Synchronized 3D Printing and Corona Charging for One-Step Prototyping of Polarized Polylactic Acid Electrets

Abstract

1. Introduction

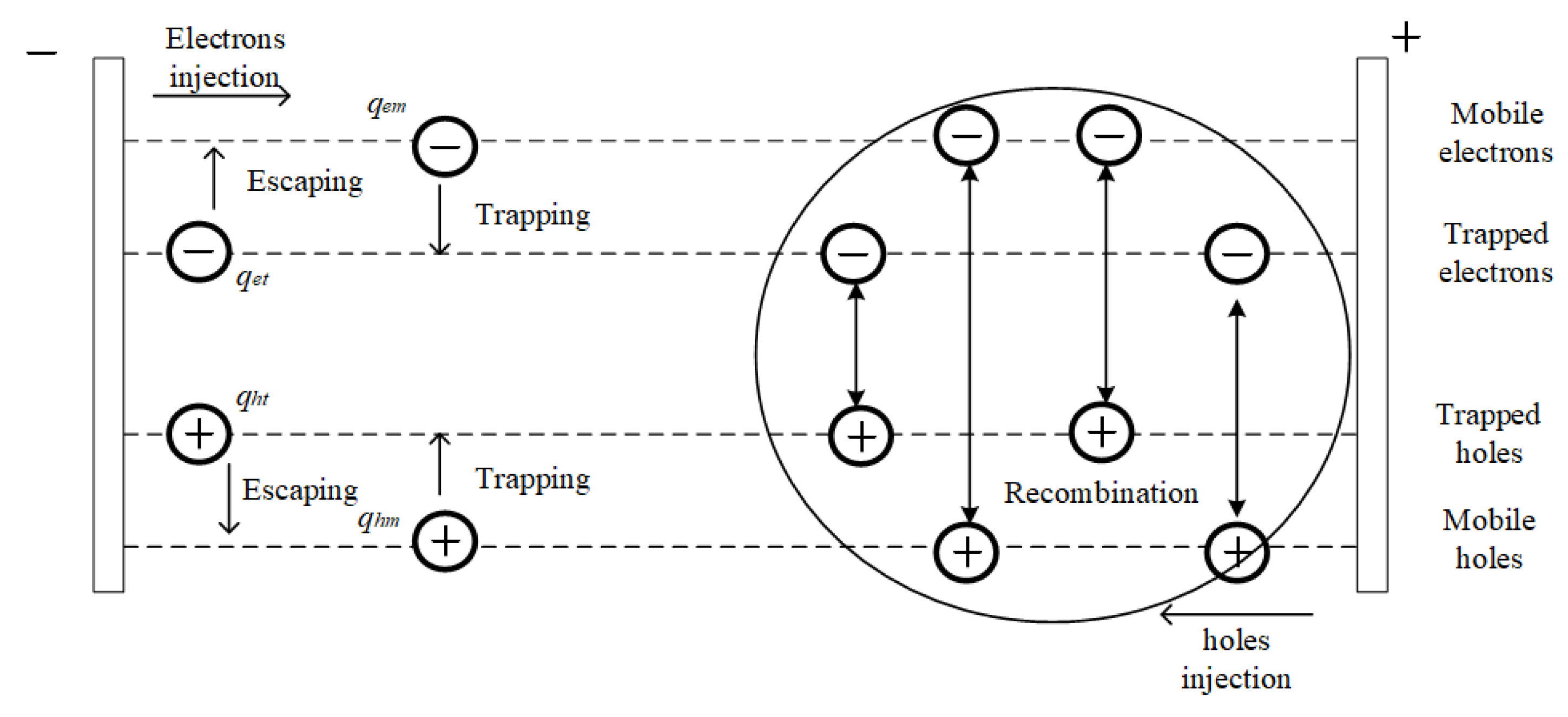

2. Model

3. Methods

4. Results and Discussion

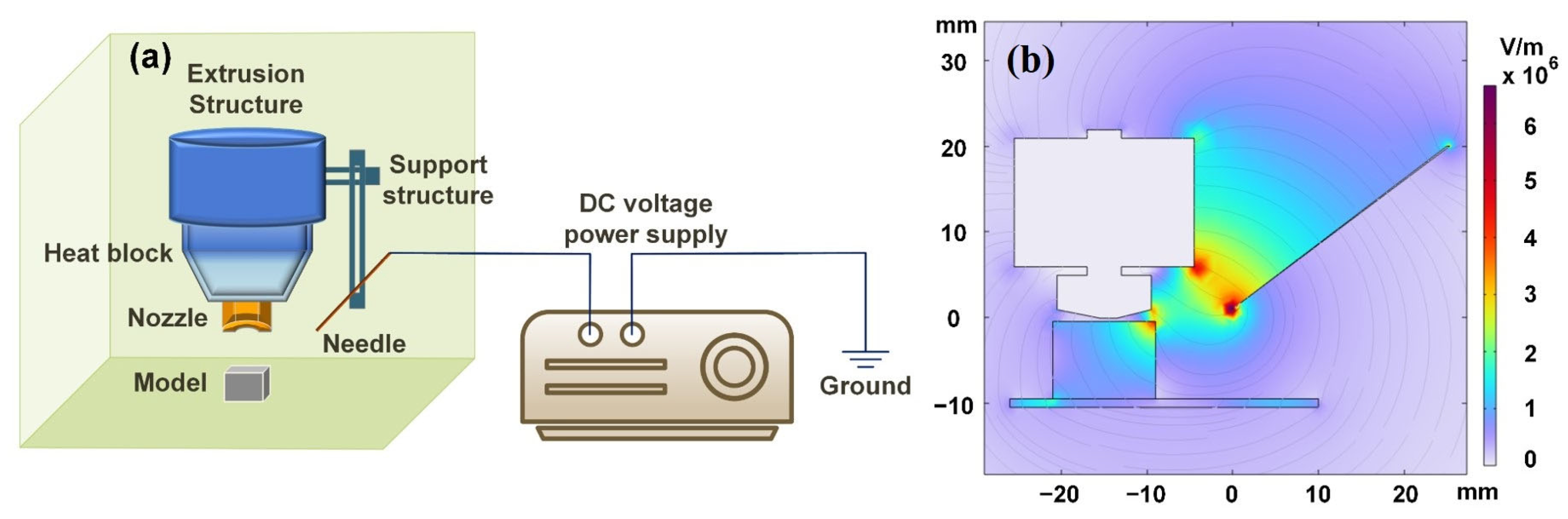

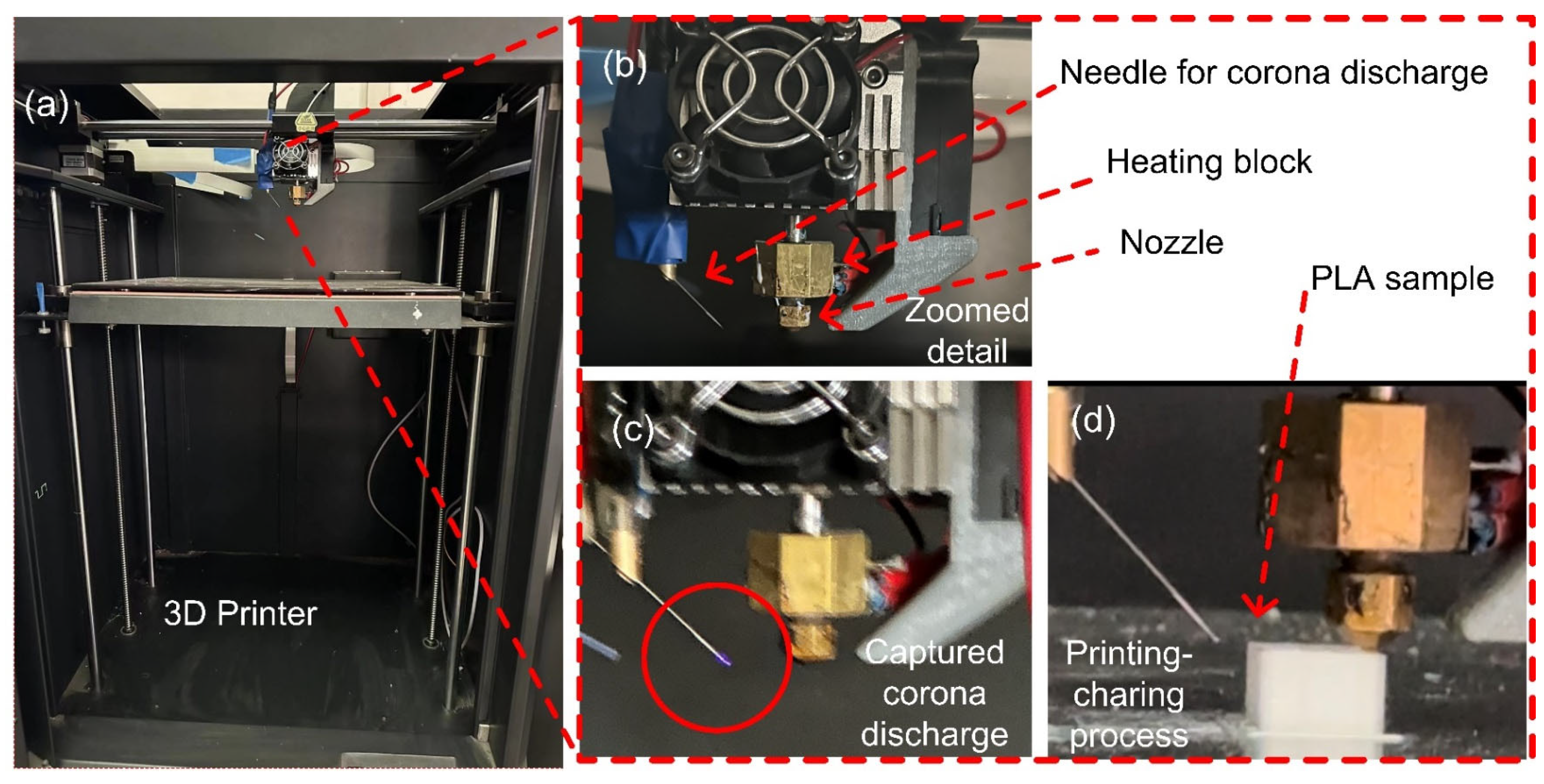

4.1. Printer Nozzle Refitting

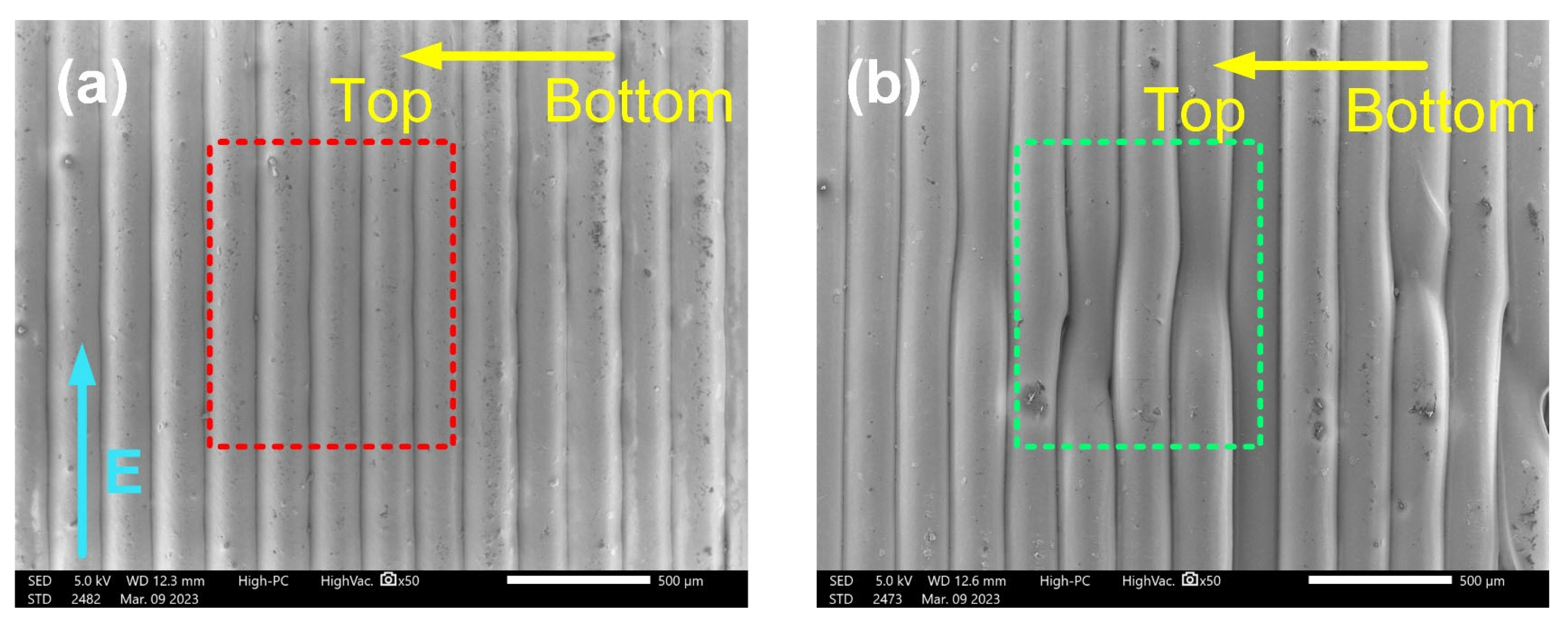

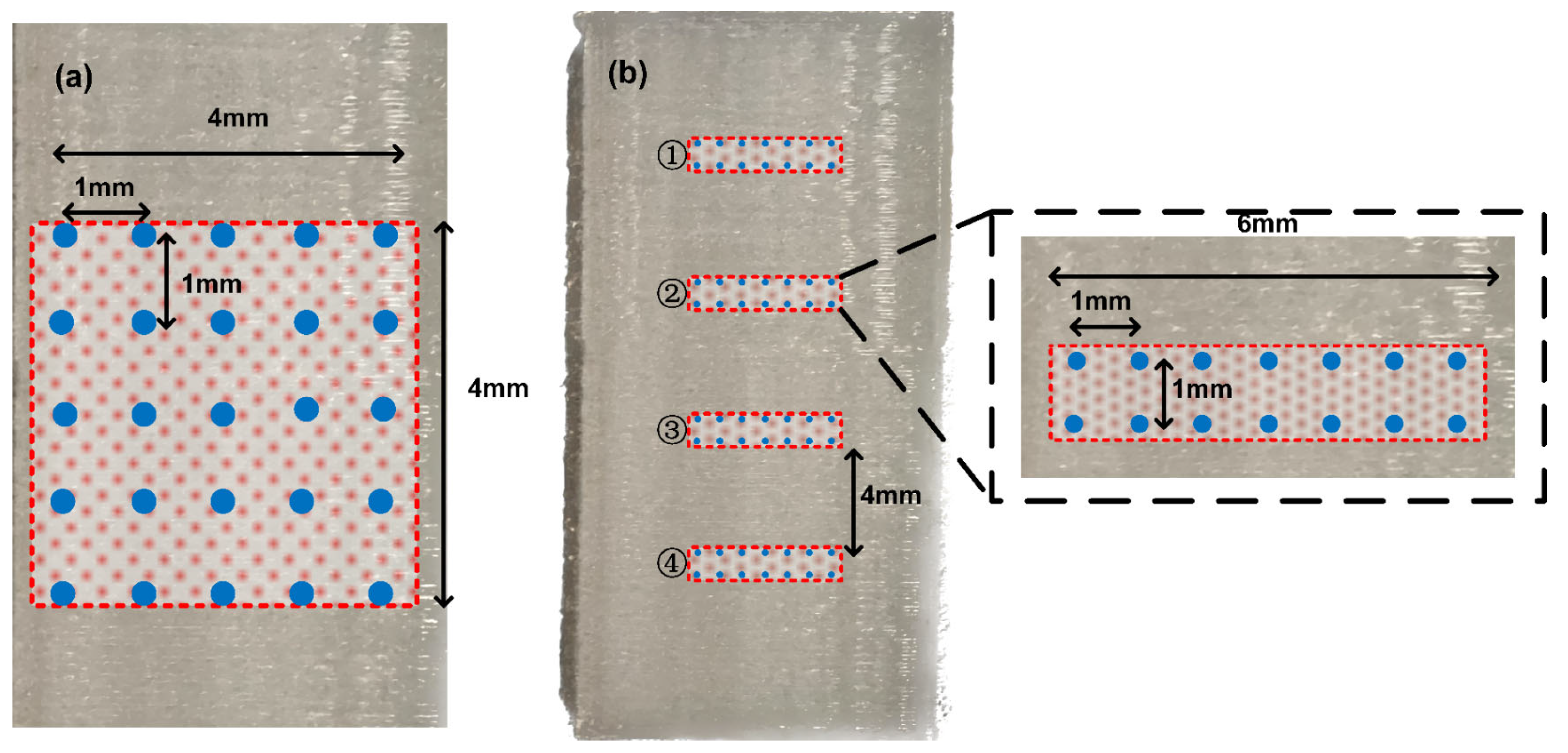

4.2. SEM Photos of Printed Samples

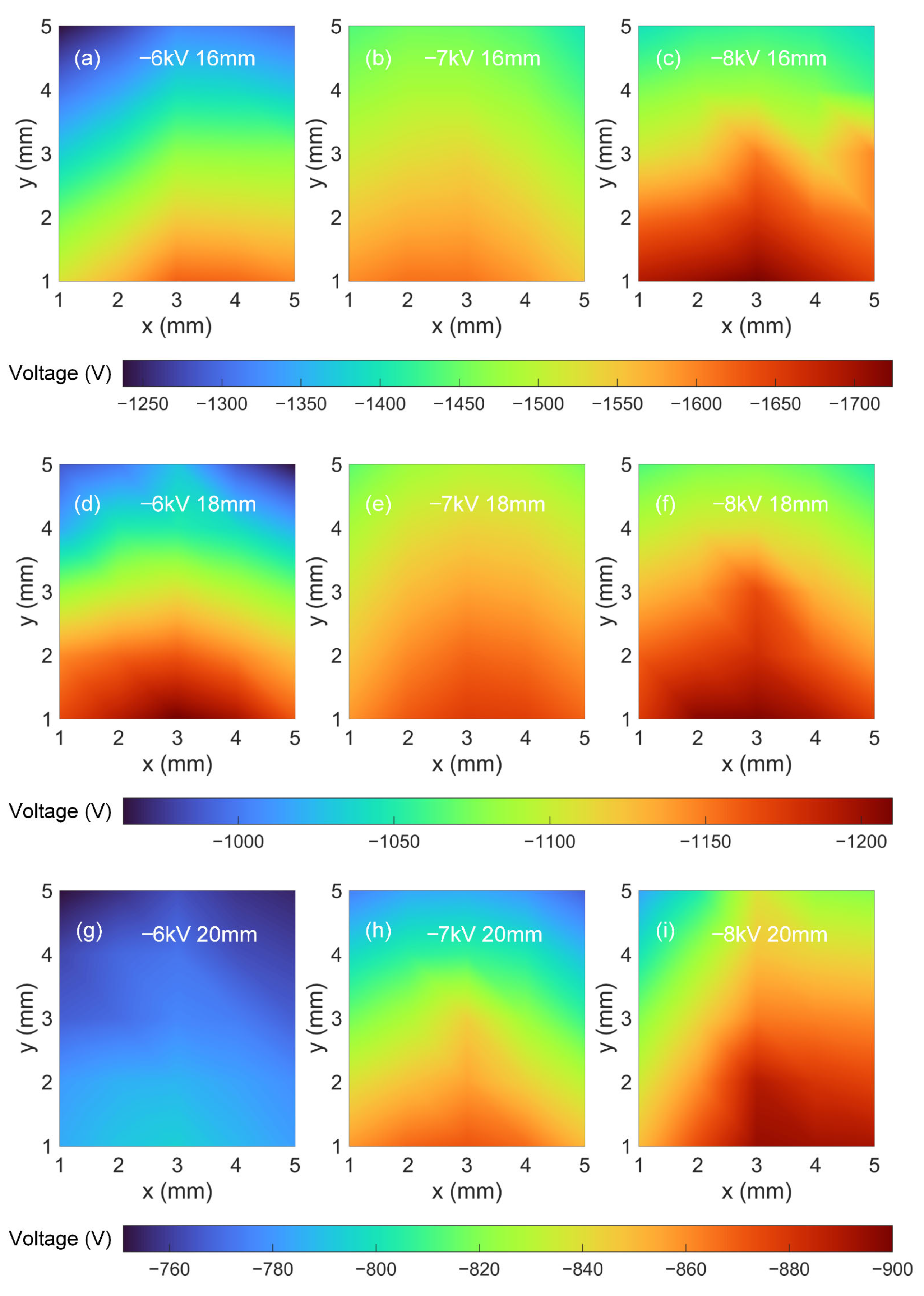

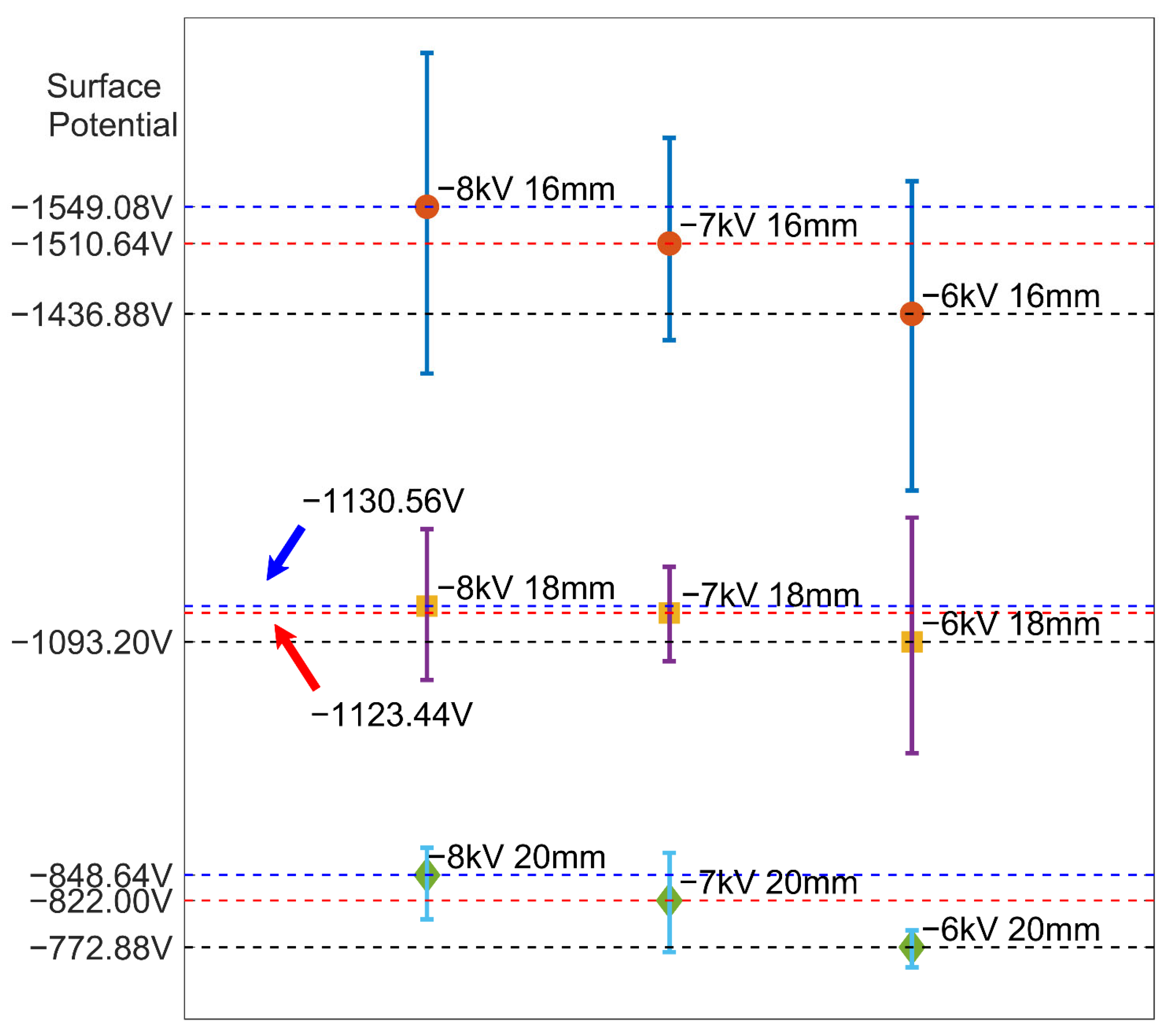

4.3. Surface Potential Measurement

4.4. Surface Potential Decay Analysis

5. Conclusions

- Relatively uniform charge distribution can be achieved on a sufficiently large sample surface, with the standard deviation of surface potential not exceeding 36.98%;

- The surface potential retention rate is improved by 5.40~32.94-fold compared to ordinary corona-charged samples;

- The proposed method has at least a 32.79% improvement in surface potential decay;

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Pt. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Murr, L.E. Metallurgy Principles Applied to Powder Bed Fusion 3D Printing/Additive Manufacturing of Personalized and Optimized Metal and Alloy Biomedical Implants: An Overview. J. Mater. Res. Technol. 2020, 9, 1087–1103. [Google Scholar] [CrossRef]

- Rodríguez-Reyna, S.L.; Mata, C.; Díaz-Aguilera, J.H.; Acevedo-Parra, H.R.; Tapia, F. Mechanical Properties Optimization for PLA, ABS and Nylon + CF Manufactured by 3D FDM Printing. Mater. Today Commun. 2022, 33, 104774. [Google Scholar] [CrossRef]

- Sandhu, K.; Singh, S.; Mustansar Hussain, C. 3D Printing of Nanomaterials Using Inkjet Printing. In Additive Manufacturing with Functionalized Nanomaterials; Micro and Nano Technologies; Singh, S., Hussain, C.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 155–192. ISBN 978-0-12-823152-4. [Google Scholar]

- Khoshnevis, B. Automated Construction by Contour Crafting—Related Robotics and Information Technologies. Autom. Constr. 2004, 13, 5–19. [Google Scholar] [CrossRef]

- Yuan, C.; Wang, T.; Dunn, M.L.; Qi, H.J. 3D Printed Active Origami with Complicated Folding Patterns. Int. J. Precis Eng. Manuf.-Green Technol. 2017, 4, 281–289. [Google Scholar] [CrossRef]

- Hao, W.; Liu, Y.; Zhou, H.; Chen, H.; Fang, D. Preparation and Characterization of 3D Printed Continuous Carbon Fiber Reinforced Thermosetting Composites. Polym. Test. 2018, 65, 29–34. [Google Scholar] [CrossRef]

- Du, J.; Fu, G.; Xu, X.; Elshahawy, A.M.; Guan, C. 3D Printed Graphene-Based Metamaterials: Guesting Multi-Functionality in One Gain. Small 2023, 2207833. [Google Scholar] [CrossRef]

- Bauer, S. Poled Polymers for Sensors and Photonic Applications. J. Appl. Phys. 1996, 80, 5531–5558. [Google Scholar] [CrossRef]

- Singh, R. A Review of Developments in Thermal Techniques for Charge Profile Measurements in Polymer Electrets. J. Electrost. 2014, 72, 322–329. [Google Scholar] [CrossRef]

- Zhang, B.; Zhou, Y.; Wang, N.; Liang, X.; Guan, Z.; Takada, T. Polarity Reversal Charging of Polypropylene Films under DC Corona Discharge. J. Electrost. 2005, 63, 657–663. [Google Scholar] [CrossRef]

- Das, D.; Waychal, A. On the Triboelectrically Charged Nonwoven Electrets for Air Filtration. J. Electrost. 2016, 83, 73–77. [Google Scholar] [CrossRef]

- Montanari, G.C. Electrical Measurements for the Characterization of Electret Properties of Cellular Polymers. IEEE Trans. Dielect. Electr. Insul. 2003, 10, 615–622. [Google Scholar] [CrossRef]

- Najihi, I.; Ennawaoui, C.; Hajjaji, A.; Boughaleb, Y. 3D Printed Cellular Piezoelectric Polymers for Smart Sensors/Autonomous Energy Harvesters. Mater. Today Proc. 2022, 66, 437–440. [Google Scholar] [CrossRef]

- Assagra, Y.A.O.; Altafim, R.A.P.; do Carmo, J.P.; Altafim, R.A.C.; Rychkov, D.; Wirges, W.; Gerhard, R. A New Route to Piezo-Polymer Transducers: 3D Printing of Polypropylene Ferroelectrets. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1668–1674. [Google Scholar] [CrossRef]

- Mirkowska, A.; Kacprzyk, R.; Rozmaryniewicz, K. Piezoelectric Structure With a 3-D Printed Mesh Layer. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 823–828. [Google Scholar] [CrossRef]

- Palitó, T.T.C.; Assagra, Y.A.O.; Altafim, R.A.P.; Carmo, J.P.; Altafim, R.A.C. Hydrophone Based on 3D Printed Polypropylene (PP) Piezoelectret. Electron. Lett. 2019, 55, 203–204. [Google Scholar] [CrossRef]

- Kierzewski, I.; Bedair, S.S.; Hanrahan, B.; Tsang, H.; Hu, L.; Lazarus, N. Adding an Electroactive Response to 3D Printed Materials: Printing a Piezoelectret. Addit. Manuf. 2020, 31, 100963. [Google Scholar] [CrossRef]

- Alison, J.M.; Hill, R.M. A Model for Bipolar Charge Transport, Trapping and Recombination in Degassed Crosslinked Polyethene. J. Phys. D Appl. Phys. 1994, 27, 1291–1299. [Google Scholar] [CrossRef]

- Cai, X.; Wang, X.; Pang, D.; Zou, X.; Yu, J.; Lu, Z. Investigation of Current Density, Recombination Rate and Space Charge Density in Polyethylene Thin Films Based on Bipolar Charge Transport Model. Mater. Res. Express 2019, 6, 096451. [Google Scholar] [CrossRef]

- Galikhanov, E., Lounev, I., Guzhova, A., Gusev, Y., Galikhanov, M., Vasilyeva, M., Akkus, B., Oktem, Y., Yalcin, L.S., Mutlu, R.B.C., et al., Eds.; Study of Polylactic Acid Electret by Dielectric Spectroscopy. In Proceedings of the 9th International Physics Conference of the Balkan Physical Union (bpu-9), Istanbul, Turkey, 24–27 August 2023; Amer Inst Physics: Melville, NY, USA, 2016; Volume 1722, p. 290002. [Google Scholar]

- Roudný, P.; Syrový, T. Thermal Conductive Composites for FDM 3D Printing: A Review, Opportunities and Obstacles, Future Directions. J. Manuf. Process. 2022, 83, 667–677. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.-Y.; Tagarielli, V.L. Measurements of the Mechanical Response of Unidirectional 3D-Printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Guzhova, A.A.; Galikhanov, M.F.; Gorokhovatsky, Y.A.; Temnov, D.E.; Fomicheva, E.E.; Karulina, E.A.; Yovcheva, T.A. Improvement of Polylactic Acid Electret Properties by Addition of Fine Barium Titanate. J. Electrost. 2016, 79, 1–6. [Google Scholar] [CrossRef]

| Physical Properties of PLA | Value |

|---|---|

| Density | 1.25 g/cm3 |

| Melting point | 449.15 K |

| Intrinsic viscosity | 1.20 dL/g |

| Glass transition temperature | 333.15 K |

| Tensile strength | 40.00 MPa |

| Elastic modulus | 3000.00 Mpa |

| Flexural modulus | 100.00 Mpa |

| Dielectric dissipation factor | 0.01 |

| Relative permittivity | 3.10 |

| Volume resistivity | 4.30 × 1017 Ω·cm |

| Process Variables | Value |

|---|---|

| Length of cuboid sample | 12 mm |

| Width of cuboid sample | 12 mm |

| Height of cuboid sample | 30 mm |

| Filling percentage | 10% |

| Printing speed | 75 mm/s |

| Printing temperature | 483.15 K |

| Charging and Printing | Time Constant τ1 | Ratio | Time Constant τ2 | Ratio |

|---|---|---|---|---|

| −8 kV, 16 mm when printing | 0.62344 | 97.8% | 58.65102 | 749.9% |

| −7 kV, 16 mm when printing | 0.90991 | 142.6% | 265.46323 | 3394.2% |

| −6 kV, 16 mm when printing | 0.03631 | 5.7% | 55.18763 | 705.6% |

| −8 kV, 18 mm when printing | 0.30525 | 47.9% | 124.25447 | 1588.7% |

| −7 kV, 18 mm when printing | 0.03888 | 6.1% | 150.76134 | 1927.6% |

| −6 kV, 18 mm when printing | 0.03671 | 5.7% | 53.67686 | 686.3% |

| −8 kV, 20 mm when printing | 0.64184 | 100.6% | 89.84725 | 1148.8% |

| −7 kV, 20 mm when printing | 0.03602 | 5.6% | 50.07511 | 640.2% |

| −6 kV, 20 mm when printing | 0.36805 | 57.7% | 68.63417 | 877.6% |

| −7.7 kV, 20 mm after printing | 0.63775 | 100.0% | 7.82101 | 100.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Song, Q.; Wu, H.; Feng, B.; Li, Y.; Bu, L. Synchronized 3D Printing and Corona Charging for One-Step Prototyping of Polarized Polylactic Acid Electrets. Polymers 2023, 15, 2520. https://doi.org/10.3390/polym15112520

Wang Z, Song Q, Wu H, Feng B, Li Y, Bu L. Synchronized 3D Printing and Corona Charging for One-Step Prototyping of Polarized Polylactic Acid Electrets. Polymers. 2023; 15(11):2520. https://doi.org/10.3390/polym15112520

Chicago/Turabian StyleWang, Zhiwei, Qinghua Song, Huarui Wu, Baolong Feng, Yeyuan Li, and Ling Bu. 2023. "Synchronized 3D Printing and Corona Charging for One-Step Prototyping of Polarized Polylactic Acid Electrets" Polymers 15, no. 11: 2520. https://doi.org/10.3390/polym15112520

APA StyleWang, Z., Song, Q., Wu, H., Feng, B., Li, Y., & Bu, L. (2023). Synchronized 3D Printing and Corona Charging for One-Step Prototyping of Polarized Polylactic Acid Electrets. Polymers, 15(11), 2520. https://doi.org/10.3390/polym15112520