Electrospun Nanofibers Based on Polymer Blends with Tunable High-Performance Properties for Innovative Fire-Resistant Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

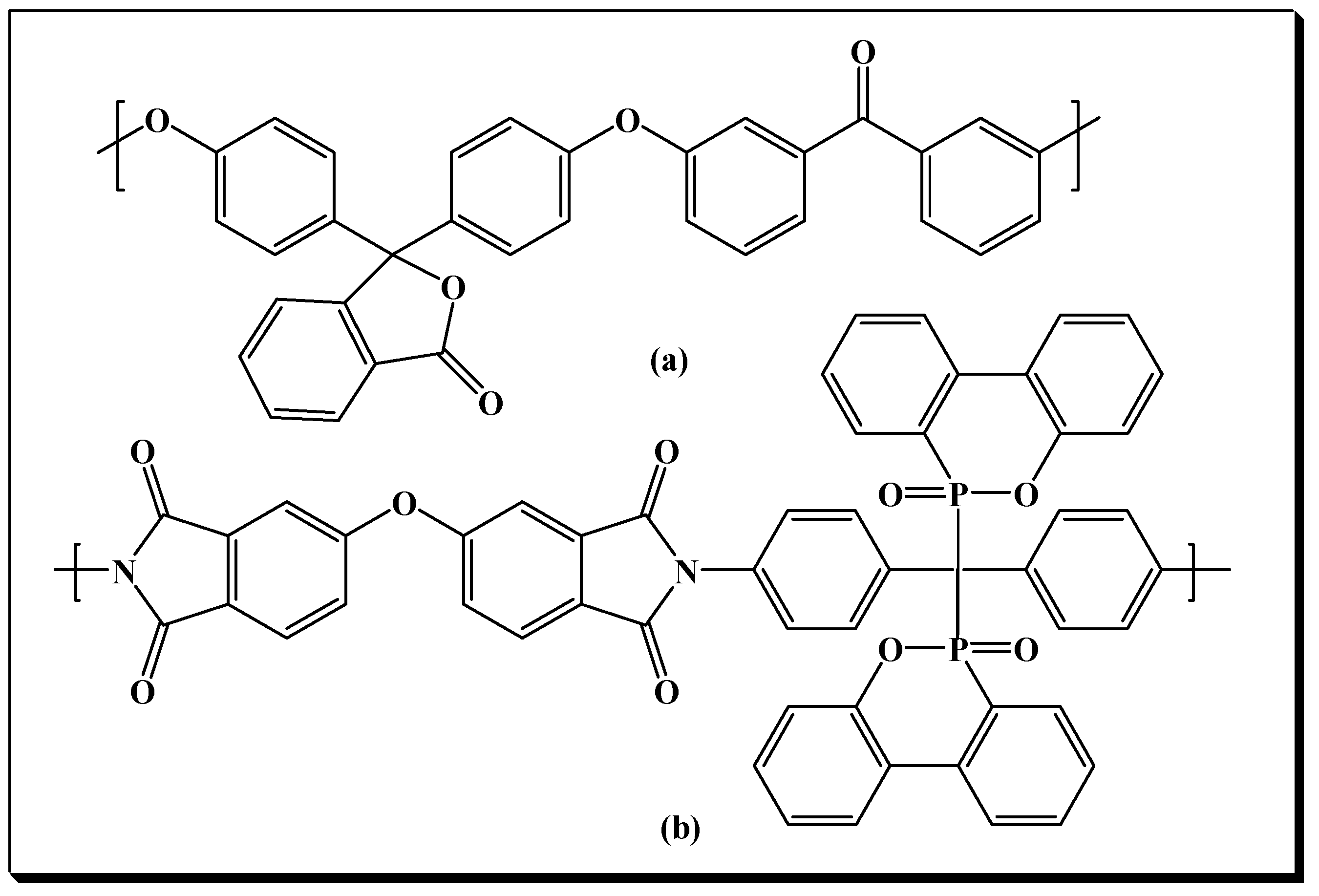

2.2. Synthesis of PEEK

2.3. Synthesis of Phosphorus-Containing Polyimide (PI-1)

2.4. Preparation of PEEK/PI-1 Solution for Electrospinning

2.5. Electrospinning Process

2.6. Measurements

2.6.1. Rheological Study

2.6.2. FTIR Spectroscopy

2.6.3. NMR Spectroscopy

2.6.4. Scanning Electron Microscopy

2.6.5. BET Analysis

2.6.6. Differential Scanning Calorimetry

2.6.7. Thermogravimetric Analysis

2.6.8. Mechanical Testing

2.6.9. Heat Treatment

2.6.10. Heat Transmission

3. Results and Discussion

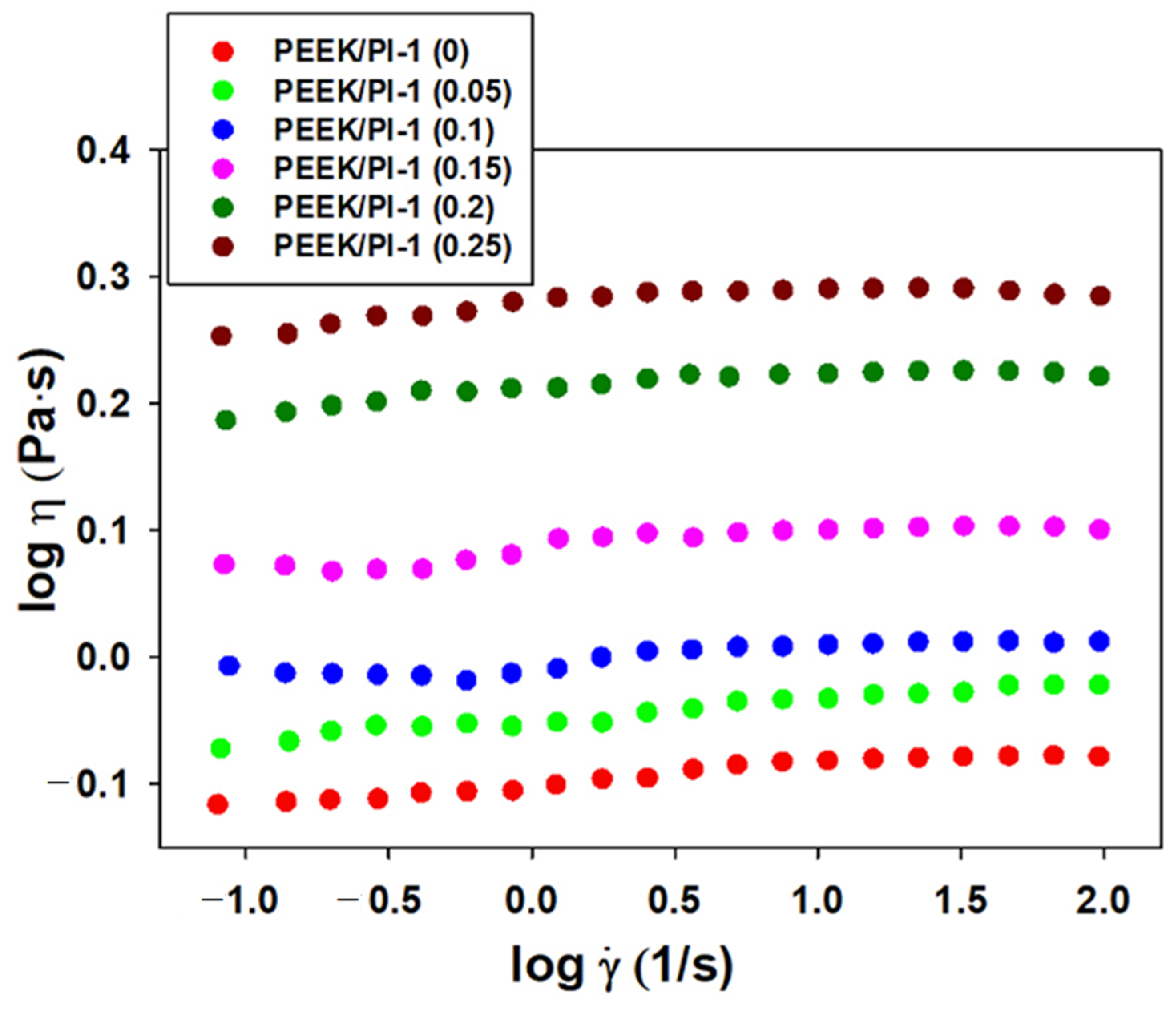

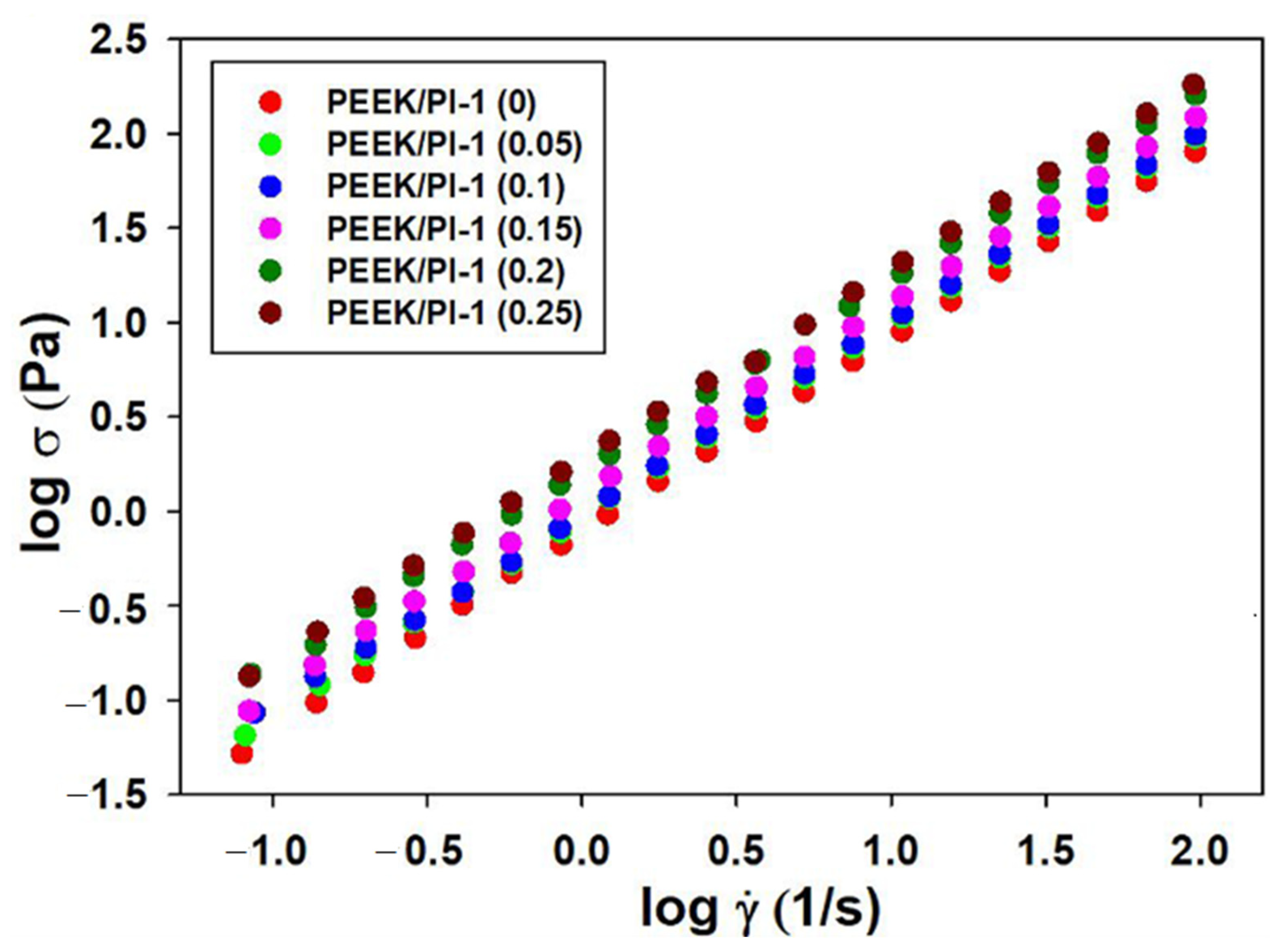

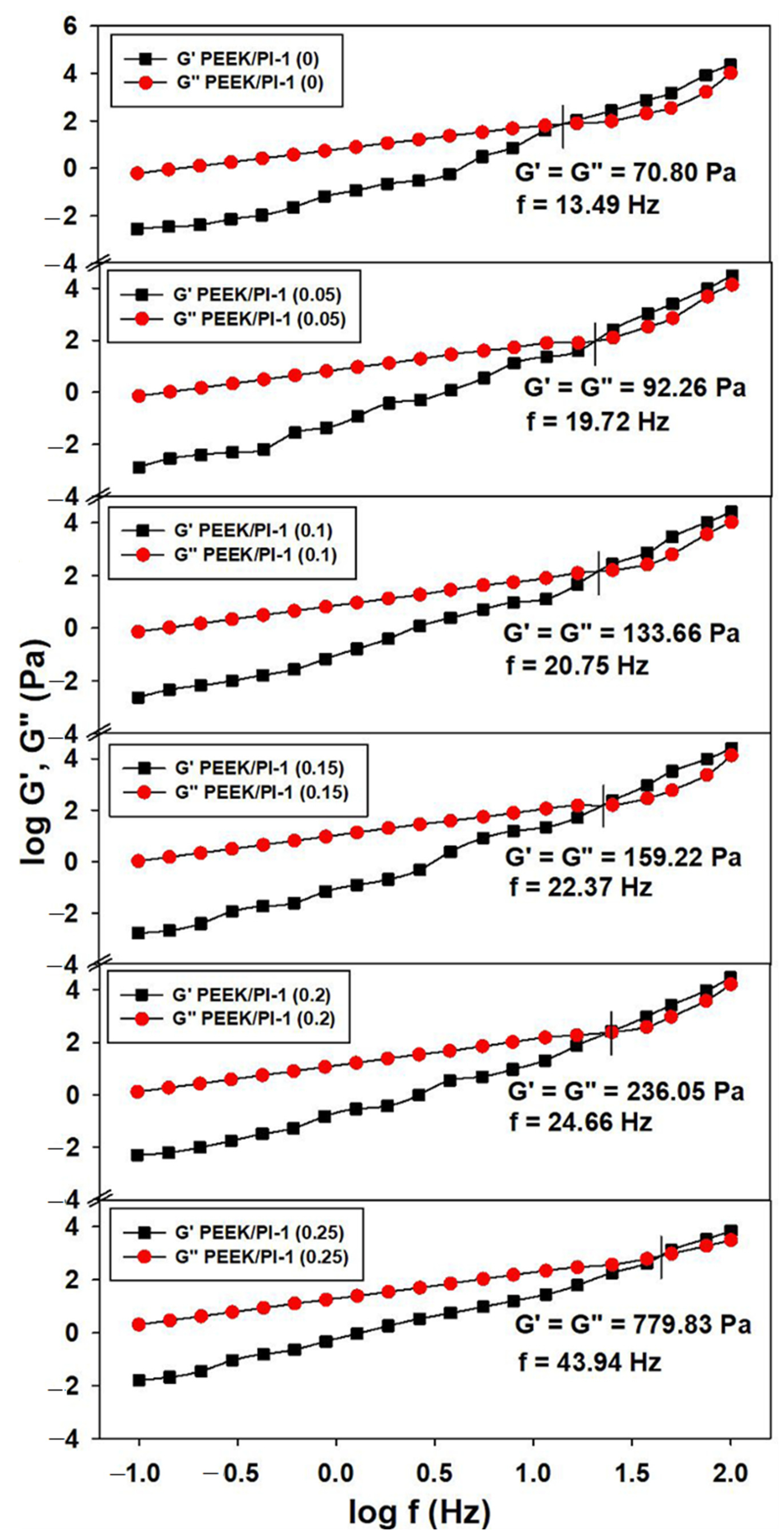

3.1. Dynamic and Steady State Rheology

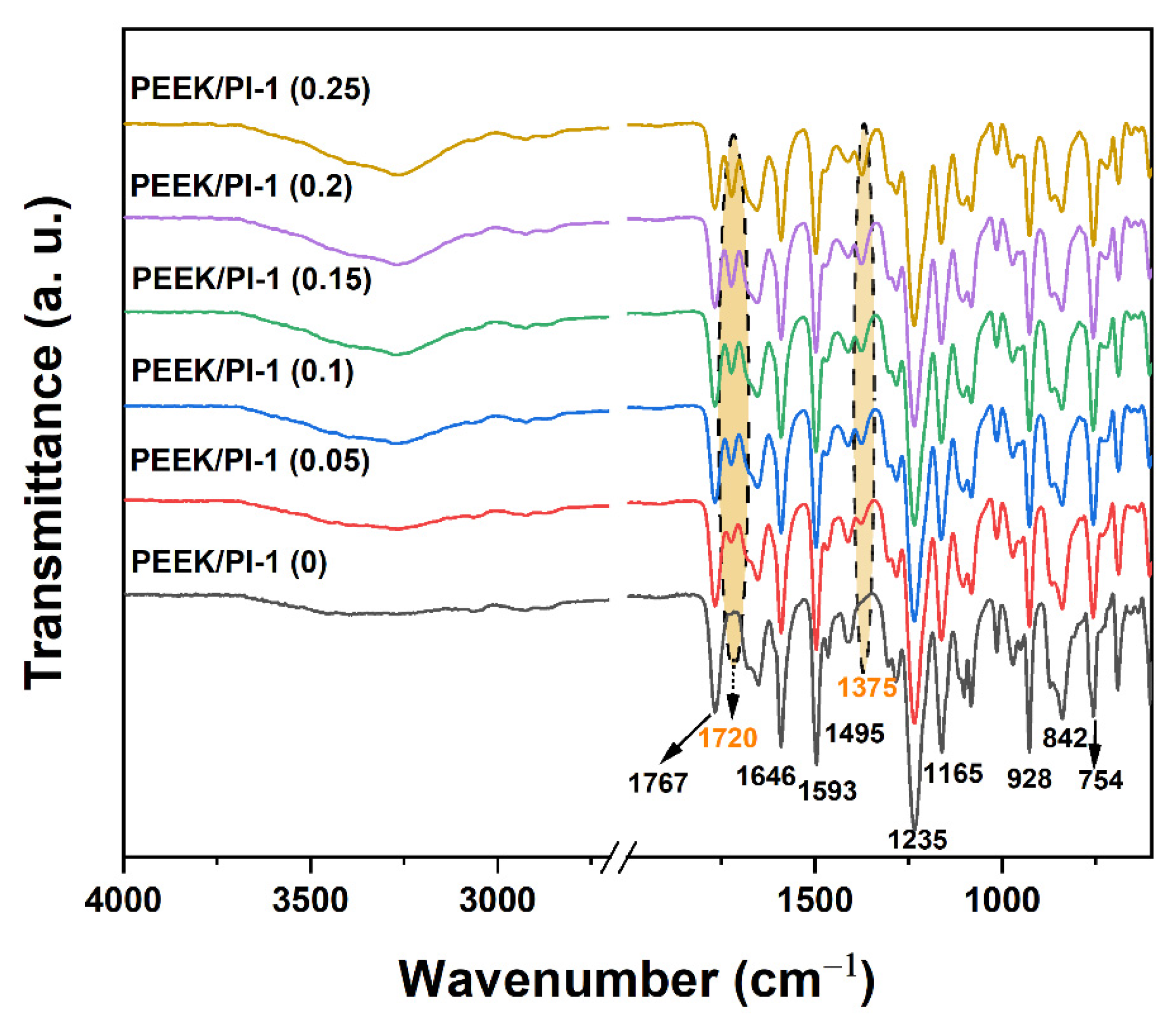

3.2. Structural Identification

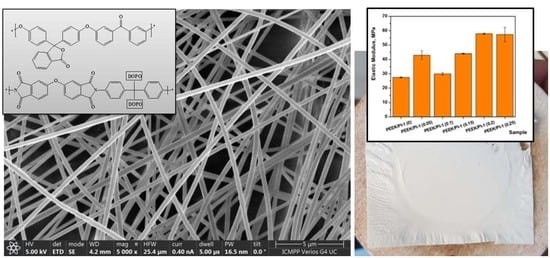

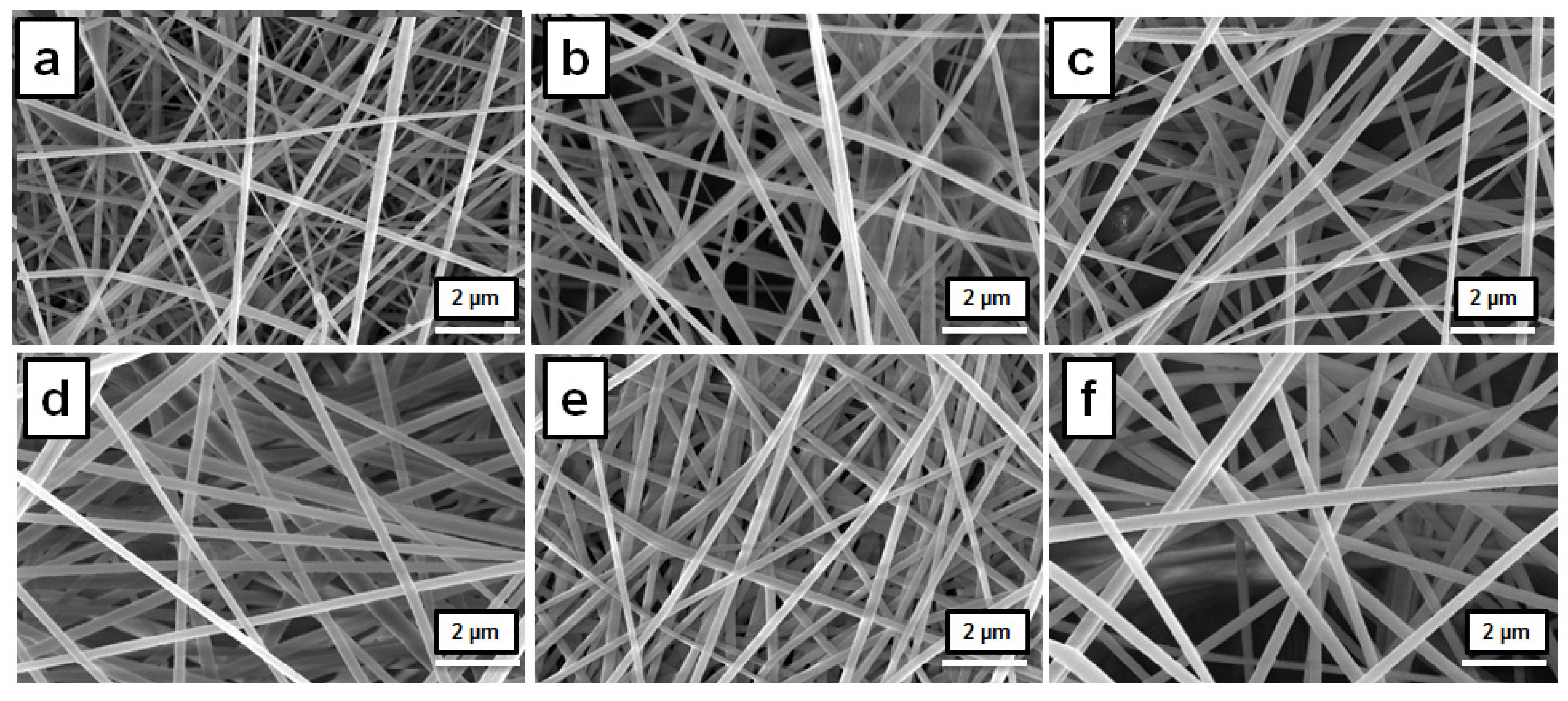

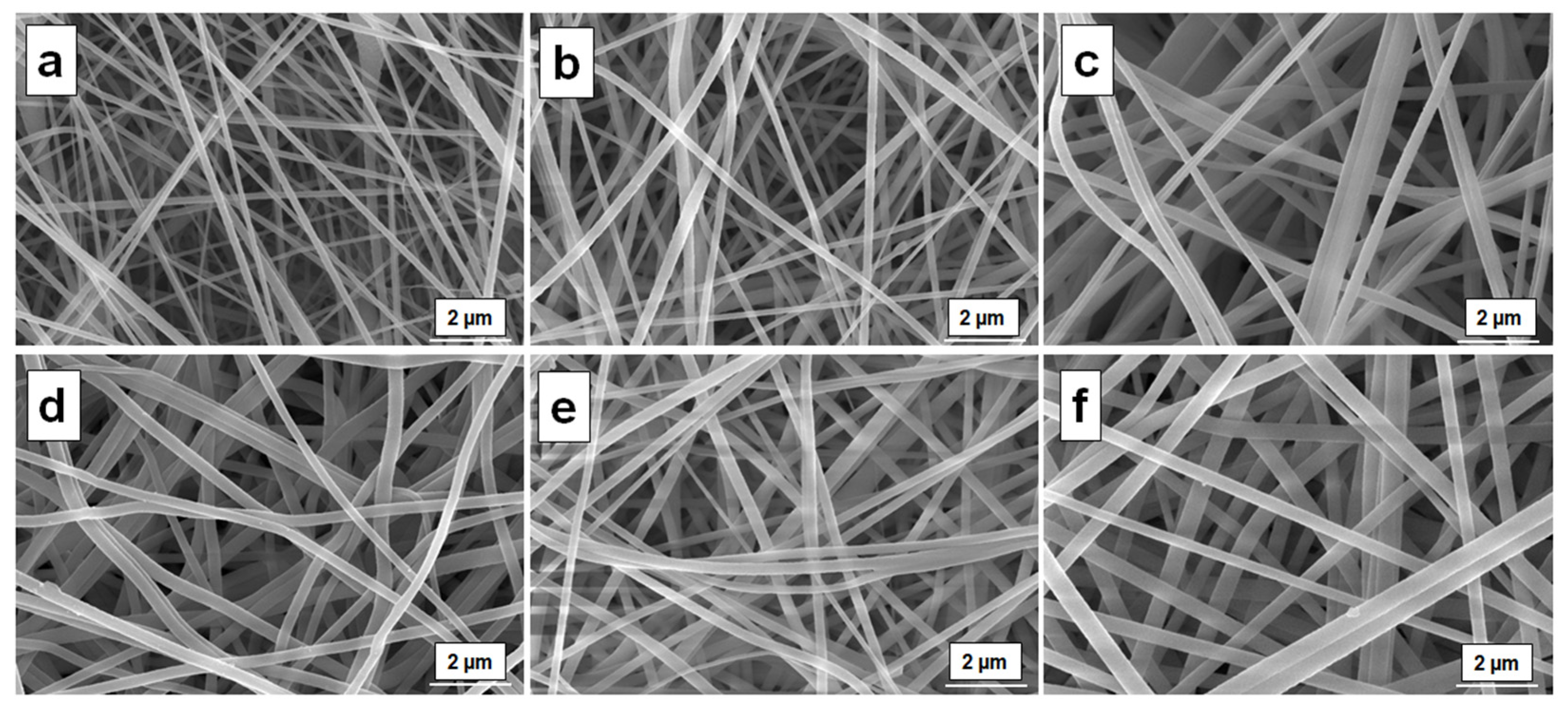

3.3. Electrospun PEEK/PI-1 Fibers Morphology

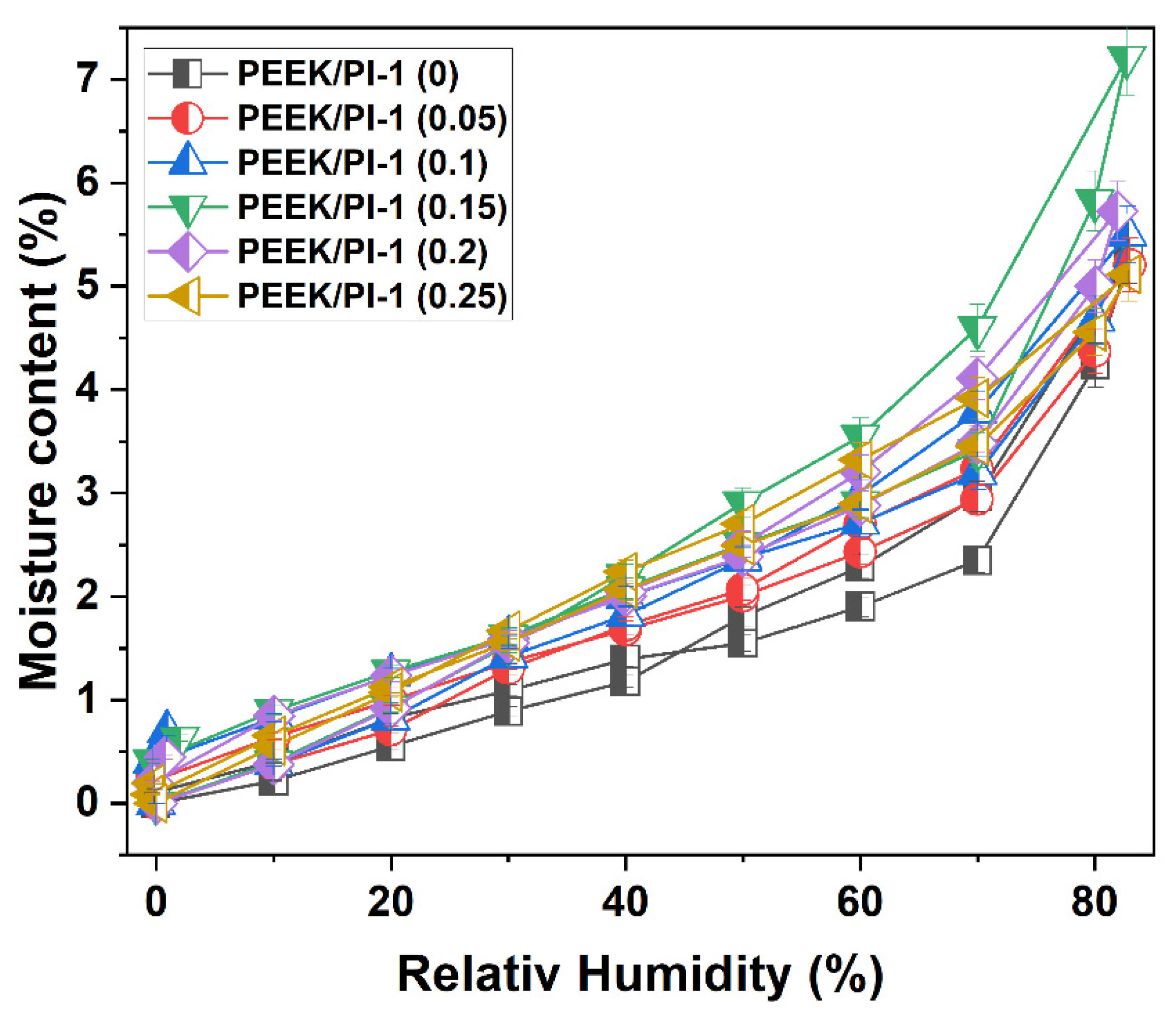

3.4. Water Vapor Sorption Behavior

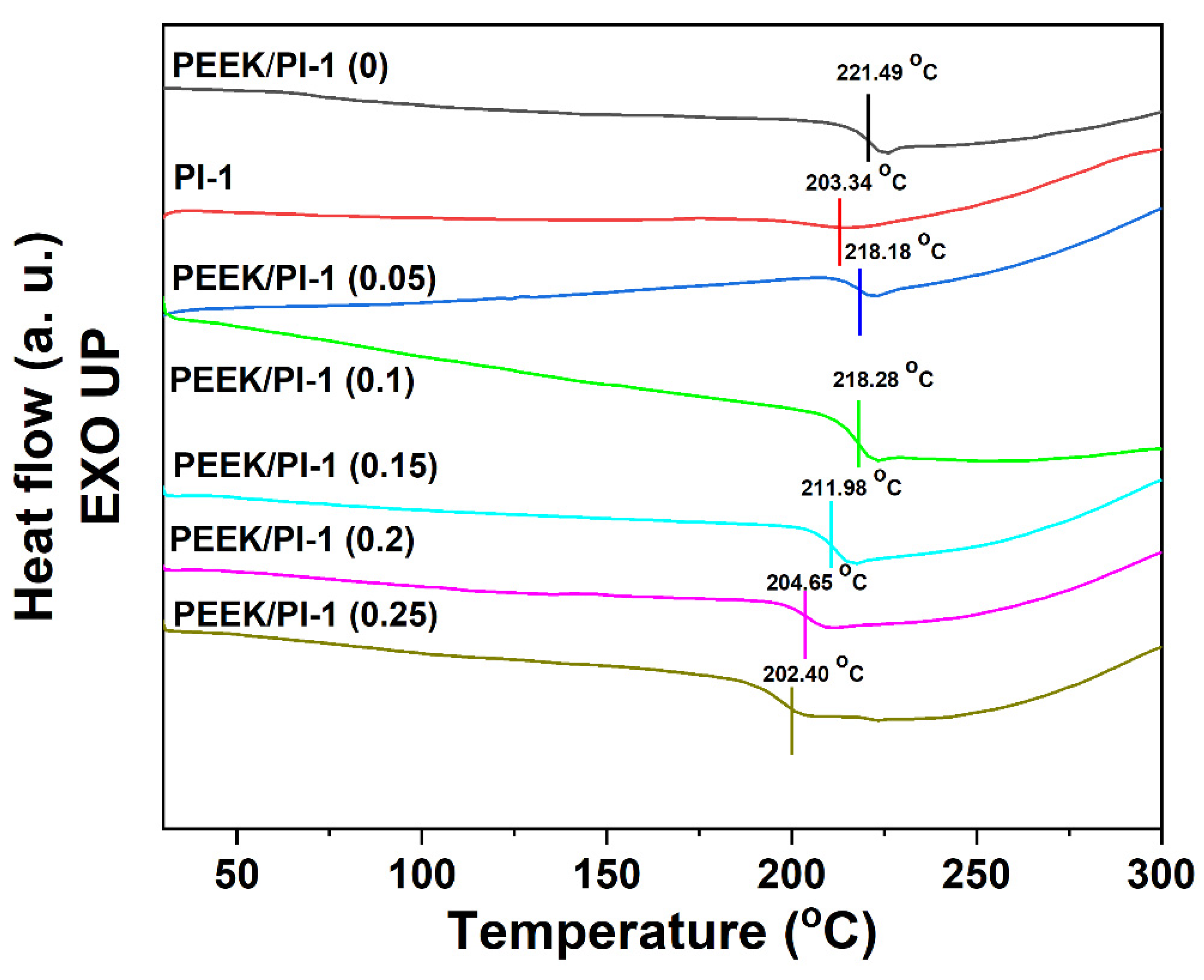

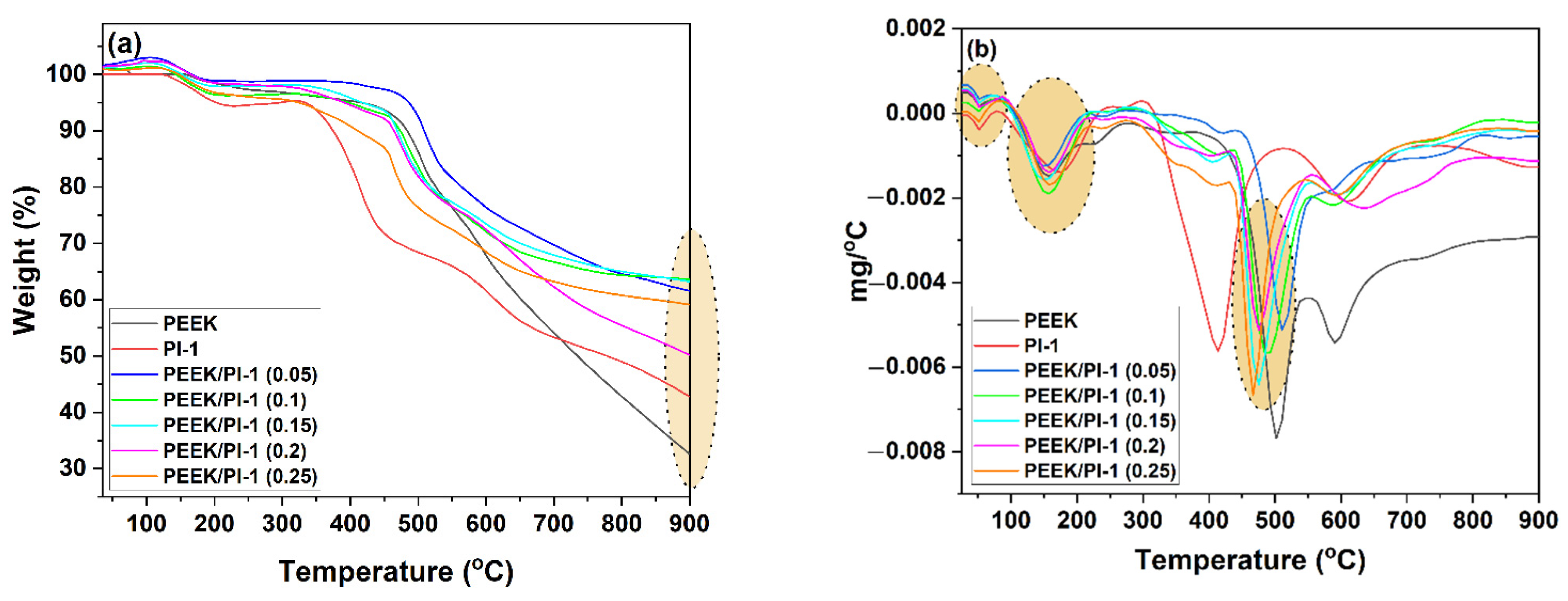

3.5. Thermal Characterization of the Electrospun PEEK/PI-1 Fibers

3.6. Water Absorption

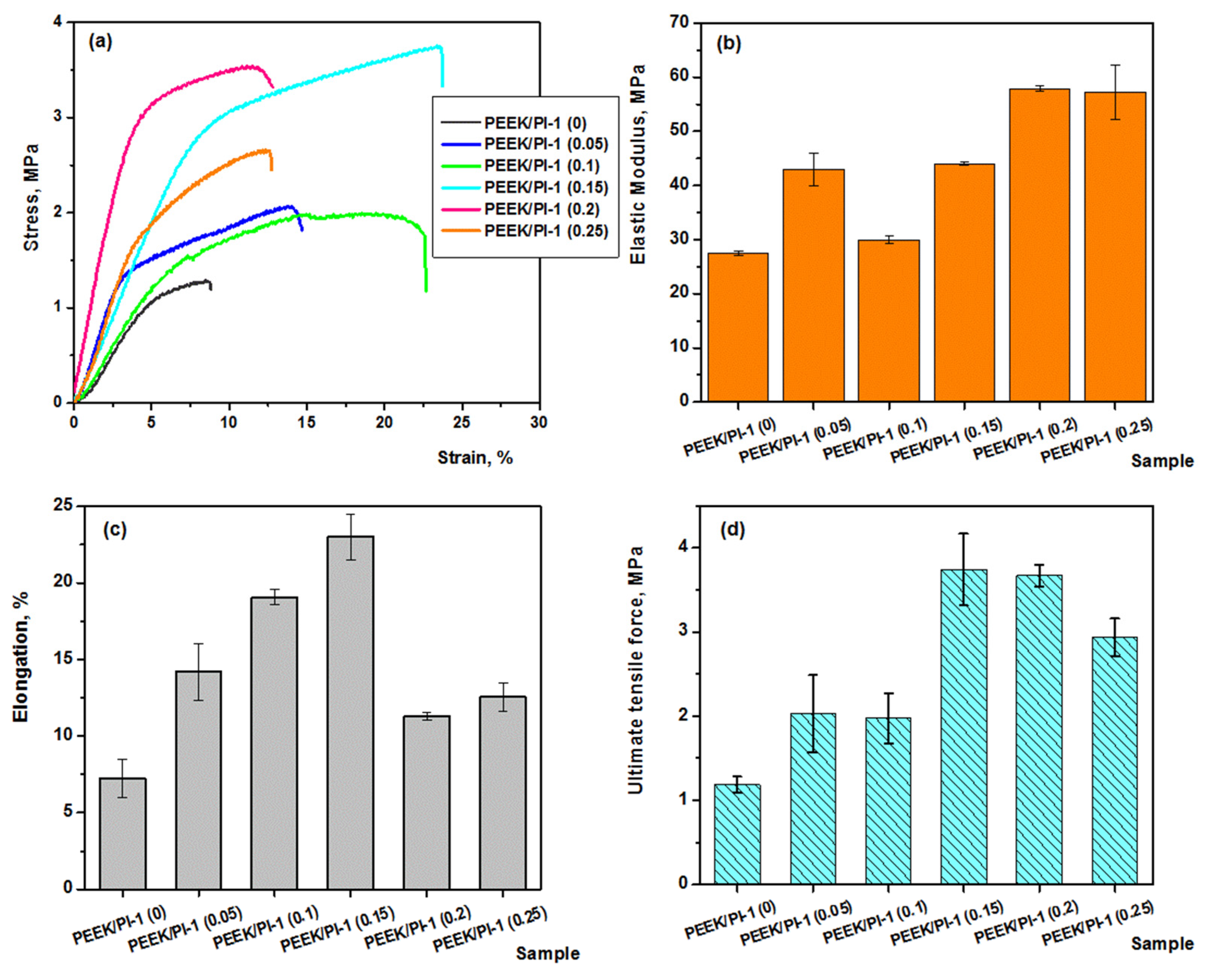

3.7. Mechanical Properties

3.8. Thermal Treatments of the Electrospun PEEK/PI-1 Fibers

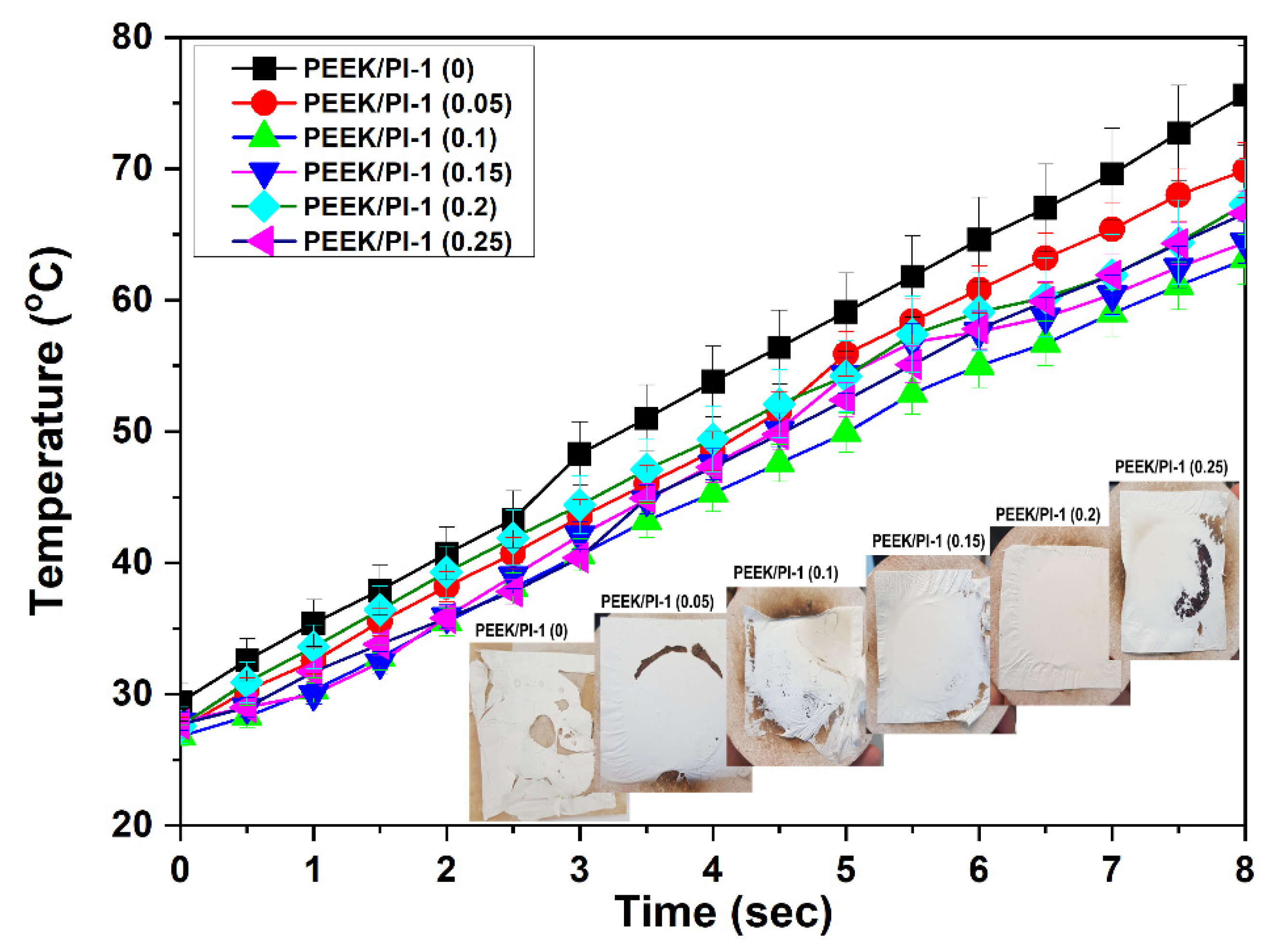

3.9. Heat Transmission Measurements on Electrospun PEEK/PI-1 Fibers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nayak, R.; Kanesalingam, S.; Houshyar, S.; Wang, L.; Padhye, R.; Vijayan, A. Evaluation of thermal, moisture management and sensorial comfort properties of superabsorbent polyacrylate fabrics for the next-to-skin layer in firefighters’ protective clothing. Text. Res. J. 2017, 88, 1077–1088. [Google Scholar] [CrossRef]

- Horrocks, A.R. Technical fibres for heat and flame protection. In Handbook of Technical Textiles, 2nd ed.; Horrocks, A.R., Anand, S.C., Eds.; Woodhead Publishing: Duxford, UK, 2016; pp. 237–270. [Google Scholar]

- Hertleer, C.; Odhiambo, S.; Van Langenhove, L. Protective clothing for firefighters and rescue workers. In Smart Textiles for Protection; Chapman, R.A., Ed.; Woodhead Publishing: Cambridge, UK, 2013; pp. 338–363. [Google Scholar]

- Kalazić, A.; Brnada, S.; Kiš, A. Thermal Protective Properties and Breathability of Multilayer Protective Woven Fabrics for Wildland Firefighting. Polymers 2022, 14, 2967. [Google Scholar] [CrossRef] [PubMed]

- Rabajczyk, A.; Zielecka, M.; Popielarczyk, T.; Sowa, T. Nanotechnology in Fire Protection—Application and Requirements. Materials 2021, 14, 7849. [Google Scholar] [CrossRef] [PubMed]

- Shaid, A.; Wang, L.; Padhye, R. Textiles for Firefighting Protective Clothing. In Firefighters’ Clothing and Equipment: Performance, Protection, and Comfort; Song, G., Wang, F., Eds.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2018; pp. 1–30. [Google Scholar]

- Nayak, R.; Houshyar, S.; Padhye, R. Recent trends and future scope in the protection and comfort of fire-fighters’ personal protective clothing. Fire Sci. Rev. 2014, 3, 4. [Google Scholar] [CrossRef]

- Sroog, C.E. Polyimides. Prog. Polym. Sci. 1991, 16, 561–694. [Google Scholar] [CrossRef]

- Wu, Z.; He, J.; Yang, H.; Yang, S. Progress in Aromatic Polyimide Films for Electronic Applications: Preparation, Structure and Properties. Polymers 2022, 14, 1269. [Google Scholar] [CrossRef]

- Sezer Hicyilmaz, A.; Celik Bedeloglu, A. Applications of polyimide coatings: A review. SN Appl. Sci. 2021, 3, 363. [Google Scholar] [CrossRef]

- Liaw, D.-J.; Wang, K.-L.; Huang, Y.-C.; Lee, K.-R.; Lai, J.-Y.; Ha, C.-S. Advanced polyimide materials: Syntheses, physical properties and applications. Prog. Polym. Sci. 2012, 37, 907–974. [Google Scholar] [CrossRef]

- Xiao, S.; Akinyi, C.; Longun, J.; Iroh, J.O. Polyimide Copolymers and Nanocomposites: A Review of the Synergistic Effects of the Constituents on the Fire-Retardancy Behavior. Energies 2022, 15, 4014. [Google Scholar] [CrossRef]

- Bourbigot, S.; Duquesne, S. Fire retardant polymers: Recent developments and opportunities. J. Mater. Chem. 2007, 17, 2283–2300. [Google Scholar] [CrossRef]

- Lu, S.-Y.; Hamerton, I. Recent developments in the chemistry of halogen-free flame retardant polymers. Prog. Polym. Sci. 2002, 27, 1661–1712. [Google Scholar] [CrossRef]

- Kumar, D.; Gupta, A.D. Aromatic Cyclolinear Phosphazene Polyimides Based on a Novel Bis-Spiro-Substituted Cyclotriphosphazene Diamine. Macromolecules 1995, 28, 6323–6329. [Google Scholar] [CrossRef]

- Liu, Y.-L.; Hsu, C.-Y.; Wu, C.-S. Polyimides possessing bulky phosphorus groups: Synthesis and characterization. J. Appl. Polym. Sci. 2003, 89, 791–796. [Google Scholar] [CrossRef]

- Liu, Y.-L.; Tsai, S.-H. Synthesis and properties of new organosoluble aromatic polyamides with cyclic bulky groups containing phosphorus. Polymer 2002, 43, 5757–5762. [Google Scholar] [CrossRef]

- Chatterjee, R.; Bisoi, S.; Kumar, A.G.; Padmanabhan, V.; Banerjee, S. Polyimides Containing Phosphaphenanthrene Skeleton: Gas-Transport Properties and Molecular Dynamics Simulations. ACS Omega 2018, 3, 13510–13523. [Google Scholar] [CrossRef]

- Serbezeanu, D.; Vlad-Bubulac, T.; Hamciuc, E.; Hamciuc, C.; Lisa, G.; Anghel, I.; Șofran, I.-E.; Preda, D.-M. Study on thermal and flame retardant properties of phosphorus-containing polyimides. Rev. Chim. 2021, 72, 13–21. [Google Scholar] [CrossRef]

- Homocianu, M.; Serbezeanu, D.; Lisa, G.; Brebu, M.; Vlad-Bubulac, T. Optical and Flame-Retardant Properties of a Series of Polyimides Containing Side Chained Bulky Phosphaphenanthrene Units. Int. J. Mol. Sci. 2022, 23, 13174. [Google Scholar] [CrossRef]

- Ahmadian, A.; Shafiee, A.; Aliahmad, N.; Agarwal, M. Overview of Nano-Fiber Mats Fabrication via Electrospinning and Morphology Analysis. Textiles 2021, 1, 206–226. [Google Scholar] [CrossRef]

- Shi, X.; Zhou, W.; Ma, D.; Ma, Q.; Bridges, D.; Ma, Y.; Hu, A. Electrospinning of Nanofibers and Their Applications for Energy Devices. J. Nanomater. 2015, 2015, 140716. [Google Scholar] [CrossRef]

- Wang, D.; Yu, J.; Duan, G.; Liu, K.; Hou, H. Electrospun polyimide nonwovens with enhanced mechanical and thermal properties by addition of trace plasticizer. J. Mater. Sci. 2020, 55, 5667–5679. [Google Scholar] [CrossRef]

- Topuz, F.; Abdulhamid, M.A.; Holtzl, T.; Szekely, G. Nanofiber engineering of microporous polyimides through electrospinning: Influence of electrospinning parameters and salt addition. Mater. Des. 2021, 198, 109280. [Google Scholar] [CrossRef]

- Hamciuc, C.; Vlad-Bubulac, T.; Bercea, M.; Suflet, D.M.; Doroftei, F.; Rîmbu, C.M.; Enache, A.A.; Kalvachev, Y.; Todorova, T.; Butnaru, M.; et al. Electrospun Copoly(ether imide) Nanofibers Doped with Silver-Loaded Zeolite as Materials for Biomedical Applications. ACS Appl. Polym. Mater. 2022, 4, 6080–6091. [Google Scholar] [CrossRef]

- Ding, Y.; Hou, H.; Zhao, Y.; Zhu, Z.; Fong, H. Electrospun polyimide nanofibers and their applications. Prog. Polym. Sci. 2016, 61, 67–103. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, X.; Dong, J.; Zhao, X. High-performance polyimide fibers. Adv. Ind. Eng. Polym. Res. 2022, 5, 107–116. [Google Scholar] [CrossRef]

- Qi, L.; Guo, C.-Y.; Huang Fu, M.-G.; Zhang, Y.; Yin, L.-m.; Wu, L.; Liu, J.-g.; Zhang, X.-m. Enhancement of Solvent Resistance of Polyimide Electrospun Mat via the UV-Assisted Electrospinning and Photosensitive Varnish. Polymers 2019, 11, 2055. [Google Scholar] [CrossRef]

- Shang, Z.; Wycisk, R.; Pintauro, P. Electrospun Composite Proton-Exchange and Anion-Exchange Membranes for Fuel Cells. Energies 2021, 14, 6709. [Google Scholar] [CrossRef]

- Topuz, F.; Abdulhamid, M.A.; Szekely, G. Superoleophilic oil-adsorbing membranes based on porous and nonporous fluorinated polyimides for the rapid remediation of oil spills. Chem. Eng. J. 2022, 449, 137821. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, J.; Liu, J.; Yang, Z.; Wang, G. Ti3C2Tx MXene Nanosheets Sandwiched between Ag Nanowire-Polyimide Fiber Mats for Electromagnetic Interference Shielding. ACS Appl. Nano Mater. 2021, 4, 13976–13985. [Google Scholar] [CrossRef]

- Serbezeanu, D.; Butnaru, I.; Varganici, C.-D.; Bruma, M.; Fortunato, G.; Gaan, S. Phosphorus-containing polyimide fibers and their thermal properties. RSC Adv. 2016, 6, 38371–38379. [Google Scholar] [CrossRef][Green Version]

- Lou, X.; Lu, B.; He, M.; Yu, Y.; Zhu, X.; Peng, F.; Qin, C.; Ding, M.; Jia, C. Functionalized carbon black modified sulfonated polyether ether ketone membrane for highly stable vanadium redox flow battery. J. Membr. Sci. 2022, 643, 120015. [Google Scholar] [CrossRef]

- Akhtar, F.H.; Abdulhamid, M.A.; Vovusha, H.; Ng, K.C.; Schwingenschlögl, U.; Szekely, G. Defining sulfonation limits of poly(ether-ether-ketone) for energy-efficient dehumidification. J. Mater. Chem. A 2021, 9, 17740–17748. [Google Scholar] [CrossRef]

- Wang, P.; Liu, X.; Wang, D.; Wang, M.; Zhang, D.; Chen, J.; Li, K.; Li, Y.; Jia, K.; Wang, Z.; et al. Recent progress on the poly(arylene ether)s-based electrospun nanofibers for high-performance applications. Mater. Res. Express 2021, 8, 122003. [Google Scholar] [CrossRef]

- El Magri, A.; El Mabrouk, K.; Vaudreuil, S. Preparation and characterization of poly(ether ether ketone)/poly(ether imide) [PEEK/PEI] blends for fused filament fabrication. J. Mater. Sci. 2021, 56, 14348–14367. [Google Scholar] [CrossRef]

- Kumar, S.; Mishra, R.K.; Nandi, T. Experimental and theoretical investigations of the high performance blends of PEEK/PEI. J. Polym. Eng. 2018, 38, 351–361. [Google Scholar] [CrossRef]

- Dominguez, S.; Derail, C.; Léonardi, F.; Pascal, J.; Brulé, B. Study of the thermal properties of miscible blends between poly(ether ketone ketone) (PEKK) and polyimide. Eur. Polym. J. 2015, 62, 179–185. [Google Scholar] [CrossRef]

- El Magri, A.; Vanaei, S.; Vaudreuil, S. An overview on the influence of process parameters through the characteristic of 3D-printed PEEK and PEI parts. High Perform. Polym. 2021, 33, 862–880. [Google Scholar] [CrossRef]

- ISO 9151; Protective clothing against heat and flame-Determination of heat transmission on exposure to flame. ISO: Geneva, Switzerland, 2016.

- EN 367; Protective Clothing. Protection against Heat and Flames. Test Method: Determining of the Heat Transmission on Exposure to Flame. European Comittee for Standardization: Brussels, Belgium, 1992.

- Bekkour, K.; Sun-Waterhouse, D.; Wadhwa, S.S. Rheological properties and cloud point of aqueous carboxymethyl cellulose dispersions as modified by high or low methoxyl pectin. Food Res. Int. 2014, 66, 247–256. [Google Scholar] [CrossRef]

- Dobos, A.-M.; Onofrei, M.-D.; Stoica, I.; Olaru, N.; Olaru, L.; Ioan, S. Influence of self-complementary hydrogen bonding on solution properties of cellulose acetate phthalate in solvent/non-solvent mixtures. Cellulose Chem. Technol. 2013, 47, 13–21. [Google Scholar]

- Gargallo, L.; Radić, D. Viscoelastic Behaviour of Polymers. In Physicochemical Behavior and Supramolecular Organization of Polymers; Gargallo, L., Radić, D., Eds.; Springer: Dordrecht, The Netherlands, 2009; pp. 43–162. [Google Scholar]

- Tirtaatmadja, V.; Tam, K.C.; Jenkins, R.D. Superposition of Oscillations on Steady Shear Flow as a Technique for Investigating the Structure of Associative Polymers. Macromolecules 1997, 30, 1426–1433. [Google Scholar] [CrossRef]

- Cassagnau, P.; Mélis, F. Non-linear viscoelastic behaviour and modulus recovery in silica filled polymers. Polymer 2003, 44, 6607–6615. [Google Scholar] [CrossRef]

- Sing, K.S.W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Sing, K.S.W. Physisorption of nitrogen by porous materials. J. Porous Mater. 1995, 2, 5–8. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Ng, E.-P.; Mintova, S. Nanoporous materials with enhanced hydrophilicity and high water sorption capacity. Microporous Mesoporous Mater. 2008, 114, 1–26. [Google Scholar] [CrossRef]

- Nistor, A.; Stiubianu, G.; Racles, C.; Cazacu, M. Evaluation of the water sorption capacity of some polymeric materials by Dynamic Vapour Sorption. Mater. Plast. 2011, 48, 33–37. [Google Scholar]

- Al-Ajaj, I.A.; Kareem, A.A. Synthesis and characterization of polyimide thin films obtained by thermal evaporation and solid state reaction. Mater. Sci. Pol. 2016, 34, 132–136. [Google Scholar] [CrossRef]

- Yan, L.; Tang, X.; Xie, X.; Xu, Z. Fire Resistance, Thermal and Anti-Ageing Properties of Transparent Fire-Retardant Coatings Modified with Different Molecular Weights of Polyethylene Glycol Borate. Polymers 2021, 13, 4206. [Google Scholar] [CrossRef]

- Serbezeanu, D.; Vlad-Bubulac, T.; Onofrei, M.D.; Doroftei, F.; Hamciuc, C.; Ipate, A.-M.; Anisiei, A.; Lisa, G.; Anghel, I.; Şofran, I.-E.; et al. Phosphorylated Poly(vinyl alcohol) Electrospun Mats for Protective Equipment Applications. Nanomaterials 2022, 12, 2685. [Google Scholar] [CrossRef]

- Cella, J.A. Degradation and stability of polyimides. Polym. Degrad. Stab. 1992, 36, 99–110. [Google Scholar] [CrossRef]

- Zhao, P.; Rao, W.; Luo, H.; Wang, L.; Liu, Y.; Yu, C. Novel organophosphorus compound with amine groups towards self-extinguishing epoxy resins at low loading. Mater. Des. 2020, 193, 108838. [Google Scholar] [CrossRef]

- Gu, J.; Liang, C.; Dang, J.; Dong, W.; Zhang, Q. Ideal dielectric thermally conductive bismaleimide nanocomposites filled with polyhedral oligomeric silsesquioxane functionalized nanosized boron nitride. RSC Adv. 2016, 6, 35809–35814. [Google Scholar] [CrossRef]

- Hamciuc, C.; Vlad-Bubulac, T.; Serbezeanu, D.; Macsim, A.-M.; Lisa, G.; Anghel, I.; Şofran, I.-E. Thermal Properties and Flammability Characteristics of a Series of DGEBA-Based Thermosets Loaded with a Novel Bisphenol Containing DOPO and Phenylphosphonate Units. Materials 2022, 15, 7829. [Google Scholar] [CrossRef] [PubMed]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Atalay, O.; Kursun Bahadir, S.; Kalaoglu, F. An Analysis on the Moisture and Thermal Protective Performance of Firefighter Clothing Based on Different Layer Combinations and Effect of Washing on Heat Protection and Vapour Transfer Performance. Adv. Mater. Sci. Eng. 2015, 2015, 540394. [Google Scholar] [CrossRef]

- Mandal, S.; Gaan, S.; Camenzind, M.; Annaheim, S.; Ross, R.M. Thermal characterization of fire-protective fabrics. In Thermal Analysis of Textiles and Fibers; Jaffe, M., Menczel, J.D., Eds.; Woodhead Publishing: Duxford, UK, 2017; pp. 357–387. [Google Scholar]

| Sample | n | K | r2 |

|---|---|---|---|

| PEEK/PI-1 (0) | 1.027 | 0.776 | 0.999 |

| PEEK/PI-1 (0.05) | 1.024 | 0.916 | 0.999 |

| PEEK/PI-1 (0.10) | 1.015 | 0.975 | 0.999 |

| PEEK/PI-1 (0.15) | 1.021 | 1.189 | 0.999 |

| PEEK/PI-1 (0.20) | 1.013 | 1.611 | 0.999 |

| PEEK/PI-1 (0.25) | 1.017 | 1.819 | 0.999 |

| Sample Codes | PEEK (mL) | Weight PI-1 (g)/(%) | Electrospinning Condition | Average Fiber Diameters (nm) |

|---|---|---|---|---|

| 15 wt% PEEK, | ||||

| PEEK/PI-1 (0) | 2 | 0/- | 22 kV a, 20 cm b, 20 µL/min c, ±25 °C d, ±49% e | 211 ± 48 |

| 15 wt% PEEK, 0.05 g PI-1, | ||||

| PEEK/PI-1 (0.05) | 2 | 0.05/12.5 | 22.7 kV, 20 cm, 20 µL/min, ±21 °C, ±56% | 212 ± 32 |

| 15 wt% PEEK, 0.1 g PI-1, | ||||

| PEEK/PI-1 (0.10) | 2 | 0.1/22.2 | 22.9 kV, 20 cm, 20 µL/min, ±23 °C, ±60% | 215 ± 53 |

| 15 wt% PEEK, 0.15 g PI-1, | ||||

| PEEK/PI-1 (0.15) | 2 | 0.15/30 | 22.2 kV, 20 cm, 20 µL/min, ±21 °C, ±45% | 252 ± 52 |

| 15 wt% PEEK, 0.2 g PI-1, | ||||

| PEEK/PI-1 (0.20) | 2 | 0.2/36.4 | 22.2 kV, 20 cm, 20 µL/min, ±21 °C, ±45% | 237 ± 54 |

| 15 wt% PEEK, 0.25 g PI-1, | ||||

| PEEK/PI-1 (0.25) | 2 | 0.25/41.6 | 22.2 kV, 20 cm, 20 µL/min, ±20 °C, ±47% | 304 ± 45 |

| Samples | Weight (%) | BET | WU (%) | |

|---|---|---|---|---|

| Area (m2/g) | Monolayer (g/g) | |||

| PEEK/PI-1 (0) | 5.2891 | 55.242 | 0.0157 | 1021.66 |

| PEEK/PI-1 (0.05) | 5.2077 | 64.021 | 0.0182 | 876.92 |

| PEEK/PI-1 (0.1) | 5.5010 | 70.561 | 0.0201 | 809.52 |

| PEEK/PI-1 (0.15) | 7.2118 | 102.870 | 0.0293 | 702.70 |

| PEEK/PI-1 (0.2) | 5.7263 | 94.188 | 0.0268 | 570.49 |

| PEEK/PI-1 (0.25) | 5.1129 | 72.913 | 0.0207 | 1297.61 |

| Samples | T5%a (°C) | T30% b (°C) | THRIc (°C) | Tmax (°C) | Residue at 900 °C |

|---|---|---|---|---|---|

| PEEK/PI-1 (0) | 423 | 591 | 257 | 60 d; 156 e; 504 f; 591 g | 33 |

| PEEK/PI-1 (0.05) | 484 | 695 | 299 | 50 d; 151 e; 512 f; 689 g | 62 |

| PEEK/PI-1 (0.10) | 396 | 627 | 262 | 50 d; 156 e; 489 f; 589 g | 63 |

| PEEK/PI-1 (0.15) | 414 | 653 | 273 | 50 d; 152 e; 474 f; 595 g | 64 |

| PEEK/PI-1 (0.20) | 396 | 625 | 261 | 60 d; 159 e; 475 f; 630 g | 51 |

| PEEK/PI-1 (0.25) | 325 | 583 | 235 | 60 d; 159 e; 467 f; 594 g | 59 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serbezeanu, D.; Hamciuc, C.; Vlad-Bubulac, T.; Onofrei, M.-D.; Bargan, A.; Rusu, D.; Suflet, D.M.; Lisa, G. Electrospun Nanofibers Based on Polymer Blends with Tunable High-Performance Properties for Innovative Fire-Resistant Materials. Polymers 2022, 14, 5501. https://doi.org/10.3390/polym14245501

Serbezeanu D, Hamciuc C, Vlad-Bubulac T, Onofrei M-D, Bargan A, Rusu D, Suflet DM, Lisa G. Electrospun Nanofibers Based on Polymer Blends with Tunable High-Performance Properties for Innovative Fire-Resistant Materials. Polymers. 2022; 14(24):5501. https://doi.org/10.3390/polym14245501

Chicago/Turabian StyleSerbezeanu, Diana, Corneliu Hamciuc, Tăchiță Vlad-Bubulac, Mihaela-Dorina Onofrei, Alexandra Bargan, Daniela Rusu, Dana Mihaela Suflet, and Gabriela Lisa. 2022. "Electrospun Nanofibers Based on Polymer Blends with Tunable High-Performance Properties for Innovative Fire-Resistant Materials" Polymers 14, no. 24: 5501. https://doi.org/10.3390/polym14245501

APA StyleSerbezeanu, D., Hamciuc, C., Vlad-Bubulac, T., Onofrei, M.-D., Bargan, A., Rusu, D., Suflet, D. M., & Lisa, G. (2022). Electrospun Nanofibers Based on Polymer Blends with Tunable High-Performance Properties for Innovative Fire-Resistant Materials. Polymers, 14(24), 5501. https://doi.org/10.3390/polym14245501