Multi-Scale Model for the Aging Performance of Particle-Filled Polymer Composites

Abstract

:1. Introduction

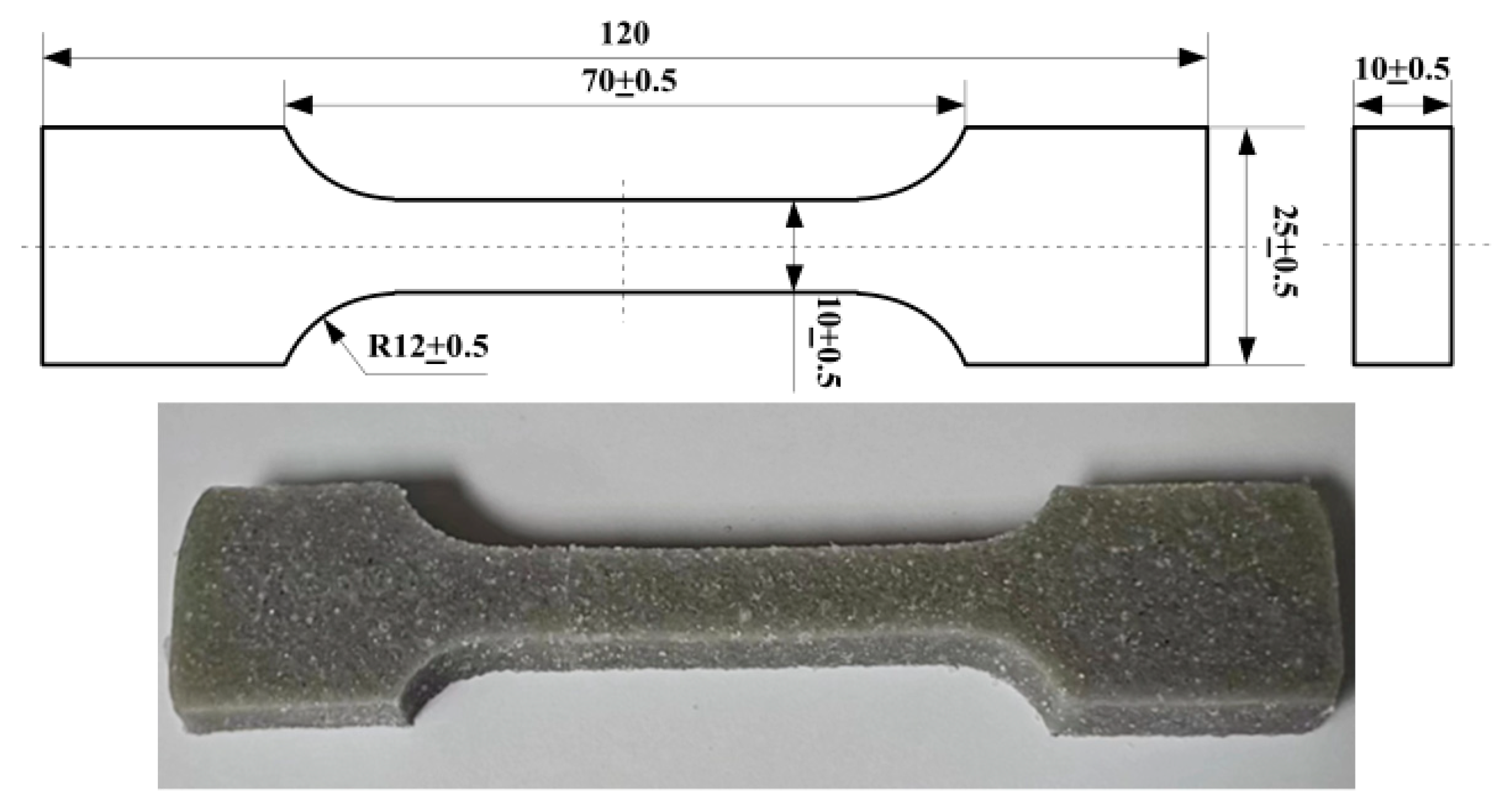

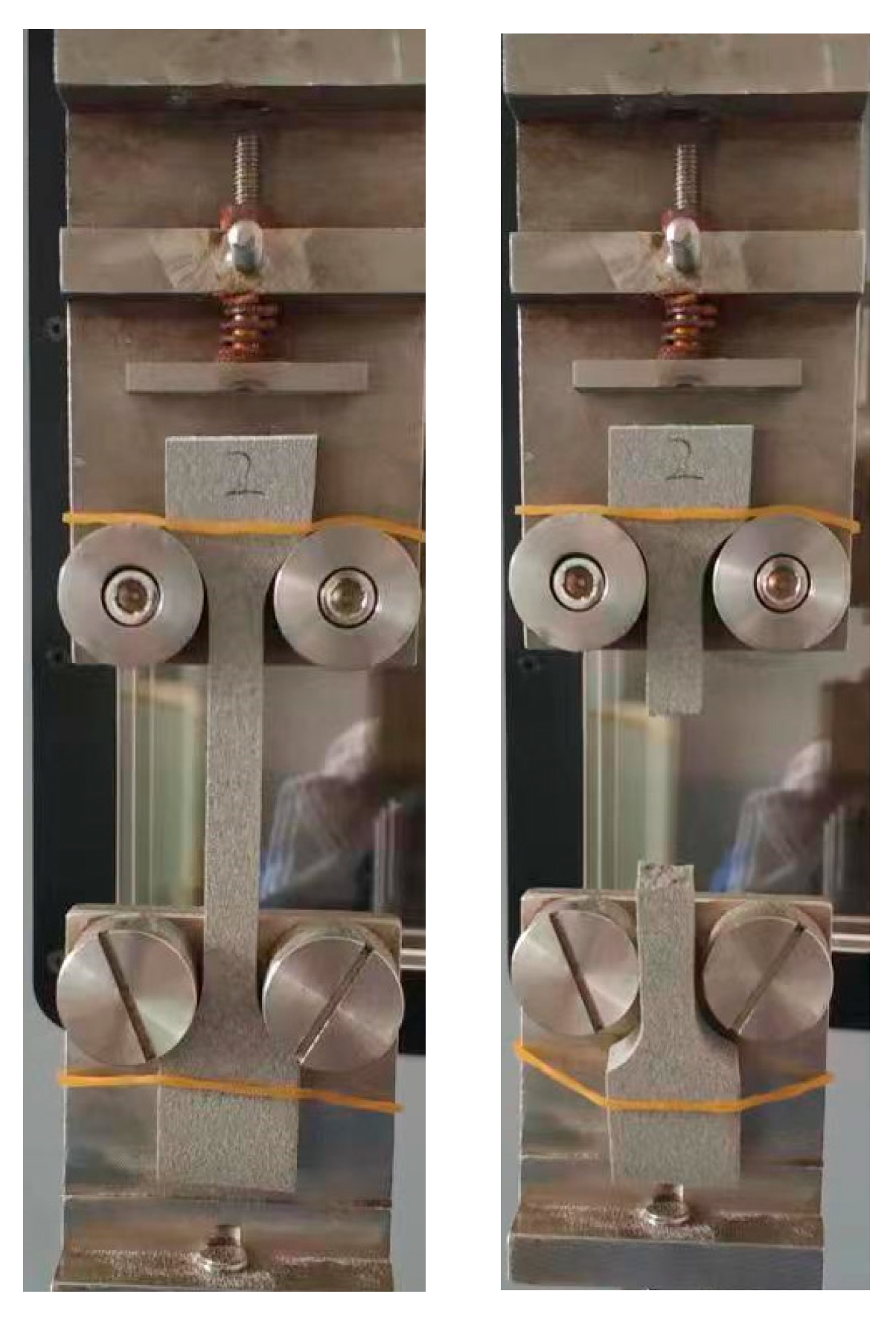

2. Materials and Methods

- To ensure the accuracy of the experiment, the lowest aging temperature should be as close to the actual storage temperature of the propellant as possible, but not too close, to avoid excessively extending the testing time;

- The highest aging temperature should be as large as possible to achieve the strongest accelerating effect while ensuring experiment safety and not changing the failure mechanism;

- It is generally recommended to control the number of acceleration temperature points within three to five, which can balance the accuracy of data statistical analysis and the cost saving of experiments.

3. Microscopic Reaction Mechanism

3.1. Chain Reaction of Oxidation

3.2. Oxygen Consumed Rate

3.3. Concentration of and

4. Construction of Multi-Scale Models

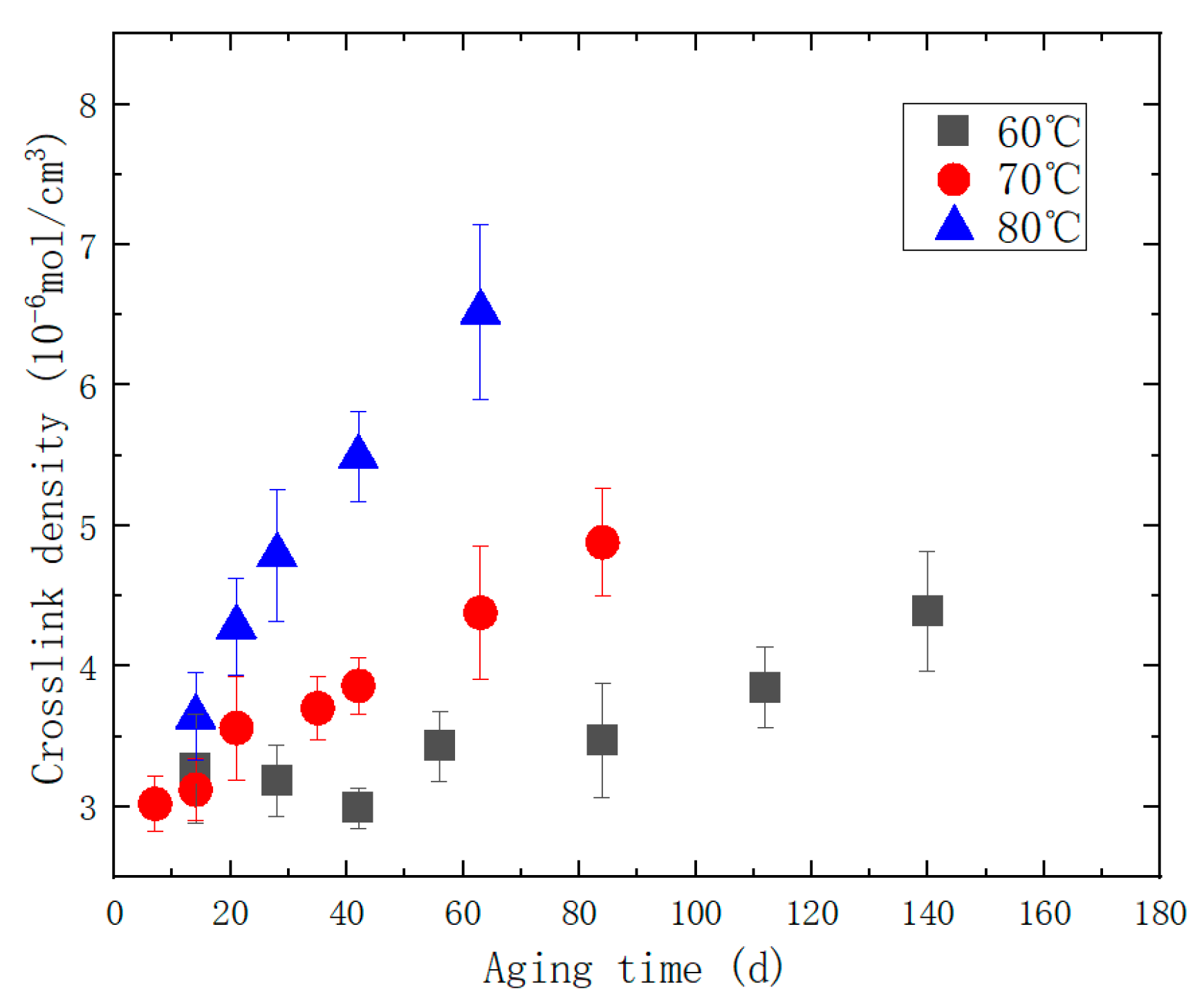

4.1. Relation between Reaction Rate and Crosslink Density

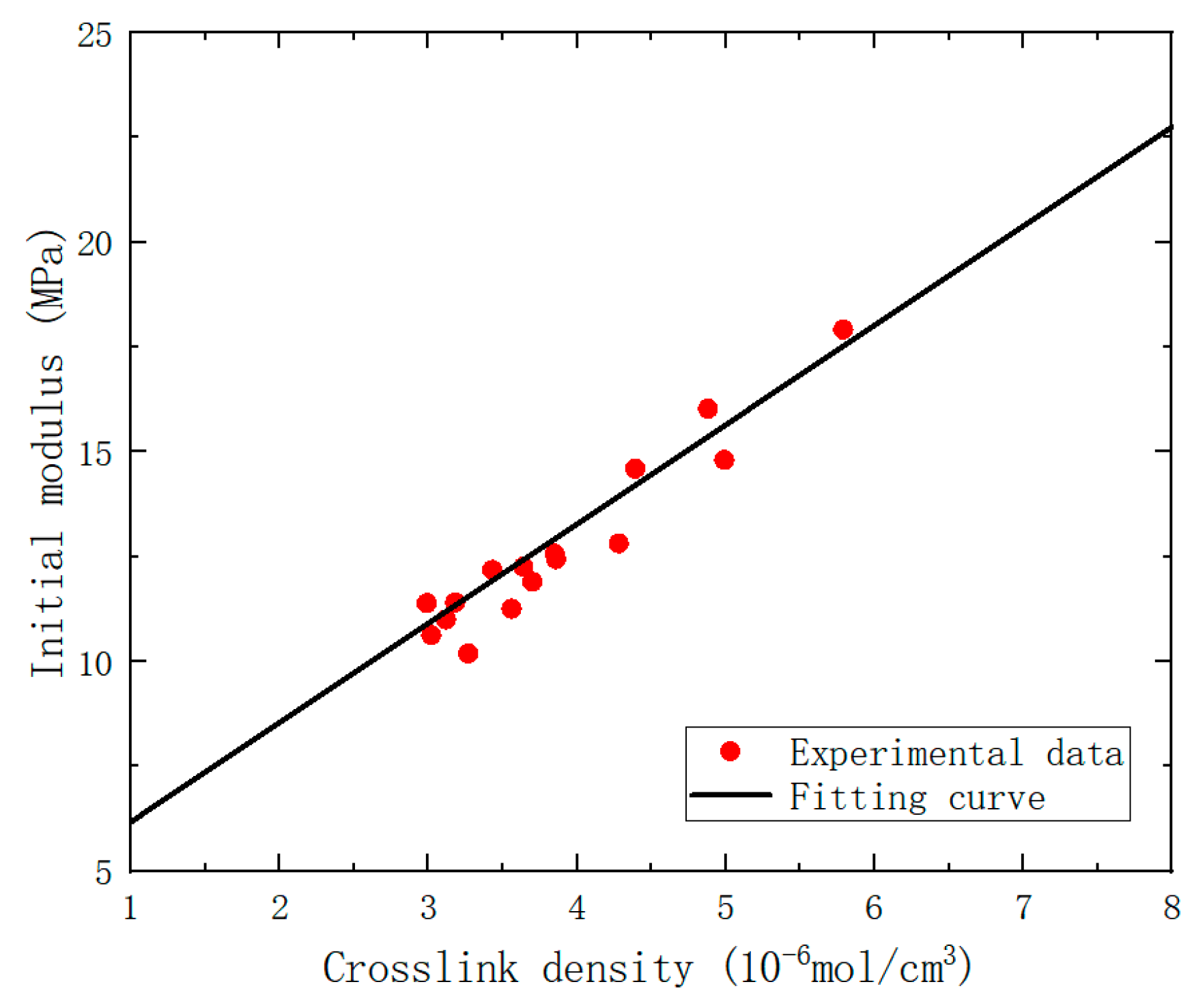

4.2. Relation between Crosslink Density and Modulus

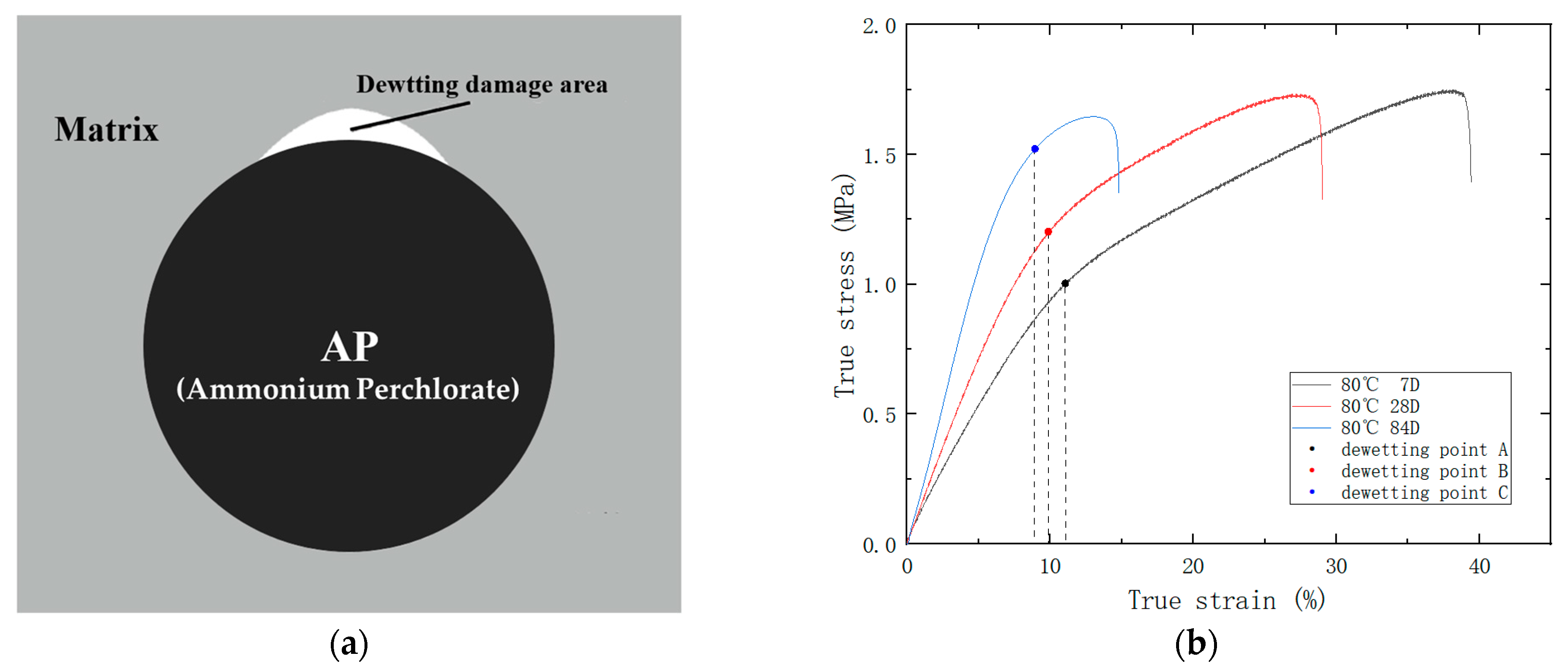

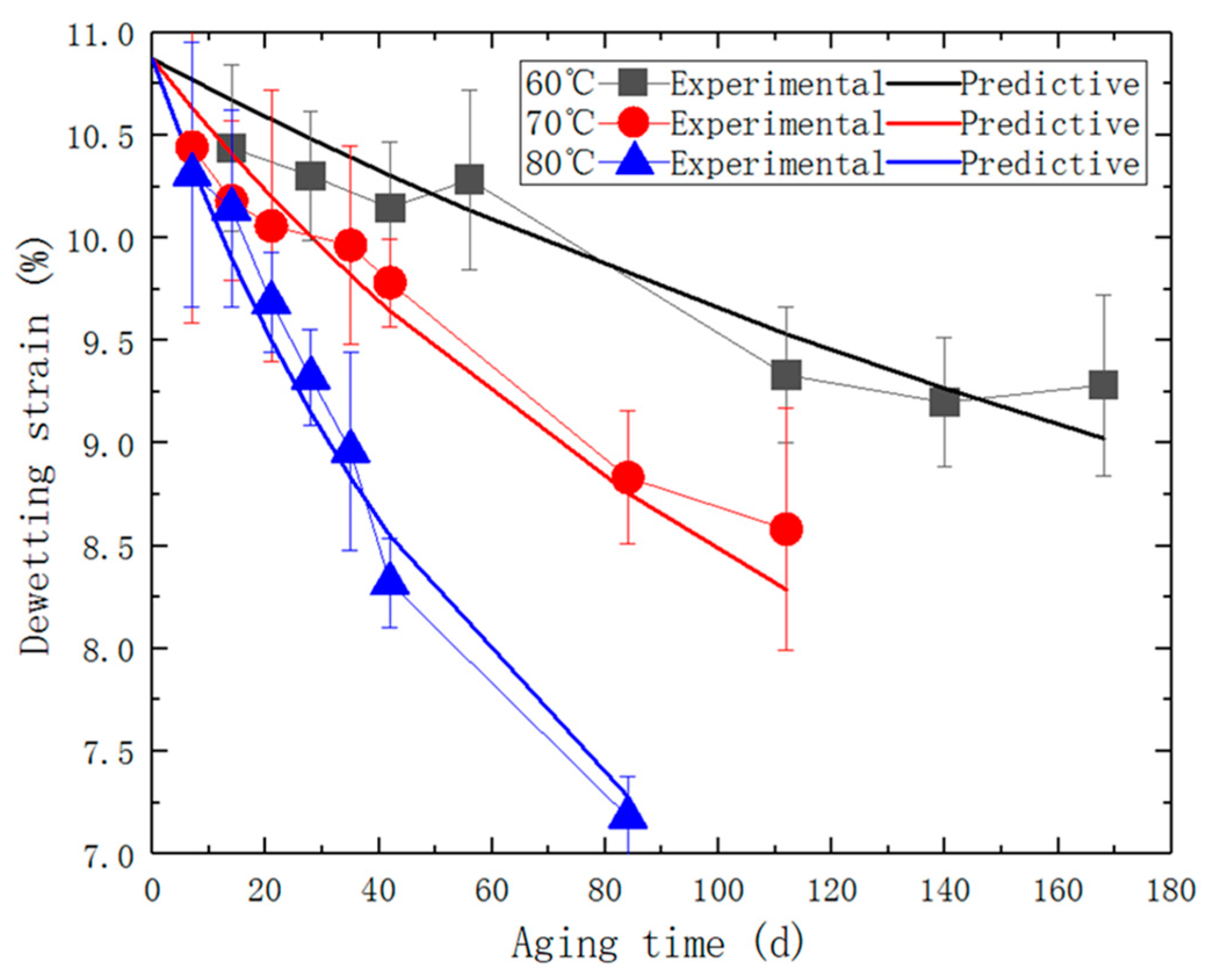

4.3. Relation between Modulus and Dewetting Strain

5. Determination of Parameters in Multi-Scale Model

5.1. Parameters for Calculation of Crosslink Density

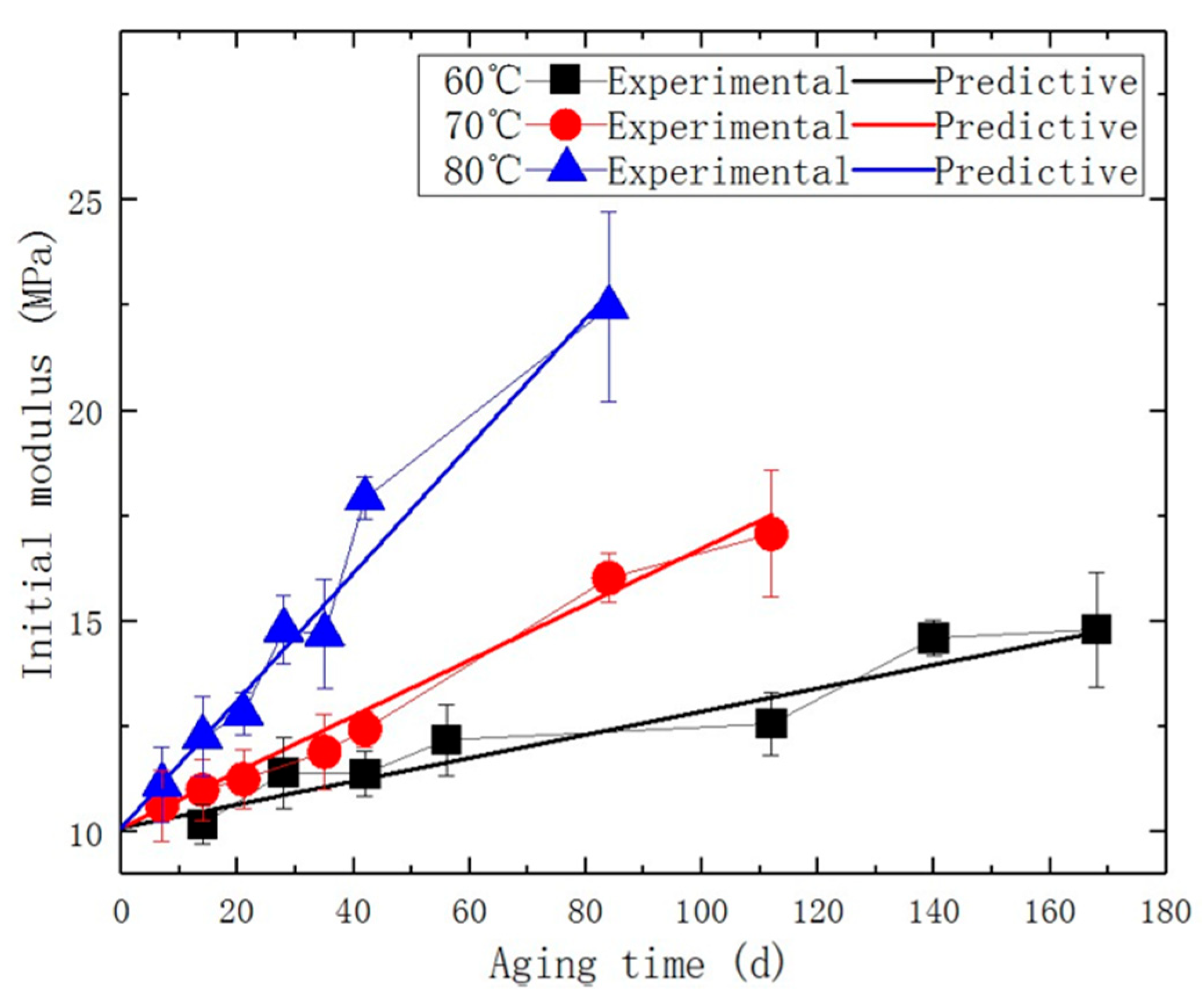

5.2. Parameters for Calculation of Initial Modulus

5.3. Parameters for Calculation of Dewetting Strain

5.4. Reliability Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Research Institute for Aging of Synthetic Materials. Aging and Anti-Aging of Polymer Materials; Chemical Industry Press: Beijing, China, 1979. [Google Scholar]

- Colin, X.; Verdu, J. Strategy for studying thermal oxidation of organic matrix composites. Compos. Sci. Technol. 2005, 65, 411–419. [Google Scholar] [CrossRef]

- Colin, X.; Verdu, J. Thermal ageing and lifetime prediction for organic matrix composites. Plast. Rubber Compos. 2003, 32, 349–356. [Google Scholar] [CrossRef]

- Decelle, J.; Huet, N.; Bellenger, V. Oxidation induced shrinkage for thermally aged epoxy networks. Polym. Degrad. Stab. 2003, 81, 239–248. [Google Scholar] [CrossRef]

- Tandon, G.; Pochiraju, K.; Schoeppner, G. Modeling of oxidative development in PMR-15 resin. Polym. Degrad. Stab. 2006, 91, 1861–1869. [Google Scholar] [CrossRef]

- Pochiraju, K.; Tandon, G.; Schoeppner, G. Evolution of stress and deformations in high-temperature polymer matrix composites during thermo-oxida tive aging. Mech. Time-Depend. Mater. 2008, 12, 45–68. [Google Scholar] [CrossRef]

- Pochiraju, K.V. Modeling thermo-oxidative aging and degradation of composites. In Long-Term Durability of Polymeric Matrix Composites; Springer: Boston, MA, USA, 2011; pp. 383–425. [Google Scholar]

- Wubuliaisan, M.; Wu, Y.; Hou, X.; Liu, X.; Wu, Y. Multiscale viscoelastic constitutive modeling of solid propellants subjected to large deformation. Int. J. Solids Struct. 2023, 262, 112084. [Google Scholar] [CrossRef]

- Tandon, G.; Pochiraju, K.; Schoeppner, G. Thermo-oxidative behavior of high-temperature PMR-15 resin and composites. Mater. Sci. Eng. 2008, 498, 150–161. [Google Scholar] [CrossRef]

- Pecora, M.; Pannier, Y.; Lafarie-Frenot, M.-C.; Gigliotti, M.; Guigon, C. Effect of thermo-oxidation on the failure properties of an epoxy resin. Polym. Test. 2016, 52, 209–217. [Google Scholar] [CrossRef]

- Bolland, J.L.; Gee, G. Kinetic studies in the chemistry of rubber and related materials. II. The kinetics of oxidation of unconjugated olefins. Trans. Faraday Soc. 1946, 42, 236–243. [Google Scholar] [CrossRef]

- Bolland, J.L. Kinetics of olefin oxidation. Q. Rev. Chem. Soc. 1949, 3, 1–21. [Google Scholar] [CrossRef]

- Tobolsky, A.V.; Metz, D.J.; Mesrobian, R.B. Low temperature autoxidation of hydrocarbons: The phenomenon of maximum rates1,2. J. Am. Chem. Soc. 1950, 72, 1942–1952. [Google Scholar] [CrossRef]

- Bateman, L.; Gee, G.; Morris, A.L.; Watson, W.F. The velocity coefficients of the chain propagation and termination reactions in olefin oxidations in liquid systems. Discuss. Faraday Soc. 1951, 10, 250–259. [Google Scholar] [CrossRef]

- Akbaş, A.; Aksoy, S.; Hasırcı, N. Effects of thermal ageing on the properties and lifetime prediction of hydroxyl-terminated polybutadiene. Polymer 1994, 35, 2568–2572. [Google Scholar] [CrossRef]

- McManus, H.L.; Foch, B.J.; Cunningham, R.A. Mechanism-based modeling of long-term degradation. J. Compos. Technol. Res. 2000, 22, 146–152. [Google Scholar]

- Wise, J.; Gillen, K.; Clough, R. An ultrasensitive technique for testing the Arrhenius extrapolation assumption for thermally aged elastomers. Polym. Degrad. Stab. 1995, 49, 403–418. [Google Scholar] [CrossRef]

- Gillen, K.T.; Celina, M.; Keenan, M.R. Methods for predicting more confident lifetimes of seals in air environments. Rubber Chem. Technol. 2000, 73, 265–283. [Google Scholar] [CrossRef]

- Gillen, K.; Celina, M.; Bernstein, R. Review of the ultrasensitive oxygen consumption method for making more reliable extrapolated predictions of polymer lifetimes. In Proceedings of the ANTEC 2004 62nd Annual Technical Conference, Chicago, IL, USA, 16–20 May 2004; Society of Plastics Engineers: Danbury, CT, USA, 2004; pp. 2289–2293. [Google Scholar]

- Gillen, K.T.; Bernstein, R.; Celina, M. Non-Arrhenius behavior for oxidative degradation of chlorosulfonated polyethylene materials. Polym. Degrad. Stab. 2005, 87, 335–346. [Google Scholar] [CrossRef]

- Celina, M.; Gillen, K.T.; Assink, R. Accelerated aging and lifetime prediction: Review of non-Arrhenius behaviour due to two competing processes. Polym. Degrad. Stab. 2005, 90, 395–404. [Google Scholar] [CrossRef]

- Gillen, K.T.; Bernstein, R.; Derzon, D.K. Evidence of non-Arrhenius behaviour from laboratory aging and 24-year field aging of polychloroprene rubber materials. Polym. Degrad. Stab. 2005, 87, 57–67. [Google Scholar] [CrossRef]

- Dalby, B.; Caraës, A. Lifetime Numerical Prediction of Solid Rocket Motors with HTPB Binder Based Propellants Using a Multiscale Model. In Proceedings of the 51st AIAA/SAE/ASEE Joint Propulsion Conference, Orlando, FL, USA, 27–29 July 2015. [Google Scholar]

- Hu, R.; Prakash, C.; Tomar, V.; Harr, M.; Gunduz, I.E.; Oskay, C. Experimentally-validated mesoscale modeling of the coupled mechanical–thermal response of AP–HTPB energetic material under dynamic loading. Int. J. Fract. 2017, 203, 277–298. [Google Scholar] [CrossRef]

- Inglis, H.M.; Geubelle, P.H.; Matouš, K.; Tan, H.; Huang, Y. Cohesive modeling of dewetting in particulate composites: Micromechanics vs. multiscale finite element analysis. Mech. Mater. 2007, 39, 580–595. [Google Scholar] [CrossRef]

- Tan, H.; Liu, C.; Huang, Y.; Geubelle, P.H. The cohesive law for the particle/matrix interfaces in high explosives. J. Mech. Phys. Solids 2005, 53, 1892–1917. [Google Scholar] [CrossRef]

- Verdu, J. Oxydative Ageing of Polymers; John Wiley & Sons: Hoboken, NJ, USA, 2012; pp. 45–89. [Google Scholar]

- Wang, J.; O’Connor, T.C.; Grest, G.S. Super-stretchable Elastomer from Cross-linked Ring Polymers. Phys. Rev. Lett. 2022, 128, 237801. [Google Scholar] [CrossRef] [PubMed]

- Sharaf, M.A. Cis-1,4-Polybutadiene. In Polymer Data Handbook; Oxford University Press Inc.: New York, NY, USA, 1999. [Google Scholar]

- Coquillat, M. Aging of Polybutadiene Based Propellants: Kinetic Modelling of Oxidation. Ph.D. Thesis, École Nationale Supérieure d’Arts et Métiers, Paris, France, 25 October 2007. [Google Scholar]

| Temperature (°C) | Aging Time (d) | |||||||

|---|---|---|---|---|---|---|---|---|

| 60 | 14 | 28 | 42 | 56 | 84 | 112 | 140 | 168 |

| 70 | 7 | 14 | 21 | 35 | 42 | 63 | 84 | 112 |

| 80 | 7 | 14 | 21 | 28 | 35 | 42 | 63 | 84 |

| Reaction Stage | Reaction Equation | Rate Constant | |

|---|---|---|---|

| Initiation | I | kI | |

| Propagation | II | kII | |

| III | kIII | ||

| IV | kIV | ||

| Termination | V | kV | |

| VI | kVI | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, C.; Wang, H.; Zhang, Y.; Zhang, M.; Shen, T.; Du, J. Multi-Scale Model for the Aging Performance of Particle-Filled Polymer Composites. Polymers 2023, 15, 3158. https://doi.org/10.3390/polym15153158

Fang C, Wang H, Zhang Y, Zhang M, Shen T, Du J. Multi-Scale Model for the Aging Performance of Particle-Filled Polymer Composites. Polymers. 2023; 15(15):3158. https://doi.org/10.3390/polym15153158

Chicago/Turabian StyleFang, Congli, Huizhen Wang, Yujiao Zhang, Minghua Zhang, Tao Shen, and Jianke Du. 2023. "Multi-Scale Model for the Aging Performance of Particle-Filled Polymer Composites" Polymers 15, no. 15: 3158. https://doi.org/10.3390/polym15153158

APA StyleFang, C., Wang, H., Zhang, Y., Zhang, M., Shen, T., & Du, J. (2023). Multi-Scale Model for the Aging Performance of Particle-Filled Polymer Composites. Polymers, 15(15), 3158. https://doi.org/10.3390/polym15153158