Novel Antiviral and Antibacterial Durable Polyester Fabrics Printed with Selenium Nanoparticles (SeNPs)

Abstract

:1. Introduction

2. Experiment

2.1. Materials

2.2. Methods

2.2.1. Synthesis of SeNPs

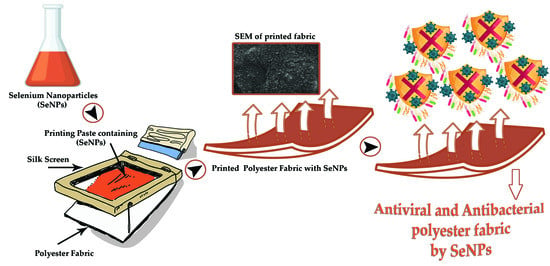

2.2.2. Printing Polyester Fabric with SeNPs

2.3. Characterization

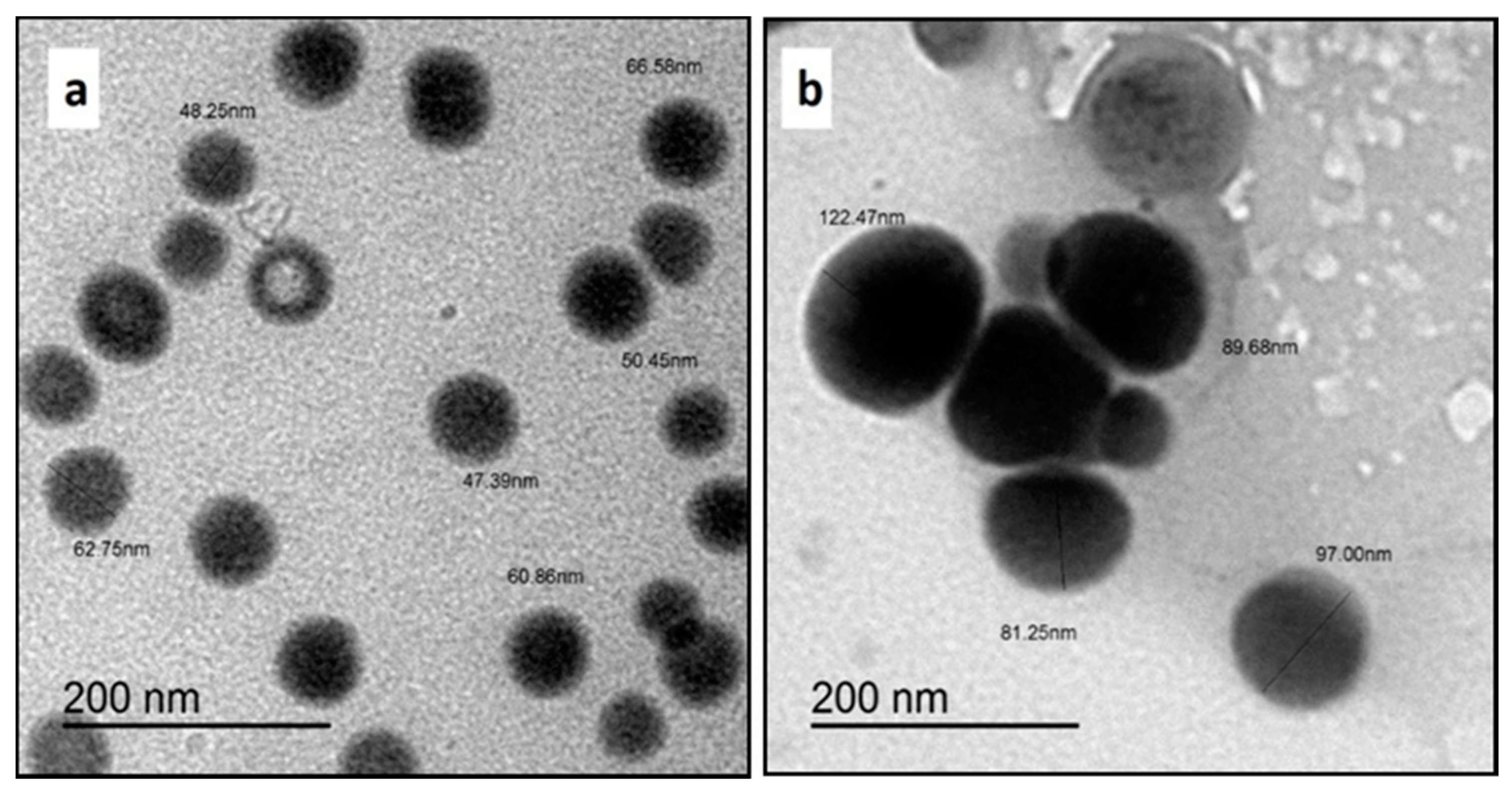

2.3.1. Transmission Electron Microscopy (TEM) Analysis of SeNPs

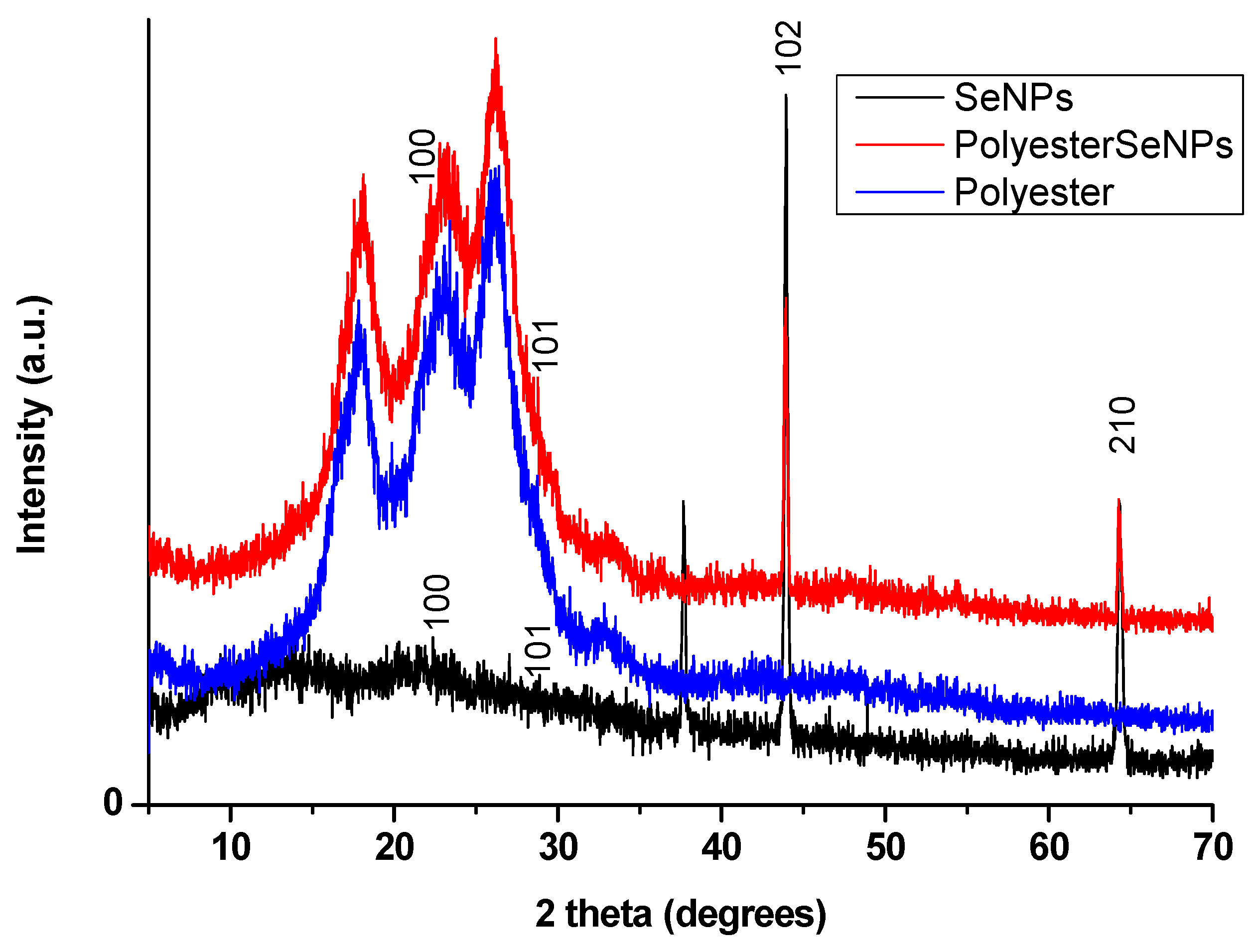

2.3.2. X-ray Diffraction (XRD) Analysis

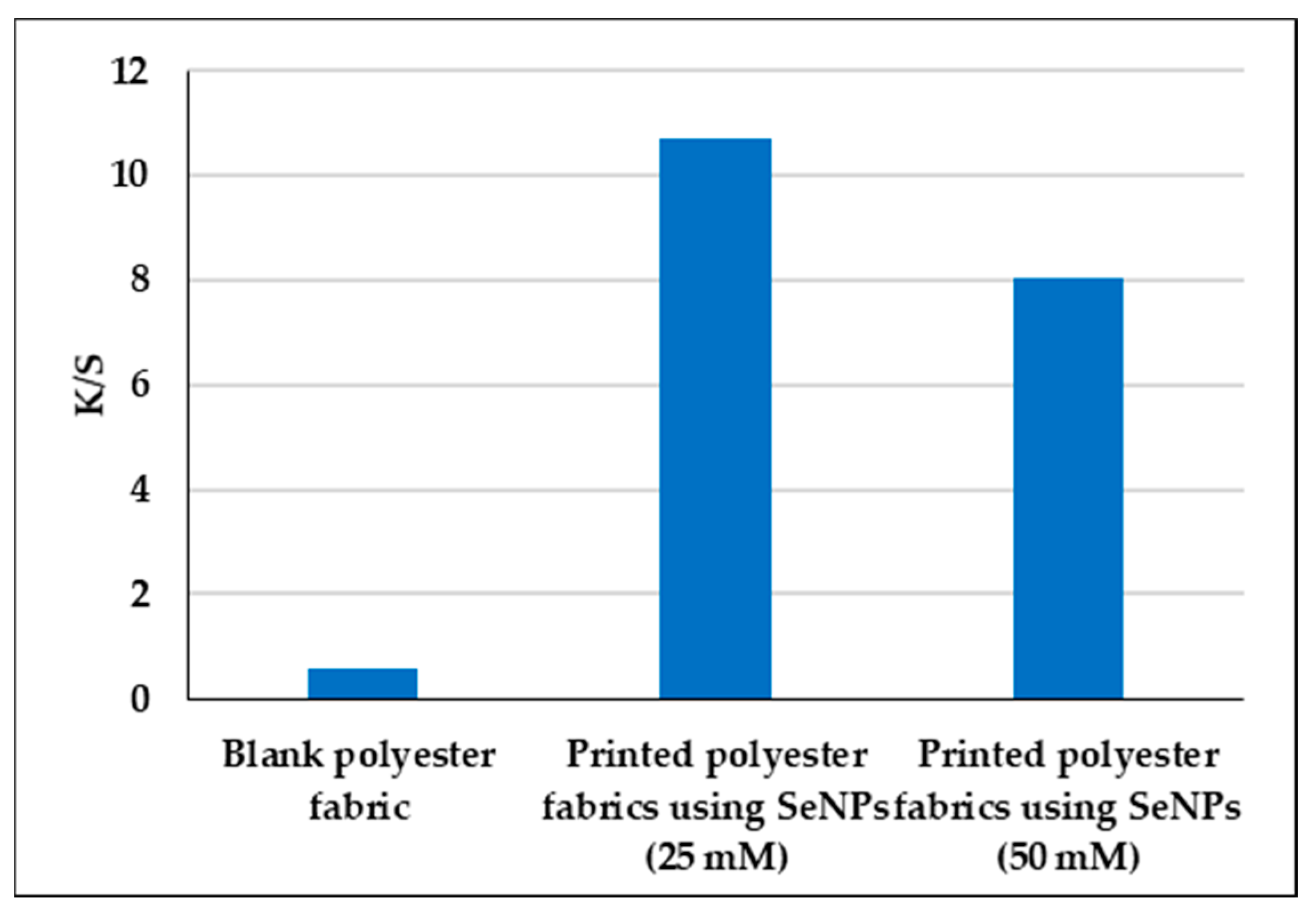

2.3.3. Evaluation of Color Strength (K/S) and Color Co-Ordinate Values of Polyester Fabrics

2.3.4. Color Fastness Properties of Polyester Fabrics

2.3.5. Mechanical Properties of Polyester Fabrics

2.3.6. SEM and EDX of Polyester Fabrics

2.3.7. Evaluation of the Antiviral Properties of Polyester Fabrics

2.3.8. Evaluation of Antibacterial Properties of Polyester Fabrics

2.3.9. Cytotoxicity Test of Polyester Fabrics

2.3.10. Statistical Analysis

3. Results and Discussion

3.1. Transmission Electron Microscopy (TEM) Analysis of SeNPs

3.2. XRD Analysis

3.3. Evaluation of Color Strength (K/S) and Color Co-Ordinate Values of Polyester Fabrics

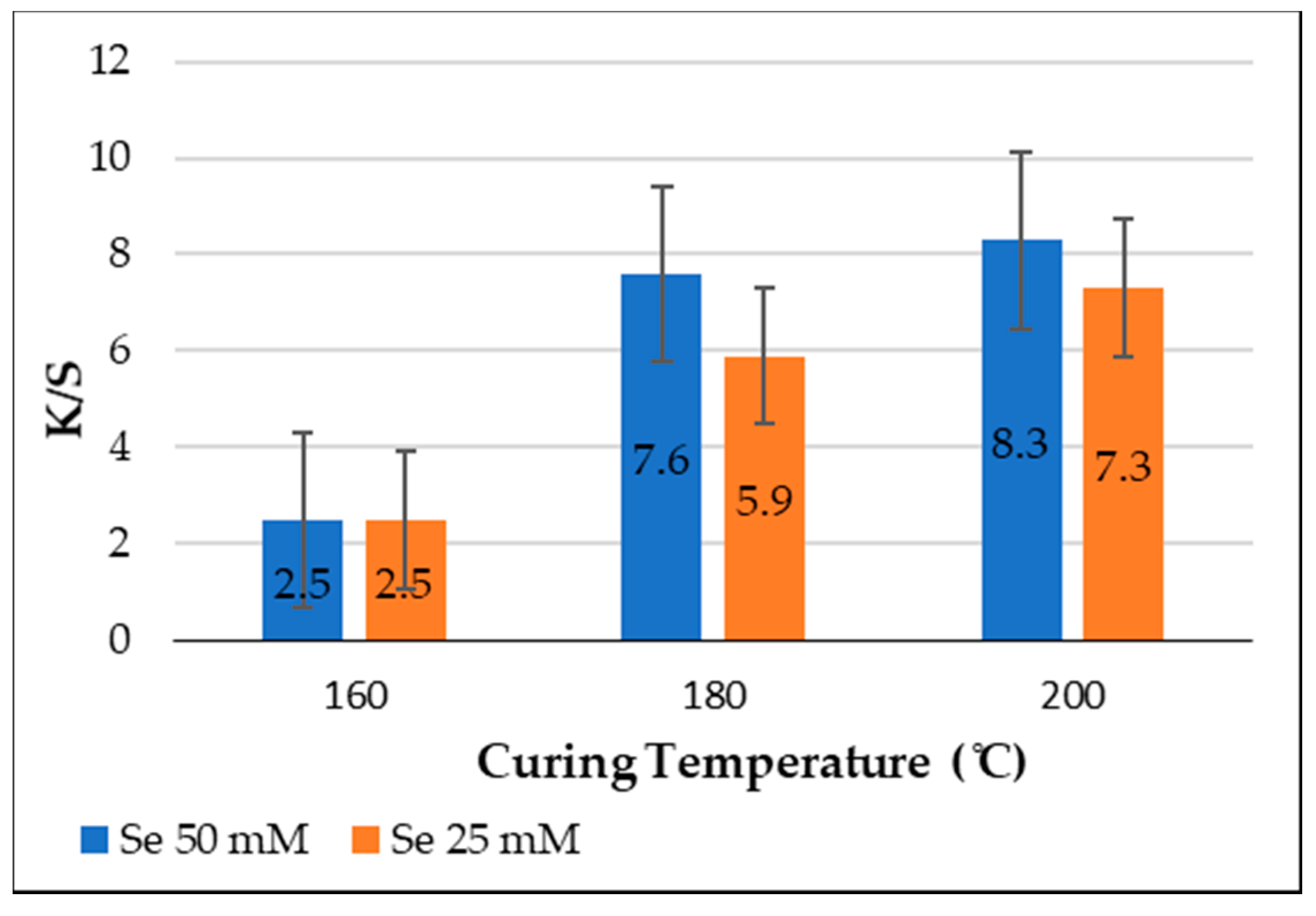

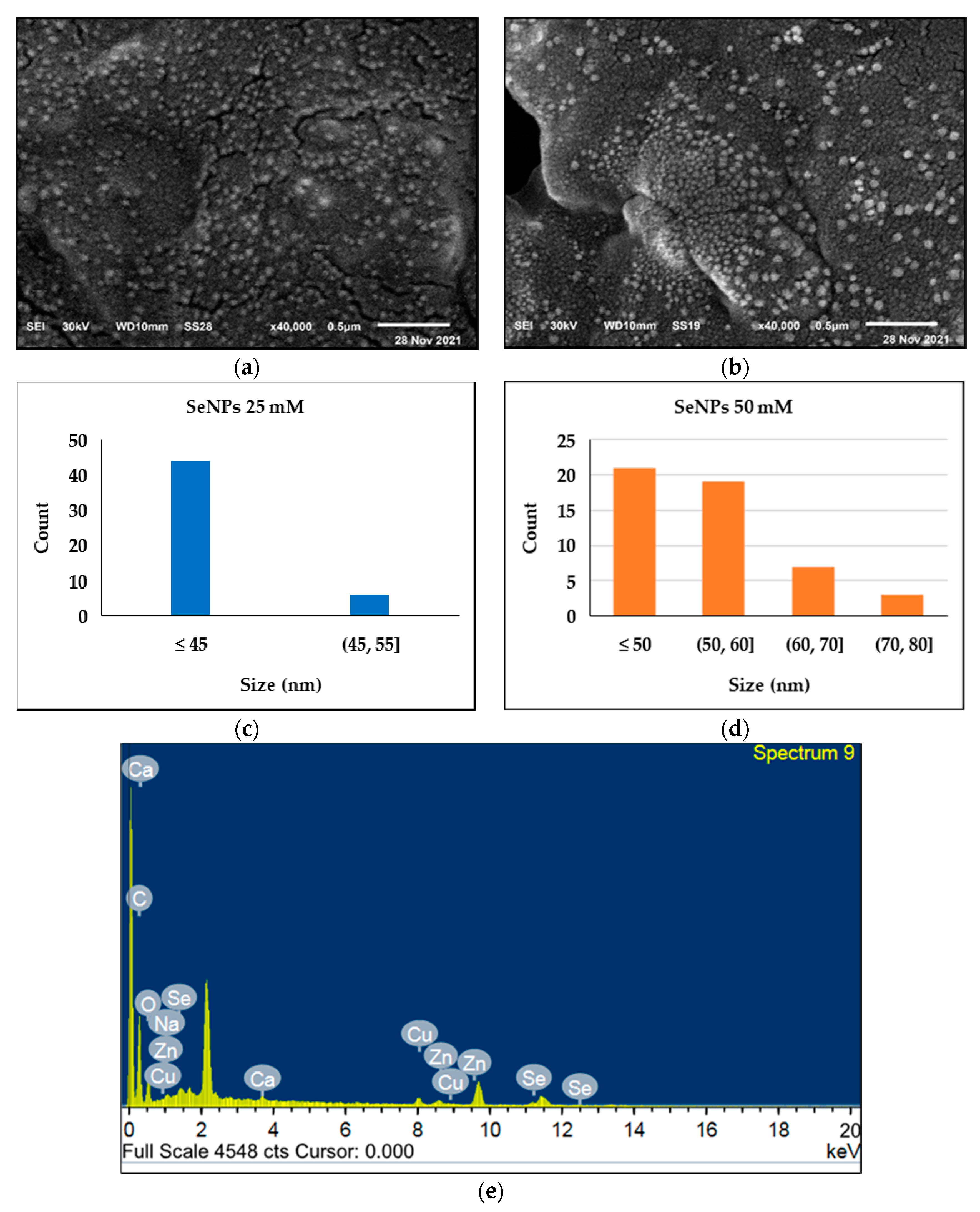

3.4. Effect of Curing Temperature on the Color Strength (K/S) of Polyester Fabrics

3.5. Effect of Curing Time on Color Strength (K/S) of Polyester Fabrics

3.6. Color Fastness Properties of Polyester Fabrics

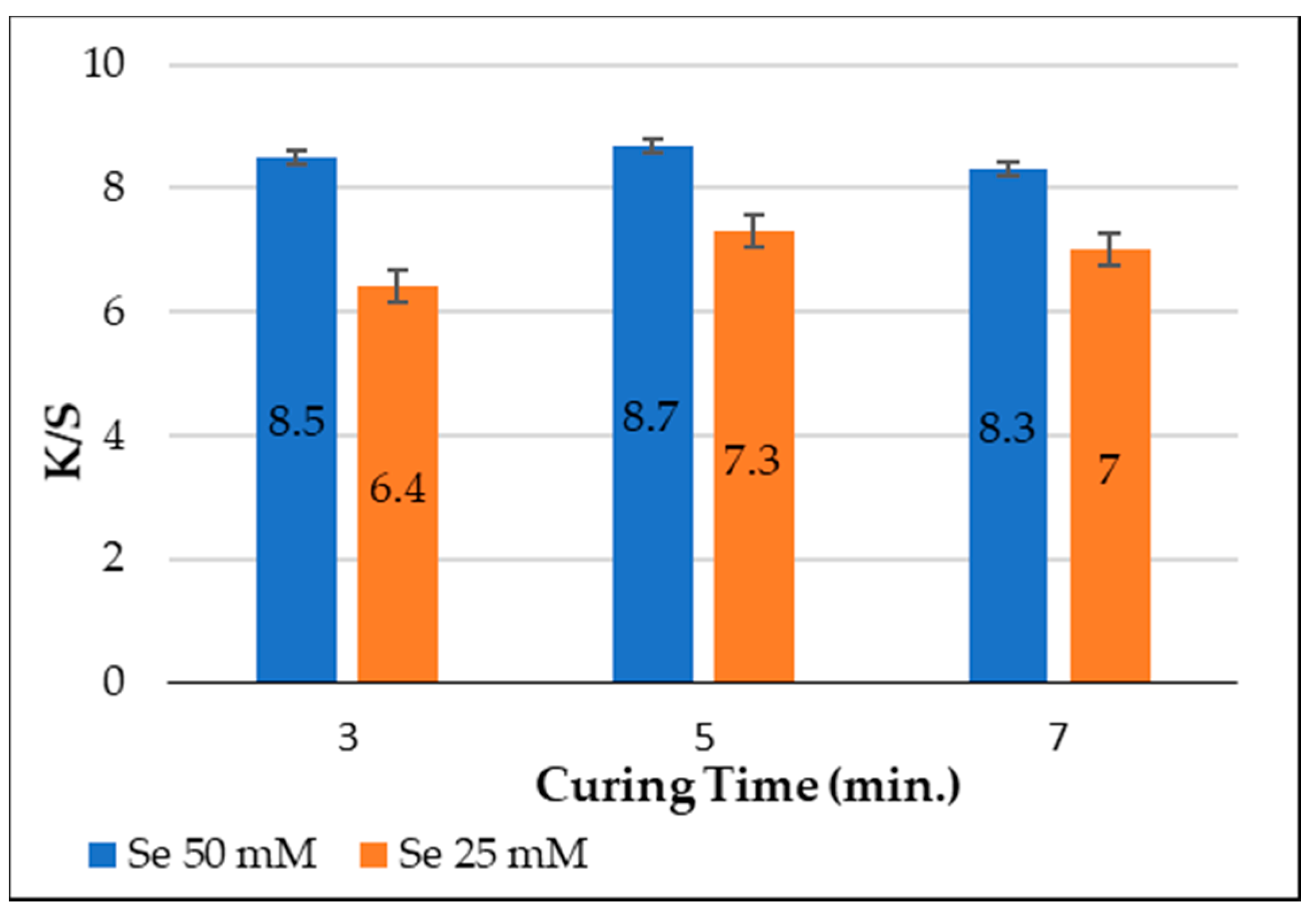

3.7. Mechanical Properties of Polyester Fabrics

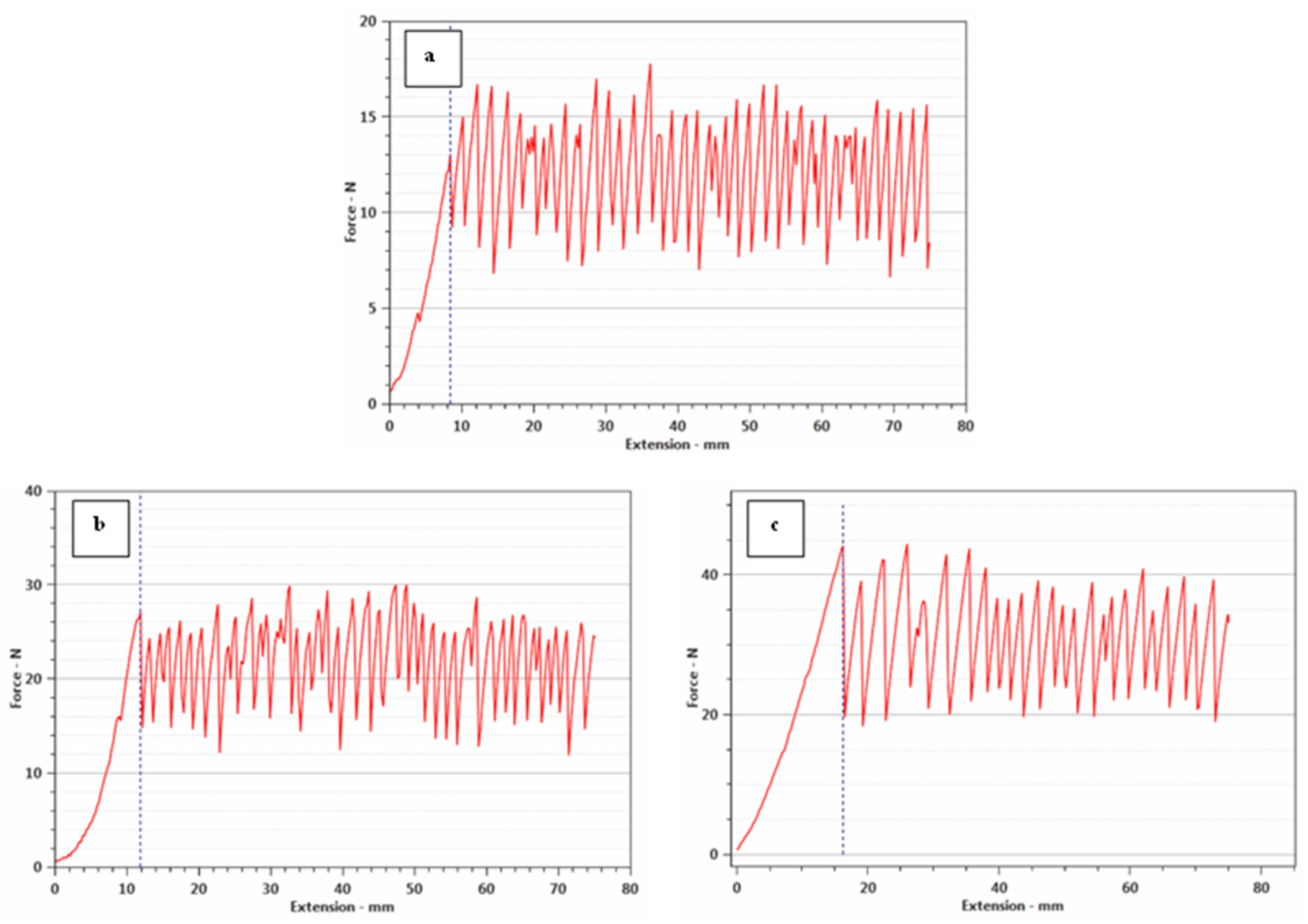

3.8. SEM and EDX Polyester Fabrics

3.9. Evaluation of the Antibacterial Properties of Polyester Fabric

3.10. Evaluation of Antiviral Properties of Polyester Fabric

3.11. Cytotoxicity Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, J.; Hu, Z.; Zabihi, F.; Chen, Z.; Zhu, M. Progress and Perspective of Antiviral Protective Material. Adv. Fiber Mater. 2020, 2, 123–139. [Google Scholar] [CrossRef]

- Masae, M.; Pitsuwan, P.; Kooptarnond, K.; Choopool, P.; Kachintararot, S.; Siriwan, J.; Ficai, A. Synthesis of TiO2 doped selenium nanoparticles using herbal turmeric powders coating on cotton fabric for antibacterial. J. Phys. Conf. Ser. 2018, 1144, 012008. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, W.; Sun, Y.; Chen, W.; Zhang, Y. Application of antiviral materials in textiles: A review. Nanotechnol. Rev. 2021, 10, 1092–1115. [Google Scholar] [CrossRef]

- Liang, L.; Ahamed, A.; Ge, L.; Fu, X.; Lisak, G. Advances in Antiviral Material Development. ChemPlusChem 2020, 85, 2105–2128. [Google Scholar] [CrossRef] [PubMed]

- Bar, G.; Biswas, D.; Pati, S.; Chaudhary, K.; Bar, M. Anti viral Finishing on Textiles - An Overview. Text. Leather Rev. 2021, 4, 5–22. [Google Scholar] [CrossRef]

- Kampf, G.; Todt, D.; Pfaender, S.; Steinmann, E. Persistence of coronaviruses on inanimate surfaces and their inactivation with biocidal agents. J. Hosp. Infect. 2020, 104, 246–251. [Google Scholar] [CrossRef] [Green Version]

- Talebian, S.; Wallace, G.G.; Schroeder, A.; Stellacci, F.; Conde, J. Nanotechnology-based disinfectants and sensors for SARS-CoV-2. Nat. Nanotechnol. 2020, 15, 618–621. [Google Scholar] [CrossRef]

- Joshi, M.; Roy, A. Antimicrobial textiles based on metal and metal oxide nano-particles. In Nanomaterials in the Wet Processing of Textiles; Wiley-VCH Verlag: Hoboken, NJ, USA, 2018; pp. 71–111. [Google Scholar]

- Gabbay, J.; Borkow, G.; Mishal, J.; Magen, E.; Zatcoff, R.; Shemer-Avni, Y. Copper Oxide Impregnated Textiles with Potent Biocidal Activities. J. Ind. Text. 2006, 35, 323–335. [Google Scholar] [CrossRef]

- Borkow, G.; Zhou, S.S.; Page, T.; Gabbay, J. A novel anti-influenza copper oxide containing respiratory face mask. PLoS ONE 2010, 5, e11295. [Google Scholar] [CrossRef] [Green Version]

- Imai, K.; Ogawa, H.; Bui, V.N.; Inoue, H.; Fukuda, J.; Ohba, M.; Yamamoto, Y.; Nakamura, K. Inactivation of high and low pathogenic avian influenza virus H5 subtypes by copper ions incorporated in zeolite-textile materials. Antivir. Res. 2012, 93, 225–233. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Li, J.; Feng, X.; Li, J.; Hao, Y.; Zhang, J.; Wang, H.; Yin, A.; Zhou, J.; Ma, X.; et al. Metal-organic frameworks with photocatalytic bactericidal activity for integrated air cleaning. Nat. Commun. 2019, 10, 2177. [Google Scholar] [CrossRef] [PubMed]

- Patai, S.; Rappoport, Z. The Chemistry of Organic Selenium and Tellurium Compounds; Wiley: Hoboken, NJ, USA, 1986; Volume 1. [Google Scholar]

- Zhang, S.-Y.; Zhang, J.; Wang, H.-Y.; Chen, H.-Y. Synthesis of selenium nanoparticles in the presence of polysaccharides. Mater. Lett. 2004, 58, 2590–2594. [Google Scholar] [CrossRef]

- AbouElmaaty, T.; Abdeldayem, S.A.; Ramadan, S.M.; Sayed-Ahmed, K.; Plutino, M.R. Coloration and Multi-Functionalization of Polypropylene Fabrics with Selenium Nanoparticles. Polymers 2021, 13, 2483. [Google Scholar] [CrossRef] [PubMed]

- Abou Elmaaty, T.M.; Abdeldayem, S.A.; Elshafai, N. Simultaneous Thermochromic Pigment Printing and Se-NP Multifunctional Finishing of Cotton Fabrics for Smart Childrenswear. Cloth. Text. Res. J. 2020, 38, 182–195. [Google Scholar] [CrossRef]

- Razmkhah, M.; Montazer, M.; Bashiri Rezaie, A.; Rad, M.M. Facile technique for wool coloration via locally forming of nano selenium photocatalyst imparting antibacterial and UV protection properties. J. Ind. Eng. Chem. 2021, 101, 153–164. [Google Scholar] [CrossRef]

- Elmaaty, T.M.A.; Raouf, S.; Sayed-Ahmed, K. Novel One Step Printing and Functional Finishing of Wool Fabric Using Selenium Nanoparticles. Fibers Polym. 2020, 21, 1983–1991. [Google Scholar] [CrossRef]

- Jia, X.; Liu, Q.; Zou, S.; Xu, X.; Zhang, L. Construction of selenium nanoparticles/β-glucan composites for enhancement of the antitumor activity. Carbohydr. Polym. 2015, 117, 434–442. [Google Scholar] [CrossRef]

- Chen, W.; Li, Y.; Yang, S.; Yue, L.; Jiang, Q.; Xia, W. Synthesis and antioxidant properties of chitosan and carboxymethyl chitosan-stabilized selenium nanoparticles. Carbohydr. Polym. 2015, 132, 574–581. [Google Scholar] [CrossRef]

- Kong, H.; Yang, J.; Zhang, Y.; Fang, Y.; Nishinari, K.; Phillips, G.O. Synthesis and antioxidant properties of gum arabic-stabilized selenium nanoparticles. Int. J. Biol. Macromol. 2014, 65, 155–162. [Google Scholar] [CrossRef]

- Wang, Q.; Barnes, L.-M.; Maslakov, K.I.; Howell, C.A.; Illsley, M.J.; Dyer, P.; Savina, I.N. In situ synthesis of silver or selenium nanoparticles on cationized cellulose fabrics for antimicrobial application. Mater. Sci. Eng. C 2021, 121, 111859. [Google Scholar] [CrossRef]

- Shakibaie, M.; Forootanfar, H.; Golkari, Y.; Mohammadi-Khorsand, T.; Shakibaie, M.R. Anti-biofilm activity of biogenic selenium nanoparticles and selenium dioxide against clinical isolates of Staphylococcus aureus, Pseudomonas aeruginosa, and Proteus mirabilis. J. Trace Elem. Med. Biol. 2015, 29, 235–241. [Google Scholar] [CrossRef] [PubMed]

- Biswas, D.P.; O’Brien-Simpson, N.M.; Reynolds, E.C.; O’Connor, A.J.; Tran, P.A. Comparative study of novel in situ decorated porous chitosan-selenium scaffolds and porous chitosan-silver scaffolds towards antimicrobial wound dressing application. J. Colloid Interface Sci. 2018, 515, 78–91. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, N.; Mukhopadhyay, M. Biosynthesis and structural characterization of selenium nanoparticles mediated by Zooglea ramigera. Powder Technol. 2013, 244, 26–29. [Google Scholar] [CrossRef]

- Yip, J.; Liu, L.; Wong, K.-H.; Leung, P.H.M.; Yuen, C.-W.M.; Cheung, M.-C. Investigation of antifungal and antibacterial effects of fabric padded with highly stable selenium nanoparticles. J. Appl. Polym. Sci. 2014, 131, 40728. [Google Scholar] [CrossRef]

- Zhai, X.; Zhang, C.; Zhao, G.; Stoll, S.; Ren, F.; Leng, X. Antioxidant capacities of the selenium nanoparticles stabilized by chitosan. J. Nanobiotechnol. 2017, 15, 4. [Google Scholar] [CrossRef] [Green Version]

- Nastulyavichus, A.; Kudryashov, S.; Smirnov, N.; Saraeva, I.; Rudenko, A.; Tolordava, E.; Ionin, A.; Romanova, Y.; Zayarny, D. Antibacterial coatings of Se and Si nanoparticles. Appl. Surf. Sci. 2019, 469, 220–225. [Google Scholar] [CrossRef]

- Huang, X.; Chen, X.; Chen, Q.; Yu, Q.; Sun, D.; Liu, J. Investigation of functional selenium nanoparticles as potent antimicrobial agents against superbugs. Acta Biomater. 2016, 30, 397–407. [Google Scholar] [CrossRef]

- Abou Elmaaty, T.; Raouf, S.; Sayed-Ahmed, K.; Plutino, M. Multifunctional Dyeing of Wool Fabrics Using Selenium Nanoparticles. Polymers 2022, 14, 191. [Google Scholar] [CrossRef]

- Abou Elmaaty, T.; Sayed-Ahmed, K.; Mohamed Ali, R.; El-Khodary, K.; Abdeldayem, S.A. Simultaneous Sonochemical Coloration and Antibacterial Functionalization of Leather with Selenium Nanoparticles (SeNPs). Polymers 2022, 14, 74. [Google Scholar] [CrossRef]

- American Association of Textile Chemists and Colorists, AATTCC 61-1996. Colorfastness to Laundering: Accelerated; AATCC 61: Research Triangle Park, NC, USA, 1996. [Google Scholar]

- American Association of Textile Chemists and Colorists, AATCC Test Method 8-1996. Colorfastness to Crocking; AATCC 8: Research Triangle Park, NC, USA, 1996. [Google Scholar]

- American Association of Textile Chemists and Colorists, AATCC16-2004. Colorfastness to Light; AATCC 16: Research Triangle Park, NC, USA, 2004. [Google Scholar]

- ASTM International, ASTM D638-14. Standard Test Method for Tensile Properties of Plastics; ASTM D638: West Conshohocken, PA, USA, 2015. [Google Scholar]

- American Association of Textile Chemists and Colorists, AATCC 61(2A). Colorfastness to Laundering; AATCC 61: Research Triangle Park, NC, USA, 1996. [Google Scholar]

- Hayden, F.G.; Cote, K.M.; Douglas, R.G., Jr. Plaque inhibition assay for drug susceptibility testing of influenza viruses. Antimicrob. Agents Chemother. 1980, 17, 865–870. [Google Scholar] [CrossRef] [Green Version]

- American Association of Textile Chemists and Colorists, AATTCC 147-2004. Antibacterial Activity Assessment of Textile Materials; AATTCC 147: Research Triangle Park, NC, USA, 2010. [Google Scholar]

- Mosmann, T. Rapid colorimetric assay for cellular growth and survival: Application to proliferation and cytotoxicity assays. J. Immunol. Methods 1983, 65, 55–63. [Google Scholar] [CrossRef]

- Vieira, A.; Stein, E.; Andreguetti, D.; Cebrián-Torrejón, G.; Domènech, A.; Colepicolo, P.; Da Costa Ferreira, A.M. Sweet Chemistry: A Green Way for Obtaining Selenium Nanoparticles Active against Cancer Cells. J. Braz. Chem. Soc. 2017, 28, 2021–2027. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; El-Zairy, E.M.R.; El-Zairy, M.R.; Khalil, H.M. Enhancing disperse printing and ultraviolet protecting of polyester-containing fabrics via pretreatment with chitosan/polyethylene glycol/dimethylol dihydroxyethylene urea. J. Ind. Text. 2012, 42, 269–282. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Ahmad, N.A.; Suhaimi, S.A.; Bakar, N.A.A.; Ahmad, W.Y.W.; Salleh, J.M. Tensile and tearing strength of uncoated and natural rubber latex coated high strength woven fabrics. In Proceedings of the 2012 IEEE Symposium on Humanities, Science and Engineering Research, Kuala Lumpur, Malaysia, 24–26 June 2012; pp. 541–545. [Google Scholar]

- Sharma, G.; Sharma, A.; Bhavesh, R.; Park, J.; Ganbold, B.; Nam, J.-S.; Lee, S.-S. Biomolecule-Mediated Synthesis of Selenium Nanoparticles using Dried Vitis vinifera (Raisin) Extract. Molecules 2014, 19, 2761–2770. [Google Scholar] [CrossRef] [PubMed]

- Makvandi, P.; Iftekhar, S.; Pizzetti, F.; Zarepour, A.; Zare, E.N.; Ashrafizadeh, M.; Agarwal, T.; Padil, V.V.T.; Mohammadinejad, R.; Sillanpaa, M.; et al. Functionalization of polymers and nanomaterials for water treatment, food packaging, textile and biomedical applications: A review. Environ. Chem. Lett. 2021, 19, 583–611. [Google Scholar] [CrossRef]

- Ferro, C.; Florindo, H.F.; Santos, H.A. Selenium Nanoparticles for Biomedical Applications: From Development and Characterization to Therapeutics. Adv. Healthc. Mater. 2021, 10, 2100598. [Google Scholar] [CrossRef]

- Machotová, J.; Kalendová, A.; Zlámaná, B.; Šňupárek, J.; Palarčík, J.; Svoboda, R. Waterborne coating binders based on self-crosslinking acrylic latex with embedded inorganic nanoparticles: A comparison of nanostructured ZnO and MgO as crosslink density enhancing agents. Coatings 2020, 10, 339. [Google Scholar] [CrossRef] [Green Version]

- Rattee, I.D. Improvements in Fabric Printing. European Patent Office. Patent No. 97301520.9. 1997. Available online: https://patents.google.com/patent/EP0799930A2/en (accessed on 4 February 2022).

- Xiang, J.; Ma, L.; Su, H.; Xiong, J.; Li, K.; Xia, Q.; Liu, G. Layer-by-layer assembly of antibacterial composite coating for leather with cross-link enhanced durability against laundry and abrasion. Appl. Surf. Sci. 2018, 458, 978–987. [Google Scholar] [CrossRef]

- Ahmed, T.; Ogulata, R.T.; Sezgin Bozok, S. Silver nanoparticles against SARS-CoV-2 and its potential application in medical protective clothing—A review. J. Text. Inst. 2021, 1–14. [Google Scholar] [CrossRef]

- Owen, L.; Shivkumar, M.; Laird, K. The Stability of Model Human Coronaviruses on Textiles in the Environment and during Health Care Laundering. mSphere 2021, 6, e00316-21. [Google Scholar] [CrossRef]

- Kangwansupamonkon, W.; Lauruengtana, V.; Surassmo, S.; Ruktanonchai, U. Antibacterial effect of apatite-coated titanium dioxide for textiles applications. Nanomed. Nanotechnol. Biol. Med. 2009, 5, 240–249. [Google Scholar] [CrossRef] [PubMed]

| Printing Paste Components | g/kg Paste |

|---|---|

| Thickener | 20 |

| Binder | 100 |

| SeNPs solution | 880 |

| Total | 1000 |

| Type | Sample | L* | a* | b* | C* | |

|---|---|---|---|---|---|---|

| Blank polyester fabric |  | 91.63 | 0.29 | 1.35 | 1.38 | - |

| Printed polyester fabrics with SeNPs (25 mM) |  | 28.38 | 3.11 | 5.13 | 6 | 63.43 |

| Printed polyester fabrics with SeNPs (50 mM) |  | 44.01 | 9.44 | 14.5 | 17.3 | 50.24 |

| Samples | Wash Fastness | Rubbing Fastness | Light Fastness | |||

|---|---|---|---|---|---|---|

| St. | Alt. | Dry | Wet | |||

| Printed polyester fabrics with SeNPs (25 mM) | 5 | 5 | 5 | 5 | 5 | 3.5 |

| Printed polyester fabrics with SeNPs (50 mM) | 5 | 5 | 5 | 5 | 5 | 3.5 |

| After 5 washing cycles (Durability test) | 5 | 5 | 5 | 5 | 5 | 3.5 |

| Warp Specimen | Elongation,a (%) | Maximum Force at Break,b (N) |

|---|---|---|

| Blank polyester sample | 40.66% | 1069 |

| Printed polyester fabrics with SeNPs (25 mM) | 44.66% | 1402.3 |

| Printed polyester fabrics with SeNPs (50 mM) | 53.34% | 1340.4 |

| SeNPs Concentration | Bacillus Cereus (G+) | Escherichia Coli (G-) | Pseudomonas Aeruginosa (G-) | Salmonella Typhi (G-) |

|---|---|---|---|---|

| Polyster fabric (blank) | - | - | - | - |

| Polyster printed with SeNPs (25 mM) | 15 | 9 | 18 | 23 |

| Polyster printed with SeNPs (25 mM) (after 5 washing cycles) | 15 | 8 | 17 | 23 |

| Polyster printed with SeNPs (50 mM) | 12 | 4 | 16 | 12 |

| Polyster printed with SeNPs (50 mM) (after 5 washing cycles) | 11 | 3 | 16 | 12 |

| Tetracycline (30 µg) | 15 | 19 | 16 | 13 |

| Ciprofloxacin (10 µg) | 18 | 21 | 17 | 15 |

| Sample Code | 60 min (Post-Treatment) | ||

|---|---|---|---|

| Tissue Plus Virus (PFU/mL) | Virus Control Count (PFU/mL) | Inhibition (%) | |

| Printed polyester fabrics with SeNPs (25 mM) | 6.6 × 105 | 8.8 × 105 | 25% |

| Polyster printed with SeNPs (25 mM) (after 5 washing cycles) | 6.6 × 105 | 8.8 × 105 | 25% |

| Printed polyester fabrics with SeNPs (50 mM) | 1.1 × 105 | 8.8 × 105 | 87.5% |

| Polyster printed with SeNPs (50 mM) (after 5 washing cycles) | 1.1 × 105 | 8.8 × 105 | 87.5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abou Elmaaty, T.; Sayed-Ahmed, K.; Elsisi, H.; Ramadan, S.M.; Sorour, H.; Magdi, M.; Abdeldayem, S.A. Novel Antiviral and Antibacterial Durable Polyester Fabrics Printed with Selenium Nanoparticles (SeNPs). Polymers 2022, 14, 955. https://doi.org/10.3390/polym14050955

Abou Elmaaty T, Sayed-Ahmed K, Elsisi H, Ramadan SM, Sorour H, Magdi M, Abdeldayem SA. Novel Antiviral and Antibacterial Durable Polyester Fabrics Printed with Selenium Nanoparticles (SeNPs). Polymers. 2022; 14(5):955. https://doi.org/10.3390/polym14050955

Chicago/Turabian StyleAbou Elmaaty, Tarek, Khaled Sayed-Ahmed, Hanan Elsisi, Shaimaa M. Ramadan, Heba Sorour, Mai Magdi, and Shereen A. Abdeldayem. 2022. "Novel Antiviral and Antibacterial Durable Polyester Fabrics Printed with Selenium Nanoparticles (SeNPs)" Polymers 14, no. 5: 955. https://doi.org/10.3390/polym14050955

APA StyleAbou Elmaaty, T., Sayed-Ahmed, K., Elsisi, H., Ramadan, S. M., Sorour, H., Magdi, M., & Abdeldayem, S. A. (2022). Novel Antiviral and Antibacterial Durable Polyester Fabrics Printed with Selenium Nanoparticles (SeNPs). Polymers, 14(5), 955. https://doi.org/10.3390/polym14050955