Experimental Investigation of the High-Temperature Rheological and Aging Resistance Properties of Activated Crumb Rubber Powder/SBS Composite-Modified Asphalt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Raw Materials

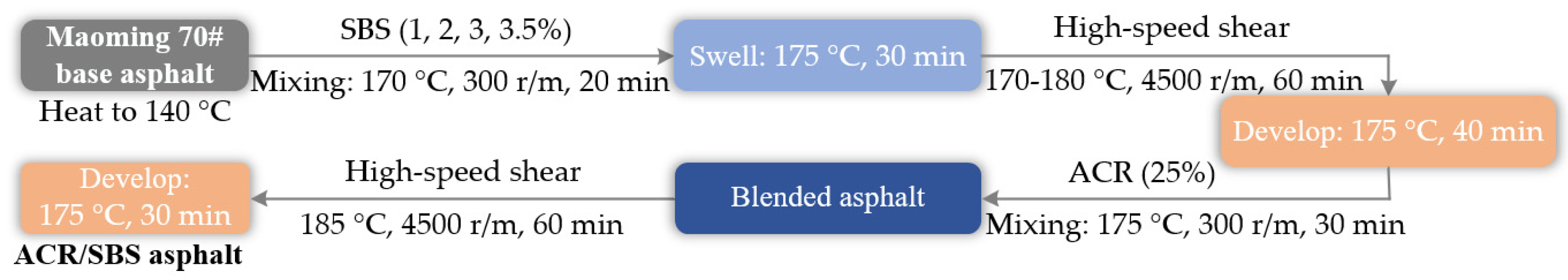

2.2. Preparation of ACR/SBS Composite-Modified Asphalt

- Place the base asphalt in an oven at 140 °C and heat it to the flowing state, and slowly add the weighed SBS (1%, 2%, 3%, and 3.5% of base asphalt by mass) with a mixing speed of 300 r/min. During the addition process, raise the temperature to 170 °C and maintain it for 20 min.

- Put the mixed asphalt in an oven at 175 °C and swell for 30 min.

- Place the swelled SBS asphalt into high-speed shear equipment, gradually increase the shear rate to about 4500 r/min, control the temperature at 170–180 °C, and then take it out after shearing for 1 h.

- Put the modified asphalt in an oven at 175 °C and develop for 40 min.

- Heat the developed SBS asphalt to the flowing state and slowly add the weighed ACR (25% of base asphalt by mass) with a mixing speed of 300 r/min. During the addition process, raise the temperature to 175 °C and maintain it for 30 min.

- Place the blended asphalt into high-speed shear equipment, gradually increase the shear rate to about 4500 r/min, control the temperature at 185 °C, and then take it out after shearing for 1 h.

- Put the prepared ACR/SBS asphalt into an oven at 175 °C for 30 min.

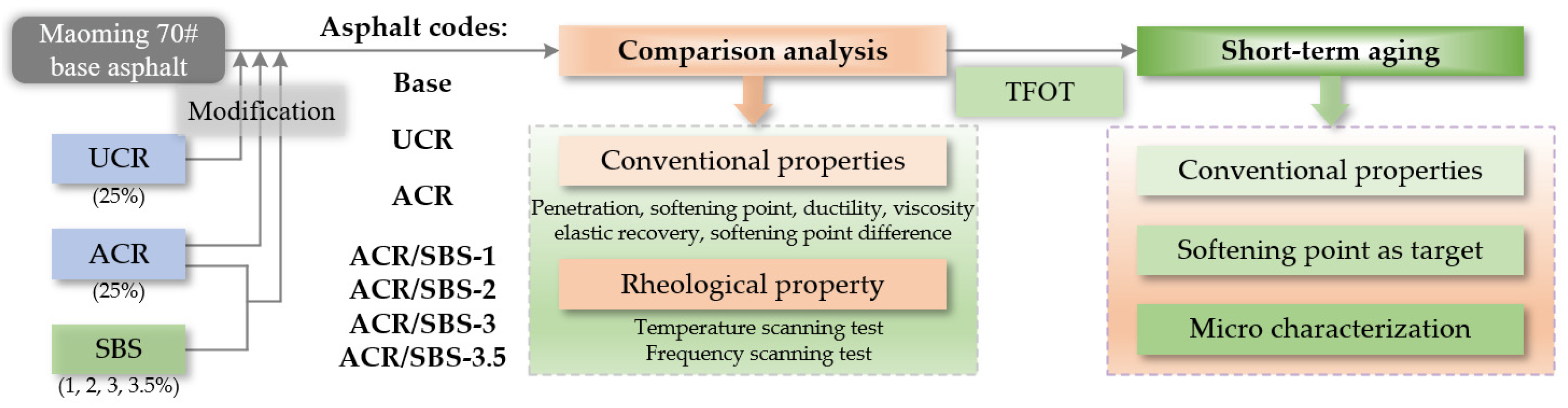

2.3. Experimental Scheme and Methods

2.3.1. Conventional Physical Properties Test

2.3.2. High-Temperature Rheological Test

2.3.3. Thin-Film Oven Test

3. Results and Discussion

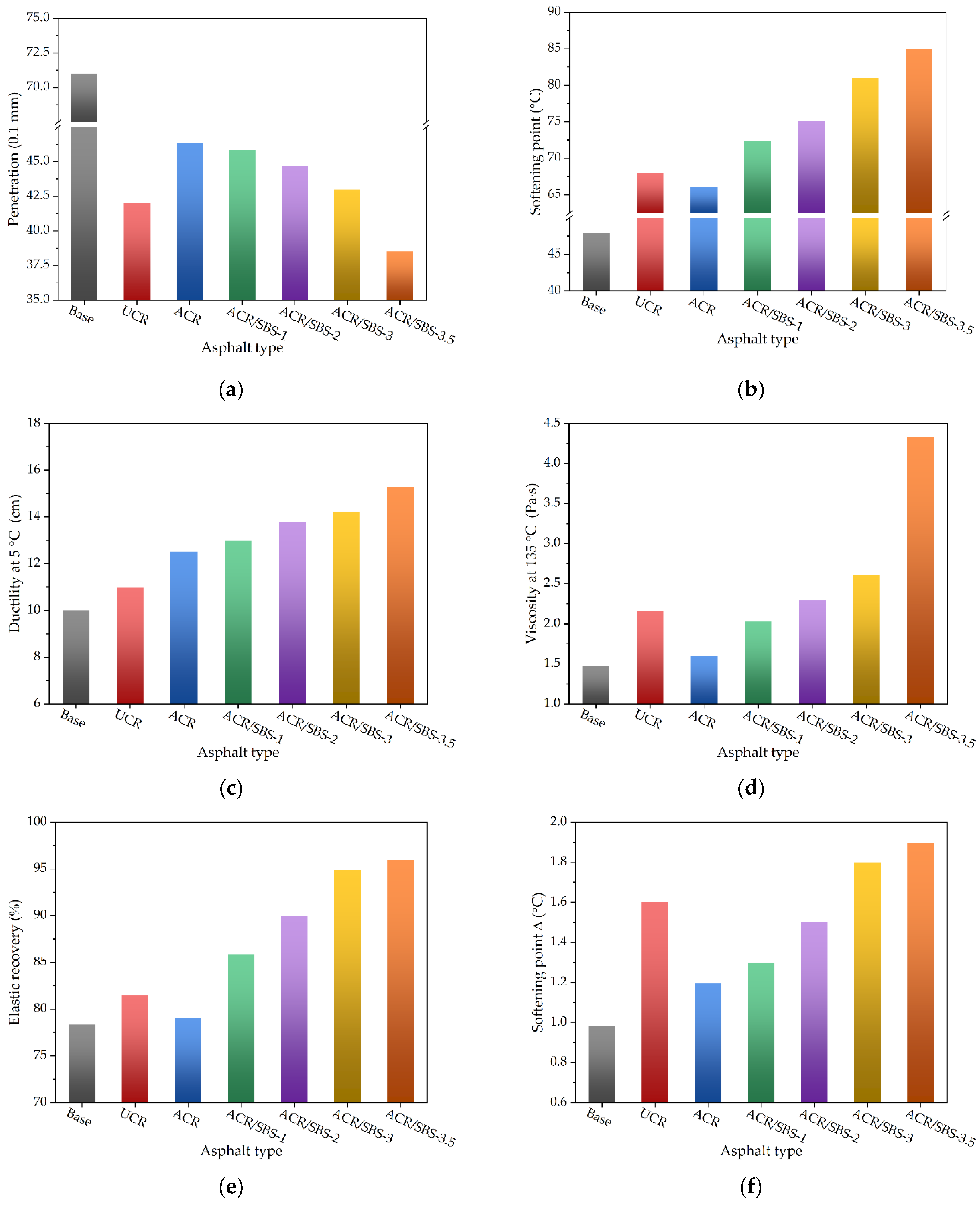

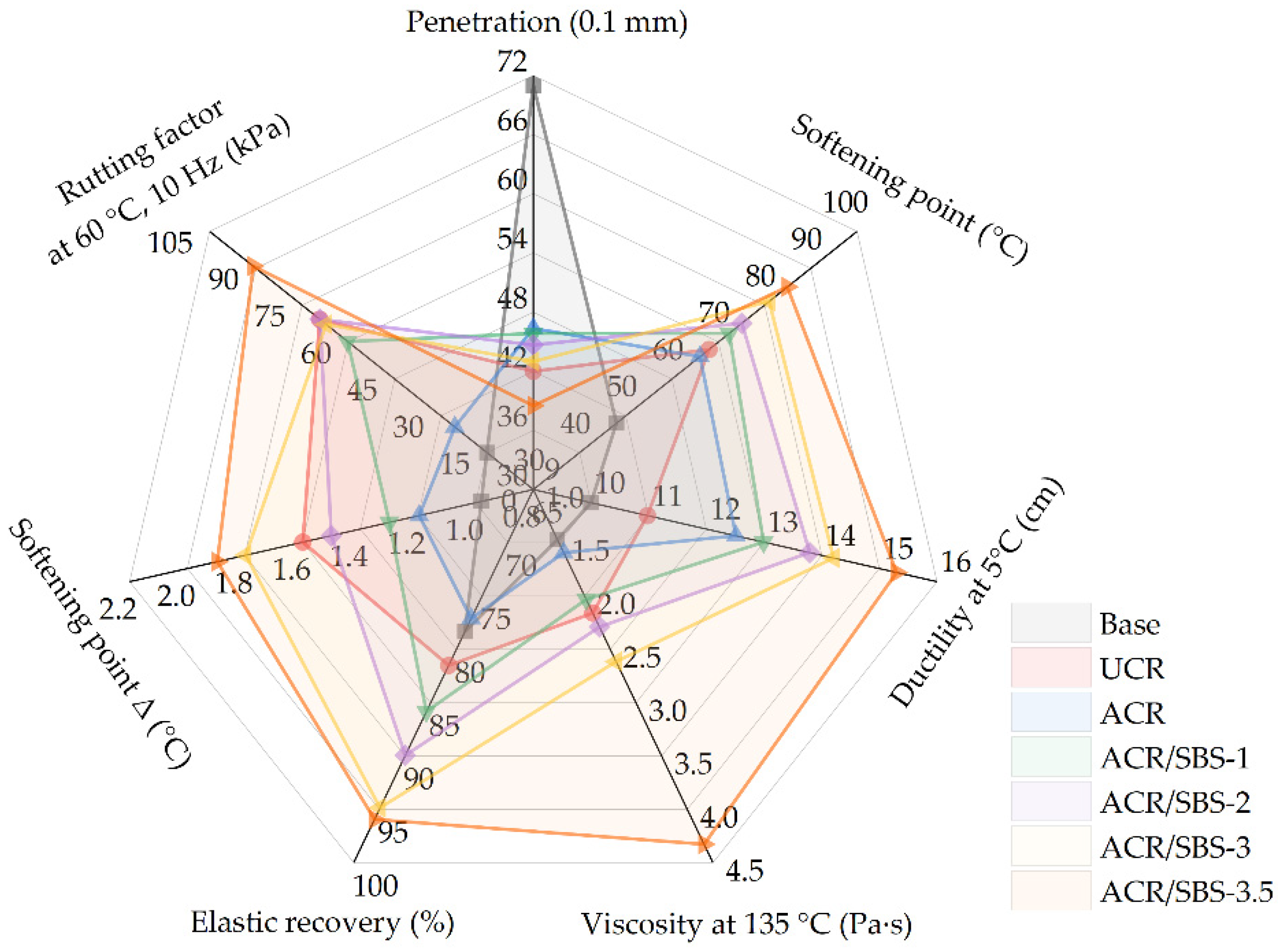

3.1. Effect of ACR/SBS on the Conventional Physical Properties of Asphalt

3.2. Effect of ACR/SBS on the High-Temperature Rheological Properties of Asphalt

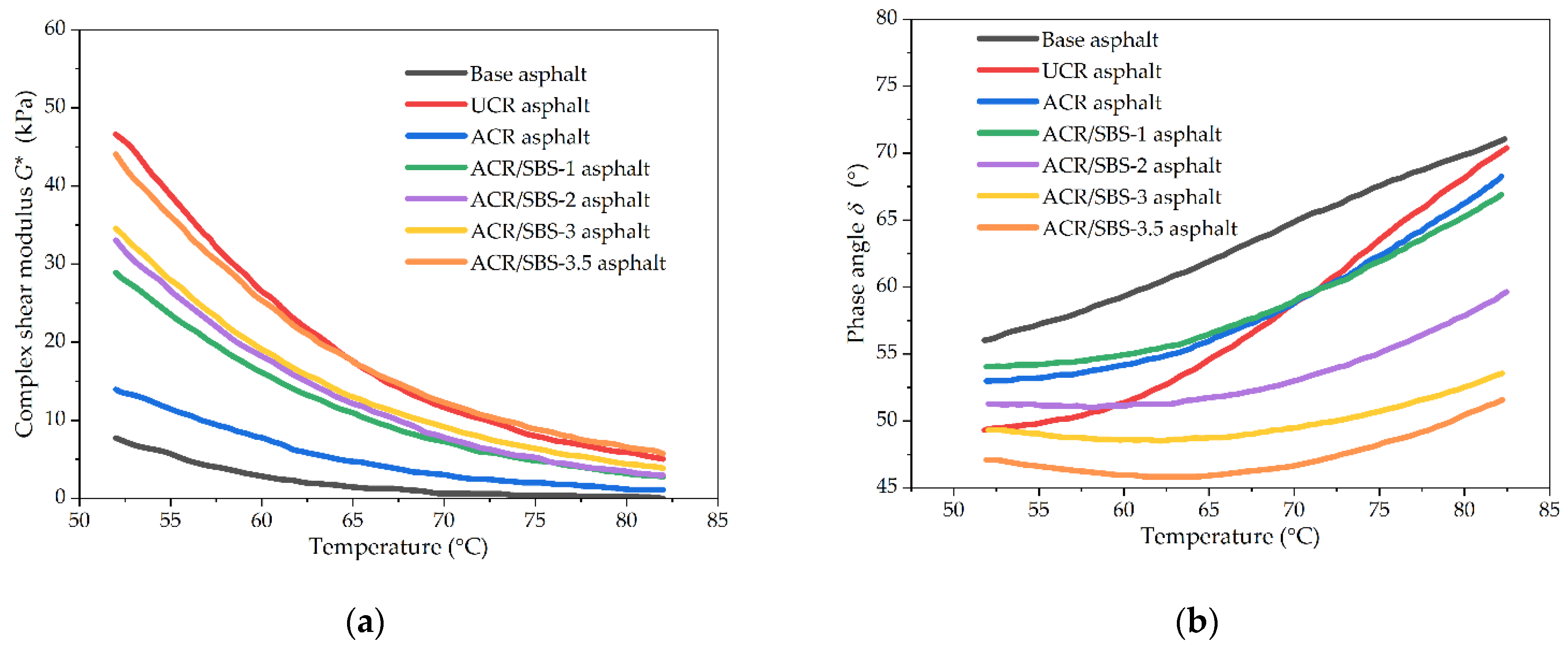

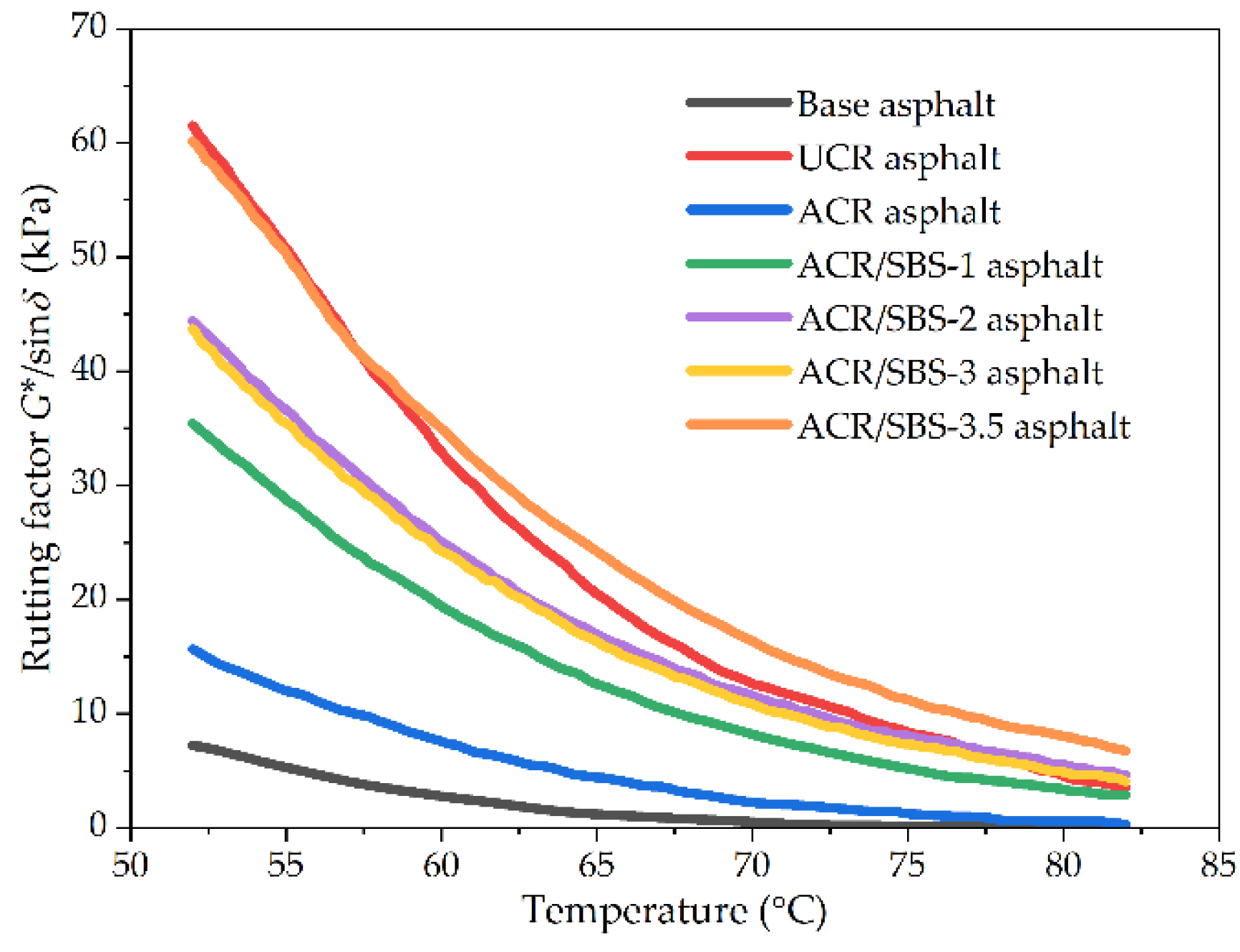

3.2.1. Temperature Scanning Test

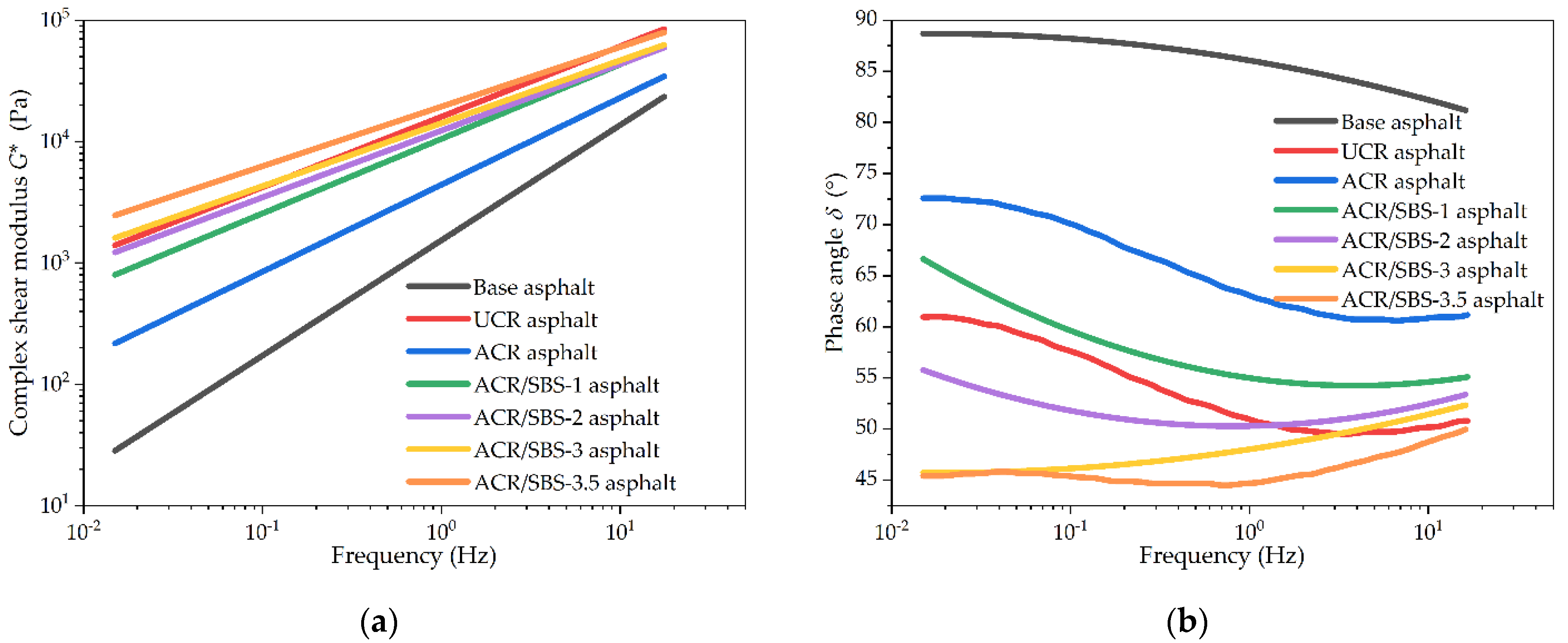

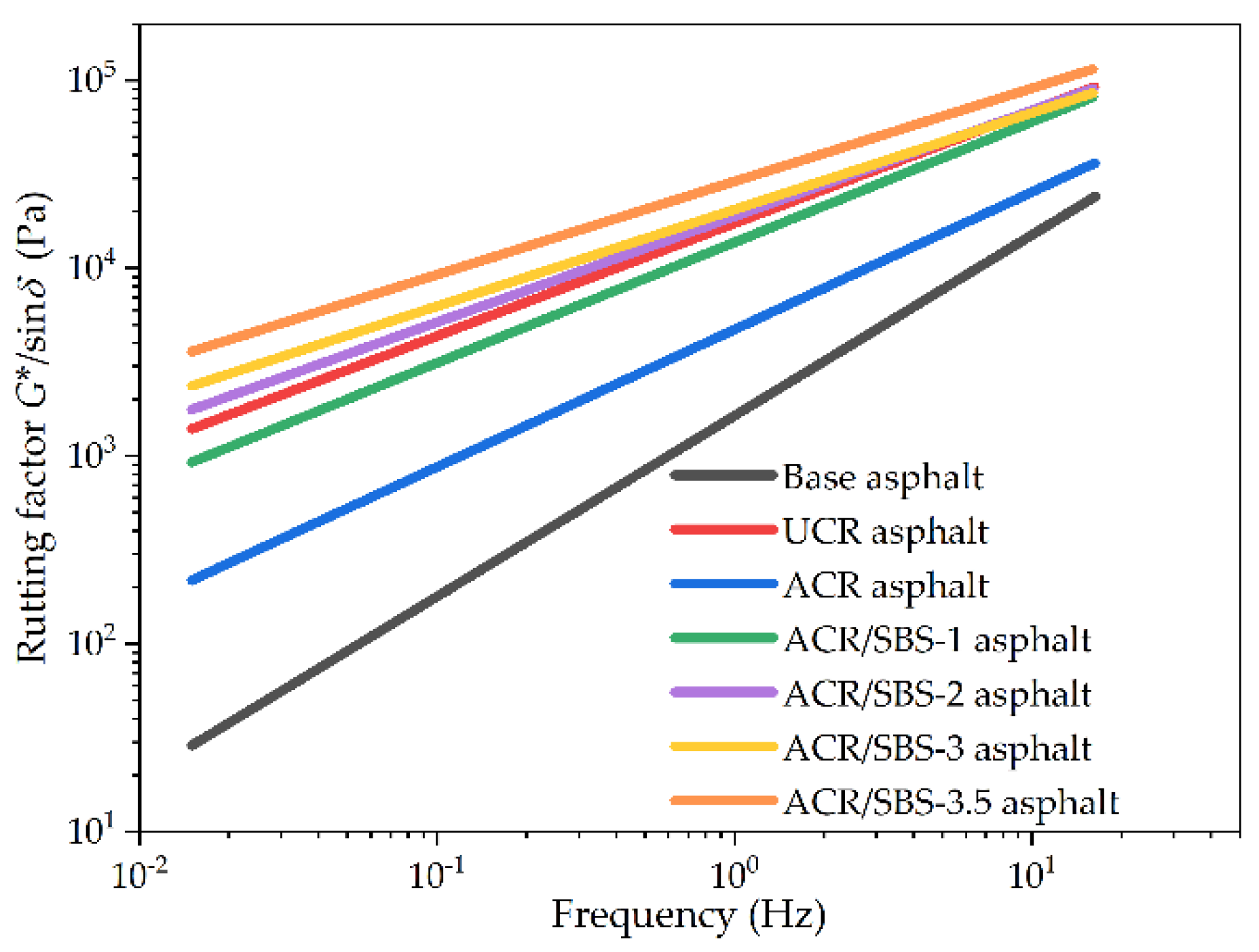

3.2.2. Frequency Scanning Test

3.3. Effect of ACR/SBS on the Aging Resistance of Asphalt

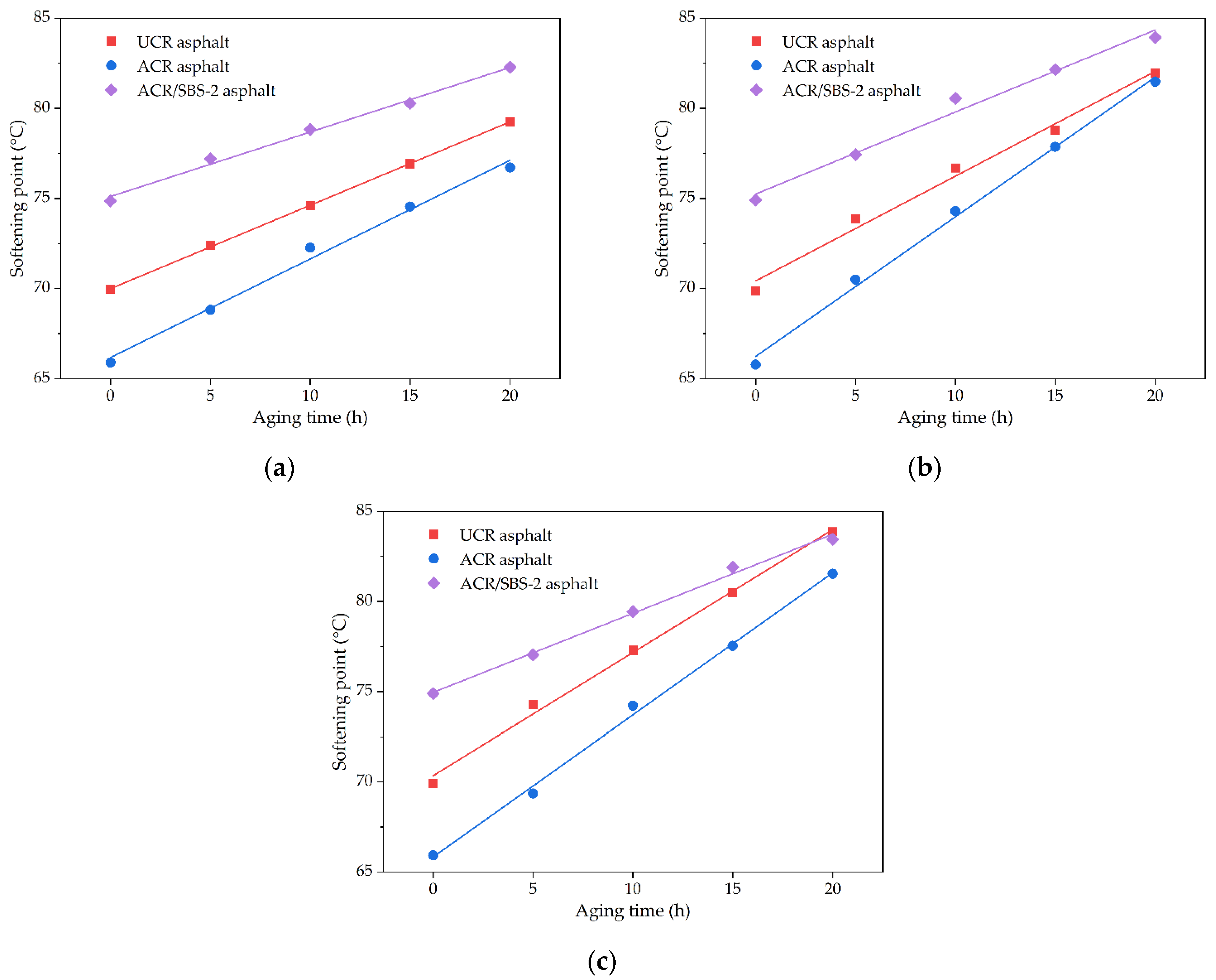

3.3.1. Conventional Physical Properties of Modified Asphalt under Short-Term Aging

3.3.2. Short-Term Aging Factors with Softening Point as Target Performance

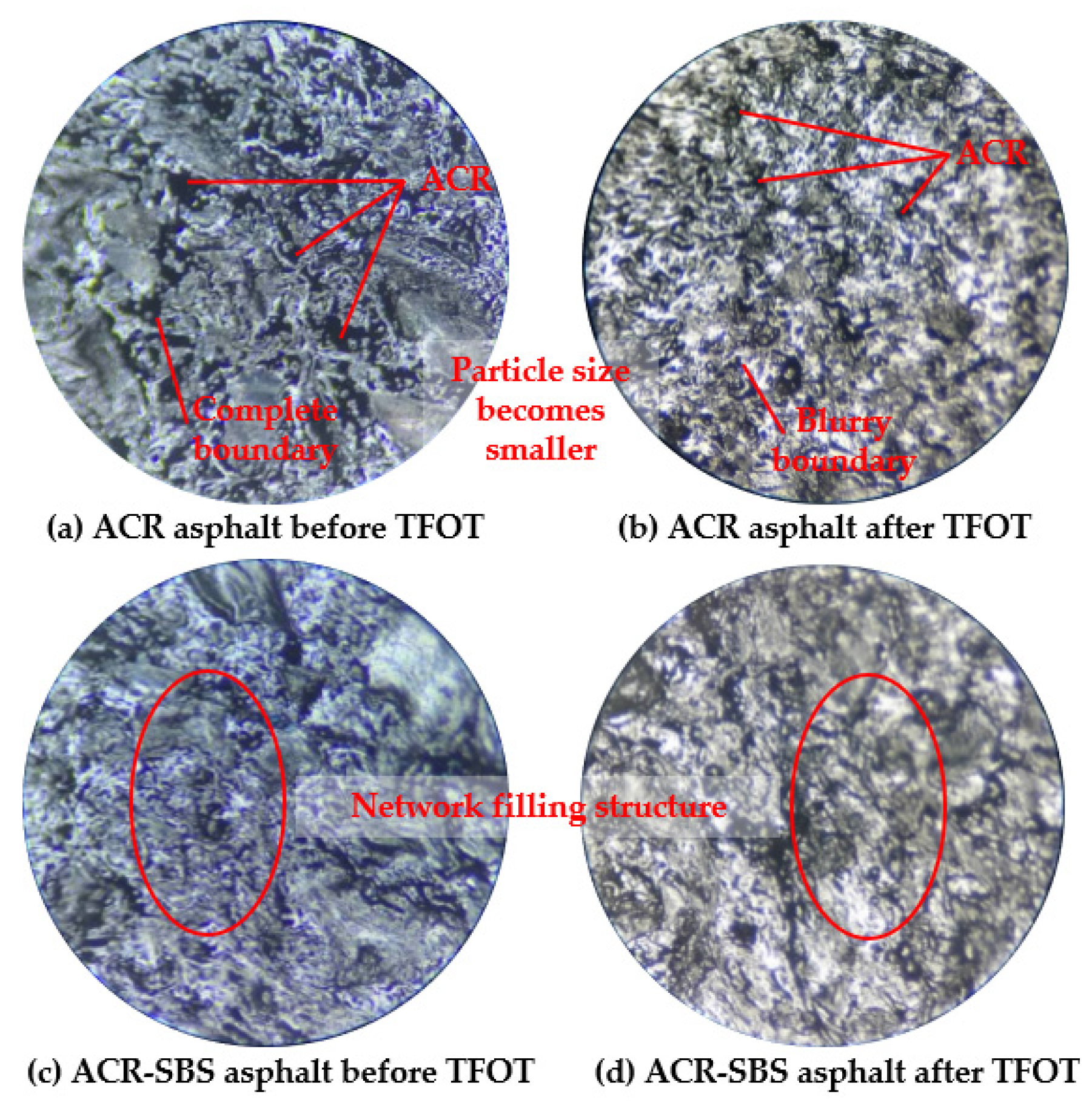

3.4. Micro-Characterization of ACR/SBS Composite-Modified Asphalt

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Picado-Santos, L.G.; Capitao, S.D.; Neves, J.M.C. Crumb rubber asphalt mixtures: A literature review. Constr. Build. Mater. 2020, 247, 118577. [Google Scholar] [CrossRef]

- Ma, T.; Wang, H.; He, L.; Zhao, Y.L.; Huang, X.M.; Chen, J. Property characterization of asphalt binders and mixtures modified by different crumb rubbers. J. Mater. Civ. Eng. 2017, 29, 04017036. [Google Scholar] [CrossRef]

- Saberi, K.F.; Fakhri, M.; Azami, A. Evaluation of warm mix asphalt mixtures containing reclaimed asphalt pavement and crumb rubber. J. Clean. Prod. 2017, 165, 1125–1132. [Google Scholar] [CrossRef]

- Riekstins, A.; Baumanis, J.; Barbars, J. Laboratory investigation of crumb rubber in dense graded asphalt by wet and dry processes. Constr. Build. Mater. 2021, 292, 123459. [Google Scholar] [CrossRef]

- Ameli, A.; Babagoli, R.; Asadi, S.; Norouzi, N. Investigation of the performance properties of asphalt binders and mixtures modified by crumb rubber and gilsonite. Constr. Build. Mater. 2021, 279, 122424. [Google Scholar] [CrossRef]

- Wang, Q.Z.; Wang, N.N.; Tseng, M.L.; Huang, Y.M.; Li, N.L. Waste tire recycling assessment: Road application potential and carbon emissions reduction analysis of crumb rubber modified asphalt in china. J. Clean. Prod. 2020, 249, 119411. [Google Scholar] [CrossRef]

- Gao, J.; Yang, J.G.; Yu, D.; Jiang, Y.; Ruan, K.G.; Tao, W.J.; Sun, C.; Luo, L.H. Reducing the variability of multi-source reclaimed asphalt pavement materials: A practice in china. Constr. Build. Mater. 2021, 278, 122389. [Google Scholar] [CrossRef]

- Gao, J.; Yao, Y.; Song, L.; Xu, J.; Yang, J. Determining the maximum permissible content of recycled asphalt pavement stockpile in plant hot-mix recycled asphalt mixtures considering homogeneity: A case study in china. Case Stud. Constr. Mater. 2022, 16, e00961. [Google Scholar] [CrossRef]

- Xu, M.Z.; Liu, J.J.; Li, W.Z.; Duan, W.F. Novel method to prepare activated crumb rubber used for synthesis of activated crumb rubber modified asphalt. J. Mater. Civ. Eng. 2015, 27, 04014173. [Google Scholar] [CrossRef]

- Yu, R.B.; Gong, Z.H.; Guo, W.H.; Zhang, H.B.; Liu, C.L. A novel grafting-modified waste rubber powder as filler in natural rubber vulcanizates. J. Appl. Polym. Sci. 2016, 133, 42993. [Google Scholar] [CrossRef]

- Zhang, H.G.; Zhang, Y.P.; Chen, J.; Liu, W.C.; Wang, W.S. Effect of desulfurization process variables on the properties of crumb rubber modified asphalt. Polymers 2022, 14, 1365. [Google Scholar] [CrossRef] [PubMed]

- Kedarisetty, S.; Biligiri, K.P.; Sousa, J.B. Advanced rheological characterization of reacted and activated rubber (rar) modified asphalt binders. Constr. Build. Mater. 2016, 122, 12–22. [Google Scholar] [CrossRef]

- Lv, S.T.; Ma, W.B.; Zhao, Z.G.; Guo, S.C. Improvement on the high-temperature stability and anti-aging performance of the rubberized asphalt binder with the lucobit additive. Constr. Build. Mater. 2021, 299, 124304. [Google Scholar] [CrossRef]

- Juganaru, T.; Bombos, M.; Vasilievici, G.; Bombos, D. Devulcanized rubber for bitumen modification. Mater. Plast. 2015, 52, 336–339. [Google Scholar]

- Shatanawi, K.M.; Biro, S.; Naser, M.; Amirkhanian, S.N. Improving the rheological properties of crumb rubber modified binder using hydrogen peroxide. Road Mater. Pavement Des. 2013, 14, 723–734. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, J.Z.; Yu, B.; Zhang, J.P.; Pei, J.Z. Evaluation and optimization of asphalt binder and mixture modified with high activated crumb rubber content. Constr. Build. Mater. 2022, 314, 125676. [Google Scholar] [CrossRef]

- Chen, Z.X.; Pei, J.Z.; Wang, T.; Amirkhanian, S. High temperature rheological characteristics of activated crumb rubber modified asphalts. Constr. Build. Mater. 2019, 194, 122–131. [Google Scholar] [CrossRef]

- Rasool, R.T.; Song, P.; Wang, S.F. Thermal analysis on the interactions among asphalt modified with sbs and different degraded tire rubber. Constr. Build. Mater. 2018, 182, 134–143. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C.B. The research for structural characteristics and modification mechanism of crumb rubber compound modified asphalts. Constr. Build. Mater. 2015, 76, 330–342. [Google Scholar] [CrossRef]

- Wang, W.S.; Tan, G.J.; Liang, C.Y.; Wang, Y.; Cheng, Y.C. Study on viscoelastic properties of asphalt mixtures incorporating sbs polymer and basalt fiber under freeze-thaw cycles. Polymers 2020, 12, 1804. [Google Scholar] [CrossRef]

- Song, L.; Zhang, G.Q.; Xie, H.F.; Gao, J. Laboratory study on cr/sbs modified asphalt: Preparation and performance characterization. J. Renew. Mater. 2022, 10, 1659–1674. [Google Scholar] [CrossRef]

- Tang, N.P.; Lv, Q.; Huang, W.D.; Lin, P.; Yan, C.Q. Chemical and rheological evaluation of aging characteristics of terminal blend rubberized asphalt binder. Constr. Build. Mater. 2019, 205, 87–96. [Google Scholar] [CrossRef]

- Yan, C.; Lv, Q.; Zhang, A.A.; Ai, C.; Huang, W.; Ren, D. Modeling the modulus of bitumen/sbs composite at different temperatures based on kinetic models. Compos. Sci. Technol. 2022, 218, 109146. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, H.X.; Zhang, H.G.; Kuang, D.L.; Wu, J.Y.; Zhang, X.L. A study on physical and rheological properties of rubberized bitumen modified by different methods. Materials 2019, 12, 3538. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.; Chen, H.X.; Zhang, H.G.; Wu, Y.C.; Kuang, D.L.; Guo, F.J. Laboratory investigation of aging resistance for rubberized bitumen modified by using microwave activation crumb rubber and different modifiers. Materials 2020, 13, 4230. [Google Scholar] [CrossRef]

- Wang, W.S.; Cheng, Y.C.; Chen, H.P.; Tan, G.J.; Lv, Z.H.; Bai, Y.S. Study on the performances of waste crumb rubber modified asphalt mixture with eco-friendly diatomite and basalt fiber. Sustainability 2019, 11, 5282. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.S.; Cheng, Y.C.; Tan, G.J.; Liu, Z.Y.; Shi, C.L. Laboratory investigation on high- and low-temperature performances of asphalt mastics modified by waste oil shale ash. J. Mater. Cycles Waste 2018, 20, 1710–1723. [Google Scholar] [CrossRef]

- Zhang, L.M.; Gao, X.K.; Wang, W.S.; Wang, H.; Zheng, K.K. Laboratory evaluation of rheological properties of asphalt binder modified by nano-tio2/caco3. Adv. Mater. Sci. Eng. 2021, 2021, 5522025. [Google Scholar] [CrossRef]

- Chen, T.; Ma, T.; Huang, X.M.; Guan, Y.S.; Zhang, Z.X.; Tang, F.L. The performance of hot-recycling asphalt binder containing crumb rubber modified asphalt based on physiochemical and rheological measurements. Constr. Build. Mater. 2019, 226, 83–93. [Google Scholar] [CrossRef]

- Zhang, J.W.; Chen, M.Z.; Wu, S.P.; Zhou, X.X.; Zhao, G.Y.; Zhao, Y.C.; Cheng, M. Evaluation of vocs inhibited effects and rheological properties of asphalt with high-content waste rubber powder. Constr. Build. Mater. 2021, 300, 124320. [Google Scholar] [CrossRef]

| Structure Type | Block Ratio | Tensile Rate (%) | Tensile Strength (MPa) | Melt Index (g/10 min) | Density (g/cm3) |

|---|---|---|---|---|---|

| Linear | 30/70 | 800 | 25 | 0.6 | 0.93 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Wang, L.; Wang, W.; Shangguan, X. Experimental Investigation of the High-Temperature Rheological and Aging Resistance Properties of Activated Crumb Rubber Powder/SBS Composite-Modified Asphalt. Polymers 2022, 14, 1905. https://doi.org/10.3390/polym14091905

Zhao Z, Wang L, Wang W, Shangguan X. Experimental Investigation of the High-Temperature Rheological and Aging Resistance Properties of Activated Crumb Rubber Powder/SBS Composite-Modified Asphalt. Polymers. 2022; 14(9):1905. https://doi.org/10.3390/polym14091905

Chicago/Turabian StyleZhao, Zhizhong, Longlin Wang, Wensheng Wang, and Xuanhao Shangguan. 2022. "Experimental Investigation of the High-Temperature Rheological and Aging Resistance Properties of Activated Crumb Rubber Powder/SBS Composite-Modified Asphalt" Polymers 14, no. 9: 1905. https://doi.org/10.3390/polym14091905

APA StyleZhao, Z., Wang, L., Wang, W., & Shangguan, X. (2022). Experimental Investigation of the High-Temperature Rheological and Aging Resistance Properties of Activated Crumb Rubber Powder/SBS Composite-Modified Asphalt. Polymers, 14(9), 1905. https://doi.org/10.3390/polym14091905