and Properties of PLA/lignin/PBAT Hybrid Blends. Polymers, 15(15), 3237. https://doi.org/10.3390/polym15153237