Evaluation of Physico-Mechanical Properties and Thermal Conduction to Energy-Saving Effects of Wood Compression Layered Structural Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

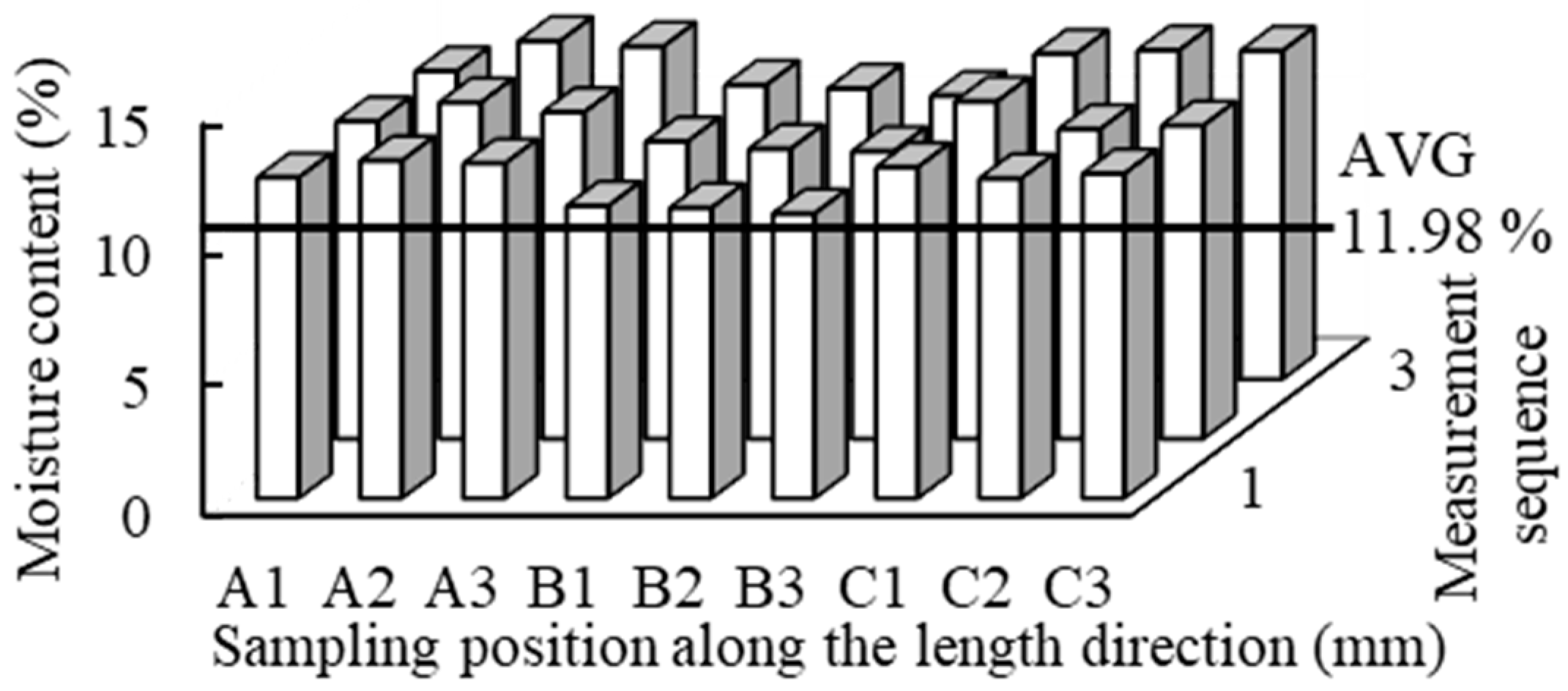

2.2. Basic Properties Measurement of Japanese Cedar

2.2.1. Moisture Content

2.2.2. Density

2.3. Development of WCLS

2.3.1. Pretreatment of Test Material before Compression

2.3.2. Selecting Conditions for Densification

2.3.3. Development of Drying-Set Treatment

2.4. Properties Determinate of WCLS

2.4.1. Basic Properties Measurement of WCLS

2.4.2. Surface Properties Measurement of WCLS

2.4.3. Measurement of Physico-Mechanical Properties of WCLS

2.4.4. Measurement of Thermal Properties of WCLS

2.4.5. Evaluation of Thermal Conductivity and Electricity Energy Consumption

2.5. Statistical Analysis

3. Results and Discussion

3.1. Basic Properties of Japanese Cedar

3.2. Surface Densification

3.2.1. Measurement of Hot-Pressing Temperature

3.2.2. Compression-Set of Surface Densification

3.3. Drying-Set Treatment

3.3.1. Compression-Set of Drying-Set Treatment

3.3.2. Compression-Set Recovery

3.4. Basic Properties of WCLS

3.4.1. Moisture Content, Density, Compression-Set and Weight Loss

3.4.2. Density Profile

3.5. Surface Properties of WCLS

Scanning Electron Microscope

3.6. Physico-Mechanical Properties of WCLS

3.6.1. The Dimensional Stability

3.6.2. Bending Strength

3.6.3. Surface Hardness

3.7. Thermal Properties of WCLS

3.7.1. The Thermogravimetric Loss

3.7.2. Glass Transition Temperature

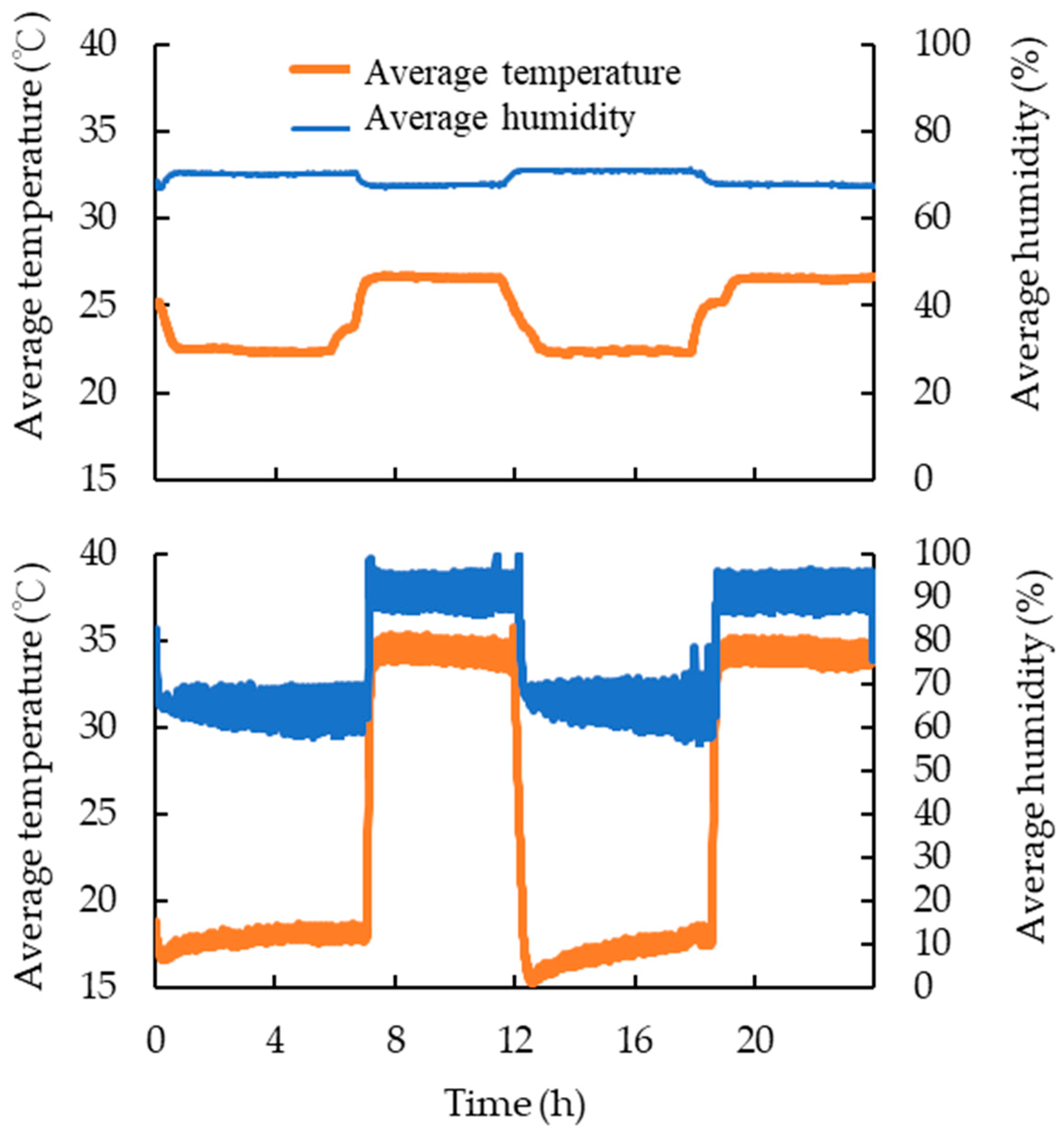

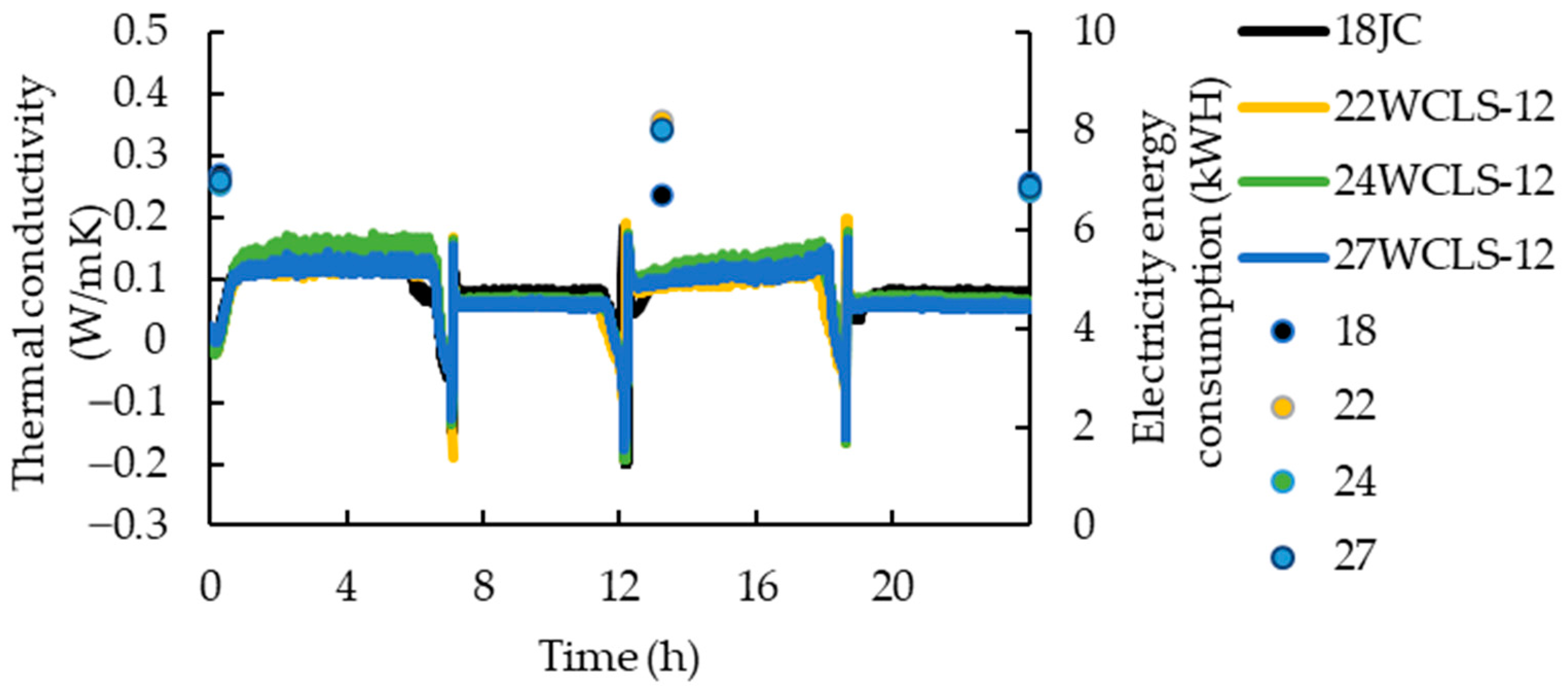

3.8. Thermal Conductivity of WCLS with Different Compression-Set Rates in Atmospheric Environment

3.9. Effects of Different Temperature and Humidity on Thermal Conductivity and Electricity Energy Consumption of WCLS

3.10. Effects of Simulated Outdoor Temperature and Humidity Changes on Thermal Conductivity and Electricity Energy Consumption of WCLS

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Organization of Nature Center of Forestry Bureau. The 4th Forest Resources Inventory Project; Organization of Nature Center of Forestry Bureau: Taipei, Taiwan, 2016; pp. 45–48. [Google Scholar]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies-a review. Iforest-Biogeosci. For. 2017, 10, 895. [Google Scholar]

- Bi, W.; Li, H.; Hui, D.; Gaff, M.; Lorenzo, R.; Corbi, I.; Ashraf, M. Effects of chemical modification and nanotechnology on wood properties. Nanotechnol. Rev. 2021, 10, 978–1008. [Google Scholar]

- Li, W.; Ren, D.; Zhang, X.; Wang, H.; Yu, Y. The furfurylation of wood pp. A nanomechanical study of modified wood cells. BioResources 2016, 11, 3614–3625. [Google Scholar]

- Navi, P.; Sandberg, D. Thermo Hydro Mechanical Processing of Wood; EPFL Press: Lausanne, Switzerland, 2012; p. 376. [Google Scholar]

- Kuo, W.L.; Lu, K.T. Characteristics of Cryptomeria japonica and Acacia confuse Heat-Treated Woods with Different Temperatures. For. Res. Q. 2012, 34, 269–286. [Google Scholar]

- Kutnar, A.; Humar, M.; KamkeF, A.; Sernek, M. Fungal decay of viscoelastic thermal compressed (VTC) wood. Eur. J. Wood Wood Prod. 2011, 69, 325–328. [Google Scholar]

- Morsing, N.; Hoffmeyer, P. Densification of Wood: The Influence of Hygrothermal Treatment on Compression of Beech Perpendicular to Gain, Kgs; BYG-Rapport; No. R-79; Technical University of Denmark (DTU): Lyngby, Denmark, 1998. [Google Scholar]

- Li, Y.F.; Gong, D.W.; Dong, X.Y.; Liu, Z.B. Mechanical properties of woodpolymer composite prepared by in-situ polymerization of methylmethacrylate and styrene. Appl. Mech. Mater. 2012, 166, 2938–2941. [Google Scholar]

- Navi, P.; Heger, F. Combined densification and thermo-hydro-mechanical processing of wood. MRS Bull. 2004, 29, 332–336. [Google Scholar]

- Inoue, M.; Norimoto, M.; Tanahashi, M.; Rowell, R.M. Steam or heat fixation of compressed wood. Wood Fiber Sci. 1993, 25, 224–235. [Google Scholar]

- Inoue, M.; Sekino, N.; Morooka, T.; Rowell, R.M.; Norimoto, M. Fixation of compressive deformation in wood by pre-steaming. J. Trop. For. Sci. 2008, 20, 273–281. [Google Scholar]

- Inoue, M.; Adachi, K.; Kanayama, K. Cupping of compressed wood resulting from set recovery. J. Jpn. Wood Res. Soc. 2001, 47, 198–204. [Google Scholar]

- Esteves, B.M.; Pereira, H. Wood modification by heat treatment A review. BioResources 2009, 4, 340–404. [Google Scholar]

- Dwianto, W.; Morooka, T.; Norimoto, M.; Kitajima, T. Stress relaxation of sugi (Cryptomeria japonica D. Don) wood in radial compression under high temperature steam. Holzforschung 1999, 53, 541–546. [Google Scholar]

- Zhang, Z.L. Effects of Annual Ring Angle, Moisture Content and Heat Treatment on the Properties of Japanese Cedar Compressed Wood. Master’s Thesis, Department of Forestry and Natural Resources National Ilan University, Yilan City, Taiwan, 2019; pp. 1–30. [Google Scholar]

- Esteves, B.; Ribeiro, F.L.; Cruz-Lopes, J.F.I.; Domingos, M.; Duarte, S.; Lisbon, P.L. Densification and heat treatment of maritime pine wood. Wood Res. 2017, 62, 373–388. [Google Scholar]

- Gao, Z.; Huang, R.; Chang, J.; Li, R.; Wu, Y. Effects of pressurized superheated-steam heat treatment on set recovery and mechanical properties of surface-compressed wood. BioResources 2019, 14, 1718–1730. [Google Scholar]

- Pelit, H.; Emiroglu, F. Density, hardness and strength properties of densified fir and aspen woods pretreated with water repellents. Holzforschung 2021, 75, 358–367. [Google Scholar]

- Blomberg, J.; Persson, B.; Blomberg, A. Effects of semi-isostatic densification of wood on the variation in strength properties with density. Wood Sci. Technol. 2005, 39, 33–350. [Google Scholar]

- Ulker, O.; Imirzi, O.; Burdurlu, E. The effect of densification temperature on some physical and mechanical properties of Scots pine (Pinus sylvestris L.). BioResources 2012, 7, 5581–5592. [Google Scholar]

- Lu, S.Y. Effect of Heat Treatment on the Chemical Properties of Three Domestic Plantation Woods. Master’s Thesis, Department of Forestry and Natural Resources National Ilan University, Yilan City, Taiwan, 2014; pp. 90–91. [Google Scholar]

- Müller, U.; Gindl, W.; Teischinger, A. Effects of cell anatomy on the plastic and elastic behaviour of different wood species loaded perpendicular to grain. Iawa J. 2003, 24, 117–128. [Google Scholar]

- Kutnar, A.; Kamke, F.A.; Sernek, M. Density profile and morphology of viscoelastic thermal compressed wood. Wood Sci. Technol. 2009, 43, 57–68. [Google Scholar]

- Tu, D.; Su, X.; Zhang, T.; Fan, W.; Zhou, Q. Thermo-mechanical densification of Populus tomentosa var. tomentosa with low moisture content. BioResources 2014, 9, 3846–3856. [Google Scholar]

- Lin, S.H.; Lin, Y.H. Properties of heat-treat wood. Q. J. For. Res. 2011, 33, 91–108. [Google Scholar]

- Sandberg, D.; Johansson, J. A new method for bending solid wood–high frequency heating of beech. In Proceedings of the European Conference on Hardwood, Gottingen, Germany, 6–9 September 2005; University of West Hungary Press: Sopron, Hungary, 2005; pp. 156–161. [Google Scholar]

- Kamperidou, V. The biological durability of thermally-and chemically-modified black pine and poplar wood against basidiomycetes and mold action. Forests 2019, 10, 1111. [Google Scholar]

- Todorović, N.; Popović, Z.; Milić, G.; Veizović, M.; Popadić, R. Quality evaluation of heat-treated sessile oak (Quercus petraea L.) wood by colour and FT-NIR spectroscopy. Wood Mater. Sci. Eng. 2022, 17, 202–209. [Google Scholar]

- Wang, S.Y. Studies on temperature and humidity conditioning efficiency of wooden materials. For. Prod. Ind. 1985, 4, 45–58. [Google Scholar]

- Liao, C.C. Studies on the Thermal Insulation Efficiency of Wooden Interior Decorative Materials and Woodebased Composite Walls. Ph.D. Thesis, Department of Forestry and Natural Resources National Taiwan University, Taipei City, Taiwan, 1998; pp. 82–233. [Google Scholar]

- Chen, C.Y. The Conditioning Effect of Compisite Walls and Roofs on The Thermal Insulation, Temperature and Relative Humidity of Wooden Structure Building. Master’s Thesis, Department of Forestry and Natural Resources National Taiwan University, Taipei City, Taiwan, 2000; pp. 33–61. [Google Scholar]

- Tsay, Y.S.; Chiang, C.M. Study on the Applicability of Moisture Buffering Materials in Taiwan. J. Archit. 2009, 69, 35–50. [Google Scholar]

- Wang, Y.H.; Lee, S.K. The Analysis of Thermal Properties Measurement and Energy Saving Simulation for Roof Insulation. J. Archit. 2008, 66, 23–34. [Google Scholar]

- Kuo, P.W. Studies on the Thermal Conductivities of Wood-based Materials. Master’s Thesis, Department of Forestry and Natural Resources National Taiwan University, Taipei City, Taiwan, 1989; pp. 41–43. [Google Scholar]

- Seo, J.; Jeon, J.; Lee, H.; Kim, S. Thermal performance analysis according to wood flooring structure for energy conservation in radiant floor heating systems. Energy Build. 2011, 43, 2039–2042. [Google Scholar]

- CNS 452; National Standards of the Republic of China Wood—Determination of Moisture Content for Physical and Mechanical tests. Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs: Taipei City, Taiwan, 2013.

- CNS 451; National Standards of the Republic of China Wood—Determination of Density for Physical and Mechanical Tests. Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs: Taipei City, Taiwan, 2013.

- Shiu, M.R.; Chen, T.Y.; Chen, H.C.; Hsu, C.H. Study on Densification of Wood Surface Layer. For. Res. Q. 2000, 22, 1–12. [Google Scholar]

- CNS 3904; National Standards of the Republic of China (2017) CNS 3904 Methods of Test for Bending and Impact of Building Boards. Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs: Taipei City, Taiwan, 2017.

- CNS 9907; National Standards of the Republic of China Hard Fiberboards. Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs: Taipei City, Taiwan, 2017.

- CNS 460; National Standards of the Republic of China Wood—Determination of Static Hardness. Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs: Taipei City, Taiwan, 2013.

- EN1534; Wood Flooring and Parquet—Determination of Resistance to Indentation-Test Method. Ente Nazionale Italiano di Unificazione: Milano, Italia, 2020.

- Yang, C.N. Development of High Efficiency Method for Wood Acetylation. Master’s Thesis, Department of Forestry and Natural Resources National Chung Hsing University, Taichung City, Taiwan, 2012; pp. 1–64. [Google Scholar]

- Asako, Y.; Kamikoga, H.; Nishimura, H.; Yamaguchi, Y. Effective thermal conductivity of compressed woods. Int. J. Heat Mass Transf. 2002, 45, 2243–2253. [Google Scholar]

- Yu, J.Y. Water Vapor Diffusion, Thermal Properties, and Energy Consumption of Interior Decoration by Using Four Domestic Plantation Wood Species. Master’s Thesis, Department of Forestry and Natural Resources National Ilan University, Yilan City, Taiwan, 2014; pp. 1–83. [Google Scholar]

- CODiS Temperature and Humidity from 2011–2020. Available online: https://e-service.cwb.gov.tw/HistoryDataQuery/ (accessed on 2 October 2020).

- Chen, J.H.; Shiue, H.C.; Kuo, P.Y.; Wang, S.Y.; Lin, F.C. Effects of Moisture Content and Density on the Compression Strength Parallel to Grain Direction of Japanese Cedar Wood. Q. J. Chin. For. 2006, 39, 67–376. [Google Scholar]

- Goring, D.A. Thermal softening of lignin, hemicellulose and cellulose. Pulp. Pap. 1963, 64, 517–527. [Google Scholar]

- Huang, T.W.; Cho, C.L. Effect of Heat Treatment on the Physical Properties of Three Domestic Plantation Wood Species (Ⅱ)-Changes of Hygroscopicity and Dimension Stability. For. Prod. Ind. 2012, 31, 175–186. [Google Scholar]

- Hwang, G.S. Effect of Heat Treatment on the Properties of Compressed Wood. Taiwan For. Sci. 1997, 12, 95–104. [Google Scholar]

- Lourenço, P.B.; Feio, A.O.; Machado, J.S. Chestnut wood in compression perpendicular to the grain: Non-destructive correlations for test results in new and old 60 wood. Constr. Build Mate. 2007, 21, 1617–1627. [Google Scholar]

- Kobayashi, Y. Shaping and Fixing the Shape of Logs by Applying Thermoplasticity of Wood-I. Wood Ind. 1993, 48, 261–264. [Google Scholar]

- Shi, J.; Peng, J.; Huang, Q.; Cai, L.; Shi, S.Q. Fabrication of densified wood via synergy of chemical pretreatment, hot-pressing and post mechanical fixation. J. Wood Sci. 2020, 66, 1–9. [Google Scholar]

- Munir, S.; Daood, S.S.; Nimmo, W.; Cunliffe, A.M.; Gibbs, B.M. Thermal analysis and devolatilization kinetics of cotton stalk, sugar cane bagasse and shea meal under nitrogen and air atmospheres. Bioresour. Technol. 2009, 100, 1413–1418. [Google Scholar]

- Lin, S.C. Application of Hot-Pressing Technology to Manufacture Flame Retardant Panels-Cryptomeria Japonica D. Don. (Plantation Species). Master’s Thesis, Department of Forestry and Natural Resources National Chiayi University, Chiayi City, Taiwan, 2005; pp. 43–44. [Google Scholar]

- Kamdem, D.P.; Pizzi, A.; Jermannaud, A. Durability of heat-treated wood. Holz Als Roh-Und Werkst. 2002, 60, 1–6. [Google Scholar]

- Hsu, W.C. An Introduction to Polymeric Materials; Wu-Nan Book Inc.: Taipei City, Taiwan, 2012; pp. 39–45. [Google Scholar]

- Chang, F.C.; Chang, F.R.; Chao, W.C.; Yang, T.H. Evaluating the Bending Properties of Heat-treated Japanese Cedar Lumber. For. Prod. Ind. 2015, 34, 59–67. [Google Scholar]

- Suleiman, B.; Larfeldt, M.J.; Leckner, B.; Gustavsson, M. Thermal conductivity and diffusivity of wood. Wood Sci. Technol. 1999, 33, 465–473. [Google Scholar]

- Cuo, C.L. The Conditioning Effect on the Temperature and Relative Humidity of Wooden Environment. Ph.D. Thesis, Graduate Institute of Forestry National Taiwan University, Taipei City, Taiwan, 1992; pp. 199–202. [Google Scholar]

| Thickness (mm) | Compress Mode | Temperature (°C) | Time (min) | Specimen Name c |

|---|---|---|---|---|

| 18 a | - | - | - | 18JC |

| 22 | CW b | 160 | 30 | 22CW160-30 |

| 60 | 22CW160-60 | |||

| 180 | 30 | 22CW180-30 | ||

| 60 | 22CW180-60 | |||

| 200 | 30 | 22CW200-30 | ||

| 60 | 22CW200-60 | |||

| 24 | CW | 160 | 30 | 24CW160-30 |

| 60 | 24CW160-60 | |||

| 180 | 30 | 24CW180-30 | ||

| 60 | 24CW180-60 | |||

| 200 | 30 | 24CW200-30 | ||

| 60 | 24CW200-60 | |||

| 27 | CW | 160 | 30 | 27CW160-30 |

| 60 | 27CW160-60 | |||

| 180 | 30 | 27CW180-30 | ||

| 60 | 27CW180-60 | |||

| 200 | 30 | 27CW200-30 | ||

| 60 | 27CW200-60 |

| Size (mm) | Compression Mode | Temperature (°C) | Time (min) | Drying-Set Mode | Time (h) | Samle Name c |

|---|---|---|---|---|---|---|

| 22 | WC a | 180 | 60 | LS b | 0 | 22WCLS-0 |

| 6 | 22WCLS-6 | |||||

| 12 | 22WCLS-12 | |||||

| 24 | 22WCLS-24 | |||||

| 24 | WC | 180 | 60 | LS | 0 | 24WCLS-0 |

| 6 | 24WCLS-6 | |||||

| 12 | 24WCLS-12 | |||||

| 24 | 24WCLS-24 | |||||

| 27 | WC | 180 | 60 | LS | 0 | 27WCLS-0 |

| 6 | 27WCLS-6 | |||||

| 12 | 27WCLS-12 | |||||

| 24 | 27WCLS-24 |

| Specimens Thickness (mm) | Moisture Content (%) | Density (kg/m3) |

|---|---|---|

| 18 | 10.78 (0.56) a(1) | 386.33 (0.04) ca |

| 22 | 9.77 (0.20) a | 427.39 (0.08) ab |

| 24 | 9.80 (0.98) a | 449.43 (0.04) bc |

| 27 | 10.05 (0.20) a | 506.98 (0.05) c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.-H.; Ho, S.-T.; Lin, H.-C. Evaluation of Physico-Mechanical Properties and Thermal Conduction to Energy-Saving Effects of Wood Compression Layered Structural Materials. Polymers 2023, 15, 3208. https://doi.org/10.3390/polym15153208

Chen Y-H, Ho S-T, Lin H-C. Evaluation of Physico-Mechanical Properties and Thermal Conduction to Energy-Saving Effects of Wood Compression Layered Structural Materials. Polymers. 2023; 15(15):3208. https://doi.org/10.3390/polym15153208

Chicago/Turabian StyleChen, Yu-Hui, Shang-Tse Ho, and Han-Chien Lin. 2023. "Evaluation of Physico-Mechanical Properties and Thermal Conduction to Energy-Saving Effects of Wood Compression Layered Structural Materials" Polymers 15, no. 15: 3208. https://doi.org/10.3390/polym15153208

APA StyleChen, Y.-H., Ho, S.-T., & Lin, H.-C. (2023). Evaluation of Physico-Mechanical Properties and Thermal Conduction to Energy-Saving Effects of Wood Compression Layered Structural Materials. Polymers, 15(15), 3208. https://doi.org/10.3390/polym15153208