Design of Large-Scale Microwave Cavity for Uniform and Efficient Plastic Heating

Abstract

:1. Introduction

2. Simulation and Experiments

2.1. Numerical Model

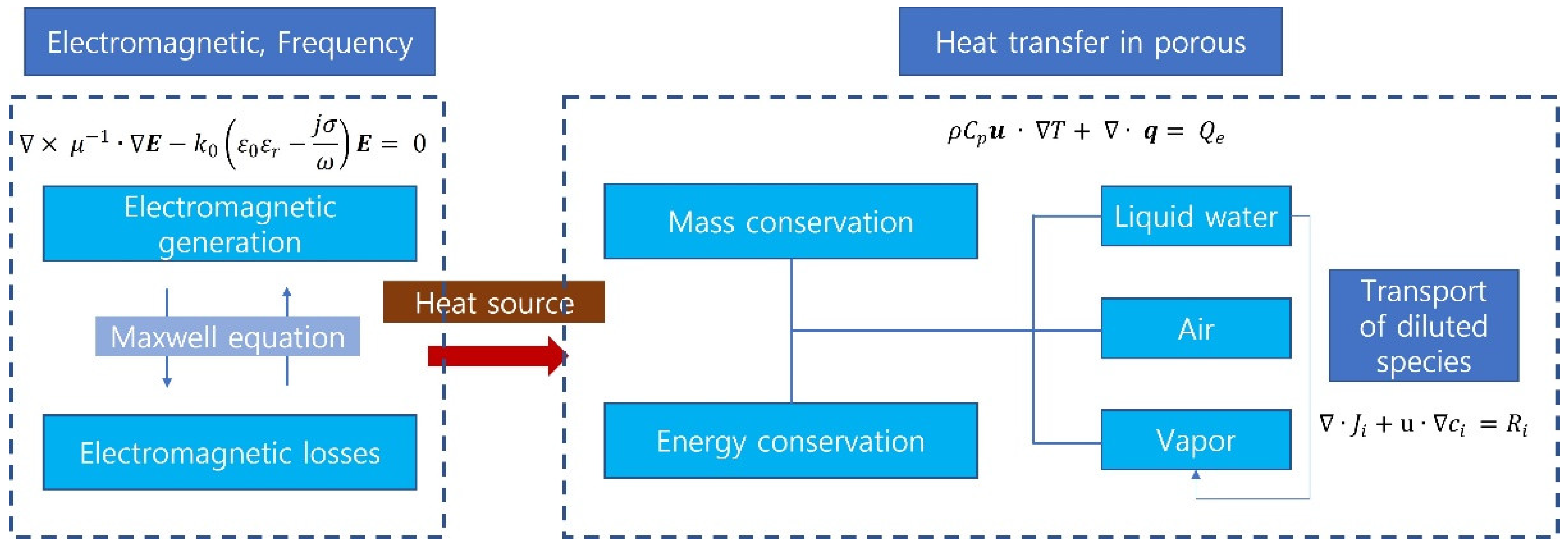

2.1.1. Simulation Domain and Modules

2.1.2. Geometry

2.1.3. Assumption

- The cavity walls and waveguides are in the impedance condition;

- The cavity walls and waveguides are completely insulated;

- All materials are homogeneous;

- Chemical reactions are not considered in the heating process;

- The heat transfer model applies only to polycarbonates;

- Shrinkage of pellets is not considered;

- The influence of air flow is not considered;

- The dielectric constant and loss factor are independent of temperature and humidity;

- The frequency of the microwave is fixed at 2.45 GHz, which remains constant.

2.1.4. Governing Equations

2.1.5. Boundary Condition

Electromagnetic Boundary Conditions

Thermal Condition

Mass Condition

2.1.6. Mesh

2.2. Experiments

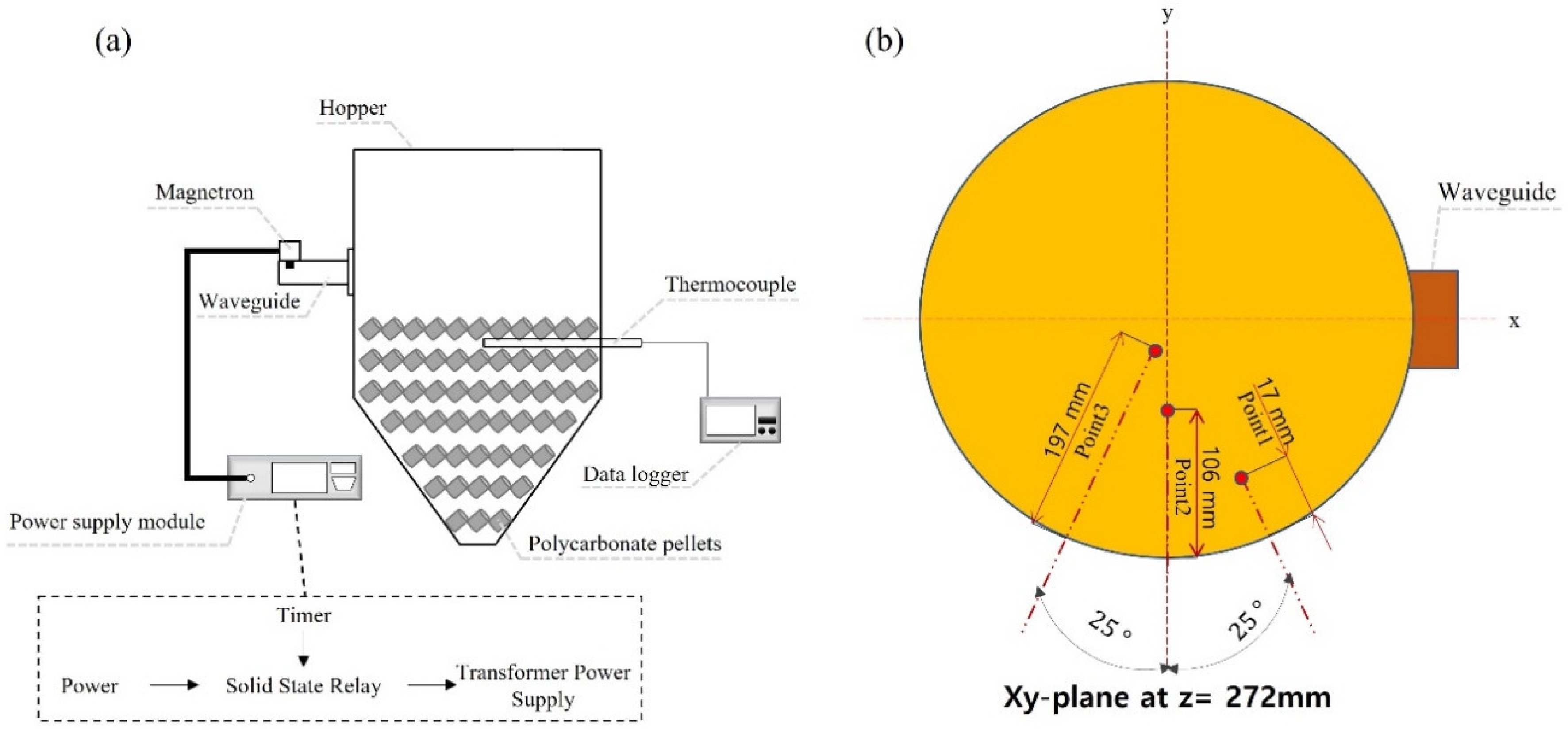

2.2.1. Experimental Setup

2.2.2. Experimental Procedure

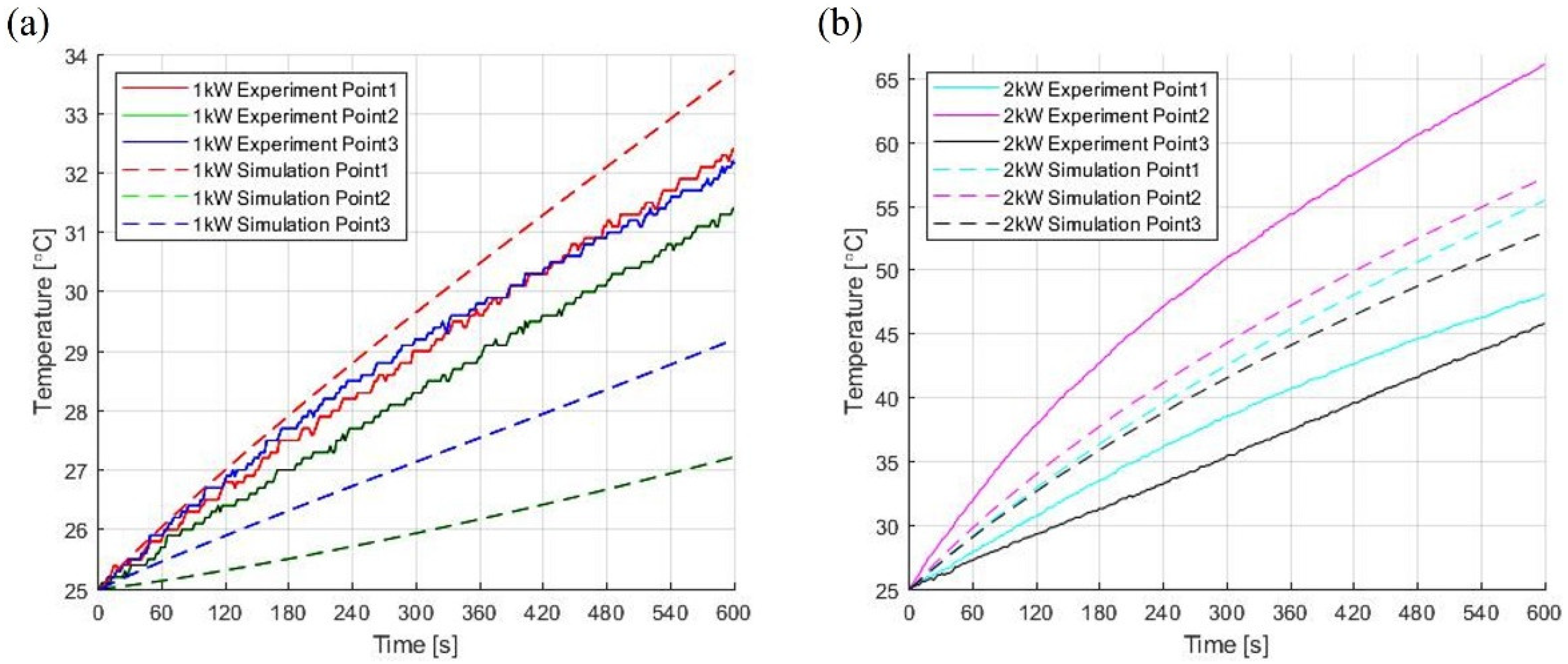

2.2.3. Experiment Validation

3. Results and Discussion

3.1. Parameters

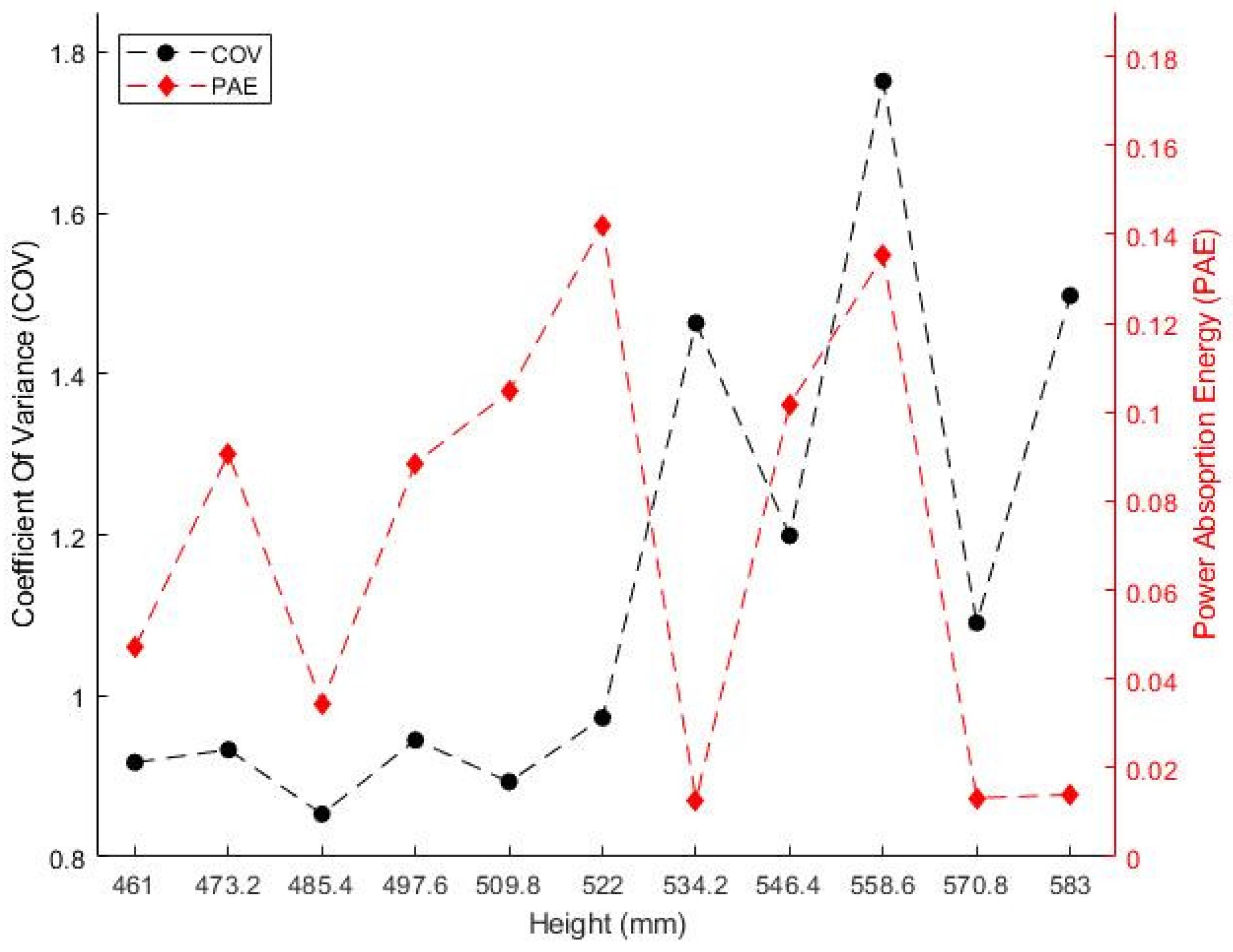

3.2. Effect of Cavity Height

3.3. Effect of a Reflector

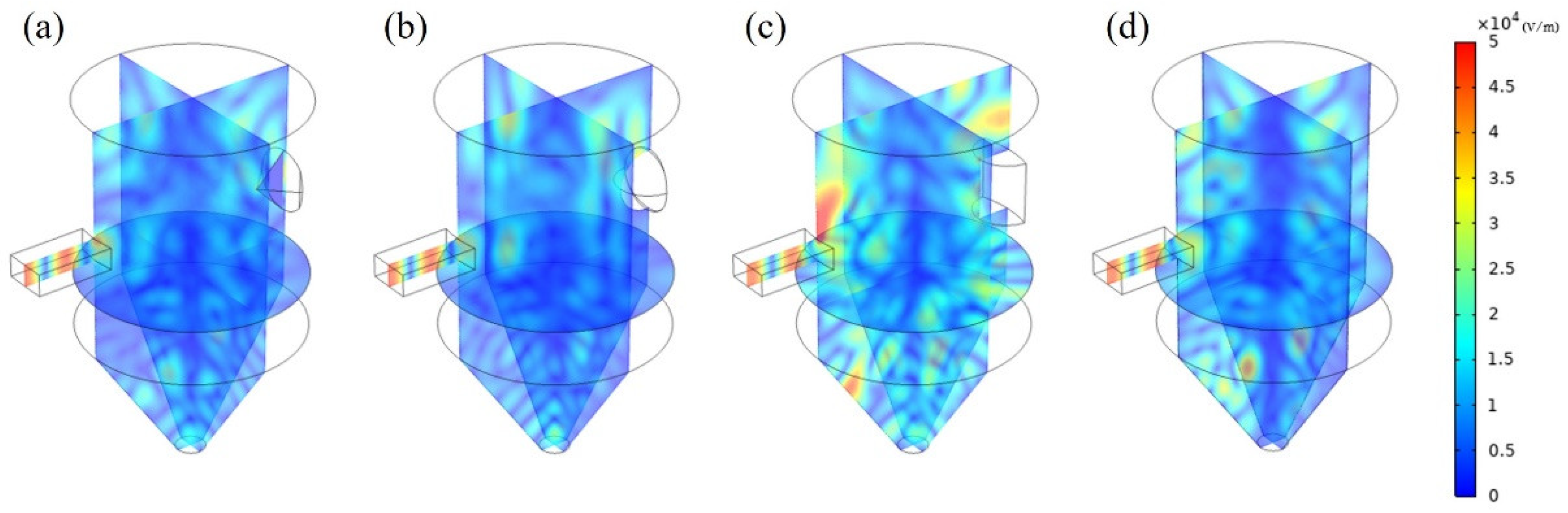

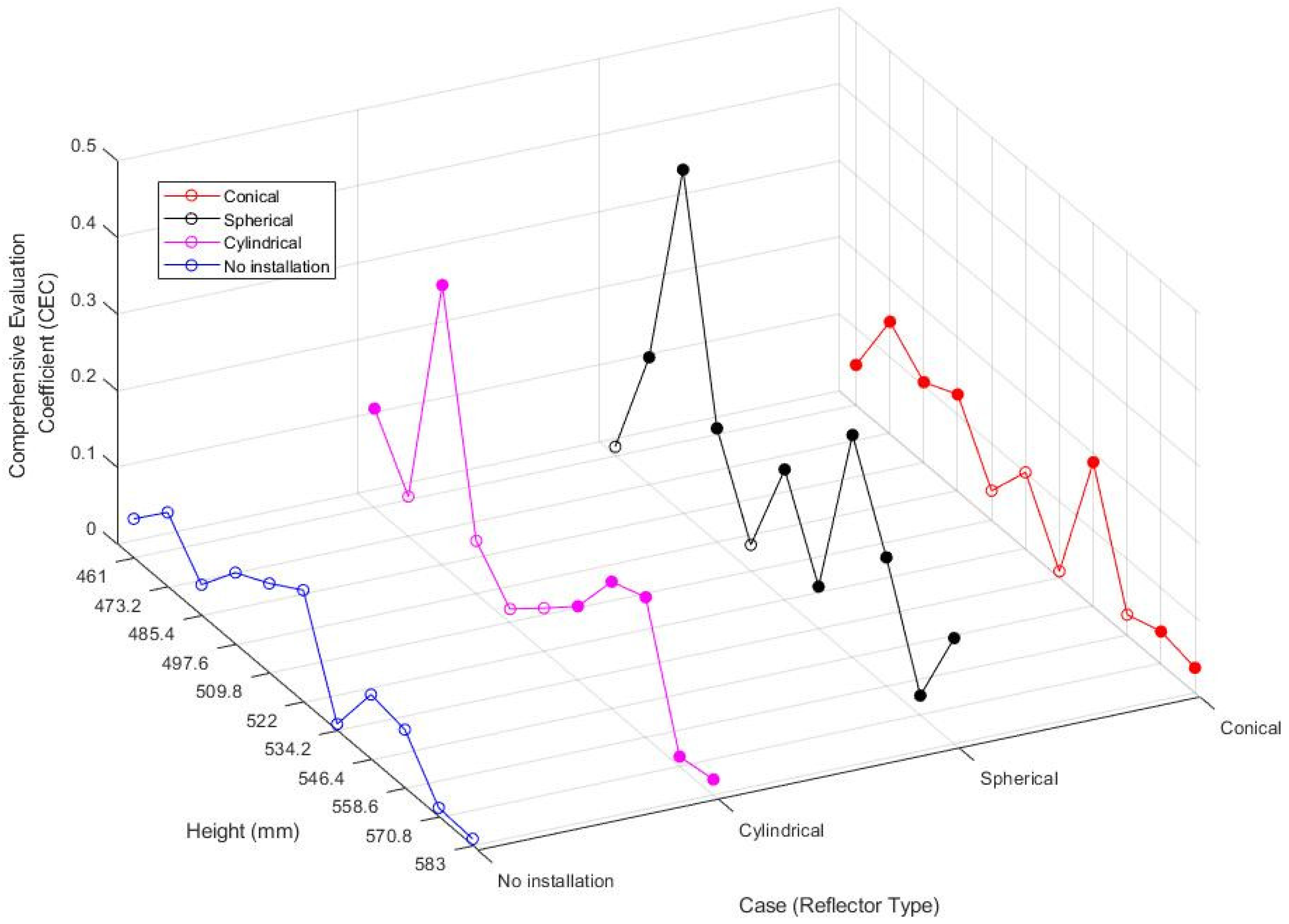

Effect of Reflector Shape

3.4. Effect of Double Waveguides

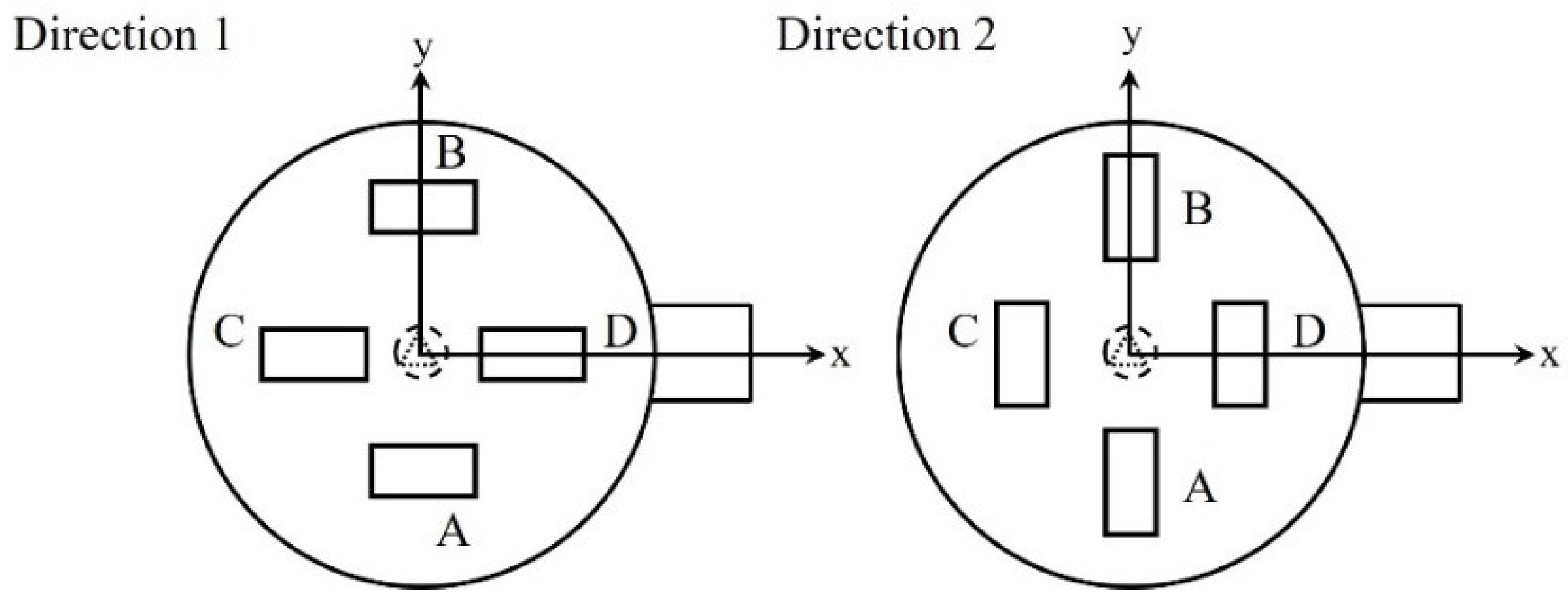

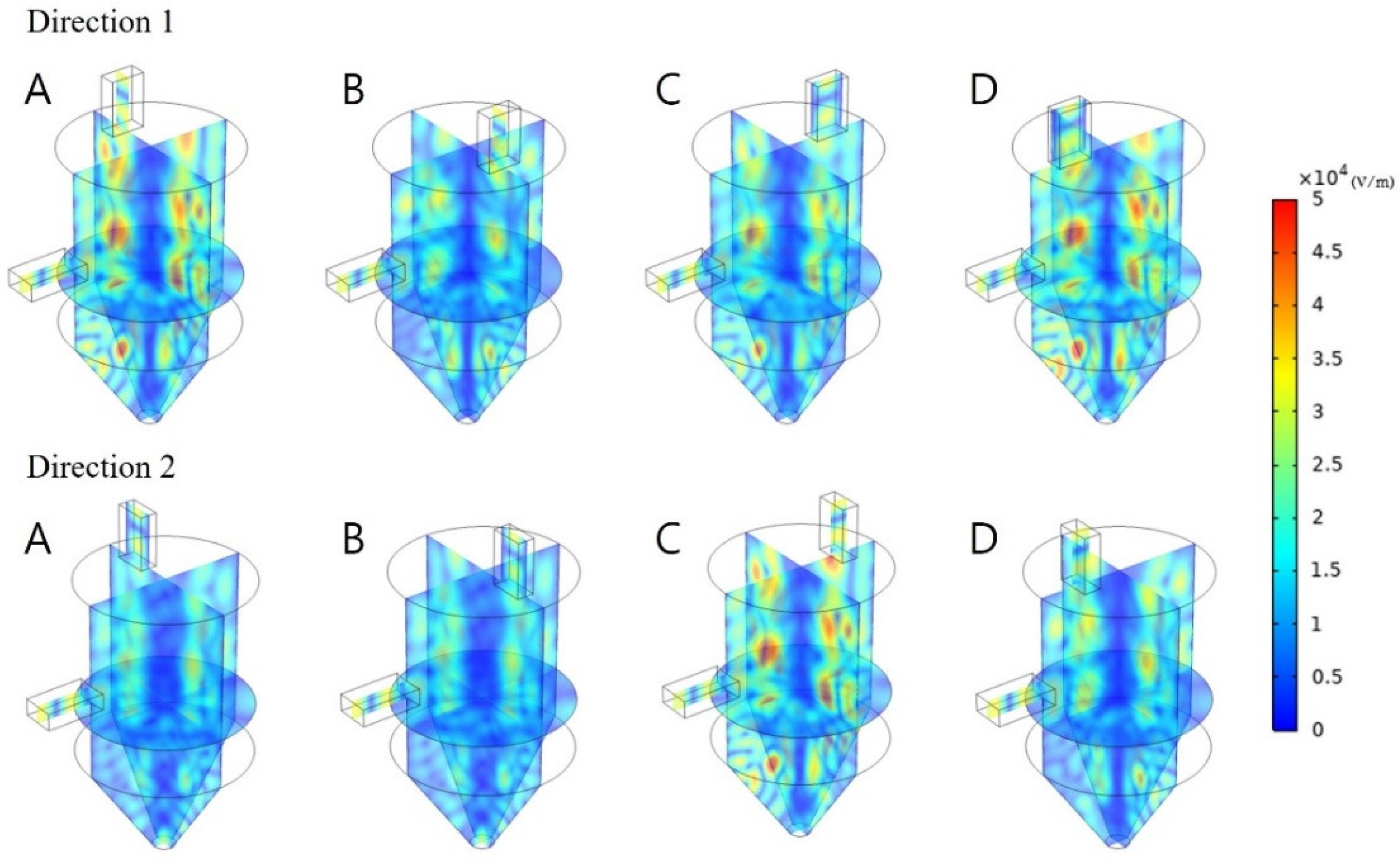

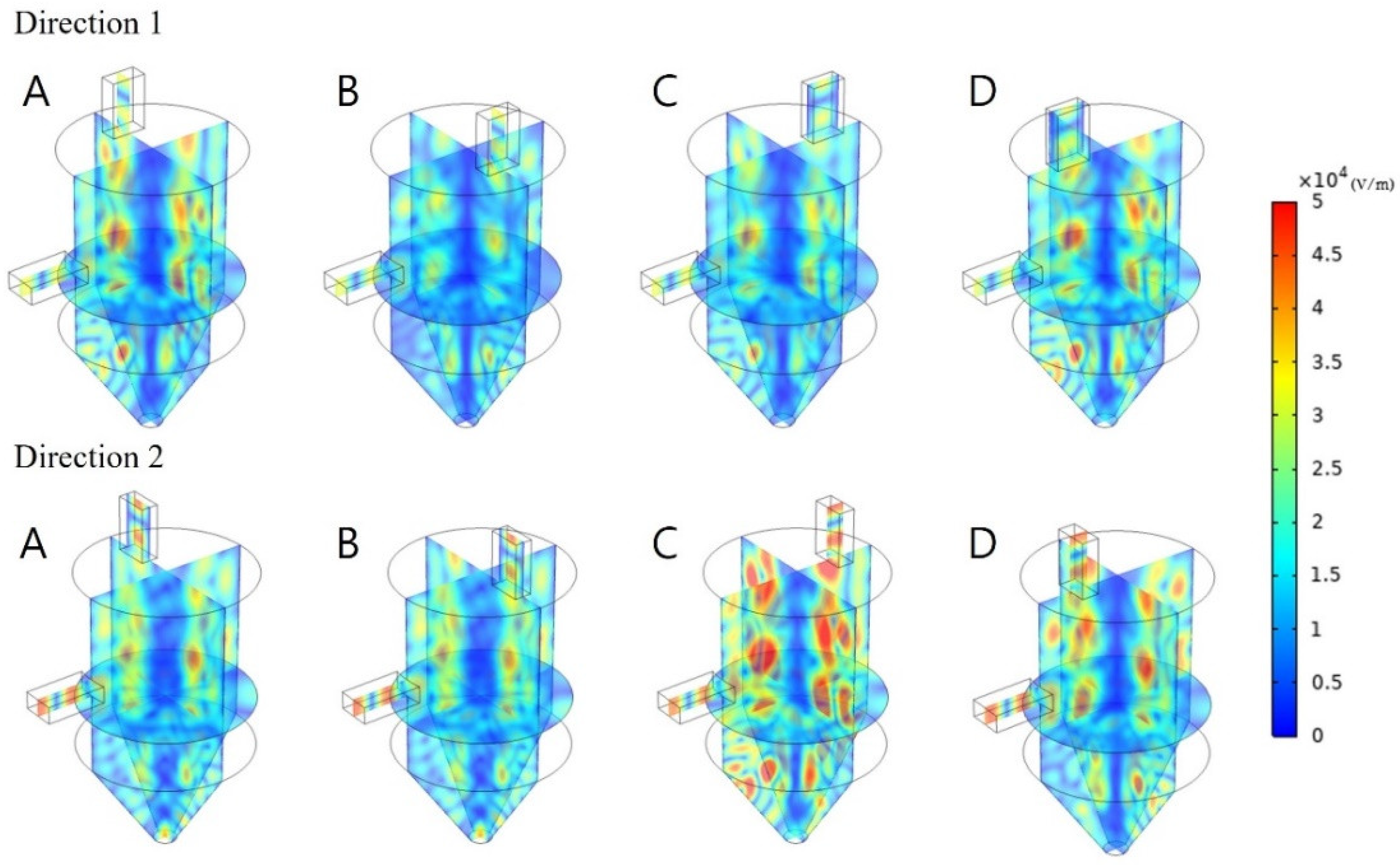

3.4.1. Effect of Double Waveguides, Position, and Direction

3.4.2. Effect of Double Waveguide Power

4. Conclusions

- (1)

- Despite a slight change in the cavity height caused by changing the wavelength by one-tenth, the electromagnetic field distribution and parameters were considerably changed. The COV value, which means heating uniformity, and the PAE value, which means heating efficiency, were changed up to double and 11 times, respectively;

- (2)

- The installation of reflectors significantly changed the electromagnetic field distribution. When reflectors were installed, uniform heating was generally achieved, and the power absorption also increased. The spherical reflector had the highest efficiency; 9 out of 11 cases showed better CEC values with a comprehensive coefficient that reflects both PAE and COV.

- (3)

- When double waveguides were used, the target material was uniformly heated, and the energy absorption increased at the same time because electromagnetic waves reached areas that were difficult to reach using the single waveguide. So, the average COV was improved by 22%, and power absorption efficiency was increased by 53% compared to the single waveguide model. These results came from the reduction of interference phenomenon by the vertical arrangement of waveguides.

- (4)

- As the applied power increased, the form of the electromagnetic field distribution did not change, although the size of the hot spot increased. The average COV value was 0.647, which was 117% lower than the basic model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency (IEA). Available online: https://www.iea.org/articles/global-energy-review-co2-emissions-in-2020 (accessed on 26 December 2021).

- Nielsen, T.D.; Hasselbalch, J.; Holmberg, K.; Stripple, J. Politics and the plastic crisis: A review throughout the plastic life cycle. Wiley Interdiscip. Rev. Energy Environ. 2020, 9, e360. [Google Scholar] [CrossRef] [Green Version]

- Oyeyinka, S.A.; Akintayo, O.A.; Adebo, O.A.; Kayitesi, E.; Njobeh, P.B. A review on the physicochemical properties of starches modified by microwave alone and in combination with other methods. Int. J. Biol. Macromol. 2021, 176, 87–95. [Google Scholar] [CrossRef] [PubMed]

- Wei, W.; Shao, Z.-S.; Chen, W.-W.; Zhang, P.-J.; Yuan, Y. A Fully Coupled Electromagnetic Irradiation, Heat and Mass Transfer Model of Microwave Heating on Concrete. IEEE Access 2020, 9, 1575–1589. [Google Scholar] [CrossRef]

- Zhu, H.; He, J.; Hong, T.; Yang, Q.; Wu, Y.; Yang, Y.; Huang, K. A rotary radiation structure for microwave heating uniformity improvement. Appl. Therm. Eng. 2018, 141, 648–658. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, X.; Luo, Z.; Sun, J.; Li, L.; Yin, X.; Li, J.; Xu, Y. Effects of inside-out heat-shock via microwave on the fruit sofmtening and quality of persimmon during postharvest storage. Food Chem. 2021, 349, 129161. [Google Scholar] [CrossRef]

- Zhan, L.; Yang, Y.; Li, W.; Wang, G.; Li, Y.; Wang, N. Drying kinetics and mechanical properties of low temperature microwave dried cashmere fibers. Text. Res. J. 2020, 90, 2745–2754. [Google Scholar] [CrossRef]

- Amini, A.; Latifi, M.; Chaouki, J. Electrification of materials processing via microwave irradiation: A review of mechanism and applications. Appl. Therm. Eng. 2021, 193, 117003. [Google Scholar] [CrossRef]

- Jie, X.; Li, W.; Slocombe, D.; Gao, Y.; Banerjee, I.; Gonzalez-Cortes, S.; Yao, B.; Almegren, H.; Alshihri, S.; Dilworth, J.; et al. Microwave-initiated catalytic deconstruction of plastic waste into hydrogen and high-value carbons. Nat. Catal. 2020, 3, 902–912. [Google Scholar] [CrossRef]

- Suriapparao, D.V.; Vinu, R. Biomass waste conversion into value-added products via microwave-assisted copyrolysis platform. Renew. Energy 2021, 170, 400–409. [Google Scholar] [CrossRef]

- Ferraro, A.; Lio, G.E.; Hmina, A.; Palermo, G.; Djouda, J.M.; Maurer, T.; Caputo, R. Tailoring of plasmonic functionalized metastructures to enhance local heating release. Nanophotonics 2021, 10, 3907–3916. [Google Scholar] [CrossRef]

- Emanuele Lio, G.; De Luca, A.; Umeton, C.P.; Caputo, R. Opto-mechanically induced thermoplasmonic response of unclonable flexible tags with hotspot fingerprint. J. Appl. Phys. 2020, 128, 093107. [Google Scholar] [CrossRef]

- Ferraro, A.; Cerza, P.; Mussi, V.; Maiolo, L.; Convertino, A.; Caputo, R. Efficient Photothermal Generation by Nanoscale Light Trapping in a Forest of Silicon Nanowires. J. Phys. Chem. C 2021, 125, 14134–14140. [Google Scholar] [CrossRef]

- Li, Q.; Ling, Y.; Zheng, H.; Chen, G.; Chen, J.; Koppala, S.; Jiang, Q.; Li, K.; Omran, M.; Gao, L. Phase microstructure and morphology evolution of MgO-PSZ ceramics during the microwave sintering process. Ceram. Int. 2021, 47, 15849–15858. [Google Scholar] [CrossRef]

- Gupta, D.; Sharma, A.K. Microwave cladding: A new approach in surface engineering. J. Manuf. Process. 2014, 16, 176–182. [Google Scholar] [CrossRef]

- Aguilar-Reynosa, A.; Romani, A.; Rodriguez-Jasso, R.M.; Aguilar, C.N.; Garrote, G.; Ruiz, H.A. Microwave heating processing as alternative of pretreatment in second-generation biorefinery: An overview. Energy Convers. Manag. 2017, 136, 50–65. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Yan, B.; Yang, Y.; Zhu, H.; Huang, K. Accordion microwave oven for uniformity and efficiency heating. Int. J. RF Microw. Comput. Eng. 2020, 30, e22190. [Google Scholar] [CrossRef]

- Li, Z.Y.; Wang, R.F.; Kudra, T. Uniformity Issue in Microwave Drying. Dry. Technol. 2011, 29, 652–660. [Google Scholar] [CrossRef]

- He, J.; Yang, Y.; Zhu, H.; Li, K.; Yao, W.; Huang, K. Microwave heating based on two rotary waveguides to improve efficiency and uniformity by gradient descent method. Appl. Therm. Eng. 2020, 178, 115594. [Google Scholar] [CrossRef]

- Ye, J.; Zhu, H.; Yang, Y.; Huang, K.; Raghavan, G.V. Dynamic analysis of a continuous-flow microwave-assisted screw propeller system for biodiesel production. Chem. Eng. Sci. 2019, 202, 146–156. [Google Scholar] [CrossRef]

- Yi, Q.; Lan, J.; Ye, J.; Zhu, H.; Yang, Y.; Wu, Y.; Huang, K. A simulation method of coupled model for a microwave heating process with multiple moving elements. Chem. Eng. Sci. 2020, 231, 116339. [Google Scholar] [CrossRef]

- Halim, S.A.; Swithenbank, J. Simulation study of parameters influencing microwave heating of biomass. J. Energy Inst. 2019, 92, 1191–1212. [Google Scholar] [CrossRef]

- Mokhta, Z.M.; Ong, M.Y.; Salman, B.; Nomanbhay, S.; Salleh, S.F.; Chew, K.W.; Show, P.-L.; Chen, W.-H. Simulation studies on microwave-assisted pyrolysis of biomass for bioenergy production with special attention on waveguide number and location. Energy 2019, 190, 116474. [Google Scholar] [CrossRef]

- Chen, R.-J.; Qiao, N.; Arowo, M.; Zou, H.-K.; Chu, G.-W.; Luo, Y.; Sun, B.-C.; Chen, J.-F. Modeling for Temperature Distribu-tion of Water in a Multiwaveguide Microwave Reactor. Ind. Eng. Chem. Res. 2020, 59, 4762–4774. [Google Scholar] [CrossRef]

- Hong, Y.-D.; Lin, B.-Q.; Li, H.; Dai, H.-M.; Zhu, C.-J.; Yao, H. Three-dimensional simulation of microwave heating coal sample with varying parameters. Appl. Therm. Eng. 2016, 93, 1145–1154. [Google Scholar] [CrossRef]

- Dominguez-Tortajada, E.; Monzo-Cabrera, J.; Morcillo, A.B.D. Uniform Electric Field Distribution in Microwave Heating Applicators by Means of Genetic Algorithms Optimization of Dielectric Multilayer Structures. IEEE Trans. Microw. Theory Tech. 2007, 55, 85–91. [Google Scholar] [CrossRef] [Green Version]

- Fu, W.; Dai, J.; Zhang, Y.; Guang, M.; Liu, Y.; Li, B. Heating performances of high density polyethylene (HDPE) plastic particles in a microwave chamber. Sustain. Energy Technol. Assess. 2021, 48, 101581. [Google Scholar] [CrossRef]

- Waudby, H.; Zein, S.H. A circular economy approach for industrial scale biodiesel production from palm oil mill effluent using microwave heating: Design, simulation, techno-economic analysis and location comparison. Process. Saf. Environ. Prot. 2021, 148, 1006–1018. [Google Scholar] [CrossRef]

- Sivagami, K.; Divyapriya, G.; Selvaraj, R.; Madhiyazhagan, P.; Sriram, N.; Nambi, I. Catalytic pyrolysis of polyolefin and multilayer packaging based waste plastics: A pilot scale study. Process. Saf. Environ. Prot. 2020, 149, 497–506. [Google Scholar] [CrossRef]

- Li, H.; Shi, S.; Lin, B.; Lu, J.; Lu, Y.; Ye, Q.; Wang, Z.; Hong, Y.; Zhu, X. A fully coupled electromagnetic, heat transfer and multiphase porous media model for microwave heating of coal. Fuel Process. Technol. 2019, 189, 49–61. [Google Scholar] [CrossRef]

- COMSOL. Heat Transfer Module User’s Guide. COMSOL Multiphysics® V5.6. 2021. Available online: www.comsol.com (accessed on 26 December 2021).

- Amini, A.; Ohno, K.; Maeda, T.; Kunitomo, K. Effect of particle size and apparent density on the initial stages of temperature increase during the microwave heating of Fe3O4. Powder Technol. 2018, 338, 101–109. [Google Scholar] [CrossRef]

- Buttress, A.; Jones, A.; Kingman, S. Microwave processing of cement and concrete materials–towards an industrial reality? Cem. Concret Res. 2015, 68, 112–123. [Google Scholar] [CrossRef]

- Lin, B.; Li, H.; Chen, Z.; Zheng, C.; Hong, Y.; Wang, Z. Sensitivity analysis on the microwave heating of coal: A coupled electromagnetic and heat transfer model. Appl. Therm. Eng. 2017, 126, 949–962. [Google Scholar] [CrossRef]

- Tamang, S.; Aravindan, S. 3D numerical modelling of microwave heating of SiC susceptor. Appl. Therm. Eng. 2019, 162, 114250. [Google Scholar] [CrossRef]

- Cui, K.; Liao, T.; Qiu, C.; Chen, H.; Zhou, J. Microwave-induced heating behavior of Y-TZP ceramics under multiphysics system. Green Process. Synth. 2020, 9, 119–130. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, X.; Chu, Y.; Li, X.; Yuan, J. A novel algorithm approach for rapid simulated microwave heating of food moving on a conveyor belt. J. Food Eng. 2020, 282, 110029. [Google Scholar] [CrossRef]

- Zhao, H.; Li, H.; Li, X.; Gao, X. Process intensification for improving the uniformity and efficiency of microwave heating reactor by bubbles-enhanced flow method. Appl. Therm. Eng. 2021, 197, 117346. [Google Scholar] [CrossRef]

- Gao, X.; Liu, X.; Yan, P.; Li, X.; Li, H. Numerical analysis and optimization of the microwave inductive heating performance of water film. Int. J. Heat Mass Transf. 2019, 139, 17–30. [Google Scholar] [CrossRef]

- Ye, J.; Xia, Y.; Yi, Q.; Zhu, H.; Yang, Y.; Huang, K.; Shi, K. Multiphysics modeling of microwave heating of solid samples in rotary lifting motion in a rectangular multi-mode cavity. Innov. Food Sci. Emerg. Technol. 2021, 73, 102767. [Google Scholar] [CrossRef]

- Zhang, Z.; Su, T.; Zhang, S. Shape Effect on the Temperature Field during Microwave Heating Process. J. Food Qual. 2018, 2018, 9169875. [Google Scholar] [CrossRef] [Green Version]

| No. | Parameters | Value or Expression | Reference |

|---|---|---|---|

| 1 | Microwave frequency | - | |

| 2 | Microwave power | - | |

| 3 | Air moisture concentration | [4] | |

| 4 | Relative permittivity of polycarbonate | [9] | |

| 5 | Thermal conductivity 1 | - | |

| 6 | Polycarbonate density 1 | - |

| Height (mm) | Evaluation | Conical | Spherical | Cylindrical | No Installation |

|---|---|---|---|---|---|

| 461 | COV | 0.638 | 1.349 | 0.612 | 0.917 |

| PAE | 0.033 | 0.016 | 0.079 | 0.047 | |

| 473.2 | COV | 1.861 | 2.010 | 1.138 | 0.933 |

| PAE | 0.271 | 0.348 | 0.058 | 0.091 | |

| 485.4 | COV | 0.646 | 0.856 | 0.640 | 0.853 |

| PAE | 0.067 | 0.384 | 0.233 | 0.034 | |

| 497.6 | COV | 0.690 | 0.979 | 1.095 | 0.945 |

| PAE | 0.087 | 0.145 | 0.074 | 0.089 | |

| 509.8 | COV | 1.549 | 1.773 | 1.240 | 0.893 |

| PAE | 0.059 | 0.060 | 0.021 | 0.105 | |

| 522 | COV | 0.982 | 0.795 | 0.898 | 0.973 |

| PAE | 0.098 | 0.135 | 0.050 | 0.142 | |

| 534.2 | COV | 1.607 | 0.800 | 1.183 | 1.463 |

| PAE | 0.013 | 0.043 | 0.113 | 0.013 | |

| 546.4 | COV | 1.090 | 0.582 | 0.683 | 1.199 |

| PAE | 0.205 | 0.168 | 0.113 | 0.102 | |

| 558.6 | COV | 1.575 | 0.978 | 0.894 | 1.764 |

| PAE | 0.042 | 0.164 | 0.163 | 0.135 | |

| 570.8 | COV | 0.800 | 0.738 | 1.218 | 1.091 |

| PAE | 0.034 | 0.019 | 0.015 | 0.013 | |

| 583 | COV | 1.244 | 0.679 | 1.650 | 1.497 |

| PAE | 0.0401 | 0.093 | 0.033 | 0.014 |

| Direction | Evaluation | A | B | C | D | Average | Single Waveguide |

|---|---|---|---|---|---|---|---|

| 1 | COV | 0.686 | 0.780 | 0.717 | 0.659 | 0.710 | 0.917 |

| PAE | 0.081 | 0.052 | 0.080 | 0.116 | 0.082 | 0.046 | |

| 2 | COV | 0.830 | 0.831 | 0.578 | 0.566 | 0.701 | 0.917 |

| PAE | 0.050 | 0.050 | 0.087 | 0.049 | 0.059 | 0.046 |

| Direction | Evaluation | A | B | C | D | Average |

|---|---|---|---|---|---|---|

| 1 | COV | 0.631 | 0.666 | 0.663 | 0.628 | 0.647 |

| PAE | 0.081 | 0.052 | 0.080 | 0.116 | 0.082 | |

| 2 | COV | 0.827 | 0.829 | 0.576 | 0.565 | 0.699 |

| PAE | 0.050 | 0.050 | 0.087 | 0.049 | 0.059 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, S.; Kim, J.; Yang, D. Design of Large-Scale Microwave Cavity for Uniform and Efficient Plastic Heating. Polymers 2022, 14, 541. https://doi.org/10.3390/polym14030541

Jeon S, Kim J, Yang D. Design of Large-Scale Microwave Cavity for Uniform and Efficient Plastic Heating. Polymers. 2022; 14(3):541. https://doi.org/10.3390/polym14030541

Chicago/Turabian StyleJeon, Sangjun, Jaekyung Kim, and Daejong Yang. 2022. "Design of Large-Scale Microwave Cavity for Uniform and Efficient Plastic Heating" Polymers 14, no. 3: 541. https://doi.org/10.3390/polym14030541

APA StyleJeon, S., Kim, J., & Yang, D. (2022). Design of Large-Scale Microwave Cavity for Uniform and Efficient Plastic Heating. Polymers, 14(3), 541. https://doi.org/10.3390/polym14030541