Predicting Characteristics of Dissimilar Laser Welded Polymeric Joints Using a Multi-Layer Perceptrons Model Coupled with Archimedes Optimizer

Abstract

1. Introduction

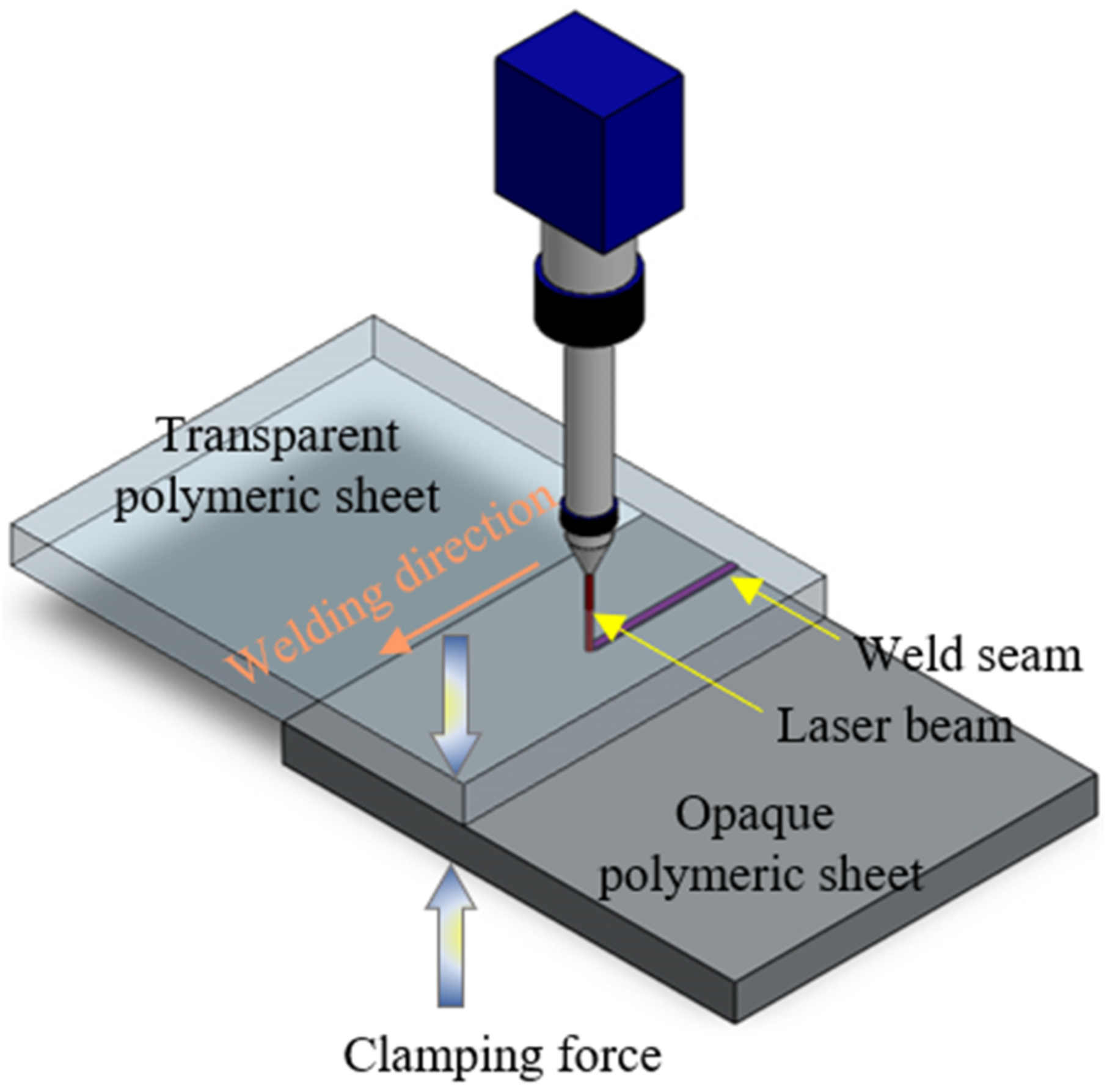

2. Experimentation

3. Modeling Approach

3.1. Multilayer Perceptron (MLP)

3.2. Archimedes Optimizer

3.3. Optimized Model

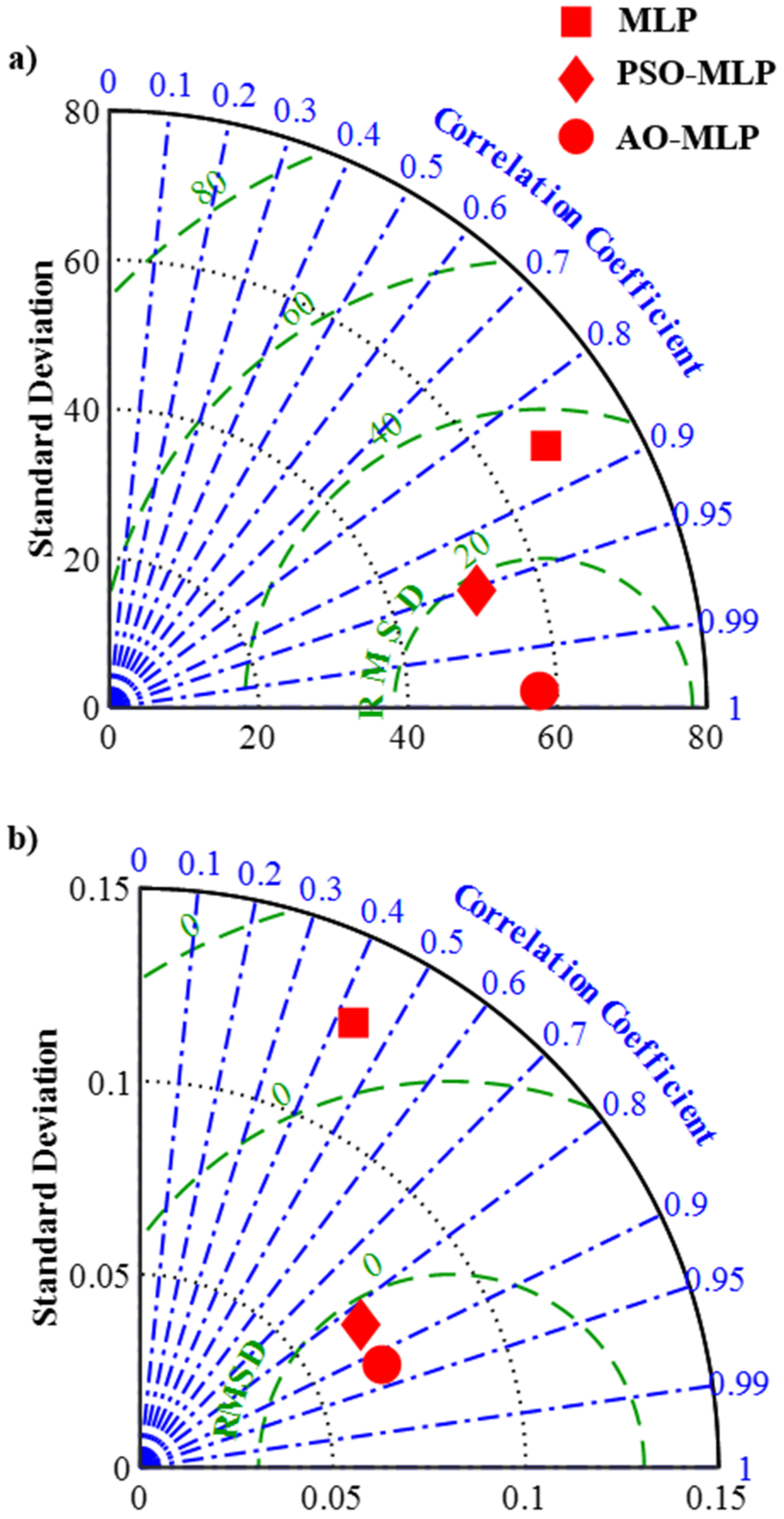

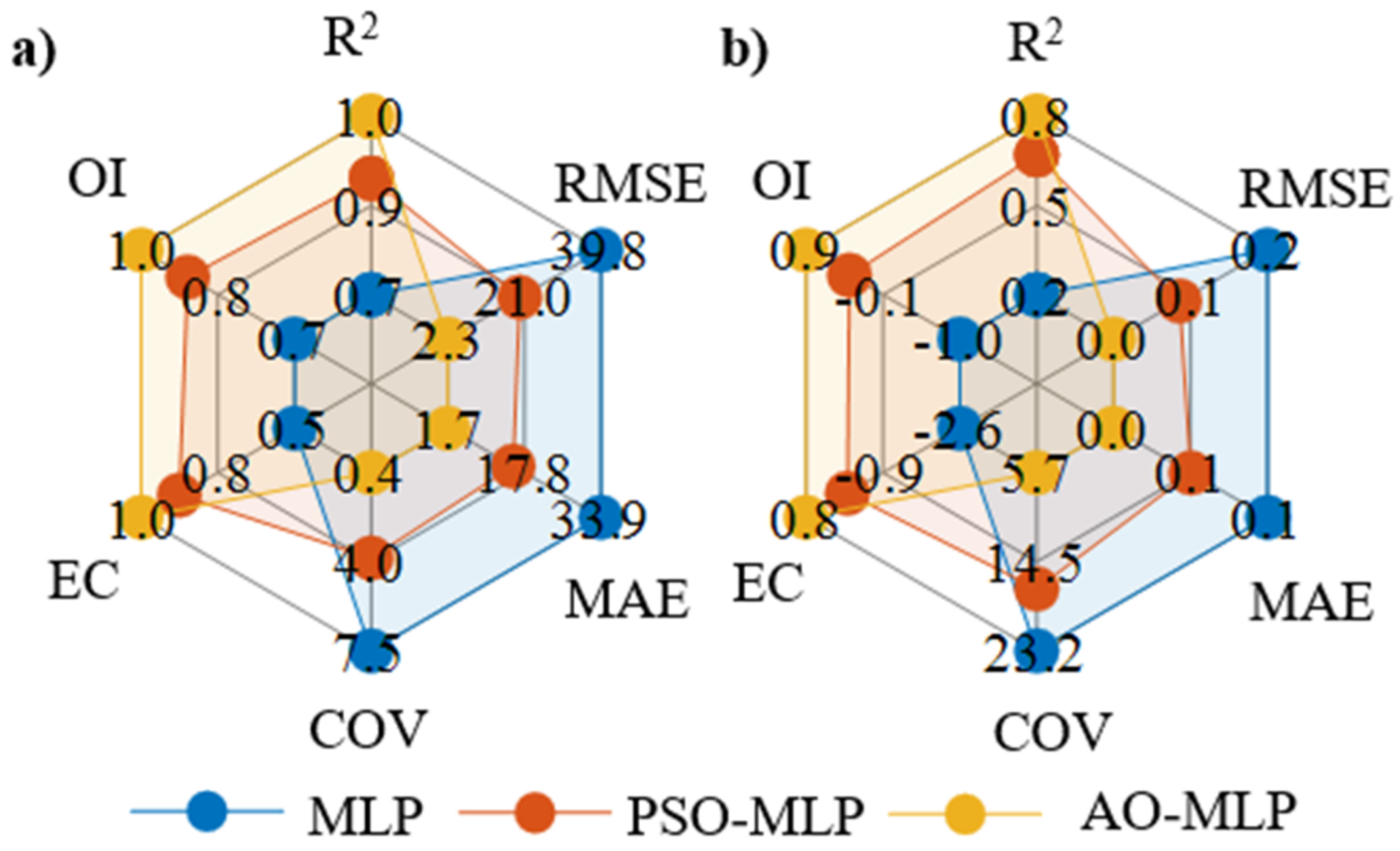

4. Results and Discussions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ramanaviciene, A.; Plikusiene, I. Polymers in Sensor and Biosensor Design. Polymers 2021, 13, 917. [Google Scholar] [CrossRef] [PubMed]

- Abu-Okail, M.; Alsaleh, N.A.; Farouk, W.; Elsheikh, A.; Abu-Oqail, A.; Abdelraouf, Y.A.; Ghafaar, M.A. Effect of dispersion of alumina nanoparticles and graphene nanoplatelets on microstructural and mechanical characteristics of hybrid carbon/glass fibers reinforced polymer composite. J. Mater. Res. Technol. 2021, 14, 2624–2637. [Google Scholar] [CrossRef]

- Xu, Y.; Niu, Q.; Zhang, L.; Yuan, C.; Ma, Y.; Hua, W.; Zeng, W.; Min, Y.; Huang, J.; Xia, R. Highly Efficient Perovskite Solar Cell Based on PVK Hole Transport Layer. Polymers 2022, 14, 2249. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Bellisario, D.; Quadrini, F.; Jestin, S.; Ravanelli, F.; Castello, M.; Li, X.; Dong, H. Nanoindentation of Multifunctional Smart Composites. Polymers 2022, 14, 2945. [Google Scholar] [CrossRef] [PubMed]

- Elsheikh, A. Bistable Morphing Composites for Energy-Harvesting Applications. Polymers 2022, 14, 1893. [Google Scholar] [CrossRef]

- Pereira, M.; Amaro, A.; Reis, P.; Loureiro, A. Effect of Friction Stir Welding Techniques and Parameters on Polymers Joint Efficiency—A Critical Review. Polymers 2021, 13, 2056. [Google Scholar] [CrossRef]

- Iftikhar, S.; Mourad, A.-H.; Sheikh-Ahmad, J.; Almaskari, F.; Vincent, S. A Comprehensive Review on Optimal Welding Conditions for Friction Stir Welding of Thermoplastic Polymers and Their Composites. Polymers 2021, 13, 1208. [Google Scholar] [CrossRef]

- Lai, H.; Fan, D.; Liu, K. The Effect of Welding Defects on the Long-Term Performance of HDPE Pipes. Polymers 2022, 14, 3936. [Google Scholar] [CrossRef]

- Amanat, N.; James, N.L.; McKenzie, D.R. Welding methods for joining thermoplastic polymers for the hermetic enclosure of medical devices. Med. Eng. Phys. 2010, 32, 690–699. [Google Scholar] [CrossRef]

- Zhao, P.; Tian, L.; Cui, X.; Xiong, X.; Wang, D.; Li, G. Hot gas implant welding of polypropylene via a three-dimensional porous copper implant. Compos. Commun. 2021, 25, 100761. [Google Scholar] [CrossRef]

- Bialaschik, M.; Schöppner, V.; Albrecht, M.; Gehde, M. Influence of material degradation on weld seam quality in hot gas butt welding of polyamides. Weld. World 2021, 65, 1161–1169. [Google Scholar] [CrossRef]

- Omer, M.A.E.; Rashad, M.; Elsheikh, A.H.; Showaib, E.A. A review on friction stir welding of thermoplastic materials: Recent advances and progress. Weld. World 2022, 66, 1–25. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Xu, J.-Y.; Lee, C.-H. Weld Strength of Friction Welding of Dissimilar Polymer Rods Fabricated by Fused Deposition Modeling. Polymers 2022, 14, 2582. [Google Scholar] [CrossRef]

- Khalil, C.; Marya, S.; Racineux, G. Magnetic Pulse Welding and Spot Welding with Improved Coil Efficiency—Application for Dissimilar Welding of Automotive Metal Alloys. J. Manuf. Mater. Process. 2020, 4, 69. [Google Scholar] [CrossRef]

- Showaib, E.A.; Elsheikh, A.H. Effect of surface preparation on the strength of vibration welded butt joint made from PBT composite. Polym. Test. 2020, 83, 106319. [Google Scholar] [CrossRef]

- Qiu, J.; Zhang, G.; Sakai, E.; Liu, W.; Zang, L. Thermal Welding by the Third Phase Between Polymers: A Review for Ultrasonic Weld Technology Developments. Polymers 2020, 12, 759. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Tsai, Q.-Z.; Li, D.-Y.; Lin, Y.-X.; Chen, W.-X. Optimization of Ultrasonic Welding Process Parameters to Enhance Weld Strength of 3C Power Cases Using a Design of Experiments Approach. Polymers 2022, 14, 2388. [Google Scholar] [CrossRef]

- Dave, F.; Ali, M.; Sherlock, R.; Kandasami, A.; Tormey, D. Laser Transmission Welding of Semi-Crystalline Polymers and Their Composites: A Critical Review. Polymers 2021, 13, 675. [Google Scholar] [CrossRef]

- Fernandes, F.A.; Pereira, A.B.; Guimarães, B.; Almeida, T. Laser Welding of Transmitting High-Performance Engineering Thermoplastics. Polymers 2020, 12, 402. [Google Scholar] [CrossRef]

- Gonçalves, L.F.; Duarte, F.M.; Martins, C.I.; Paiva, M.C. Laser welding of thermoplastics: An overview on lasers, materials, processes and quality. Infrared Phys. Technol. 2021, 119, 103931. [Google Scholar] [CrossRef]

- Acherjee, B. Laser transmission welding of polymers—A review on welding parameters, quality attributes, process monitoring, and applications. J. Manuf. Process. 2021, 64, 421–443. [Google Scholar] [CrossRef]

- Acherjee, B.; Kuar, A.S.; Mitra, S.; Misra, D. Laser transmission welding of polycarbonates: Experiments, modeling, and sensitivity analysis. Int. J. Adv. Manuf. Technol. 2014, 78, 853–861. [Google Scholar] [CrossRef]

- Acherjee, B. Laser transmission welding of polymers—A review on process fundamentals, material attributes, weldability, and welding techniques. J. Manuf. Process. 2020, 60, 227–246. [Google Scholar] [CrossRef]

- Nguyen, N.-P.; Behrens, S.; Brosda, M.; Olowinsky, A.; Gillner, A. Laser transmission welding of absorber-free semi-crystalline polypropylene by using a quasi-simultaneous irradiation strategy. Weld. World 2020, 64, 1227–1235. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, H.; Wu, C.; Han, F.; Yan, H. A cleaner production method for laser transmission welding of two transparent PMMA parts using multi-core copper wire. J. Mater. Res. Technol. 2022, 16, 1–12. [Google Scholar] [CrossRef]

- Wang, C.; Yu, X.; Wang, C.; Liu, Y.; Xia, Z. Laser transmission welding of Polyarylsulfone using zinc particles absorber. Infrared Phys. Technol. 2021, 118, 103892. [Google Scholar] [CrossRef]

- Jankus, S.M.; Bendikiene, R. Effect of the meltdown on thermoplastic joint produced by quasi-simultaneous laser transmission welding. CIRP J. Manuf. Sci. Technol. 2022, 39, 104–114. [Google Scholar] [CrossRef]

- Yu, X.; Long, Q.; Chen, Y.; Liu, Y.; Yang, C.; Jia, Q.; Wang, C. Laser transmission welding of dissimilar transparent thermoplastics using different metal particle absorbents. Opt. Laser Technol. 2022, 150, 108005. [Google Scholar] [CrossRef]

- Acherjee, B. Laser transmission welding of dissimilar plastics: 3-D FE modeling and experimental validation. Weld. World 2021, 65, 1429–1440. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Elaziz, M.A.; Das, S.R.; Muthuramalingam, T.; Lu, S. A new optimized predictive model based on political optimizer for eco-friendly MQL-turning of AISI 4340 alloy with nano-lubricants. J. Manuf. Process. 2021, 67, 562–578. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Panchal, H.; Ahmadein, M.; Mosleh, A.O.; Sadasivuni, K.K.; Alsaleh, N.A. Productivity forecasting of solar distiller integrated with evacuated tubes and external condenser using artificial intelligence model and moth-flame optimizer. Case Stud. Therm. Eng. 2021, 28, 101671. [Google Scholar] [CrossRef]

- Zayed, M.E.; Zhao, J.; Li, W.; Elsheikh, A.H.; Elaziz, M.A.; Yousri, D.; Zhong, S.; Mingxi, Z. Predicting the performance of solar dish Stirling power plant using a hybrid random vector functional link/chimp optimization model. Sol. Energy 2021, 222, 1–17. [Google Scholar] [CrossRef]

- Khoshaim, A.B.; Moustafa, E.B.; Bafakeeh, O.T.; Elsheikh, A.H. An Optimized Multilayer Perceptrons Model Using Grey Wolf Optimizer to Predict Mechanical and Microstructural Properties of Friction Stir Processed Aluminum Alloy Reinforced by Nanoparticles. Coatings 2021, 11, 1476. [Google Scholar] [CrossRef]

- Elmaadawy, K.; Elaziz, M.A.; Elsheikh, A.H.; Moawad, A.; Liu, B.; Lu, S. Utilization of random vector functional link integrated with manta ray foraging optimization for effluent prediction of wastewater treatment plant. J. Environ. Manag. 2021, 298, 113520. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Sharshir, S.W.; Elaziz, M.A.; Kabeel, A.; Guilan, W.; Haiou, Z. Modeling of solar energy systems using artificial neural network: A comprehensive review. Sol. Energy 2019, 180, 622–639. [Google Scholar] [CrossRef]

- El-Said, E.M.; Elaziz, M.A.; Elsheikh, A.H. Machine learning algorithms for improving the prediction of air injection effect on the thermohydraulic performance of shell and tube heat exchanger. Appl. Therm. Eng. 2021, 185, 116471. [Google Scholar] [CrossRef]

- AbuShanab, W.S.; Elaziz, M.A.; Ghandourah, E.I.; Moustafa, E.B.; Elsheikh, A.H. A new fine-tuned random vector functional link model using Hunger games search optimizer for modeling friction stir welding process of polymeric materials. J. Mater. Res. Technol. 2021, 14, 1482–1493. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Elaziz, M.A.; Vendan, A. Modeling ultrasonic welding of polymers using an optimized artificial intelligence model using a gradient-based optimizer. Weld. World 2022, 66, 27–44. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Shehabeldeen, T.A.; Zhou, J.; Showaib, E.; Elaziz, M.A. Prediction of laser cutting parameters for polymethylmethacrylate sheets using random vector functional link network integrated with equilibrium optimizer. J. Intell. Manuf. 2020, 32, 1377–1388. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, Y.; Zheng, J.; Huang, J.; Tang, X. Adaptive filling modeling of butt joints using genetic algorithm and neural network for laser welding with filler wire. J. Manuf. Process. 2017, 30, 553–561. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Buvanashekaran, G.; Sankaranarayanasamy, K. Modeling of laser beam welding of stainless steel sheet butt joint using neural networks. CIRP J. Manuf. Sci. Technol. 2010, 3, 80–84. [Google Scholar] [CrossRef]

- Bagchi, A.; Saravanan, S.; Kumar, G.S.; Murugan, G.; Raghukandan, K. Numerical simulation and optimization in pulsed Nd: YAG laser welding of Hastelloy C-276 through Taguchi method and artificial neural network. Optik 2017, 146, 80–89. [Google Scholar] [CrossRef]

- Banerjee, N.; Biswas, A.; Kumar, M.; Sen, A.; Maity, S. Modeling of laser welding of stainless steel using artificial neural networks. Mater. Today Proc. 2022, 66, 1784–1788. [Google Scholar] [CrossRef]

- Mathivanan, K.; Plapper, P. Artificial neural network to predict the weld status in laser welding of copper to aluminum. Procedia CIRP 2021, 103, 61–66. [Google Scholar] [CrossRef]

- Lei, Z.; Shen, J.; Wang, Q.; Chen, Y. Real-time weld geometry prediction based on multi-information using neural network optimized by PCA and GA during thin-plate laser welding. J. Manuf. Process. 2019, 43, 207–217. [Google Scholar] [CrossRef]

- Yusof, M.; Ishak, M.; Ghazali, M. Weld depth estimation during pulse mode laser welding process by the analysis of the acquired sound using feature extraction analysis and artificial neural network. J. Manuf. Process. 2021, 63, 163–178. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, B.; Yao, Y.; Tan, C.; Feng, J. A spectroscopic method based on support vector machine and artificial neural network for fiber laser welding defects detection and classification. NDT E Int. 2019, 108, 102176. [Google Scholar] [CrossRef]

- Moustafa, E.B.; Hammad, A.H.; Elsheikh, A.H. A new optimized artificial neural network model to predict thermal efficiency and water yield of tubular solar still. Case Stud. Therm. Eng. 2022, 30, 101750. [Google Scholar] [CrossRef]

- Pavithra, S.; Veeramani, T.; Subha, S.S.; Kumar, P.S.; Shanmugan, S.; Elsheikh, A.H.; Essa, F. Revealing prediction of perched cum off-centered wick solar still performance using network based on optimizer algorithm. Process Saf. Environ. Prot. 2022, 161, 188–200. [Google Scholar] [CrossRef]

- Elaziz, M.A.; Senthilraja, S.; Zayed, M.E.; Elsheikh, A.H.; Mostafa, R.R.; Lu, S. A new random vector functional link integrated with mayfly optimization algorithm for performance prediction of solar photovoltaic thermal collector combined with electrolytic hydrogen production system. Appl. Therm. Eng. 2021, 193, 117055. [Google Scholar] [CrossRef]

- Najjar, I.; Sadoun, A.; Elaziz, M.A.; Abdallah, A.; Fathy, A.; Elsheikh, A.H. Predicting kerf quality characteristics in laser cutting of basalt fibers reinforced polymer composites using neural network and chimp optimization. Alex. Eng. J. 2022, 61, 11005–11018. [Google Scholar] [CrossRef]

- Elaziz, M.A.; El-Said, E.M.; Elsheikh, A.H.; Abdelaziz, G.B. Performance prediction of solar still with a high-frequency ultrasound waves atomizer using random vector functional link/heap-based optimizer. Adv. Eng. Softw. 2022, 170, 103142. [Google Scholar] [CrossRef]

- Elaziz, M.A.; Ghoneimi, A.; Elsheikh, A.H.; Abualigah, L.; Bakry, A.; Nabih, M. Predicting Shale Volume from Seismic Traces Using Modified Random Vector Functional Link Based on Transient Search Optimization Model: A Case Study from Netherlands North Sea. Nonrenewable Resour. 2022, 31, 1775–1791. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Muthuramalingam, T.; Shanmugan, S.; Ibrahim, A.M.M.; Ramesh, B.; Khoshaim, A.B.; Moustafa, E.B.; Bedairi, B.; Panchal, H.; Sathyamurthy, R. Fine-tuned artificial intelligence model using pigeon optimizer for prediction of residual stresses during turning of Inconel 718. J. Mater. Res. Technol. 2021, 15, 3622–3634. [Google Scholar] [CrossRef]

- Babikir, H.A.; Elaziz, M.A.; Elsheikh, A.H.; Showaib, E.A.; Elhadary, M.; Wu, D.; Liu, Y. Noise prediction of axial piston pump based on different valve materials using a modified artificial neural network model. Alex. Eng. J. 2019, 58, 1077–1087. [Google Scholar] [CrossRef]

- Alsaiari, A.O.; Moustafa, E.B.; Alhumade, H.; Abulkhair, H.; Elsheikh, A. A coupled artificial neural network with artificial rabbits optimizer for predicting water productivity of different designs of solar stills. Adv. Eng. Softw. 2023, 175, 103315. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Elaziz, M.A.; Ramesh, B.; Egiza, M.; Al-Qaness, M.A. Modeling of drilling process of GFRP composite using a hybrid random vector functional link network/parasitism-predation algorithm. J. Mater. Res. Technol. 2021, 14, 298–311. [Google Scholar] [CrossRef]

- Datta, S.; Das, A.K.; Raza, M.S.; Saha, P.; Pratihar, D.K. Study on laser beam butt-welding of NiTinol sheet and input-output modelling using neural networks trained by metaheuristic algorithms. Mater. Today Commun. 2022, 32, 104089. [Google Scholar] [CrossRef]

- Liu, B.; Jin, W.; Lu, A.; Liu, K.; Wang, C.; Mi, G. Optimal design for dual laser beam butt welding process parameter using artificial neural networks and genetic algorithm for SUS316L austenitic stainless steel. Opt. Laser Technol. 2020, 125, 106027. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, X.; Katayama, S. Weld appearance prediction with BP neural network improved by genetic algorithm during disk laser welding. J. Manuf. Syst. 2015, 34, 53–59. [Google Scholar] [CrossRef]

- Wu, C.; Wang, C.; Kim, J.-W. Welding sequence optimization to reduce welding distortion based on coupled artificial neural network and swarm intelligence algorithm. Eng. Appl. Artif. Intell. 2022, 114, 105142. [Google Scholar] [CrossRef]

- Kumar, D.; Sarkar, N.S.; Acherjee, B.; Kuar, A.S. Beam wobbling effects on laser transmission welding of dissimilar polymers: Experiments, modeling, and process optimization. Opt. Laser Technol. 2022, 146, 107603. [Google Scholar] [CrossRef]

- Hashim, F.A.; Hussain, K.; Houssein, E.H.; Mabrouk, M.S.; Al-Atabany, W. Archimedes optimization algorithm: A new metaheuristic algorithm for solving optimization problems. Appl. Intell. 2021, 51, 1531–1551. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Saba, A.I.; Panchal, H.; Shanmugan, S.; Alsaleh, N.A.; Ahmadein, M. Artificial Intelligence for Forecasting the Prevalence of COVID-19 Pandemic: An Overview. Healthcare 2021, 9, 1614. [Google Scholar] [CrossRef]

| Property | Thermal Conductivity at 25 °C (W/mK) | Specific Heat (J/(kg °C)) | Density (kg/m3) | Glass Transition Temperature (°C) | Linear Thermal Expansion (×10−5/k) | Poisson’s Ratio | Young’s Modulus (MPa) | Luminance Transmission |

|---|---|---|---|---|---|---|---|---|

| PC | 0.20 | 1100 | 1160 | 141 | 6.5 | 0.399 | 2400 | 89% |

| PMMA | 0.21 | 1270 | 1190 | 83 | 6.3 | 0.328 | 3300 | 92% |

| Laser Power (W) | Welding Speed (mm/s) | Pulse Frequency (kHz) | Wobble Frequency (kHz) | Wobble Width (mm) | Seam Width (mm) | Shear Strength (N) | |

|---|---|---|---|---|---|---|---|

| 1 | 7.89 | 2 | 25 | 1 | 0.4 | 0.479 | 471.24 |

| 2 | 8.35 | 2 | 25 | 1 | 0.4 | 0.619 | 487.23 |

| 3 | 7.89 | 2 | 35 | 1 | 0.4 | 0.403 | 474.38 |

| 4 | 8.35 | 2 | 35 | 1 | 0.4 | 0.589 | 488.87 |

| 5 | 7.89 | 4 | 25 | 1 | 0.4 | 0.443 | 446.08 |

| 6 | 8.35 | 4 | 25 | 1 | 0.4 | 0.507 | 462.18 |

| 7 | 7.89 | 4 | 35 | 1 | 0.4 | 0.359 | 461.72 |

| 8 | 8.35 | 4 | 35 | 1 | 0.4 | 0.515 | 476.22 |

| 9 | 7.89 | 2 | 25 | 1 | 0.8 | 0.543 | 475.44 |

| 10 | 8.35 | 2 | 25 | 1 | 0.8 | 0.643 | 487.43 |

| 11 | 7.89 | 2 | 35 | 1 | 0.8 | 0.546 | 465.08 |

| 12 | 8.35 | 2 | 35 | 1 | 0.8 | 0.71 | 483.57 |

| 13 | 7.89 | 4 | 25 | 1 | 0.8 | 0.519 | 429.78 |

| 14 | 8.35 | 4 | 25 | 1 | 0.8 | 0.602 | 439.77 |

| 15 | 7.89 | 4 | 35 | 1 | 0.8 | 0.509 | 431.92 |

| 16 | 8.35 | 4 | 35 | 1 | 0.8 | 0.654 | 445.41 |

| 17 | 7.89 | 2 | 25 | 5 | 0.4 | 0.634 | 543.24 |

| 18 | 8.35 | 2 | 25 | 5 | 0.4 | 0.681 | 562.98 |

| 19 | 7.89 | 2 | 35 | 5 | 0.4 | 0.586 | 552.13 |

| 20 | 8.35 | 2 | 35 | 5 | 0.4 | 0.668 | 572.37 |

| 21 | 7.89 | 4 | 25 | 5 | 0.4 | 0.529 | 495.33 |

| 22 | 8.35 | 4 | 25 | 5 | 0.4 | 0.495 | 513.08 |

| 23 | 7.89 | 4 | 35 | 5 | 0.4 | 0.453 | 522.72 |

| 24 | 8.35 | 4 | 35 | 5 | 0.4 | 0.508 | 539.97 |

| 25 | 7.89 | 2 | 25 | 5 | 0.8 | 0.577 | 479.69 |

| 26 | 8.35 | 2 | 25 | 5 | 0.8 | 0.548 | 500 |

| 27 | 7.89 | 2 | 35 | 5 | 0.8 | 0.587 | 477.03 |

| 28 | 8.35 | 2 | 35 | 5 | 0.8 | 0.682 | 497.32 |

| 29 | 7.89 | 4 | 25 | 5 | 0.8 | 0.493 | 402.28 |

| 30 | 8.35 | 4 | 25 | 5 | 0.8 | 0.422 | 419.03 |

| 31 | 7.89 | 4 | 35 | 5 | 0.8 | 0.526 | 417.17 |

| 32 | 8.35 | 4 | 35 | 5 | 0.8 | 0.553 | 434.41 |

| 33 | 7.89 | 3 | 30 | 3 | 0.6 | 0.531 | 497.65 |

| 34 | 8.35 | 3 | 30 | 3 | 0.6 | 0.642 | 517.77 |

| 35 | 8.12 | 3 | 25 | 3 | 0.6 | 0.618 | 616.82 |

| 36 | 8.12 | 3 | 35 | 3 | 0.6 | 0.587 | 646.59 |

| 37 | 8.12 | 2 | 30 | 3 | 0.6 | 0.613 | 607.47 |

| 38 | 8.12 | 4 | 30 | 3 | 0.6 | 0.487 | 566.94 |

| 39 | 8.12 | 3 | 30 | 3 | 0.4 | 0.452 | 541.29 |

| 40 | 8.12 | 3 | 30 | 3 | 0.8 | 0.475 | 498.12 |

| 41 | 8.12 | 3 | 30 | 1 | 0.6 | 0.682 | 507.71 |

| 42 | 8.12 | 3 | 30 | 5 | 0.6 | 0.739 | 524.71 |

| 43 | 8.12 | 3 | 30 | 3 | 0.6 | 0.591 | 582.43 |

| 44 | 8.12 | 3 | 30 | 3 | 0.6 | 0.602 | 577.43 |

| 45 | 8.12 | 3 | 30 | 3 | 0.6 | 0.579 | 580.12 |

| 46 | 8.12 | 3 | 30 | 3 | 0.6 | 0.574 | 574.43 |

| 47 | 8.12 | 3 | 30 | 3 | 0.6 | 0.613 | 579.23 |

| 48 | 8.12 | 3 | 30 | 3 | 0.6 | 0.598 | 582.58 |

| 49 | 8.12 | 3 | 30 | 3 | 0.6 | 0.585 | 578.57 |

| 50 | 8.12 | 3 | 30 | 3 | 0.6 | 0.583 | 572.41 |

| Statistical Criteria | Shear Strength, N | Seam Width, mm | ||||

|---|---|---|---|---|---|---|

| MLP | PSO-MLP | AO-MLP | MLP | PSO-MLP | AO-MLP | |

| Maximum | 122.709 | 59.834 | 8.464 | 0.416 | 0.142 | 0.099 |

| Minimum | 3.117 | 0.512 | 0.026 | 0.004 | 0.0003 | 0.0008 |

| Average | 33.925 | 15.462 | 1.729 | 0.127 | 0.075 | 0.024 |

| Standard deviation | 21.018 | 12.669 | 1.505 | 0.085 | 0.036 | 0.022 |

| R2 | RMSE | MAE | COV | EC | OI | ||

| Shear strength | MLP | 0.735 | 39.798 | 33.925 | 7.523 | 0.531 | 0.684 |

| PSO-MLP | 0.907 | 19.909 | 15.462 | 3.839 | 0.882 | 0.901 | |

| AO-MLP | 0.998 | 2.283 | 1.729 | 0.447 | 0.998 | 0.994 | |

| Seam Width | MLP | 0.187 | 0.153 | 0.127 | 23.198 | −2.602 | −1.002 |

| PSO-MLP | 0.705 | 0.084 | 0.075 | 17.117 | −0.084 | 0.347 | |

| AO-MLP | 0.847 | 0.0321 | 0.023 | 5.708 | 0.841 | 0.878 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moustafa, E.B.; Elsheikh, A. Predicting Characteristics of Dissimilar Laser Welded Polymeric Joints Using a Multi-Layer Perceptrons Model Coupled with Archimedes Optimizer. Polymers 2023, 15, 233. https://doi.org/10.3390/polym15010233

Moustafa EB, Elsheikh A. Predicting Characteristics of Dissimilar Laser Welded Polymeric Joints Using a Multi-Layer Perceptrons Model Coupled with Archimedes Optimizer. Polymers. 2023; 15(1):233. https://doi.org/10.3390/polym15010233

Chicago/Turabian StyleMoustafa, Essam B., and Ammar Elsheikh. 2023. "Predicting Characteristics of Dissimilar Laser Welded Polymeric Joints Using a Multi-Layer Perceptrons Model Coupled with Archimedes Optimizer" Polymers 15, no. 1: 233. https://doi.org/10.3390/polym15010233

APA StyleMoustafa, E. B., & Elsheikh, A. (2023). Predicting Characteristics of Dissimilar Laser Welded Polymeric Joints Using a Multi-Layer Perceptrons Model Coupled with Archimedes Optimizer. Polymers, 15(1), 233. https://doi.org/10.3390/polym15010233