1. Introduction

1.1. The Hydrodynamic Scaling Model

In two prior articles [

1,

2], we considered the simulational tests of the Rouse–Zimm [

3,

4] and Kirkwood–Riseman [

5] models for chain dynamics in polymeric fluids. We demonstrated that the behavior of model polymer chains in simulated melts and simulated dilute solutions under shear was entirely inconsistent with the Rouse model. To the very limited extent that the simulations asked the necessary questions, polymer behavior was found to be consistent with the Kirkwood–Riseman model. It was, however, appropriate to ask whether there are good tests of the Kirkwood–Riseman model, and whether the model passes those tests. This review article treats that question, finding that appropriate tests [

6] do indicate the validity of the Kirkwood–Riseman model as extended to non-dilute solutions.

The original model of Kirkwood and Riseman referred to a single-polymer molecular moving through a Newtonian fluid. Historically, it was reasonable to attempt to extend the model to calculate, e.g., the concentration dependence of the viscosity

. Note related papers by Brinkman [

7], Riseman and Ullmann [

8], Saito [

9,

10], Yamakawa [

11], Freed and Edwards [

12,

13,

14], Freed and Perico [

15], and Altenberger et al. [

16]. There was awareness in these reports that the long-range nature of hydrodynamic interactions can lead to improper integrals in generating pseudovirial series for

. Edwards and Freed proposed [

12,

13,

14] that the needed integrals were in fact proper due to a hypothesized process of hydrodynamic screening, but later calculations by Freed and Perico [

15] and by Altenberger et al. [

16] demonstrated that there is in fact no such phenomenon as hydrodynamic screening in polymer solutions.

In the decades since the aforementioned work was performed, scientific interest shifted from hydrodynamic models to the tube/reptation models of polymer dynamics. In many of these models, polymer motion over short time periods, and polymer motion (’reptation’) through the hypothesized tubes in entangled polymeric fluids, were assumed to be described by Rouseian dynamics. However, as we previously found [

1,

2], simulations show that the Rouse model does not describe polymer motions in the melt.

At one time, it appeared plausible that the tube model for polymer melts could also be applied to polymer solutions [

17]. Reviews [

18,

19,

20] instead concluded that reptation/tube/scaling models are not applicable to polymer solutions, at least for the solutions of polymers in commonly studied concentration and molecular weight ranges. A monograph-length examination of a wide range of polymer solution properties [

21] came to a similar conclusion.

This review considers an approach that effectively extends the Kirkwood–Riseman model from a dilute solution to concentrated solutions. The results are collectively described as the hydrodynamic scaling model. This model provides an alternative to tube/reptation models, which assume the use of Rouseian dynamics. The Kirkwood–Riseman and tube/reptation models differ in their assumptions as to the important forces between polymers and as to their domains of validity. There are two intermolecular forces under consideration, namely topological forces (chain crossing constraints) and solvent-mediated hydrodynamic forces. Reptation models take chain crossing constraints to be the dominant interaction and hydrodynamic interactions to provide at most secondary corrections. The hydrodynamic scaling model takes hydrodynamic forces to be the dominant interaction and chain crossing constraints to provide secondary corrections. Tube/reptation models refer to entangled polymer systems, systems in which the polymer concentration and molecular weight are large enough that chain motion is confined to tubes formed by neighboring chains. Tube/reptation models are not applicable to unentangled polymer systems, in which the polymers are too short or too dilute to form tubes. The hydrodynamic scaling model is applicable to dilute as well as non-dilute solutions of polymers having any molecular weight, small or large.

The hydrodynamic scaling model for the dynamics of non-dilute polymer solution has been presented in an extended series of papers [

6,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30,

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47]. The objective here is to present the results of these papers in a coherent way, showing what has been calculated thus far and what remains to be accomplished. The model arises from the Kirkwood–Riseman model [

5]; it transcends the earlier work of Kirkwood and Riseman by including hydrodynamic interactions between different polymer molecules.

Five major components of the model are readily identified:

First, the hydrodynamic scaling model presumes that the dominant interactions between neutral polymers in solution are the solvent-mediated hydrodynamic forces. Chain crossing constraints are taken to provide at most secondary corrections. How is this possible? Because hydrodynamic forces are strong, the nearby segments of different polymer molecules move in unison with each other, so the effects of chain crossing constraints are greatly reduced. When two chains are close to each other, each chain drags the other along, rather than each chain acting as a stationary obstacle to block the other chain’s movements.

Second, following the Kirkwood–Riseman [

5] model, each polymer chain is treated as a line of frictional centers (“beads”) separated by a series of frictionless links (“springs”). The hydrodynamic interactions between beads on different chains are taken to be described by the Oseen tensor [

4] and its modern short-range extensions [

48].

Third, the above assumptions are used to obtain a pseudovirial expansion for the concentration dependence of each transport coefficient, as a power series in concentration.

Fourth, to extend the model to elevated concentrations, we have recourse to self-similarity [

23] or to renormalization group methods [

41]. The renormalization group method of choice is the Altenberger–Dahler positive function renormalization group [

49,

50,

51,

52,

53]. Altenberger and Dahler developed this group from Shirkov’s general treatment of renormalization analysis, based on functional self-similarity [

54,

55,

56]. While renormalization group methods are indirect, they allow one to extrapolate lower-order pseudovirial expansions to elevated concentrations.

Fifth, the quantitative success of the hydrodynamic scaling model is in part based on polymer statics. In particular, it has been theoretically predicted [

57] and experimentally demonstrated [

57,

58] that, in solution, polymer coils contract as the polymer concentration is increased. This fairly modest degree of chain contraction has a substantial effect on the predicted concentration dependencies of the polymer transport coefficients.

The hydrodynamic scaling model was first used to treat the self-diffusion coefficient

of polymers in solution, predicting the functional form for the dependence of

on polymer concentration

c and polymer molecular weight

M. Physical interpretations and predictions of numerical values for the functional form’s parameters have been provided [

23,

27,

28,

29]. The model has been extended to consider the effect of polymer concentration on the mobility of the individual beads of a polymer chain and on the mobility of small probe molecules in the surrounding solution [

35]. An extended calculation predicted the low-shear viscosity of non-dilute polymer solutions [

45]. The consideration of the inferred fixed-point-structure of the renormalization group led to an ansatz [

42] that qualitatively determines the frequency dependencies of the storage and loss moduli. The validity of the hydrodynamic scaling model is shown by a huge mass of experimental data, as found in my companion volumes

Phenomenology of Polymer Solution Dynamics [

21,

59]. In the following, the discussion of experiments will be limited to results that test particular aspects of the hydrodynamic scaling model.

1.2. Reptation/Scaling and Hydrodynamic Scaling Models Compared

This section compares the reptation/scaling and hydrodynamic scaling models. The major emphasis is on points where the two models are entirely different. Failure to recognize the great disparities between the two models occasionally leads to confusion in the literature. Readers should recognize that there are large numbers of modestly different reptation/scaling treatments and several different hydrodynamic treatments.

The core physical difference between the reptation/scaling and hydrodynamic scaling treatments is that the models do not agree as to which forces dominate the polymer solution dynamics. Many models [

17] assume that, at elevated concentrations, chain crossing (topological) constraints (“entanglements”) between polymer chains are the dominant physical interactions. In these models, hydrodynamic interactions between chains serve primarily to dress the bare monomer drag coefficients. Hydrodynamic scaling models assert, to the contrary, that hydrodynamic forces are dominant. In these models, excluded-volume and chain crossing constraints are taken to provide only secondary corrections to the hydrodynamic interactions. The hydrodynamic scaling model is not unique in assuming the dominance of hydrodynamic interactions. Oono’s renormalization group treatment of mutual diffusion shares with the hydrodynamic scaling model the assumption that hydrodynamic forces are dominant [

60].

Corresponding to the assumptions as to the nature of the dominant forces, there are assumptions as to the concentration ranges in which the models are valid. Reptation/scaling models require that the concentration is large enough that neighboring polymer coils overlap with each other and form entanglements, circumstances where chain crossing constraints are particularly significant. As a result, there is a lowest concentration , the overlap concentration, below which tube model/reptation models are inappropriate. Tube models describe small concentrations as constituting the dilute regime, while in the reptation models, concentrations include the overlapping semidilute, entangled, and concentrated regimes.

Entanglements are not significant in the hydrodynamic scaling model, whose validity extends up from extreme dilution toward the melt. However, within the hydrodynamic scaling model, a transition concentration regime is expected, above which typical gaps between polymer chains are similar in size to individual solvent molecules. At larger concentrations, the typical gaps are smaller than solvent molecules, so that it appears inappropriate to describe solvent dynamics in terms of continuum fluid mechanics.

Entanglement-based models were originally applied to described the diffusion of a single polymer molecule, the

probe chain, through a chemically cross-linked gel, the polymer

matrix. In a cross-linked gel, the chains of the matrix cannot move over large distances [

61]. Probe chains must thread their way through the matrix, like a very long snake threading its way through a grove of bamboo.

To transfer the entanglement model from probe chains in a cross-linked gel to probe chains in a polymer solution, it was hypothesized that the motions of probe chains in cross-linked gels and in polymer solutions can be given the same description. Unlike a gel, in the solution, the matrix chains are free to move. Entanglement-based models assume that, on the time scales of interest, these being the time scales on which the probe chains move, the matrix chains are effectively stationary. The entangled matrix chains of a polymer solution are said to form a transient lattice or pseudogel that constrains probe chain motions in the same way that a true cross-linked gel constrains probe chain motions, namely the probe chain can only move parallel to its own chain contour.

In the hydrodynamic scaling model, there is no transient lattice or pseudogel. In non-dilute solutions and melts, chains remain free to translate and to rotate around their center of masses, though their motions are delayed by other neighboring chains.

In the tube/reptation models, it is implicitly assumed that, when the probe chain encounters some neighboring matrix chains, the probe chain does not drag the matrix chain along; instead, the probe chain is brought to a stop by the matrix chain. No rationale for this implicit assumption is provided. It is thus assumed in reptation-scaling models that a long polymer chain in a non-dilute polymer solution can only move through solution in the ways that the chain can move through a true cross-linked gel, namely over large distances, and the probe chain only moves parallel to its own length. The hydrodynamic scaling models make an opposite assumption, namely that when polymer chains encounter each other, the chain segments on neighboring chains tend to move in parallel directions, so they do not block each others’ motions.

Many entanglement-based models incorporate a second, independent assumption, the

scaling assumption, which proposes that polymer transport coefficients such as the self-diffusion coefficient

depend on polymer concentration

c and polymer molecular weight

M via scaling laws, e.g.,

where

and

are scaling exponents. The business of entanglement models and experimental studies is then to calculate or measure the exponents

and

. Presumably, a complete model would also compute the scaling prefactor

and supply the ranges of

c and

M for which the model should be accurate, but much early work treated

as an undetermined constant.

The hydrodynamic scaling model usually predicts stretched exponentials:

This functional form theoretically arises from the Altenberger–Dahler positive-function renormalization group, when it is used to extrapolate

from smaller to larger concentrations, as treated in

Section 6. The model quantitatively predicts

and

, quantitatively predicts the molecular weight dependence of

, and reduces the calculation of

to a single parameter

a, the same

a describing

and

.

1.3. Historical Matters Aside

The hydrodynamic scaling model arose from a series of entirely empirical observations. Experimental studies of the diffusion of microscopic polystyrene latex spheres (as probes) through solutions of non-neutralized polyacrylic acid, poly-ethylene oxide, and bovine serum albumin (as matrices) [

62,

63,

64,

65,

66,

67] found that the concentration dependence of the probe’s diffusion coefficient

could be described to good accuracy by stretched exponentials in polymer concentration,

viz.,

where

c is the polymer concentration,

is the probe diffusion coefficient in the limit of low concentration, and in the original work,

and

were fitting parameters. The comparison of these experimental results [

22] revealed that

was consistently in the range of 0.5–1.0, while over two orders of magnitude in the polymer molecular weight

M, one had:

for

. Measurements with different probe sizes found that

is approximately independent of the probe sphere radius

R.

Furthermore, in most of these systems,

did not track the solution viscosity via

. In this non-Stokes–Einsteinian behavior, probes diffused faster than expected from their known sizes and the solution viscosity. Obvious artifacts, including polymer adsorption by the spheres and polymer-driven sphere aggregation, would cause the spheres to diffuse slower than expected, indicating that this non-Stokes–Einsteinian behavior was not simply an artifact. Non-Stokes–Einsteinian behavior, which was noticed well before Equation (

3) and the dependencies of

and

on

M and

R were identified, was the driving motivation for the previous [

62,

63,

64,

65,

66,

67] experimental work.

Equation (

3) was then compared [

20] with the published studies of the polymer self-diffusion coefficient

, finding that

uniformly follows a similar equation:

Equation (

5) was therefore identified [

20] as the

universal scaling equation for polymer self-diffusion. The functional form of Equation (

3) has since been tested [

25,

37,

39] against the literature reports of the polymer solution viscosity

, sedimentation coefficient

s, rotational diffusion coefficient

, and the dielectric relaxation time

. In each case, these transport coefficients have stretched exponential concentration dependencies with various prefactors and exponents

and

.

Several features of Equation (

3), as revealed in Refs. [

20,

22], were not in accordance with expectations from entanglement-based models of polymer solution dynamics. In particular: (i) The concentration dependence was found to be a stretched exponential in

c, not the expected power law in

c; (ii) The concentration dependence was described over all concentrations studied by a single set of parameters

, with no indication of a transition in dynamic behavior between a “dilute” regime (in which hydrodynamics was expected to dominate) and a “semidilute” regime (in which polymer coils overlapped and entanglements were proposed to dominate); (iii) For probe diffusion (spheres diffusing through random-coil polymers), in the semidilute regime

was found to be dependent on—rather than independent of—polymer molecular weight; (iv) In the semidilute regime,

was found to be nearly independent of the probe radius, even though it had been expected to have a strong dependence on the probe radius; and (v)

of large probes was expected to be determined by the macroscopic solution viscosity, which it was not. Furthermore, (vi) in the dilute solutions,

was often proposed in the context of reptation/scaling models to be nearly independent of

c. None of the expectations (i)–(vi) were met in the studied systems.

How might this set of discrepancies between the universal scaling Equation (

3) and expectations based on entanglement models be resolved? First, one could always propose that the agreement between the universal scaling equation and the particular datasets with which it had been compared was a curiosity, an empirical coincidence having no real importance. In that case, the equation would be an accident having no relationship to fundamental theoretical considerations. Second, one could propose that the agreement arose because the universal scaling equation is remarkably flexible. This second proposal encounters the information-theoretic obstacle that the equation has three free parameters (and the measurable zero-concentration limiting constant

), so it can therefore cover neither more nor less of the possible solution space than can any other reasonable three-parameter equation.

Finally, the criticism was advanced that Equation (

3) is purely empirical and has no physical content. This final criticism led to the clear recommendation [

68] that the proponents of Equation (

3) needed to find an ab initio theoretical derivation of Equation (

3), preferably a derivation that reveals the physical interpretations of

and

. The remainder of this article reviews the research program that generated the requested derivation. Equation (

3), including ab initio numerical values for

and

and their molecular weight dependencies, was obtained. We review the papers that supplied that derivation, ending antiquated suggestions that the universal scaling equation and its parameters are purely empirical and have no physical interpretation.

1.4. Precis of the Work

This section presents an outline of the remainder of this article.

In

Section 2, we first discuss the less-studied Kirkwood–Riseman model, because the Kirkwood–Riseman model provides the foundation for determining hydrodynamic interactions between polymer chains. As an example, the drag coefficient of a Kirkwood–Riseman polymer is calculated.

Section 3 presents our extended Kirkwood–Riseman model. The extension calculates chain–chain hydrodynamic interactions. It thus provides the physical basis for the hydrodynamic scaling model.

Section 3.1 presents the modern bead–bead hydrodynamic interaction tensors including short-range and three-bead interactions.

Section 3.2 shows how to move from bead–bead to chain–chain hydrodynamic interactions in the context of the Kirkwood–Riseman model.

Section 4 uses the extended Kirkwood–Riseman model to calculate, through

, the concentration dependence of the polymer self-diffusion coefficient.

Section 5 uses the model to calculate the concentration dependence of the viscosity.

Section 5.1 calculates the flow field

created by the scattering of a shear field

by a polymer chain, and the additional flow field

created by the scattering of flow field

by a second polymer.

Section 5.2 calculates the power dissipated by various polymer chains exposed to flow fields

,

, and

.

Section 5.3 calculates the total shear field that would be experimentally determined as a result of these flow fields, leading to a determination in

Section 5.4 of the intrinsic viscosity and the Huggins coefficient for the extended Kirkwood–Riseman model.

Section 6 considers paths for extending the hydrodynamic calculation of pseudovirial coefficients, as seen in

Section 4 and

Section 5, to determine polymer dynamics at elevated concentrations.

Section 6.1 considers self-similarity rationales.

Section 6.2 develops the mathematical basis for the alternative approach, the Altenberger–Dahler positive-function renormalization group.

Section 7 then uses the positive-function renormalization group to extend the calculations of

Section 4 and

Section 5 to large concentrations. The universal scaling equation for polymer self-diffusion is obtained.

Section 8 presents an ansatz for computing the frequency dependencies of the bulk and shear moduli. The ansatz,

two-parameter temporal scaling, arises from the inferred fixed-point structure of the positive-function renormalization group calculation of the shear viscosity.

Section 9 offers single-paragraph summaries, in publication order, of the theoretical and phenomenological papers that describe the hydrodynamic scaling model.

Section 10 summarizes the experimental results testing various aspects of the hydrodynamic scaling model. The tests confirm the validity of the model.

Section 11 discusses the results here, and considers consider where the hydrodynamic scaling model has gaps and omissions, thereby identifying a few directions for future research.

2. Single-Chain Behavior

2.1. The Models

This section discusses models for single-chain polymer motion. There are two major classes of models, namely models based on the Kirkwood–Riseman [

5] treatment, and models based on the treatments of Rouse [

3] and Zimm [

4]. Qualitatively, the two classes of model supply radically different descriptions for chain motion in dilute solutions. The hydrodynamic scaling model is based on extensions of the Kirkwood–Riseman model, while in contrast, many tube/reptation models reference the original Rouse treatment. I have previously discussed [

1,

2] the Rouse model in detail and will not repeat that discussion here. A major emphasis of this Section is therefore to alert readers familiar with Rouse and Zimm models as to the very different way in which Kirkwood and Riseman described the movements of an individual polymer coil.

In all of these models, a polymer chain is treated as a series of beads, pairs of beads that are connected by links. The polymer interacts hydrodynamically with the solvent via the beads, each of which acts as a small sphere or point that applies a frictional force on the solvent. The links are hydrodynamically inert. They serve to control the distances between the beads. In the Rouse and Zimm models, the beads are abstractions representing the hydrodynamic friction of a subsection of the polymer, while the links are treated as the subsections of the polymer chain, each subsection being barely long enough to have a Gaussian distribution of lengths. In the original Kirkwood–Riseman model, the beads were taken to be monomer units, while the links were the covalent bonds connecting one monomer to the next. In some modern applications of the Kirkwood–Riseman model, the beads and links are interpreted in the Rouse and Zimm sense.

In the Rouse and Zimm models, each subsection acts as a Hookian spring. Each subsection generates an attractive force on the two beads to which it is attached. The force has magnitude , where k is an effective spring constant and ℓ is the distance between the two beads; the force acts along the line of centers connecting the beads. In these models, the unstretched (rest) length of each subsection is zero.

In the original Kirkwood–Riseman model, the links are covalent bonds having rigid lengths and bond angles, but perhaps a potential energy for torsion. Within the model, the effect of the links is to determine the statistico-mechanical distribution functions for the distances between pairs of beads along the polymer chain. Because the beads of the original Kirkwood–Riseman model are monomers, the number of beads in a Kirkwood–Riseman chain can be very large, much larger than the number of beads in a Rouse or Zimm model for the same polymer. For beads that are well separated along the chain, in the Kirkwood–Riseman model, the distribution function for the bead–bead distance is assumed to be a Gaussian.

These models for polymer dynamics make contradictory assumptions as to which polymer chain motions are of interest in solutions. In the Kirkwood–Riseman model, the interesting motions of the beads are described as whole-body motion. In whole-body motion, the polymer beads may experience equal linear displacements, and they may rotate around the polymer center of mass, but the displacements and rotations are such that the chain motion does not alter the relative positions of the polymer beads. The phrase whole-body motion does not mean that the polymer coil is mechanically rigid. A full description of the motions of N polymer beads requires coordinates. The whole body motion description extracts from these coordinates a set of six collective coordinates, describing whole-body translations and rotations, with the remaining motions are described as the internal modes.

Kirkwood and Riseman are entirely specific that the polymer coil in their model has internal motions, so that the relative positions of beads fluctuate with respect to each other. However, in the Kirkwood–Riseman model, the whole-body motions are assumed to dominate polymer solution dynamics. Internal motions are taken to provide corrections to the dominant chain motions, the whole body displacements and rotations. The internal motions are coarse-grained out, so bead velocities are approximated as being the components created by the polymer translational and angular velocities. Kirkwood and Riseman did not compute the magnitude of the internal mode corrections.

In contrast to the Kirkwood–Riseman model, the Rouse and Zimm models assume that the beads move relative to each other. The relative motions of the beads are driven by attractive forces between adjoining beads, as created by the links. These relative motions are described by the Rouse–Zimm polymer internal modes, and are taken to dominate polymer solution dynamics. Rouse and Zimm model polymer coils do perform whole-body translation, but translation does not to contribute to the polymer solution’s viscosity.

2.2. Kirkwood–Riseman Model

We consider the Kirkwood–Riseman model [

5], whose ansatz provides the basis of the hydrodynamic scaling model. The Kirkwood–Riseman model is much less discussed than the Rouse and Zimm models and their extensions are, in part because it is more mathematically demanding, and in part because Kirkwood and Riseman used a less familiar notation. This presentation of the Kirkwood–Riseman model has therefore been reset in a more modern form.

The Kirkwood–Riseman model describes a chain of

N beads connected by links having a length of

. The links are covalent bonds, with adjoining links separated by a rigid angle

. Successive three-bead planes are related by a torsion angle

. In the original model, the potential energy was taken to be independent of the angle

. The effective bond length, the contribution of each link to the distance between distant beads, is:

For beads

ℓ and

s that are well separated, Kirkwood and Riseman supply several average values, notably:

Here, beads ℓ and s have locations and , is the vector from bead ℓ to bead s, , and is the location of the center of mass of the polymer, so that is the vector from the center of mass to bead ℓ. The final equation assumes that has a normal distribution.

The Kirkwood–Riseman model assumes that polymer beads have a long-range hydrodynamic interaction, as described by the Oseen tensor:

which gives the fluid flow created at a point

by a force

applied to the solution at point

. The vector from point

i to point

j is

, with magnitude

and corresponding unit vector

. Here,

is the solvent viscosity. In Equation (

11) and its associated notation, there is no assumption that there is a polymer bead at point

. The theoretical model treats the force as a point source, and assumes that the presence of the polymer has no effect on the solvent’s viscosity, an assumption that is experimentally known to be incorrect [

69,

70,

71,

72]. The fluid flow induced at

by

is:

Within the model, the forces

arise because the beads are moving with respect to the fluid. If a bead is stationary with respect to the local fluid flow, it exerts no force on the fluid. The force exerted on the fluid by a bead

ℓ is determined by the velocity

of the bead, the velocity

that the fluid would have had, at the point

, if the bead were not present, and the drag coefficient

of the bead, namely:

Because the beads are treated as points, a single bead is assumed to exert no torque on the surrounding fluid.

We now come to the modeled dynamics of the polymer. The beads are taken to lie along a Gaussian chain, meaning that, on average, their concentration declines with the distance from the center of mass, as a Gaussian in that distance. The velocities of the individual beads are taken to be entirely determined by the time-dependent chain center-of-mass velocity

and chain rotational velocity

as:

, as given by Equation (

13), is the velocity that the bead

ℓ would have, if it were part of a rigid body that had translational velocity

and rotational velocity

. We therefore describe the chain motions as whole-body translation and whole-body rotation. As noted above, Kirkwood and Riseman recognized that polymer molecules also have internal coordinates whose fluctuations contribute to the bead velocities, leading to an extra velocity component, different for each bead, in Equation (

14), but those components were neglected as an approximation.

What forces act on a polymer chain? The model assumption is that, in the absence of external forces, over long times, the polymer’s translational and rotational accelerations must both average to zero. Under these conditions, the long-time averages of the sum of the forces and of the sum of the torques on each chain must both vanish. The zero-force and zero-torque conditions determine the response of the polymer to an external force or to an external torque.

As an example of the effect of hydrodynamic interactions, we consider the drag coefficient (and hence the diffusion coefficient) of a polymer chain. The analysis of Zwanzig [

73] is followed. Note that Kirkwood and Riseman took

to be the force on the solvent, while Zwanzig takes

to be the force on the bead, so the papers have sign differences. We have a polymer chain whose beads have arbitrary velocities

, while the fluid at

has an unperturbed velocity

. The hydrodynamic interactions perturb the fluid flow at

, so the actual fluid velocity at

is:

However, the hydrodynamic force that a bead

k exerts on the solvent is:

where

f is the drag coefficient of a single bead. Combining the above two equations,

Subtracting

from each side of the equation,

which allows us to write:

The new matrix

is:

where the rule

has been applied and

is the

identity matrix.

Matrix inversion gives the

in terms of the

and the inverse of

, namely:

so the force on a bead

k due to its hydrodynamic interactions with the solvent becomes:

The minus sign appears because is the force of the bead on the solvent, not vice versa.

The drag coefficient

of the polymer chain is obtained by choosing all bead velocities to be equal to

and the unperturbed fluid velocity to be zero, and calculating the total of the drag forces on all beads of the chain, leading to:

Bead–bead hydrodynamic interactions, as described by the Oseen tensor, thus perturb the drag coefficient of the whole chain.

3. Extended Kirkwood–Riseman Model

Here, we consider the extension of the Kirkwood–Riseman model to treat multiple polymer chains. The calculation refers to time scales that are sufficiently long that polymer inertia can be neglected. The solvent is treated as a continuum fluid. Each polymer chain is treated as a line of beads that interacts with the solvent by applying to the solvent a series of point forces. The point forces create solvent flows and hydrodynamic forces on other polymer beads, the flows and forces being described by mobility tensors . Beads on each chain are linked by springs; a spring is a hydrodynamically inert coupler that determines the distribution of bead–bead distances. We only consider ghost chains that can pass through each other; excluded volume interactions only serve to set the minimum distances of approach between pairs of beads. Chain motions are approximated by whole-chain translation and rotation; internal modes that change the shape of a chain have not yet been included in the hydrodynamic scaling model.

3.1. Bead–Bead Hydrodynamic Interactions

The effects of hydrodynamic interactions are usefully described by mobility tensors . These tensors give the hydrodynamic force on a bead (or chain) i due to the force a bead (or chain) j exerts on the solvent; is allowed. Separate expressions are needed for the self () and distinct ( components of . For the calculations here, we begin with the that relate the force on bead i to the force that bead j applies to the solvent. After some work, we end with a second set of mobility tensors that give the force and torque on a chain i due to a force or torque applied to the solution by a chain j.

The mobility tensors are specifically of interest because they determine the self-diffusion coefficient via:

Here,

is Boltzmann’s constant and

T is the absolute temperature. For spheres in solution, the mobility tensors can be expanded as power series in

, where

a is a sphere radius and

r is the distance between the spheres, as developed by Kynch [

48], Mazur and van Saarloos [

74], this author [

75], and Ladd [

76]. Part of the expansion improves the accuracy of the hydrodynamic interaction tensor for spheres that are close to each other. Other extensions describe additional interactions between three or more spheres. The lowest-order approximation to the hydrodynamic interaction between two spheres is the Oseen tensor. The

can be expanded as [

48,

74,

75]:

for the self terms, and:

for the distinct terms.

The leading terms of the

and

tensors are [

74]:

where only the lowest order term (in

) of each tensor is shown. See Mazur and van Saarloos [

74] for the higher-order terms. Here,

is the unit tensor,

, the unit vector is

,

is the solvent viscosity, and

is an outer product.

and describe the hydrodynamic interactions of a pair of interacting spheres. describes the velocity induced in particle i due to a force applied to particle j, while describes the retardation of a moving particle i due to the scattering by particle j of the wake set up by i. and describe the interactions between trios of interacting spheres. describes the velocity of particle i by a hydrodynamic wake set up by particle l, the wake being scattered by an intermediate particle m before reaching i. describes the retardation of a moving particle i due to the scattering, first by m and then by l, of the wake set up by i.

In most of the following, the individual beads are taken to be small relative to the distances between beads on different polymer chains, so only the lowest-order (in

) term is used to describe the bead–bead interactions, this being the Oseen tensor of Equation (

29).

3.2. Chain–Chain Hydrodynamic Interactions

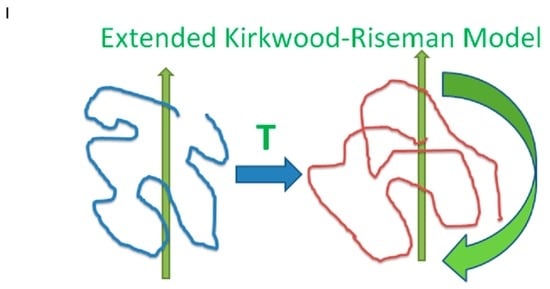

Having considered the hydrodynamic interactions between polymer beads, we now advance to calculate the hydrodynamic interactions between the pairs of polymer chains. The method of reflections is used to compute the interchain hydrodynamic interactions. A chain whose beads move with respect to the solvent creates flows in the surrounding solvent. These flows act on other chains. In response to those flows, the other chains move. Those chain motions induce additional solvent flows. The hydrodynamic equations are linear, so if a chain A is subject to flows due to chains B and C, the flow acting on chain A is the sum of the flows created by B acting on A and by C acting on A. Because the flow properties are linear, all hydrodynamic effects can be obtained by considering a line of chains, with each chain acting on the next in line. We say that the process is scattering: The flow created by each chain is scattered when it encounters the next chain in the line. It is not assumed that each chain in a line must be different from all the other chains in a line; the line of chains may loop back on itself so that a given chain appears in the line more than once. A crude image of the hydrodynamic effect of one moving chain on the next is given by this paper’s graphical abstract. A chain (left, blue line) moves (green vertical arrow) and puts forces on the fluid. In response, the fluid moves, symbolically represented by the horizontal arrow labeled “T”. The second chain (right, red line) responds by translating and rotating (two green arrows).

The chains in a line are labeled 1, 2, 3, …. The center-of-mass location of chain j is the vector , with j labeling which of the chains is involved. The location of a bead i with respect to its chain’s center-of-mass is . Each step of the calculation here involves only beads on a single chain, so does not need a separate label specifying the chain of which it is a part. The vectors from the center of mass of each chain in the line to the next chain’s center of mass are the vectors , with . Solvent flows are denoted ; they are implicit functions of position even if no dependence on is specified. An imposed solvent flow, such as a fluid shear field, is denoted ; in a quiescent liquid, . Solvent flows created by the first, second, … chains in a sequence are denoted , , …, respectively.

The velocity

of a bead

j that is located on chain

i may be divided between the center-of-mass motion, whole-body rotation, and internal mode motions as:

Here, the chain’s center-of-mass velocity is , the chain’s angular velocity around its center of mass is , and the bead motions arising from chain internal modes are denoted by . The superscripts on and identify the reflection that created those parts of and .

The chain center-of-mass velocity is:

is determined by averaging over the

N beads of chain

i, namely:

The

and

are independent of

, so

can be determined from Equation (

31) as:

The instantaneous-square chain radius is .

The model describes the low-frequency regime. The chain linear and angular momenta fluctuate, but over the time scales of interest herein, the fluctuations average towards zero. For the same reason, contributions to fluid flow from the higher-frequency

are not taken into account. If the fluctuations in the total linear momentum and total angular momentum of each chain average towards zero, from the fundamental mechanics the total force and total torque on each chain after the first must also average towards zero. (The first chain in a line may also be subject to external forces, torques, or fluid flows, and so is a special case.) One obtains:

and:

The four Equations (

33)–(

36) take us from the fluid velocity

at the beads of chain

n to the center-of-mass translational and rotational velocities

and

of chain

n. The

and

depend on the relative positions of the chains.

For the calculation of the self-diffusion coefficient, the first chain in the series is presumed to have some initial velocity that corresponds to its performing translational motion. For the calculation of the viscosity increment, the first chain in the series finds itself in a velocity shear. As will be seen, each chain moves at the local flow velocity. Each chain rotates so as to attempt to comply at its every point with the imposed shear flow. Each chain can translate and rotate, but its local velocity at every bead cannot be the same as the velocity that the fluid would have had at the same point if the chain were absent.

4. Extended Kirkwood–Riseman Model: Self-Diffusion

We now implement the method of reflections as described above. We begin with polymer chain 1 that has linear velocity

and angular velocity

with respect to the unperturbed and hence quiescent solvent. A bead

j on chain 1 then has the velocity

, plus a component corresponding to the internal modes that we are neglecting. The flow

induced at

by all

M beads of chain 1 is:

In the spirit of the Kirkwood–Riseman calculation, we now average over detailed relative locations of the individual beads. Functions of the vector from the center of mass replace the functions of the bead label j. All sums over beads are replaced with the integrals , being a vector from the chain center of mass to a point within the chain, with being the density of beads at , and being the effective drag coefficient of the beads at . The integral of over the complete chain is the total drag coefficient . Correlations in the shapes of nearby chains are neglected.

A series expansion for the Oseen tensor is

, namely:

The resulting induced flow field, to the lowest order in the series expansion, is:

In the above, . Terms odd in vanish by symmetry. , the chain drag coefficient, is . By direct calculation, . Here, and are the radii of gyration and the hydrodynamic radius of the chain, with additional numerical subscripts on and being used to identify which chain’s radii are under consideration.

The result of these steps is:

The indicated terms are the longest-range parts of the flow field created by the motions of the first chain. By expanding to a higher order in , one would obtain higher-order in terms .

The calculation now proceeds by iteration. The flow field exerts forces on the next chain in the series. The zero-force and zero-torque conditions let us calculate the linear and angular velocities and of the next chain. Under the approximation that we neglect chain internal modes, the beads of the next chain move with velocities . These beads cannot simply move with the solvent. As a result, the beads of chain 2 exert forces on the solvent, thereby creating a new flow field , where is now measured from the center of mass of chain 2.

The force on a representative bead

i of chain 2, due to the flow field

scattered by chain 1, is:

where

is the bead’s drag coefficient. The bead is at

, a displacement by

from the displacement

of the center of mass of chain 2 from the center of mass of chain 1.

The zero-force and zero-torque conditions are then applied to chain 2. To do this, beads at the locations

are again replaced with a bead density

, and the flow field

is given a series expansion, centered on the center-of-mass of chain 2, in the powers of

. The zero-force condition starts as:

while the zero-torque condition starts as:

After noting that everything except

itself is independent of

, while terms odd in

integrate to zero, and integrating on

, one finds:

and:

the subscript on the

∇ being the variable with respect to which the derivatives are taken. Taking the spherical averages, one finally reaches [

41]:

The flow field due to scattering from chain 2 is:

The calculation of higher-order scattering events proceeds by iteration. From the linear and angular velocities

and

of chain

n in the sequence, we compute the induced fluid flow field

at the location of chain

. From the flow field, we compute the linear and angular velocities

and

of chain

. We can now repeat the process

ad infinitum. The final calculation only needs the part of

created by the linear velocity

of the first bead, namely:

This form does not include the contribution to from .

The terms of the mobility tensors

are obtained from the

or the

by setting

and suppressing the

. One obtains for the relevant parts of the mobility tensor:

and:

Taking appropriate ensemble averages over these tensors leads to a pseudovirial expansion for the self-diffusion coefficient, viz.,

The numerical coefficient in the term was obtained by Monte Carlo integration.

We have now used a generalization of the Kirkwood–Riseman model to treat interchain hydrodynamic interactions. The motions of each chain set up wakes in the surrounding fluid. The surrounding fluid drives the motion of other chains in the fluid, creating fresh wakes which act on still further chains in the sequence. Our generalization has several lacunae. Intrachain hydrodynamics were not included in the calculation. The accuracy of the calculation will diminish when chains overlap, due to the strong interchain hydrodynamic interactions between pairs of nearly adjacent beads.

Short-Range Hydrodynamic Effects

The purpose of this subsection is to reveal some of the ways in which higher-order hydrodynamic interactions modify polymer dynamics. I follow the results of Phillies and Kirkitelos [

35]. There are very considerable opportunities for extending the results of Ref. [

35].

Equations (

27)–(

30) introduce short-range hydrodynamic interactions, corrections to the Oseen tensor approximation that become most important when the diffusing bodies are close together. Consequences of short-range hydrodynamic interactions for the diffusion of colloidal spheres have been intensively studied [

77]. Because beads of the same polymer are obliged to remain close to each other, the effects of short-range hydrodynamic interactions are reasonably expected to be at least as important for polymer dynamics as for colloid dynamics. Several authors [

12,

78,

79] have developed multiple scattering approaches for treating polymer–polymer interactions, but none of these developments have included short-range interactions. Freed [

80] previously identified the use of short-range hydrodynamic interactions as an unexplored possibility in this context.

Some effects of short-range interactions on polymer diffusion have already been examined. The Oseen tensor

effectively approximates the interacting bodies as points, an approximation conspicuously dubious when treating the diffusion of a linear rod polymer around its major axis. Bernal [

81] models a rod as a shell of small spheres in order to remove the approximation. The DeWames–Zwanzig singularity [

82,

83] in the Kirkwood–Riseman [

5] treatment of translational diffusion by a rigid rod was shown by Yamakawa [

84] to be eliminated by including the

corrections to the Oseen tensor.

Phillies and Kirkitelos [

35] made two applications of the short-range hydrodynamic interaction tensors. First, they calculated the chain–chain hydrodynamic interaction tensors including bead–bead interactions out to the

level, both for the chain–chain

and to a higher level for the chain–chain

. They further calculated the effect of the short-range hydrodynamic interactions on the diffusion coefficients of a free monomer and for a monomer bead incorporated into a polymer chain in solution. These effects are entirely distinct from the contribution of short-range hydrodynamic interactions to the chain–chain hydrodynamic interaction tensors. Because the beads of a polymer are always close to other beads of the same chain, at no polymer concentration can the diffusion coefficient of a chain monomer be as large as the diffusion coefficient of a free monomer. At concentrations below the overlap concentration, solvent molecules readily penetrate into polymer coils, but polymer chains do not interpenetrate a great deal. As a result, the addition of polymer molecules to a dilute solution is more effective at delaying the motion of free monomers than at delaying the motion of monomer units of a given polymer chain. At polymer concentrations above the chain overlap concentration, the total polymer concentration is the same everywhere in the solution, but the correlation hole created by a chain of interest ensures that the concentration of the other chains, near the beads of the chain of interest, is never as large as the average concentration of chains in the solution. As a result, the effect of interchain interactions on the mobility of a given polymer bead is never as large as the effect of the same interactions on the mobility of a free monomer in the solution.

Higher-order hydrodynamic interactions make contributions of the same nature to the drag coefficients of a free monomer and a whole chain. However, the contributions to the free monomer and chain drag coefficients are not equal; nor are they multiplicative, contrary to the core assumption behind the common practice of normalizing polymer transport data with small-molecule diffusion coefficient data as a correction for ’monomer friction effects’. The notion that the concentration dependence for for free monomers or solvent molecules reveals the concentration dependence of the mobility of monomer units within a polymer chain is therefore incorrect. However, the effect of interchain interactions on the free monomer mobility and on the mobility of monomer units of polymers can be calculated separately.

5. Extended Kirkwood–Riseman Model for the Viscosity

This section considers the contribution to the solution viscosity from chain–chain hydrodynamic interactions, as obtained from an extended Kirkwood–Riseman model. We obtain the lead terms in a pseudovirial expansion for . The underlying hydrodynamic interactions depend on the interchain distance r as or , so the convergence of the pseudovirial expansion’s cluster integrals is potentially delicate. Our general approach is to apply a velocity field to the solution, and calculate the additional power dissipation caused by the polymer beads as they move with respect to the solvent.

5.1. Flow Fields from Scattering of a Shear Field

We choose to impose a spatially oscillatory flow field:

is the bare velocity field and k is the spatial oscillation frequency. The oscillations are not time-dependent, so the shear magnitude is . The mean-square average shear is . The shear is assumed to be sufficiently weak that the average spherical symmetry of the polymer chain is not perturbed.

The effect of the spatial oscillations is to ensure that the total of the external forces, applied to the fluid to create the flow field, vanishes. At the end of the calculation, we take the limit

. As seen below, the scattering of the velocity field by the polymer molecules makes an additional contribution to the flow field, so that the experimentally measured velocity field will not be the field given by Equation (

52). The observable shear field will include the contributions due to the scattering of the imposed shear field by all the polymers in the solution.

The power

P dissipated by polymer chains in a solution flow is:

Here, the sum proceeds over all N beads of each of the M chains in some volume V, with being the drag coefficient of bead j of chain i, being the velocity of that bead, and being the velocity that the solvent would have had, at the location of the bead in question, if the bead had been absent.

The viscosity increment is extracted from

P via the relationship:

where the velocity shear was simplified to correspond to the flow field directions described by Equation (

52).

To describe the polymer chains and their motions, we use the same notation as that introduced in the previous section. Because the fluid motions are not the same as in the self-diffusion problem, the calculational details change.

Each chain’s center-of-mass translational velocity is the average of the velocities of its

N beads, so:

The translational, rotational, and internal mode components of the chain motion are independent of each other, so the rotational velocity vectors

follow from:

As in the previous section, the zero-force and zero-torque Equations (

35) and (

36) determine how each chain moves.

The applied solvent flow within chain

is obtained from

via a Taylor expansion around the center of mass of chain

, to wit:

The are in part determined by , the location of the first chain, and those of the with , these being the displacement vectors taking one from chain 1 to chain n.

For the first chain, after making a Taylor series expansion of the fluid velocity around the chain center of mass

(with

and

), the zero-force condition may be written:

Because we are discussing weak shear,

is spherically symmetric, so only terms even in

survive integration, leading to:

Up to terms in , the first chain simply moves with the velocity that the solvent would have had, at the chain’s center of mass location, if the chain were not present.

Substituting for

and

, the corresponding zero-torque condition is:

We denote

. Applying an extended series of identities seen in Ref. [

45], one finally obtains:

which is the result of Kirkwood and Riseman [

5] for a single chain in a shear. The chain on the average rotates at half the shear rate at its center of mass.

Chain 1 cannot be stationary at every bead with respect to the fluid. For example, it is doing whole-body rotation, so some of its beads are moving in directions perpendicular to the direction of the fluid flow. The fluid flow, bead velocity, and Oseen tensor then combine to give the fluid flow

induced by the first polymer chain, namely:

A Taylor-series expansion of the Oseen tensor is:

where:

Upon substituting in Equation (

62) for

,

, and

, and applying identities for integrals over

, the induced flow is:

The process now advances by iteration.

acts through a vector

on chain 2 inducing in it a translational velocity:

and a rotational velocity:

Here, .

The fluid flow that has been double scattered by chains 1 and 2 is:

Phillies [

45] supplies the corresponding large expressions for

,

, and

.

5.2. Power Dissipated by Chains in a Shear Field

We now advance to calculate the power dissipated by the polymer molecules as they move with respect to the fluid. The simplest case refers to dilute chains in a shear

, for which Equation (

53) becomes:

and

are canceled. In the model, internal chain modes are neglected, so the

does not modify the viscosity. Changing variables from

to

, applying needed identities for the integrals on

, and averaging

over chain configurations and positions,

The average over chain positions is needed because the shear rate depends on the position. In the above calculation, the limit could have been taken either before or after the positional average.

We calculated above the scattering of the shear field by a specific first chain to a specific second chain, etc. The flow field acting on a given bead includes the original shear field and also all scattered flows that reach that bead. On the same line, the center-of-mass velocity and rotation rate of a given chain are simply the sums of the center-of-mass velocities and rotation rates induced by all flows acting on the given chain.

We now introduce a systematical notation that includes all scattering events. The chain locations are more useful as variables than the displacement vectors. The flow created at

by single scattering from a chain at

is:

Similarly, the double-scattered flow at due to beads 2 and 3 is , and so forth.

The total flow field at

due to single scattering of the shear field by all chains other than the representative chain 1 is:

For double-scattered flows, a similar notation arises,

with the restriction on the double sum being that the last chain in the series cannot be chain 1.

What we next do is to calculate all of the flow fields at the representative chain 1. This includes the original shear field at chain 1, and the flow fields created at chain 1 by each of the other chains in the solution, and the flow fields that were created by one chain and scattered by a second chain before reaching chain 1. We then calculate the power dissipation due to chain 1, averaged over all locations of all chains, calculating the total shear gradient, and finally find the contribution of the representative chain 1 to the viscosity increment.

Chain 1 is a representative chain, it could equally be any chain in the solution. If chain 1 is at

, so

, the

,

,…induce chain motions

,

, etc., as calculated above. The zeroth-scattering-order velocities

and

are created by the initial shear field. The higher-order parts of

and

, the parts with

, are due to scattering by all combinations of other particles, so:

and correspondingly:

In these sums, the neighboring arguments of a , , or must be distinct.

The total velocity at chain 1 is:

while for rotation;

The Debye form for the power dissipated by a representative chain is obtained from a sum over the

N beads of the chains:

We advance with Taylor series expansions in

. As seen above, to lowest order in

,

and

cancel term-by-term for all

n, so:

The square generates three sorts of terms. Averaging over chain configurations,

Terms in with average towards zero.

In addition:

and:

while from the zero torque condition:

We obtain the general form for the power dissipation, namely:

with:

The Einstein derivative notation:

(where

represent the three Cartesian coordinates) is in use. The average is over all chain locations. In the first sum,

is allowed. For example, a particle rotating at

is moving not only with respect to the driving flow

but also with respect to the original imposed shear field

.

5.3. The Total Shear Field

In the previous subsection, the bare shear field was . The polymer motions and the flow fields that they create can all be traced back to the bare shear field and subsequent scattering events. However, if one performed a viscosity measurement, one applies a force, obtains some shear rate, and measures the required force and the corresponding shear field.

We considered fluid flows and power dissipation created by an imposed shear field

. The imposed field created further flows

,

, ⋯ via scattering from the polymers in solution. All flows are part of the total flow

and its associated shear,

. Physically, only the total flow can be experimentally measured. The imposed shear is inaccessible to physical observation, so it must be replaced by the total shear. There is here a physical analogy with the replacement made in calculating the dielectric constant, in which the induced dipoles and the total electric field including material contributions must both be calculated, as discussed in this context by Peterson and Fixman [

85].

The shear field at

, due to scattering by a polymer a displacement

away, is:

A similar but more complex form [

45] gives the shear transmitted from double scattering through

and

to a location

. An ensemble average over all particle locations, practicable thanks to Mathematica for doing the final integrals, gives the parts of the total shear arising from single and double scattering. For single scattering, one has:

where

c is the number density of polymer molecules. For the double-scattered shear,

Integrals of

over all space do not converge. Because we chose a spatially oscillatory imposed shear field, in preparation for later taking a small-

limit, we obtained convergent integrals for

and

, at least when

and

are integrated over ranges

, the limits

and

are then taken. From Equations (

52), (

88) and (

89), we obtain the total shear through second-order concentration contributions, namely:

5.4. Linear and Quadratic Terms—The Huggins Coefficient

We now calculate seriatim the contributions

to the dissipated power, in Equation (

84). On dividing out the square of the total shear, Equation (

90), a pseudovirial series for the viscosity is obtained.

The lowest-order term in the series is

. Combining the results above for

and

, and taking needed derivatives and integrals:

where

is the ensemble average over-chain center-of-mass locations. Including contributions by all

polymer molecules,

The full power series for P is infinite. To evaluate, we must truncate or resume the series. Here, we advance by truncation. There are two obvious choices of truncation variable. Terms could be ordered by the number of scattering events that they include. Terms could also be ordered by how many different particles they include. The lowest-order truncation gives the terms with zero scattering events and one polymer chain; these are the terms analyzed by Kirkwood and Riseman. All higher-order truncations are of mixed order: either they include all terms with a given number of particles but omit some terms involving a given number of scattering events, or alternatively they include all terms involving a given number of scattering events, but omit some terms involving a given number of particles. Higher-order includes terms that only involve a few chains but incorporate many scattering events, because flow fields can be scattered back and forth between two chains an arbitrary number of times. However, the forms for , , and show that each scattering event reduces the interaction range by an additional factor of . By analogy with the equilibrium theory of electrolyte solutions, we retain the longest-range interactions, in which a couples distinct chains. These interactions, the ring diagrams, provide the leading terms of . They describe scattering by a series of scattering chains at , finally reaching chain 1 at . Particle 1 is simply a representative particle; we compute all the scattered flows acting on particle 1, and use them to compute the total power dissipated by chain 1.

The model here leads to a power series in , thus agreeing with the phenomenological observation that is a good reducing variable for c. , evaluated above, is proportional to . In , in the factors and , the chains in the a and b terms may be the same or may be entirely or partly different. For each independent , the ensemble average yields a factor , which is the number of different polymer chains that j could have represented. Each chain appearing in one of the corresponds to a scattering event, each event giving a factor . The leading terms of the are thus , so the power series for P itself is an expansion in powers of .

At long range, the hydrodynamic interaction tensors describing the

and

depend on interparticle spacings as

. Divergences were avoided because we took a sinusoidal imposed flow

and then took the long-wavelength

limit. The hydrodynamic interaction tensors also diverge at short range. We supply an effective short-range cutoff, because the physical

and

are finite at small

r. Peterson and Fixman [

85] proposed a related cutoff, namely that two overlapped chains were approximated as moving as a rigid dumbbell.

We now compute the

contributions to

, these being the

with

or

. Terms with two chains and more scattering events are allowed by the formalism but will be smaller because the interactions will be shorter-ranged. For

:

Here, is Boltzmann’s constant, , T is the absolute temperature, is the potential energy, is the normalizing factor, and the p and q label chains. The average over internal chain coordinates gives an .

All terms of the sum over

p and

q are identical save for the label. The ensemble average is:

The non-zero derivative of

is:

where

is the

x component of

. The matching derivative of

is:

refers to the final particle in the scattering sequence; points from the penultimate to the ultimate particle of the scattering sequence.

The angular velocities appear in Equations (

61) and (

67). In these equations,

is the shear at the first particle of the scattering series, namely

and

, respectively. The identity

is then applied. The ensemble average only depends on

through

, which vanishes on averaging over

.

Recalling the standard form:

for the radial distribution function, here with

,

In the radial integral, the lower cutoff is not required for

. Without the

, the

diverges at a large

R; the angular integral vanishes; and the

is improper. The proper long-wavelength limit results from taking

and then taking

. If the shear were linear and not oscillatory in space,

would be undefined, as observed three-quarters of a century ago by Saito [

10].

Choosing

to be parallel to the X axis, a useful identity is [

86]:

Here, is a spherical Bessel function, and is the angle between and .

On invoking spherical coordinates, recourse to Mathematica gives:

How can this term be negative? Mathematically, in the intrinsically positive form

the term

can be negative; in the calculation here,

can play the role of a

. Physically, Equation (

100) is negative because

causes chain 1 to rotate, thereby reducing the velocity difference between chain 1’s beads’ velocities and

, so dissipation is reduced by this term.

We now turn to

. Writing

and

as sums over all the other particles in the system,

Only the self (

) terms of Equation (

101) are significant; the distinct (

) terms give an effect cubic in concentration. To

:

The convergence here at large

R is sufficiently strong that the integrals and the

limit can be exchanged, giving:

requires a short-range cutoff

a for the convergence of

. Such a cutoff is physically appropriate. Equations (

65) and (

67) represent the long-range parts of series expansions. Short-range terms that prevent divergence are represented herein by the cutoff distance. Inserting such a cutoff into

has little effect.

Via integration, one obtains:

In terms of the series

of:

the Huggins coefficient being

,

and:

The cutoff radius a is a crude approximation. A sound treatment of hydrodynamics of interpenetrated random coils is needed. One reasonably expects a to be moderately smaller than S.

7. From Renormalization Group to Universal Scaling

In this section, we advance from the hydrodynamic calculations of

Section 4 and

Section 5 and the positive-function renormalization group approach developed in

Section 6.2 to extrapolate the concentration dependence of

and

. We invoke the Altenberger–Dahler positive-function renormalization group and Equation (

51) for the concentration and chain radius dependencies of

to extrapolate

to larger concentrations. Equation (

51) includes both

and

; these are approximated as being a single radius

. We identify the concentration variable of the renormalization group calculation as the physical concentration

c, and choose

as the dimensionless coupling parameter.

is identified as

at

.

All dependence on

R is now explicit. The renormalized pseudovirial coefficients are:

and:

At concentration

,

, and

c and

R are both dimensionless. These equations differ from the expressions employed by Altenberger and Dahler [

49,

50] in one significant way. In the earlier calculations,

c and

R always appeared as the product

, so that the

term of their virial expansion depended on

R as

. Here, the

c and

R dependencies are distinct.

is transformed into

by dividing by

.

of the prior section is identified as

. All dependence of

on

R can be moved to the numerator via the expansion

. So long as one truncates at

, which is the highest-order limit of the original hydrodynamic series, one finds:

Identifying the concentration variable

z of the prior section with

c here,

arises from the logarithmic derivative of

as:

The other generator,

, is determined by

, its first and second derivatives evaluated at

, and

to be:

The final approximation follows from

after expanding the denominator in powers of

, applying a geometric series expansion, and only retaining terms of order

and lower. Altenberger and Dahler now offer the approximation that the dependence of

on

for

is given by the dependence of

on

R at

by replacing

R in the latter with

. With this approximation:

Noting

, an integral with respect to

yields:

and

have opposite signs, with

, and

, so

is well behaved. The prediction for

is:

with the functional behavior of

appearing in Equation (

140). Ref. [

41] performed a numerical integration of these equations, showing that

is very nearly a simple exponential in

c, and that the calculated

is very nearly independent of

so long as

is small enough that

. The reference further noted evidence from the viscosity measurements that the renormalization group development could have an interesting fixed-point structure, but that here only the fixed point at the origin would be taken into account.

As the final step in the analysis, the issue of the concentration dependence of

was considered at the level of approximation of the Daoud formula, in Equation (

115). The proposed approach to calculating

was to imagine using the positive-function renormalization group separately for each final concentration, in each case performing the process with chains whose size was independent of concentration but which were the correct size for the target final concentration. The needed integration of Equation (

141) was analytically performed by limiting terms to the

level, leading to:

or finally:

which is the universal scaling equation. The above analysis finds that this result is the

approximation of a more accurate result.

Reference [

41] also demonstrates that exponentials and stretched exponentials in

c and

R are invariants of the positive-function group transformation: If you start with a stretched exponential in

c and

R, you end up with a stretched exponential in

c and

R as the outcome of the renormalization transformation.

8. Polymer Solution Viscoelasticity from Two-Parameter Temporal Scaling

We now make a change of pace. The use of renormalization group procedures to extrapolate and to elevated concentrations suggested using renormalization group approaches to infer the frequency dependencies of those properties. In the above, the calculations of hydrodynamic interactions were primary, with the self-similarity or the positive-function renormalization group being used to extend those calculations to elevated polymer concentrations. In this section, we focus almost entirely on the renormalization group properties of the calculation, deducing the aspects of the fixed-point structure of the renormalization group for the viscosity from empirical evidence. We then extend this analysis to a two-parameter form, thereby inferring the functional form for the frequency dependence of the loss and storage moduli.

The approach was put into effect in Ref. [

42], which introduced a two-parameter temporal scaling to calculate how the loss modulus

depends on frequency. The approach was entirely successful so far as it went, but has limitations that still need to be overcome. First, temporal scaling predicts the functional dependence of

and therefore the storage modulus

on

; however, in its current form temporal scaling gives no information on any numerical parameters found in the predicted functions. Temporal scaling does not yet predict how those parameters depend on polymer concentration or molecular weight, let alone what values the parameters have. Second, temporal scaling does not invoke a molecular model of a polymer solution. As a result, its predictions are substantially noncommunicating with the treatments of polymer viscoelasticity that begin with detailed models for molecular motions and intermolecular forces, such as those by Graessley [

87,

88], Bird et al. [

89,

90], and Raspaud et al. [

91].

Two-Parameter Temporal Scaling: Fundamental Approaches

The two-parameter temporal scaling approach has five theoretical parts and an experimental confirmation.

The five theoretical parts lead us to the frequency dependence of

. First, the renormalization group derivation of the universal scaling equation for

is used to treat the low-shear solution viscosity

. Second, the phenomenological [

21] behavior of the solution viscosity is examined. Third, the experimental phenomenology for

is used to infer the fixed-point structure of the full renormalization group treatment of

. Fourth, we advance from one- to two-parameter scaling by recognizing that

is the low-frequency limit of

. Fifth, from the inferred fixed-point structure of the associated renormalization group, we infer how

depends on

at a fixed

c. Finally, a comparison is made with the experimental literature, finding that the two-parameter temporal scaling approach correctly predicts the observed frequency dependencies. In more detail:

First, as discussed above, the hydrodynamic scaling model for self-diffusion leads to power series for , which the positive-function renormalization group approach transforms into an exponential concentration dependence for . The corresponding hydrodynamic calculation for the viscosity, and the same renormalization group approach, leads to an exponential concentration dependence for . In each case, the effect of chain contraction with increasing polymer concentration is to replace the simple-exponential concentration dependence with a stretched-exponential concentration dependence.

The remainder of the analysis only invokes the renormalization group aspect of the calculation, and depends not at all on the assumption of the hydrodynamic scaling model that interchain interactions in the solution are dominated by hydrodynamics. If interchain interactions were instead dominated by chain crossing constraints or by

cryptocrystallites [

92], the low-concentration behavior was still a power series in concentration, the renormalization group part of the analysis would only suffer quantitative changes.

Second, there is an extensive experimental phenomenology for polymer solution viscosity. Reviews [

21,

59] of nearly the entirety of the phenomenological literature on

find that

indeed has the predicted stretched-exponential concentration dependence. In many but not all systems, there is an elevated concentration

above which

instead depends on

c as a power law:

in

c and not as a stretched exponential in

c. Here,

and

x are phenomenological constants. We describe the transition at

as the

solutionlike-meltlike transition. When the transition occurs, the transition concentration is typically

, with