New Building Blocks for Self-Healing Polymers

Abstract

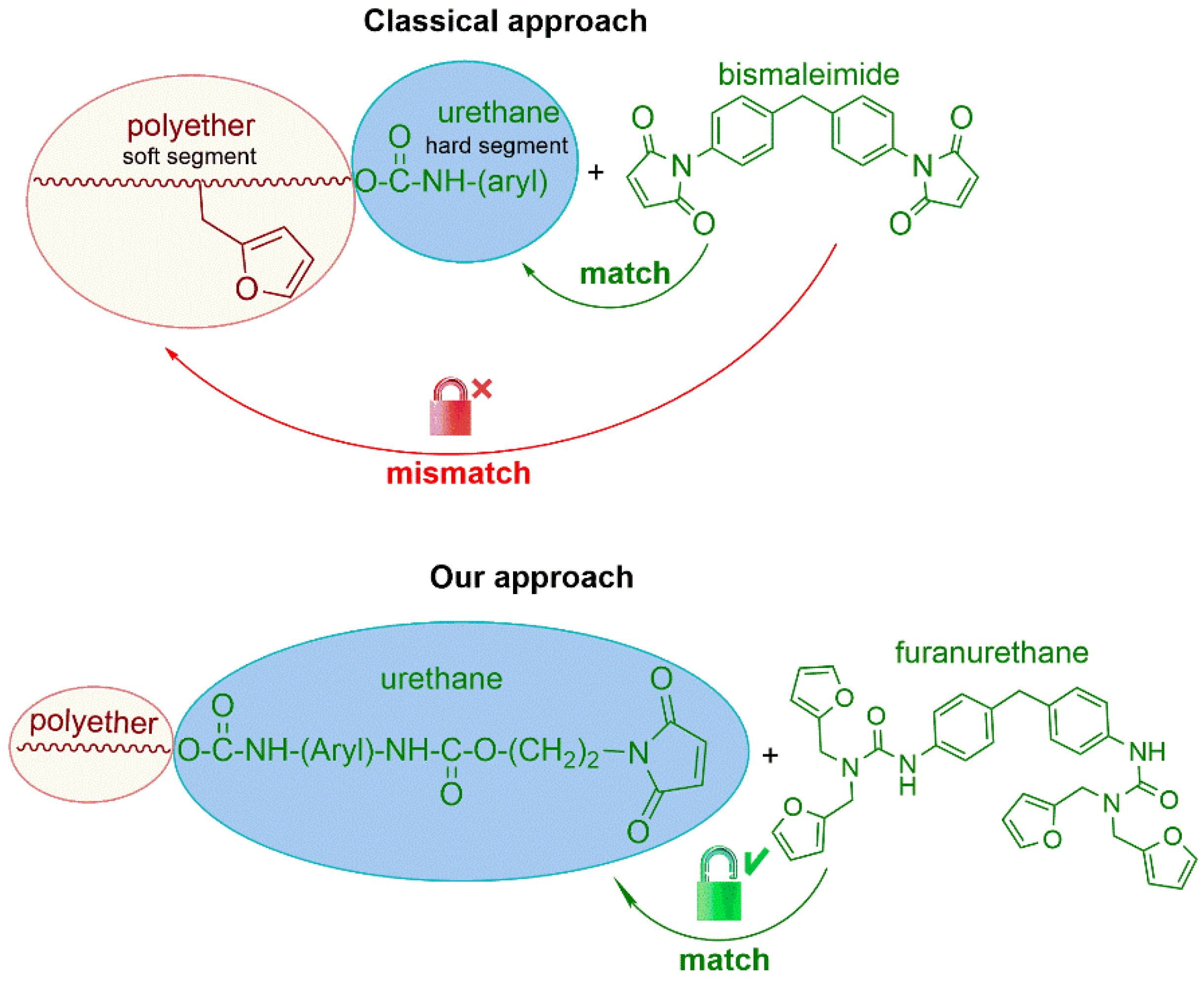

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization and Measurement

3. Results

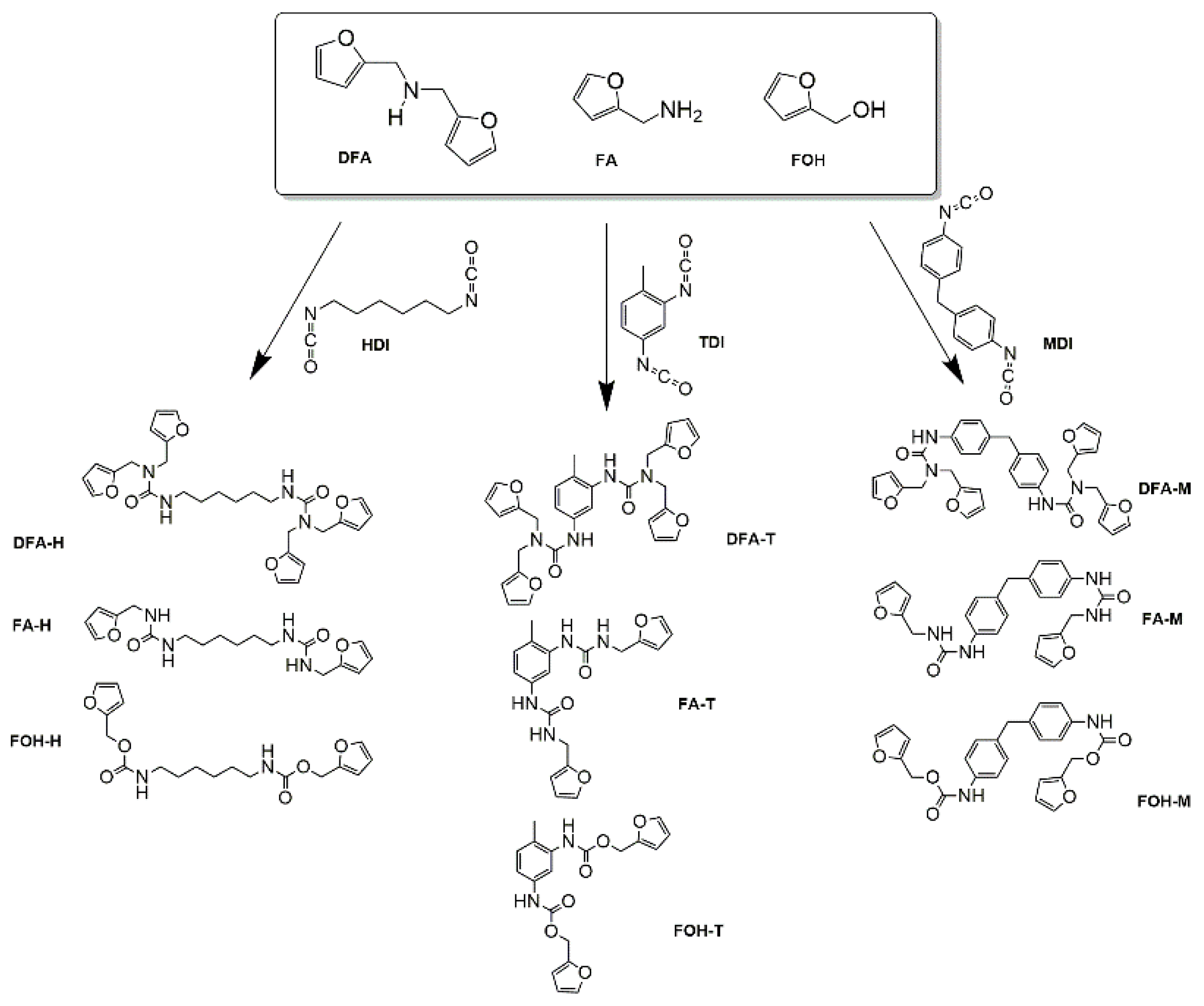

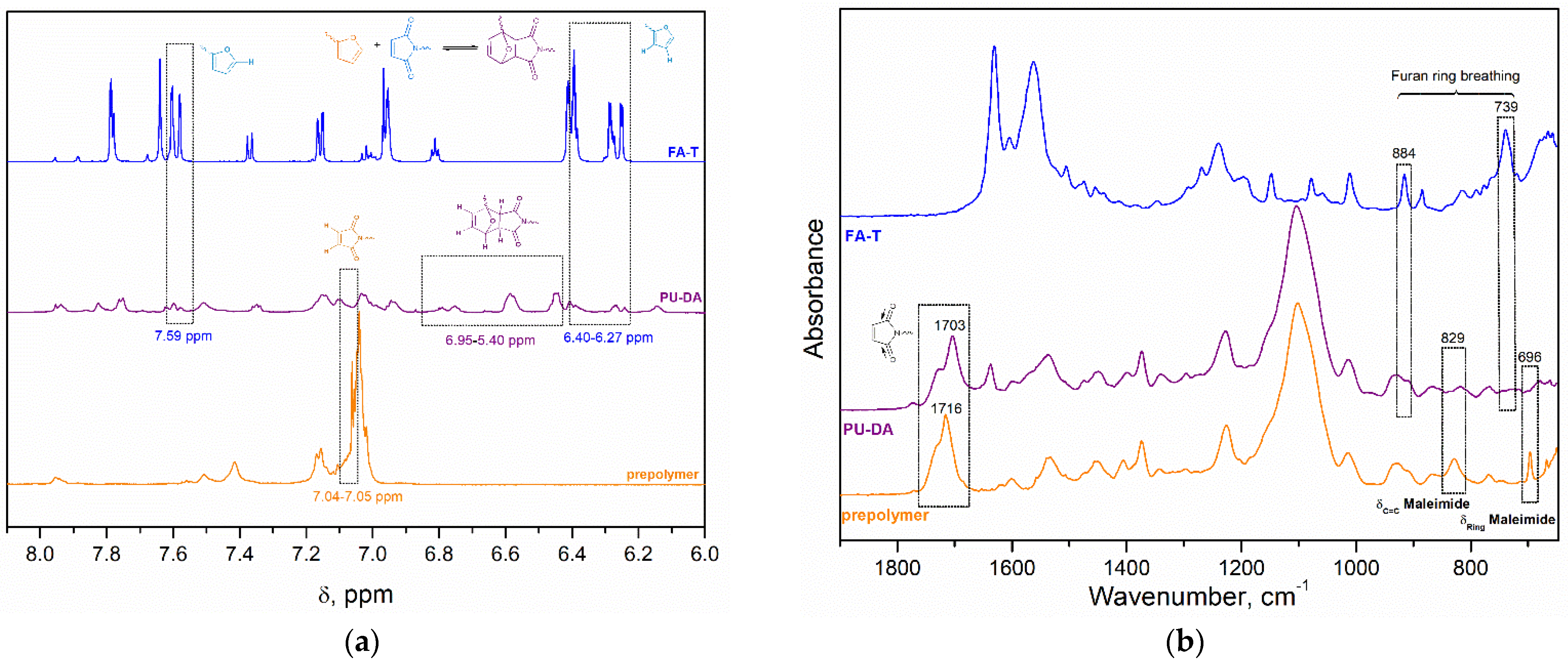

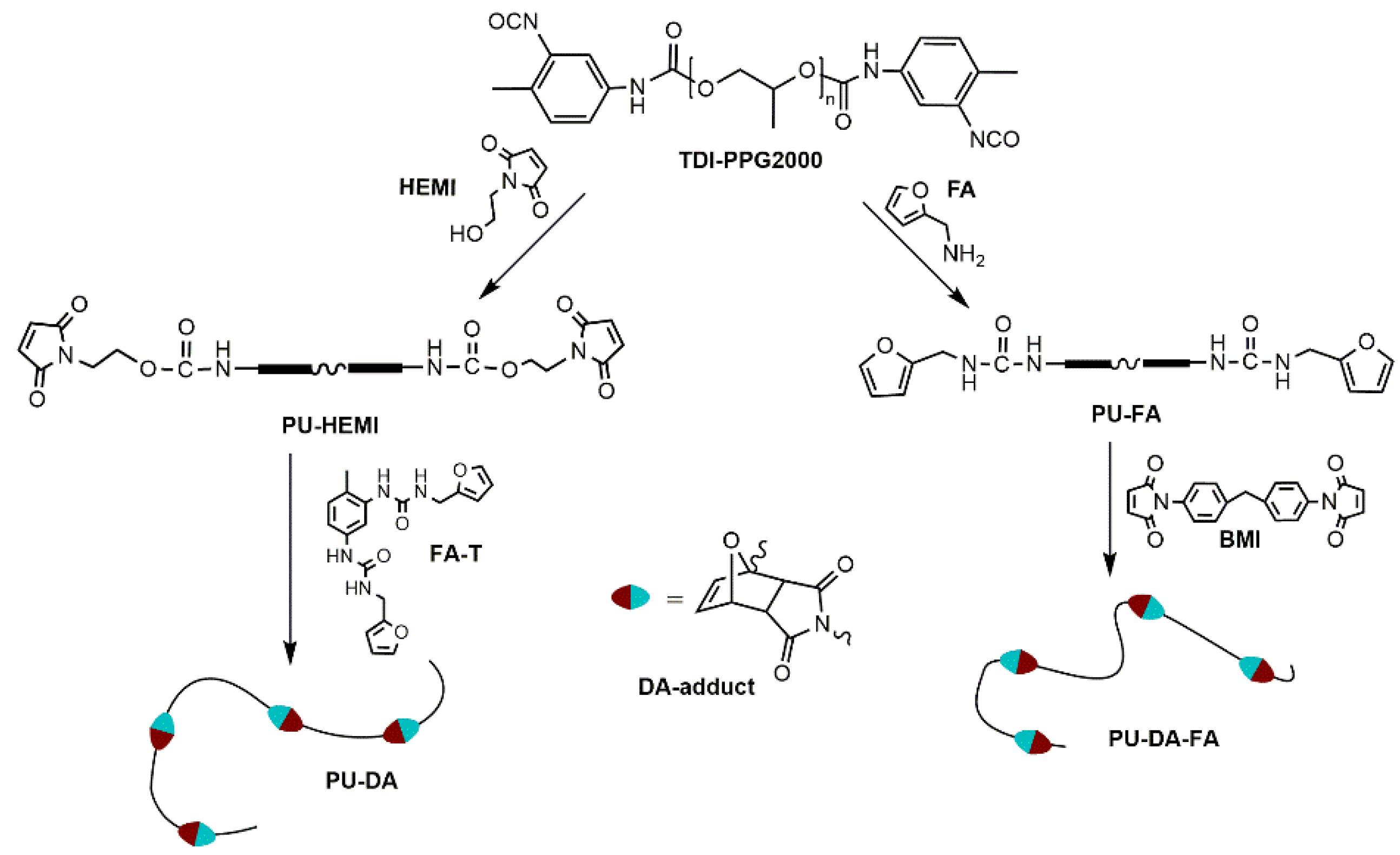

3.1. Preparation Process for Furanic Curing Agents

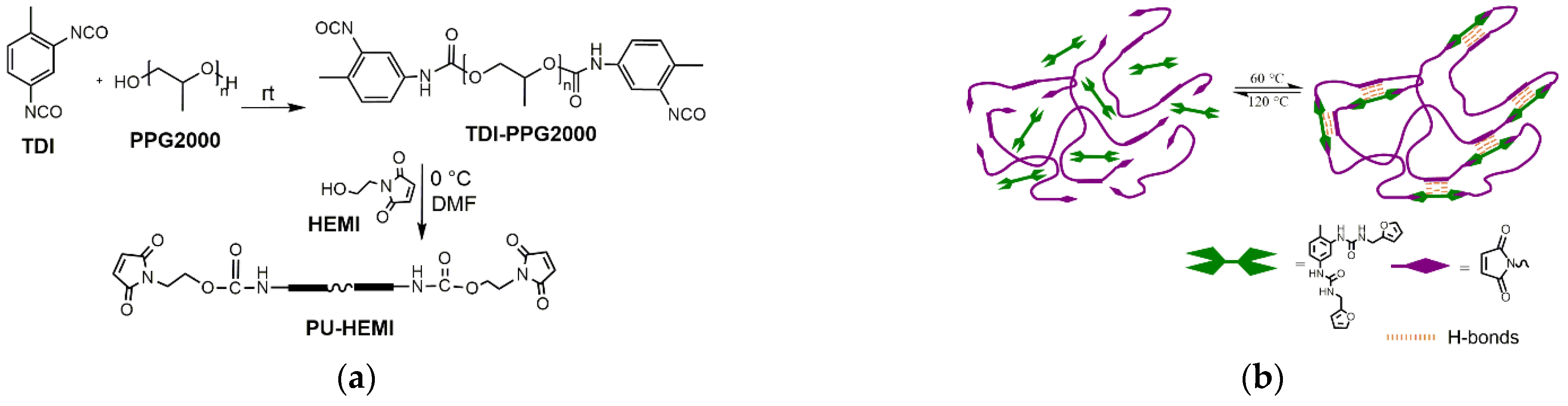

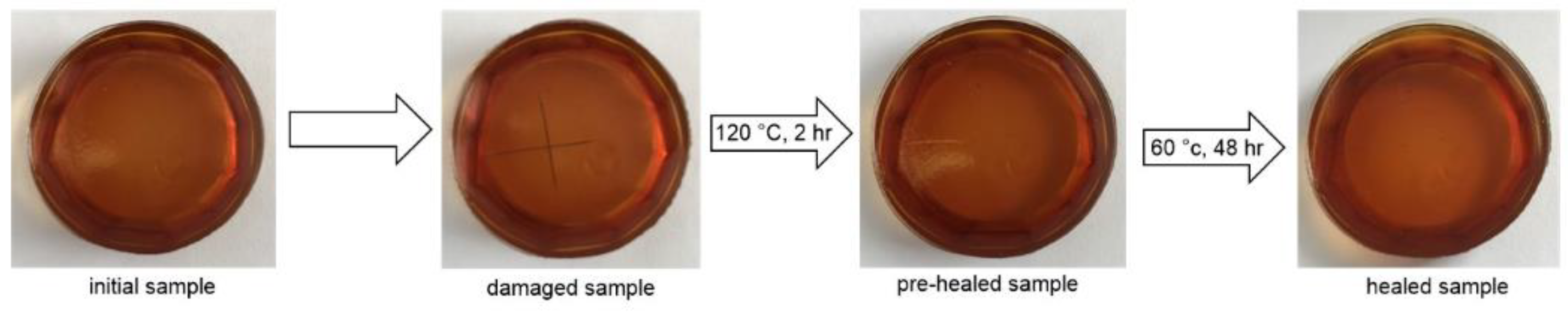

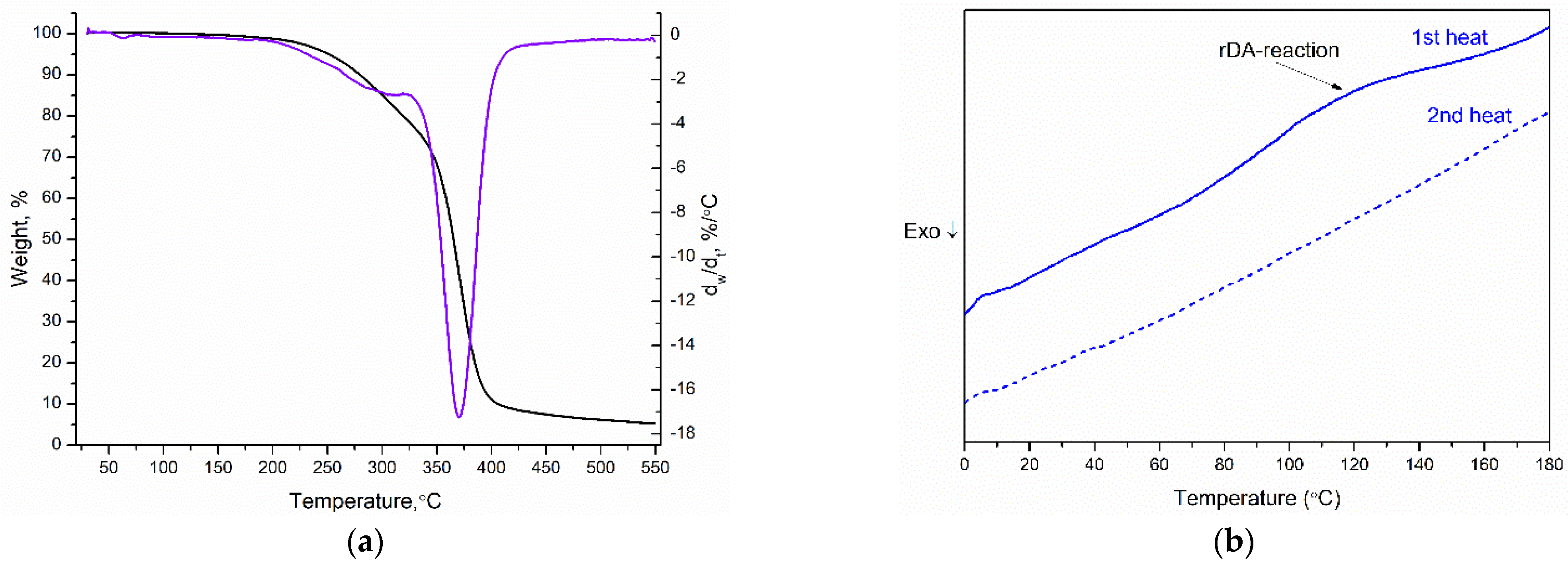

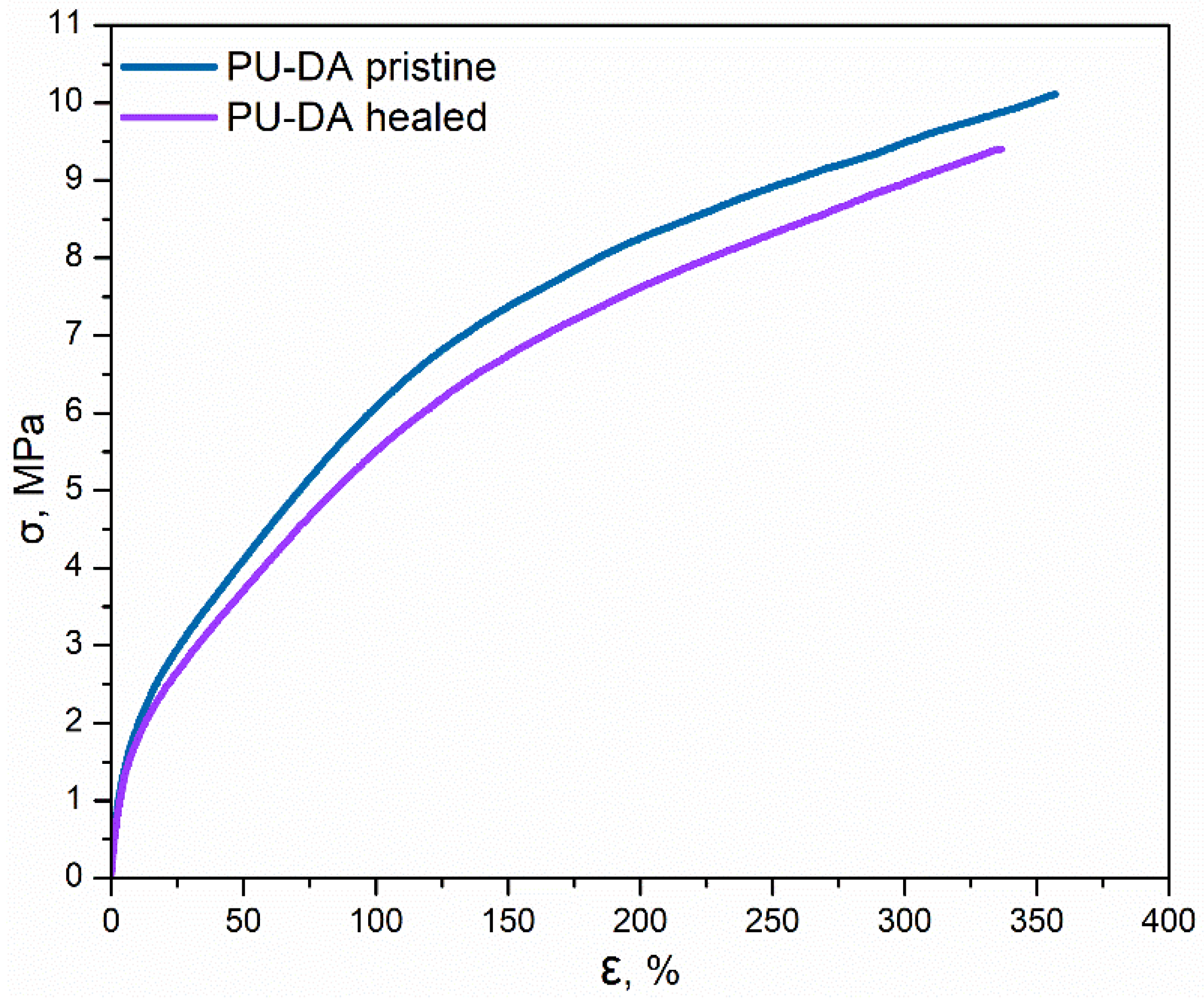

3.2. Structures, Properties, and Thermal Remendability of Self-Healing Polyurethanes

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Magnin, A.; Pollet, E.; Phalip, V.; Avérous, L. Evaluation of biological degradation of polyurethanes. Biotechnol. Adv. 2020, 39, 107457. [Google Scholar] [CrossRef] [PubMed]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications—A review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef]

- Elsheikh, A. Bistable Morphing Composites for Energy-Harvesting Applications. Polymers 2022, 14, 1893. [Google Scholar] [CrossRef]

- Kurańska, M.; Prociak, A.; Cabulis, U.; Kirpluks, M.; Ryszkowska, J.; Auguścik, M. Innovative porous polyurethane-polyisocyanurate foams based on rapeseed oil and modified with expandable graphite. Ind. Crop. Prod. 2017, 95, 316–323. [Google Scholar] [CrossRef]

- Connolly, M.; King, J.; Shidaker, T.; Duncan, A. Pultruding Polyurethane Composite Profiles: Practical Guidelines for Injection Box Design, Component Metering Equipment and Processing. In Proceedings of the 2005 Convention and Trade Show American Composites Manufacturers Association, Columbus, OH, USA, 28–30 September 2005. [Google Scholar]

- Babaarslan, O.; Sarıoğlu, E.; Avcı, M.E. A comparative study on performance characteristics of multicomponent core-spun yarns containing cotton/PET/elastane. J. Text. Inst. 2020, 111, 775–784. [Google Scholar] [CrossRef]

- Datta, J.; Kopczyńska, P.; Simón, D.; Rodríguez, J.F. Thermo-Chemical Decomposition Study of Polyurethane Elastomer Through Glycerolysis Route with Using Crude and Refined Glycerine as a Transesterification Agent. J. Polym. Environ. 2018, 26, 166–174. [Google Scholar] [CrossRef]

- Anuar Sharuddin, S.D.; Abnisa, F.; Wan Daud, W.M.A.; Aroua, M.K. A review on pyrolysis of plastic wastes. Energy Convers. Manag. 2016, 115, 308–326. [Google Scholar] [CrossRef]

- Kemona, A.; Piotrowska, M. Polyurethane Recycling and Disposal: Methods and Prospects. Polymers 2020, 12, 1752. [Google Scholar] [CrossRef]

- Gerlock, J.L.; Braslaw, J.; Mahoney, L.R.; Ferris, F.C. Reaction of polyurethane foam with dry steam: Kinetics and mechanism of reactions. J. Polym. Sci. Polym. Chem. Ed. 1980, 18, 541–557. [Google Scholar] [CrossRef]

- Zia, K.M.; Bhatti, H.N.; Bhatti, I.A. Methods for polyurethane and polyurethane composites, recycling and recovery: A review. React. Funct. Polym. 2007, 67, 675–692. [Google Scholar] [CrossRef]

- Yang, K.; Grant, J.C.; Lamey, P.; Joshi-Imre, A.; Lund, B.R.; Smaldone, R.A.; Voit, W. Diels–Alder Reversible Thermoset 3D Printing: Isotropic Thermoset Polymers via Fused Filament Fabrication. Adv. Funct. Mater. 2017, 27, 1700318. [Google Scholar] [CrossRef]

- Yuan, T.; Zhang, L.; Li, T.; Tu, R.; Sodano, H.A. 3D Printing of a self-healing, high strength, and reprocessable thermoset. Polym. Chem. 2020, 11, 6441–6452. [Google Scholar] [CrossRef]

- Blaiszik, B.J.; Kramer, S.L.B.; Olugebefola, S.C.; Moore, J.S.; Sottos, N.R.; White, S.R. Self-Healing Polymers and Composites. Annu. Rev. Mater. Res. 2010, 40, 179–211. [Google Scholar] [CrossRef]

- Varghese, S.; Lele, A.; Mashelkar, R. Metal-ion-mediated healing of gels. J. Polym. Sci. Part A Polym. Chem. 2006, 44, 666–670. [Google Scholar] [CrossRef]

- Meure, S.; Wu, D. The Biomimetic Approach to Self Healing Polymer Composite Development in the Aerospace Industry. In Proceedings of the First International Conference on Self Healing Materials, Noordwijk aan Zee, The Netherlands, 18–20 April 2007. [Google Scholar]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef]

- Toohey, K.S.; Sottos, N.R.; Lewis, J.A.; Moore, J.S.; White, S.R. Self-healing materials with microvascular networks. Nat. Mater. 2007, 6, 581–585. [Google Scholar] [CrossRef]

- Wool, R.P. Self-healing materials: A review. Soft Matter 2008, 4, 400–418. [Google Scholar] [CrossRef]

- Chen, X.; Dam, M.A.; Ono, K.; Mal, A.; Shen, H.; Nutt, S.R.; Sheran, K.; Wudl, F. A Thermally Re-mendable Cross-Linked Polymeric Material. Science 2002, 295, 1698–1702. [Google Scholar] [CrossRef]

- Chen, X.; Wudl, F.; Mal, A.K.; Shen, H.; Nutt, S.R. New Thermally Remendable Highly Cross-Linked Polymeric Materials. Macromolecules 2003, 36, 1802–1807. [Google Scholar] [CrossRef]

- Platonova, E.O.; Vlasov, E.; Pavlov, A.A.; Kireynov, A.; Nelyub, V.A.; Polezhaev, A.V. Self-healing polyurethane based on a difuranic monomer from biorenewable source. J. Appl. Polym. Sci. 2019, 136, 47869. [Google Scholar] [CrossRef]

- Plaisted, T.A.; Nemat-Nasser, S. Quantitative evaluation of fracture, healing and re-healing of a reversibly cross-linked polymer. Acta Mater. 2007, 55, 5684–5696. [Google Scholar] [CrossRef]

- Murphy, E.B.; Bolanos, E.; Schaffner-Hamann, C.; Wudl, F.; Nutt, S.R.; Auad, M.L. Synthesis and Characterization of a Single-Component Thermally Remendable Polymer Network: Staudinger and Stille Revisited. Macromolecules 2008, 41, 5203–5209. [Google Scholar] [CrossRef]

- Platonova, E.; Chechenov, I.; Pavlov, A.; Solodilov, V.; Afanasyev, E.; Shapagin, A.; Polezhaev, A. Thermally Remendable Polyurethane Network Cross-Linked via Reversible Diels–Alder Reaction. Polymers 2021, 13, 1935. [Google Scholar] [CrossRef] [PubMed]

- Varganici, C.-D.; Ursache, O.; Gaina, C.; Gaina, V.; Rosu, D.; Simionescu, B.C. Synthesis and Characterization of a New Thermoreversible Polyurethane Network. Ind. Eng. Chem. Res. 2013, 52, 5287–5295. [Google Scholar] [CrossRef]

- Ursache, O.; Gaina, C.; Gaina, V. Polyurethanes based on thermoreversible networks designed by Diels-Alder reaction. Express Polym. Lett. 2017, 11, 467–478. [Google Scholar] [CrossRef]

- Yang, S.; Du, X.; Deng, S.; Qiu, J.; Du, Z.; Cheng, X.; Wang, H. Recyclable and self-healing polyurethane composites based on Diels-Alder reaction for efficient solar-to-thermal energy storage. Chem. Eng. J. 2020, 398, 125654. [Google Scholar] [CrossRef]

- Gol’dfarb, Y.L.; Ostapenko, é.G.; Vinogradova, V.G.; Zverev, A.N.; Polyakov, A.V.; Yanovskii, A.I.; Yufit, D.S.; Struchkov, Y.T. Synthesis, structures, and redox properties of some new dithiocarbamates that include a heteroaromatic ring. Chem. Heterocycl. Compd. 1987, 23, 740–747. [Google Scholar] [CrossRef]

- Salewska, N.; Milewska, M.J. Efficient Method for the Synthesis of Functionalized Basic Maleimides. J. Heterocycl. Chem. 2014, 51, 999–1003. [Google Scholar] [CrossRef]

- Celli, A.; Colonna, M.; Gandini, A.; Gioia, C.; Lacerda, T.M.; Vannini, M. Polymers from Monomers Derived from Biomass. In Chemicals and Fuels from Bio-Based Building Blocks; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2016; pp. 315–350. [Google Scholar]

- Raquez, J.-M.; Vanderstappen, S.; Meyer, F.; Verge, P.; Alexandre, M.; Thomassin, J.-M.; Jérôme, C.; Dubois, P. Design of Cross-Linked Semicrystalline Poly(ε-caprolactone)-Based Networks with One-Way and Two-Way Shape-Memory Properties through Diels-Alder Reactions. Chem.-A Eur. J. 2011, 17, 10135–10143. [Google Scholar] [CrossRef]

- Liu, X.; Du, P.; Liu, L.; Zheng, Z.; Wang, X.; Joncheray, T.; Zhang, Y. Kinetic study of Diels–Alder reaction involving in maleimide–furan compounds and linear polyurethane. Polym. Bull. 2013, 70, 2319–2335. [Google Scholar] [CrossRef]

- Lakatos, C.; Katalin, C.; Papp, R.; Karger-Kocsis, J.; Zsuga, M.; Keki, S. Segmented linear shape memory polyurethanes with thermoreversible Diels-Alder coupling: Effects of polycaprolactone molecular weight and diisocyanate type. Express Polym. Lett. 2016, 10, 324–336. [Google Scholar] [CrossRef]

- Lakatos, C.; Czifrák, K.; Karger-Kocsis, J.; Daróczi, L.; Zsuga, M.; Kéki, S. Shape memory crosslinked polyurethanes containing thermoreversible Diels-Alder couplings. J. Appl. Polym. Sci. 2016, 133, 44145. [Google Scholar] [CrossRef]

- Feng, L.; Yu, Z.; Bian, Y.; Lu, J.; Shi, X.; Chai, C. Self-healing behavior of polyurethanes based on dual actions of thermo-reversible Diels-Alder reaction and thermal movement of molecular chains. Polymer 2017, 124, 48–59. [Google Scholar] [CrossRef]

- Engel, T.; Kickelbick, G. Thermoreversible Reactions on Inorganic Nanoparticle Surfaces: Diels-Alder Reactions on Sterically Crowded Surfaces. Chem. Mater. 2013, 25, 149–157. [Google Scholar] [CrossRef]

- Ramesh, S.; Sivasamy, A.; Kim, J.-H. Synthesis and characterization of maleimide-functionalized polystyrene-SiO2/TiO2 hybrid nanocomposites by sol–gel process. Nanoscale Res. Lett. 2012, 7, 350. [Google Scholar] [CrossRef]

- Gaina, C.; Ursache, O.; Gaina, V. Re-Mendable Polyurethanes. Polym.-Plast. Technol. Eng. 2011, 50, 712–718. [Google Scholar] [CrossRef]

- Du, P.; Liu, X.; Zheng, Z.; Wang, X.; Joncheray, T.; Zhang, Y. Synthesis and characterization of linear self-healing polyurethane based on thermally reversible Diels–Alder reaction. RSC Adv. 2013, 3, 15475–15482. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, R.; Wu, Q.; Chen, T.; Sun, P. Bio-Inspired High-Performance and Recyclable Cross-Linked Polymers. Adv. Mater. 2013, 25, 4912–4917. [Google Scholar] [CrossRef]

| Characteristic | PU-DA | PU-DA-FA |

|---|---|---|

| Mn | 5300 | 2900 |

| Mw | 19,200 | 5000 |

| PDI | 3.6 | 1.7 |

| Sample | E (MPa) | ηE (%) | σt (MPa) | ησ (%) | ε (%) |

|---|---|---|---|---|---|

| Pristine PU-DA | 32.9 | 100 | 9.8 | 93 | 334 |

| Healed PU-DA | 32.8 | 9.1 | 280 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Platonova, E.; Ponomareva, P.; Lokiaeva, Z.; Pavlov, A.; Nelyub, V.; Polezhaev, A. New Building Blocks for Self-Healing Polymers. Polymers 2022, 14, 5394. https://doi.org/10.3390/polym14245394

Platonova E, Ponomareva P, Lokiaeva Z, Pavlov A, Nelyub V, Polezhaev A. New Building Blocks for Self-Healing Polymers. Polymers. 2022; 14(24):5394. https://doi.org/10.3390/polym14245394

Chicago/Turabian StylePlatonova, Elena, Polina Ponomareva, Zalina Lokiaeva, Alexander Pavlov, Vladimir Nelyub, and Alexander Polezhaev. 2022. "New Building Blocks for Self-Healing Polymers" Polymers 14, no. 24: 5394. https://doi.org/10.3390/polym14245394

APA StylePlatonova, E., Ponomareva, P., Lokiaeva, Z., Pavlov, A., Nelyub, V., & Polezhaev, A. (2022). New Building Blocks for Self-Healing Polymers. Polymers, 14(24), 5394. https://doi.org/10.3390/polym14245394