Effect of Sizing Agent on the Mechanical, Thermal, and Electrical Performance of Basalt Fiber/Epoxy Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Samples

2.2.1. Preparation of Sizing Agent

2.2.2. Sizing Treatment of Basalt Fiber

2.2.3. Preparation of Basalt Fiber/Epoxy Resin Composites

2.3. Methods

2.3.1. SEM Morphologies

2.3.2. Thermal and Mechanical Tests

2.3.3. Insulating Property Test

3. Results and Discussion

3.1. SEM Analysis

3.2. Thermal and Mechanical Properties

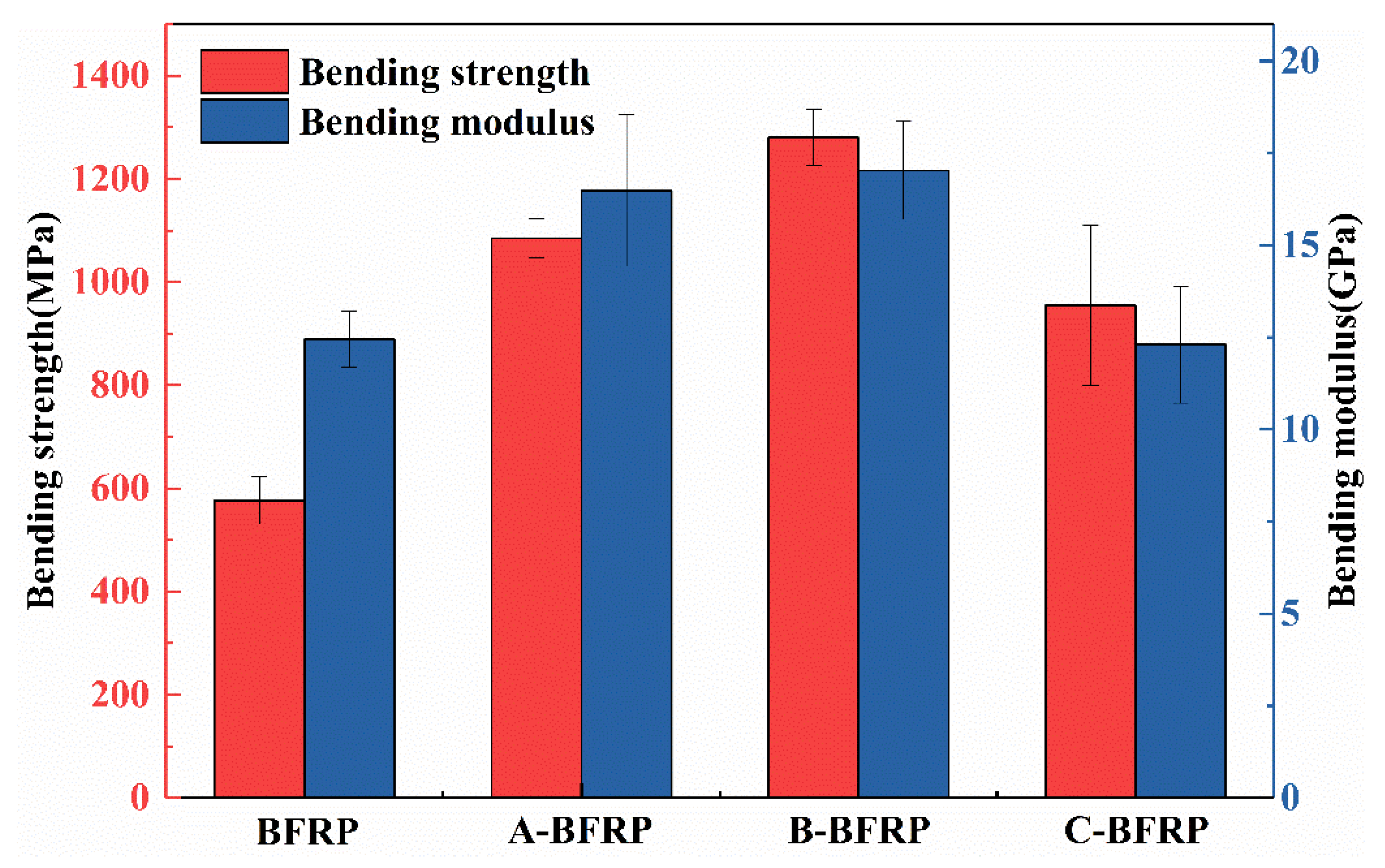

3.2.1. Bending Properties

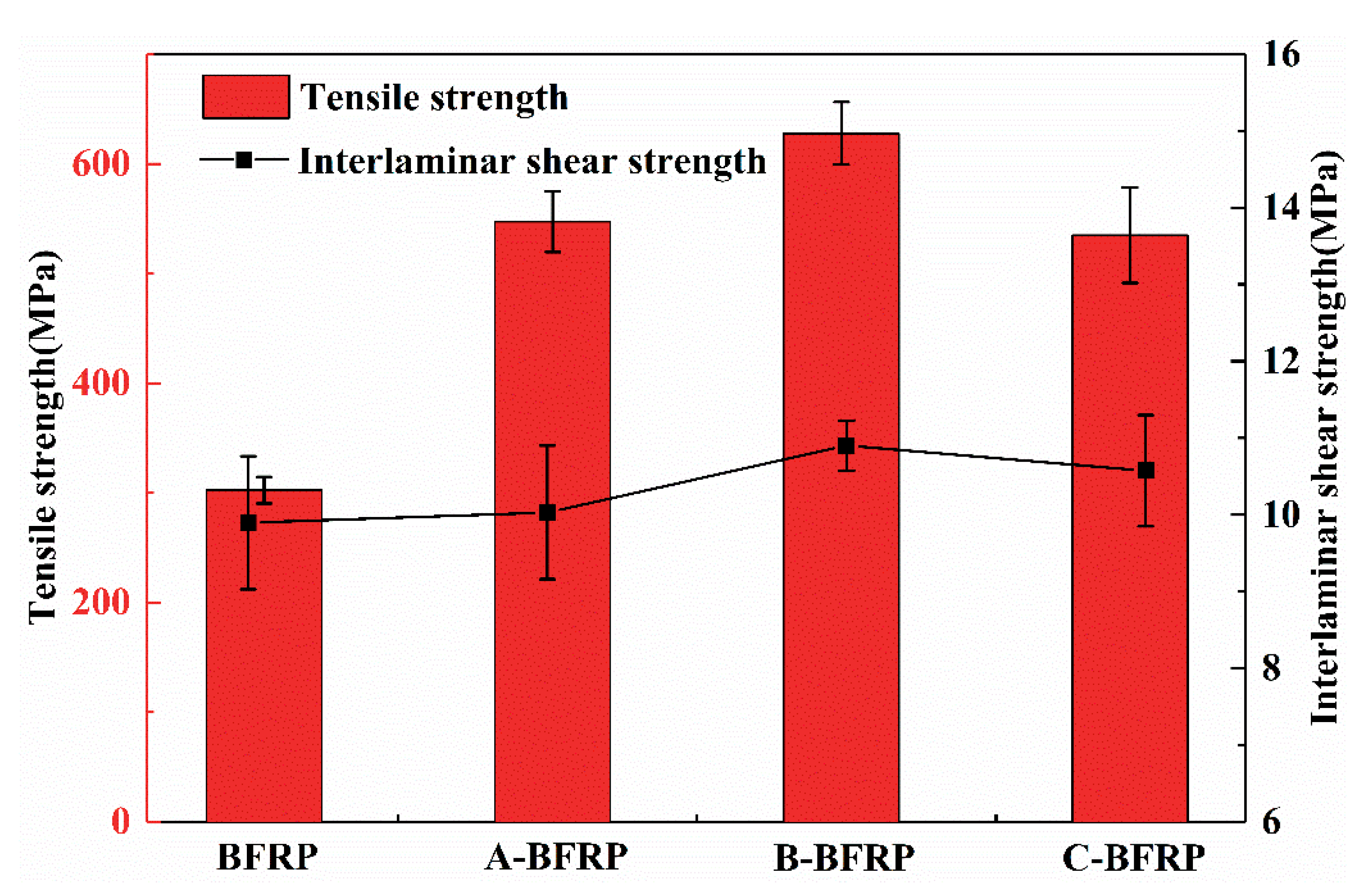

3.2.2. Tensile Properties

3.2.3. Interlaminar Shear Properties

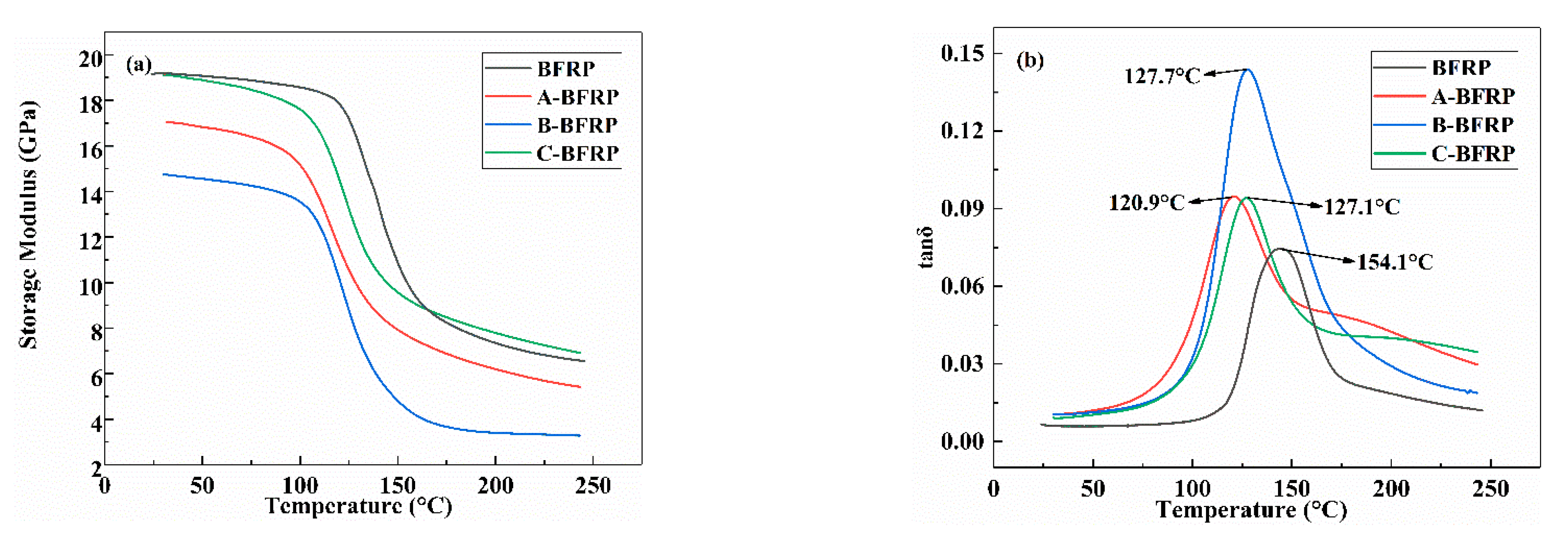

3.2.4. DMA

3.3. Insulating Properties

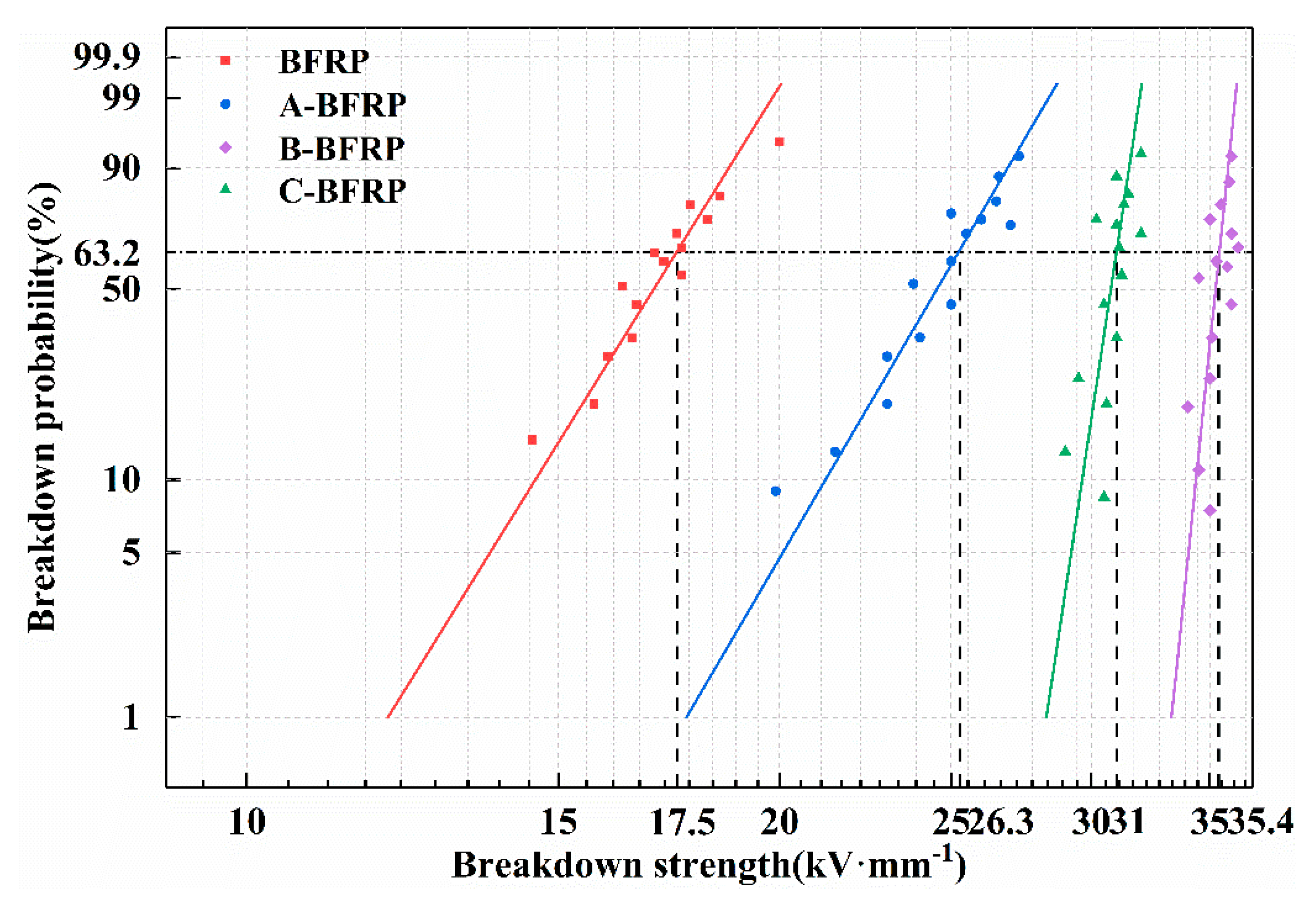

3.3.1. Breakdown Strength

3.3.2. Leakage Current

3.3.3. Dielectric Loss

4. Conclusions

- (1)

- It can be observed by SEM that the sizing agent can form a film on the surface of the fiber, which can improve the sizing effect of the fiber and resin. However, when the concentration of the sizing agent is sufficiently high, the greatly increased bunching property will cause the phenomenon of binding between the fibers.

- (2)

- The infiltration-modified composites’ mechanical characteristics showed various degrees of improvement. B-BFRP experienced increases in bending strength, bending modulus, tensile strength, and interlaminar shear strength of 122%, 34%, 102%, and 10.2%, respectively. Through DMA experiments, it was discovered that the addition of a sizing agent can lower the material’s elasticity and storage modulus while also reducing the Tg of the composite material.

- (3)

- Compared with the unmodified BFRP, the insulation properties of the modified composites generally showed a trend of increasing first and then decreasing. Among them, sizing agent B has the best effect on improving the insulation performance of composite materials: the breakdown strength can be increased by 112%, and the leakage current and dielectric loss factor can be reduced by 25.4% and 15.6%, respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lou, K.K.; Kang, A.H.; Xiao, P.; Wu, Z.G.; Li, B.; Wang, X.Y. Effects of basalt fiber coated with different sizing agents on performance and microstructures of asphalt mixture. Constr. Build. Mater. 2021, 266, 121–155. [Google Scholar]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.J.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar]

- Wang, X.; Zhao, X.; Wu, Z.S. Fatigue degradation and life prediction of basalt fiber-reinforced polymer composites after saltwater corrosion. Mater. Des. 2019, 163, 108768. [Google Scholar]

- Fiore, V.; Di, B.G.; Valenza, A. Glass-basalt/epoxy hybrid composites for marine applications. Mater. Des. 2011, 32, 2091–2099. [Google Scholar] [CrossRef]

- Matykiewicz, D.; Barczewski, M.; Knapski, D.; Skorczewska, K. Hybrid effects of basalt fibers and basalt powder on thermomechanical properties of epoxy composites. Compos. Part B Eng. 2017, 125, 157–164. [Google Scholar]

- Torres, J.P.; Hoto, R.; Andres, J.; Garcia-Manrique, J.A. Manufacture of green-composite sandwich structures with basalt fiber and bioepoxy resin. Adv. Mater. Sci. Eng. 2013, 2013, 214506. [Google Scholar]

- Wang, R.Z.; Li, L. Characterization of the interface and its influence on the fiber-reinforced composite material. Hi-Tech Fiber Appl. 2008, 33, 18–20. (In Chinese) [Google Scholar]

- Wang, Q.X.; Ding, Y.N.; Randl, N. Investigation on the alkali resistance of basalt fiber and its textile in different alkaline environments. Constr. Build. Mater. 2021, 272, 121670. [Google Scholar]

- Nasir, V.; Karimipour, H.; Taheri-Behrooz, F.; Shokrieh, M.M. Corrosion behaviour and crack formation mechanism of basalt fibre in sulphuric acid. Corros. Sci. 2012, 64, 1–7. [Google Scholar] [CrossRef]

- Arslan, C.; Dogan, M. The effects of silane coupling agents on the mechanical properties of basalt fiber reinforced poly(butylene terephthalate) composites. Compos. Part B Eng. 2018, 146, 145–154. [Google Scholar]

- Wang, G.J.; Liu, Y.W.; Guo, Y.J.; Zhang, Z.X.; Xu, M.X.; Yang, Z.X. Surface modification and characterizations of basalt fibers with non-thermal plasma. Surf. Coat. Technol. 2007, 20, 6565–6568. [Google Scholar] [CrossRef]

- Zhu, M.M.; Ma, J.X. Basalt fiber modified with lanthanum-ethylenediaminetetraacetic acid as potential reinforcement of cyanate matrix composites. Appl. Surf. Sci. 2019, 464, 636–643. [Google Scholar] [CrossRef]

- Xing, D.; Xi, X.Y.; Qi, M.G.; Zheng, Q.B.; Ma, P.C. Optimization on the formulation of sizing to enhance the mechanical properties of basalt fiber. J. Text. Inst. 2020, 112, 515–525. [Google Scholar] [CrossRef]

- Chu, Q. Development of Sizing Agent for Continuous Basalt Fibers and Its Effect on the Fiber Porperty. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2010. (In Chinese). [Google Scholar]

- Wei, B.; Cao, H.L.; Song, S.H. Tensile behavior contrast of basalt and glass fibers after chemical treatment. Mater. Des. 2010, 31, 4244–4250. [Google Scholar] [CrossRef]

- Zuo, C.X.; Si, J.W.; Li, J.Y.; Zhang, P.P.; Ning, W.K.; Wei, C.D.; Miao, S.D. Synthesis of water-soluble polyurethane and using as sizing for continuous basalt fiber. J. Funct. Polym. 2022. Available online: https://kns.cnki.net/kcms/detail/31.1633.O6.20220110.1505.005.html (accessed on 17 July 2022). (In Chinese).

- Wang, Z.T.; Luo, H.J.; Zhang, J.; Chen, H.W.; Zhang, L.; Wu, L.L.; Jiang, H. Water-soluble polysiloxane sizing for improved heat resistance of basalt fiber. Mater. Chem. Phys. 2021, 272, 125024. [Google Scholar] [CrossRef]

- Jia, H.; Liu, C.; Qiao, Y.; Zhang, Y.; Fan, K.Y.; Zhang, M.X.; Jian, X.G. Highly enhancing the interfacial and mechanical properties of basalt fiber/poly(phthalazinone ether nitrile ketone) composite by thermoplastic sizing agents with different structures. Polymers 2022, 14, 2947. [Google Scholar] [CrossRef]

- Chen, Z.W.; Huang, Y.D. Preparation and performance of fumed silica-stabilized epoxy resin pickering emulsion for basalt fiber-sizing agents. Adv. Compos. Hybrid Mater. 2021, 4, 1205–1214. [Google Scholar] [CrossRef]

- Zeng, Y.; Yu, K.J.; Qian, K. Study on surface modification and interfacial effect of basalt fiber. J. Mater. Sci. Technol. 2019, 37, 612–618. [Google Scholar]

- Yang, J.H. Surface Treatment on Basalt Fiber and Its Composites Performance Evaluation. Master’s Thesis, Donghua University, Shanghai, China, 2015. (In Chinese). [Google Scholar]

- Zheng, Y.W.; Wang, X.Y.; Wu, G.S. Chemical modification of carbon fiber with diethylenetriaminepentaacetic acid/halloysite nanotube as a multifunctional interfacial reinforcement for silicone resin composites. Polym. Adv. Technol. 2020, 31, 527–535. [Google Scholar] [CrossRef]

- Xiao, F.; Zhu, L.Z.; Yu, L.L. Evaluation of interfacial compatibility in wood flour/polypropylene composites by using dynamic thermomechanical analysis. Polym. Compos. 2020, 41, 3606–3614. [Google Scholar] [CrossRef]

- Yang, H.J.; Wu, Z.F.; Zou, Y.; Yang, X.L. Preparation of ϕ50 mm modified polyurethane/basalt fiber composite insulator core rod. Compos. Sci. Eng. 2018, 6, 62–65. (In Chinese) [Google Scholar]

- Li, T.J.; Zhang, B.; Wu, J. The dielectric properties of PI/ZnO composite films based on trap level distribution. CES TEMS 2022, 37, 1554–1562. (In Chinese) [Google Scholar]

| Number | Epoxy Emulsion Film- Forming Agent (wt%) | Acrylic Emulsion Film- Forming Agent (wt%) | Polyurethane Emulsion Film-Forming Agent (wt%) | Coupling Agent (wt%) | Lubricant (wt%) | Antistatic Agent (wt%) |

|---|---|---|---|---|---|---|

| A | 5 | 2 | 0 | 1 | 0.4 | 0.1 |

| B | 5 | 2 | 1 | 1 | 0.4 | 0.1 |

| C | 5 | 2 | 2 | 1 | 0.4 | 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, L.; Fu, X.; Zhang, C.; Chen, L.; Chen, X.; Fu, C.; Yu, Y.; Liu, H. Effect of Sizing Agent on the Mechanical, Thermal, and Electrical Performance of Basalt Fiber/Epoxy Composites. Polymers 2022, 14, 3533. https://doi.org/10.3390/polym14173533

Ma L, Fu X, Zhang C, Chen L, Chen X, Fu C, Yu Y, Liu H. Effect of Sizing Agent on the Mechanical, Thermal, and Electrical Performance of Basalt Fiber/Epoxy Composites. Polymers. 2022; 14(17):3533. https://doi.org/10.3390/polym14173533

Chicago/Turabian StyleMa, Long, Xiaotao Fu, Cong Zhang, Lincong Chen, Xiaolin Chen, Chuanfu Fu, Yunfei Yu, and Hechen Liu. 2022. "Effect of Sizing Agent on the Mechanical, Thermal, and Electrical Performance of Basalt Fiber/Epoxy Composites" Polymers 14, no. 17: 3533. https://doi.org/10.3390/polym14173533

APA StyleMa, L., Fu, X., Zhang, C., Chen, L., Chen, X., Fu, C., Yu, Y., & Liu, H. (2022). Effect of Sizing Agent on the Mechanical, Thermal, and Electrical Performance of Basalt Fiber/Epoxy Composites. Polymers, 14(17), 3533. https://doi.org/10.3390/polym14173533