Ultra-Broadband and Compact TM-Pass Polarizer Based on Graphene-Buried Polymer Waveguide

Abstract

:1. Introduction

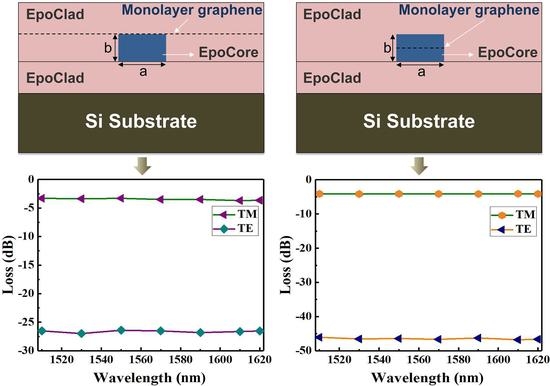

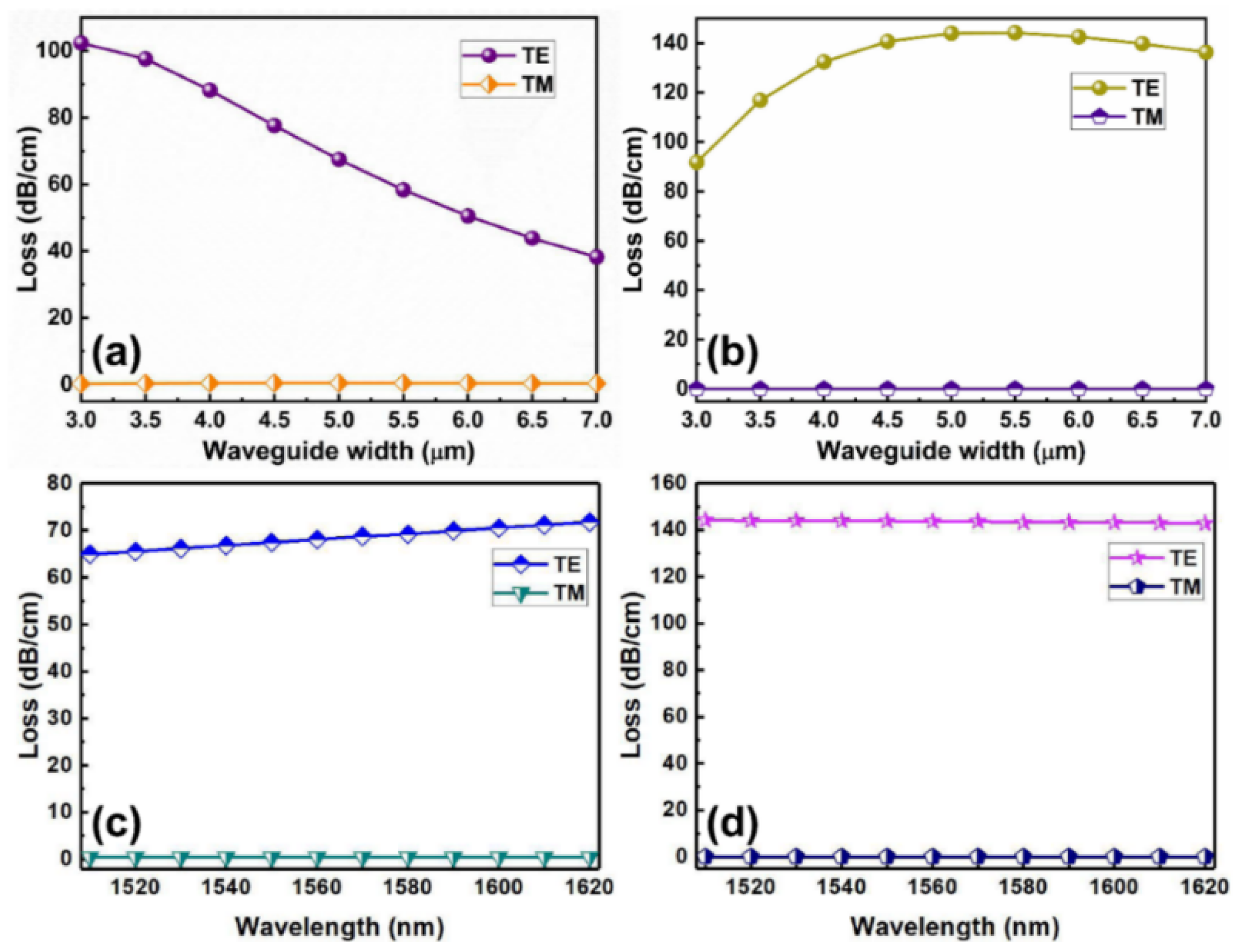

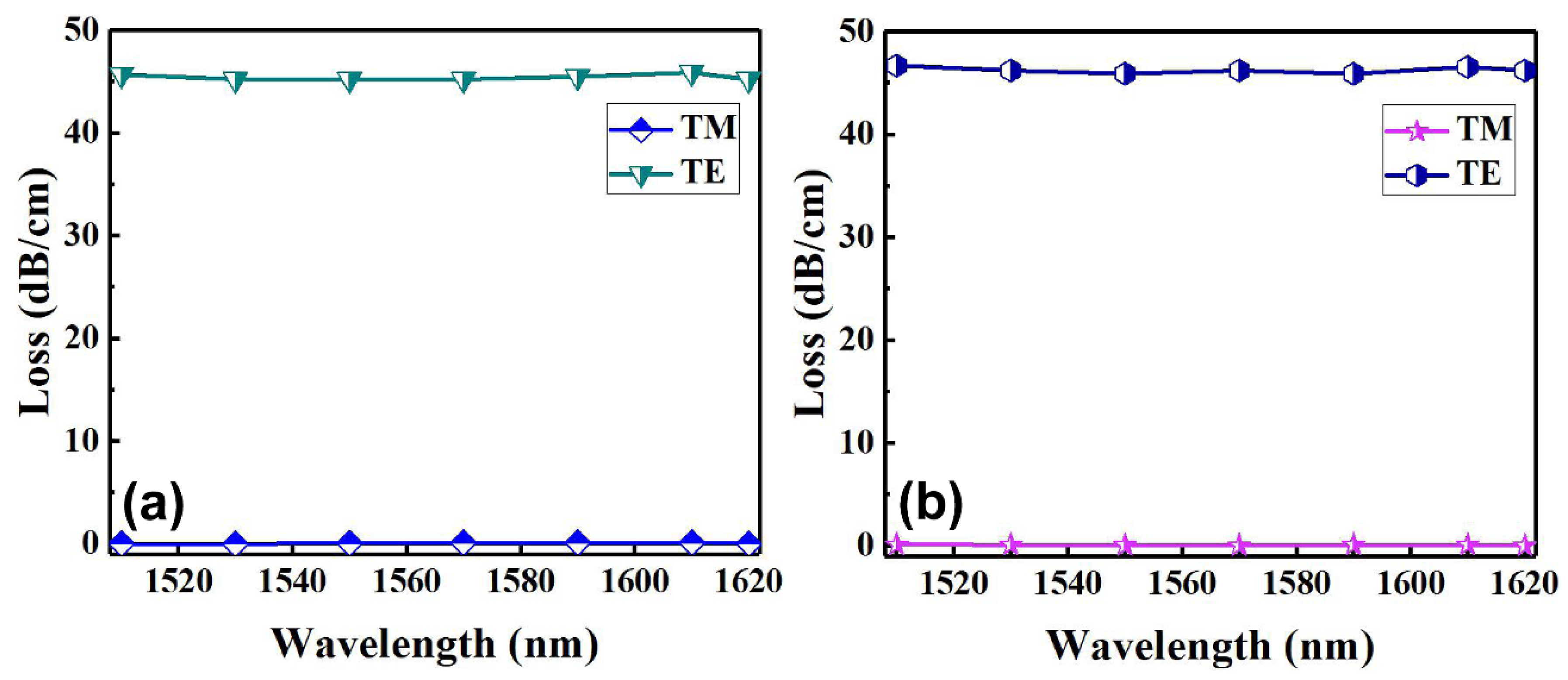

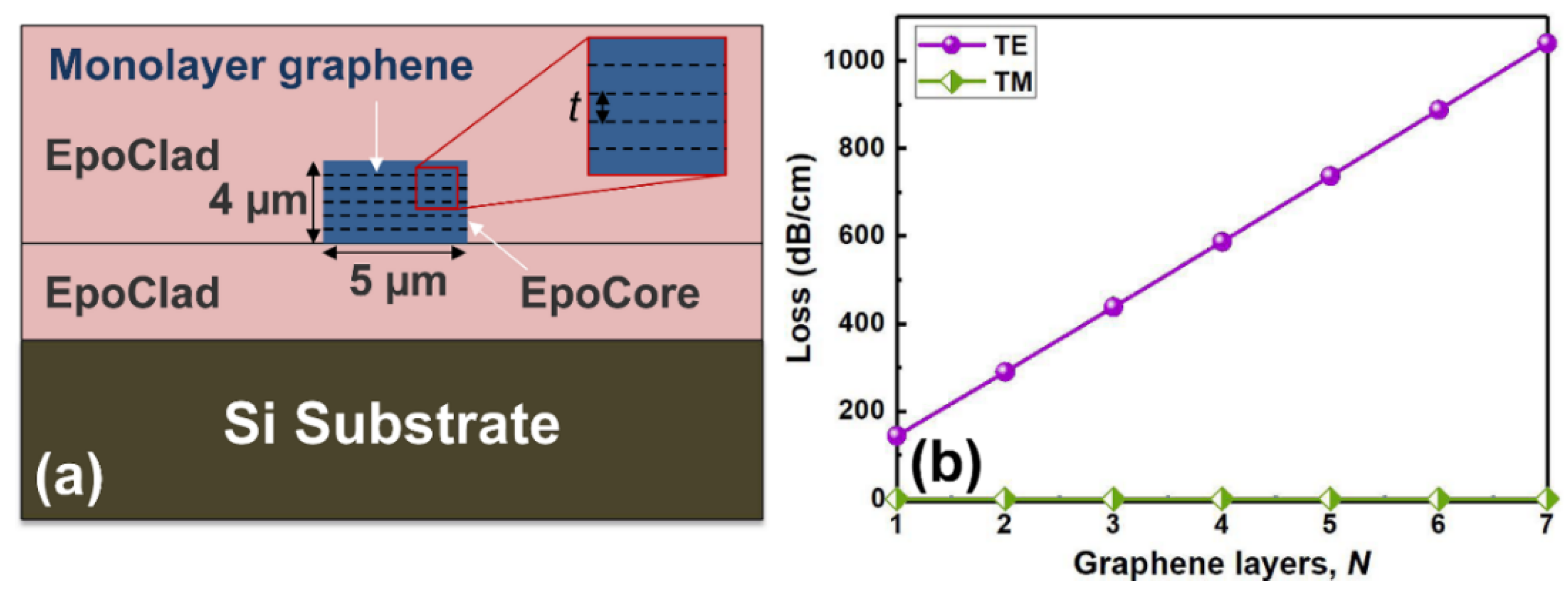

2. Device Design and Simulation

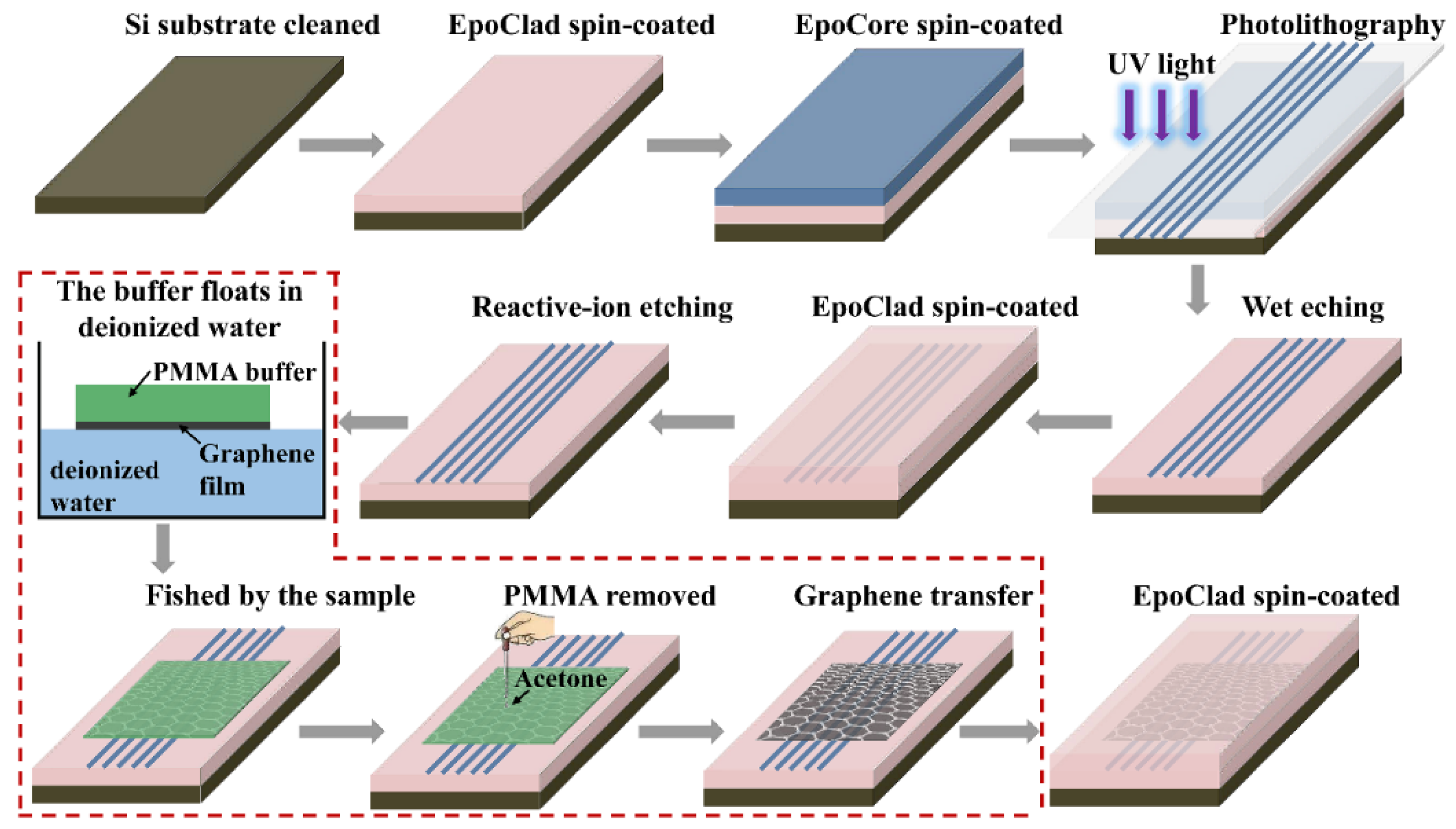

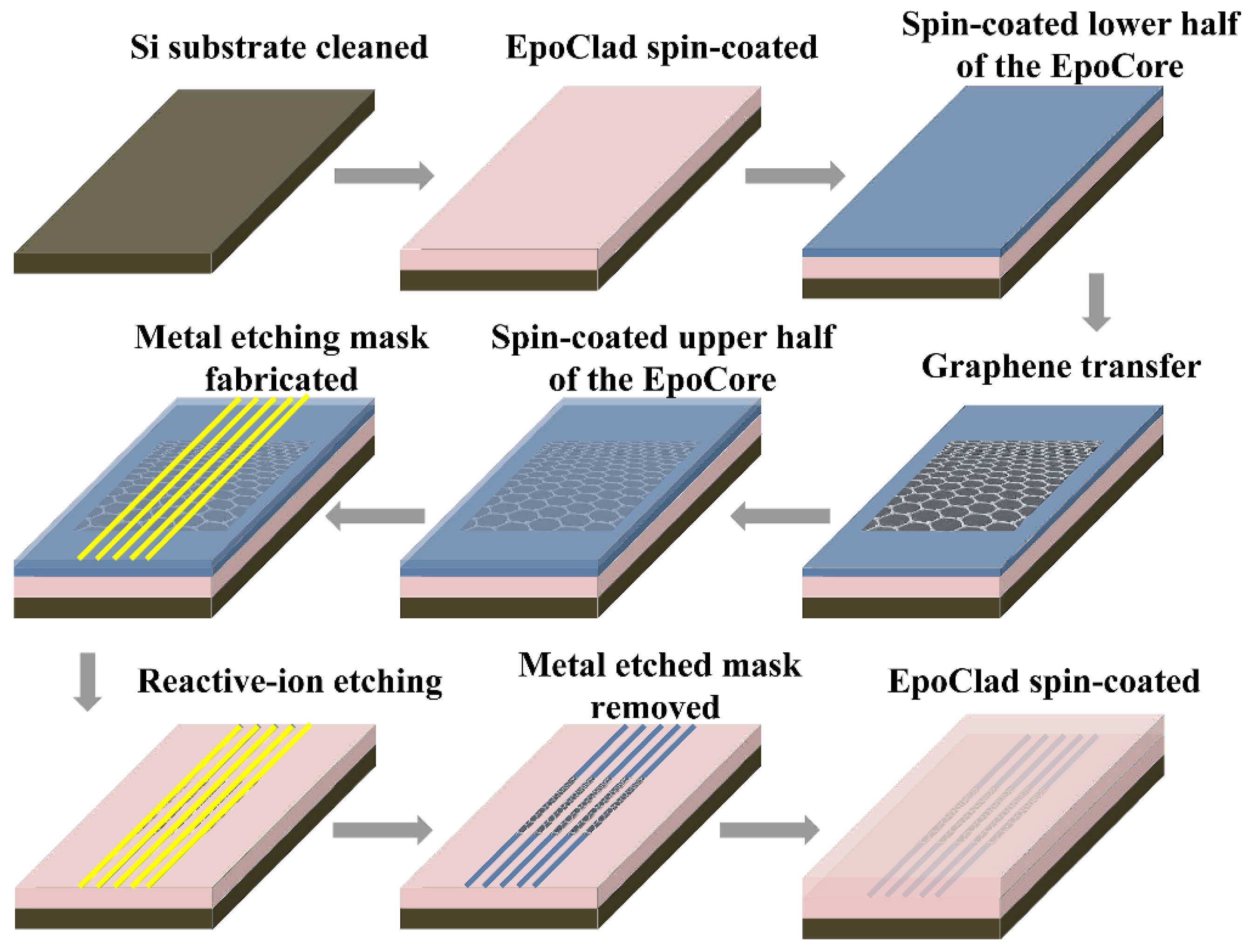

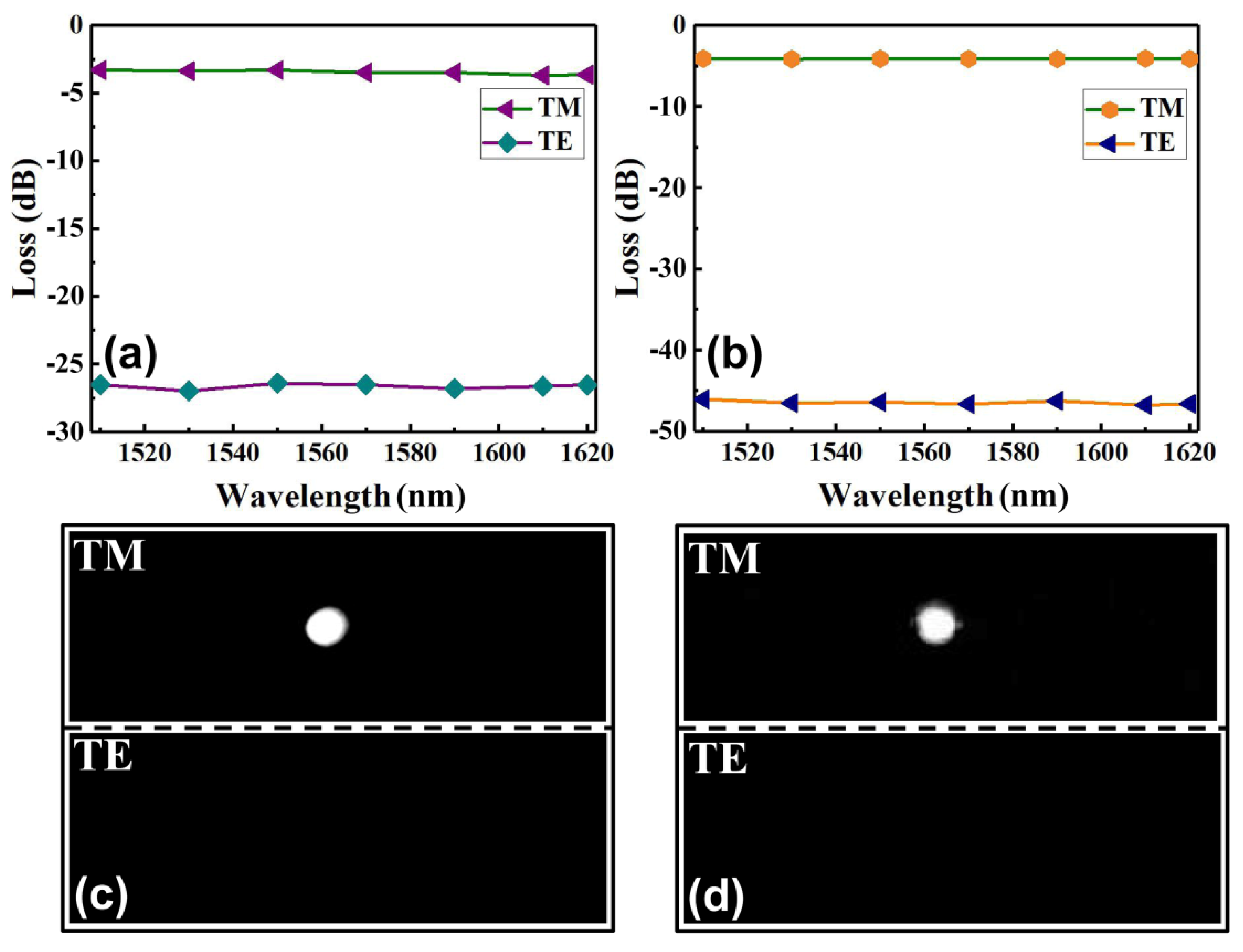

3. Device Fabrication and Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, C.H.; Pang, L.; Tsai, C.H.; Levy, U.; Fainman, Y. Compact and integrated TM-pass waveguide polarizer. Opt. Express 2015, 13, 5347–5352. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abadia, N.; Saber, M.G.; Bello, F.; Samani, A.; El-Fiky, E.; Wang, Y.; Donegan, J.F.; Plant, D.V. CMOS-compatible multi-band plasmonic TE-pass polarizer. Opt. Express 2018, 26, 30292–30304. [Google Scholar] [CrossRef] [PubMed]

- Bao, Q.L.; Zhang, H.; Wang, B.; Ni, Z.H.; Lim, C.H.Y.X.; Wang, Y.; Tang, D.Y.; Loh, K.P. Broadband graphene polarizer. Nature Photonics 2011, 5, 411–415. [Google Scholar] [CrossRef]

- Zhou, F.; Du, W. A graphene-based all-fiber TE/TM switchable polarizer. J. Opt. 2018, 20, 035401. [Google Scholar] [CrossRef]

- Butt, M.A.; Khonina, S.N.; Kazanskiy, N.L. 2D-Photonic crystal heterostructures for the realization of compact photonic devices. Photonics Nanostruct. Fundam. Appl. 2021, 44, 100903. [Google Scholar] [CrossRef]

- Rahman, B.M.A.; Obayya, S.S.A.; Boonthittanont, W.; Heaton, J.M. Novel Polarization-Maintaining Semiconductor Waveguide. IEEE Photonics Technol. Lett. 2004, 16, 807–809. [Google Scholar] [CrossRef]

- Qiu, F.; Spring, A.M.; Maeda, D.; Ozawa, M.A.; Odoi, K.; Aoki, I.; Otomo, A.; Yokoyama, S. TiO2 ring-resonator-based EO polymer modulator. Opt. Express 2014, 22, 14101–14107. [Google Scholar] [CrossRef]

- Eng, D.L.K.; Kozacik, S.T.; Kosilkin, I.V.; Wilson, J.P.; Ross, D.D.; Shi, S.Y.; Dalton, L.; Olbricht, B.C.; Prather, D.W. Simple Fabrication and Processing of an All-Polymer Electrooptic Modulator. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 190–195. [Google Scholar] [CrossRef]

- Chu, R.; Guan, C.Y.; Yang, J.; Zhu, Z.; Li, P.; Shi, J.H.; Tian, P.X.; Yuan, L.B.; Brambilla, G. High extinction ratio D-shaped fiber polarizers coated by a double graphene/PMMA stack. Opt. Express 2017, 25, 13278–13285. [Google Scholar] [CrossRef]

- Xu, H.N.; Shi, Y.C. On-chip silicon TE-pass polarizer based on asymmetrical directional couplers. IEEE Photonics Technol. Lett. 2017, 29, 861–864. [Google Scholar] [CrossRef]

- Ying, Z.F.; Wang, G.H.; Zhang, X.P.; Huang, Y.; Ho, H.P.; Zhang, Y.X. Ultracompact TE-pass polarizer based on a hybrid plasmonic waveguide. IEEE Photonics Technol. Lett. 2015, 27, 201–204. [Google Scholar] [CrossRef]

- Yu, W.Q.; Dai, S.X.; Zhao, Q.F.; Li, J.Y.; Liu, J.G. Wideband and compact TM-pass polarizer based on hybrid plasmonic grating in LNOI. Opt. Express 2019, 27, 34857–34863. [Google Scholar] [CrossRef] [PubMed]

- Sinha, R.K.; Kalra, Y. Design of optical waveguide polarizer using photonic band gap. Opt. Express 2006, 14, 10790–10794. [Google Scholar] [CrossRef]

- Ni, B.; Xiao, J.B. Subwavelength-grating-based compact and broadband TE-pass polarizer for slot waveguides on a SOI platform. J. Opt. Soc. Amer. B 2019, 36, 2126–2133. [Google Scholar] [CrossRef]

- Ni, B.; Xiao, J.B. Broadband TE-pass slot waveguide polarizer using an asymmetrical directional coupler. Appl. Opt. 2018, 57, 4032–4038. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Zhu, S.Y.; Zhang, H.J.; Liow, T.Y.; Lo, G.Q. CMOS compatible horizontal nanoplasmonic slot waveguides TE-pass polarizer on silicon-on-insulator platform. Opt. Express 2013, 21, 12790–12796. [Google Scholar] [CrossRef] [PubMed]

- Yin, X.; Ke, X.M.; Chen, L.; Zhang, T.; Li, J.H.; Zhu, Z.S.; Li, X. Ultra-broadband TE-pass polarizer using a cascade of multiple few-Layer graphene embedded silicon waveguides. J. Lightwave Technol. 2016, 34, 3181–3187. [Google Scholar] [CrossRef]

- Yin, X.; Zhang, T.; Chen, L.; Li, X. Ultra-compact TE-pass polarizer with graphene multilayer embedded in a silicon slot waveguide. Opt. Lett. 2015, 40, 1733–1736. [Google Scholar] [CrossRef]

- Dangel, R.; Hofrichter, J.; Horst, F.; Jubin, D.; Porta, A.L.; Meier, N.; Soganci, I.M.; Weiss, J.; Offrein, B.J. Polymer waveguides for electro-optical integration in data centers and high-performance computers. Opt. Express 2019, 23, 4736–4750. [Google Scholar] [CrossRef]

- Katopodis, V.; Groumas, P.; Zhang, Z.; Dinu, R.; Miller, E.; Konczykowska, A.; Dupuy, J.Y.; Beretta, A.; Dede, A.; Choi, J.H.; et al. Polymer enabled 100 Gbaud connectivity for datacom applications. Opt. Commun. 2016, 362, 13–21. [Google Scholar] [CrossRef]

- Kim, J.T.; Choi, C.G. Graphene-based polymer waveguide polarizer. Opt. Express 2011, 20, 3556–3562. [Google Scholar] [CrossRef] [PubMed]

- Li, R.Z.; Zhang, L.J.; Hu, W.; Wang, L.D.; Tang, J.; Zhang, T. Flexible TE-Pass Polymer Waveguide Polarizer. With Low Bending Loss. IEEE Photon. Techno. Lett. 2016, 28, 2601–2604. [Google Scholar] [CrossRef]

- Khan, M.U.; Justice, J.; Petäjä, J.; Korhonen, T.; Boersma, A.; Wiegersma, S.; Karppinen, M.; Corbett, B. Multi-level single mode 2D polymer waveguide optical interconnects using nano-imprint lithography. Opt. Express 2015, 23, 14630–14639. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Ma, L.; He, Z.Y. 3D polymer directional coupler for on-board optical interconnects at 1550 nm. Opt. Express 2018, 26, 16344–16351. [Google Scholar] [CrossRef] [PubMed]

- Lian, T.H.; Yang, K.D.; Wang, X.B.; Jiang, M.H.; Sun, S.J.; Niu, D.H.; Zhang, D.M. Electro-Absorption Optical Modulator Based on Graphene-Buried Polymer Waveguides. IEEE Photon. J. 2020, 12, 6601610. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, B.; Lian, T.; Sun, S.; Zhu, M.; Che, Y.; Sun, X.; Wang, X.; Zhang, D. Ultra-Broadband and Compact TM-Pass Polarizer Based on Graphene-Buried Polymer Waveguide. Polymers 2022, 14, 1481. https://doi.org/10.3390/polym14071481

Lin B, Lian T, Sun S, Zhu M, Che Y, Sun X, Wang X, Zhang D. Ultra-Broadband and Compact TM-Pass Polarizer Based on Graphene-Buried Polymer Waveguide. Polymers. 2022; 14(7):1481. https://doi.org/10.3390/polym14071481

Chicago/Turabian StyleLin, Baizhu, Tianhang Lian, Shijie Sun, Mu Zhu, Yuanhua Che, Xueqing Sun, Xibin Wang, and Daming Zhang. 2022. "Ultra-Broadband and Compact TM-Pass Polarizer Based on Graphene-Buried Polymer Waveguide" Polymers 14, no. 7: 1481. https://doi.org/10.3390/polym14071481

APA StyleLin, B., Lian, T., Sun, S., Zhu, M., Che, Y., Sun, X., Wang, X., & Zhang, D. (2022). Ultra-Broadband and Compact TM-Pass Polarizer Based on Graphene-Buried Polymer Waveguide. Polymers, 14(7), 1481. https://doi.org/10.3390/polym14071481