Considering Electrospun Nanofibers as a Filler Network in Electrospun Nanofiber-Reinforced Composites to Predict the Tensile Strength and Young’s Modulus of Nanocomposites: A Modeling Study

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Method

3. Theoretical Models

3.1. Models for Tensile Strength

3.2. Models for Young’s Modulus

4. Results and Discussion

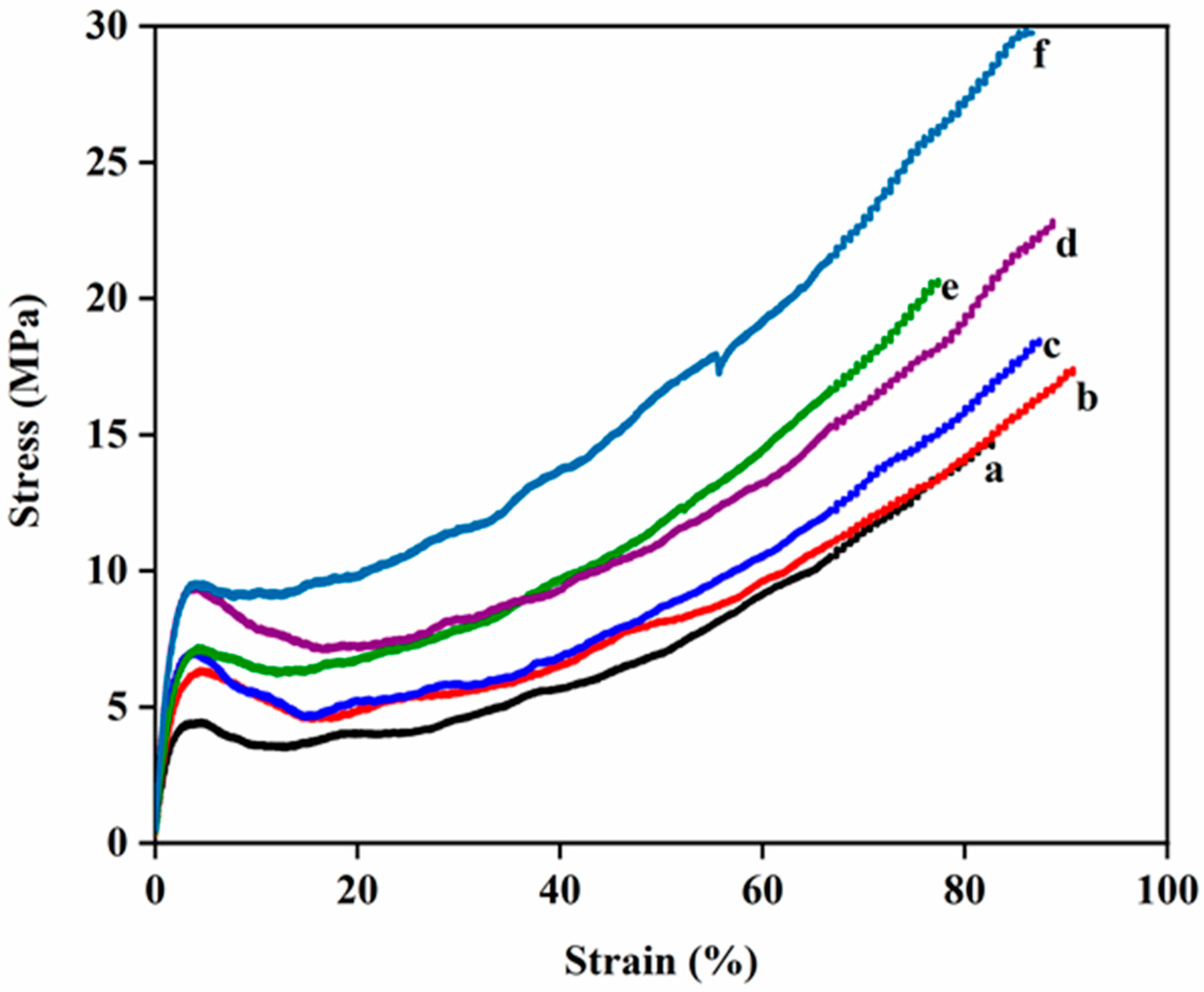

4.1. Tensile Strength of the Nanofiber-Reinforced Composites

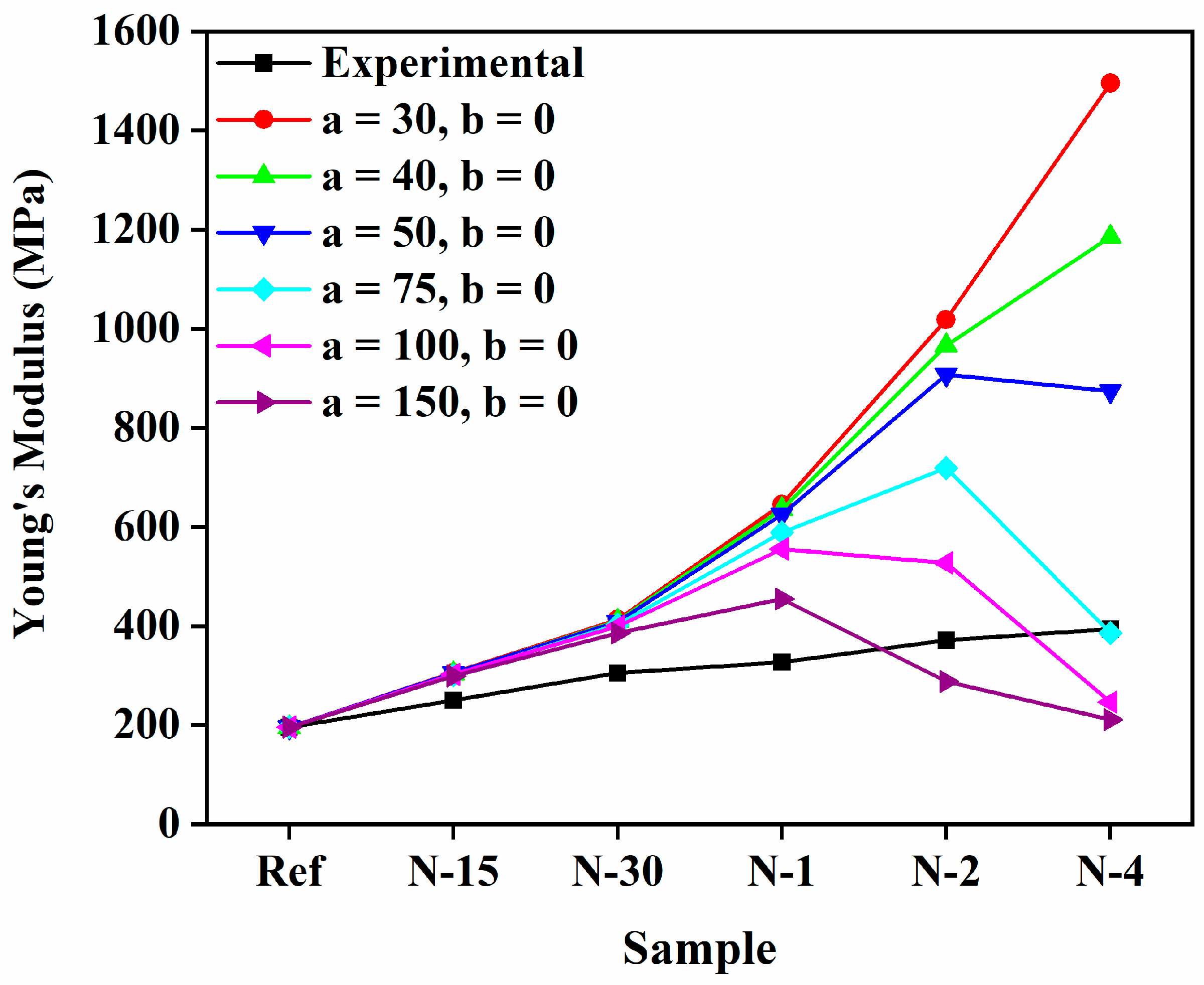

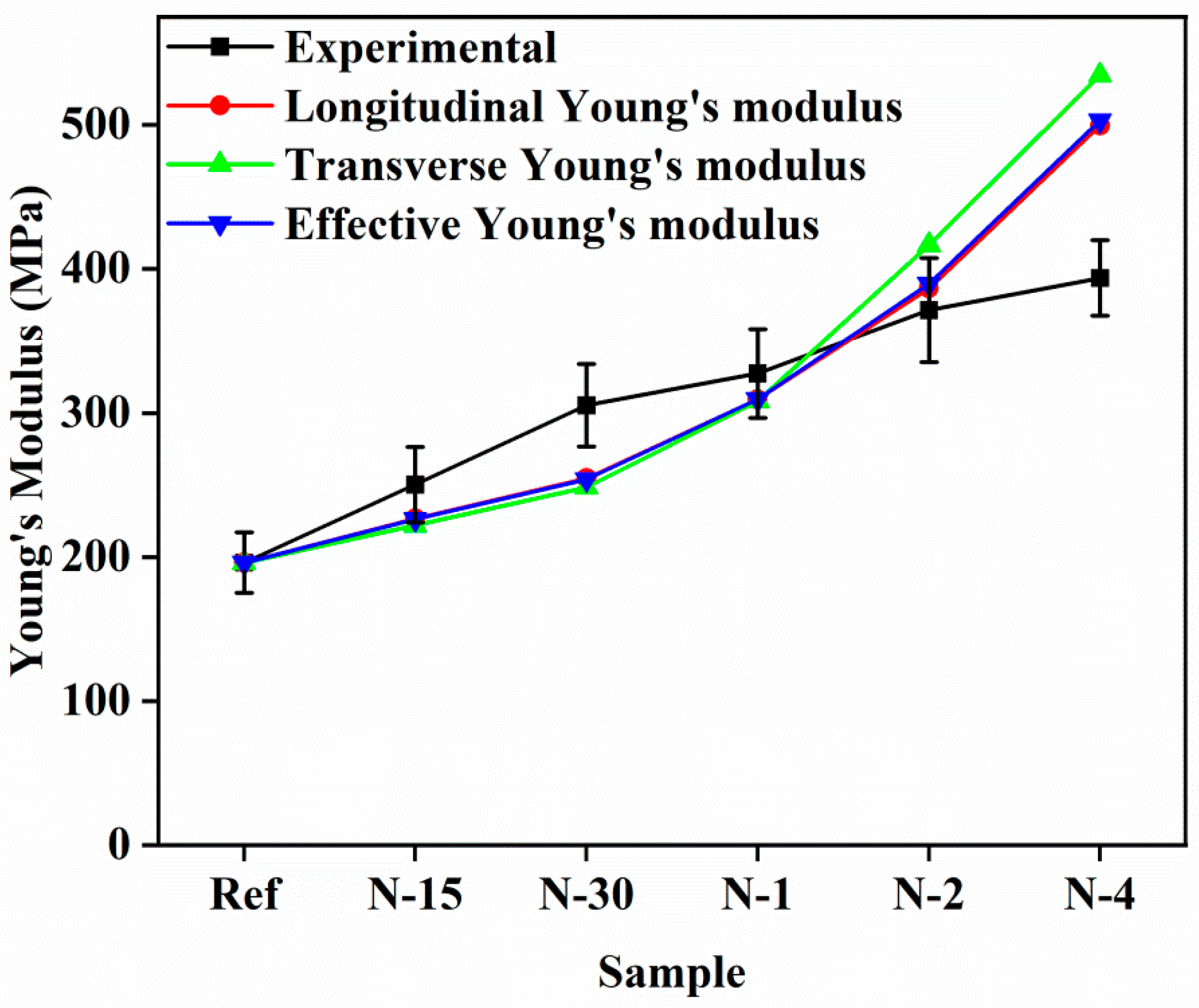

4.2. Young’s Modulus of the Nanofiber-Reinforced Composites

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, D.J.; Jo, M.J.; Nam, S.Y. A review of polymer-nanocomposite electrolyte membranes for fuel cell application. J. Ind. Eng. Chem. 2015, 21, 36–52. [Google Scholar] [CrossRef]

- Hussain, F.; Hojjati, M.; Okamoto, M.; Gorga, R.E. Review article: Polymer-matrix Nanocomposites, Processing, Manufacturing, and Application: An Overview. J. Compos. Mater. 2006, 40, 1511–1575. [Google Scholar] [CrossRef]

- Abdullahi Hassan, Y.; Hu, H. Current status of polymer nanocomposite dielectrics for high-temperature applications. Compos. Part A Appl. Sci. Manuf. 2020, 138, 106064. [Google Scholar] [CrossRef]

- Hu, H.; Zhang, F.; Luo, S.; Chang, W.; Yue, J.; Wang, C.-H. Recent advances in rational design of polymer nanocomposite dielectrics for energy storage. Nano Energy 2020, 74, 104844. [Google Scholar] [CrossRef]

- Miculescu, M.; Thakur, V.K.; Miculescu, F.; Voicu, S.I. Graphene-based polymer nanocomposite membranes: A review. Polym. Adv. Technol. 2016, 27, 844–859. [Google Scholar] [CrossRef]

- Valavala, P.K.; Odegard, G.M. Modeling techniques for determination of mechanical properties of polymer nanocomposites. Rev. Adv. Mater. Sci. 2005, 9, 34–44. [Google Scholar]

- Maghsoudlou, M.A.; Barbaz Isfahani, R.; Saber-Samandari, S.; Sadighi, M. Effect of interphase, curvature and agglomeration of SWCNTs on mechanical properties of polymer-based nanocomposites: Experimental and numerical investigations. Compos. Part B Eng. 2019, 175, 107119. [Google Scholar] [CrossRef]

- Rahmat, M.; Hubert, P. Carbon nanotube-polymer interactions in nanocomposites: A review. Compos. Sci. Technol. 2011, 72, 72–84. [Google Scholar] [CrossRef]

- Lee, J.K.Y.; Chen, N.; Peng, S.; Li, L.; Tian, L.; Thakor, N.; Ramakrishna, S. Polymer-based composites by electrospinning: Preparation & functionalization with nanocarbons. Prog. Polym. Sci. 2018, 86, 40–84. [Google Scholar]

- Daglar, O.; Altinkok, C.; Acik, G.; Durmaz, H. Electrospinning of Poly(1,4-Cyclohexanedimethylene Acetylene Dicarboxylate): Study on the Morphology, Wettability, Thermal and Biodegradation Behaviors. Macromol. Chem. Phys. 2020, 221, 2000310. [Google Scholar] [CrossRef]

- Gavande, V.; Im, D.; Jin, Y.; Lim, K.T.; Lee, W.K. 3D bio polybutylene succinate electrospun nanofiber scaffolds for biomimetic structure. Mol. Cryst. Liq. Cryst. 2020, 706, 55–61. [Google Scholar] [CrossRef]

- Kumbar, S.G.; James, R.; Nukavarapu, S.P.; Laurencin, C.T. Electrospun nanofiber scaffolds: Engineering soft tissues. Biomed. Mater. 2008, 3, 034002. [Google Scholar] [CrossRef] [PubMed]

- Ghosal, K.; Agatemor, C.; Špitálsky, Z.; Thomas, S.; Kny, E. Electrospinning tissue engineering and wound dressing scaffolds from polymer-titanium dioxide nanocomposites. Chem. Eng. J. 2019, 358, 1262–1278. [Google Scholar] [CrossRef]

- Gavande, V.; Lee, S.; Im, D.; Nagappan, S.; Ha, C.S.; Lee, W.K. Polyketone nanofiber: An effective reinforcement for the development of novel UV-curable, highly transparent and flexible polyurethane nanocomposite films. Polym. Int. 2020, 69, 1008–1017. [Google Scholar] [CrossRef]

- Jiang, S.; Chen, Y.; Duan, G.; Mei, C.; Greiner, A.; Agarwal, S. Electrospun nanofiber reinforced composites: A review. Polym. Chem. 2018, 9, 2685–2720. [Google Scholar] [CrossRef]

- Gavande, V.; Im, D.; Lee, W.K. Development of highly transparent UV-curable nylon 6 nanofiber-reinforced polyurethane acrylate nanocomposite coatings for pre-coated metals. J. Appl. Polym. Sci. 2021, 138, 50614. [Google Scholar] [CrossRef]

- Anstey, A.; Chang, E.; Kim, E.S.; Rizvi, A.; Kakroodi, A.R.; Park, C.B.; Lee, P.C. Nanofibrillated polymer systems: Design, application, and current state of the art. Prog. Polym. Sci. 2021, 113, 101346. [Google Scholar] [CrossRef]

- Huang, C.; Xu, X.; Fu, J.; Yu, D.G.; Liu, Y. Recent Progress in Electrospun Polyacrylonitrile Nanofiber-Based Wound Dressing. Polymers 2022, 14, 3266. [Google Scholar] [CrossRef]

- Chew, S.Y.; Hufnagel, T.C.; Lim, C.T.; Leong, K.W. Mechanical properties of single electrospun drug-encapsulated nanofibres. Nanotechnology 2006, 17, 3880–3891. [Google Scholar] [CrossRef]

- Papkov, D.; Zou, Y.; Andalib, M.N.; Goponenko, A.; Cheng, S.Z.D.; Dzenis, Y.A. Simultaneously strong and tough ultrafine continuous nanofibers. ACS Nano 2013, 7, 3324–3331. [Google Scholar] [CrossRef]

- Mosallanezhad, P.; Nazockdast, H.; Ahmadi, Z.; Rostami, A. Fabrication and characterization of polycaprolactone/chitosan nanofibers containing antibacterial agents of curcumin and ZnO nanoparticles for use as wound dressing. Front. Bioeng. Biotechnol. 2022, 10, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Altinkok, C.; Acik, G.; Daglar, O.; Durmaz, H.; Tunc, I.; Agel, E. A facile approach for the fabrication of antibacterial nanocomposites: A case study for AgNWs/Poly(1,4-Cyclohexanedimethylene Acetylene Dicarboxylate) composite networks by aza-Michael addition. Eur. Polym. J. 2022, 169, 111130. [Google Scholar] [CrossRef]

- Wang, G.; Yu, D.; Kelkar, A.D.; Zhang, L. Electrospun nanofiber: Emerging reinforcing filler in polymer matrix composite materials. Prog. Polym. Sci. 2017, 75, 73–107. [Google Scholar] [CrossRef]

- Gavande, V.; Im, D.; Jin, Y.; Lee, W.-K. Fabrication of toughest and transparent electrospun nylon 6 nanofiber-reinforced PVA composites. Mol. Cryst. Liq. Cryst. 2021, 729, 48–54. [Google Scholar] [CrossRef]

- Sun, L.; Han, R.P.S.; Wang, J.; Lim, C.T. Modeling the size-dependent elastic properties of polymeric nanofibers. Nanotechnology 2008, 19, 455706. [Google Scholar] [CrossRef]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Nicolais, L.; Narkis, M. Stress-strain behavior of styrene-acrylonitrile/glass bead composites in the glassy region. Polym. Eng. Sci. 1971, 11, 194–199. [Google Scholar] [CrossRef]

- Pukánszky, B. Influence of interface interaction on the ultimate tensile properties of polymer composites. Composites 1990, 21, 255–262. [Google Scholar] [CrossRef]

- Abraham, R.; Selvin Thomas, P.; Kuryan, S.; Issac, J.; Nandakumar, K.; Thomas, S. Structural and mechanical properties of YBCO-polystyrene composites. J. Appl. Polym. Sci. 2010, 118, 1027–1041. [Google Scholar] [CrossRef]

- Kundalwal, S.I. Review on Modeling of Mechanical and Thermal Properties of Nano- and Micro-Composites. arXiv 2017, arXiv:1708.00764. [Google Scholar]

- Salam, H.; Dong, Y. Theoretical modelling analysis on tensile properties of bioepoxy/clay nanocomposites using epoxidised soybean oils. J. Nanomater. 2019, 2019, 4074869. [Google Scholar] [CrossRef]

- Halpin, J.C. Stiffness and Expansion Estimates for Oriented Short Fiber Composites. J. Compos. Mater. 1969, 3, 732–734. [Google Scholar] [CrossRef]

- Patterson, W.; Force, A. The Halpin-Tsai Equations: A Review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar]

- Marathe, U.; Padhan, M.; Bijwe, J. Carbon nanotubes—A powerful nano-filler for enhancing the performance properties of polyetherketoneketone composites and adhesives. Compos. Sci. Technol. 2021, 210, 108813. [Google Scholar]

- Marathe, U.; Padhan, M.; Bijwe, J. Various attributes controlling the performance of nano-composites and adhesives of TiC-PAEK. Compos. Sci. Technol. 2021, 214, 108969. [Google Scholar] [CrossRef]

- Ounaies, Z.; Sun, L.H.; Gao, X.L.; Whalen, C.A.; Yang, Z.G. Preparation, characterization, and modeling of carbon nanofiber/epoxy nanocomposites. J. Nanomater. 2011, 2011, 307589. [Google Scholar]

- Luo, Z.; Li, X.; Shang, J.; Zhu, H.; Fang, D. Modified rule of mixtures and Halpin–Tsai model for prediction of tensile strength of micron-sized reinforced composites and Young’s modulus of multiscale reinforced composites for direct extrusion fabrication. Adv. Mech. Eng. 2018, 10, 1–10. [Google Scholar] [CrossRef]

- Yeh, M.K.; Tai, N.H.; Liu, J.H. Mechanical behavior of phenolic-based composites reinforced with multi-walled carbon nanotubes. Carbon N. Y. 2006, 44, 1–9. [Google Scholar] [CrossRef]

- Kurita, H.; Ishigami, R.; Wu, C.; Narita, F. Mechanical properties of mechanically-defibrated cellulose nanofiber reinforced epoxy resin matrix composites. J. Compos. Mater. 2021, 55, 455–464. [Google Scholar] [CrossRef]

- Hu, H.; Onyebueke, L.; Abatan, A. Characterizing and Modeling Mechanical Properties of Nanocomposites-Review and Evaluation. J. Miner. Mater. Charact. Eng. 2010, 9, 275–319. [Google Scholar]

- Venkateshwaran, N.; Elayaperumal, A. Modeling and evaluation of tensile properties of randomly oriented banana/epoxy composite. J. Reinf. Plast. Compos. 2011, 30, 1957–1967. [Google Scholar] [CrossRef]

| Samples | Theoretical Density | Practical Density | wt% of Nanofibers | Volume Fraction of the Nanofibers | Volume Fraction of the PUA Matrix |

|---|---|---|---|---|---|

| PUA | 1.19 | 1.1968 | 0 | 0 | 100 |

| N-15 | 1.2 | 1.1964 | 0.0038 | 0.004 | 99.96 |

| N-30 | 1.2 | 1.1957 | 0.0075 | 0.008 | 99.92 |

| N-60 | 1.19 | 1.1944 | 0.015 | 0.017 | 99.83 |

| N-2 h | 1.19 | 1.1928 | 0.03 | 0.033 | 99.67 |

| N-4 h | 1.19 | 1.1918 | 0.06 | 0.066 | 99.34 |

| Sample | Tensile Strength at Break (MPa) | % Elongation at Break | Tensile Strength at Yield (MPa) | Young’s Modulus (MPa) | |

|---|---|---|---|---|---|

| PUA films | 15.20 ± 2.36 | 75.45 ± 7.74 | 5.78 ± 0.93 | 196.09 ± 20.99 | |

| N6/PUA nanocomposite films | N-15 | 17.42 ± 1.01 | 90.66 ± 3.12 | 6.71 ± 0.44 | 250.25 ± 26.33 |

| N-30 | 18.46 ± 0.82 | 86.22 ± 2.68 | 6.88 ± 1.07 | 305.34 ± 28.73 | |

| N-60 | 20.88 ± 0.46 | 84.77 ± 5.31 | 7.45 ± 0.95 | 327.47 ± 30.82 | |

| N-2 h | 22.89 ± 0.50 | 89.44 ± 6 | 10 ± 2.31 | 371. 35 ± 36.11 | |

| N-4 h | 28.14 ± 2.36 | 86.55 ± 2.29 | 9.93 ± 1.28 | 393.72 ± 26.20 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gavande, V.; Nagappan, S.; Lee, W.-K. Considering Electrospun Nanofibers as a Filler Network in Electrospun Nanofiber-Reinforced Composites to Predict the Tensile Strength and Young’s Modulus of Nanocomposites: A Modeling Study. Polymers 2022, 14, 5425. https://doi.org/10.3390/polym14245425

Gavande V, Nagappan S, Lee W-K. Considering Electrospun Nanofibers as a Filler Network in Electrospun Nanofiber-Reinforced Composites to Predict the Tensile Strength and Young’s Modulus of Nanocomposites: A Modeling Study. Polymers. 2022; 14(24):5425. https://doi.org/10.3390/polym14245425

Chicago/Turabian StyleGavande, Vishal, Saravanan Nagappan, and Won-Ki Lee. 2022. "Considering Electrospun Nanofibers as a Filler Network in Electrospun Nanofiber-Reinforced Composites to Predict the Tensile Strength and Young’s Modulus of Nanocomposites: A Modeling Study" Polymers 14, no. 24: 5425. https://doi.org/10.3390/polym14245425

APA StyleGavande, V., Nagappan, S., & Lee, W.-K. (2022). Considering Electrospun Nanofibers as a Filler Network in Electrospun Nanofiber-Reinforced Composites to Predict the Tensile Strength and Young’s Modulus of Nanocomposites: A Modeling Study. Polymers, 14(24), 5425. https://doi.org/10.3390/polym14245425