Controlling the Fiber Stress Distribution with Variable-Frequency Step Roll for Tunable Spun Yarn Structures

Abstract

1. Introduction

2. Theoretical Analysis

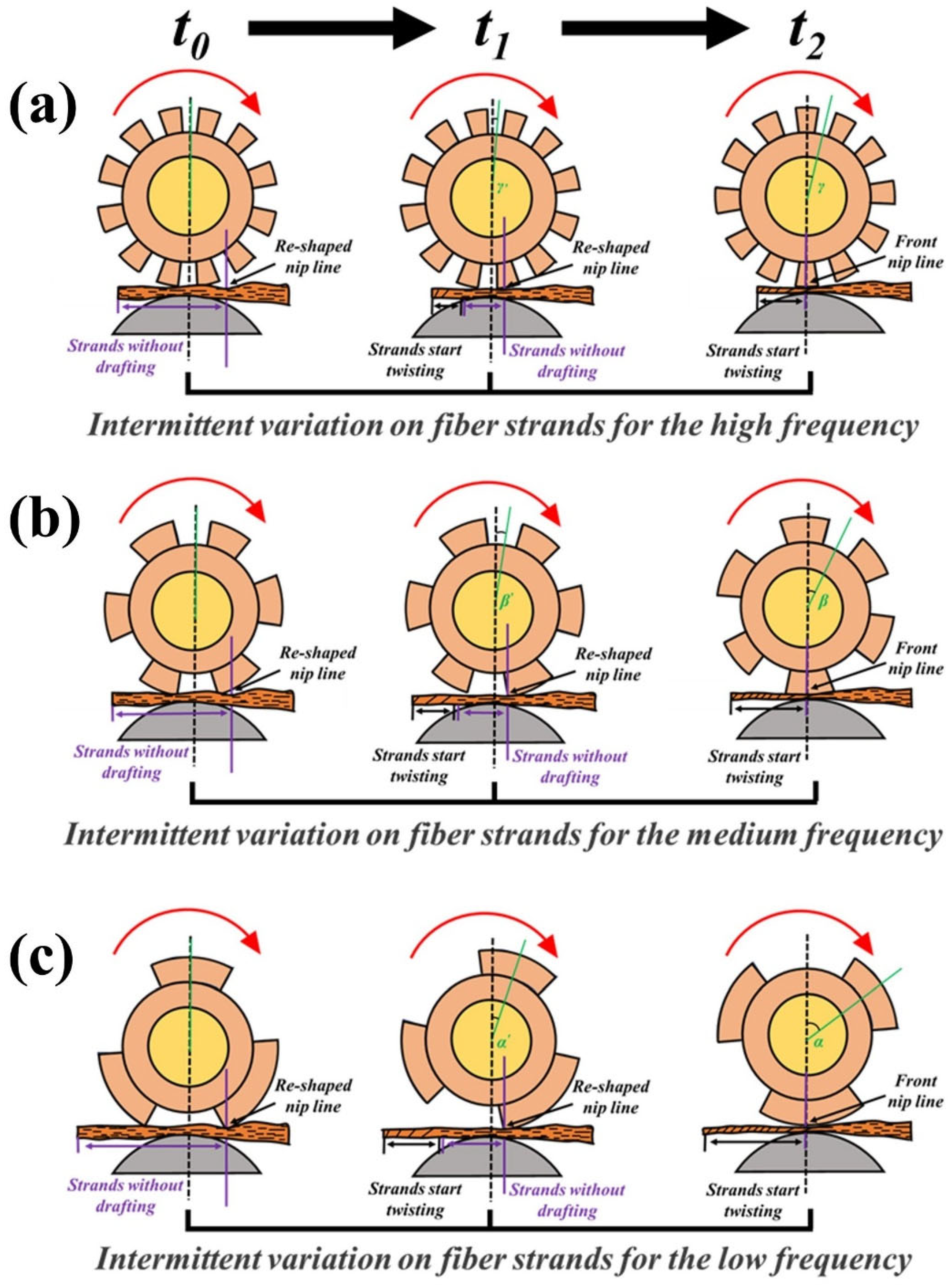

2.1. Geometric Analysis of the Frequency and Groove Position of the Step Roll Affecting the Fiber Stress Distribution

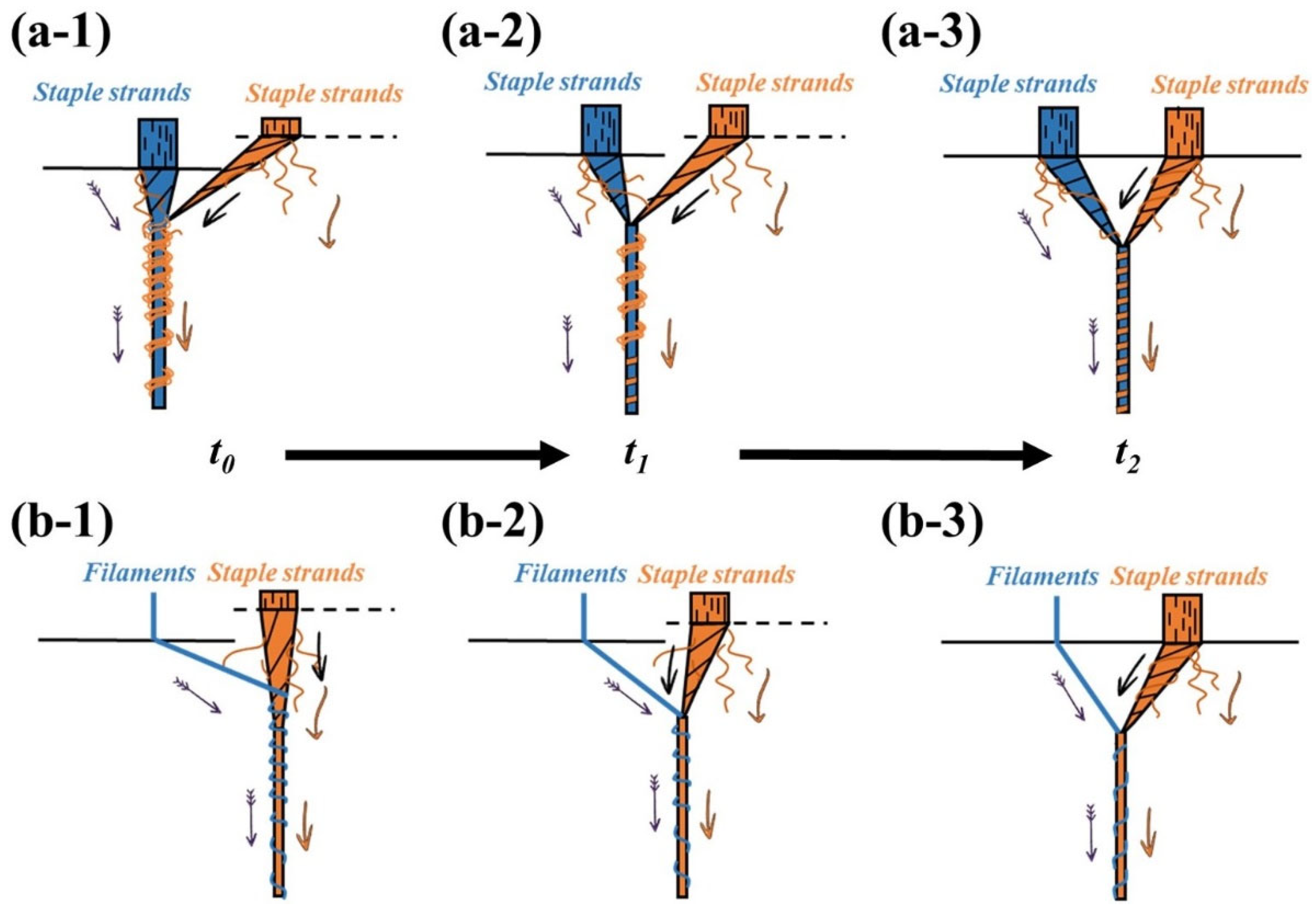

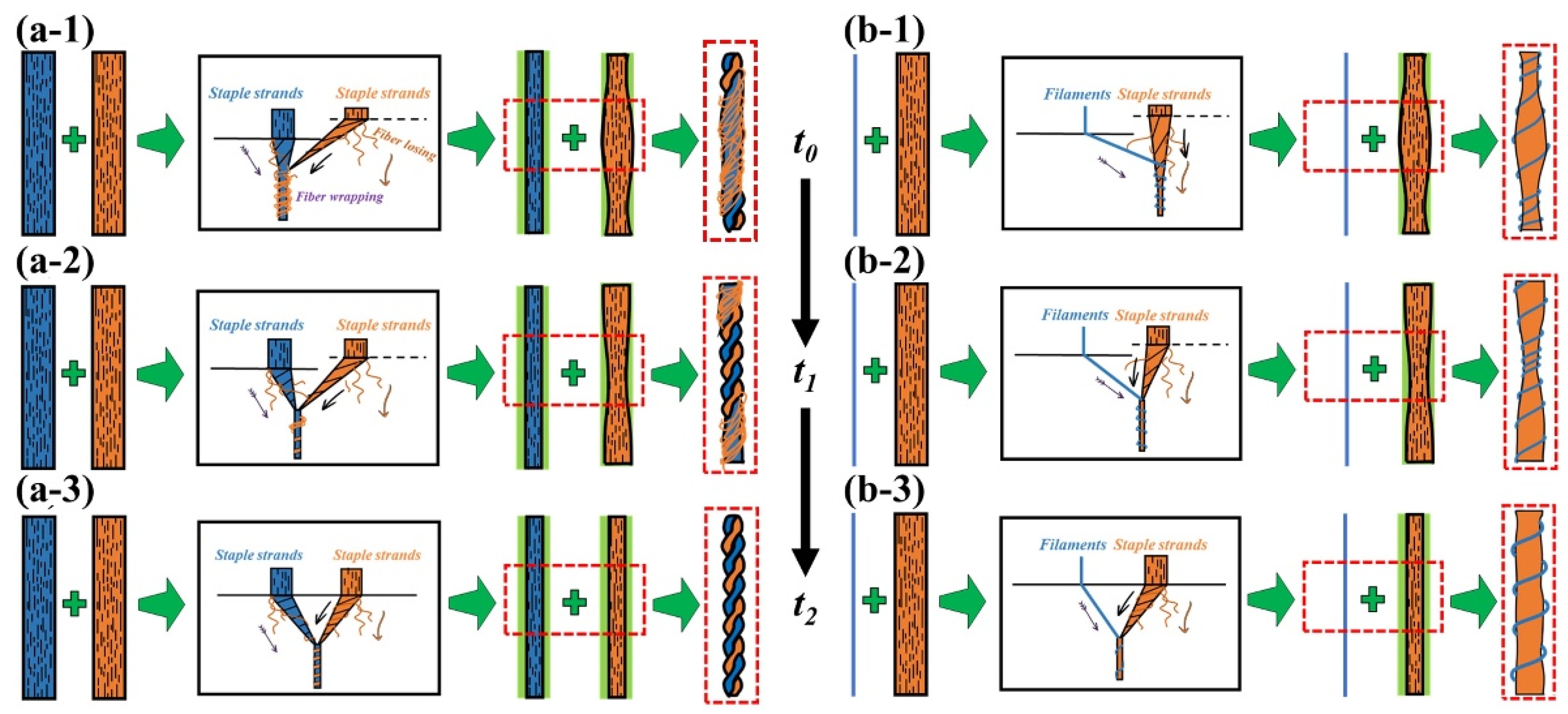

2.2. Geometric Analysis of the Groove Position for the Step Roll Affecting the Shape of the Yarn-Forming Triangle Area and Fiber Wrapping Form

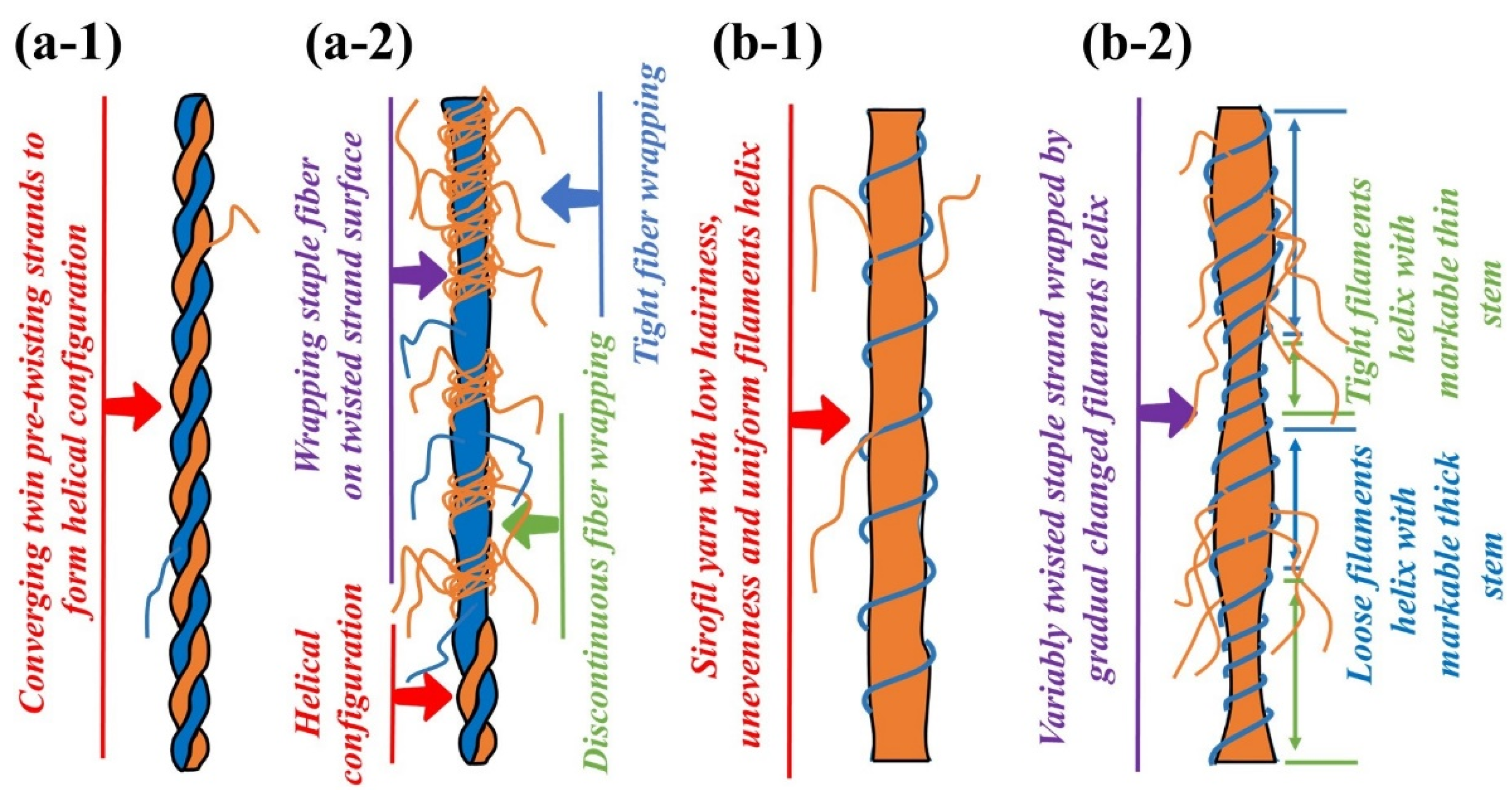

2.3. The Model of the Effect of Step Roll Frequency and Groove Position on Yarn Structure

3. Materials and Methods

3.1. Materials

3.2. Experimental Details

4. Results and Discussion

4.1. Dynamic Change in Yarn-Forming Triangle Area

4.2. Comparison of Surface Structure of Yarns Spun by Different Step Rolls

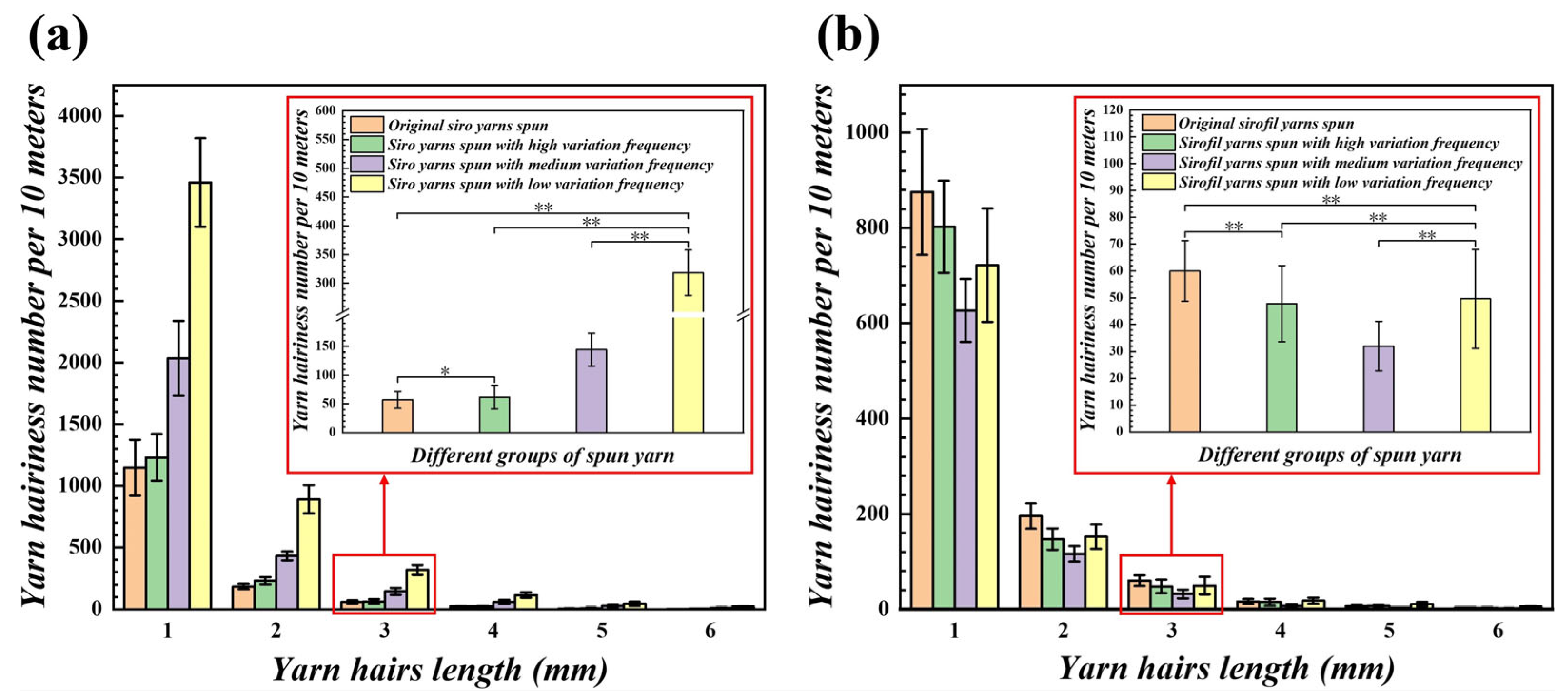

4.3. Comparison of Hairiness of Yarns Spun by Different Step Rolls

4.4. Comparison of Evenness of Yarns Spun by Different Step Rolls

4.5. Comparison of Tensile Properties of Yarns Spun by Different Rolls

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Statistical Test Results for 3 mm Hairiness Index of Different Yarns (Figure 9) at a Significance Level of 0.05 are Shown in Table A1 and Table A2

| Student-Newman-Keulsa a | |||||

|---|---|---|---|---|---|

| Subset for Alpha = 0.05 | |||||

| VAR00001 | N | 1 | 2 | 3 | 4 |

| 1. Original siro spun yarns | 30 | 57.2 | |||

| 2. Siro yarns spun with high variation frequency | 30 | 61.8 | |||

| 3. Siro yarns spun with medium variation frequency | 30 | 144.6 | |||

| 4. Siro yarns spun with low variation frequency | 30 | 318.6 | |||

| Sig. | 1.000 | 1.000 | 1.000 | 1.000 | |

| Student-Newman-Keulsa a | |||||

|---|---|---|---|---|---|

| Subset for Alpha = 0.05 | |||||

| VAR00001 | N | 1 | 2 | 3 | 4 |

| 1. Original sirofil spun yarns | 30 | 60 | |||

| 2. Sirofil yarns spun with high variation frequency | 30 | 47.8 | |||

| 3. Sirofil yarns spun with medium variation frequency | 30 | 32 | |||

| 4. Sirofil yarns spun with low variation frequency | 30 | 49.6 | |||

| Sig. | 1.000 | 1.000 | 1.000 | 1.000 | |

Appendix B. Statistical Test Results for Linear Density of Different Yarns (Figure A1) at a Significance Level of 0.05 are Shown in Table A3 and Table A4

| Student-Newman-Keulsa a | |||||

|---|---|---|---|---|---|

| Subset for Alpha = 0.05 | |||||

| VAR00001 | N | 1 | |||

| 1. Original siro spun yarns | 30 | 19.6 | |||

| 2. Siro yarns spun with high variation frequency | 30 | 19.5 | |||

| 3. Siro yarns spun with medium variation frequency | 30 | 19.4 | |||

| 4. Siro yarns spun with low variation frequency | 30 | 19.2 | |||

| Sig. | 0.113 | ||||

| Student-Newman-Keulsa a | |||||

|---|---|---|---|---|---|

| Subset for Alpha = 0.05 | |||||

| VAR00001 | N | 1 | 2 | 3 | 1 |

| 1. Original sirofil spun yarns | 30 | 19.3 | |||

| 2. Sirofil yarns spun with high variation frequency | 30 | 19.6 | |||

| 3. Sirofil yarns spun with medium variation frequency | 30 | 19.7 | |||

| 4. Sirofil yarns spun with low variation frequency | 30 | 19.5 | |||

| Sig. | 0.260 | ||||

Appendix C. Statistical Test Results for Irregularities of Different Yarns (Figure 10) at a Significance Level of 0.05 are Shown in Table A5 and Table A6

| Student-Newman-Keulsa a | |||||

|---|---|---|---|---|---|

| Subset for Alpha = 0.05 | |||||

| VAR00001 | N | 1 | 2 | 3 | 4 |

| 1. Original siro spun yarns | 30 | 10.29 | |||

| 2. Siro yarns spun with high variation frequency | 30 | 10.43 | |||

| 3. Siro yarns spun with medium variation frequency | 30 | 12.05 | |||

| 4. Siro yarns spun with low variation frequency | 30 | 17.85 | |||

| Sig. | 1.000 | 1.000 | 1.000 | 1.000 | |

| Student-Newman-Keulsa a | |||||

|---|---|---|---|---|---|

| Subset for Alpha = 0.05 | |||||

| VAR00001 | N | 1 | 2 | 3 | 4 |

| 1. Original sirofil spun yarns | 30 | 9.49 | |||

| 2. Sirofil yarns spun with high variation frequency | 30 | 9.63 | |||

| 3. Sirofil yarns spun with medium variation frequency | 30 | 12.46 | |||

| 4. Sirofil yarns spun with low variation frequency | 30 | 17.36 | |||

| Sig. | 1.000 | 1.000 | 1.000 | 1.000 | |

Appendix D. Statistical Test Results for Tensile Properties of Different Yarns (Figure 12) at a Significance Level of 0.05 are Shown in Table A7 and Table A8

| Student-Newman-Keulsa a | |||||

|---|---|---|---|---|---|

| Subset for Alpha = 0.05 | |||||

| VAR00001 | N | 1 | 2 | 3 | 4 |

| 1. Original siro spun yarns | 30 | 594.33 | |||

| 2. Siro yarns spun with high variation frequency | 30 | 574.94 | |||

| 3. Siro yarns spun with medium variation frequency | 30 | 482.01 | |||

| 4. Siro yarns spun with low variation frequency | 30 | 342.27 | |||

| Sig. | 1.000 | 1.000 | 1.000 | 1.000 | |

| Student-Newman-Keulsa a | |||||

|---|---|---|---|---|---|

| Subset for Alpha = 0.05 | |||||

| VAR00001 | N | 1 | 2 | 3 | 4 |

| 1. Original sirofil spun yarns | 30 | 600.77 | |||

| 2. Sirofil yarns spun with high variation frequency | 30 | 586.4 | |||

| 3. Sirofil yarns spun with medium variation frequency | 30 | 444.53 | |||

| 4. Sirofil yarns spun with low variation frequency | 30 | 394.76 | |||

| Sig. | 1.000 | 1.000 | 1.000 | 1.000 | |

References

- Soltani, P.; Johari, M.S. A study on siro-, solo-, compact-, and conventional ring-spun yarns. Part I: Structural and migratory properties of the yarns. J. Text. Inst. 2012, 103, 622–628. [Google Scholar] [CrossRef]

- Su, X.; Liu, X.; Li, S. Research on mutual relationships of flange ring and traveler on ring spinning system. Int. J. Cloth. Sci. Technol. 2019, 31, 32–57. [Google Scholar] [CrossRef]

- Liu, X.; Su, X. Yarn hairiness on ring spinning with modified yarn path. Indian J. Fibre Text. Res. 2016, 41, 221–225. [Google Scholar]

- Feng, J.; Xu, B.G.; Tao, X.M.; Hua, T. Theoretical study of a spinning triangle with its application in a modified ring spinning system. Text. Res. J. 2010, 80, 1456–1464. [Google Scholar] [CrossRef]

- Liu, X.; Su, X. Study on Spinning triangles in the common ring spinning and Super draft ring spinning systems. Fibers Polym. 2016, 17, 940–953. [Google Scholar] [CrossRef]

- Wei, L.; Huang, S.; Zhu, T.; Su, X. Research on shape of spinning triangles in the ring spinning system. J. Text. Inst. 2016, 107, 420–430. [Google Scholar] [CrossRef]

- Xu, D.; Su, Z.; Fan, H.; Yang, W.; Fang, J.; Liu, K.; Xu, W. Improving spun yarn properties by contacting fiber strand with special-shape condensed surfaces. J. Text. Inst. 2022, 113, 2408–2419. [Google Scholar] [CrossRef]

- Zubair, M.; Neckář, T.B.; Malik, Z.A. Predicting specific stress of cotton staple ring spun yarns: Experimental and theoretical results. Fibres Text. East. Eur. 2017, 2, 43–47. [Google Scholar] [CrossRef]

- Liu, X.; Liu, W.; Zhang, H.; Su, X. Research on pneumatic compact spun yarn quality. J. Text. Inst. 2015, 106, 431–442. [Google Scholar] [CrossRef]

- Xia, Z.; Xu, W.; Zhang, M.; Qiu, W.; Feng, S. Reducing ring spun yarn hairiness via spinning with a contact surface. Fibers Polym. 2012, 13, 670–674. [Google Scholar] [CrossRef]

- Yu, H.; Liu, K.; Jun, C.; Fu, C.; Xia, Z.; Xu, W. Comparative study of ring yarn properties spun with static and rotary grooved contact surfaces. Text. Res. J. 2018, 88, 1812–1823. [Google Scholar] [CrossRef]

- Xia, Z.; Feng, Y.; Guo, Q.; Ye, W.; Xu, W. A comparative study of hair trapping by a short grooved surface during conventional and siro-spinning. Text. Res. J. 2016, 86, 2032–2042. [Google Scholar] [CrossRef]

- Islam, M.I.; Uddin, A.J. Enhancing the quality of elastane-cotton core yarn by compact spinning. Heliyon 2022, 8, e09562. [Google Scholar] [CrossRef] [PubMed]

- Lyu, J.; Cheng, L. Simulation of airflow in the condensing zone of a modified compact spinning device and analysis of its yarn properties. J. Text. Inst. 2023, 114, 175–181. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, C.; Su, Z.; Chen, Z.; Gao, C.; Gong, H.; Xu, W.; Xu, D.; Liu, K. Enhancing the Spun Yarn Properties by Controlling Fiber Stress Distribution in the Spinning Triangle with Rotary Heterogeneous Contact Surfaces. Polymers 2022, 15, 176. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.F.; Lam, N.Y.; Yan, F.; Yang, C.; Li, L. Numerical study of the three-dimensional preliminary flow field in the ring spinning triangle. Text. Res. J. 2016, 86, 1728–1737. [Google Scholar] [CrossRef]

- Duo, X.; Can, G.; Chong, G.; Yingcun, L.; Ziyi, S.; Changjin, K.; Keshuai, L.; Jian, F.; Weilin, X. Novel composite yarn with a wavy-network structure produced by various delivery speed ratios and untwisting factors. Text. Res. J. 2022, 92, 4551–4562. [Google Scholar] [CrossRef]

- Xia, Z.; Wang, H.S.; Ye, W. A method to produce ring single yarn with fancy and anti-frictional structure by feeding filaments in front of the front roller nip. Text. Res. J. 2020, 90, 631–640. [Google Scholar] [CrossRef]

- Xia, Z.; Guo, Q.; Ye, W.; Chen, J.; Feng, S.; Ding, C. Comparative study of fiber trapping by filaments in conventional and diagonal sirofil systems. Text. Res. J. 2018, 88, 1581–1592. [Google Scholar] [CrossRef]

- Xia, Z.; Liu, H.; Huang, J.; Gu, S.; Xu, W. A study on the influence of a surface-contacting spinning strand on yarn appearance during sirofil spinning. Text. Res. J. 2015, 85, 128–139. [Google Scholar] [CrossRef]

- Xia, Z.; Wang, C.; Fu, C.; Wei, J.; Xu, W. Novel composite siro-spinning with forced migrations of filaments. Text. Res. J. 2019, 89, 3927–3936. [Google Scholar] [CrossRef]

- Xia, Z.; Tang, J.; Ye, W. A novel concept to produce periodic varied structural composite yarn via cyclical changing of the spacing between filaments and the strand. Text. Res. J. 2019, 89, 2998–3006. [Google Scholar] [CrossRef]

- Xu, D.; Fan, H.; Li, J.; Yang, W.; Liu, K.; Xu, W. Comparative Analysis of the Properties of Yarn Spun by Rotary Threaded Surfaces with Different Pitches. J. Nat. Fibers 2022, 19, 4835–4845. [Google Scholar] [CrossRef]

- Xia, Z.; Wang, X.; Ye, W.; Eltahir, H.A.; Xu, W. Fiber trapping comparison of embeddable and locatable spinning with sirofil and siro core-spinning with flute pipe air suction. Text. Res. J. 2012, 82, 1255–1262. [Google Scholar] [CrossRef]

- Wan, A.; Yu, W.; Jiang, G. Pilling properties of wool single jersey made of compact and conventional ring yarns after anti-felting treatment. Text. Res. J. 2014, 84, 673–683. [Google Scholar] [CrossRef]

- CN FZ/T 01086-2020; Textiles—Determination of Yarn Hairiness—Projection Counting Method. China National Textile Standardization Technical Committee: Beijing, China, 2020; Ministry of Industry and Information Technology: Beijing, China, 2020; pp. 1–4.

- CN GB/T 3292.1-2008; Textiles—Unevenness of Textile Strands—Part 1: Capacitance Method. China Standardization Administration: Beijing, China, 2008; National Textile and Apparel Council: Beijing, China, 2008; pp. 1–5.

- CN GB/T 3916-2013; Textiles—Yarns from Packages—Determination of Single-End Breaking Force and Elongation at Break Using Constant Rate of Extension (CRE) Tester. China National Textile Standardization Technical Committee: Beijing, China, 2013; National Textile and Apparel Council: Beijing, China, 2013; pp. 1–6.

- Zhang, D.; Cheng, L. Comparison of two different yarn evenness test methods. Mod. Appl. Sci. 2010, 4, 71. [Google Scholar] [CrossRef]

- Gulsevincler, E.; Usal, M.R.; Yilmaz, D. Yarn evenness parameters optimization in jetring spinning process. J. Text. Inst. 2020, 111, 540–549. [Google Scholar] [CrossRef]

- Quan, J.; He, Q.; Cheng, L.; Yu, J.; Xue, W. Investigation into novel drafting systems on ring spinning frame for improving yarn properties. Text. Res. J. 2022, 92, 3413–3425. [Google Scholar] [CrossRef]

- Xu, D.; Fan, H.; Chen, Z.; Gao, C.; Liu, K.; Fang, J.; Xu, W. Comparative Analysis of the Evenness Properties of Yarn Spun Using a Sinusoidal Pressure Bar. J. Nat. Fibers 2022, 19, 14561–14578. [Google Scholar] [CrossRef]

| Parameter | Numerical Value |

|---|---|

| Theoretical spindle speed (r/min) | 4500 |

| Theoretical linear density (tex) | 19.7 |

| Whole draft ratio | 36.2 |

| Twist factor | 400 |

| Twist direction | Z |

| Twist shrinkage (%) | 3.5 |

| Front roller speed (m/min) | 12.01 |

| Bar spacer (mm) | 3.0 |

| Ring type | PG1/2 3854 |

| Traveler type | 6903 4/0 |

| Groove width of high-frequency step roll (mm) | 3 |

| Groove width of medium-frequency step roll (mm) | 6 |

| Groove width of low-frequency step roll (mm) | 9 |

| Yarn Code | Yarn Type |

|---|---|

| OSY | Original siro spun yarns |

| HSY | Siro yarns spun with high-variation frequency |

| MSY | Siro yarns spun with medium-variation frequency |

| LSY | Siro yarns spun with low-variation frequency |

| OSFY | Original sirofil spun yarns |

| HSFY | Sirofil yarns spun with high-variation frequency |

| MSFY | Sirofil yarns spun with medium-variation frequency |

| LSFY | Sirofil yarns spun with low-variation frequency |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Z.; Li, W.; Chen, Z.; Wang, P.; Su, Z.; Sun, Y.; Liu, K.; Xu, D.; Xu, W. Controlling the Fiber Stress Distribution with Variable-Frequency Step Roll for Tunable Spun Yarn Structures. Polymers 2023, 15, 2974. https://doi.org/10.3390/polym15132974

Peng Z, Li W, Chen Z, Wang P, Su Z, Sun Y, Liu K, Xu D, Xu W. Controlling the Fiber Stress Distribution with Variable-Frequency Step Roll for Tunable Spun Yarn Structures. Polymers. 2023; 15(13):2974. https://doi.org/10.3390/polym15132974

Chicago/Turabian StylePeng, Zhiyong, Wei Li, Ze Chen, Pinxun Wang, Ziyi Su, Yue Sun, Keshuai Liu, Duo Xu, and Weilin Xu. 2023. "Controlling the Fiber Stress Distribution with Variable-Frequency Step Roll for Tunable Spun Yarn Structures" Polymers 15, no. 13: 2974. https://doi.org/10.3390/polym15132974

APA StylePeng, Z., Li, W., Chen, Z., Wang, P., Su, Z., Sun, Y., Liu, K., Xu, D., & Xu, W. (2023). Controlling the Fiber Stress Distribution with Variable-Frequency Step Roll for Tunable Spun Yarn Structures. Polymers, 15(13), 2974. https://doi.org/10.3390/polym15132974