Furan as Impurity in Green Ethylene and Its Effects on the Productivity of Random Ethylene–Propylene Copolymer Synthesis and Its Thermal and Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Polymerization Process: Synthesis of Random Ethylene–Propylene Copolymer

2.2. Gas Chromatography Analysis with Selective Mass Detector (GC-FID)

2.3. Melt Flow Index—MFI

2.4. Thermogravimetric Analysis—TGA

2.5. Analysis of Mechanical Properties

2.5.1. Injection Molding

2.5.2. Test Specimen Preparation

2.5.3. Tensile Test

2.5.4. Flexural Test

2.5.5. Impact Test

3. Results

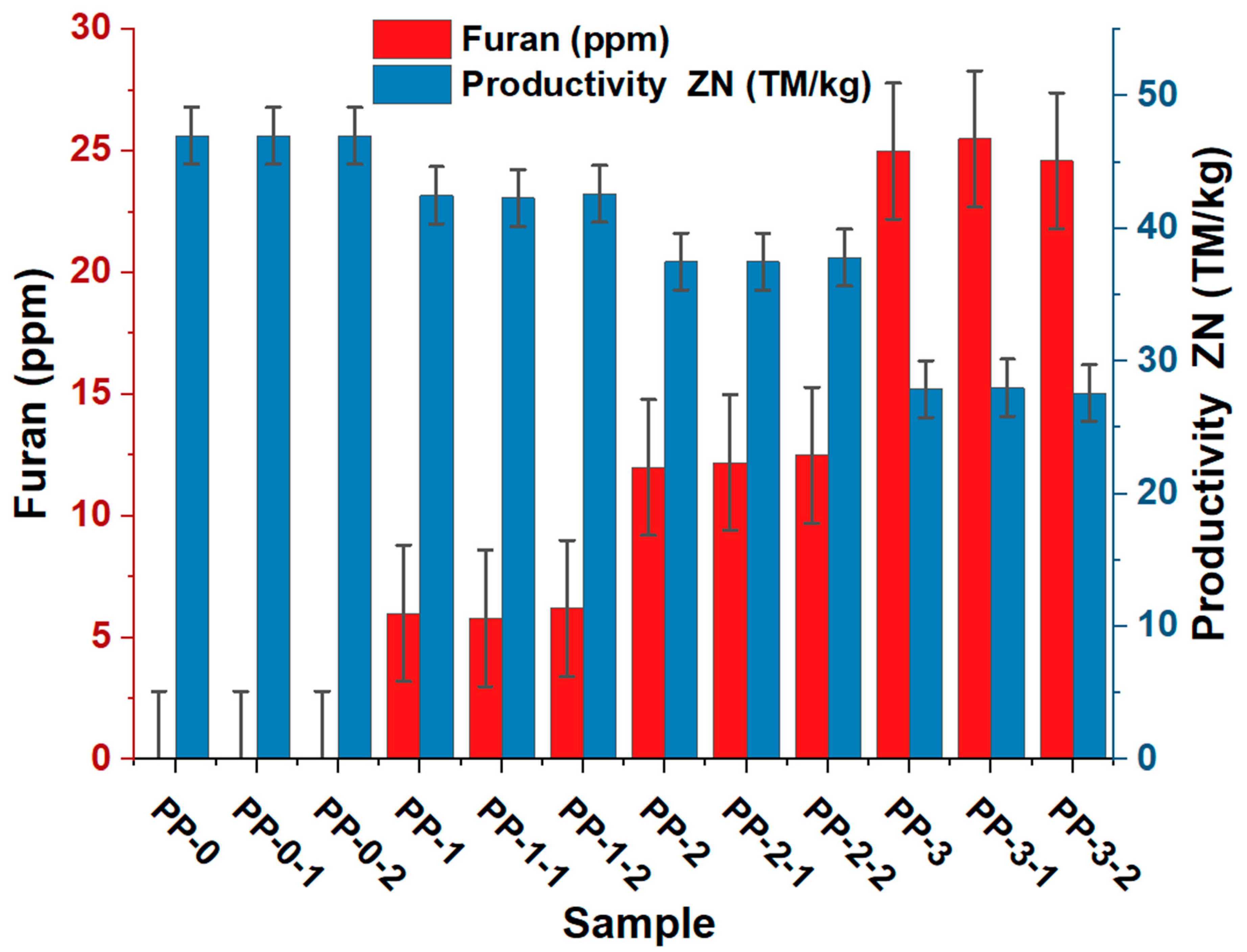

3.1. Effects of Furan on the Polymerization Process of Green Random Copolymer Rat

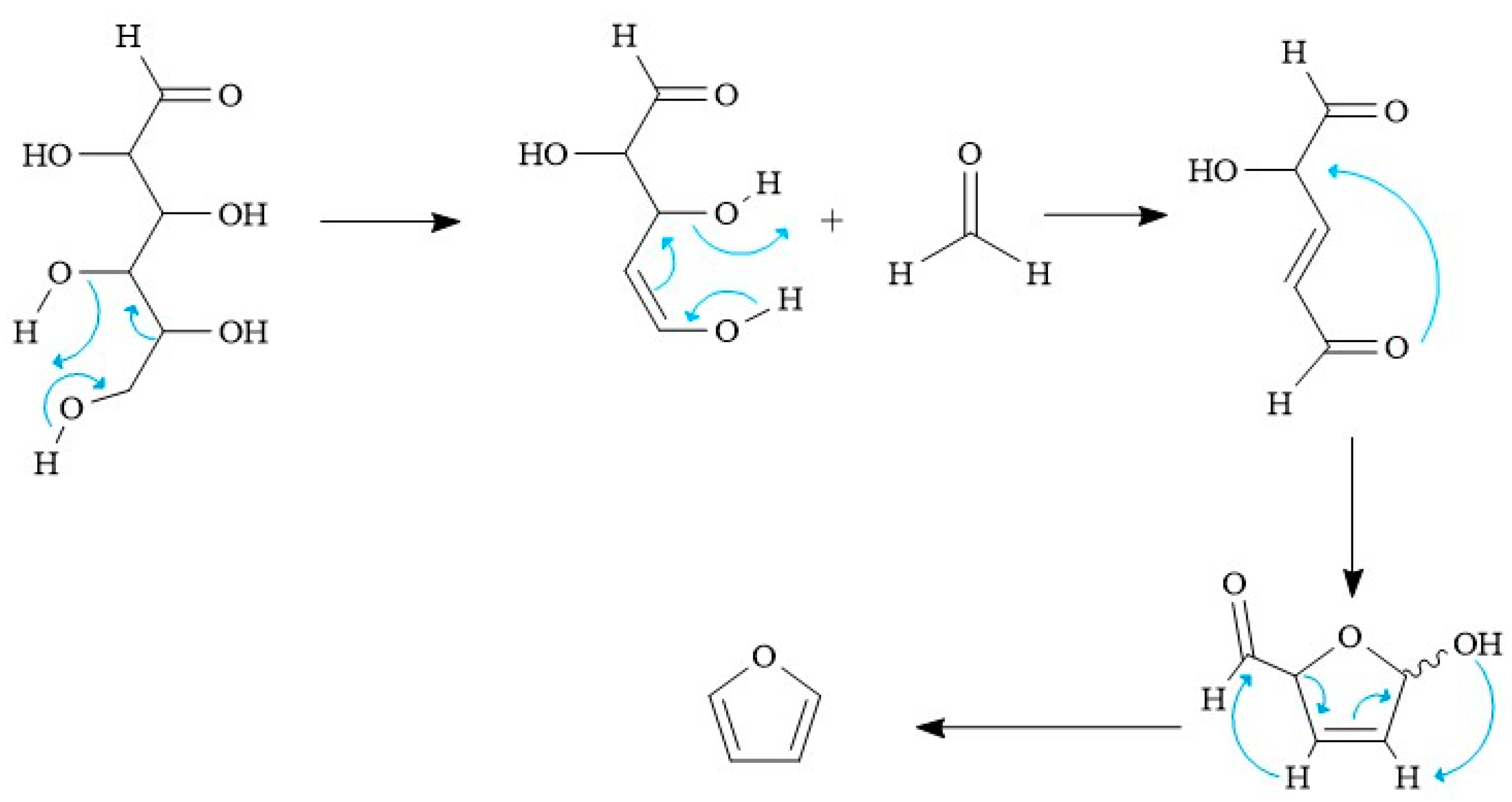

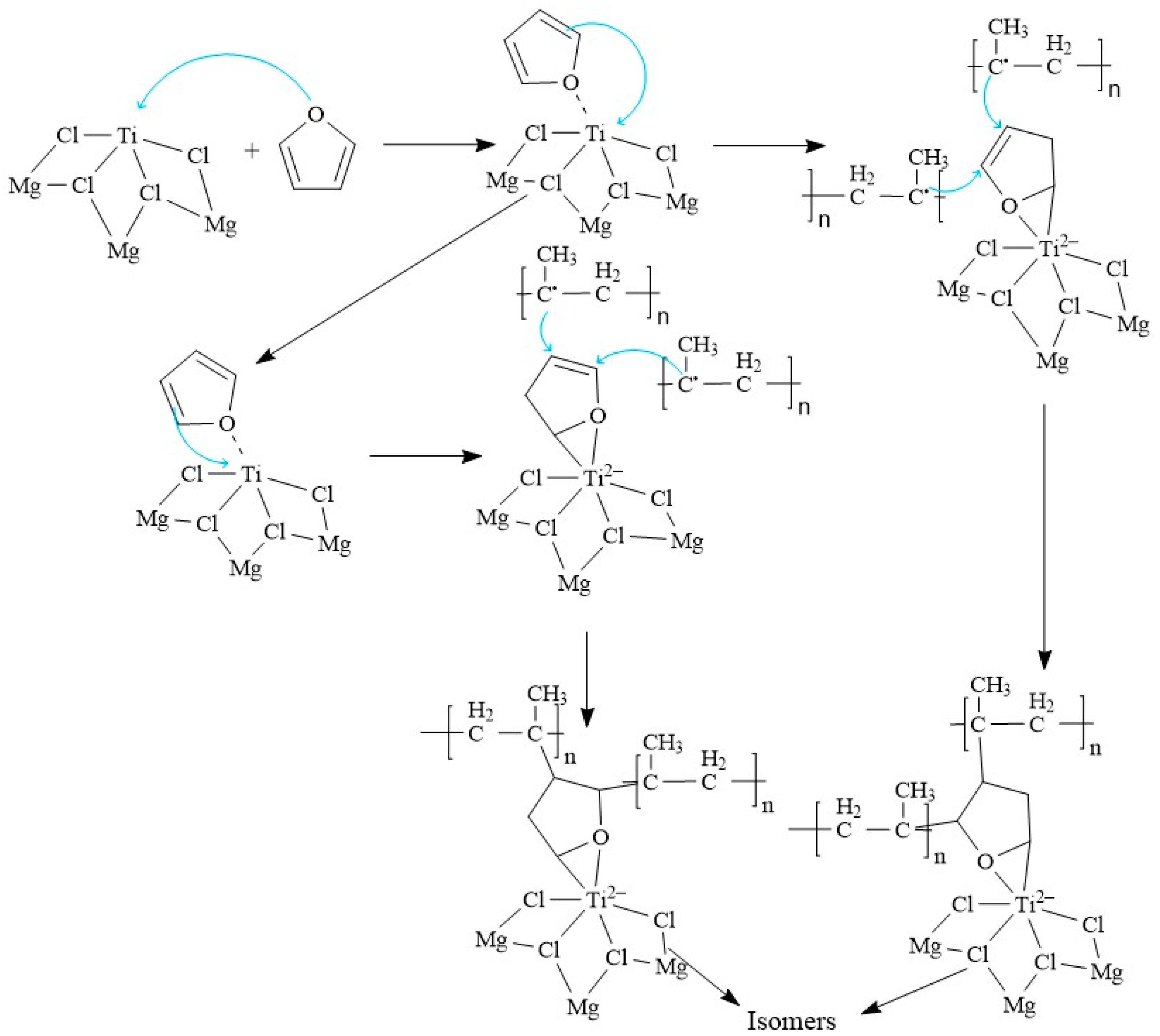

Proposed Mechanism of Action of Furan on the ZN Catalyst

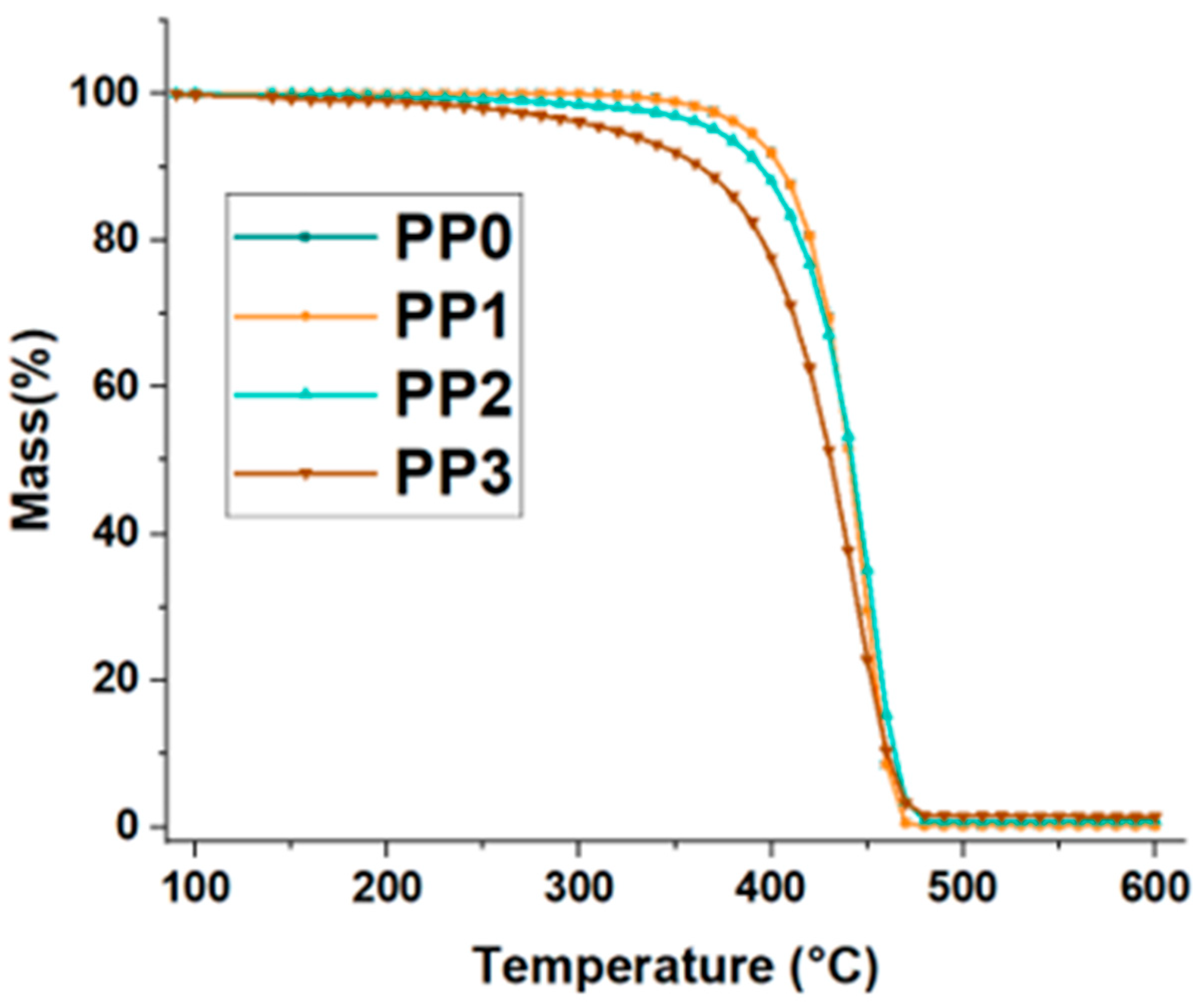

3.2. Effects of Furan on the TGA of the Random Copolymer

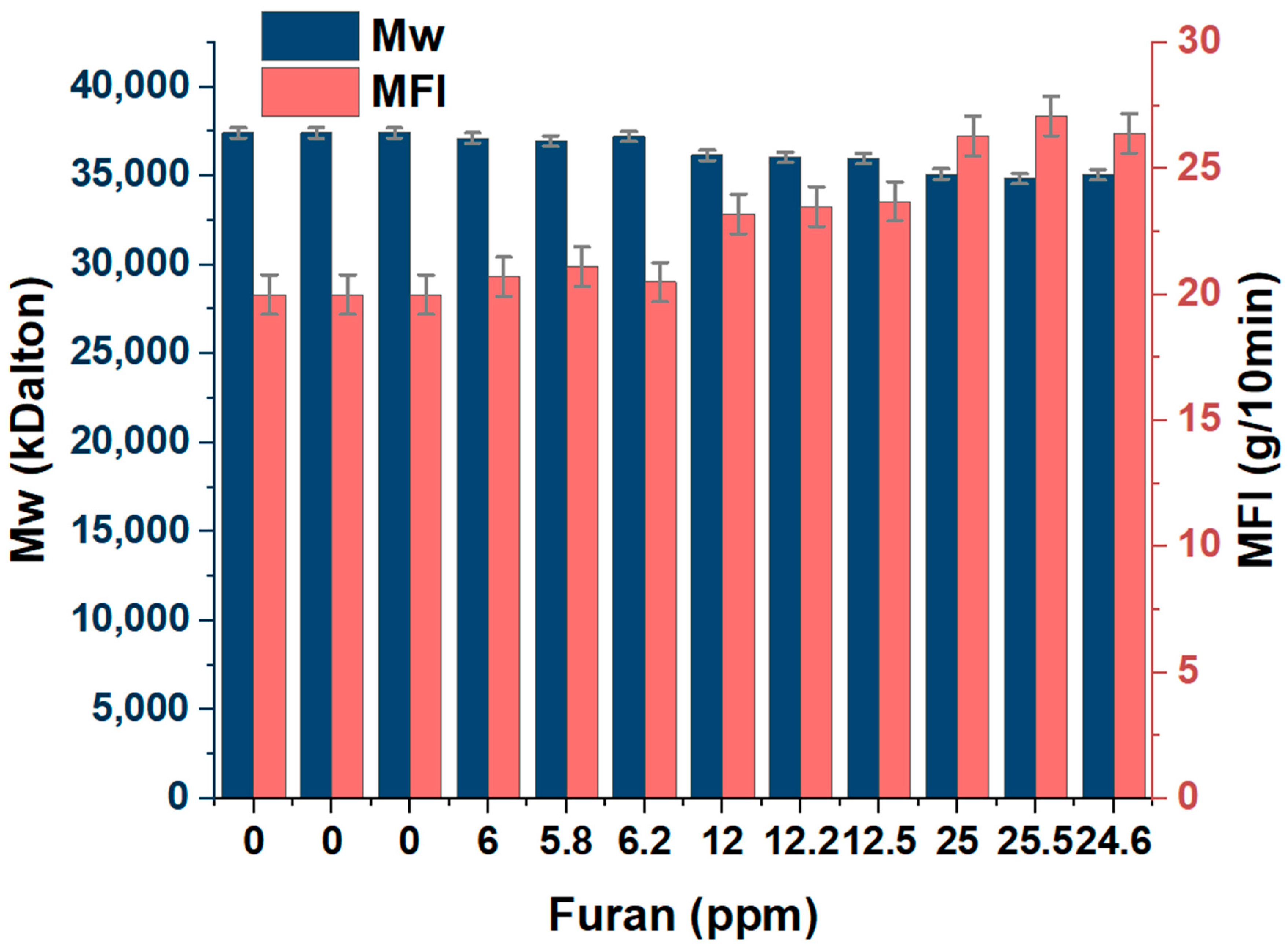

3.3. Effects of Furan on the MFI of the Green Random Copolymer

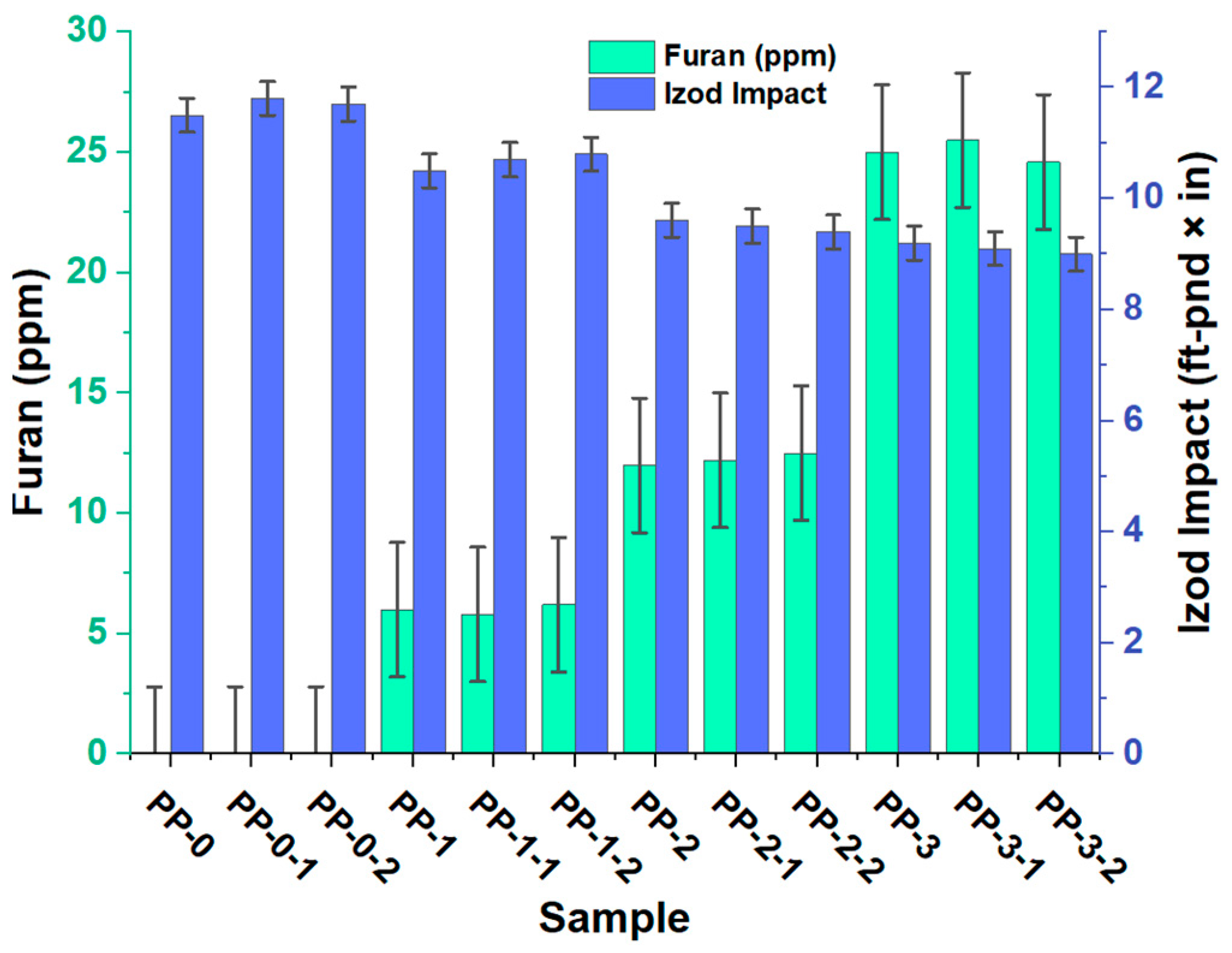

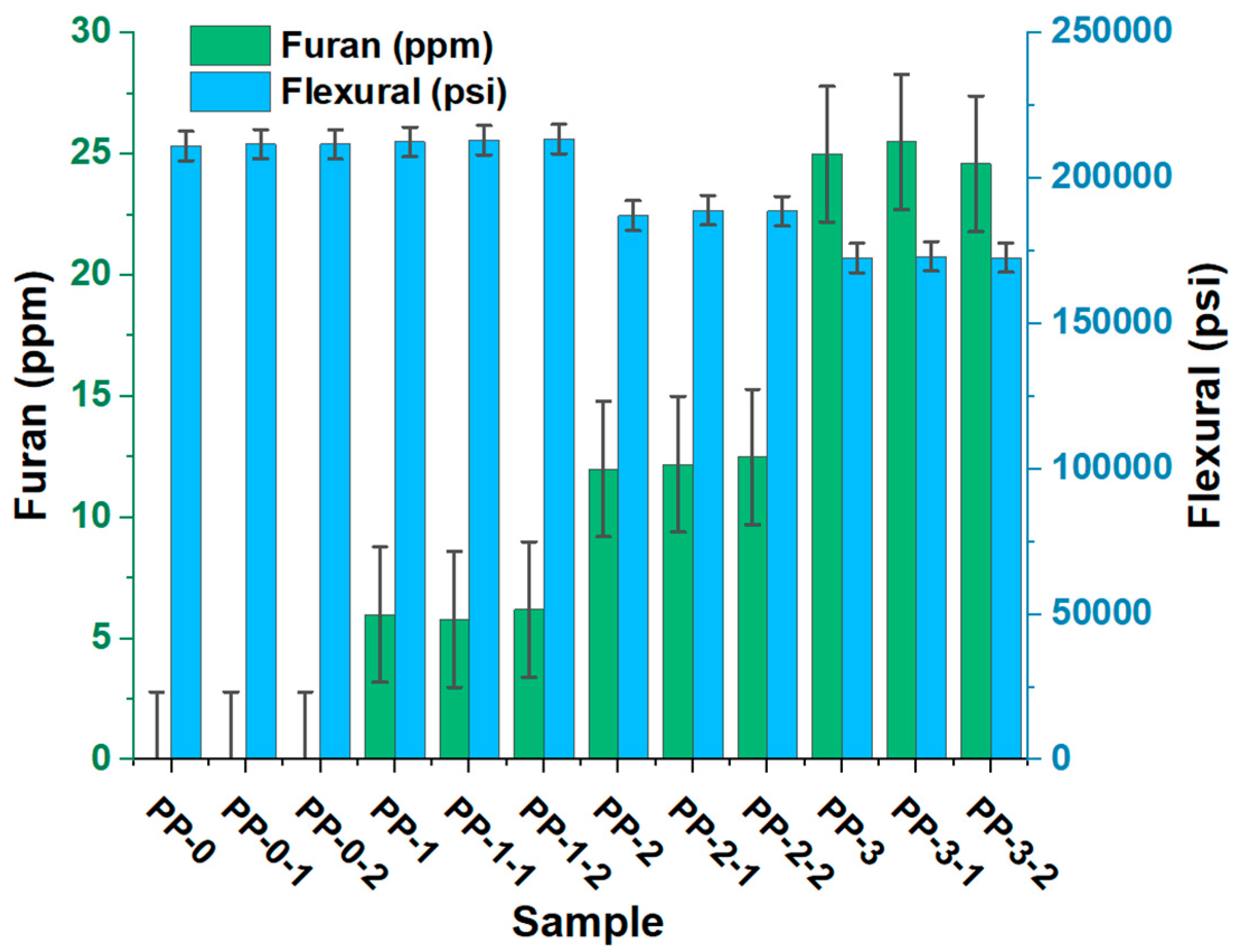

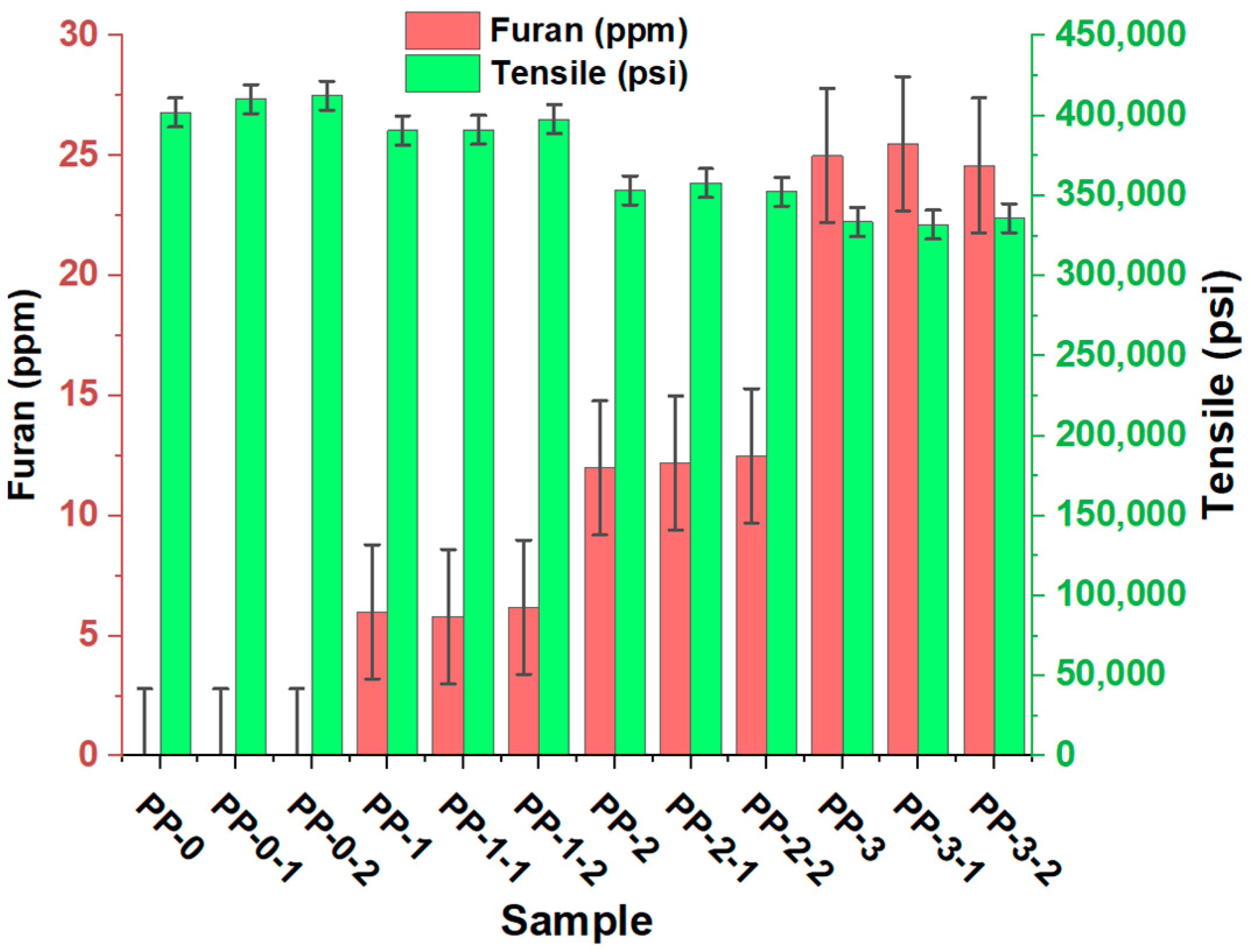

3.4. Effects of Furan on the Mechanical Properties (Tensile, Flexural, and Impact) of the Random Green Copolymer

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hernández, J.; Guerra, Y.; Espinosa, E. Development and Application of a Principal Component Analysis Model to Quantify the Green Ethylene Content in Virgin Impact Copolymer Resins During Their Synthesis on an Industrial Scale. J. Polym. Environ. 2022, 30, 4800–4808. [Google Scholar] [CrossRef]

- Hernández, J.; Rodríguez, E. Determination of phenolic antioxidants additives in industrial wastewater from polypropylene production using solid phase extraction with high-performance liquid chromatography. J. Chromatogr. A 2019, 1607, 460442. [Google Scholar] [CrossRef] [PubMed]

- Hernández, J.; Lopez, J. Quantifcation of poisons for Ziegler Natta catalysts and efects on the production of polypropylene by gas chromatographic with simultaneous detection: Pulsed discharge helium ionization, mass spectrometry and fame ionization. J. Chromatogr. A 2020, 1614, 460–736. [Google Scholar] [CrossRef]

- Hernández, J.; Cano, H.; Guerra, Y.; Polo, E.; Ríos, J.; Vivas, R.; Oviedo, J. Identifcation and quantifcation of microplastics in effluents of wastewater treatment plant by differential scanning calorimetry (DSC). Sustainability 2022, 14, 4920. [Google Scholar] [CrossRef]

- Picó, Y.; Soursou, V.; Alfarhan, A.; El-Sheikh, M.; Barceló, D. First evidence of microplastics occurrence in mixed surface and treated wastewater from two major Saudi Arabian cities and assessment of their ecological risk. J. Hazard. Mater. 2021, 416, 125–747. [Google Scholar] [CrossRef]

- Mallow, O.; Spacek, S.; Schwarzböck, T.; Fellner, J.; Rechberger, H. A new thermoanalytical method for the quantifcation of microplastics in industrial wastewater. Environ. Pollut. 2020, 259, 113–862. [Google Scholar] [CrossRef] [PubMed]

- Vajravel, S.; Sirin, S.; Kosourov, S.; Allahverdiyeva, Y. Towards sustainable ethylene production with cyanobacterial artifcial bioflms. Green Chem 2020, 22, 6404–6414. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, R.; Zhang, T. Three-phase electrochemistry for green ethylene production. Curr. Opin. Electrochem. 2021, 30, 100–789. [Google Scholar] [CrossRef]

- Penteado, A.; Kim, M.; Godini, H.; Esche, E.; Repke, J. Biogas as a renewable feedstock for green ethylene production via oxidative coupling of methane: Preliminary feasibility study. Chem. Eng. Trans. 2017, 61, 589–594. [Google Scholar] [CrossRef]

- Du, Z.; Xu, J.; Dong, Q.; Fan, Z. Thermal fractionation and efect of comonomer distribution on the crystal structure of ethylene-propylene copolymers. Polymer 2009, 50, 2510–2515. [Google Scholar] [CrossRef]

- Rani, M.; Marchesi, C.; Federici, S.; Rovelli, G.; Alessandri, I.; Vassalini, I.; Ducoli, S.; Borgese, L.; Zacco, A.; Bilo, F.; et al. Miniaturized near-infrared (MicroNIR) spectrometer in plastic waste sorting. Materials 2019, 12, 2740. [Google Scholar] [CrossRef] [PubMed]

- Hernández, J.; Guerra, Y.; Puello, E.; Marquez, E. Effects of Different Concentrations of Arsine on the Synthesis and Final Properties of Polypropylene. Polymers 2022, 14, 3123. [Google Scholar] [CrossRef] [PubMed]

- Hernández, J.; López, J. Experimental study of the auto-catalytic effect of triethylaluminum and TiCl4 residuals at the onset of non-additive polypropylene degradation and their impact on thermo-oxidative degradation and pyrolysis. J. Anal. Appl. Pyrolysis 2021, 155, 105052. [Google Scholar] [CrossRef]

- Mardueño, S.; Barron, J.; Verdin, B.; Mendeleev, E.; Montalvo, R. Química Orgánica Introducción a la Química Heterocíclica; Universidad Autónoma de Nayarit, México: Tepic, Mexico, 2013; p. 181. [Google Scholar]

- Ruiz, M.L. Tesis Sobre Determinación y Evaluación de las Emisiones de Dioxinas y Furanos en la Producción de Cemento en España; Universidad Complutense de Madrid (UCM): Madrid, Spain, 2007. [Google Scholar]

- Sarra, A.J. Dioxinas y furanos derivados de la combustión. Rev. Científica De La Univ. De Belgrano 2018, 1, 143–157. [Google Scholar]

- González, P. Tesis Sobre Contribución al Control de la Contaminación por Cloropropanoles en el Ámbito Alimentario Mediante el Desarrollo de Nuevas Metodologías Analíticas; Universidad de Santiago de Compostela: Santiago, Spain, 2015. [Google Scholar]

- Pedreschi, F. Tesis Technologies for Furan Mitigation in Highly Consumed Chilean Foods Processed at High Temperatures; Pontifica Universidad Católica de Chile: Santiago, Chile, 2015. [Google Scholar]

- Cahuaya, M.A. Tesis Sobre la Determinación de Dioxinas y Furanos en Harina de Pescado por Cromatografía de Gases Acoplada a Espectrometría de Masas Triple Cuadrupolo; Universidad Peruana Cayetano Heredia: San Martín de Porres District, Peru, 2021. [Google Scholar]

- Naccha, L.R. Tesis Sobre Cuantificación de Dioxinas por Cromatografía de Gases; Universidad Autónoma de Nuevo León: San Nicolás de los Garza, México, 2010. [Google Scholar]

- Cobo, M.I.; Hoyos, A.E.; Aristizábal, B.; de Correa, C.M. Dioxinas y furanos en cenizas de incineración. Rev. Fac. De Ing. Univ. De Antioq. 2004, 32, 26–38. [Google Scholar]

- Shubhra, Q.T.H.; Alam, A.K.M.M.; Quaiyyum, M.A. Mechanical properties of polypropylene composites: A review. J. Thermoplast. Compos. Mater. 2013, 26, 362–391. [Google Scholar] [CrossRef]

- Karol, F.J.; Jacobson, F.I. Catalysis and the Unipol Process. Stud. Surf. Sci. Catal. 1986, 25, 323–337. [Google Scholar]

- Hernández, J.A. Tesis Sobre el Uso de Aditivos Sostenibles en la Estabilización Térmica del Polipropileno en su Proceso de Síntesis; Universidad Politecnica de Valencia: Valencia, Spain, 2018. [Google Scholar]

- Quinteros, J.G. Tesis sobre Sintesis y Aplicaciones de Ligandos Arsinas. Estudios de Sistemas Catalíticos de Pd y Au; Universidad Nacional de Córdoba: Córdoba, Spain, 2016. [Google Scholar]

- Treichel, P.M. A Review of: “Phosphine, Arsine, and Stibine Complexes of The Transition Elements. C. A. McAuliffe and W. Levason, Elsevier Scientific Publishing Co., Amsterdam, The Netherlands, 1979, 546 pp, $84.50”. Synth. React. Inorganic Met. Nano-Metal Chem. 1979, 9, 507–508. [Google Scholar] [CrossRef]

- Alsabri, A.; Tahir, F.; Al-Ghamdi, S.G. Life-Cycle Assessment of Polypropylene Production in the Gulf Cooperation Council (GCC) Region. Polymers 2021, 13, 3793. [Google Scholar] [CrossRef]

- Caicedo, C.; Crespo, L.M.; Cruz, H.D.L.; Álvarez, N.A. Propiedades termo-mecánicas del Polipropileno: Efectos durante el reprocesamiento. Ing. Investig. Y Tecnol. 2017, 18, 245–252. [Google Scholar]

- Caceres, C.A.; Canevarolo, S.V. Correlação entre o Índice de Fluxo à Fusão ea Função da Distribuição de Cisão de Cadeia durante a degradação termo-mecânica do polipropileno. Polimeros 2006, 16, 294–298. [Google Scholar] [CrossRef]

- Ferg, E.E.; Bolo, L.L. A correlation between the variable melt flow index and the molecular mass distribution of virgin and recycled polypropylene used in the manufacturing of battery cases. Polym. Test. 2013, 32, 1452–1459. [Google Scholar] [CrossRef]

- Yan, H.; Hui-li, Y.; Gui-bao, Z.; Hui-liang, Z.; Ge, G.; Li-song, D. Rheological, Thermal and Mechanical Properties of Biodegradable Poly(propylene carbonate)/Polylactide/Poly(1,2-propylene glycol adipate) Blown Films. Chin. J. Polym. Sci. 2015, 12, 1702–1712. [Google Scholar] [CrossRef]

- Suraj, K.; Sanjay, L. Evaluation of mechanical properties of polypropylene—Acrylonitrile butadiene styrene blend reinforced with cowrie shell [Cypraeidae] powder. Mater. Proc. 2022, 50, 1644–1652. [Google Scholar] [CrossRef]

- Chacon, H.; Cano, H.; Fernández, J.H.; Guerra, Y.; Puello-Polo, E.; Ríos-Rojas, J.F.; Ruiz, Y. Effect of Addition of Polyurea as an Aggregate in Mortars: Analysis of Microstructure and Strength. Polymers 2022, 14, 1753. [Google Scholar] [CrossRef]

- Hernández-Fernández, J.; Castro-Suarez, J.R.; Toloza, C.A.T. Iron Oxide Powder as Responsible for the Generation of Industrial Polypropylene Waste and as a Co-Catalyst for the Pyrolysis of Non-Additive Resins. Int. J. Mol. Sci. 2022, 23, 1708. [Google Scholar] [CrossRef]

- Hernández-Fernández, J.; Rayón, E.; López, J.; Arrieta, M.P. Enhancing the Thermal Stability of Polypropylene by Blending with Low Amounts of Natural Antioxidants. Macromol. Mater. Eng. 2019, 304, 1900379. [Google Scholar] [CrossRef]

- Hernández-Fernández, J. Quantification of oxygenates, sulphides, thiols and permanent gases in propylene. A multiple linear regression model to predict the loss of efficiency in polypropylene production on an industrial scale. J. Chromatogr. A 2020, 1628, 461478. [Google Scholar] [CrossRef]

- Joaquin, H.F.; Juan, L.M. Autocatalytic influence of different levels of arsine on the thermal stability and pyrolysis of polypropylene. J. Anal. Appl. Pyrolysis 2022, 161, 105385. [Google Scholar] [CrossRef]

- Hernández-Fernández, J.; Cano, H.; Aldas, M. Impact of Traces of Hydrogen Sulfide on the Efficiency of Ziegler–Natta Catalyst on the Final Properties of Polypropylene. Polymers 2022, 14, 3910. [Google Scholar] [CrossRef]

- Hernández-Fernández, J.; Ortega-Toro, R.; Castro-Suarez, J.R. Theoretical–Experimental Study of the Action of Trace Amounts of Formaldehyde, Propionaldehyde, and Butyraldehyde as Inhibitors of the Ziegler–Natta Catalyst and the Synthesis of an Ethylene–Propylene Copolymer. Polymers 2023, 15, 1098. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Fernández, J.; Vivas-Reyes, R.; Toloza, C.A.T. Experimental Study of the Impact of Trace Amounts of Acetylene and Methylacetylene on the Synthesis, Mechanical and Thermal Properties of Polypropylene. Int. J. Mol. Sci. 2022, 23, 2148. [Google Scholar] [CrossRef] [PubMed]

| Materials | Supplier Used | Purity |

|---|---|---|

| Diisobutyl phthalate (DIBP) | (In-house donor) Sudchemie, Germany | 99.99% |

| Triethylaluminium | (Co-catalyst)Merck, Germany | 98% |

| Cyclohexyl methyl dimethoxysilane (CMDS) | (External donor) Merck, Germany | 99.9% |

| Hydrogen | Lynde | 99.999% |

| Nitrogen | Lynde | 99.999% |

| Ethylene | Airgas | 99.999% |

| Propylene | Airgas | 99.999% |

| Materials | Run | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PP0 | PP0-1 | PP0-2 | PP1 | PP1-1 | PP1-2 | PP2 | PP2-1 | PP2-2 | PP3 | PP3-1 | PP3-2 | |

| Catalyst, kg/h | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Propylene TM/h | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| Green ethylene | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| TEAL, kg/h | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

| Hydrogen, g/h | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Furan (ppm) | 0 | 0 | 0 | 6 | 5.8 | 6.2 | 12 | 12.2 | 12.5 | 25 | 25.5 | 24.6 |

| Selectivity control agent, mol/h | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| T, °C | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 |

| Pressure, bar | 27 | 27 | 27 | 27 | 27 | 27 | 27 | 27 | 27 | 27 | 27 | 27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández-Fernández, J.; Puello-Polo, E.; Márquez, E. Furan as Impurity in Green Ethylene and Its Effects on the Productivity of Random Ethylene–Propylene Copolymer Synthesis and Its Thermal and Mechanical Properties. Polymers 2023, 15, 2264. https://doi.org/10.3390/polym15102264

Hernández-Fernández J, Puello-Polo E, Márquez E. Furan as Impurity in Green Ethylene and Its Effects on the Productivity of Random Ethylene–Propylene Copolymer Synthesis and Its Thermal and Mechanical Properties. Polymers. 2023; 15(10):2264. https://doi.org/10.3390/polym15102264

Chicago/Turabian StyleHernández-Fernández, Joaquín, Esneyder Puello-Polo, and Edgar Márquez. 2023. "Furan as Impurity in Green Ethylene and Its Effects on the Productivity of Random Ethylene–Propylene Copolymer Synthesis and Its Thermal and Mechanical Properties" Polymers 15, no. 10: 2264. https://doi.org/10.3390/polym15102264

APA StyleHernández-Fernández, J., Puello-Polo, E., & Márquez, E. (2023). Furan as Impurity in Green Ethylene and Its Effects on the Productivity of Random Ethylene–Propylene Copolymer Synthesis and Its Thermal and Mechanical Properties. Polymers, 15(10), 2264. https://doi.org/10.3390/polym15102264