Experimental Research and Numerical Analysis of CFRP Retrofitted Masonry Triplets under Shear Loading

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Brick Units

2.1.2. Mortar

2.1.3. CFRP Strips

2.2. Shear Triplet Tests Setup and Procedure

3. Results and Discussion

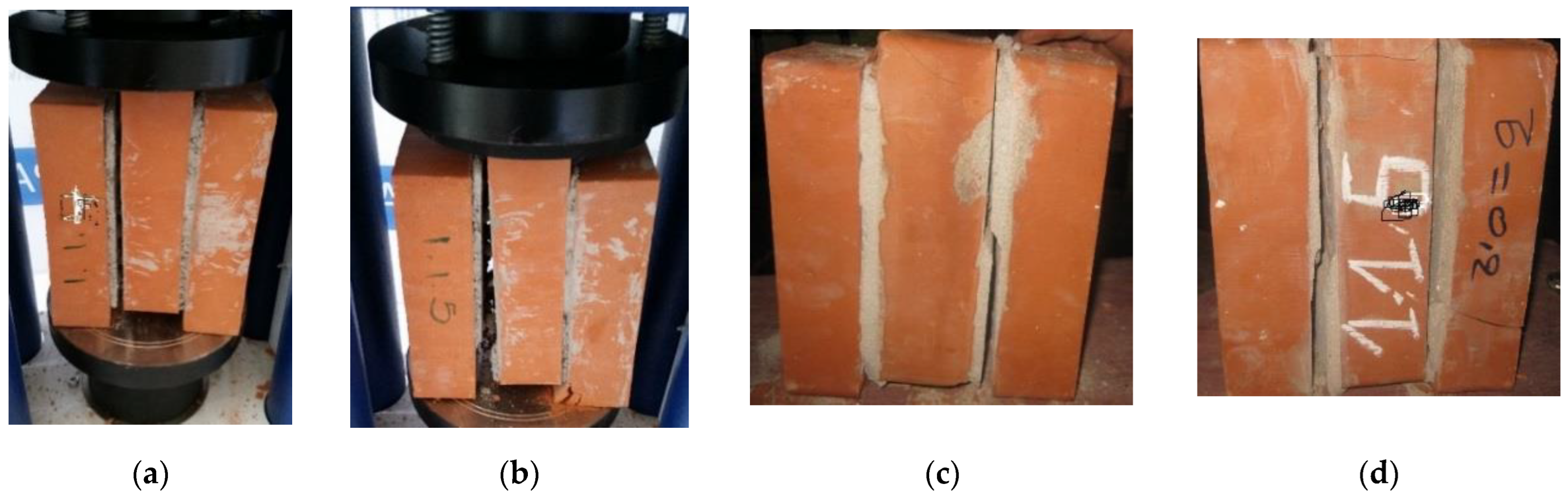

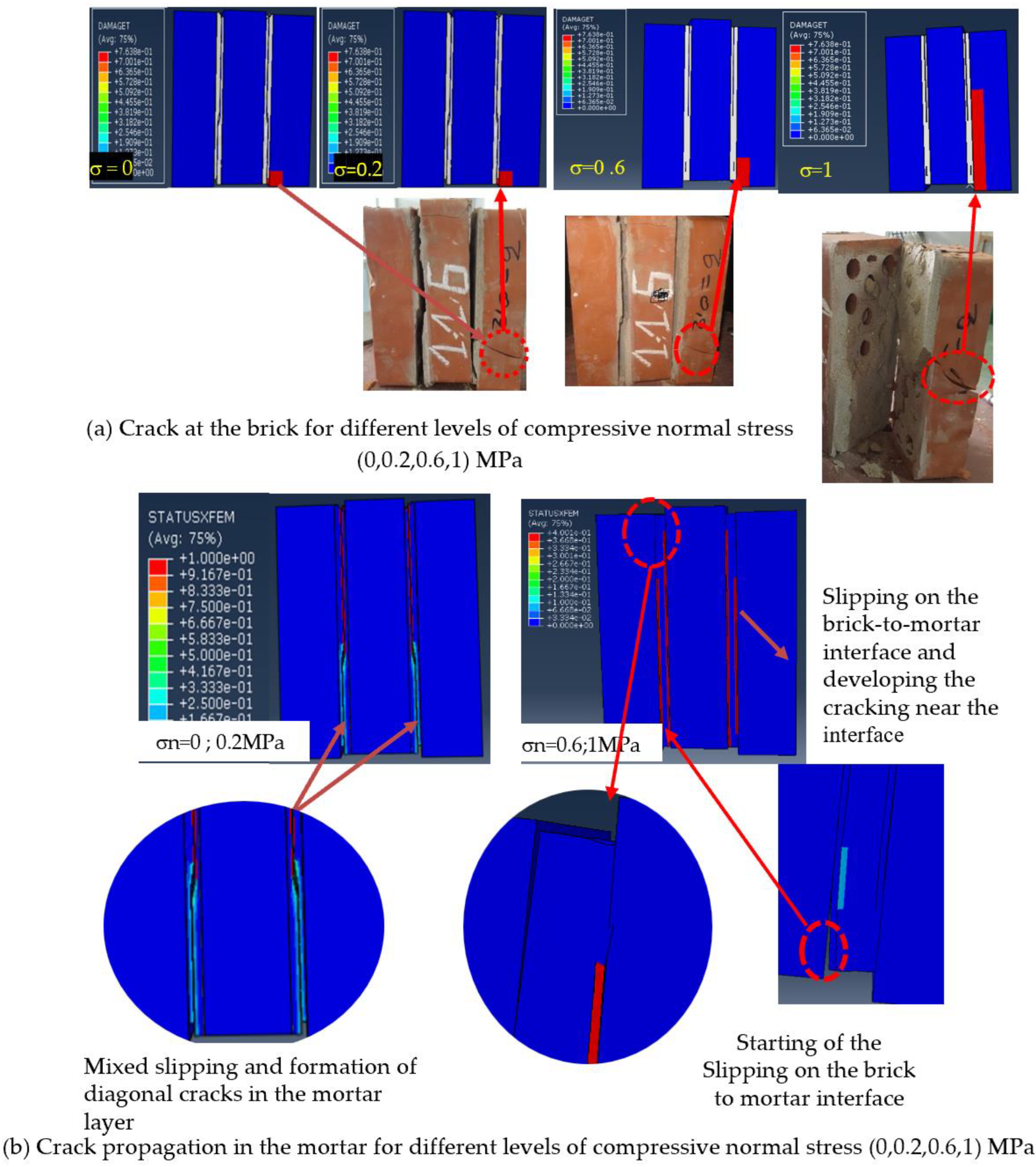

3.1. Failure Patterns

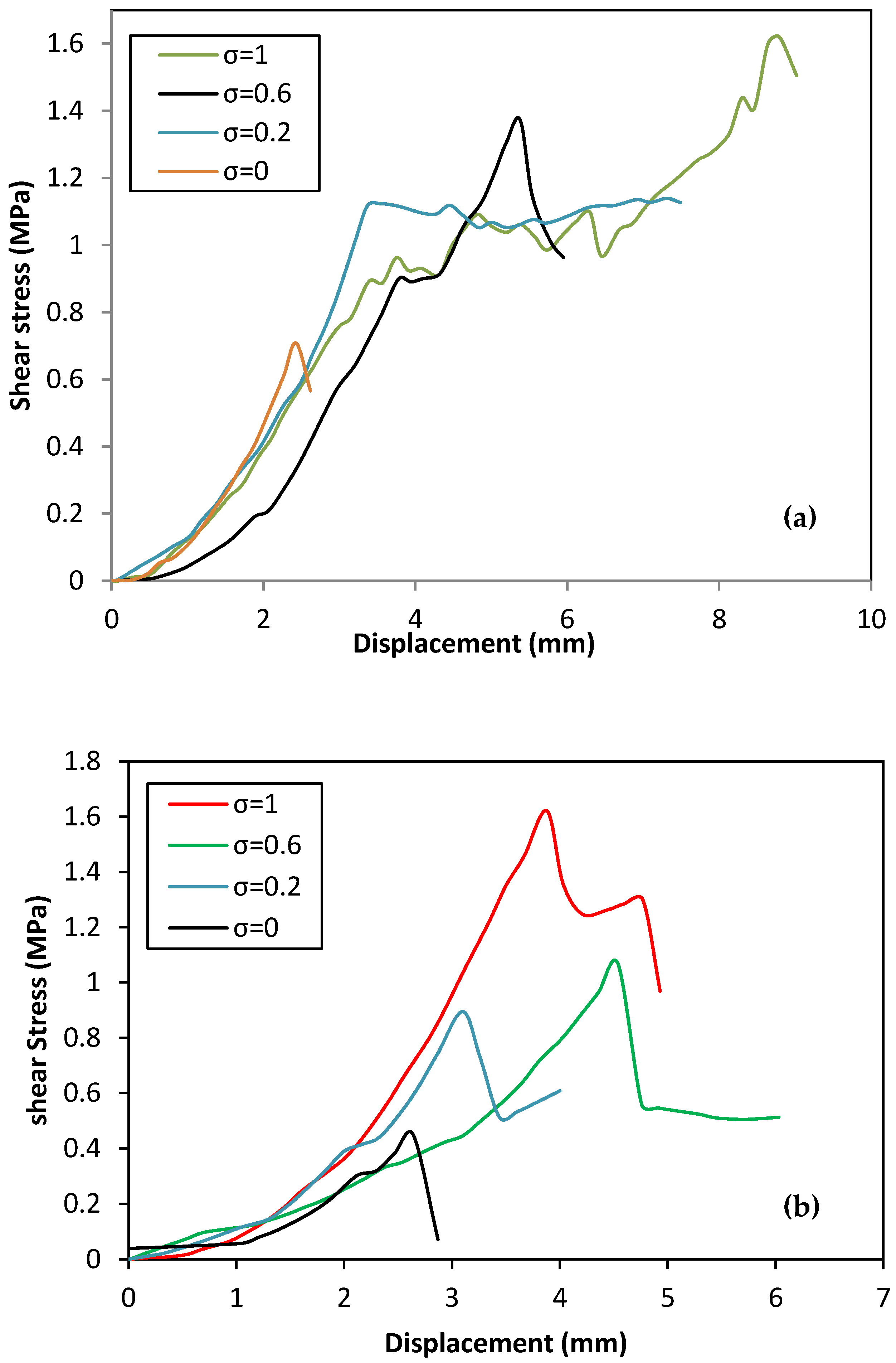

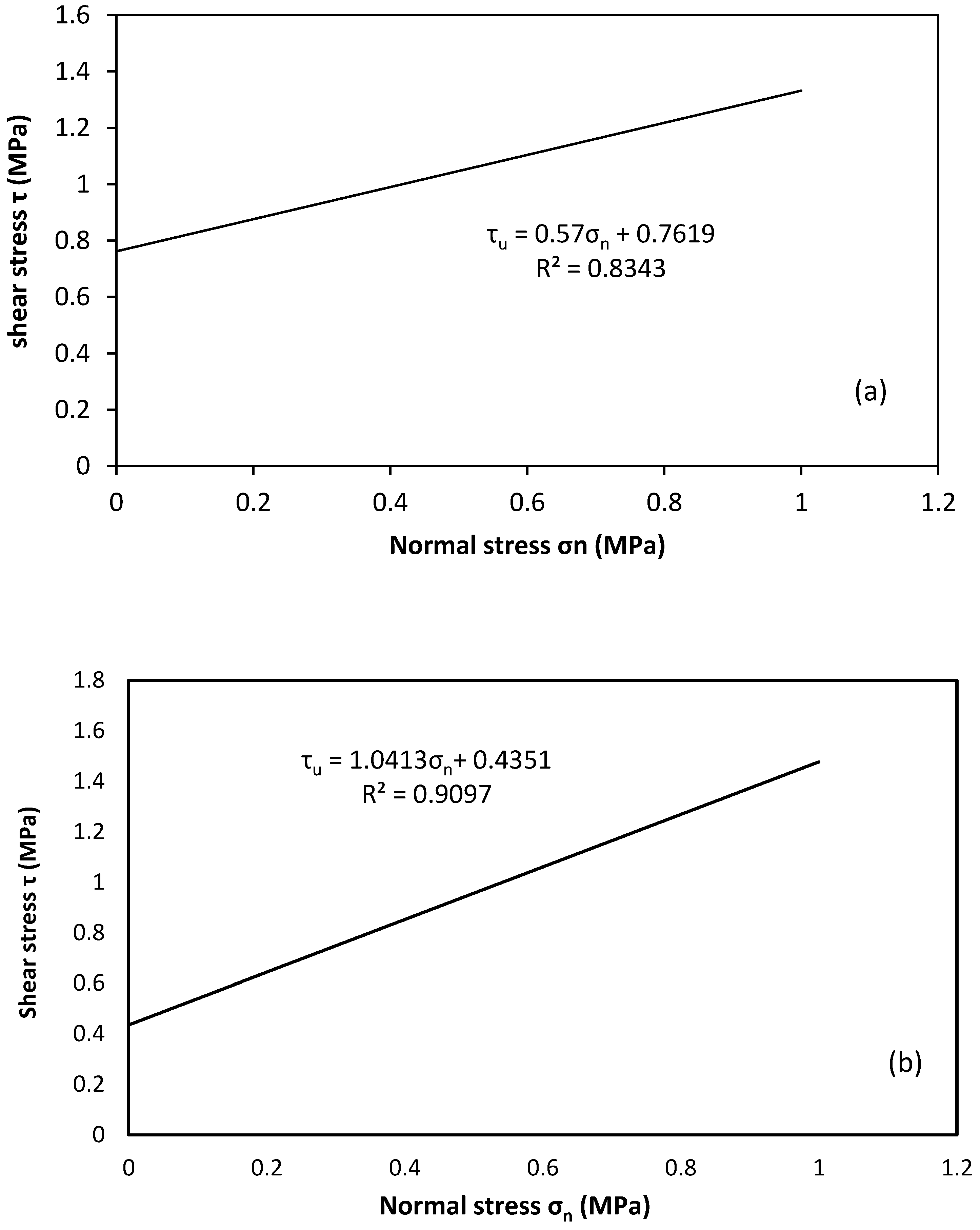

3.2. Joint Strength Parameters (Joint Shear Test)

3.3. CFRP-Reinforced Shear Triplets

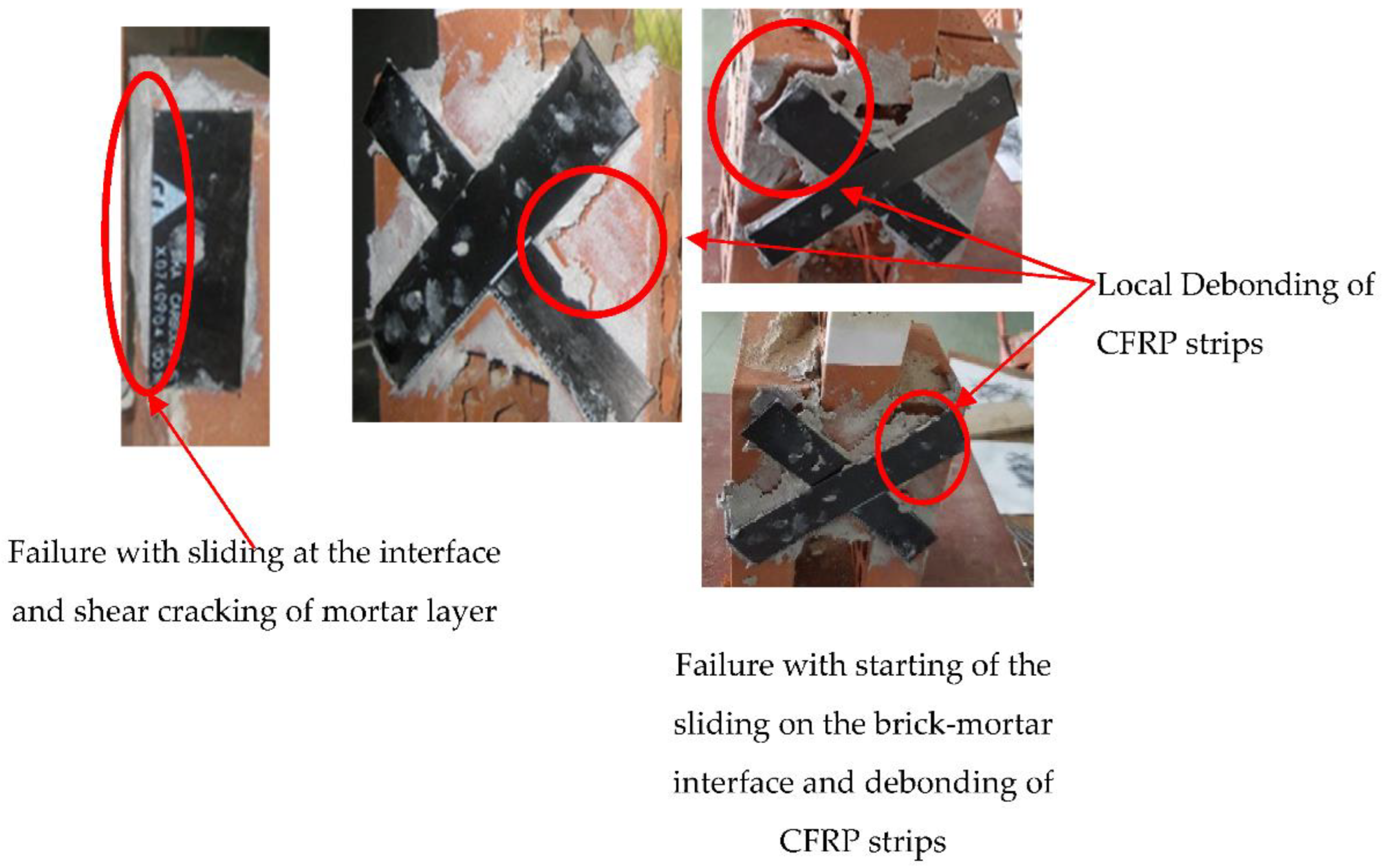

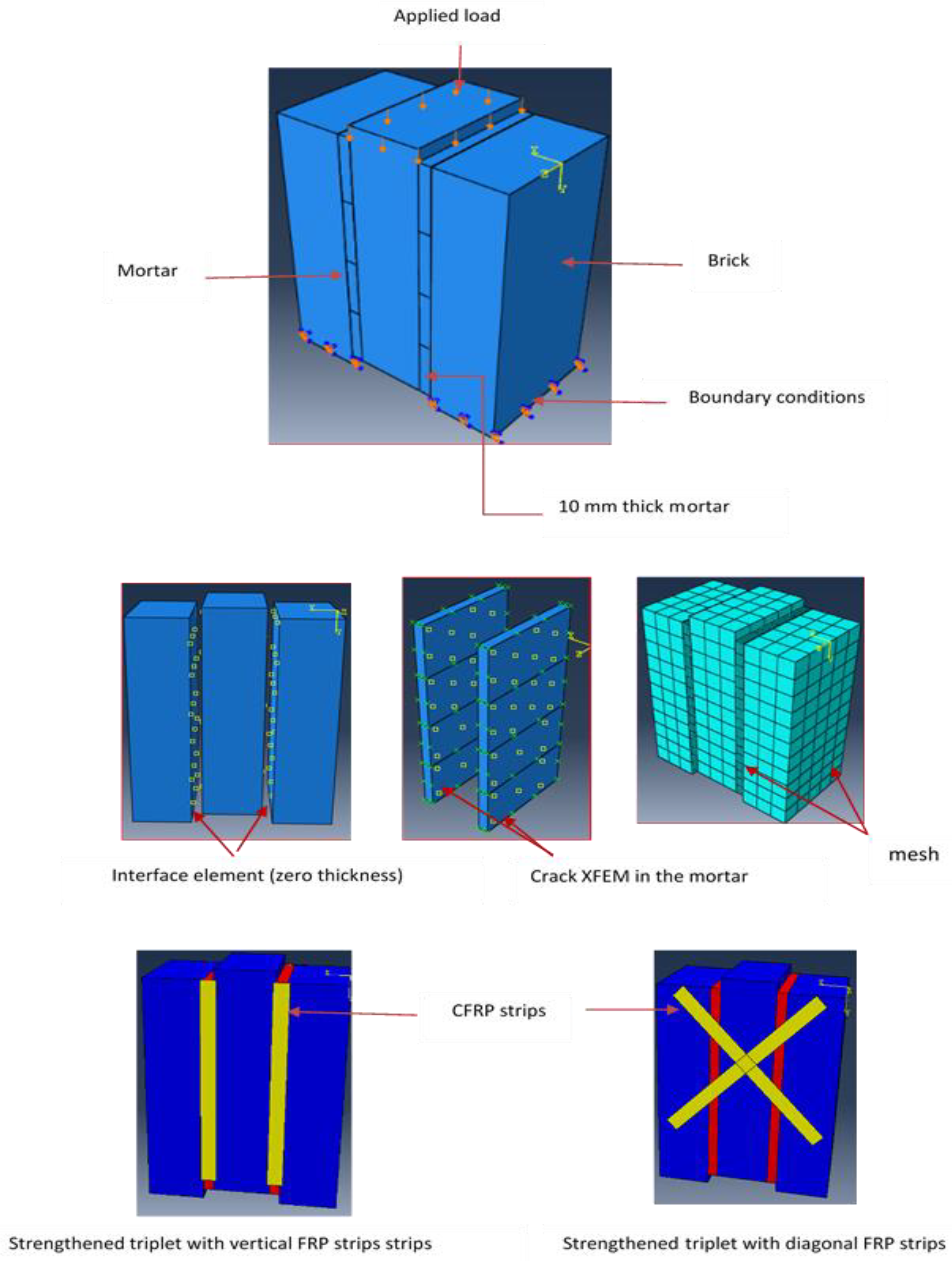

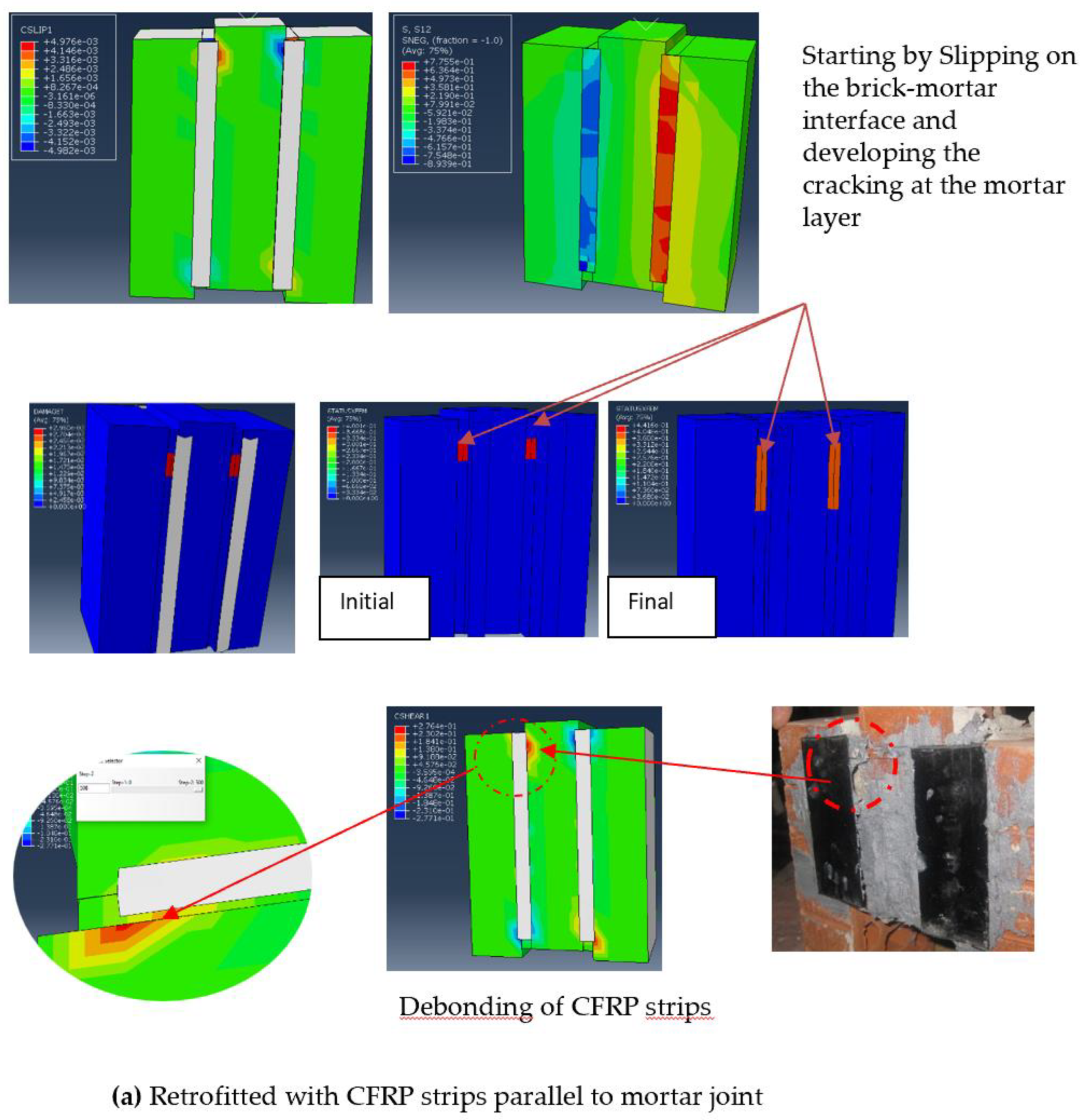

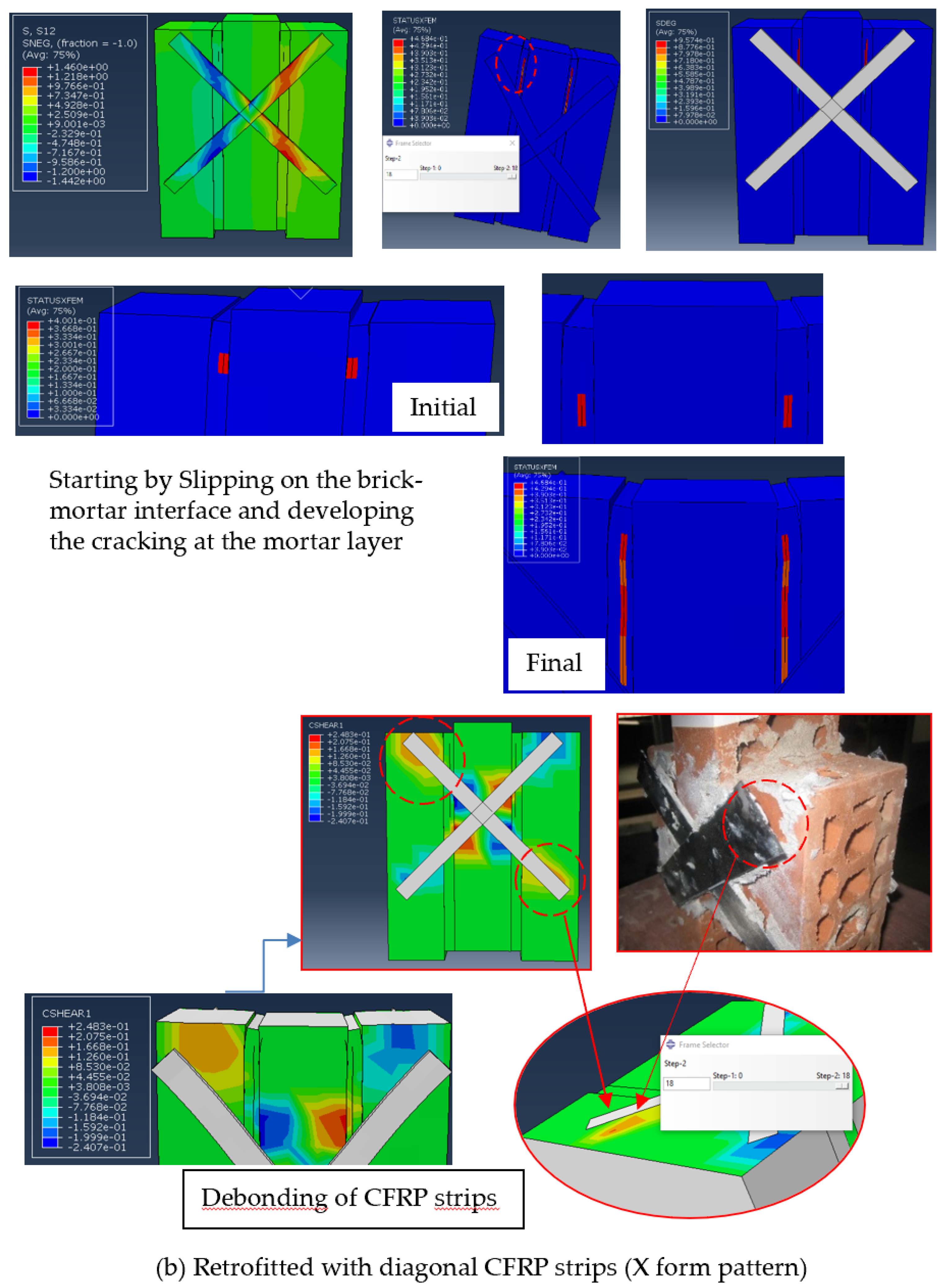

3.4. Numerical Modelling and Set-Up

3.4.1. Mechanical Model for Brick and Mortar

- The dilation angle(s) (ψ) is 12° to 30°. In this study, the dilation angle was 20°.

- The eccentricity parameter (e) ranges from 0 to 0.1 and is assumed to be 0.1.

- Viscosity parameter = 0.001.

- () the ratio between the initial equi-biaxial compressive strength and uni-axial compressive strength of masonry when the default value was used (1.16).

- (K) the ratio of the second stress invariant on the tensile meridian when the default value was used (0.67).

3.4.2. Interface Properties

3.4.3. Modelling of CFRP and Masonry to CFRP Bond Interface

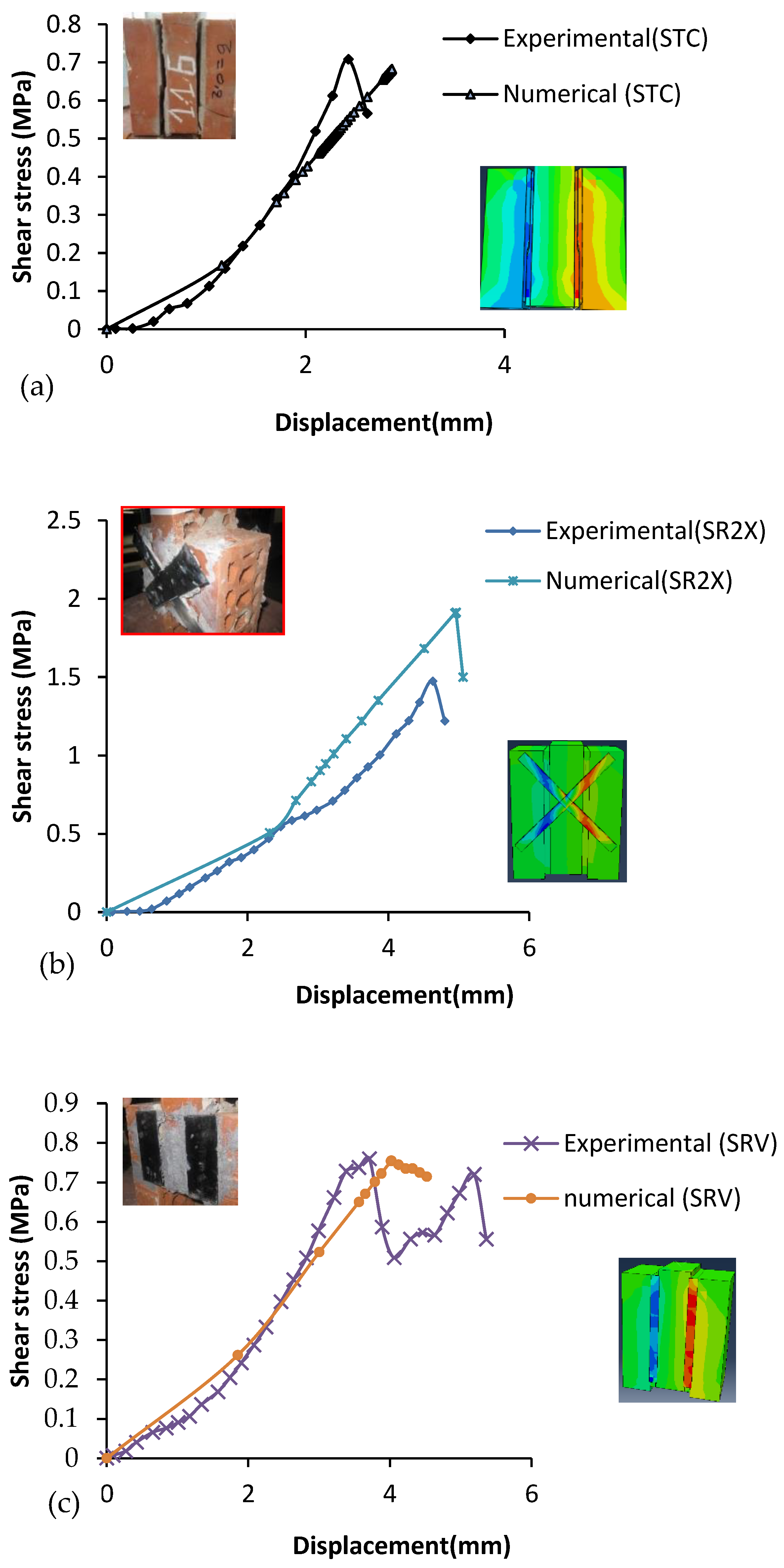

3.5. Numerical Results for Finite Element Modelling and Comparison with Experimental Results

4. Conclusions

- The strength of the mortar has a limited effect on the peak shear stress. The other two parameters, namely cohesion (c) and internal friction angle (ϕ), also vary with the mortar strength. On the other hand, higher confining pressure levels increased the shear capacity of the interface.

- The cohesion (c) is independent of normal stress and decreased with decreasing mortar strength, whereas the coefficient of friction increased with increasing mortar strength.

- Beyond the shear response, the triplet failure modes were sensibly affected by the compression level, independent from the mortar joint properties.

- The tensile damage at the bottom of the brick largely depended on the applied level of pre-compression stress.

- For reinforced shear triplets, the failure was governed by the brick and mortar tensile properties rather than that of CFRP strips, due to their relatively high strength.

- Specimens provided with diagonal reinforcement exhibited a higher strength enhancement than those with vertical reinforcement for two types of specimens. In this case, the diagonal configuration in both types of mortar proved to be effective in restricting brick–mortar interface separation and maintaining specimen integrity.

- A significantly higher contribution from CFRP was observed regarding strengthened shear triplets, for which the strength increase provided by CFRP was in the range of 107 to 150%, depending on the reinforcement configuration.

- The significant increase in ductility and shear capacity was achieved by diagonal CFRP reinforcement on both sides of the masonry specimen.

- The extended finite element method (XFEM) was suitable for modelling crack propagation in the mortar layer. It also helped to recognise the region where cracking occurred in the mortar layer and where the specimen failed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Segura, J.; Bernat, E.; Mendizábal, V.; Pelà, L.; Roca, P.; Gil, L. Experimental comparison of two testing setups for characterizing the shear mechanical properties of masonry. J. Build. Eng. 2021, 44, 103277. [Google Scholar] [CrossRef]

- EN 1052-3; Methods of test for masonry–Part 3: Determination of initial shear strength. European Committee for Standardization: Brussels, Belgium, 2007.

- Pelà, L.; Kasioumi, K.; Roca, P. Experimental evaluation of the shear strength of aerial lime mortar brickwork by standard tests on triplets and non-standard tests on core samples. Eng. Struct. 2017, 136, 441–453. [Google Scholar] [CrossRef]

- Cavalheiro, O.; Pedroso, G. Experimental Data on Hollow Block Prisms Using Direct Shear Test. In Proceedings of the 12th International Brick/Block Masonry Conference, Madrid, Spain, 25–28 June 2000; pp. 433–440. [Google Scholar]

- Sarhosis, V.; Sheng, Y. Identification of material parameters for low bond strength masonry. Eng. Struct. 2014, 60, 100–110. [Google Scholar] [CrossRef]

- Capozucca, R. Shear behaviour of historic masonry made of clay bricks. Open Constr. Build. Technol. J. 2011, 5, 89–96. [Google Scholar] [CrossRef]

- Guerreiro, J.; Proença, J.M.; Ferreira, J.G.; Gago, A.S. Bonding and anchoring of a CFRP reinforced render for the external strengthening of old masonry buildings. Constr. Build. Mater. 2017, 155, 56–64. [Google Scholar] [CrossRef]

- Babatunde, S.A. Review of strengthening techniques for masonry using fiber reinforced polymers. Compos. Struct. 2017, 161, 246–255. [Google Scholar] [CrossRef]

- Hernoune, H.; Benabed, B.; Alshugaa, M.; Abousnina, R.; Guettala, A. Strengthening of masonry walls with CFRP composite: Experiments and numerical modeling. Építöanyag 2020, 72, 2–11. [Google Scholar] [CrossRef]

- Son, S.-H.; An, J.-H.; Song, J.-H.; Hong, Y.-S.; Jang, H.-S.; Eun, H.-C. In-Plane Strengthening of Unreinforced Masonry Walls by Glass Fiber-Reinforced Polyurea. Civ. Eng. J. 2021, 7, 2119–2129. [Google Scholar] [CrossRef]

- El-Diasity, M.; Okail, H.; Kamal, O.; Said, M. Structural performance of confined masonry walls retrofitted using ferrocement and GFRP under in-plane cyclic loading. Eng. Struct. 2015, 94, 54–69. [Google Scholar] [CrossRef]

- Gudayu, A.D.; Steuernagel, L.; Meiners, D.; Gideon, R. Effect of surface treatment on moisture absorption, thermal, and mechanical properties of sisal fiber. J. Ind. Text. 2020, 1528083720924774. [Google Scholar] [CrossRef]

- Mohan, T.; Kanny, K. Chemical treatment of sisal fiber using alkali and clay method. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1989–1998. [Google Scholar] [CrossRef]

- Mahmood, H.; Ingham, J.M. Diagonal compression testing of FRP-retrofitted unreinforced clay brick masonry wallettes. J. Compos. Constr. 2011, 15, 810–820. [Google Scholar] [CrossRef]

- Haroun, M.; Mosallam, A.; Allam, K. Cyclic in-plane shear of concrete masonry walls strengthened by FRP laminates. ACI Specia L Publ. 2005, 230, 327–340. [Google Scholar]

- Hamid, A.A.; El-Dakhakhni, W.; Hakam, Z.H.R.; Elgaaly, M. Behavior of composite unreinforced masonry–fiber-reinforced polymer wall assemblages under in-plane loading. J. Compos. Constr. 2005, 9, 73–83. [Google Scholar] [CrossRef]

- Li, T.; Silva, P.F.; Belarbi, A.; Nanni, A.; Myers, J.J. Retrofit of un-reinforced infill masonry walls with FRP. J. Compos. Constr. 2001, 5, 559–563. [Google Scholar]

- Tumialan, J.G.; Morbin, A.; Nanni, A.; Modena, C. Shear strengthening of masonry walls with FRP composites. In Composites; Composites Fabricators Association: Tampa, FL, USA, 2001; pp. 3–6. [Google Scholar]

- Lanivschi, C.E. State of the art for strengthening masonry with fibre reinforced polymers. Bul. Inst. Politeh. Din Lasi Sect. Constr. Arhit. 2012, 58, 97. [Google Scholar]

- Hernoune, H.; Benabed, B.; Kanellopoulos, A.; Al-Zuhairi, A.H.; Guettala, A. Experimental and numerical study of behaviour of reinforced masonry walls with NSM CFRP strips subjected to combined loads. Buildings 2020, 10, 103. [Google Scholar] [CrossRef]

- ElGawady, M.A.; Lestuzzi, P.; Badoux, M. In-plane seismic response of URM walls upgraded with FRP. J. Compos. Constr. 2005, 9, 524–535. [Google Scholar] [CrossRef]

- Dizhur, D.; Griffith, M.; Ingham, J. In-plane shear improvement of unreinforced masonry wall panels using NSM CFRP strips. J. Compos. Constr. 2013, 17, 04013010. [Google Scholar] [CrossRef]

- Korany, Y.; Drysdale, R. Rehabilitation of masonry walls using unobtrusive FRP techniques for enhanced out-of-plane seismic resistance. J. Compos. Constr. 2006, 10, 213–222. [Google Scholar] [CrossRef]

- Saghafi, M.; Safakhah, S.; Kheyroddin, A.; Mohammadi, M. In-plane shear behavior of FRP strengthened masonry walls. APCBEE Procedia 2014, 9, 264–268. [Google Scholar] [CrossRef]

- Camli, U.S.; Binici, B. Strength of carbon fiber reinforced polymers bonded to concrete and masonry. Constr. Build. Mater. 2007, 21, 1431–1446. [Google Scholar] [CrossRef]

- Grande, E.; Imbimbo, M.; Sacco, E. Bond behaviour of CFRP laminates glued on clay bricks: Experimental and numerical study. Compos. Part B Eng. 2011, 42, 330–340. [Google Scholar] [CrossRef]

- Willis, C.; Yang, Q.; Seracino, R.; Griffith, M. Bond behaviour of FRP-to-clay brick masonry joints. Eng. Struct. 2009, 31, 2580–2587. [Google Scholar] [CrossRef]

- Alcaino, P.; Santa-Maria, H. Experimental response of externally retrofitted masonry walls subjected to shear loading. J. Compos. Constr. 2008, 12, 489–498. [Google Scholar] [CrossRef]

- D’Altri, A.M.; Sarhosis, V.; Milani, G.; Rots, J.; Cattari, S.; Lagomarsino, S.; Sacco, E.; Tralli, A.; Castellazzi, G.; de Miranda, S. Modeling strategies for the computational analysis of unreinforced masonry structures: Review and classification. Arch. Comput. Methods Eng. 2020, 27, 1153–1185. [Google Scholar] [CrossRef]

- Kabir, M.; Kalali, A. In-Plane Numerical Modelling Of Sterngthened Perforated Masonry Walls Using Frp Under Cyclic Loading. Asian J. Civ. Eng. 2013, 14, 161–179. [Google Scholar]

- Pantò, B.; Chisari, C.; Macorini, L.; Izzuddin, B. A macroscale modelling approach for nonlinear analysis of masonry arch bridges. In Proceedings of the SAHC, Online, 1–29 September 2021. [Google Scholar]

- Calderón, S.; Arnau, O.; Sandoval, C. Detailed micro-modeling approach and solution strategy for laterally loaded reinforced masonry shear walls. Eng. Struct. 2019, 201, 109786. [Google Scholar] [CrossRef]

- D’Altri, A.M.; de Miranda, S.; Castellazzi, G.; Sarhosis, V. A 3D detailed micro-model for the in-plane and out-of-plane numerical analysis of masonry panels. Comput. Struct. 2018, 206, 18–30. [Google Scholar] [CrossRef]

- Wang, J.Z.; Heath, A.; Walker, P. Numerical analysis of triplet shear test on brickwork masonry. In Advanced Materials Research; Trans Tech Publications: Stafa-Zurich, Switzerland, 2014. [Google Scholar]

- Puchades, M.M.; Judge, R.; Beattie, G. Uncertainty in the numerical modelling of masonry triplet tests under dynamic loading. Int. J. Saf. Secur. Eng. 2016, 6, 438–448. [Google Scholar]

- EN 771–1; Specification for Masonry Units-Part 1: Clay Masonry Units. British Standards Institute: London, UK, 2003.

- Vasconcelos, G.; Lourenço, P. Experimental characterization of stone masonry in shear and compression. Constr. Build. Mater. 2009, 23, 3337–3345. [Google Scholar] [CrossRef]

- EN 1015–11:1999; Methods of test for mortar for masonry. Determination of flexural and compressive strength of hardened mortar. Slovenian Institute for Standardization: Ljubljana, Slovenia, 1999.

- Crisafulli, F.J.; Carr, A.J.; Park, R. Analytical modelling of infilled frame structures. Bull. N. Z. Soc. Earthq. Eng. 2000, 33, 30–47. [Google Scholar] [CrossRef]

- EN 1052–1053:2002; Methods of test for masonry, Part 3: Determination of initial shear strength. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2002.

- Prakash, S.S.; Alagusundaramoorthy, P. Study on brick masonry infill walls with air gap. In Proceedings of the Ninth Canadian Conference on Earthquake Engineering, Ottawa, ON, Canada, 26–29 June 2007. [Google Scholar]

- Bompa, D.; Elghazouli, A. Experimental and numerical assessment of the shear behaviour of lime mortar clay brick masonry triplets. Constr. Build. Mater. 2020, 262, 120571. [Google Scholar] [CrossRef]

- Abdou, L.; Saada, R.A.; Meftah, F.; Mebarki, A. Experimental investigations of the joint-mortar behaviour. Mech. Res. Commun. 2006, 33, 370–384. [Google Scholar] [CrossRef]

- Lourenço, P.B. Structural Masonry Analysis: Recent Developments and Prospects; University of Newcastle: Callaghan, Australia, 2008. [Google Scholar]

- Paulay, T.; Priestley, M.N. Seismic Design of Reinforced Concrete and Masonry Buildings; Wiley: New york, NY, USA, 1992. [Google Scholar]

- Lubliner, J.; Oliver, J.; Oller, S.; Oñate, E. A plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Abaqus, F. Analysis User’s Manual 6.14; Dassault Systemes Simulia Corp.: Providence, RI, USA, 2011. [Google Scholar]

- Tao, Y. Fibre Reinforced Polymer (FRP) Strengthened Masonry Arch Structures; ERA: Bella Vista, Australia, 2013. [Google Scholar]

- Obaidat, Y.T.; Heyden, S.; Dahlblom, O.; Abu-Farsakh, G.; Abdel-Jawad, Y. Retrofitting of reinforced concrete beams using composite laminates. Constr. Build. Mater. 2011, 25, 591–597. [Google Scholar] [CrossRef]

- Barros, J.A.; Almeida, J.; Lourenço, P.B. Characterization of brick and brick–mortar interface under uniaxial tension. In Proceedings of the VII International Seminar on Structural Masonry for Developing Countries, Belo Horizonte, Brazil, 18–20 September 2002. [Google Scholar]

- Beatie, G. Joint Fracture in Reinforced and Unreinforced Masonry under Quasi-Static and Dynamic Loading; University of Liverpool: Liverpool, UK, 2003. [Google Scholar]

- Fouchal, F. Contribution à la Modélisation Numérique des Interfaces Dans Les Structures Maçonnées; Université de Reims Champagne-Ardenne: Reims, France, 2006. [Google Scholar]

- Sarhosis, V.; Lemos, J. A detailed micro-modelling approach for the structural analysis of masonry assemblages. Comput. Struct. 2018, 206, 66–81. [Google Scholar] [CrossRef]

| Unit Weight (kg/m3) | Compressive Strength (MPa) | Young’s Modulus (MPa) | Poisson’s Ratio |

|---|---|---|---|

| 1371 | 24.20 | 10,000.13 | 0.2 |

| Type of Mortar | Compressive Strength [MPa] | COV [%] | Flexural Strength [MPa] | Young’s Modulus E (MPa) |

|---|---|---|---|---|

| Mortar A (1:1:3) | 7.187 | 5 | 3.341 | 3639.24 |

| Mortar B (1:1:5) | 3.643 | 1.453 | 1821.87 |

| Properties | Value |

|---|---|

| Width CFRP (mm) | 15 |

| Thicknes (mm) | 2.5 |

| ECFRP (MPa) | 165,000 |

| FtCFRP (MPa) | 3100 |

| Rupture strain (%) | 1.7 |

| Specimens | Mortar Type | C | φ | |||||

|---|---|---|---|---|---|---|---|---|

| ST00A | A | 0 | 7.19 | 25 | 16.41 | 0.71 | 0.762 | 0.57 |

| ST02A | 0.2 | 26.11 | 1.13 | |||||

| ST06A | 0.6 | 31.67 | 1.37 | |||||

| ST10A | 1 | 37.9 | 1.64 | |||||

| ST00B | B | 0 | 3.64 | 25 | 10.17 | 0.44 | 0.435 | 1.04 |

| ST02B | 0.2 | 20.8 | 0.9 | |||||

| ST06B | 0.6 | 24.49 | 1.06 | |||||

| ST10B | 1 | 37.42 | 1.62 |

| Type of Mortar | Specimens Type | Ultimate Shear Strength (MPa) | Improvement Percentage (%) | Ultimate Displacement | Improvement Percentage (%) |

|---|---|---|---|---|---|

| A | STC (113T) | 0.71 | - | 2.43 | - |

| SRV (113RV) | 0.76 | 7 | 3.71 | 52.67 | |

| SRX (113RX) | 0.96 | 35.21 | 3.93 | 61.72 | |

| SR2X (113R2X) | 1.47 | 107 | 4.63 | 90.53 | |

| B | STC (115T) | 0.44 | - | 2.64 | - |

| SRV (115RV) | 0.5 | 14 | 3.37 | 27.65 | |

| SRX (115RX) | 0.6 | 36 | 2.79 | 5.68 | |

| SR2X (115R2X) | 1.1 | 150 | 3.9 | 47.72 |

| Elastic Parameters | Plasticity Parameters | |||

|---|---|---|---|---|

| Brick | Mortar(B) | |||

| Density (γ) (kg/m3) | 2200 | 1800 | dilatancy angle (ψ) | 20 |

| Young Modulus (E) (MPa) | 10,000 | 1880 | Eccentricity parameter (e) | 0.1 |

| Poisson’s ratio (μ) | 0.2 | 0.18 | 1.16 | |

| Stress ratio in the meridian in tension (k) | 0.67 | |||

| Viscosity parameter (ν) (m2/s) | 0.001 | |||

| Parameters | Magnitude | |

|---|---|---|

| Normal stiffness (Knn) | 40 | |

| Shear stifness (Kss) | 16 | |

| Friction Coefficient | 1.04 | |

| Damage Initiation (N/mm2) | Normal | 2 |

| Shear I | 0.44 | |

| Shear II | 0.44 | |

| Evolution Fracture energies (Nmm/mm2) | Gfc | - |

| GFI | 0.018 | |

| GFII | 0.2 | |

| Horizontal Stress σn (MPa) | Shear Bond Strength τ (MPa) | Percentage of Error (%) | Ultimate Displacement (mm) | Percentage of Error (%) | ||

|---|---|---|---|---|---|---|

| Experiment Results | Numerical Results | Experiment Results | Numerical Results | |||

| 0 N/mm2 | 0.71 | 0.68 | 3 | 2.87 | 2.8 | 7 |

| 0.2 N/mm2 | 0.9 | 0.86 | 4 | 3.1 | 3.06 | 4 |

| 0.6N/mm2 | 1.06 | 0.97 | 9 | 4.54 | 4.55 | 1 |

| 1 N/mm2 | 1.62 | 1.88 | 26 | 4.09 | 4.58 | 49 |

| Type of Retrofitting | Shear Bond Strength τ (MPa) | Percentage of Error (%) | Ultimate Displacement (mm) | Percentage of Error (%) | ||

|---|---|---|---|---|---|---|

| Experiment Results | Numerical Results | Experiment Results | Numerical Results | |||

| Vertical strips double sides | 0.76 | 0.76 | 0 | 4.71 | 4.52 | 19 |

| Diagonal strips(X) double side | 1.47 | 1.68 | 21 | 5.1 | 4.96 | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernoune, H.; Benabed, B.; Abousnina, R.; Alajmi, A.; Alfadhili, A.M.G.; Shalwan, A. Experimental Research and Numerical Analysis of CFRP Retrofitted Masonry Triplets under Shear Loading. Polymers 2022, 14, 3707. https://doi.org/10.3390/polym14183707

Hernoune H, Benabed B, Abousnina R, Alajmi A, Alfadhili AMG, Shalwan A. Experimental Research and Numerical Analysis of CFRP Retrofitted Masonry Triplets under Shear Loading. Polymers. 2022; 14(18):3707. https://doi.org/10.3390/polym14183707

Chicago/Turabian StyleHernoune, Houria, Benchaa Benabed, Rajab Abousnina, Abdalrahman Alajmi, Abdullah M GH Alfadhili, and Abdullah Shalwan. 2022. "Experimental Research and Numerical Analysis of CFRP Retrofitted Masonry Triplets under Shear Loading" Polymers 14, no. 18: 3707. https://doi.org/10.3390/polym14183707

APA StyleHernoune, H., Benabed, B., Abousnina, R., Alajmi, A., Alfadhili, A. M. G., & Shalwan, A. (2022). Experimental Research and Numerical Analysis of CFRP Retrofitted Masonry Triplets under Shear Loading. Polymers, 14(18), 3707. https://doi.org/10.3390/polym14183707