An Overview on Carbon Fiber-Reinforced Epoxy Composites: Effect of Graphene Oxide Incorporation on Composites Performance

Abstract

:1. Introduction

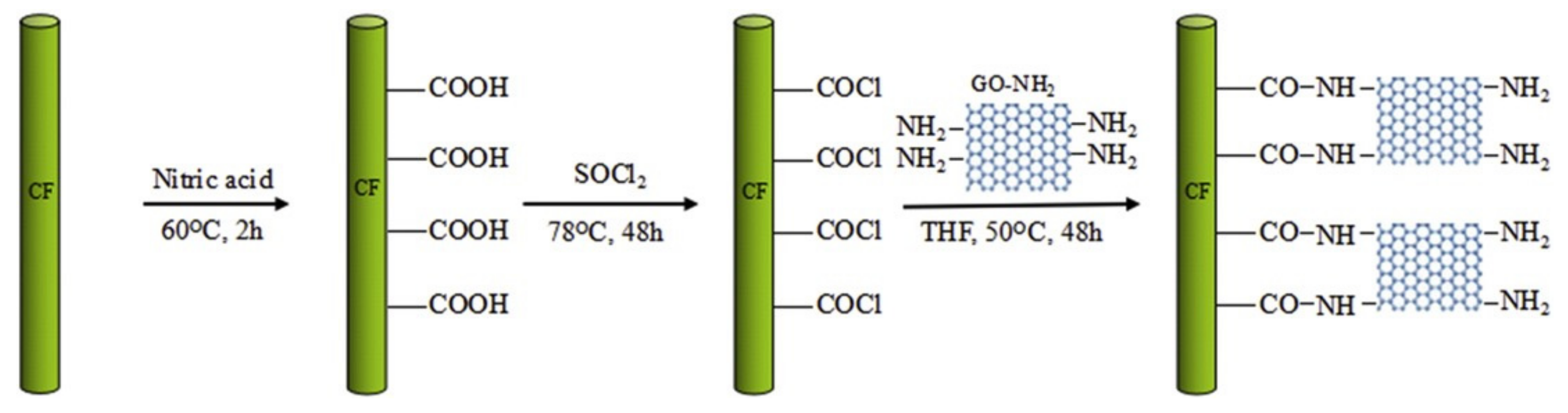

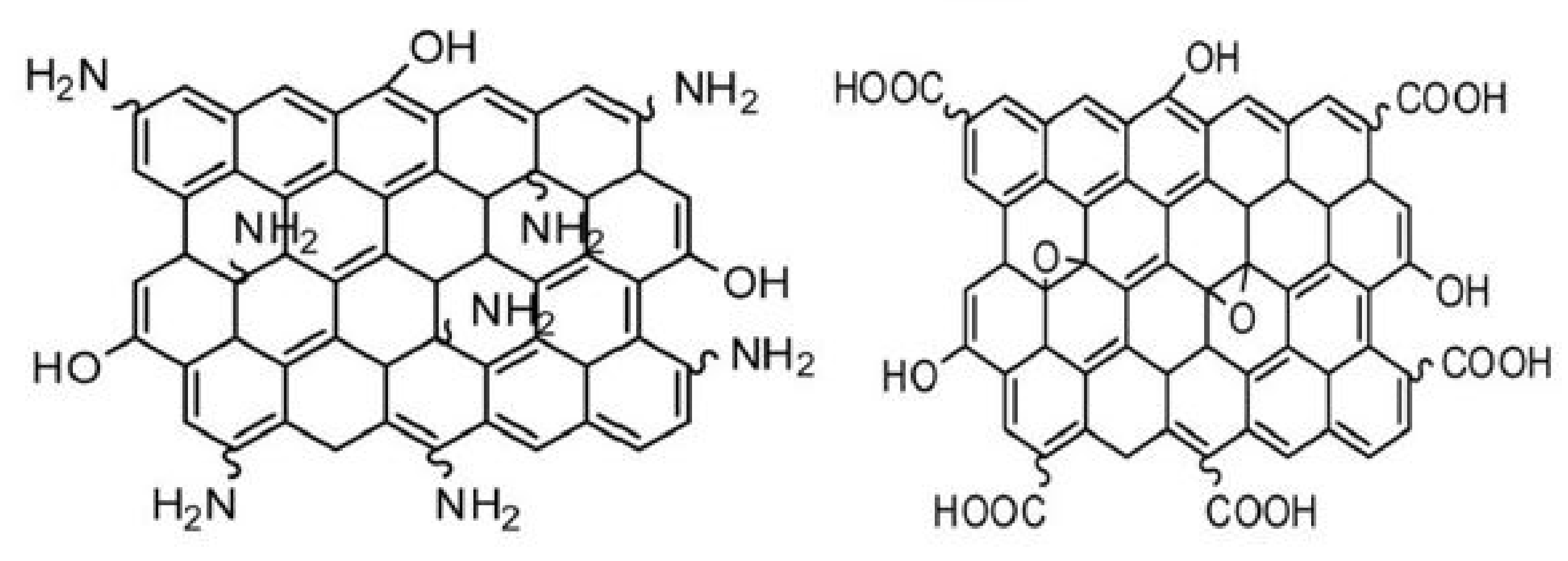

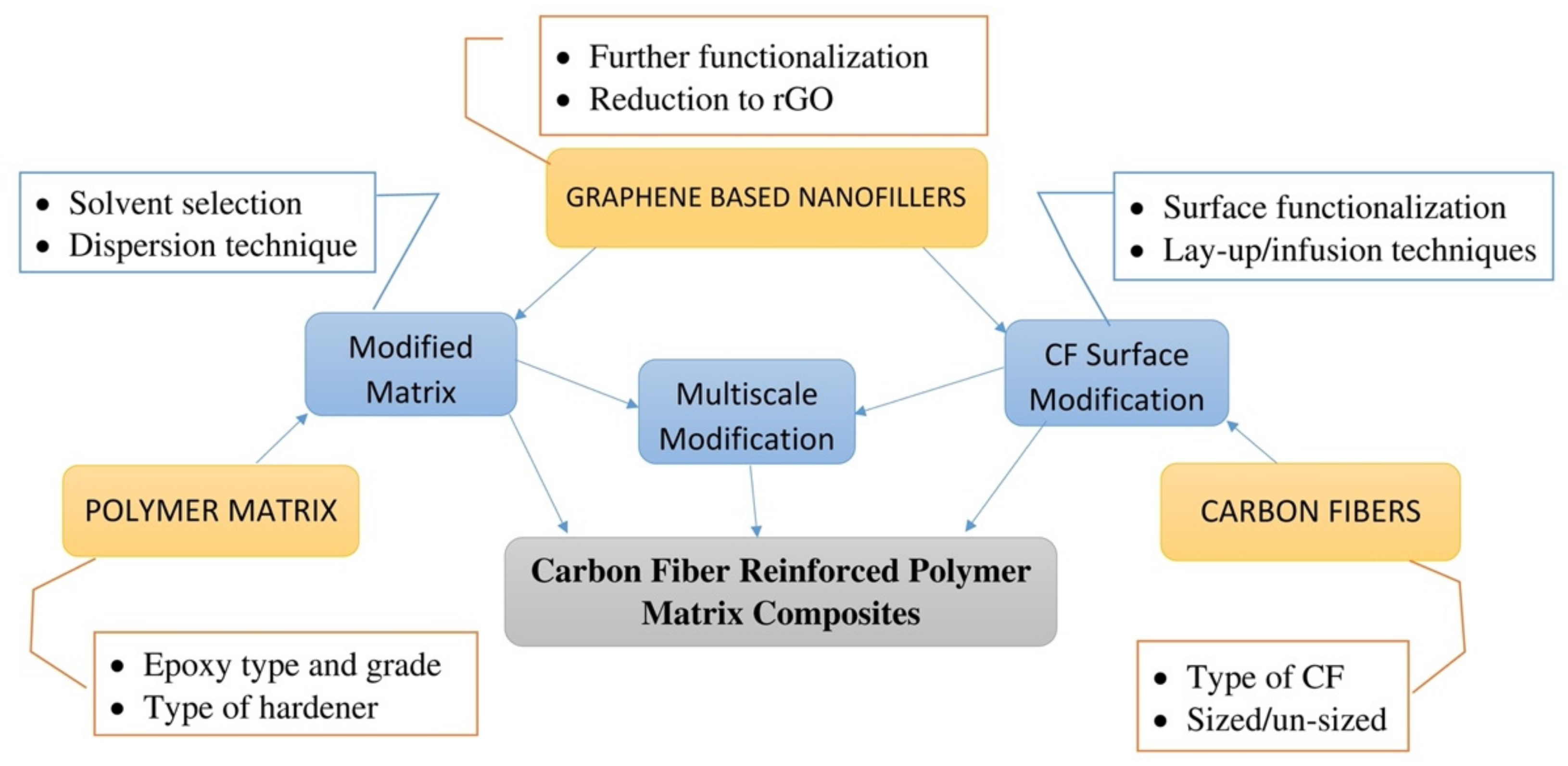

2. Functionalization of Graphene Oxide Nanosheets

3. Functionalization of (Fiber/Polymer/Symbiosis) Using Different Groups-Decorated GO Nanosheets

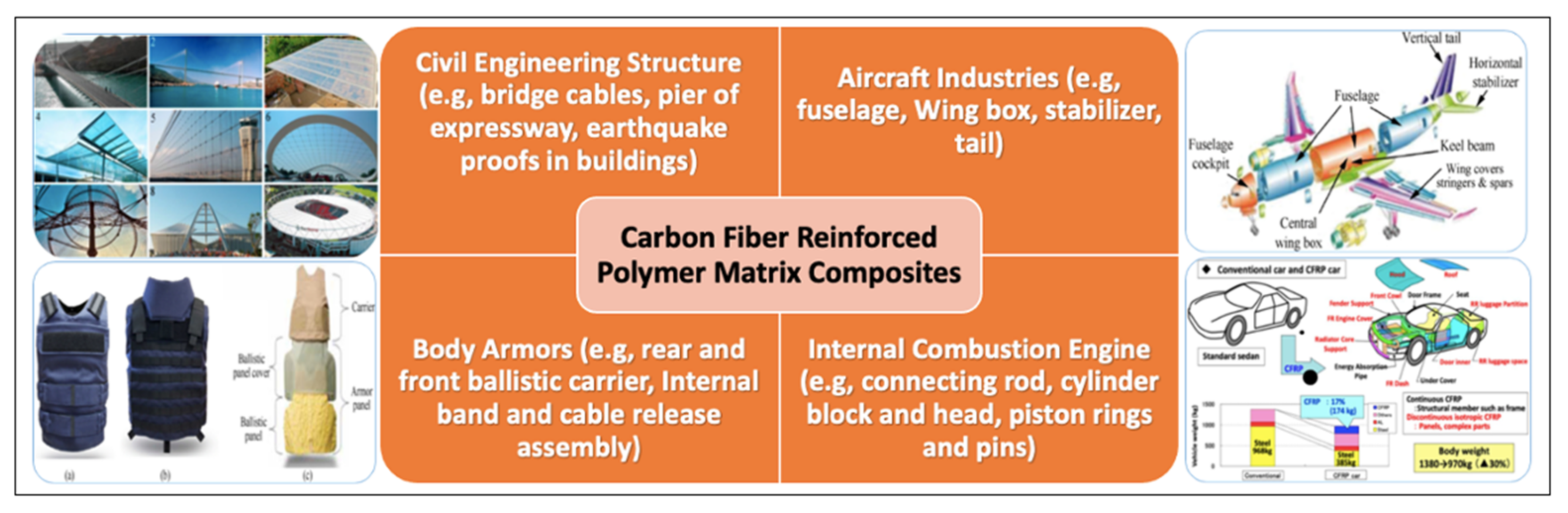

3.1. Modification of Carbon Fibers Using Different Groups-Decorated GO Nanosheets

3.2. Modification of Polymer Matrix Using Different Groups Decorated GO Nanosheets

3.3. Modification of Both (Fiber/Matrix) Using Different Groups-Decorated GO Nanosheets

4. Effect of Functionalization on CFRPs Properties

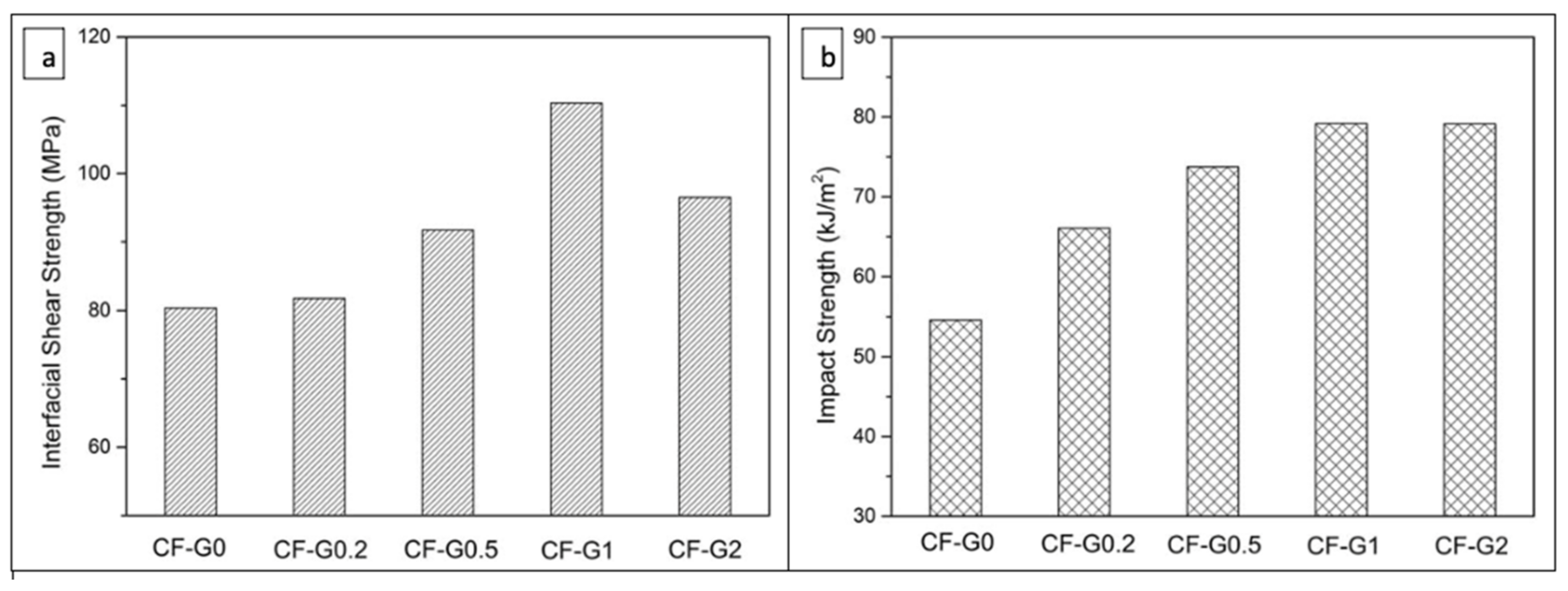

4.1. Mechanical Properties

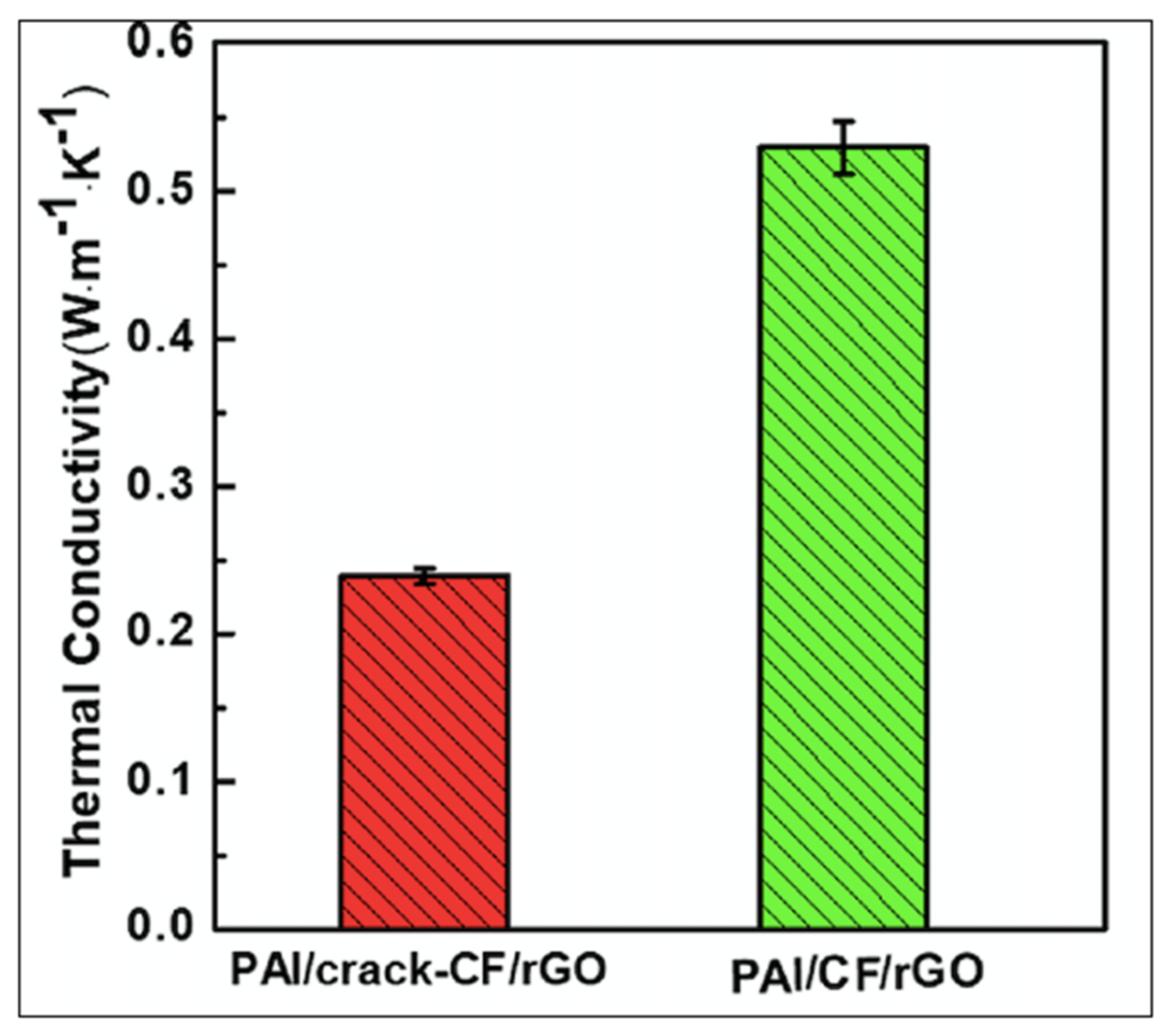

4.2. Thermal Conductivity

4.3. Electrical Conductivity

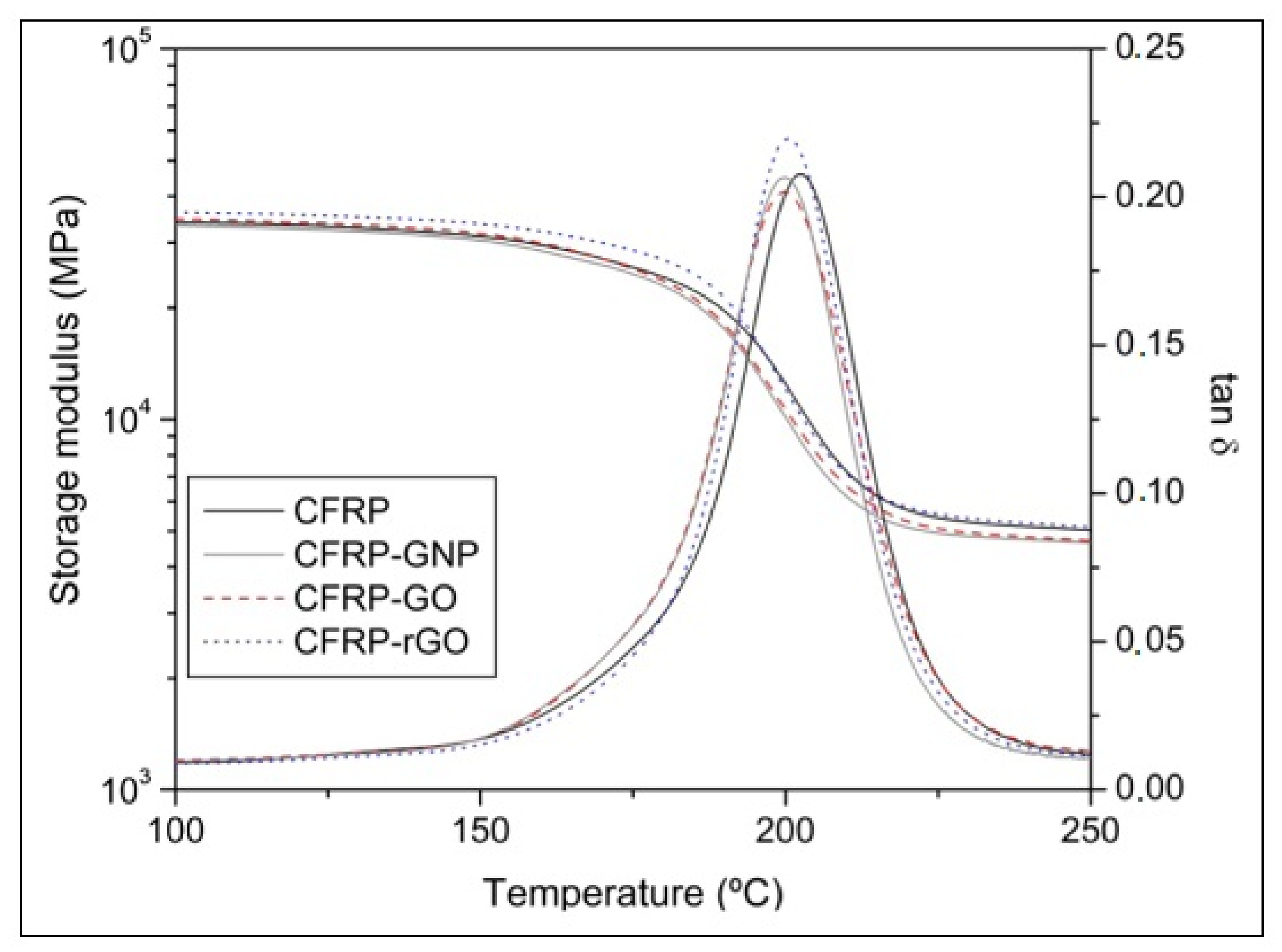

4.4. Viscoelastic Properties

5. Applications of Carbon Fiber-Reinforced Polymer Composites

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Kaw, A.K.; Group, F. Mechanics of Composite Materials; CRC Press: Boca Raton, FL, USA; Taylor & Francis: Milton Park, UK, 2006. [Google Scholar]

- Centre, A.C. The role of delamination in failure of fibre-reinforced composites. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2012, 370, 1850–1870. [Google Scholar]

- Hao, W.; Tang, C.; Yuan, Y.; Ma, Y. Investigation of dynamic mode I matrix crack- fiber bundle interaction in composites using caustics. Compos. Part B 2016, 92, 395–404. [Google Scholar] [CrossRef]

- Vertuccio, L.; Foglia, F.; Pantani, R.; Romero-Sánchez, M.D.; Calderón, B.; Guadagno, L. Carbon nanotubes and expanded graphite based bulk nanocomposites for de-icing applications. Compos. Part B Eng. 2021, 207, 108583. [Google Scholar] [CrossRef]

- Spinelli, G.; Lamberti, P.; Tucci, V.; Guadagno, L.; Vertuccio, L. Damage monitoring of structural resins loaded with carbon fillers: Experimental and theoretical study. Nanomaterials 2020, 10, 434. [Google Scholar] [CrossRef] [Green Version]

- Guadagno, L.; Vertuccio, L.; Naddeo, C.; Calabrese, E.; Barra, G.; Raimondo, M.; Sorrentino, A.; Binder, W.H.; Michael, P.; Rana, S. Self-healing epoxy nanocomposites via reversible hydrogen bonding. Compos. Part B Eng. 2019, 157, 1–13. [Google Scholar] [CrossRef]

- Guadagno, L.; Sorrentino, A.; Delprat, P.; Vertuccio, L. Design of multifunctional composites: New strategy to save energy and improve mechanical performance. Nanomaterials 2020, 10, 2285. [Google Scholar] [CrossRef]

- Guadagno, L.; Vietri, U.; Raimondo, M.; Vertuccio, L.; Barra, G.; De Vivo, B.; Lamberti, P.; Spinelli, G.; Tucci, V.; De Nicola, F.; et al. Correlation between electrical conductivity and manufacturing processes of nanofilled carbon fiber reinforced composites. Compos. Part B Eng. 2015, 80, 7–14. [Google Scholar] [CrossRef]

- Guadagno, L.; Vertuccio, L.; Naddeo, C.; Raimondo, M.; Barra, G.; De Nicola, F.; Volponi, R.; Lamberti, P.; Spinelli, G.; Tucci, V. Electrical current map and bulk conductivity of carbon fiber-reinforced nanocomposites. Polymers 2019, 11, 1865. [Google Scholar] [CrossRef] [Green Version]

- Guadagno, L.; Raimondo, M.; Vittoria, V.; Bedsole, R.W.; Park, C.; Bogert, P.B. Influence of carbon nanoparticles/epoxy matrix interaction on mechanical, electrical and transport properties of structural advanced materials. Nanotechnology 2017, 28, 094001. [Google Scholar] [CrossRef]

- Guadagno, L.; Vertuccio, L.; Foglia, F.; Raimondo, M.; Barra, G.; Sorrentino, A.; Pantani, R.; Calabrese, E. Flexible eco-friendly multilayer film heaters. Compos. Part B Eng. 2021, 224, 109208. [Google Scholar]

- Nasser, J.; Zhang, L.; Sodano, H. Laser induced graphene interlaminar reinforcement for tough carbon fiber/epoxy composites. Compos. Sci. Technol. 2021, 201, 108493. [Google Scholar] [CrossRef]

- Koh, T.M.; Isa, M.D.; Feih, S.; Mouritz, A.P. Composites: Part B Experimental assessment of the damage tolerance of z-pinned T-stiffened composite panels. Compos. Part B 2013, 44, 620–627. [Google Scholar] [CrossRef]

- Kumar, A.; Shukla, M. Race Tracking and Related Issues in Liquid Composite Moulding Process. J. Manuf. Sci. Prod. 2014, 14, 209–217. [Google Scholar] [CrossRef]

- Severini, F.; Formaro, L.; Pegoraro, M.; Posca, L. Chemical modification of carbon fiber surfaces. Carbon 2002, 40, 735–741. [Google Scholar] [CrossRef]

- Imran, K.A.; Shivakumar, K.N. Graphene-modified carbon/epoxy nanocomposites: Electrical, thermal and mechanical properties. J. Compos. Mater. 2018, 53, 93–106. [Google Scholar] [CrossRef]

- Yao, X.; Gao, X.; Jiang, J.; Xu, C.; Deng, C.; Wang, J. Comparison of carbon nanotubes and graphene oxide coated carbon fiber for improving the interfacial properties of carbon fiber/epoxy composites. Compos. Part B Eng. 2018, 132, 170–177. [Google Scholar] [CrossRef]

- Chakradhar, K.V.P.; Subbaiah, K.V.; Kumar, M.A. Blended Epoxy/Polyester Polymer Nanocomposites: Effect of ‘Nano’ on Mechanical Properties. Polym. Plast. Technol. Eng. 2012, 51, 92–96. [Google Scholar] [CrossRef]

- Ji, X.; Xu, Y.; Zhang, W.; Cui, L.; Liu, J. Review of functionalization, structure and properties of graphene/polymer composite fibers. Compos. Part A Appl. Sci. Manuf. 2016, 87, 29–45. [Google Scholar] [CrossRef]

- NSahoo, G.; Rana, S.; Cho, J.W.; Li, L.; Chan, S.H. Polymer nanocomposites based on functionalized carbon nanotubes. Prog. Polym. Sci. 2010, 35, 837–867. [Google Scholar]

- Fouda, H.; Guo, L.; Yue, Y.; Chen, K.; Elsharkawy, K. Synthesis and Characterization of Hybrid CF/MWCNTS/Epoxy Resin Composite System. IOP Conf. Ser. Mater. Sci. Eng. 2017, 220, 012021. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Wu, J.; Gao, L.; Liu, T.; Zhong, W.; Sui, G.; Yang, X. Influence of a liquid-like MWCNT reinforcement on interfacial and mechanical properties of carbon fiber filament winding composites. Polymer 2016, 90, 193–203. [Google Scholar] [CrossRef]

- Baek, Y.; Shin, P.; Kim, J.; Park, H.; Devries, K.L.; Park, J. Thermal transfer, interfacial, and mechanical properties of carbon fiber/polycarbonate-CNT composites using infrared thermography. Polym. Test. 2020, 81, 106247. [Google Scholar] [CrossRef]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A. review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Koirala, P.; van de Werken, N.; Lu, H.; Baughman, R.H.; Ovalle-Robles, R.; Tehrani, M. Using ultra-thin interlaminar carbon nanotube sheets to enhance the mechanical and electrical properties of carbon fiber reinforced polymer composites. Compos. Part B 2021, 216, 108842. [Google Scholar] [CrossRef]

- Duongthipthewa, A.; Su, Y.; Zhou, L. Electrical conductivity and mechanical property improvement by low-temperature carbon nanotube growth on carbon fiber fabric with nanofiller incorporation. Compos. Part B 2020, 182, 107581. [Google Scholar] [CrossRef]

- Ambekar, S.D.; Kumar, V. Optimization of flexural strength of CFRP hybrid nano composites containing nanoZnO and nanoclay particles. Int. J. Interact. Des. Manuf. 2019, 13, 0123456789. [Google Scholar] [CrossRef]

- Jian, L. Effect of surface treatment on enhancing interfacial strength of carbon fiber/polyimide composites. J. Thermoplast. Compos. Mater. 2020, 0892705720925141. [Google Scholar] [CrossRef]

- Xu, T.; Zhou, S.; Cui, S.; Song, N.; Shi, L.; Ding, P. Three-dimensional carbon fiber-graphene network for improved thermal conductive properties of polyamide-imide composites. Compos. Part B 2019, 178, 107495. [Google Scholar] [CrossRef]

- Jony, B.; Zainuddin, S. Fatigue analysis and fracture toughness of graphene reinforced carbon fibre polymer composites. Fatigue Fract. Eng. Mater. Struct. 2020, 44, 461–474. [Google Scholar]

- Salavagione, H.J.; Martínez, G.; Ellis, G. Recent advances in the covalent modification of graphene with polymers. Macromol. Rapid Commun. 2011, 32, 1771–1789. [Google Scholar] [CrossRef]

- Kośla, K.; Olejnik, M.; Olszewska, K. Preparation and properties of composite materials containing graphene structures and their applicability in personal protective equipment: A. Review. Rev. Adv. Mater. Sci. 2020, 59, 215–242. [Google Scholar] [CrossRef]

- Aliyev, E.; Filiz, V.; Khan, M.M.; Lee, Y.J.; Abetz, C.; Abetz, V. Structural characterization of graphene oxide: Surface functional groups and fractionated oxidative debris. Nanomaterials 2019, 9, 1180. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, C.; Yuan, R.; Wang, X. Selective reduction of graphene oxide. Carbon 2014, 71, 345. [Google Scholar]

- Yan, J.A.; Chou, M.Y. Oxidation functional groups on graphene: Structural and electronic properties. Phys. Rev. B-Condens. Matter Mater. Phys. 2010, 82, 21–24. [Google Scholar] [CrossRef]

- Kim, J.; Cha, J.; Chung, B.; Ryu, S.; Hong, S.H. Fabrication and mechanical properties of carbon fiber/epoxy nanocomposites containing high loadings of noncovalently functionalized graphene nanoplatelets. Compos. Sci. Technol. 2020, 192, 108101. [Google Scholar] [CrossRef]

- Lee, C.Y.; Bae, J.H.; Kim, T.Y.; Chang, S.H.; Kim, S.Y. Using silane-functionalized graphene oxides for enhancing the interfacial bonding strength of carbon/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2015, 75, 11–17. [Google Scholar] [CrossRef]

- Zhang, R.L.; Gao, B.; Ma, Q.H.; Zhang, J.; Cui, H.Z.; Liu, L. Directly grafting graphene oxide onto carbon fiber and the effect on the mechanical properties of carbon fiber composites. Mater. Des. 2016, 93, 364–369. [Google Scholar] [CrossRef]

- Chen, L.; Jin, H.; Xu, Z.; Shan, M.; Tian, X.; Yang, C.; Wang, Z.; Cheng, B. A design of gradient interphase reinforced by silanized graphene oxide and its effect on carbon fiber/epoxy interface. Mater. Chem. Phys. 2014, 145, 186–196. [Google Scholar] [CrossRef]

- Wang, X.; Xing, W.; Zhang, P.; Song, L.; Yang, H.; Hu, Y. Covalent functionalization of graphene with organosilane and its use as a reinforcement in epoxy composites. Compos. Sci. Technol. 2012, 72, 737–743. [Google Scholar] [CrossRef]

- Adeel, M.; Bilal, M.; Rasheed, T.; Sharma, A.; Iqbal, H.M.N. Graphene and graphene oxide: Functionalization and nano-bio-catalytic system for enzyme immobilization and biotechnological perspective. Int. J. Biol. Macromol. 2018, 120, 1430–1440. [Google Scholar] [CrossRef]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.M.; Bezerra, W.B.A.; da Costa, G.F.F.; da Luz, F.S.; Pinheiro, W.A.; Monteiro, S.N. Mechanical properties of composites with graphene oxide functionalization of either epoxy matrix or curaua fiber reinforcement. Integr. Med. Res. 2020, 9, 13390–13401. [Google Scholar] [CrossRef]

- Qu, C.; Wu, T.; Huang, G.-W.; Li, N.; Li, M.; Ma, J.-L.; Liu, Y.; Xiao, H.-M. Improving cryogenic mechanical properties of carbon fiber reinforced composites based on epoxy resin toughened by hydroxyl-terminated polyurethane. Compos. Part B Eng. 2021, 210, 108569. [Google Scholar] [CrossRef]

- Nie, H.J.; Xu, Z.; Tang, B.-L.; Dang, C.-Y.; Yang, Y.-R.; Zeng, X.-L.; Lin, B.-C.; Shen, X.-J. The effect of graphene oxide modified short carbon fiber on the interlaminar shear strength of carbon fiber fabric/epoxy composites. J. Mater. Sci. 2021, 56, 488–496. [Google Scholar] [CrossRef]

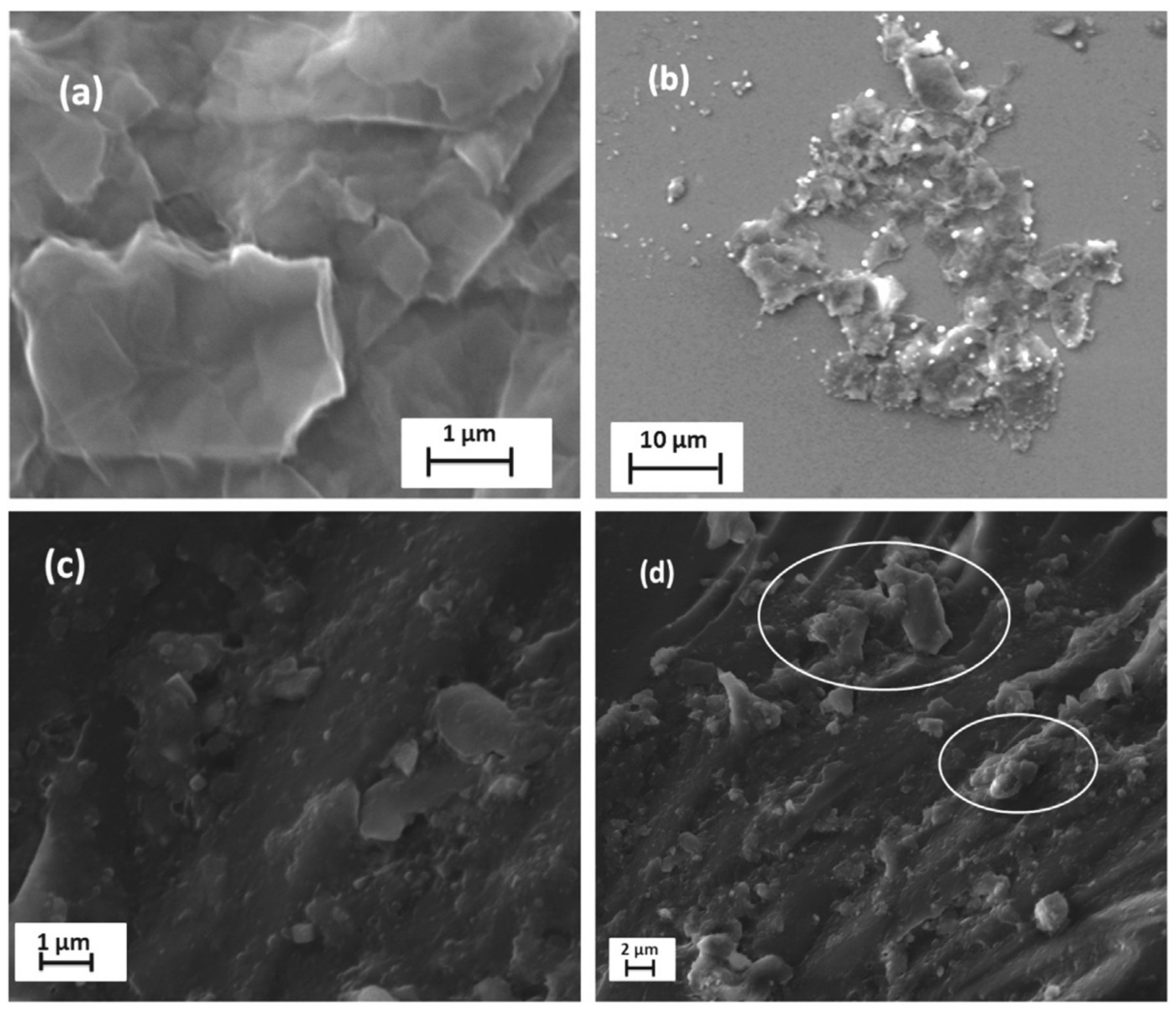

- Zhang, X.; Fan, X.; Yan, C.; Li, H.; Zhu, Y.; Li, X.; Yu, L. Interfacial Microstructure and Properties of Carbon Fiber Composites Modified with Graphene Oxide. Appl. Mater. Interfaces 2012, 4, 1543–1552. [Google Scholar] [CrossRef]

- Qin, W.; Vautard, F.; Drzal, L.T.; Yu, J. Composites: Part B Mechanical and electrical properties of carbon fiber composites with incorporation of graphene nanoplatelets at the fiber—Matrix interphase. Compos. Part B 2015, 69, 335–341. [Google Scholar] [CrossRef]

- Fan, W.; Li, J.; Zheng, Y. Improved thermo-oxidative stability of three-dimensional and four-directional braided carbon fiber/epoxy hierarchical composites using graphene-reinforced gradient interface layer. Polym. Test. 2015, 44, 177–185. [Google Scholar] [CrossRef]

- Li, L.; Yan, C.; Xu, H.; Liu, N.; Shi, P.; Zhu, Y.; Chen, G.; Wu, X.; Liu, W. Improving the interfacial properties of carbon fiber–epoxy resin composites with a graphene-modified sizing agent. J. Appl. Polym. Sci. 2019, 136, 136. [Google Scholar]

- Chen, J.; Wu, J.; Ge, H.; Zhao, D.; Liu, C.; Hong, X. Reduced Graphene Oxide Deposited Carbon Fiber Reinforced Polymer Composites for Electromagnetic Interference Shielding. Compos. Part A 2015, 82, 141–150. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.; Sun, S.; Li, X.; Zhao, F.; Jiang, B.; Huang, Y. Electrophoretic deposition of graphene oxide on continuous carbon fibers for reinforcement of both tensile and interfacial strength. Compos. Sci. Technol. 2016, 135, 46–53. [Google Scholar]

- Wang, P.; Yang, J.; Liu, W.; Tang, X.-Z.; Zhao, K.; Lu, X.; Xu, S. Tunable crack propagation behavior in carbon fiber reinforced plastic laminates with polydopamine and graphene oxide treated fibers. JMADE 2017, 113, 68–75. [Google Scholar] [CrossRef] [Green Version]

- Luo, W.; Zhang, B.; Zou, H.; Liang, M.; Chen, Y. Enhanced interfacial adhesion between polypropylene and carbon fiber by graphene oxide/polyethyleneimine coating. J. Ind. Eng. Chem. 2017, 51, 129–139. [Google Scholar] [CrossRef]

- Wang, X.; Li, C.; Chi, Y. Effect of Graphene Nanowall Size on the Interfacial Strength of Carbon Fiber Reinforced Composites. Nanomaterials 2018, 8, 414. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Ding, J.; Sun, X.; Wang, Y. Research of Functional Graphene Nanosheets Modified Carbon Fiber Reinforced Cyanate Ester Resin Composites on Thermal and Electrical Conductivities Properties. J. Nanosci. Nanotechnol. 2017, 17, 3695–3701. [Google Scholar] [CrossRef]

- Wang, F.; Cai, X. Improvement of mechanical properties and thermal conductivity of carbon fiber laminated composites through depositing graphene nanoplatelets on fibers. J. Mater. Sci. 2019, 54, 3847–3862. [Google Scholar] [CrossRef]

- Article, F.L.; Zhang, M.; Jin, L.; Liu, L.; Li, N.; Shang, L.; Li, M.; Xao, L.; Ao, Y. Enhancing interfacial properties of carbon fibers reinforced epoxy composites via Layer-by-Layer self assembly GO/SiO2 multilayers films on carbon fibers surface. Appl. Surf. Sci. 2018, 470, 543–554. [Google Scholar]

- Yan, F.; Liu, L.; Li, K.; Jin, L.; Zhang, M.; Liu, Y.; Xiao, L.; Ao, Y. A novel π bridging method to graft graphene oxide onto carbon fiber for interfacial enhancement of epoxy composites. Compos. Sci. Technol. 2021, 201, 108489. [Google Scholar] [CrossRef]

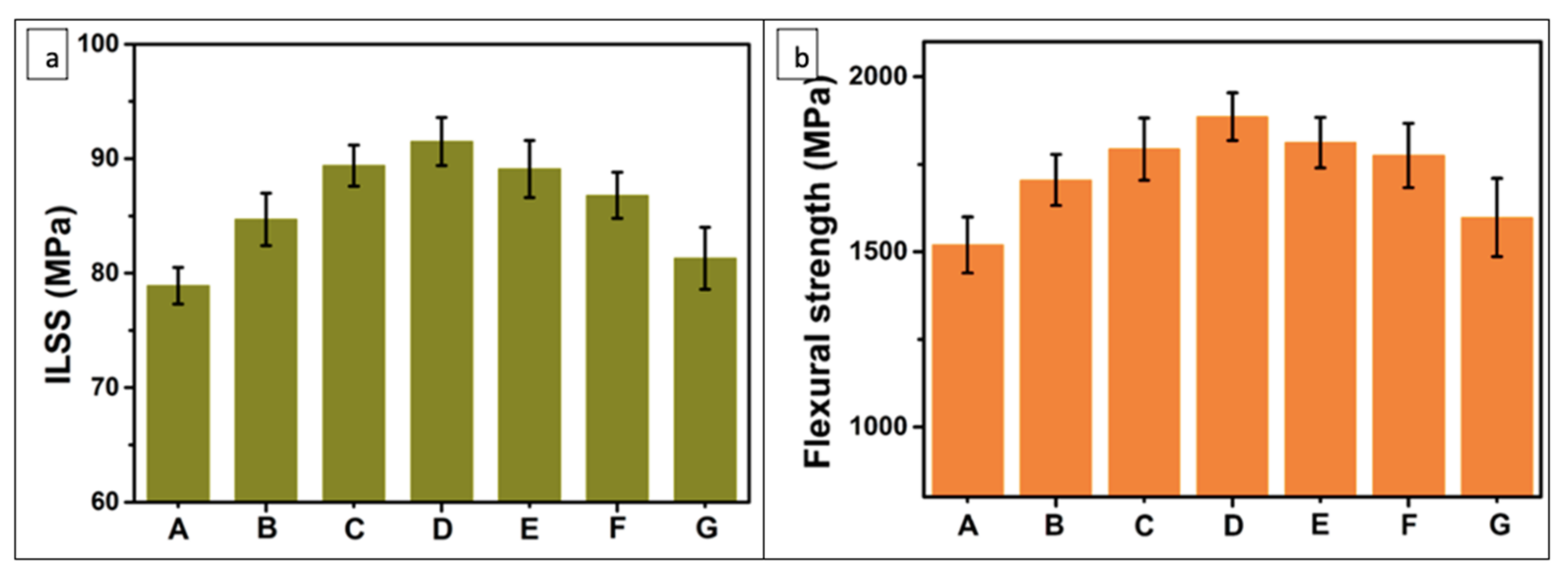

- Cheng, X.; Yokozeki, T.; Wu, L.; Wang, H.; Zhang, J.; Koyanagi, J.; Weng, Z.; Sun, Q.-F. Electrical conductivity and interlaminar shear strength enhancement of carbon fiber reinforced polymers through synergetic effect between graphene oxide and polyaniline. Compos. Part A Appl. Sci. Manuf. 2016, 90, 243–249. [Google Scholar] [CrossRef]

- He, R.; Chang, Q.; Huang, X.; Bo, J. Improved mechanical properties of carbon fiber reinforced PTFE composites by growing graphene oxide on carbon fiber surface. Compos. Interfaces 2018, 25, 995–1004. [Google Scholar] [CrossRef]

- Ashori, A.; Rahmani, H.; Bahrami, R. Preparation and characterization of functionalized graphene oxide/carbon fiber/epoxy nanocomposites. Polym. Test. 2015, 48, 82–88. [Google Scholar] [CrossRef] [Green Version]

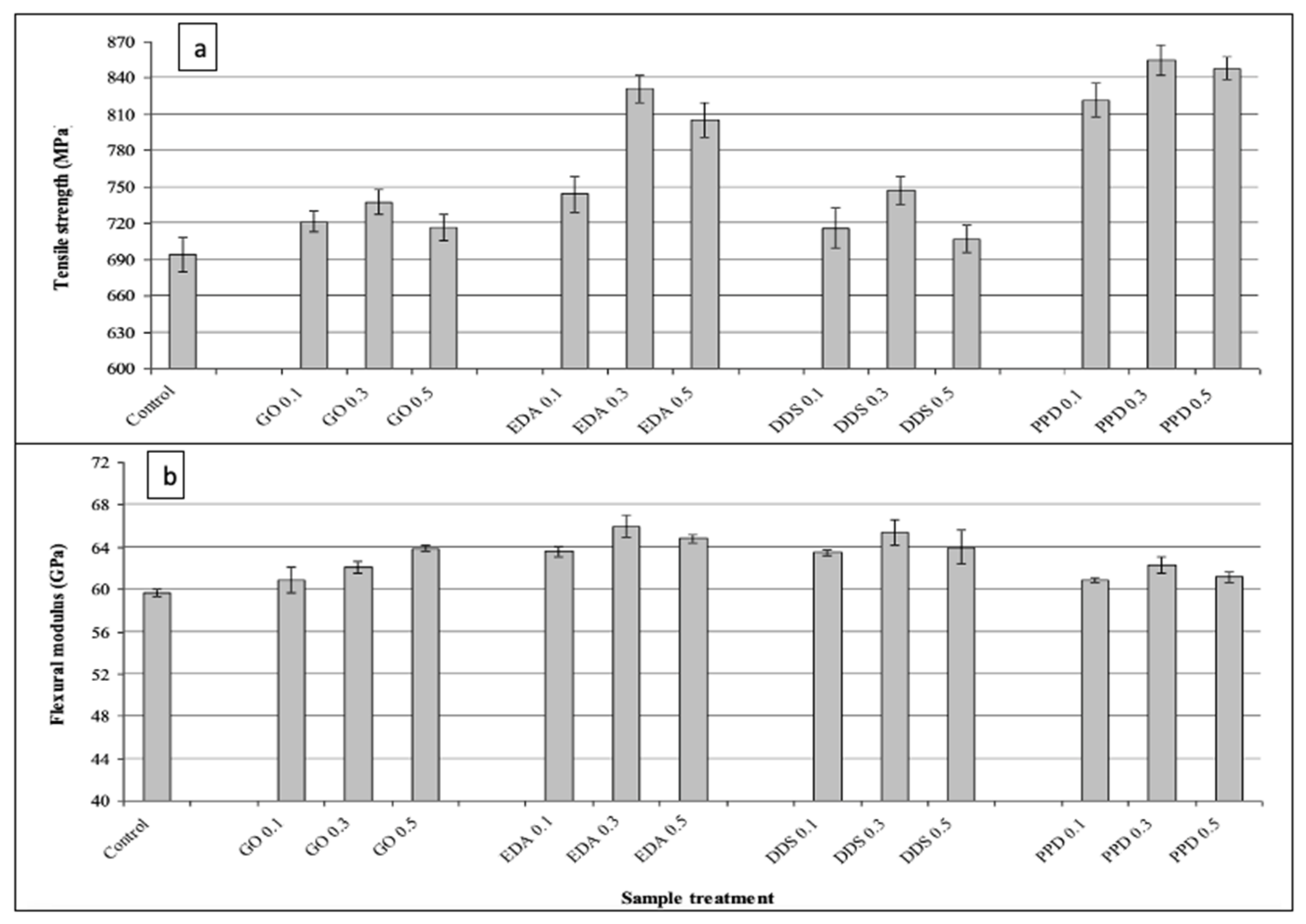

- Watson, G.; Starost, K.; Bari, P.; Faisal, N.; Mishra, S.; Njuguna, J. Tensile and Flexural Properties of Hybrid Graphene Oxide/Epoxy Carbon Fibre Reinforced Composites. IOP Conf. Ser. Mater. Sci. Eng. 2017, 195, 012009. [Google Scholar] [CrossRef] [Green Version]

- Adak, N.C.; Chhetri, S.; Kuila, T.; Murmu, N.C.; Samanta, P.; Lee, J.H. Effects of hydrazine reduced graphene oxide on the inter-laminar fracture toughness of woven carbon fiber/epoxy composite. Compos. Part B Eng. 2018, 149, 22–30. [Google Scholar] [CrossRef]

- Adak, N.C.; Chhetri, S.; Murmu, N.C.; Samanta, P.; Kuila, T.; Lee, J.H. Experimental and numerical investigation on the mechanical characteristics of polyethylenimine functionalized graphene oxide incorporated woven carbon fibre/epoxy composites. Compos. Part B Eng. 2019, 156, 240–251. [Google Scholar] [CrossRef]

- Li, Y.; Tian, H.; Zhang, J.; Zou, W.; Wang, H.; Du, Z.; Zhang, C. Fabrication and properties of rigid polyurethane nanocomposite foams with functional isocyanate modified graphene oxide. Polym. Compos. 2020, 41, 5126–5134. [Google Scholar] [CrossRef]

- Pathak, A.K.; Garg, H.; Singh, M.; Yokozeki, T.; Dhakate, S.R. Enhanced interfacial properties of graphene oxide incorporated carbon fiber reinforced epoxy nanocomposite: A systematic thermal properties investigation. J. Polym. Res. 2019, 26, 23. [Google Scholar] [CrossRef]

- Senis, E.C.; Golosnoy, I.O.; Dulieu-Barton, J.M.; Thomsen, O.T. Enhancement of the electrical and thermal properties of unidirectional carbon fibre/epoxy laminates through the addition of graphene oxide. J. Mater. Sci. 2019, 54, 8955–8970. [Google Scholar] [CrossRef] [Green Version]

- Pathak, A.K.; Borah, M.; Gupta, A.; Yokozeki, T.; Dhakate, S.R. Improved mechanical properties of carbon fiber/graphene oxide-epoxy hybrid composites. Compos. Sci. Technol. 2016, 135, 28–38. [Google Scholar] [CrossRef]

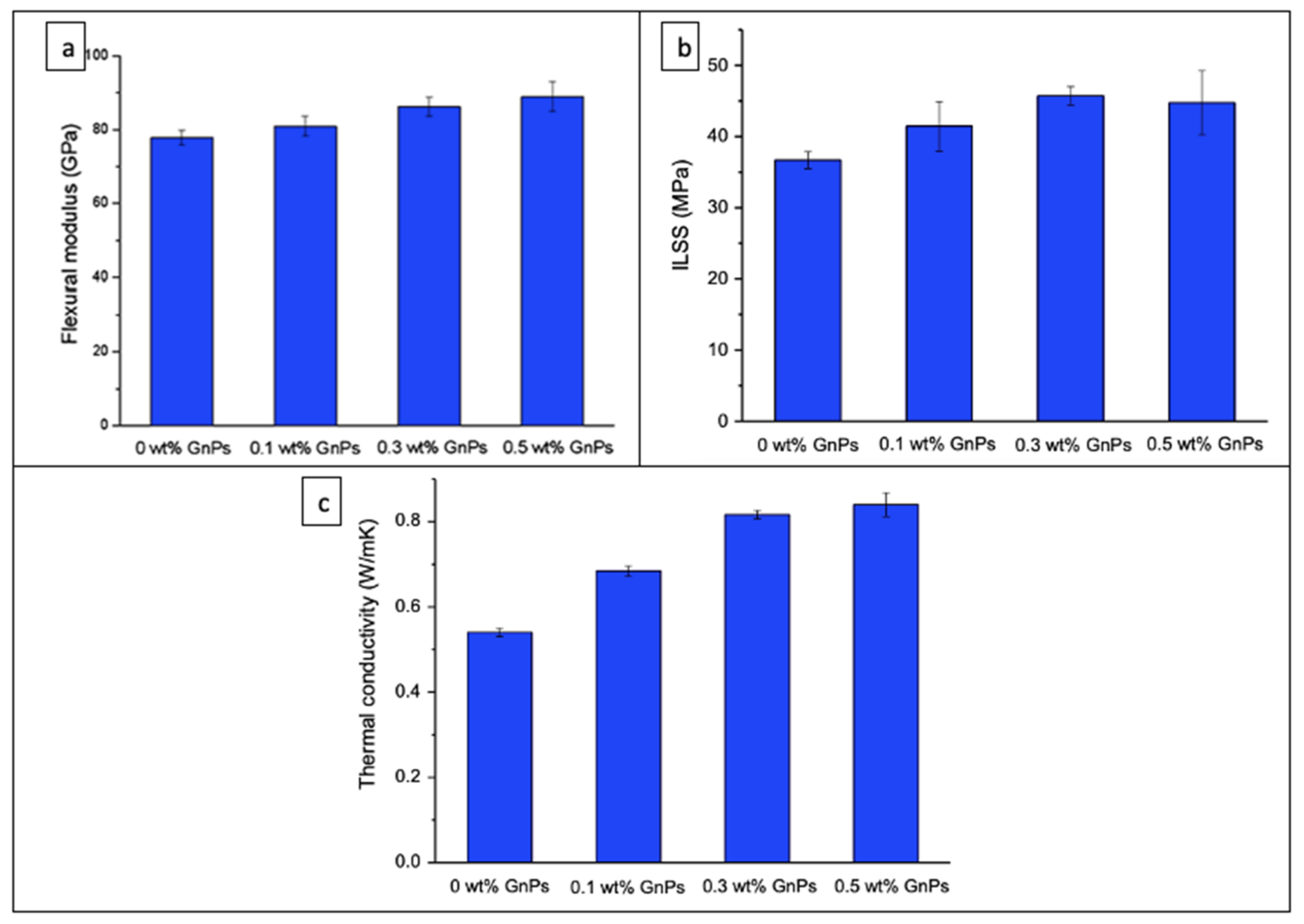

- Li, Y.; Zhang, H.; Huang, Z.; Bilotti, E.; Peijs, T. Graphite Nanoplatelet Modified Epoxy Resin for Carbon Fibre Reinforced Plastics with Enhanced Properties. J. Nanomater. 2017, 2017, 5194872. [Google Scholar] [CrossRef] [Green Version]

- Bowman, S.; Hu, X.; Jiang, Q.; Qiu, Y.; Liu, W.; Wei, Y. Effects of graphene-oxide-modified coating on the properties of carbon-fiber-reinforced polypropylene composites. Coating 2018, 8, 149. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Yan, F.; Li, M.; Zhang, M.; Xiao, L.; Shang, L.; Ao, Y. Improving interfacial properties of hierarchical reinforcement carbon fibers modified by graphene oxide with different bonding types. Compos. Part A Appl. Sci. Manuf. 2018, 107, 616–625. [Google Scholar] [CrossRef]

- Vázquez-Moreno, J.M.; Sánchez-Hidalgo, R.; Sanz-Horcajo, E.; Viña, J.; Verdejo, R.; López-Manchado, M.A. Preparation and mechanical properties of graphene/carbon fiber-reinforced hierarchical polymer composites. J. Compos. Sci. 2019, 3, 30. [Google Scholar] [CrossRef] [Green Version]

- Ra, M.; Nitzsche, F.; Laliberte, J.; Thibault, J.; Labrosse, M.R. Simultaneous Reinforcement of Matrix and Fibers for Enhancement of Mechanical Properties of Graphene-Modified Laminated Composites. Polym. Compos. 2018, 40, E1732–E1745. [Google Scholar]

- Li, N.; Yang, X.; Bao, F.; Pan, Y.; Wang, C.; Chen, B.; Zong, L.; Liu, C.; Wang, J.; Jian, X. Improved Mechanical Properties of Copoly (Phthalazinone Ether Sulphone)s Composites Reinforced by Multiscale Carbon Fibre/Graphene Oxide Reinforcements: A Step Closer to Industrial Production. Polymers 2019, 11, 237. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-García, V.; Gómez, J.; Cristiano, F.; Gude, M.R. Industrial manufacturing and characterization of multiscale CFRP laminates made from prepregs containing graphene-related materials Industrial manufacturing and characterization of multiscale CFRP laminates made from prepregs containing graphene-related m. Mater. Res. Express 2020, 7, 075601. [Google Scholar] [CrossRef]

- Xu, J.; Xu, D.; Wang, X.; Long, S.; Yang, J. Improved interfacial shear strength of carbon fiber/polyphenylene sulfide composites by graphene. High Perform. Polym. 2017, 29, 913–921. [Google Scholar] [CrossRef]

- Jiang, D.; Liu, L.; Wu, G.; Zhang, Q.; Long, J.; Wu, Z.; Xie, F.; Huang, Y. Mechanical Properties of Carbon Fiber Composites Modified With Graphene Oxide in the Interphase. Polym. Compos. 2017, 28, 2425–2432. [Google Scholar] [CrossRef]

- Jenkins, P.; Liu, L.; Wu, G.; Zhang, Q.; Long, J.; Wu, Z.; Xie, F.; Huang, Y. Influence of Reduced Graphene Oxide on Epoxy/Carbon Fiber-Reinforced Hybrid Composite: Flexural and Shear Properties under Varying Temperature Conditions. Adv. Eng. Mater. 2019, 21, 1800614. [Google Scholar] [CrossRef]

- Cho, B.G.; Joshi, S.R.; Lee, J.; Park, Y.B.; Kim, G.H. Direct growth of thermally reduced graphene oxide on carbon fiber for enhanced mechanical strength. Compos. Part B Eng. 2020, 193, 108010. [Google Scholar] [CrossRef]

- Yuan, X.; Zhu, B.; Cai, X.; Qiao, K.; Zhao, S.; Yu, J. Influence of different surface treatments on the interfacial adhesion of graphene oxide/carbon fiber/epoxy composites. Appl. Surf. Sci. 2018, 458, 996–1005. [Google Scholar] [CrossRef]

- Filho, F.D.G.; da Luz, F.S.; Oliveira, M.S.; Pereira, A.C.; Costa, U.O.; Monteiro, S.N. Thermal behavior of graphene oxide-coated piassava fiber and their epoxy composites. J. Mater. Res. Technol. 2020, 9, 5343–5351. [Google Scholar] [CrossRef]

- Deshmukh, K.; Kovářík, T.; Muzaffar, A.; Ahamed, M.B.; Pasha, S.K.K. Mechanical analysis of polymers. In Polymer Science and Innovative Applications; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Vertuccio, L.; Guadagno, L.; Spinelli, G.; Lamberti, P.; Zarrelli, M.; Russo, S.; Iannuzzo, G. Smart coatings of epoxy based CNTs designed to meet practical expectations in aeronautics. Compos. Part B Eng. 2018, 147, 42–46. [Google Scholar] [CrossRef]

- Paul, R.; Dai, L. Interfacial aspects of carbon composites. Compos. Interfaces 2018, 6440, 1–67. [Google Scholar] [CrossRef]

- Ozkan, D.; Gok, M.S.; Karaoglanli, A.C. Carbon Fiber Reinforced Polymer (CFRP) Composite Materials, Their Characteristic Properties, Industrial Application Areas and Their Machinability. Adv. Struct. Mater. 2020, 124, 235–253. [Google Scholar]

- Karataş, M.A.; Gökkaya, H. A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def. Technol. 2018, 14, 318–326. [Google Scholar] [CrossRef]

- Wan, Y.; Takahashi, J. Development of carbon fiber-reinforced thermoplastics for mass-produced automotive applications in japan. J. Compos. Sci. 2021, 5, 86. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P. Dynamic impact protective body armour: A comprehensive appraisal on panel engineering design and its prospective materials. Def. Technol. 2021, 17, 2027–2049. [Google Scholar] [CrossRef]

- Liu, Y.; Zwingmann, B.; Schlaich, M. Carbon fiber reinforced polymer for cable structures-a review. Polymers 2015, 7, 2078–2099. [Google Scholar] [CrossRef] [Green Version]

- Olofin, I.; Liu, R. The Application of Carbon Fibre Reinforced Polymer (CFRP) Cables in Civil Engineering Structures. Int. J. Civ. Eng. 2015, 2, 1–5. [Google Scholar] [CrossRef]

- Myagkov, L.L.; Mahkamov, K.; Chainov, N.D.; Makhkamova, I. Advanced and conventional internal combustion engine materials. In Alternative Fuels and Advanced Vehicle Technologies for Improved Environmental Performance: Towards Zero Carbon Transportation; Woodhead Publishing: Sawston, UK, 2014. [Google Scholar]

- Benzait, Z.; Trabzon, L. A review of recent research on materials used in polymer–matrix composites for body armor application. J. Compos. Mater. 2018, 52, 3241–3263. [Google Scholar] [CrossRef]

| Composite | Fiber | Matrix | Modification Type | Processing Technique | Mechanical Properties (without Functionalization) | Mechanical Properties (with Functionalization) | References |

|---|---|---|---|---|---|---|---|

| CF/GO/epoxy | AS4 3K 8HS carbon fiber | 1.0 wt.% GO/Epon 828 epoxy resin and Epicure W curing agent | Matrix modified | Compression molding | Mode I fracture toughness (GIC)-191.4 J/m2 Mode II fracture toughness (GIIC)-978.9 J/m2 | Mode I fracture toughness (GIC)-203.2 J/m2 Mode II fracture toughness (GIIC)-917.9 J/m2 | [16] |

| CF/GO/epoxy | T300 carbon fiber | 0.3 wt.% GO/epoxy resin LY556 and triethylenetetramine (TETA) hardener | Matrix modified | Hydraulic pressing | Flexural strength-425 MPa ILSS-32.2 MPa | Flexural strength-710 MPa ILSS-40.8 MPa | [67] |

| CF/GO/PI | IM7 8552 carbon fiber | Laser-induced GO array/Polyimide substrate | Matrix modified | Manual pressured roller | Short beam strength-121 MPa Mode I fracture toughness (GIC)-292 J/m2 Mode II fracture toughness (GIIC)-1.3 KJ/m2 Tensile strength-2.0 GPa | Short beam strength-122 MPa Mode I fracture toughness (GIC)-425 J/m2 Mode II fracture toughness (GIIC)-1.5 KJ/m2 Tensile strength-2.5 GPa | [12] |

| PAI/CFs/GO | GO/PAN-based carbon fiber | Polyamide-imide | Fiber modified | Compression molding | Tensile strength-34.13 MPa Tensile modulus-3.03 GPa Fracture toughness-101.11 J/m3 | Tensile strength-38.41 MPa Tensile modulus-2.22 GPa Fracture toughness-106.40 J/m3 | [29] |

| SCF-GO7.5/epoxy | 5.0 wt.% GO/T700S carbon fiber | E20 and E50 epoxy resin | Fiber modified | Autoclave | Interfacial shear strength-72.0 MPa Interlaminar shear strength-45.5 MPa Tensile strength-1446.7 MPa | Interfacial shear strength-97.2 MPa Interlaminar shear strength-51.3 MPa Tensile strength-1942.1 MPa | [45] |

| GO/CF/epoxy | 0.5 wt.% GO/carbon fiber | MGS RIM 135 epoxy resin and Rim 37, RIM134 hardener | Fiber modified | Vacuum-assisted resin infusion molding | Tensile strength-1525 MPa Young’s modulus-5.2 GPa ILSS-65.4 MPa | Tensile strength-1726 MPa Young’s modulus-8.6 GPa ILSS-52.6 MPa | [63] |

| ACF- D400-GO | GO/T700SC carbon fiber | D400 | Fiber modified | Hydraulic pressing | Tensile strength-6.24 GPa Interfacial shear strength-91.3 MPa | Tensile strength-5.02 GPa Interfacial shear strength-82.2 MPa | [39] |

| rGO/CF-U | GO/T700SC carbon fiber | - | Fiber modified | Electrophoretic deposition | Tensile strength-5.06 GPa Interfacial shear strength-53 MPa | Tensile strength-6.11 GPa Interfacial shear strength-79.5 MPa | [50] |

| LBL 10 Go/CF/PP | 10 layer GO/Carbon fiber | Polypropylene | Fiber modified | Knotting-melting | Tensile strength-5.2 GPa Interfacial shear strength-4.4 MPa | Tensile strength-5.3 GPa Interfacial shear strength-10.1 MPa | [52] |

| PDA-GO-CF/epoxy | GO/T300 carbon fiber | Epolam 5015 epoxy resin and amine hardener | Fiber modified | Wet lay-up | Mode I fracture toughness (GIC)-630 J/m2 Mode II fracture toughness (GIIC)-1625 J/m2 | Mode I fracture toughness (GIC)-900 J/m2 Mode II fracture toughness (GIIC)-1720 J/m2 | [51] |

| rGO/CF/epoxy | 0.2 wt.% GO/Plain weave carbon cloth | LAPOX C51 epoxy resin and lapox AH-428 hardener | Fiber modified | Vacuum assisted resin transfer molding | Interlaminar shear strength-23.3 MPa In-plane fracture toughness (kIC)-20.6 MPa.m1/2 Impact toughness-5.2 J | Interlaminar shear strength-43 MPa In-plane fracture toughness (kIC)-27.3 MPa.m1/2 Impact toughness-10.4 J | [62] |

| Composite | Fiber | Matrix | Modification Type | Processing Technique | Thermal Conductivity (with Functionalization) (W/mK) | Thermal Conductivity (with Functionalization) (W/mK) | References |

|---|---|---|---|---|---|---|---|

| CF/GO/epoxy | AS4 3K 8HS Carbon fiber | 1.0 wt.% GO/Epon 828 epoxy resin and Epicure W curing agent | Matrix modified | Compression molding | 0.68 | 0.72 | [16] |

| PAI/CFs/rGO | rGO/PAN-based carbon fiber | Polyamide-imide | Fiber modified | Compression molding | 0.27 | 0.53 | [29] |

| CF/GNP-epoxy | T700 carbon fiber | 5 wt.% GNP/MVR444 epoxy resin and MVR444H hardener | Matrix modified | Vacuum-assisted resin infusion | 0.6 | 0.8 | [68] |

| CF/GN-ester | T700 carbon fiber | Bisphenol A dicyanate ester | Matrix modified | Mold pressing | 4.89 | 5.10 | [54] |

| GO-CF/PAPI | Carbon fiber | Polyaryl polymethylene isocyanate | Fiber modified | Hydraulic pressing | 0.18 | 0.23 | [63] |

| CF/GO-epoxy | Zoltek Panex carbon fiber | GO/ER 5300 epoxy resin | Fiber modified | Vacuum-assisted resin infusion molding | 0.83 | 0.87 | [66] |

| GNPs-CF/epoxy | 0.5 wt.% GNPs-carbon fiber | LY1564 epoxy resin and Aradur 3486 hardener | Fiber modified | Vacuum-assisted resin infusion | 0.53 | 0.84 | [55] |

| Composite | Fiber | Matrix | Modification Type | Processing Technique | Electrical Conductivity (without Functionalization) (S/m) | Electrical Conductivity (with Functionalization) (S/m) | References |

|---|---|---|---|---|---|---|---|

| CF/GO/epoxy | AS4 3K 8HS Carbon fiber | 1.0 wt.% GO/Epon 828 epoxy resin and Epicure W curing agent | Matrix modified | Compression molding | 5.65 × 10−4 | 1.31 × 10−3 | [16] |

| CF/GO/epoxy | CJ20T carbon fiber | 6002 epoxy resin and HARTCURE-10 curing agent | Matrix modified | Hand lay-up | 4.5 | 6.2 | [55] |

| GNPs/CF/epoxy | GNPs/PAN-based AS4 carbon fiber | Epon 828 epoxy resin | Fiber modified | Prepreg and hand lay-up | 5.6 | 6.8 | [47] |

| CF/GNP-epoxy | T700 carbon fiber | 5 wt.% GNP/MVR444 epoxy resin and MVR444H hardener | Matrix modified | Vacuum-assisted resin infusion | 0.3 | 0.60 | [68] |

| CF/GN-ester | T700 carbon fiber | GN/Bisphenol-A dicyanate ester | Matrix modified | Mold pressing | 0.89 | 1.4 | [54] |

| GO/CF/EP | GO/PAN-based carbon fiber | TDE-85 epoxy resin | Fiber modified | Vacuum-assisted resin transfer molding | 1.02 | 1.37 | [78] |

| GNPs-CF/epoxy | T700G carbon fiber | Bisphenol A dicyanate epoxy resin | Fiber modified | Vacuum-assisted resin transfer molding | 6.4 | 8.9 | [56] |

| CF/GO-epoxy | Zoltek Panex carbon fiber | GO/ER 5300 epoxy resin | Fiber modified | Vacuum-assisted resin infusion molding | 0.34 | 0.561 | [67] |

| Composite | Fiber | Matrix | Modification Type | Processing Technique | Viscoelastic Properties (without Functionalization) | Viscoelastic Properties (with Functionalization) | References |

|---|---|---|---|---|---|---|---|

| CF/GO/PI | IM7 8552 carbon fiber | Laser-induced GO array/Polyimide substrate | Matrix modified | Manual pressured roller | Storage modulus (E’)-109 GPa Loss modulus (E’’)-2.3 GPa Tg-210 °C | Storage modulus (E’)-100 GPa Loss modulus (E’’)-3.5 GPa Tg-240 °C | [12] |

| LBL 10 Go/CF/PP | Carbon fiber | Polypropylene | Fiber modified | Knotting-melting | Storage modulus (E’)-6.03 GPa Loss modulus (E’’)-452.3 MPa Tg-8.12 °C | Storage modulus (E’)-7.09 GPa Loss modulus (E’’)-571.1 MPa Tg-10.48 °C | [39] |

| rGO/CF/epoxy | 0.2 wt.% GO/Plain weave carbon cloth | LAPOX C51 epoxy resin and lapox AH-428 hardener | Fiber modified | Vacuum-assisted resin transfer molding | Storage modulus (E’)-5327 GPa Loss modulus (E’’)-57 GPa Tg-47 °C | Storage modulus (E’)-7525 GPa Loss modulus (E’’)-63 GPa Tg-59 °C | [58] |

| CF/GO/epoxy | CJ20T carbon fiber | 6002 epoxy resin and HARTCURE-10 curing agent | Epoxy modified | Hand lay-up | Storage modulus (E’)-135 GPa Loss modulus (E’’)-87 GPa Tg-41 °C | Storage modulus (E’)-150 GPa Loss modulus (E’’)-100 GPa Tg-54 °C | [55] |

| PEI-FGO/epoxy/CF | Plain weave carbon cloth | LAPOX C51 epoxy resin and lapox AH-428 hardener | Fiber modified | Vacuum-assisted resin transfer molding | Storage modulus (E’)-302 GPa Loss modulus (E’’)-34 GPa Tg-43 °C | Storage modulus (E’)-410 GPa Loss modulus (E’’)-49 GPa Tg-58 °C | [57] |

| Salinized GO-CF/epoxy | 0.5 wt.% GO/T700S carbon fiber | HS5392 epoxy resin | Fiber modified | Resin transfer molding | Storage modulus (E’)-37 GPa Tg-97 °C | Storage modulus (E’)-40 GPa Tg-109 °C | [36] |

| GO-CF/epoxy | 0.3 wt.% GO/T300 carbon fiber | LY556 epoxy resin and TETA hardener | Fiber modified | Hand lay-up | Storage modulus (E’)-27.9 GPa Tg-108.7 °C | Storage modulus (E’)-32.5 GPa Tg-123.9 °C | [65] |

| GO-CF/epoxy | 0.5 wt.% GO/T700 carbon fiber | PPBES resin | Fiber modified | Solution impregnation | Storage modulus (E’)-34.3 GPa Tg-187 °C | Storage modulus (E’)-44.5 GPa Tg-250 °C | [78] |

| GO-CF/epoxy | 1 wt.% GO/Carbon fiber | DER331 epoxy resin | Fiber modified | Mold pressing | Storage modulus (E’)-85 GPa Tg-123 °C | Storage modulus (E’)-120 GPa Tg-175 °C | [79] |

| Property | Tensile Strength | Elastic Modulus | Elongation at Rupture | Density | Thermal Coefficient of Expansion | Poisson’s Ratio |

|---|---|---|---|---|---|---|

| Steel cable | 1670 N/mm2 | 205,000 N/mm2 | 6.0% | 7850 kg/m3 | 1.2 × 10−5 K−1 | 0.3 |

| CFRP Cable | 2700 N/mm2 | 160,000 N/mm2 | 1.6% | 1600 kg/m3 | 0.2 × 10−6 K−1 | 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharma, H.; Kumar, A.; Rana, S.; Guadagno, L. An Overview on Carbon Fiber-Reinforced Epoxy Composites: Effect of Graphene Oxide Incorporation on Composites Performance. Polymers 2022, 14, 1548. https://doi.org/10.3390/polym14081548

Sharma H, Kumar A, Rana S, Guadagno L. An Overview on Carbon Fiber-Reinforced Epoxy Composites: Effect of Graphene Oxide Incorporation on Composites Performance. Polymers. 2022; 14(8):1548. https://doi.org/10.3390/polym14081548

Chicago/Turabian StyleSharma, Harsh, Ajay Kumar, Sravendra Rana, and Liberata Guadagno. 2022. "An Overview on Carbon Fiber-Reinforced Epoxy Composites: Effect of Graphene Oxide Incorporation on Composites Performance" Polymers 14, no. 8: 1548. https://doi.org/10.3390/polym14081548

APA StyleSharma, H., Kumar, A., Rana, S., & Guadagno, L. (2022). An Overview on Carbon Fiber-Reinforced Epoxy Composites: Effect of Graphene Oxide Incorporation on Composites Performance. Polymers, 14(8), 1548. https://doi.org/10.3390/polym14081548