High Performance Polymer Composites: A Role of Transfer Films in Ensuring Tribological Properties—A Review †

Abstract

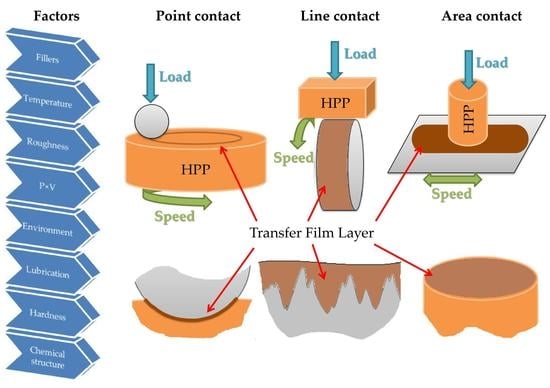

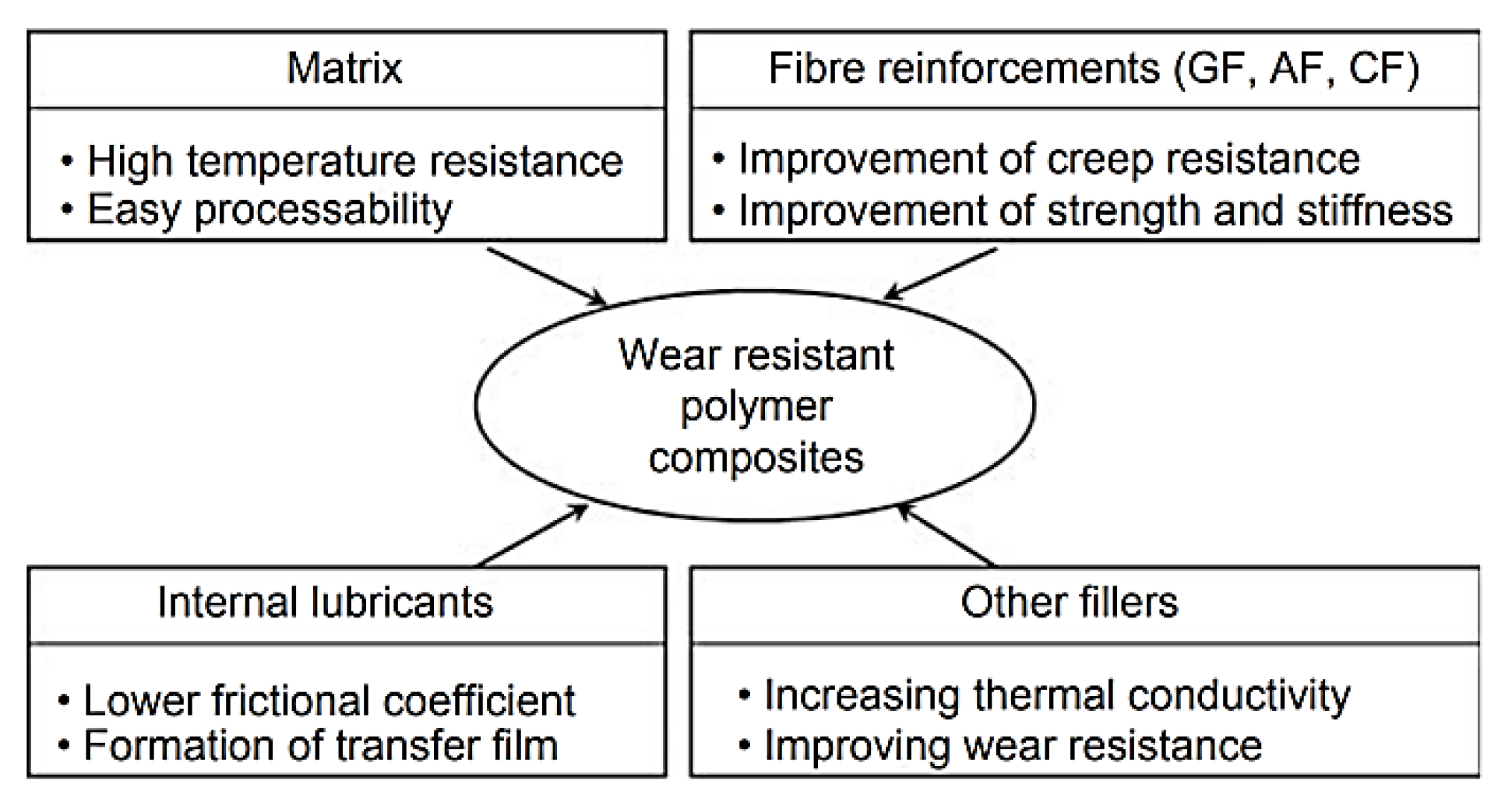

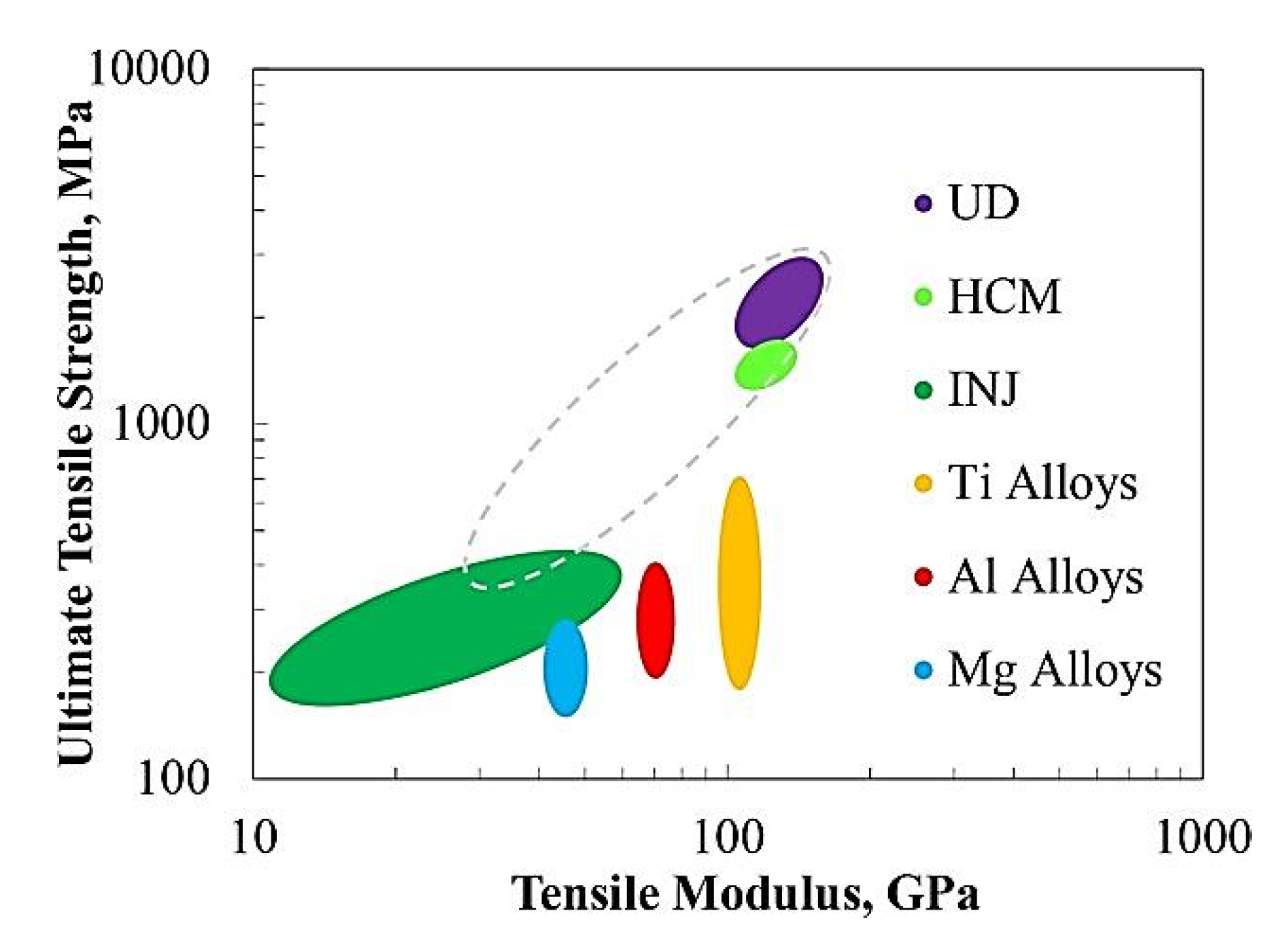

1. Introduction

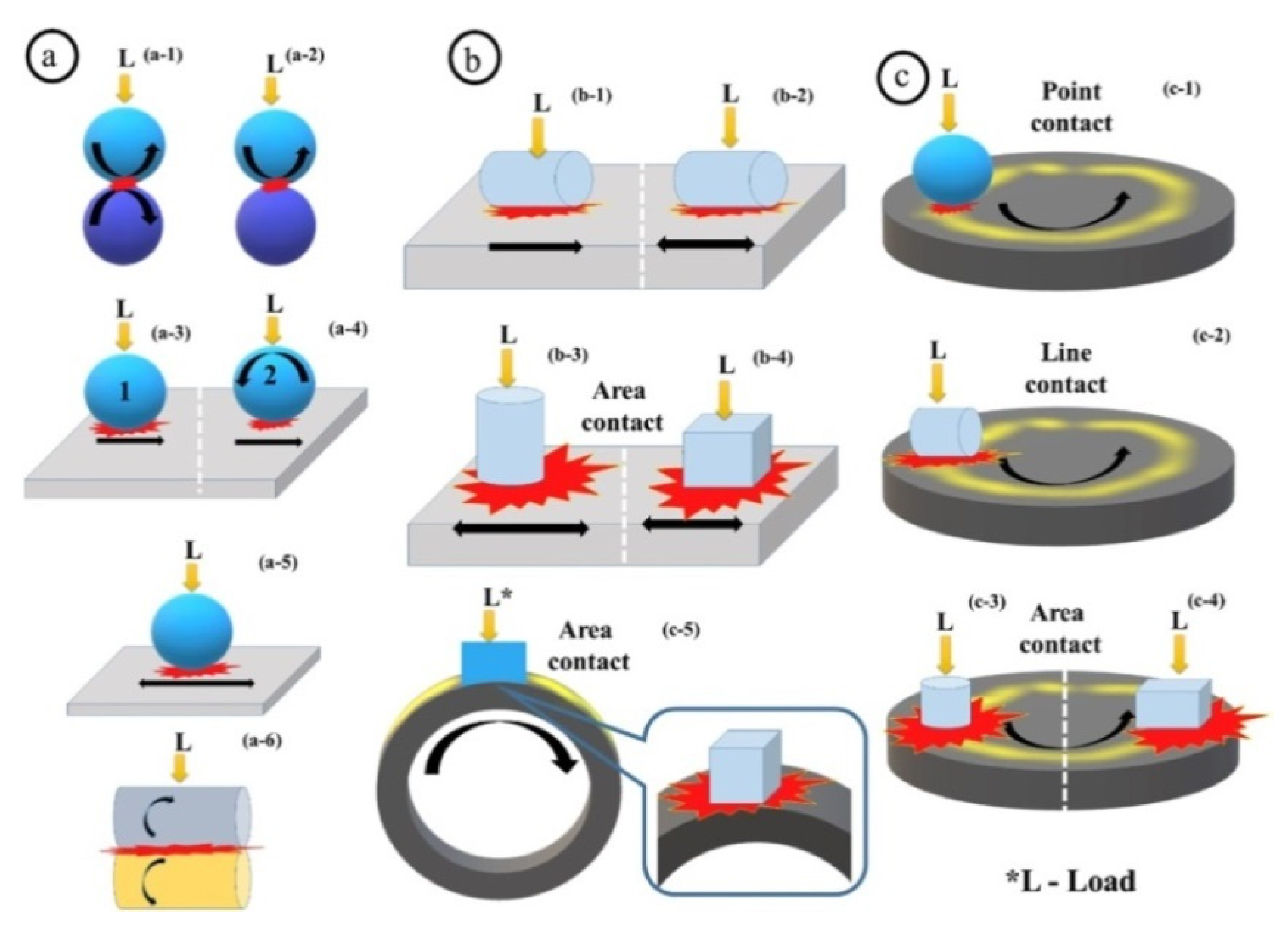

2. Point Contacts

2.1. Neat HPP

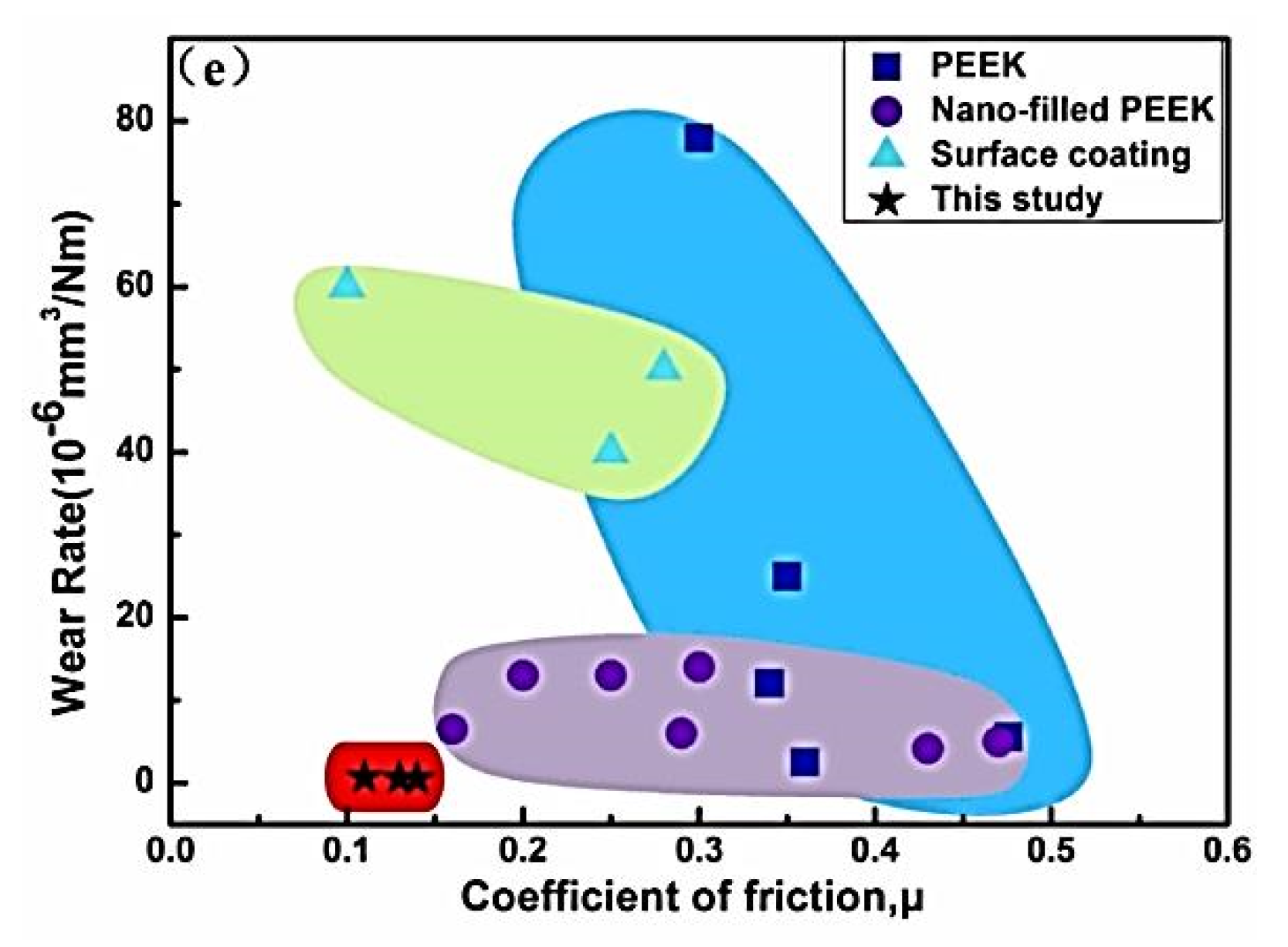

2.2. Reinforced HPP-Based Composites

2.3. Solid-Lubricant Fillers

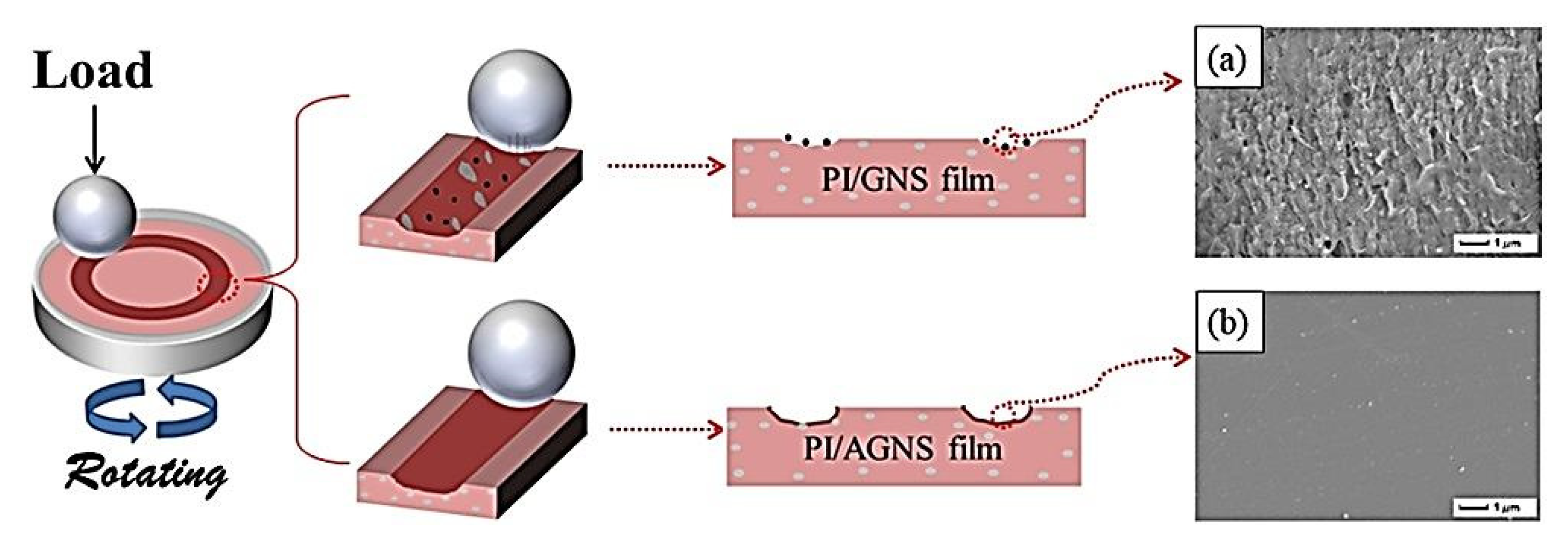

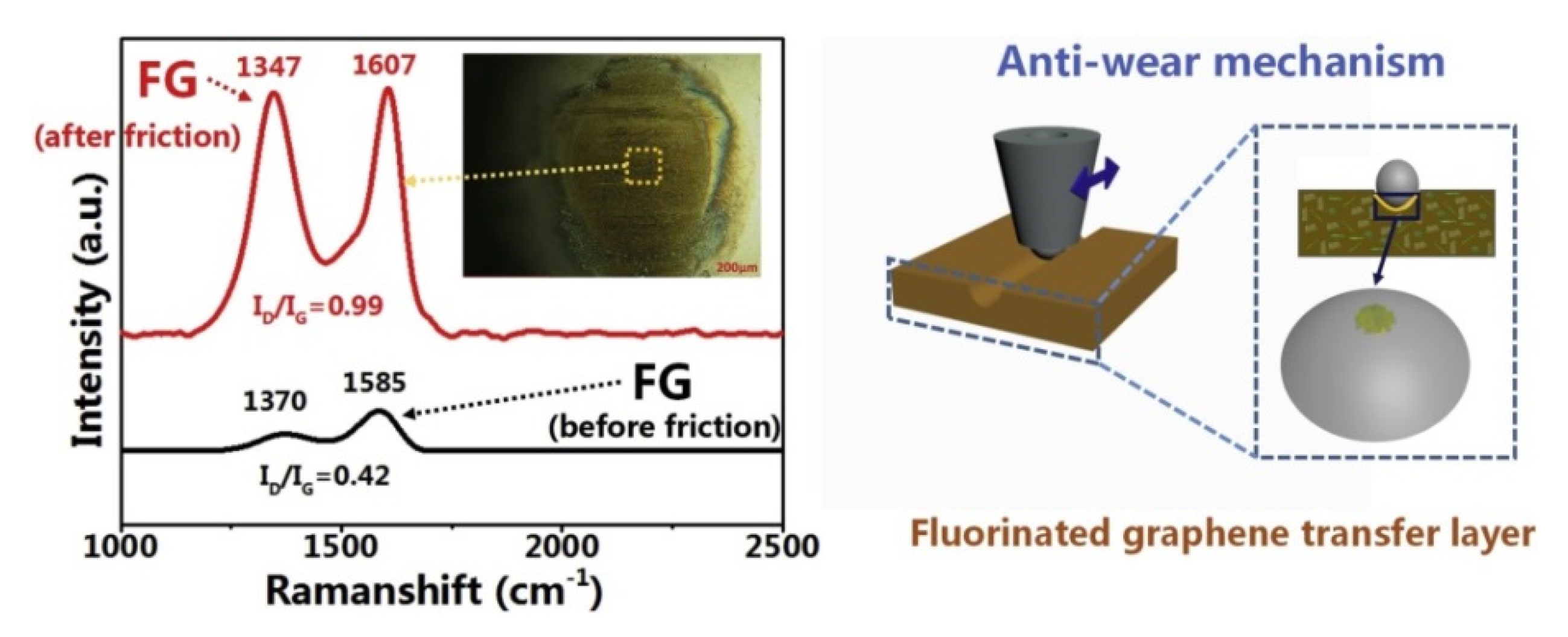

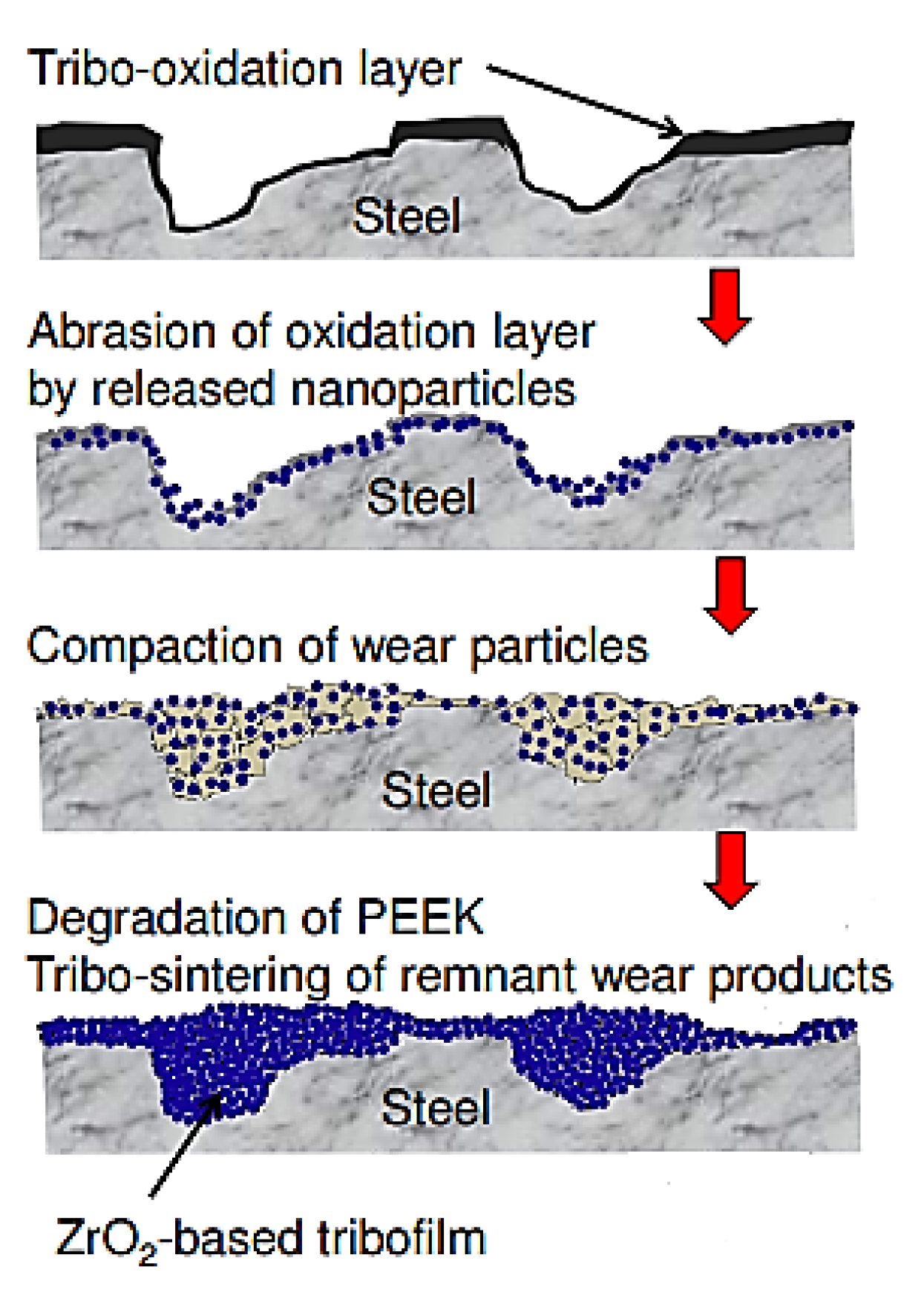

2.4. Nanofillers

3. Line Contacts

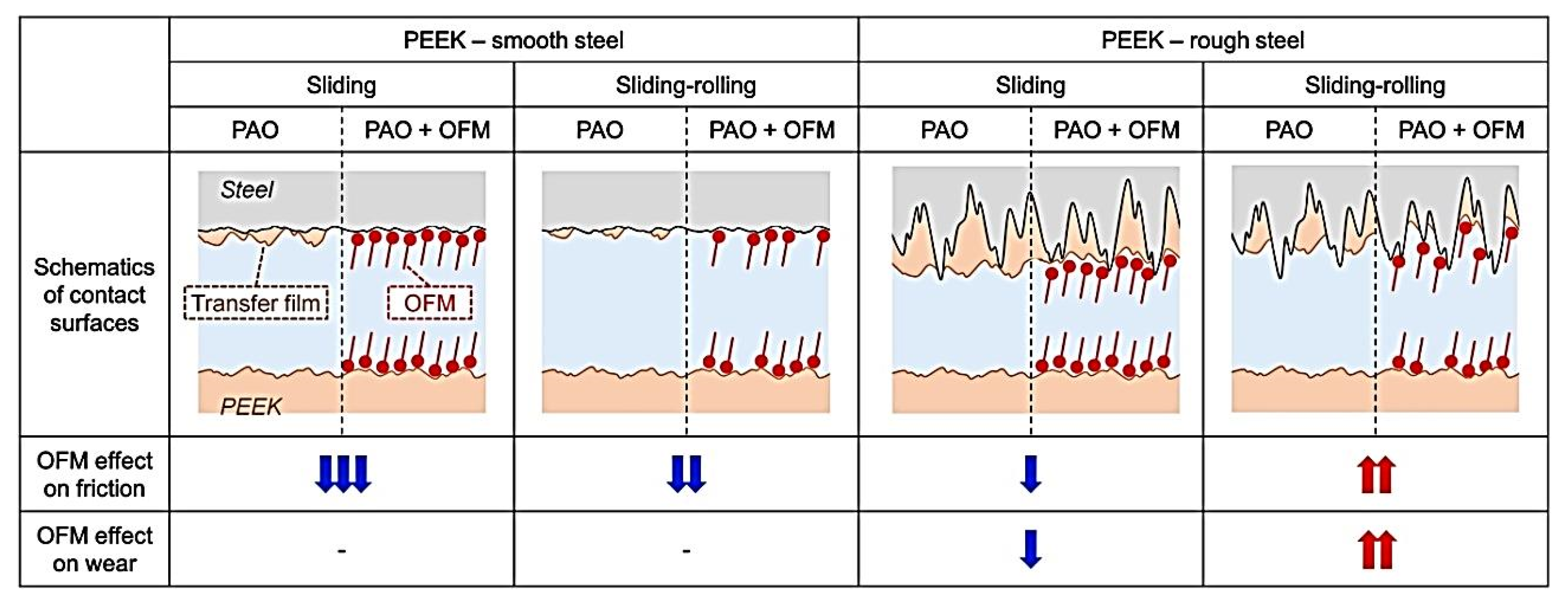

3.1. Neat HPPs

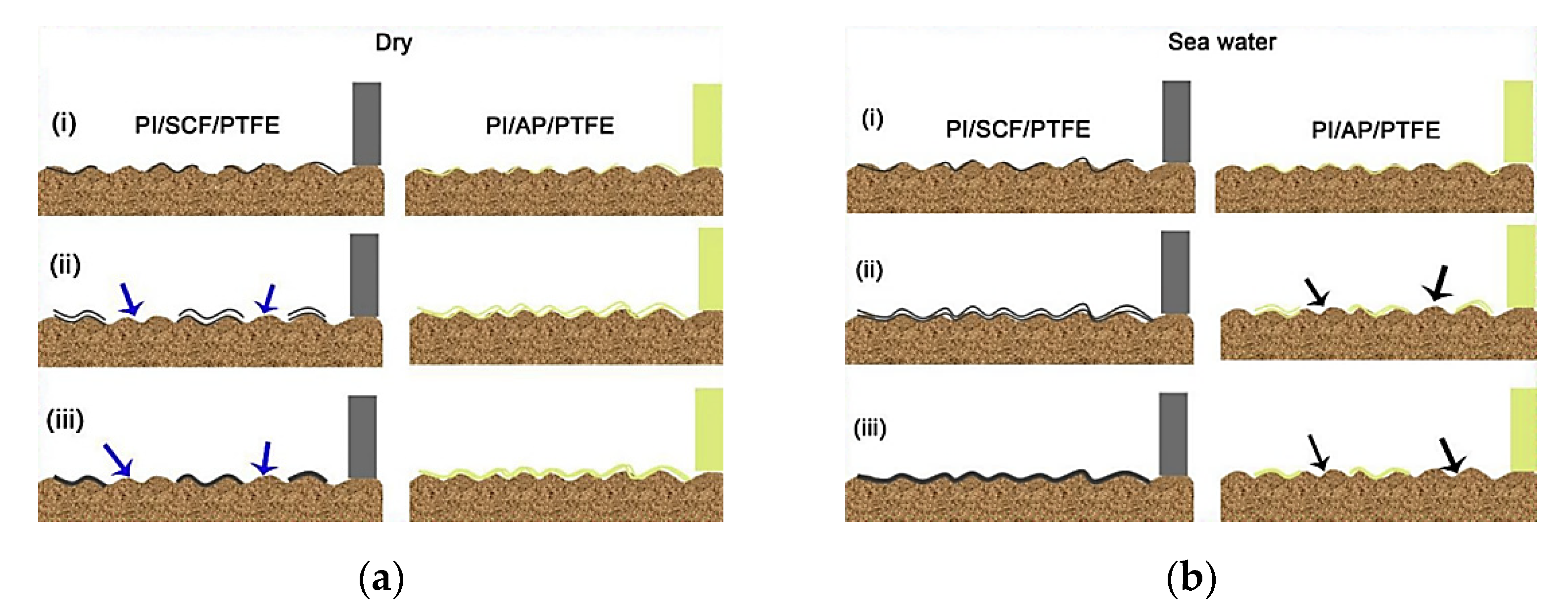

3.2. Polymer-Polymer Composites

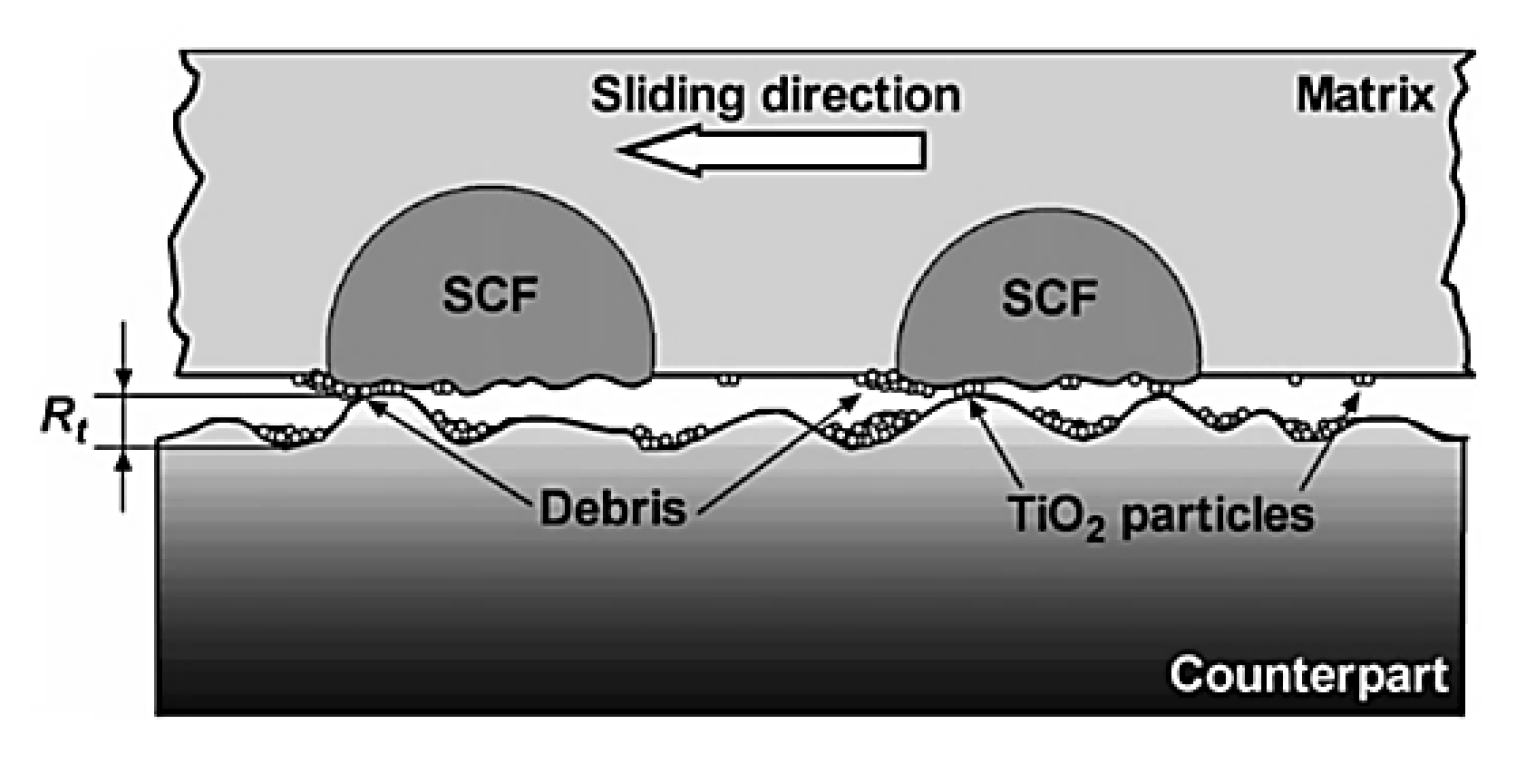

3.3. Fiber-Reinforced Two-Component Composites

3.4. Three-Component Reinforced Composites

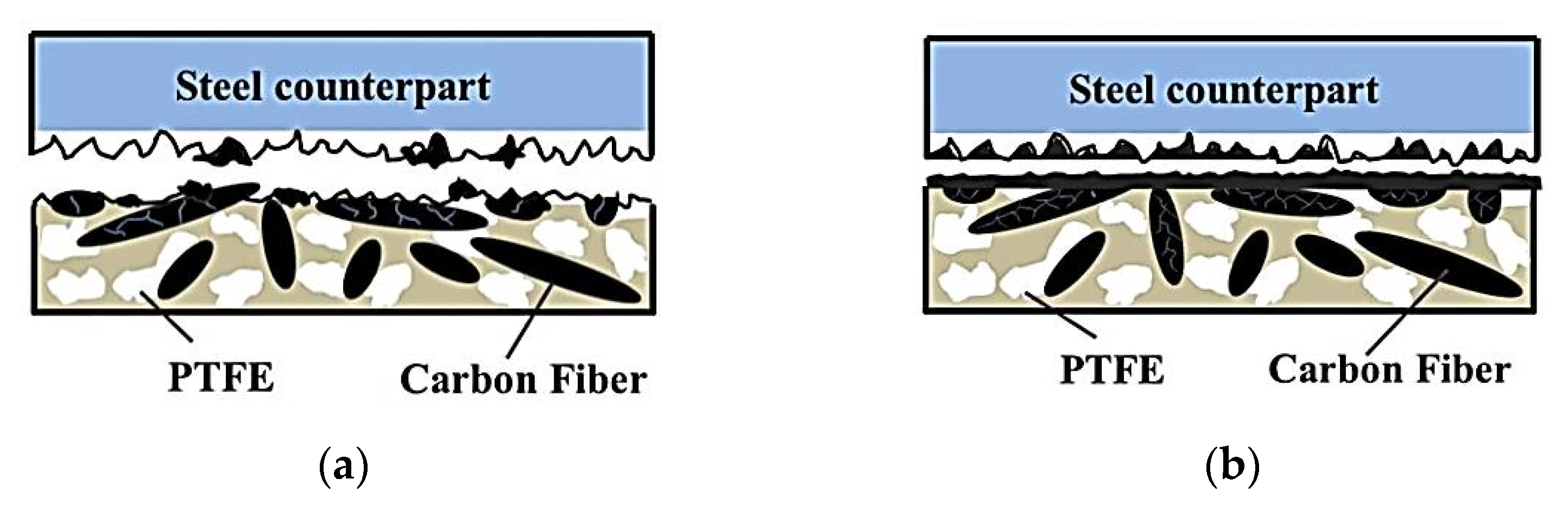

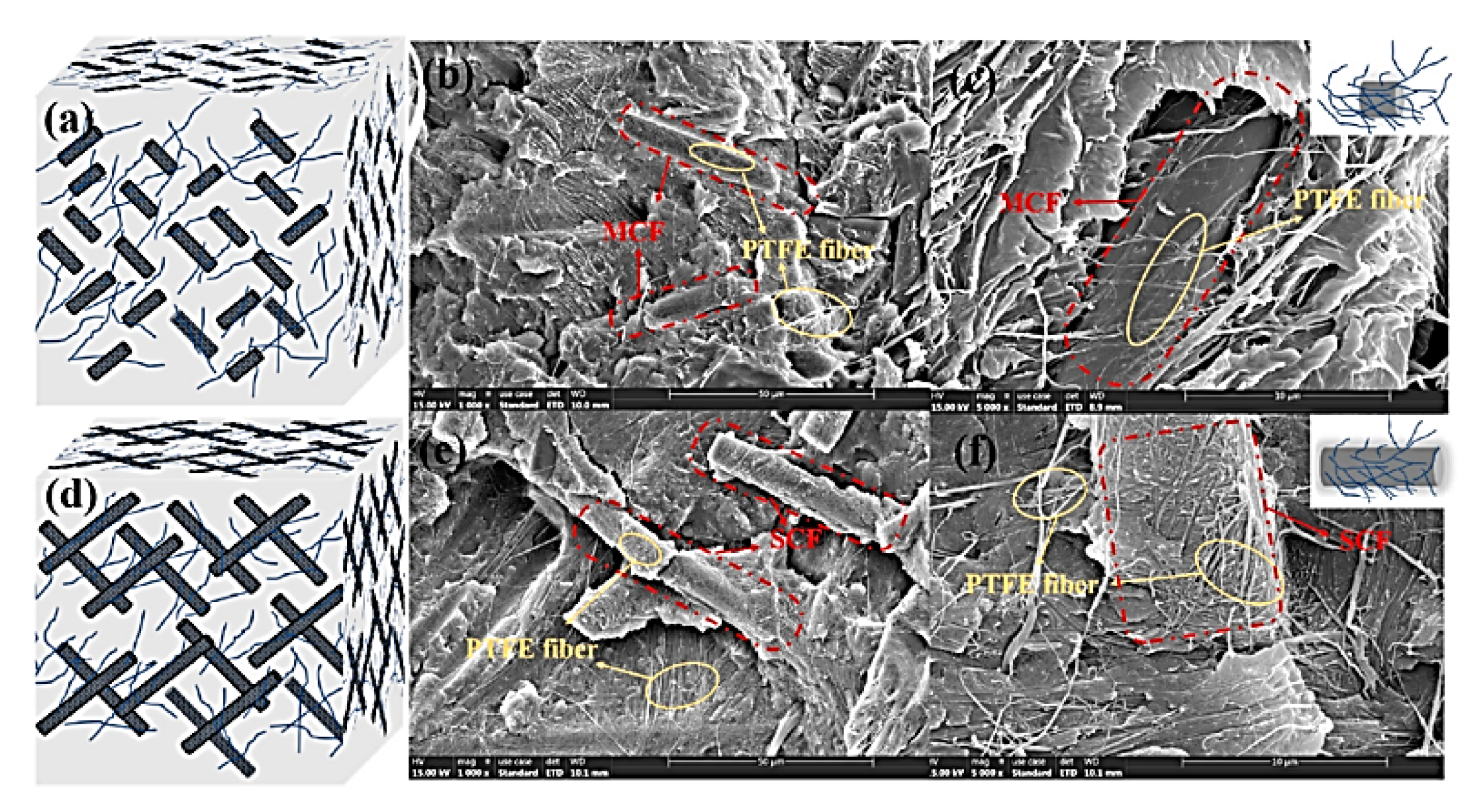

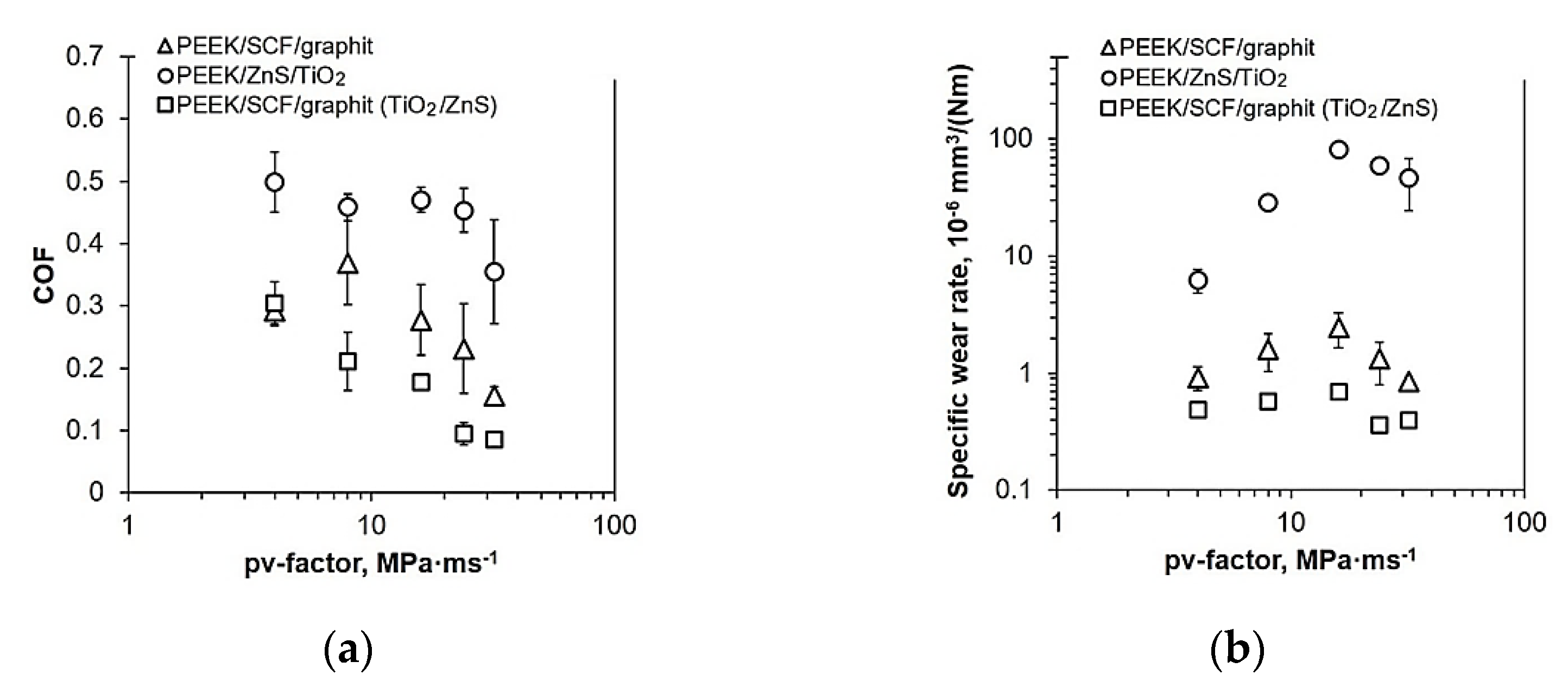

3.5. Multi-Component Reinforced Composites

3.6. Two-Component Nanocomposites

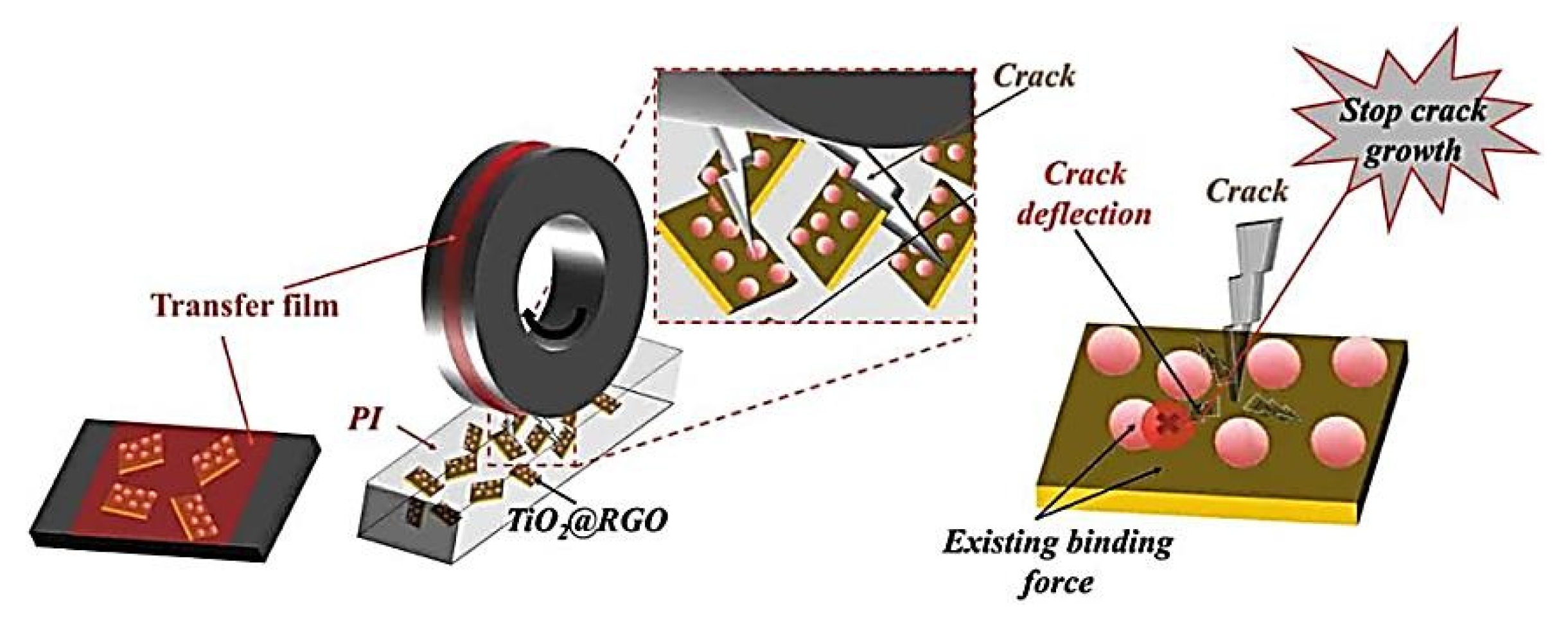

3.7. Three-Component Nanocomposites

3.8. Multicomponent Nanocomposites

4. Plane Contacts

4.1. Neat Polymers

4.2. Reinforced HPP-Based Composites

4.3. Solid Lubricants

4.4. Nanofillers

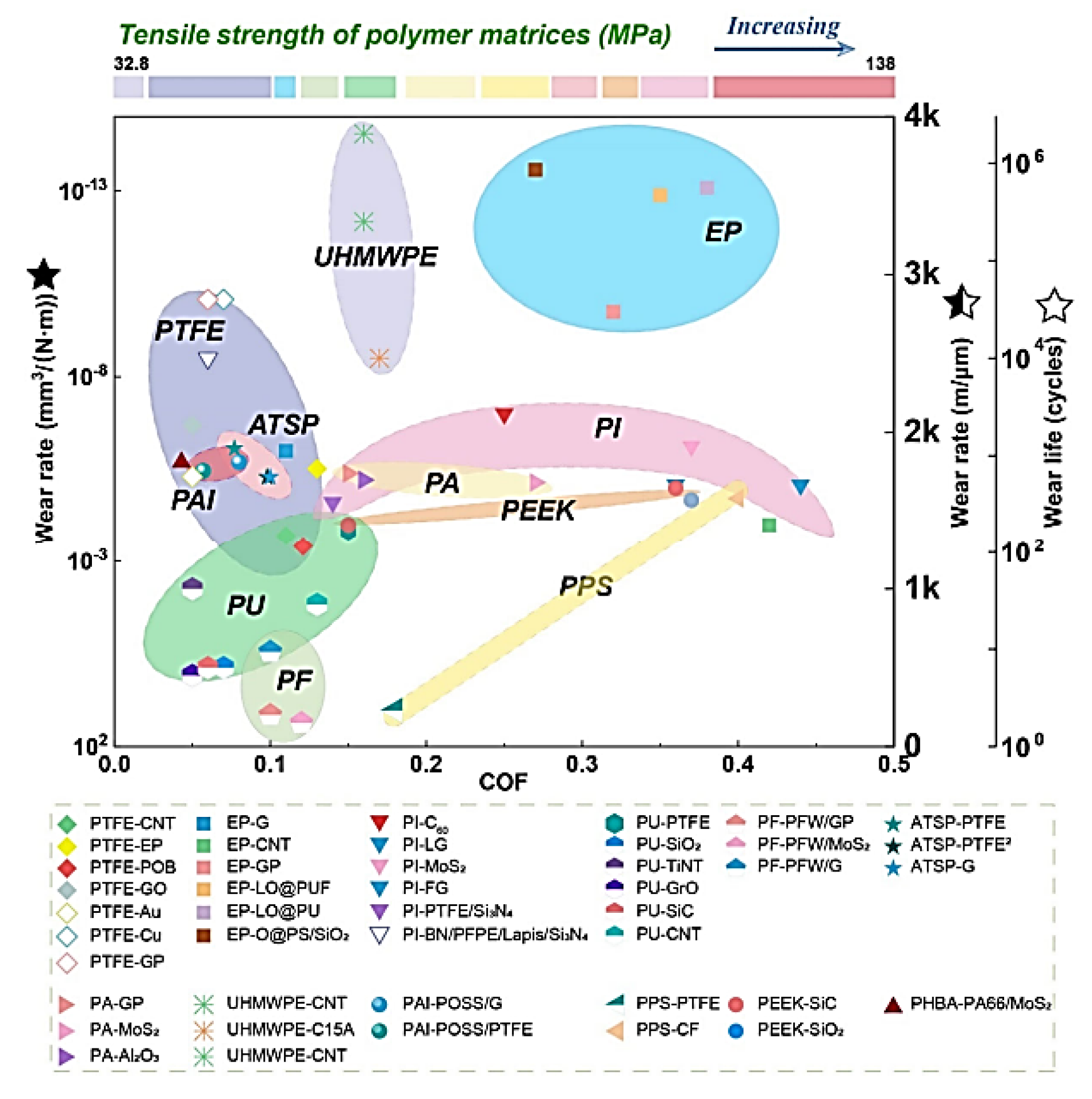

5. Discussion and Concluding Remarks

5.1. Point Contacts

5.2. Line Contacts

5.3. Flat (Area) Contacts

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ABS | acrylonitrile butadiene-styrene |

| AF | aramid fibers |

| AGNS | amine-functionalized graphene nanosheets |

| AM | additive manufacturing |

| APK | aliphatic polyketone |

| APTES | aminopropyltriethoxysilane |

| BF | basalt fibers |

| B-o-D | Ball-on-Disk |

| B-o-F | Ball-on-Flat |

| B-o-P | Ball-on-Prizm |

| CFc | carbon fabric |

| CF | carbon fiber |

| CNF | carbon nanofibers |

| CNT | carbon nanotube |

| CoF | coefficient of Friction |

| CSL | calf serum lubrication |

| DSF | dry sliding friction |

| DMS | dimethylsiloxane |

| EBA | ethylene butyl acrylate |

| EDS | energy dispersive X-ray spectroscopy |

| EG | expanded graphite |

| FG | fluorinated graphene |

| FGO | fluorinated graphene oxide |

| F-o-F | Flat-on-Flat |

| GFs | glass fibers |

| GN | graphene |

| GNPs | graphene nanoplatelets |

| Gr | graphite |

| HA | hydroxyapatite |

| HAP | hertzian average pressure |

| HPP | high performance polymers |

| ILFG | ionic liquid functionalized graphene |

| LF | loading force |

| LRV | linear reciprocating velocity |

| LWF | long woven fibers |

| MPS | mesoporous silica |

| MHS | maximum Hertzian stress |

| MWCNTs | multi-walled carbon nanotubes |

| N/D | no data |

| P | applied load |

| PA6 | polyamide 6 |

| PAEK | polyaryletherketone |

| PAI | polyamide-imide |

| PAN | polyacrylonitrile |

| PBI | polybenzimidizole |

| PC | polycarbonate |

| PEEK | polyetheretherketone |

| PEI | polyetherimide |

| PES | polyethersulfone |

| PET | polyethylene terephthalate |

| PI | polyimide |

| P-o-D | Pin-on-Disk |

| P-o-F | Pin-on-Flat |

| PPL | polyphenylene |

| PPS | polyphenylene sulfide |

| PPSU | polyphenylsulfone |

| PSU | polysulfone |

| PTCDA | perylene-3,4,9,10-tetracarboxylic acid dianhydride |

| PTFE | polytetrafluoroethylene |

| PTW | potassium titanate whiskers |

| PVDF | polyvinylidene fluoride |

| RF | reciprocating friction |

| RH | relative humidity |

| R-o-D | Ring-on-Disk |

| R-o-R | Ring-on-Ring |

| RR | rotation radius |

| RS | reciprocating sliding |

| RT | room temperature |

| SGF | short glass fibers |

| SCF | short carbon fiber |

| SEM | scanning electron microscopy |

| SL | solid lubricant |

| SROF | short randomly oriented fibers |

| SWL | sea water lubrication |

| TF | transfer film |

| V | sliding speed |

| UHMWPE | ultra-high molecular weight polyethylene |

| WL | water lubrication |

| WR | wear rate |

| XPS | X-ray photoelectron spectroscopy |

References

- Briscoe, B.J.; Sinha, S.K. Chapter 1—Tribological applications of polymers and their composites–past, present and future prospects. In Tribology of Polymeric Nanocomposites. Friction and Wear of Bulk Materials and Coatings, 2nd ed.; Friedrich, K., Schlarb, A., Eds.; Butterworth-Heinemann: Oxford, UK, 2013; pp. 1–22. [Google Scholar]

- Bahadur, S.; Schwartz, C. Chapter 2—The effect of nanoparticle fillers on transfer film formation and the tribological behavior of polymers. In Tribology of Polymeric Nanocomposites. Friction and Wear of Bulk Materials and Coatings, 2nd ed.; Friedrich, K., Schlarb, A., Eds.; Butterworth-Heinemann: Oxford, UK, 2013; pp. 23–48. [Google Scholar]

- Chang, L.; Zhang, Z.; Ye, L.; Friedrich, K. Chapter 3—Synergistic effects of nanoparticles and traditional tribofillers on sliding wear of polymeric hybrid composites. In Tribology of Polymeric Nanocomposites. Friction and Wear of Bulk Materials and Coatings, 2nd ed.; Friedrich, K., Schlarb, A., Eds.; Butterworth-Heinemann: Oxford, UK, 2013; pp. 49–89. [Google Scholar]

- Padhan, M.; Marathe, U.; Bijwe, J. Tribology of Poly(etherketone) composites based on nano-particles of solid lubricants. Compos. Part B Eng. 2020, 201, 108323. [Google Scholar] [CrossRef]

- Wang, Q.; Pei, X. Chapter 4—The influence of nanoparticle fillers on the friction and wear behavior of polymer matrices. In Tribology of Polymeric Nanocomposites. Friction and Wear of Bulk Materials and Coatings, 2nd ed.; Friedrich, K., Schlarb, A., Eds.; Butterworth-Heinemann: Oxford, UK, 2013; pp. 91–118. [Google Scholar]

- Ashby, M.F. Materials Selection in Mechanical Design, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2011; p. 646. [Google Scholar]

- Ren, Y.; Zhang, L.; Xie, G.; Li, Z.; Chen, H.; Gong, H.; Xu, W.; Guo, D.; Luo, J. A review on tribology of polymer composite coatings. Friction 2021, 9, 429–470. [Google Scholar] [CrossRef]

- Kurdi, A.; Chang, L. Recent Advances in High Performance Polymers—Tribological Aspects. Lubricants 2019, 7, 2. [Google Scholar] [CrossRef]

- De Leon, A.C.C.; da Silva, Í.G.M.; Pangilinan, K.D.; Chen, Q.; Caldona, E.B.; Advincula, R.C. High performance polymers for oil and gas applications. React. Funct. Polym. 2021, 162, 104878. [Google Scholar] [CrossRef]

- Chen, G.; Mohanty, A.K.; Misra, M. Progress in research and applications of Polyphenylene Sulfide blends and composites with carbons. Compos. Part B Eng. 2021, 209, 108553. [Google Scholar] [CrossRef]

- Zuo, P.; Tcharkhtchi, A.; Shirinbayan, M.; Fitoussi, J.; Bakir, F. Overall Investigation of Poly (Phenylene Sulfide) from Synthesis and Process to Applications-A Review. Macromol. Mater. Eng. 2019, 304, 1800686. [Google Scholar] [CrossRef]

- Theivendran, K.; Arshad, F.; Hanif, U.; Reito, A.; Griffin, X.; Foot, C.J. Carbon fibre reinforced PEEK versus traditional metallic implants for orthopaedic trauma surgery: A systematic review. J. Clin. Orthop. Trauma 2021, 23, 101674. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Zahedi, S.A.; Ismail, S.O.; Omigbodun, F.T. 3D printing of PEEK and its composite to increase biointerfaces as a biomedical material—A review. Colloids Surf. B 2021, 203, 111726. [Google Scholar] [CrossRef]

- Verma, S.; Sharma, N.; Kango, S.; Sharma, S. Developments of PEEK (Polyetheretherketone) as a biomedical material: A focused review. Eur. Polym. J. 2021, 147, 110295. [Google Scholar] [CrossRef]

- Alexakou, E.; Damanaki, M.; Zoidis, P.; Bakiri, E.; Mouzis, N.; Smidt, G.; Kourtis, S. PEEK High Performance Polymers: A Review of Properties and Clinical Applications in Prosthodontics and Restorative Dentistry. Eur. J. Prosthodont. Restor. Dent. 2019, 27, 113–121. [Google Scholar]

- Oladapo, B.I.; Zahedi, S.A.; Omigbodun, F.T. A systematic review of polymer composite in biomedical engineering. Eur. Polym. J. 2021, 154, 110534. [Google Scholar] [CrossRef]

- Ma, H.; Suonan, A.; Zhou, J.; Yuan, Q.; Liu, L.; Zhao, X.; Lou, X.; Yang, C.; Li, D.; Zhang, Y. PEEK (Polyether-ether-ketone) and its composite materials in orthopedic implantation. Arab. J. Chem. 2021, 14, 102977. [Google Scholar] [CrossRef]

- Singh, S.; Prakash, C.; Wang, H.; Yu, X.; Ramakrishna, S. Plasma treatment of polyether-ether-ketone: A means of obtaining desirable biomedical characteristics. Eur. Polym. J. 2019, 118, 561–577. [Google Scholar] [CrossRef]

- Veazey, D.; Hsu, T.; Gomez, E.D. Next generation high-performance carbon fiber thermoplastic composites based on polyaryletherketones. J. Appl. Polym. Sci. 2016, 134, 44441. [Google Scholar] [CrossRef]

- Liaw, D.J.; Wang, K.L.; Huang, Y.C.; Lee, K.R.; Lai, J.Y.; Ha, C.S. Advanced polyimide materials: Syntheses, physical properties and applications. Prog. Polym. Sci. 2012, 37, 907–974. [Google Scholar] [CrossRef]

- Ogbonna, V.E.; Popoola, P.I.; Popoola, O.M.; Adeosun, S.O. A review on recent advances on improving polyimide matrix nanocomposites for mechanical, thermal, and tribological applications: Challenges and recommendations for future improvement. J. Thermoplast. Compos. Mater. 2021, 089270572110079. [Google Scholar] [CrossRef]

- Ogbonna, V.E.; Popoola, A.P.I.; Popoola, O.M.; Adeosun, S.O. A review on polyimide reinforced nanocomposites for mechanical, thermal, and electrical insulation application: Challenges and recommendations for future improvement. Polym. Bull. 2020, 79, 663–695. [Google Scholar] [CrossRef]

- Constantin, C.P.; Aflori, M.; Damian, R.F.; Rusu, R.D. Biocompatibility of Polyimides: A Mini-Review. Materials 2019, 12, 3166. [Google Scholar] [CrossRef]

- Puhan, D.; Wong, J. Properties of Polyetheretherketone (PEEK) transferred materials in a PEEK-steel contact. Tribol. Int. 2019, 135, 189–199. [Google Scholar] [CrossRef]

- Wang, M. The tribological performance of engineered micro-surface topography by picosecond laser on PEEK. Ind. Lubr. Tribol. 2019, 72, 172–179. [Google Scholar] [CrossRef]

- Cho, M. Friction and wear of a hybrid surface texturing of polyphenylene sulfide-filled micropores. Wear 2016, 346–347, 158–167. [Google Scholar] [CrossRef]

- Duan, C.; Yang, Z.; Zhang, D.; Tao, L.; Wang, Q.; Wang, T. Effect of isomerism on mechanical and tribological properties of thermoplastic polyimide films. Tribol. Int. 2018, 121, 373–380. [Google Scholar] [CrossRef]

- Fareed, M.I. Effect of operating conditions on the tribological performance of polyether ether ketone (PEEK). Adv. Polym. Technol. 2018, 37, 1537–1543. [Google Scholar] [CrossRef]

- Tatsumi, G.; Ratoi, M.; Shitara, Y.; Sakamoto, K.; Mellor, B.G. Effect of organic friction modifiers on lubrication of PEEK-steel contact. Tribol. Int. 2020, 151, 106513. [Google Scholar] [CrossRef]

- Laux, K.A.; Jean-Fulcrand, A.; Sue, H.J.; Bremner, T.; Wong, J.S.S. The influence of surface properties on sliding contact temperature and friction for polyetheretherketone (PEEK). Polymer 2016, 103, 397–404. [Google Scholar] [CrossRef]

- Yahiaoui, M.; Chabert, F.; Paris, J.Y.; Nassiet, V.; Denape, J. Friction, acoustic emission, and wear mechanisms of a PEKK polymer. Tribol. Int. 2019, 132, 154–164. [Google Scholar] [CrossRef]

- Jean-Fulcrand, A.; Masen, M.A.; Bremner, T.; Wong, J.S.S. Effect of temperature on tribological performance of polyetheretherketone-polybenzimidazole blend. Tribol. Int. 2019, 129, 5–15. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, C.; Nardin, P.; Li, W.Y.; Liao, H.; Coddet, C. Effects of sliding velocity and applied load on the tribological mechanism of amorphous poly-ether–ether–ketone (PEEK). Tribol. Int. 2008, 41, 79–86. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Hokkirigawa, K. Friction and Wear Properties of PEEK Resin Filled with RB Ceramics Particles under Water Lubricated Condition. Tribol. Online 2016, 11, 653–660. [Google Scholar] [CrossRef][Green Version]

- Dong, F.; Hou, G.; Cao, F.; Yan, F.; Liu, L.; Wang, J. The lubricity and reinforcement of carbon fibers in polyimide at high temperatures. Tribol. Int. 2016, 101, 291–300. [Google Scholar] [CrossRef]

- Lv, M.; Zheng, F.; Wang, Q.; Wang, T.; Liang, Y. Friction and wear behaviors of carbon and aramid fibers reinforced polyimide composites in simulated space environment. Tribol. Int. 2015, 92, 246–254. [Google Scholar] [CrossRef]

- Puhan, D.; Jiang, S.; Wong, J.S.S. Effect of carbon fiber inclusions on polymeric transfer film formation on steel. Compos. Sci. Technol. 2022, 217, 109084. [Google Scholar] [CrossRef]

- Jacobs, O.; Jaskulka, R.; Yan, C.; Wu, W. On the effect of counterface material and aqueous environment on the sliding wear of various PEEK compounds. Tribol. Lett. 2005, 18, 359–372. [Google Scholar] [CrossRef]

- Greco, A.C.; Erck, R.; Ajayi, O.; Fenske, G. Effect of reinforcement morphology on high-speed sliding friction and wear of PEEK polymers. Wear 2011, 271, 2222–2229. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, Y.; Tang, J.; Gao, J. Friction and Wear Behavior of Polyimide Composites Reinforced by Surface-Modified Poly-p-Phenylenebenzobisoxazole (PBO) Fibers in High Ambient Temperatures. Polymers 2019, 11, 1805. [Google Scholar] [CrossRef]

- Li, E.Z.; Guo, W.L.; Wang, H.D.; Xu, B.S.; Liu, X.T. Research on Tribological Behavior of PEEK and Glass Fiber Reinforced PEEK Composite. Phys. Procedia 2013, 50, 453–460. [Google Scholar] [CrossRef]

- Duan, C.; Yuan, D.; Yang, Z.; Li, S.; Tao, L.; Wang, Q.; Wang, T. High wear-resistant performance of thermosetting polyimide reinforced by graphitic carbon nitride (g-C3N4) under high temperature. Compos. Part A Appl. Sci. Manuf. 2018, 113, 200–208. [Google Scholar] [CrossRef]

- Zhao, Y.; Qi, X.; Ma, J.; Dong, Y.; Yang, Y. Effects of polyimide/silica and polyimide/pores fillers on the morphology, thermal, mechanical, and tribological properties of polytetrafluoroethylene composites. Polym. Compos. 2019, 41, 1435–1446. [Google Scholar] [CrossRef]

- Song, J.; Yu, Y.; Zhao, G.; Qiu, J.; Ding, Q. Comparative study of tribological properties of insulated and conductive polyimide composites. Friction 2020, 8, 507–516. [Google Scholar] [CrossRef]

- Demian, C.; Liao, H.; Lachat, R.; Costil, S. Investigation of surface properties and mechanical and tribological behaviors of polyimide based composite coatings. Surf. Coat. Technol. 2013, 235, 603–610. [Google Scholar] [CrossRef]

- Zhang, G.; Li, W.Y.; Cherigui, M.; Zhang, C.; Liao, H.; Bordes, J.M.; Coddet, C. Structures and tribological performances of PEEK (poly-ether-ether-ketone)-based coatings designed for tribological application. Prog. Org. Coat. 2007, 60, 39–44. [Google Scholar] [CrossRef]

- Lal, B.; Alam, S.; Mathur, G.N. Tribo-investigation on PTFE lubricated PEEK in harsh operating conditions. Tribol. Lett. 2007, 25, 71–77. [Google Scholar] [CrossRef]

- Zhao, Y.; Qi, X.; Dong, Y.; Ma, J.; Zhang, Q.; Song, L.; Yang, Y.; Yang, Q. Mechanical, thermal and tribological properties of polyimide/nano-SiO2 composites synthesized using an in-situ polymerization. Tribol. Int. 2016, 103, 599–608. [Google Scholar] [CrossRef]

- Zhou, S.; Li, W.; Zhao, W.; Li, Q.; Liu, C.; Fang, Z.; Gao, X. Tribological behaviors of polyimide composite coatings containing carbon nanotubes and fluorinated graphene with hybrid phase or blend phase. Prog. Org. Coat. 2020, 147, 105800. [Google Scholar] [CrossRef]

- Chen, B.; Li, X.; Li, X.; Jia, Y.; Yang, J.; Yang, G.; Li, C. Friction and Wear Properties of Polyimide-Based Composites with a Multiscale Carbon Fiber-Carbon Nanotube Hybrid. Tribol. Lett. 2017, 65, 111. [Google Scholar] [CrossRef]

- Yuan, H.; Yang, S.; Liu, X.; Wang, Z.; Ma, L.; Hou, K.; Yang, Z.; Wang, J. Polyimide-based lubricating coatings synergistically enhanced by MoS2@HCNF hybrid. Compos. Part A Appl. Sci. Manuf. 2017, 102, 9–17. [Google Scholar] [CrossRef]

- Zhu, L.; You, L.; Shi, Z.; Song, H.; Li, S. An investigation on the graphitic carbon nitride reinforced polyimide composite and evaluation of its tribological properties. J. Appl. Polym. Sci. 2017, 134, 45403. [Google Scholar] [CrossRef]

- Chen, B.; Li, X.; Jia, Y.; Li, X.; Yang, J.; Yan, F.; Li, C. MoS2 nanosheets-decorated carbon fiber hybrid for improving the friction and wear properties of polyimide composite. Compos. Part A Appl. Sci. Manuf. 2018, 109, 232–238. [Google Scholar] [CrossRef]

- Min, C.; Liu, D.; Qian, J.; He, Z.; Jia, W.; Song, H.; Guo, L. High mechanical and tribological performance polyimide nanocomposites using amine-functionalized graphene nanosheets. Tribol. Int. 2019, 131, 1–10. [Google Scholar] [CrossRef]

- Zhou, S.; Li, W.; Zhao, W.; Liu, C.; Fang, Z.; Gao, X. Tribological behaviors of polyimide composite films enhanced with fluorographene. Colloids Surf. A 2019, 580, 123707. [Google Scholar] [CrossRef]

- Min, C.; He, Z.; Liang, H.; Liu, D.; Dong, C.; Song, H.; Huang, Y. High mechanical and tribological performance of polyimide nanocomposite reinforced by fluorinated graphene oxide. Polym. Compos. 2020, 41, 1624–1635. [Google Scholar] [CrossRef]

- Zhao, Z.; Ma, Y.; Wan, H.; Ye, Y.; Chen, L.; Zhou, H.; Chen, J. Preparation and tribological behaviors of polyamide-imide/polytetrafluoroethylene lubricating coatings reinforced by in-situ synthesized CeO2 nanoparticles. Polym. Test. 2021, 96, 107100. [Google Scholar] [CrossRef]

- Puértolas, J.A.; Castro, M.; Morris, J.A.; Ríos, R.; Ansón-Casaos, A. Tribological and mechanical properties of graphene nanoplatelet/PEEK composites. Carbon 2019, 141, 107–122. [Google Scholar] [CrossRef]

- Wu, T.; Zhang, X.; Chen, K.; Chen, Q.; Yu, Z.; Feng, C.; Qi, J.; Zhang, D. The antibacterial and wear-resistant nano-ZnO/PEEK composites were constructed by a simple two-step method. J. Mech. Behav. Biomed. Mater. 2022, 126, 104986. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.; Pei, X.; Zhao, F.; Zhang, L.; Li, G.; Zhang, G. Tribofilm growth at sliding interfaces of PEEK composites and steel at low velocities. Tribol. Int. 2020, 151, 106456. [Google Scholar] [CrossRef]

- Li, C.; Yan, F. Effect of Blowing Air and Floating Sand-dust Particles on the Friction and Wear Behavior of PTFE, UHMWPE and PI. Tribol. Lett. 2008, 32, 189–198. [Google Scholar] [CrossRef]

- Li, C.; Yan, F. A comparative investigation of the wear behavior of PTFE and PI under dry sliding and simulated sand-dust conditions. Wear 2009, 266, 632–638. [Google Scholar] [CrossRef]

- Ma, Y.; Cong, P.; Liu, X.; Lv, R.; Li, T. Effect of Heat Treatment on the Mechanical and Tribological Properties of Polyphenylene Sulfide Fiber Materials. J. Macromol. Sci. Part B Phys. 2014, 53, 1786–1799. [Google Scholar] [CrossRef]

- Chen, J.; Guo, Q.; Zhang, S.; Wang, X.; Shao, X. Research on Friction and Wear Behaviors of PEEK/PEI/PES Plastics Alloys under Sliding Contact Condition. Procedia Eng. 2012, 36, 285–291. [Google Scholar] [CrossRef]

- Kim, S.S.; Shin, M.W.; Jang, H. The Wear Mechanism of a Polyphenylene Sulfide (PPS) Composite Mixed with Ethylene Butyl Acrylate (EBA). Tribol. Lett. 2012, 47, 165–173. [Google Scholar] [CrossRef]

- Shi, Y.; Zhou, S.; Zou, H.; Liang, M.; Chen, Y. In situ micro-fibrillization and post annealing to significantly improve the tribological properties of polyphenylene sulfide/polyamide 66/polytetrafluoroethylene composites. Compos. Part B Eng. 2021, 216, 108841. [Google Scholar] [CrossRef]

- Chen, B.; Wang, J.; Yan, F. Comparative investigation on the tribological behaviors of CF/PEEK composites under sea water lubrication. Tribol. Int. 2012, 52, 170–177. [Google Scholar] [CrossRef]

- Gebhard, A.; Bayerl, T.; Schlarb, A.K.; Friedrich, K. Increased wear of aqueous lubricated short carbon fiber reinforced polyetheretherketone (PEEK/SCF) composites due to galvanic fiber corrosion. Wear 2010, 268, 871–876. [Google Scholar] [CrossRef]

- Oyamada, T.; Ono, M.; Miura, H.; Kuwano, T. Effect of Gas Environment on Friction Behavior and Tribofilm Formation of PEEK/Carbon Fiber Composite. Tribol. Trans. 2013, 56, 607–614. [Google Scholar] [CrossRef]

- Xu, H.; Feng, Z.; Chen, J.; Zhou, H. Tribological behavior of the carbon fiber reinforced polyphenylene sulfide (PPS) composite coating under dry sliding and water lubrication. Mater. Sci. Eng. A 2006, 416, 66–73. [Google Scholar] [CrossRef]

- Zhao, G.; Hussainova, I.; Antonov, M.; Wang, Q.; Wang, T. Friction and wear of fiber reinforced polyimide composites. Wear 2013, 301, 122–129. [Google Scholar] [CrossRef]

- Zhao, G.; Hussainova, I.; Antonov, M.; Wang, Q.; Wang, T.; Yung, D.L. Effect of temperature on sliding and erosive wear of fiber reinforced polyimide hybrids. Tribol. Int. 2015, 82, 525–533. [Google Scholar] [CrossRef]

- Zhang, X.; Pei, X.; Wang, Q. Friction and wear properties of polyimide matrix composites reinforced with short basalt fibers. J. Appl. Polym. Sci. 2009, 111, 2980–2985. [Google Scholar] [CrossRef]

- Zhang, X.; Pei, X.; Wang, Q. The tribological properties of acid- and diamine-modified carbon fiber reinforced polyimide composites. Mater. Chem. Phys. 2009, 115, 825–830. [Google Scholar] [CrossRef]

- Zhang, X.; Pei, X.; Jia, Q.; Wang, Q. Effects of carbon fiber surface treatment on the tribological properties of 2D woven carbon fabric/polyimide composites. Appl. Phys. A 2009, 95, 793–799. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Q.; Li, Y.; Zhou, S.; Zou, H.; Liang, M. Enhanced mechanical and tribological properties in polyphenylene sulfide/polytetrafluoroethylene composites reinforced by short carbon fiber. Compos. Part B Eng. 2016, 91, 579–588. [Google Scholar] [CrossRef]

- Shi, Y.; Zhou, S.T.; Heng, Z.G.; Liang, M.; Wu, Y.; Chen, Y.; Zou, H.W. Interlocking Structure Formed by Multiscale Carbon Fiber–Polytetrafluoroethylene Fiber Hybrid Significantly Enhances the Friction and Wear Properties of Polyphenylene Sulfide Based Composites. Ind. Eng. Chem. Res. 2019, 58, 16541–16551. [Google Scholar] [CrossRef]

- Zhang, X.; Pei, X.; Wang, Q. Friction and wear properties of basalt fiber reinforced/solid lubricants filled polyimide composites under different sliding conditions. J. Appl. Polym. Sci. 2009, 114, 1746–1752. [Google Scholar] [CrossRef]

- Li, J. Tribological properties of polyimide composites filled with glass fibre and graphite. Plast. Rubber Compos. 2009, 38, 248–252. [Google Scholar] [CrossRef]

- Zhang, Z.; Breidt, C.; Chang, L.; Friedrich, K. Wear of PEEK composites related to their mechanical performances. Tribol. Int. 2004, 37, 271–277. [Google Scholar] [CrossRef]

- Zhang, G.; Rasheva, Z.; Schlarb, A.K. Friction and wear variations of short carbon fiber (SCF)/PTFE/graphite (10vol.%) filled PEEK: Effects of fiber orientation and nominal contact pressure. Wear 2010, 268, 893–899. [Google Scholar] [CrossRef]

- Rasheva, Z.; Zhang, G.; Burkhart, T. A correlation between the tribological and mechanical properties of short carbon fibers reinforced PEEK materials with different fiber orientations. Tribol. Int. 2010, 43, 1430–1437. [Google Scholar] [CrossRef]

- Zhang, X.R.; Pei, X.Q.; Wang, Q.H. Friction and wear studies of polyimide composites filled with short carbon fibers and graphite and micro SiO2. Mater. Des. 2009, 30, 4414–4420. [Google Scholar] [CrossRef]

- Lv, X.; Wang, X.; Tang, S.; Wang, D.; Yang, L.; He, A.; Tang, T.; Wei, J. Incorporation of molybdenum disulfide into polyetheretherketone creating biocomposites with improved mechanical, tribological performances and cytocompatibility for artificial joints applications. Colloids Surf. B 2020, 189, 110819. [Google Scholar] [CrossRef]

- Zhang, L.; Qi, H.; Li, G.; Wang, D.; Wang, T.; Wang, Q.; Zhang, G. Significantly enhanced wear resistance of PEEK by simply filling with modified graphitic carbon nitride. Mater. Des. 2017, 129, 192–200. [Google Scholar] [CrossRef]

- Zhang, L.; Li, G.; Guo, Y.; Qi, H.; Che, Q.; Zhang, G. PEEK reinforced with low-loading 2D graphitic carbon nitride nanosheets: High wear resistance under harsh lubrication conditions. Compos. Part A Appl. Sci. Manuf. 2018, 109, 507–516. [Google Scholar] [CrossRef]

- Zhang, G.; Schlarb, A.K.; Tria, S.; Elkedim, O. Tensile and tribological behaviors of PEEK/nano-SiO2 composites compounded using a ball milling technique. Compos. Sci. Technol. 2008, 68, 3073–3080. [Google Scholar] [CrossRef]

- Pan, S.; Shen, H.; Zhang, L. Effect of carbon nanotube on thermal, tribological and mechanical properties of 3D printing polyphenylene sulfide. Addit. Manuf. 2021, 47, 102247. [Google Scholar] [CrossRef]

- Cai, H.; Yan, F.; Xue, Q. Investigation of tribological properties of polyimide/carbon nanotube nanocomposites. Mater. Sci. Eng. A 2004, 364, 94–100. [Google Scholar] [CrossRef]

- Cai, H.; Yan, F.; Xue, Q.; Liu, W. Investigation of tribological properties of Al2O3-polyimide nanocomposites. Polym. Test. 2003, 22, 875–882. [Google Scholar] [CrossRef]

- Wu, J.; Liu, H.; Wang, H.; Ma, W.; Wang, T.; Wang, Q. Effects of TiO2 decorated reduced graphene oxide on mechanical and tribological properties of thermosetting polyimide. Compos. Interfaces 2021, 1–14. [Google Scholar] [CrossRef]

- Liu, H.; Jia, Y.; Wang, H.; Duan, C.; Wang, T.; Wang, Q. Ultra-high compression and wear resistant hybrid filled polyimide composite: Synergistic effect of Fe2O3 decorated RGO. J. Appl. Polym. Sci. 2020, 137, 49222. [Google Scholar] [CrossRef]

- Ruan, H.; Zhang, Q.; Liao, W.; Li, Y.; Huang, X.; Xu, X.; Lu, S. Enhancing tribological, mechanical, and thermal properties of polyimide composites by the synergistic effect between graphene and ionic liquid. Mater. Des. 2020, 189, 108527. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Q.; Ruan, H.; Li, F.; Xu, X.; Huang, X.; Lu, S. Improving the tribological and mechanical properties of polyimide composites by incorporating functionalized graphene. High Perform. Polym. 2020, 32, 21–29. [Google Scholar] [CrossRef]

- Liu, H.; Wang, T.; Wang, Q. Tribological Properties of Thermosetting Polyimide/TiO2 Nanocomposites Under Dry Sliding and Water-Lubricated Conditions. J. Macromol. Sci. Part B Phys. 2012, 51, 2284–2296. [Google Scholar] [CrossRef]

- Qiao, H.B.; Guo, Q.; Tian, A.G.; Pan, G.L.; Xu, L.B. A study on friction and wear characteristics of nanometer Al2O3/PEEK composites under the dry sliding condition. Tribol. Int. 2007, 40, 105–110. [Google Scholar] [CrossRef]

- Wan, H.; Jia, Y.; Ye, Y.; Xu, H.; Cui, H.; Chen, L.; Zhou, H.; Chen, J. Tribological behavior of polyimide/epoxy resin-polytetrafluoroethylene bonded solid lubricant coatings filled with in situ-synthesized silver nanoparticles. Prog. Org. Coat. 2017, 106, 111–118. [Google Scholar] [CrossRef]

- Zhenhua, L. The effect of titanium dioxide on the tribological properties of carbon fiber-reinforced polyimide composites. J. Thermoplast. Compos. Mater. 2013, 28, 257–264. [Google Scholar] [CrossRef]

- Su, C.; Xue, F.; Li, T.; Xin, Y.; Wang, M. Study on the Tribological Properties of Carbon Fabric/Polyimide Composites Filled with SiC Nanoparticles. J. Macromol. Sci. Part B Phys. 2016, 55, 627–641. [Google Scholar] [CrossRef]

- Guo, L.; Qi, H.; Zhang, G.; Wang, T.; Wang, Q. Distinct tribological mechanisms of various oxide nanoparticles added in PEEK composite reinforced with carbon fibers. Compos. Part A Appl. Sci. Manuf. 2017, 97, 19–30. [Google Scholar] [CrossRef]

- Ginzburg, B.M.; Lyashkov, A.I.; Savitskii, A.V.; Sobolev, N.Z.; Tochil’nikov, D.G. Comparison of tribological properties of various carbon plastics under water-lubricated sliding friction. J. Frict. Wear 2009, 30, 53–57. [Google Scholar] [CrossRef]

- Gao, C.; Fan, S.; Zhang, S.; Zhang, P.; Wang, Q. Enhancement of tribofilm formation from water lubricated PEEK composites by copper nanowires. Appl. Surf. Sci. 2018, 444, 364–376. [Google Scholar] [CrossRef]

- Fan, S.; Gao, C.; Yang, G.; Zhang, Y.; Zhang, C.; Song, N.; Zhang, S.; Zhang, P.; Zhang, Z.; Ke, S. Enhancing wear-resistance of Cu nanowires filled polyetheretherketone-based composites under water lubrication conditions via magnetic response to tribofilm. Tribol. Int. 2021, 153, 106601. [Google Scholar] [CrossRef]

- Lin, L.; Schlarb, A.K. Effect of the varied load conditions on the tribological performance and the thermal characteristics of PEEK-based hybrid composites. Tribol. Int. 2016, 101, 218–225. [Google Scholar] [CrossRef]

- Zhang, G.; Wetzel, B.; Wang, Q. Tribological behavior of PEEK-based materials under mixed and boundary lubrication conditions. Tribol. Int. 2015, 88, 153–161. [Google Scholar] [CrossRef]

- Zhang, D.; Qi, H.; Zhao, F.; Zhang, G.; Wang, T.; Wang, Q. Tribological performance of PPS composites under diesel lubrication conditions. Tribol. Int. 2017, 115, 338–347. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, X.; Pei, X. Study on the synergistic effect of carbon fiber and graphite and nanoparticle on the friction and wear behavior of polyimide composites. Mater. Des. 2010, 31, 3761–3768. [Google Scholar] [CrossRef]

- Panda, J.N.; Bijwe, J.; Pandey, R.K. On the significant tribo-potential of PAEK based composites and their dry bearings. Tribol. Int. 2020, 142, 105994. [Google Scholar] [CrossRef]

- Laux, K.A.; Schwartz, C.J. Effects of contact pressure, molecular weight, and supplier on the wear behavior and transfer film of polyetheretherketone (PEEK). Wear 2013, 297, 919–925. [Google Scholar] [CrossRef]

- Yan, Y.; Meng, Z.; Xin, X.; Liu, H.; Yan, F. Tribological Behavior and Thermal Stability of Thermoplastic Polyimide/Poly (Ether Ether Ketone) Blends at Elevated Temperature. J. Macromol. Sci. Part B Phys. 2020, 60, 1–15. [Google Scholar] [CrossRef]

- Wang, H.; Liu, D.; Yan, L.; Wang, C.; Yang, S.; Zhu, Y. Tribological simulation of porous self-lubricating PEEK composites with heat-stress coupled field. Tribol. Int. 2014, 77, 43–49. [Google Scholar] [CrossRef]

- Wang, H.; Wang, G.; Zhang, S.; Yang, S.; Zhu, Y. Tribological performances on porous polyphenylene sulfide self-lubricating composites with super wear resistance. J. Thermoplast. Compos. Mater. 2012, 27, 82–92. [Google Scholar] [CrossRef]

- Tóth, L.F.; Sukumaran, J.; Szebényi, G.; De Baets, P. Tribo-mechanical interpretation for advanced thermoplastics and the effects of wear-induced crystallization. Wear 2019, 440–441, 203083. [Google Scholar] [CrossRef]

- Qi, H.; Zhang, L.; Zhang, G.; Wang, T.; Wang, Q. Comparative study of tribochemistry of ultrahigh molecular weight polyethylene, polyphenylene sulfide and polyetherimide in tribo-composites. J. Colloid Interface Sci. 2018, 514, 615–624. [Google Scholar] [CrossRef]

- Duan, Y.; Cong, P.; Liu, X.; Li, T. Friction and Wear of Polyphenylene Sulfide (PPS), Polyethersulfone (PES) and Polysulfone (PSU) Under Different Cooling Conditions. J. Macromol. Sci. Part B Phys. 2009, 48, 604–616. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Takashima, T. Friction and wear of water lubricated PEEK and PPS sliding contacts. Wear 2002, 253, 820–826. [Google Scholar] [CrossRef]

- Shen, C.; Khonsari, M.M.; Spadafora, M.; Ludlow, C. Tribological Performance of Polyamide-Imide Seal Ring Under Seawater Lubrication. Tribol. Lett. 2016, 62, 39. [Google Scholar] [CrossRef]

- Theiler, G.; Gradt, T. Influence of counterface and environment on the tribological behaviour of polymer materials. Polym. Test. 2021, 93, 106912. [Google Scholar] [CrossRef]

- Borruto, A. A new material for hip prosthesis without considerable debris release. Med. Eng. Phys. 2010, 32, 908–913. [Google Scholar] [CrossRef]

- Davim, J.P.; Marques, N.; Baptista, A.M. Effect of carbon fibre reinforcement in the frictional behaviour of Peek in a water lubricated environment. Wear 2001, 251, 1100–1104. [Google Scholar] [CrossRef]

- Davim, J.P.; Cardoso, R. Effect of the reinforcement (carbon or glass fibres) on friction and wear behaviour of the PEEK against steel surface at long dry sliding. Wear 2009, 266, 795–799. [Google Scholar] [CrossRef]

- Unal, H.; Sen, U.; Mimaroglu, A. Dry sliding wear characteristics of some industrial polymers against steel counterface. Tribol. Int. 2004, 37, 727–732. [Google Scholar] [CrossRef]

- Panda, J.; Bijwe, J.; Pandey, R.K. Optimization of the amount of short glass fibers for superior wear performance of PAEK Composites. Compos. Part A Appl. Sci. Manuf. 2019, 116, 158–168. [Google Scholar] [CrossRef]

- Kumar, R.; Malaval, B.; Antonov, M.; Zhao, G. Performance of polyimide and PTFE based composites under sliding, erosive and high stress abrasive conditions. Tribol. Int. 2020, 147, 106282. [Google Scholar] [CrossRef]

- Tang, Q.; Chen, J.; Liu, L. Tribological behaviours of carbon fibre reinforced PEEK sliding on silicon nitride lubricated with water. Wear 2010, 269, 541–546. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, D. Comparative investigation on the tribological behavior of reinforced plastic composite under natural seawater lubrication. Mater. Des. 2013, 51, 983–988. [Google Scholar] [CrossRef]

- Harsha, A.; Tewari, U. Tribo performance of polyaryletherketone composites. Polym. Test. 2002, 21, 697–709. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Hashimoto, M. Friction and wear of water lubricated PEEK and PPS sliding contacts. Wear 2004, 257, 181–189. [Google Scholar] [CrossRef]

- Bijwe, J.; Sen, S.; Ghosh, A. Influence of PTFE content in PEEK–PTFE blends on mechanical properties and tribo-performance in various wear modes. Wear 2005, 258, 1536–1542. [Google Scholar] [CrossRef]

- Hufenbach, W.; Kunze, K.; Bijwe, J. Sliding wear behaviour of PEEK-PTFE blends. J. Synth. Lubr. 2003, 20, 227–240. [Google Scholar] [CrossRef]

- Burris, D.L.; Sawyer, W.G. Tribological behavior of PEEK components with compositionally graded PEEK/PTFE surfaces. Wear 2007, 262, 220–224. [Google Scholar] [CrossRef]

- Jones, M.R.; McGhee, E.O.; Marshall, S.L.; Hart, S.M.; Urueña, J.M.; Niemi, S.R.; Pitenis, A.A.; Schulze, K.D. The Role of Microstructure in Ultralow Wear Fluoropolymer Composites. Tribol. Trans. 2019, 62, 135–143. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, J.; Zhu, Y.; Meng, Y.; Zhu, Y. The fabrication, nano/micro-structure, heat- and wear-resistance of the superhydrophobic PPS/PTFE composite coatings. J. Colloid Interface Sci. 2013, 402, 253–258. [Google Scholar] [CrossRef]

- Qi, H.; Li, G.; Zhang, G.; Liu, G.; Yu, J.; Zhang, L. Distinct tribological behaviors of polyimide composites when rubbing against various metals. Tribol. Int. 2020, 146, 106254. [Google Scholar] [CrossRef]

- Xie, G.Y.; Zhuang, G.S.; Sui, G.X.; Yang, R. Tribological behavior of PEEK/PTFE composites reinforced with potassium titanate whiskers. Wear 2010, 268, 424–430. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, G.; Wang, H.; Zhang, S.; Yang, S. Tribological properties of porous PPS/PTFE composite filled with mesopore titanium oxide whisker. J. Appl. Polym. Sci. 2013, 129, 2321–2327. [Google Scholar] [CrossRef]

- Zalaznik, M.; Kalin, M.; Novak, S.; Jakša, G. Effect of the type, size and concentration of solid lubricants on the tribological properties of the polymer PEEK. Wear 2016, 364–365, 31–39. [Google Scholar] [CrossRef]

- Cho, M.H.; Bahadur, S.; Pogosian, A.K. Friction and wear studies using Taguchi method on polyphenylene sulfide filled with a complex mixture of MoS2, Al2O3, and other compounds. Wear 2005, 258, 1825–1835. [Google Scholar] [CrossRef]

- Panda, J.N.; Bijwe, J.; Pandey, R.K. Tribo-performance enhancement of PAEK composites using nano/micro-particles of metal chalcogenides. Compos. Sci. Technol. 2018, 167, 7–23. [Google Scholar] [CrossRef]

- Song, J.; Zhao, G.; Ding, Q.; Qiu, J. Reciprocating friction and wear of polyimide composites filled with solid lubricants. J. Polym. Eng. 2018, 38, 363–370. [Google Scholar] [CrossRef]

- Song, J.; Liu, X.; Zhao, G.; Ding, Q.; Qiu, J. Effect of surface roughness and reciprocating time on the tribological properties of the polyimide composites. Polym. Eng. Sci. 2019, 59, 483–489. [Google Scholar] [CrossRef]

- Panda, J.N.; Bijwe, J.; Pandey, R.K. Comparative potential assessment of solid lubricants on the performance of poly aryl ether ketone (PAEK) composites. Wear 2017, 384–385, 192–202. [Google Scholar] [CrossRef]

- Padhan, M.; Marathe, U.; Bijwe, J. A complex interdependence of thermal conductivity and lubricity of two solid lubricants to control the tribo-performance of PAEK based composites. Wear 2020, 458–459, 203406. [Google Scholar] [CrossRef]

- Theiler, G.; Gradt, T. Tribological characteristics of polyimide composites in hydrogen environment. Tribol. Int. 2015, 92, 162–171. [Google Scholar] [CrossRef]

- Rodriguez, V.; Sukumaran, J.; Schlarb, A.K.; De Baets, P. Influence of solid lubricants on tribological properties of polyetheretherketone (PEEK). Tribol. Int. 2016, 103, 45–57. [Google Scholar] [CrossRef]

- Liu, L.; Yan, F.; Gai, F.; Xiao, L.; Shang, L.; Li, M.; Ao, Y. Enhanced tribological performance of PEEK/SCF/PTFE hybrid composites by graphene. RSC Adv. 2017, 7, 33450–33458. [Google Scholar] [CrossRef]

- Jiang, Z.; Gyurova, L.A.; Schlarb, A.K.; Friedrich, K.; Zhang, Z. Study on friction and wear behavior of polyphenylene sulfide composites reinforced by short carbon fibers and sub-micro TiO2 particles. Compos. Sci. Technol. 2008, 68, 734–742. [Google Scholar] [CrossRef]

- Theiler, G.; Gradt, T. Friction and wear of PEEK composites in vacuum environment. Wear 2010, 269, 278–284. [Google Scholar] [CrossRef]

- Qi, H.; Hu, C.; Zhang, G.; Yu, J.; Zhang, Y.; He, H. Comparative study of tribological properties of carbon fibers and aramid particles reinforced polyimide composites under dry and sea water lubricated conditions. Wear 2019, 436–437, 203001. [Google Scholar] [CrossRef]

- Unal, H.; Kurt, M.; Mimaroglu, A. Tribological performance of industrial polyamide-imide and its composite under different cooling conditions. J. Polym. Eng. 2012, 32, 201–206. [Google Scholar] [CrossRef]

- Lin, L.; Schlarb, A.K. Tribological response of the PEEK/SCF/graphite composite by releasing rigid particles into the tribosystem. Tribol. Int. 2019, 137, 173–179. [Google Scholar] [CrossRef]

- Hedayati, M.; Salehi, M.; Bagheri, R.; Panjepour, M.; Naeimi, F. Tribological and mechanical properties of amorphous and semi-crystalline PEEK/SiO2 nanocomposite coatings deposited on the plain carbon steel by electrostatic powder spray technique. Prog. Org. Coat. 2012, 74, 50–58. [Google Scholar] [CrossRef]

- Cho, M.H.; Bahadur, S. A study of the thermal, dynamic mechanical, and tribological properties of polyphenylene sulfide composites reinforced with carbon nanofibers. Tribol. Lett. 2006, 25, 237–245. [Google Scholar] [CrossRef]

- Cho, M.H.; Bahadur, S. Friction and wear of polyphenylene sulfide composites filled with micro and nano CuO particles in water-lubricated sliding. Tribol. Lett. 2007, 27, 45–52. [Google Scholar] [CrossRef]

- Cho, M. The Flexural and Tribological Behavior of Multi-Walled Carbon Nanotube–Reinforced Polyphenylene Sulfide Composites. Mater. Trans. 2008, 49, 2801–2807. [Google Scholar] [CrossRef]

- Guo, L.; Zhu, H.Q.; Sun, Y.B. A Study of Tribological Properties of Polyphenylene Sulfide Composities Reinforced with CNT and CNF. Appl. Mech. Mater. 2012, 184–185, 872–875. [Google Scholar] [CrossRef]

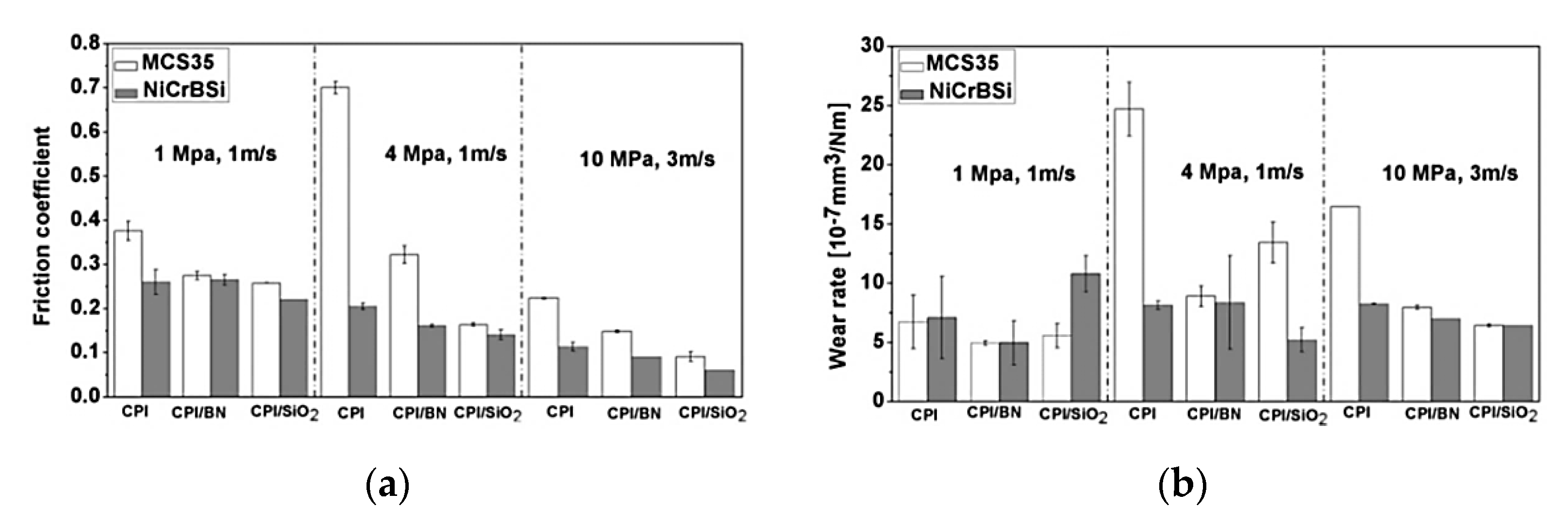

- Qi, H.; Li, G.; Liu, G.; Zhang, C.; Zhang, G.; Wang, T.; Wang, Q. Comparative study on tribological mechanisms of polyimide composites when sliding against medium carbon steel and NiCrBSi. J. Colloid Interface Sci. 2017, 506, 415–428. [Google Scholar] [CrossRef]

- Song, F.; Wang, Q.; Wang, T. High mechanical and tribological performance of polyimide nanocomposites reinforced by chopped carbon fibers in adverse operating conditions. Compos. Sci. Technol. 2016, 134, 251–257. [Google Scholar] [CrossRef]

- Ma, J.; Qi, X.; Dong, Y.; Zhao, Y.; Zhang, Q.; Fan, B.; Yang, Y. Transfer film formation mechanism and tribochemistry evolution of a low-wear polyimide/mesoporous silica nanocomposite in dry sliding against bearing steel. Tribol. Int. 2018, 120, 233–242. [Google Scholar] [CrossRef]

- Golchin, A.; Friedrich, K.; Noll, A.; Prakash, B. Tribological behavior of carbon-filled PPS composites in water lubricated contacts. Wear 2015, 328–329, 456–463. [Google Scholar] [CrossRef]

- Panda, J.N.; Bijwe, J.; Pandey, R.K. Particulate PTFE as a super-efficient secondary solid lubricant in PAEK composites for exceptional performance in adhesive wear mode. Compos. Part C Open Access 2021, 4, 100110. [Google Scholar] [CrossRef]

- Iyer, S.B.; Dube, A.; Dube, N.M.; Roy, P.; Sailaja, R.R.N. Sliding wear and friction characteristics of polymer nanocomposite PAEK-PDMS with nano-hydroxyapatite and nano-carbon fibres as fillers. J. Mech. Behav. Biomed. Mater. 2018, 86, 23–32. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Li, D.; Yang, W.; Xiao, C.; Wei, M. Effects of different amine-functionalized graphene on the mechanical, thermal, and tribological properties of polyimide nanocomposites synthesized by in situ polymerization. Polymer 2018, 140, 56–72. [Google Scholar] [CrossRef]

- Jia, Z.; Hao, C.; Yan, Y.; Yang, Y. Effects of nanoscale expanded graphite on the wear and frictional behaviors of polyimide-based composites. Wear 2015, 338–339, 282–287. [Google Scholar] [CrossRef]

- Yijun, S.; Liwen, M.; Xin, F.; Xiaohua, L. Tribological behavior of carbon nanotube and polytetrafluoroethylene filled polyimide composites under different lubricated conditions. J. Appl. Polym. Sci. 2011, 121, 1574–1578. [Google Scholar] [CrossRef]

- Lin, G.; Xie, G.; Sui, G.; Yang, R. Hybrid effect of nanoparticles with carbon fibers on the mechanical and wear properties of polymer composites. Compos. Part B Eng. 2012, 43, 44–49. [Google Scholar] [CrossRef]

- Panin, S.V.; Lyukshin, B.A.; Bochkareva, S.A.; Kornienko, L.A.; Nguyen, D.A.; Hiep, L.T.M.; Panov, I.L.; Grishaeva, N.Y. Material Design Methodology for Optimized Wear-Resistant Thermoplastic–Matrix Composites Based on Polyetheretherketone and Polyphenylene Sulfide. Materials 2020, 13, 524. [Google Scholar] [CrossRef]

- Panin, S.V.; Luo, J.; Alexenko, V.O.; Buslovich, D.G.; Kornienko, L.A.; Bochkareva, S.A.; Panov, I.L. The effect of annealing of milled carbon fibers on the mechanical and tribological properties of solid-lubricant thermoplastic polyimide-based composites. Polym. Eng. Sci. 2020, 60, 2735–2748. [Google Scholar] [CrossRef]

- Panin, S.V.; Luo, J.; Buslovich, D.G.; Alexenko, V.O.; Kornienko, L.A.; Bochkareva, S.A.; Byakov, A.V. Experimental—FEM Study on Effect of Tribological Load Conditions on Wear Resistance of Three-Component High-Strength Solid-Lubricant PI-Based Composites. Polymers 2021, 13, 2837. [Google Scholar] [CrossRef]

- Panin, S.V.; Nguyen, D.A.; Buslovich, D.G.; Alexenko, V.O.; Pervikov, A.V.; Kornienko, L.A.; Berto, F. Effect of Various Type of Nanoparticles on Mechanical and Tribological Properties of Wear-Resistant PEEK + PTFE-Based Composites. Materials 2021, 14, 1113. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panin, S.V.; Alexenko, V.O.; Buslovich, D.G. High Performance Polymer Composites: A Role of Transfer Films in Ensuring Tribological Properties—A Review. Polymers 2022, 14, 975. https://doi.org/10.3390/polym14050975

Panin SV, Alexenko VO, Buslovich DG. High Performance Polymer Composites: A Role of Transfer Films in Ensuring Tribological Properties—A Review. Polymers. 2022; 14(5):975. https://doi.org/10.3390/polym14050975

Chicago/Turabian StylePanin, Sergey V., Vladislav O. Alexenko, and Dmitry G. Buslovich. 2022. "High Performance Polymer Composites: A Role of Transfer Films in Ensuring Tribological Properties—A Review" Polymers 14, no. 5: 975. https://doi.org/10.3390/polym14050975

APA StylePanin, S. V., Alexenko, V. O., & Buslovich, D. G. (2022). High Performance Polymer Composites: A Role of Transfer Films in Ensuring Tribological Properties—A Review. Polymers, 14(5), 975. https://doi.org/10.3390/polym14050975