An Analytical Model for Cure-Induced Deformation of Composite Laminates

Abstract

:1. Introduction

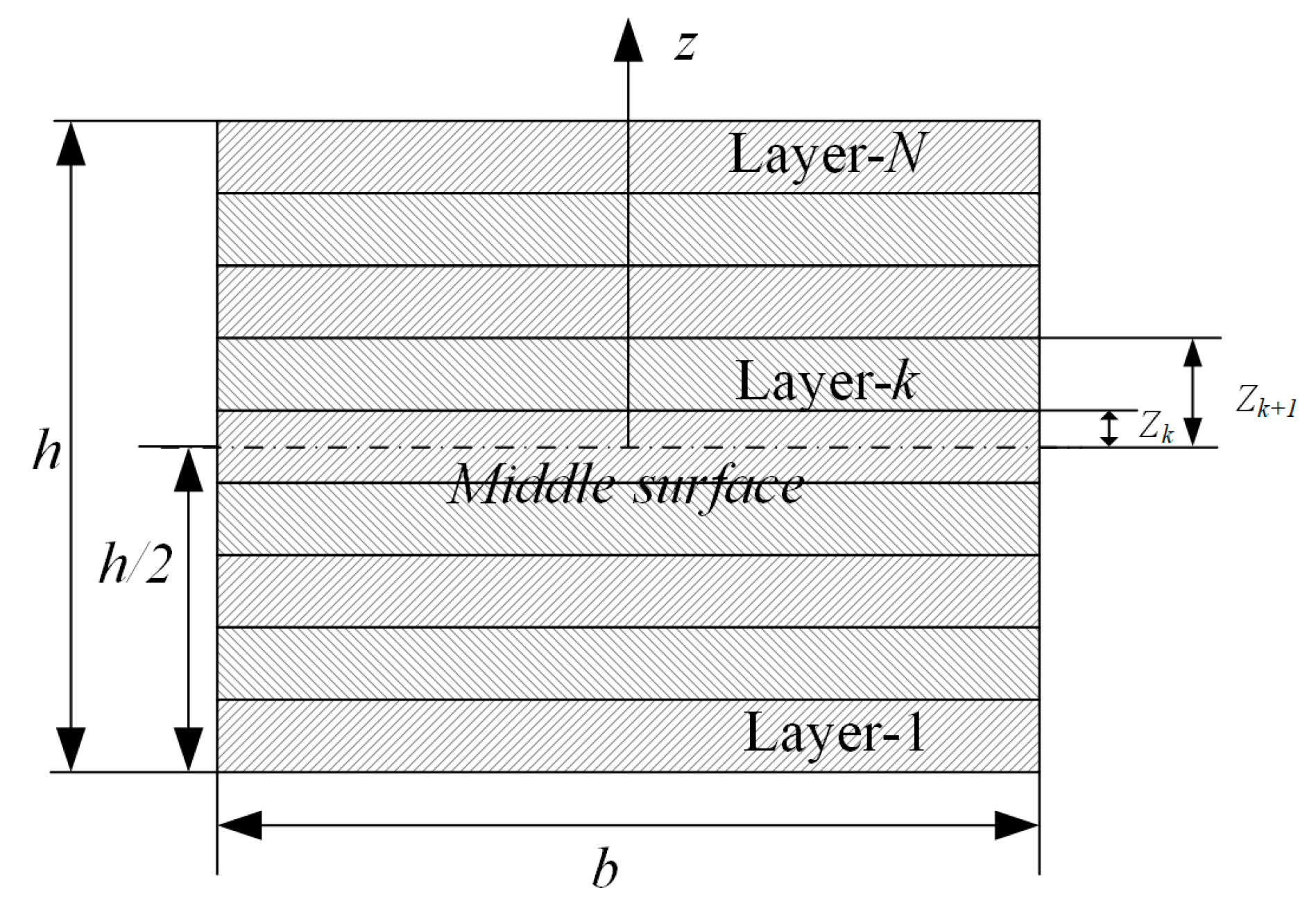

2. Theoretical Formulations

2.1. Curing Deformation without Consideration of Tool Constraints

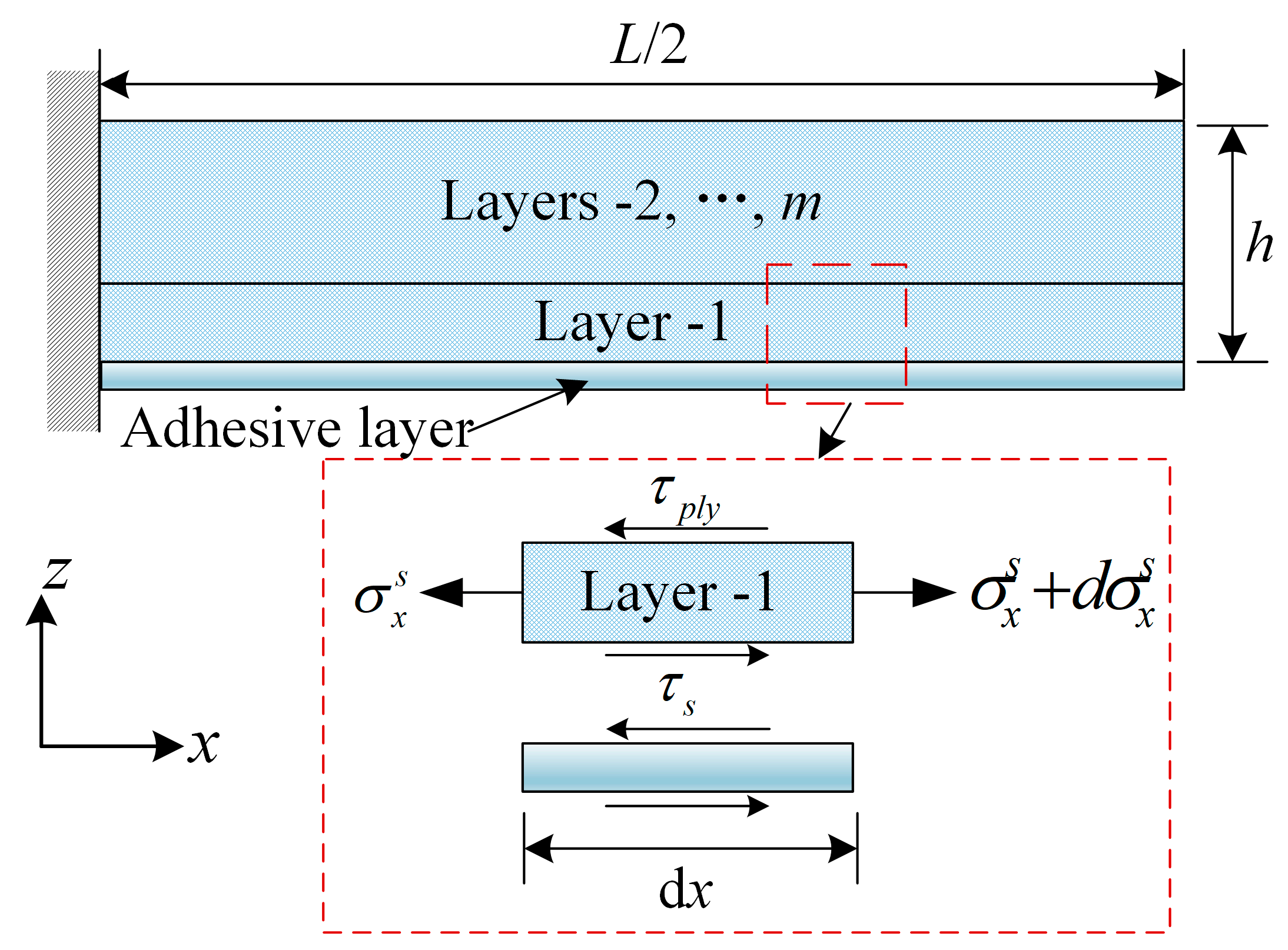

2.2. Curing Deformation Considering Mold Constraints

3. Results and Discussion

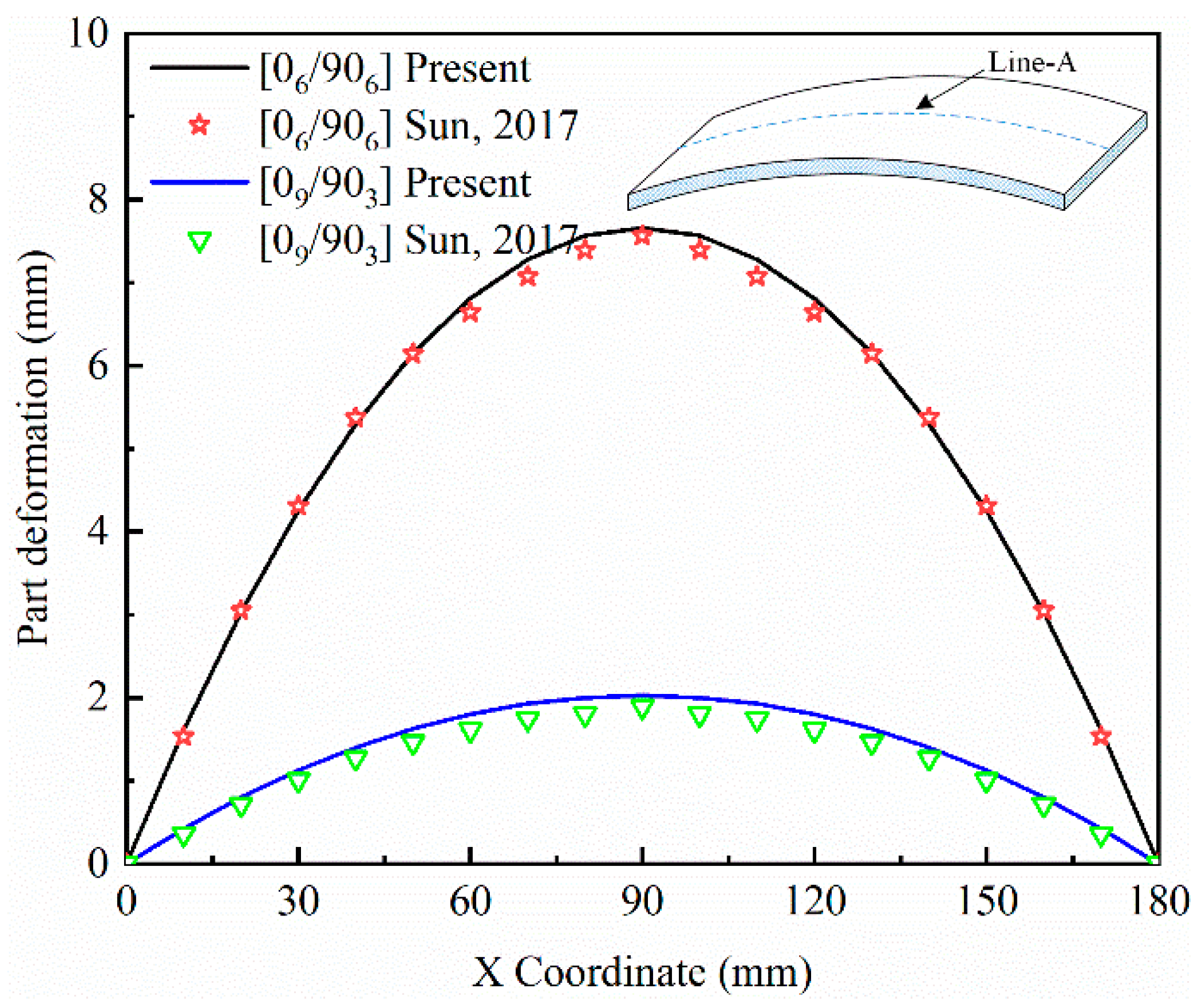

3.1. Comparison Studies

3.2. Parametric Analysis

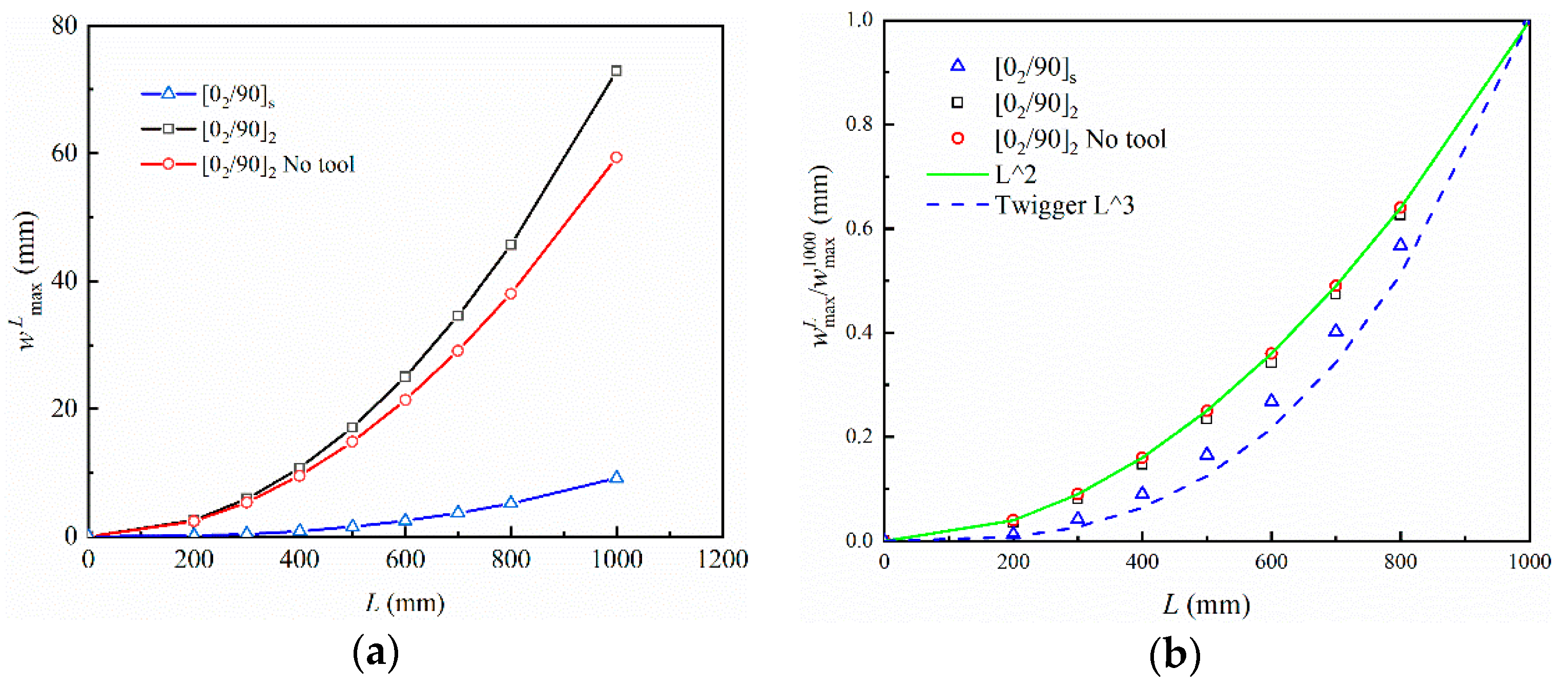

3.2.1. Influence of Geometric Dimensions

3.2.2. Influence of Curing Temperature Cycles

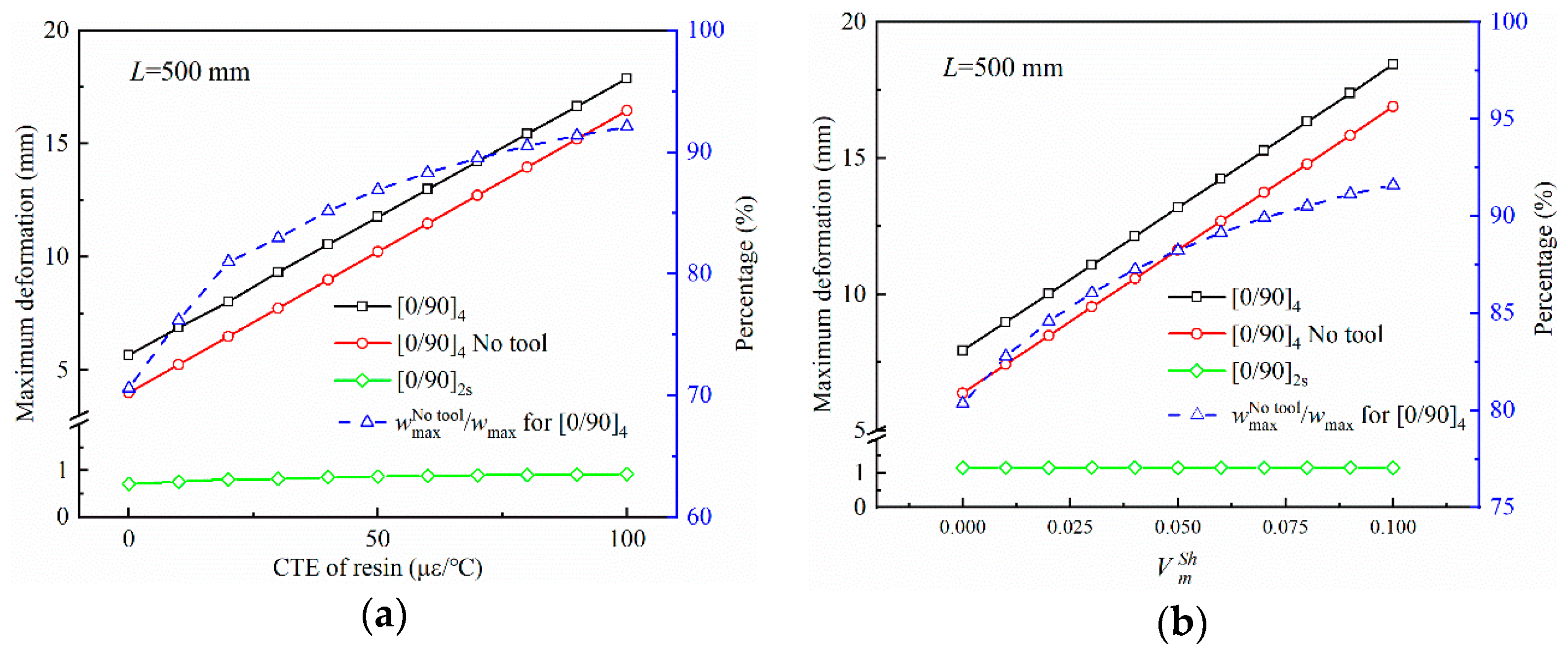

3.2.3. Influence of Resin Characteristics

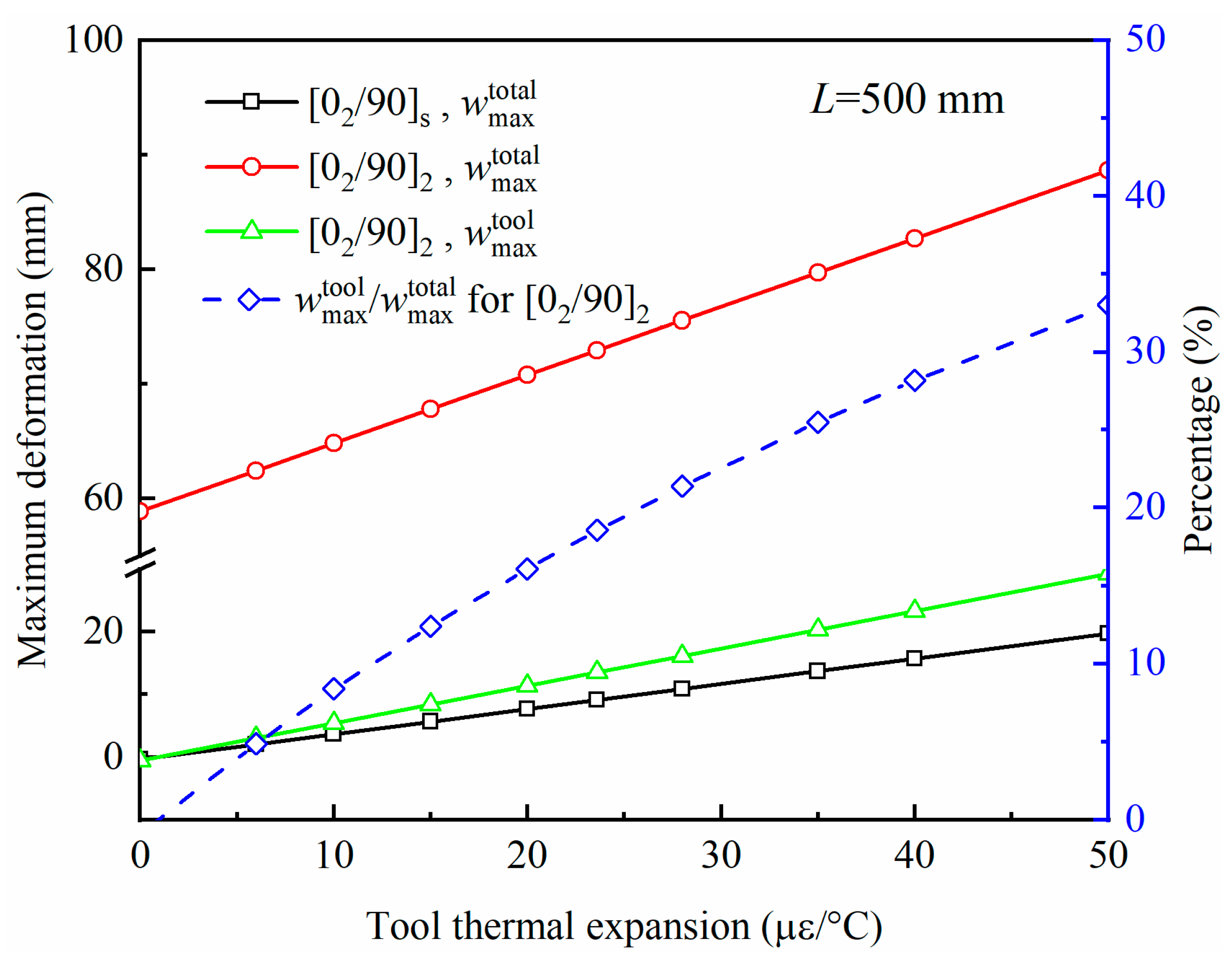

3.2.4. Influence of Tool Thermal Expansion

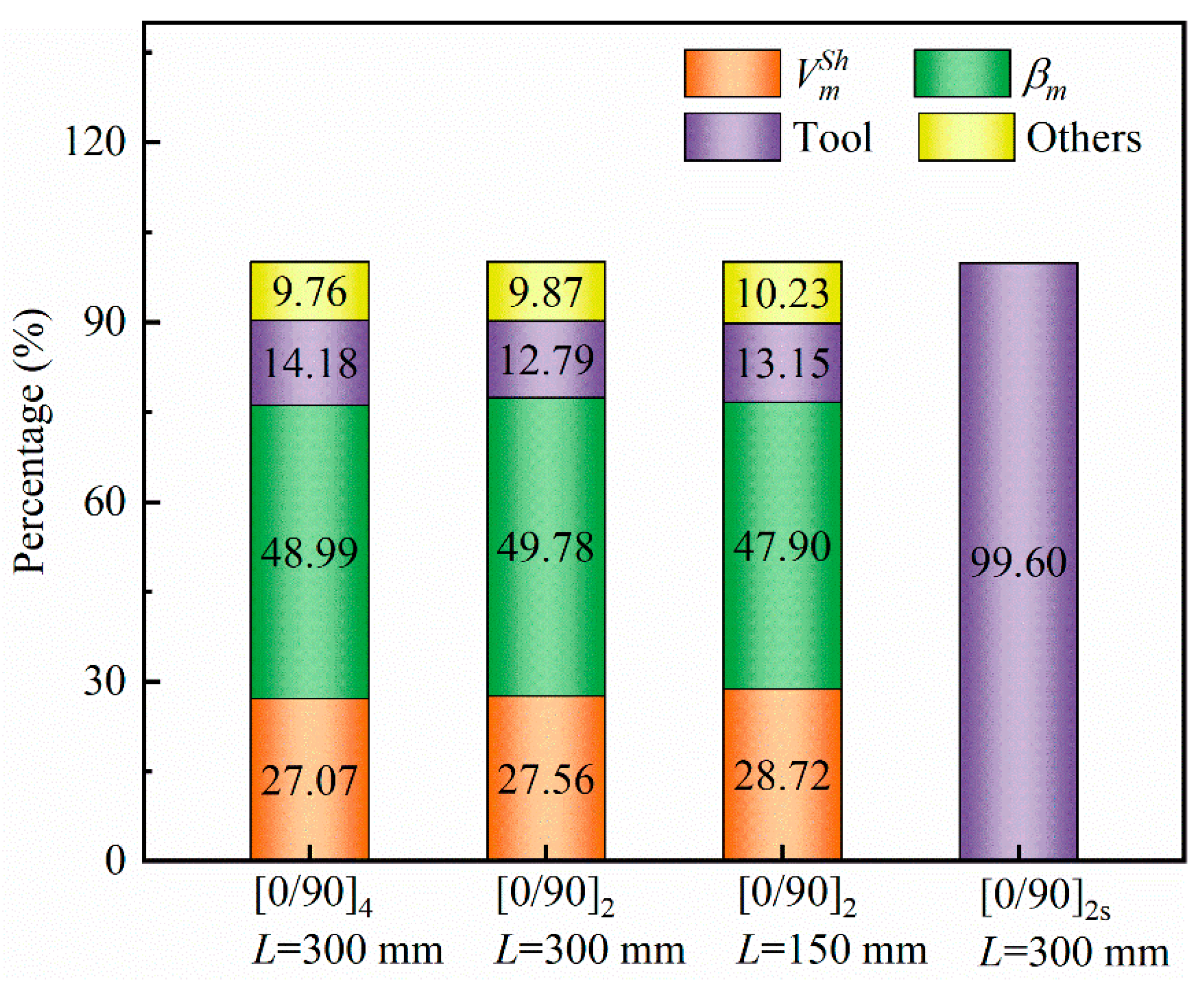

3.2.5. Contribution of Different Factors to Curing Deformation

4. Conclusions

- The analytical model proposed in this work can deal with the issues of process-induced stresses and deformations during the curing process of composite parts, considering the coupled stiffness of laminate composites. The results of the model can be trusted in comparison with the results of previous literature and FEM. The analytical model makes it easier and faster to analyze curing behavior and provides a deeper understanding of the physical mechanisms of curing deformation in composites. The influence of different factors on curing deformation can be evaluated individually.

- Geometry has a considerable influence on the curing deformation of composite parts. However, for a composite part with definite geometric dimensions, curing deformation is largely attributed to the tool–part interaction, curing shrinkage, and high thermal expansion of the resin. For composite parts with asymmetrical lay-up, the curing deformations of composite parts are mainly due to their own anisotropy, including the anisotropy of each layer of laminate in macroscopic aspect, and the anisotropy of resin and fiber in microscopic aspect. The enhancement and suppression of curing deformation by the tool–part interaction depend on the lay-up sequence. The curing deformation of symmetrically layered parts is mainly due to the influence of the tool.

- From the point of view of reducing curing distortion, composites with low curing shrinkage and CTE resins are the best choices, followed by a tool with low-thermal-expansion material. Adjustments to the cure cycle can improve manufacturing accuracy to a certain extent. Finally, tool compensation may be required to achieve zero curing deformation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Park, E.T.; Lee, Y.; Kim, J.; Kang, B.S.; Song, W. Experimental Study on Microwave-Based Curing Process with Thermal Expansion Pressure of PTFE for Manufacturing Carbon Fiber/Epoxy Composites. Materials 2019, 12, 3737. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baran, I.; Cinar, K.; Ersoy, N.; Akkerman, R.; Hattel, J.H. A Review on the Mechanical Modeling of Composite Manufacturing Processes. Arch. Comput. Methods Eng. 2016, 24, 365–395. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Muc, A.; Romanowicz, P.; Chwal, M. Description of the Resin Curing Process-Formulation and Optimization. Polymers 2019, 11, 127. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hui, X.; Xu, Y.; Zhang, W.; Zhang, W. Multiscale collaborative optimization for the thermochemical and thermomechanical cure process during composite manufacture. Compos. Sci. Technol. 2022, 224, 109455. [Google Scholar] [CrossRef]

- Kappel, E. Spring-in of curved CFRP/foam-core sandwich structures. Compos. Struct. 2015, 128, 155–164. [Google Scholar] [CrossRef]

- Hörberg, E.; Nyman, T.; Åkermo, M.; Hallström, S. Thickness effect on spring-in of prepreg composite L-profiles—An experimental study. Compos. Struct. 2019, 209, 499–507. [Google Scholar] [CrossRef]

- Shah, D.B.; Patel, K.M.; Patel, A.I.; Pariyal, V.; Joshi, S.J. Experimental investigation on spring-back deformation during autoclave curing of parabolic antenna reflectors. Compos. Part A Appl. Sci. Manuf. 2018, 115, 134–146. [Google Scholar] [CrossRef]

- Patel, A.; Kravchenko, O.; Manas-Zloczower, I. Effect of Curing Rate on the Microstructure and Macroscopic Properties of Epoxy Fiberglass Composites. Polymers 2018, 10, 125. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Zheng, X.; Gao, L.; Yan, L.; Song, G.; Zhang, S. Comparative study on the effect of cure parameters on residual deformation for thermoset composite laminates. J. Compos. Mater. 2021, 55, 2591–2604. [Google Scholar] [CrossRef]

- Yu, Y.; Ashcroft, I.A.; Swallowe, G. An experimental investigation of residual stresses in an epoxy–steel laminate. Int. J. Adhes. Adhes. 2006, 26, 511–519. [Google Scholar] [CrossRef]

- Fernlund, G.; Rahman, N.; Courdji, R.; Bresslauer, M.; Poursartip, A.; Willden, K.; Nelson, K. Experimental and numerical study of the effect of cure cycle, tool surface, geometry, and lay-up on the dimensional fidelity of autoclave-processed composite parts. Compos. Part A Appl. Sci. Manuf. 2002, 33, 341–351. [Google Scholar] [CrossRef]

- Chen, C.; Nesbitt, S.; Reiner, J.; Vaziri, R.; Poursartip, A.; Fernlund, G. Cure path dependency of static and dynamic mode II interlaminar fracture toughness of interlayer toughened composite laminates. Compos. Sci. Technol. 2020, 200, 108444. [Google Scholar] [CrossRef]

- Chen, C.; Poursartip, A.; Fernlund, G. Cure-dependent microstructures and their effect on elastic properties of interlayer toughened thermoset composites. Compos. Sci. Technol. 2020, 197, 108241. [Google Scholar] [CrossRef]

- De Oliveira, R.; Lavanchy, S.; Chatton, R.; Costantini, D.; Michaud, V.; Salathé, R.; Månson, J.A.E. Experimental investigation of the effect of the mould thermal expansion on the development of internal stresses during carbon fibre composite processing. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1083–1090. [Google Scholar] [CrossRef]

- Moretti, L.; Olivier, P.; Castanié, B.; Bernhart, G. Experimental study and in-situ FBG monitoring of process-induced strains during autoclave co-curing, co-bonding and secondary bonding of composite laminates. Compos. Part A Appl. Sci. Manuf. 2021, 142, 106224. [Google Scholar] [CrossRef]

- Al-Dhaheri, M.; Khan, K.A.; Umer, R.; van Liempt, F.; Cantwell, W.J. Process induced deformations in composite sandwich panels using an in-homogeneous layup design. Compos. Part A Appl. Sci. Manuf. 2020, 137, 106020. [Google Scholar] [CrossRef]

- Long, Y.; Yu, W.; Pipes, R.B.; Forghani, A.; Poursartip, A.; Gordnian, K. Simulation of composites curing using mechanics of structure genome based shell model. Compos. Part A Appl Sci. Manuf. 2022, 154, 106766. [Google Scholar] [CrossRef]

- Parambil, N.K.; Chen, B.R.; Deitzel, J.M.; Gillespie, J.W. A methodology for predicting processing induced thermal residual stress in thermoplastic composite at the microscale. Compos. Part B Eng. 2022, 231, 109562. [Google Scholar] [CrossRef]

- Mezeix, L.; Seman, A.; Nasir, M.N.M.; Aminanda, Y.; Rivai, A.; Castanié, B.; Olivier, P.; Ali, K.M. Spring-back simulation of unidirectional carbon/epoxy flat laminate composite manufactured through autoclave process. Compos. Struct. 2015, 124, 196–205. [Google Scholar] [CrossRef]

- Kim, D.-H.; Kim, S.-W.; Lee, I. Evaluation of curing process-induced deformation in plain woven composite structures based on cure kinetics considering various fabric parameters. Compos. Struct. 2022, 287, 115379. [Google Scholar] [CrossRef]

- Qiao, W.; Yao, W. Modelling of Process-Induced Deformation for Composite Parts Considering Tool-Part Interaction. Materials 2020, 13, 4503. [Google Scholar] [CrossRef] [PubMed]

- Kawagoe, Y.; Kawai, K.; Kumagai, Y.; Shirasu, K.; Kikugawa, G.; Okabe, T. Multiscale modeling of process-induced residual deformation on carbon-fiber-reinforced plastic laminate from quantum calculation to laminate scale finite-element analysis. Mech. Mater. 2022, 170, 104332. [Google Scholar] [CrossRef]

- Luo, L.; Zhang, B.; Zhang, G.; Xu, Y. Rapid prediction of cured shape types of composite laminates using a FEM-ANN method. Compos. Struct. 2020, 238, 111980. [Google Scholar] [CrossRef]

- Mezeix, L.; Nasir, M.N.M.; Aminanda, Y.; Rivai, A.; Ali, K.M. Parameter Study of Tool-Laminate Interface through Simulation for Composite Manufacturing Using Autoclave Process. Appl. Mech. Mater. 2014, 606, 113–117. [Google Scholar] [CrossRef]

- Johnston, A.; Vaziri, R.; Poursartip, A. A Plane Strain Model for Process-Induced Deformation of Laminated Composite Structures. J. Compos. Mater. 2001, 35, 1435–1469. [Google Scholar] [CrossRef]

- Dai, J.; Xi, S.; Li, D. Numerical Analysis of Curing Residual Stress and Deformation in Thermosetting Composite Laminates with Comparison between Different Constitutive Models. Materials 2019, 12, 572. [Google Scholar] [CrossRef] [Green Version]

- Ding, A.; Li, S.; Wang, J.; Zu, L. A three-dimensional thermo-viscoelastic analysis of process-induced residual stress in composite laminates. Compos. Struct. 2015, 129, 60–69. [Google Scholar] [CrossRef]

- Benavente, M.; Marcin, L.; Courtois, A.; Lévesque, M.; Ruiz, E. Numerical analysis of viscoelastic process-induced residual distortions during manufacturing and post-curing. Compos. Part A Appl. Sci. Manuf. 2018, 107, 205–216. [Google Scholar] [CrossRef]

- White, S.R.; Kim, Y.K. Process-Induced Residual Stress Analysis Of As4/3501-6 Composite Material. Mech Adv. Mater. Struct. 1998, 5, 153–186. [Google Scholar] [CrossRef]

- Zhang, J.T.; Zhang, M.; Li, S.X.; Pavier, M.J.; Smith, D.J. Residual stresses created during curing of a polymer matrix composite using a viscoelastic model. Compos. Sci. Technol. 2016, 130, 20–27. [Google Scholar] [CrossRef] [Green Version]

- Zhang, G.; Wang, J.; Ni, A.; Hu, H.; Ding, A.; Li, S. Process-induced deformation of L-shaped variable-stiffness composite structures during cure. Compos. Struct. 2019, 230, 111461. [Google Scholar] [CrossRef]

- Ersoy, N.; Garstka, T.; Potter, K.; Wisnom, M.R.; Porter, D.; Stringer, G. Modelling of the spring-in phenomenon in curved parts made of a thermosetting composite. Compos. Part A Appl. Sci. Manuf. 2010, 41, 410–418. [Google Scholar] [CrossRef]

- Liu, X.; Guan, Z.; Wang, X.; Jiang, T.; Geng, K.; Li, Z. Study on cure-induced residual stresses and spring-in deformation of L-shaped composite laminates using a simplified constitutive model considering stress relaxation. Compos. Struct. 2021, 272, 114203. [Google Scholar] [CrossRef]

- Blanco, S.; You, H.; Kerekes, T.W.; Yun, G.J. Cure-induced residual stress buildup and distortions of CFRP laminates with stochastic thermo-chemical and viscoelastic models: Experimental verifications. Mech. Adv. Mater. Struct. 2021, 22, 1–17. [Google Scholar] [CrossRef]

- Yuan, Z.; Wang, Y.; Peng, X.; Wang, J.; Wei, S. An analytical model on through-thickness stresses and warpage of composite laminates due to tool–part interaction. Compos. Part B Eng. 2016, 91, 408–413. [Google Scholar] [CrossRef]

- Sun, L.; Wang, J.; Ni, A.; Li, S.; Ding, A. Modelling and experiment of process-induced distortions in unsymmetrical laminate plates. Compos. Struct. 2017, 182, 524–532. [Google Scholar] [CrossRef]

- Arafath, A.R.A.; Vaziri, R.; Poursartip, A. Closed-form solution for process-induced stresses and deformation of a composite part cured on a solid tool: Part I—Flat geometries. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1106–1117. [Google Scholar] [CrossRef]

- Twigg, G.; Poursartip, A.; Fernlund, G. Tool–part interaction in composites processing. Part I: Experimental investigation and analytical model. Compos. Part A Sci. Manuf. 2004, 35, 121–133. [Google Scholar] [CrossRef]

- Abouhamzeh, M.; Sinke, J.; Jansen, K.M.B.; Benedictus, R. Closed form expression for residual stresses and warpage during cure of composite laminates. Compos. Struct. 2015, 133, 902–910. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Potter, K.D.; Ersoy, N. Shear-lag Analysis of the Effect of Thickness on Spring-in of Curved Composites. J. Compos. Mater. 2006, 41, 1311–1324. [Google Scholar] [CrossRef]

- Che, L.; Zhou, Z.; Fang, G.; Ma, Y.; Dong, W.; Zhang, J. Cured shape prediction of fiber metal laminates considering interfacial interaction. Compos. Struct. 2018, 194, 564–574. [Google Scholar] [CrossRef]

- Kravchenko, O.G.; Kravchenko, S.G.; Pipes, R.B. Chemical and thermal shrinkage in thermosetting prepreg. Compos. Part A Sci. Manuf. 2016, 80, 72–81. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, J.; Ni, A. Process-Induced Stress and Deformation of Variable-Stiffness Composite Cylinders during Curing. Materials 2019, 12, 259. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kravchenko, O.G.; Kravchenko, S.G.; Pipes, R.B. Cure history dependence of residual deformation in a thermosetting laminate. Compos. Part A Sci. Manuf. 2017, 99, 186–197. [Google Scholar] [CrossRef]

- Wang, Q.; Gao, L.; Wang, X.; Dong, Q.; Wan, G.; Du, T.; Guo, Y.; Zhang, C.; Jia, Y. Numerical analysis and fiber Bragg grating monitoring of thermocuring processes of carbon fiber/epoxy laminates. Polym. Test. 2017, 62, 287–294. [Google Scholar] [CrossRef]

- Abdelal, G.F.; Robotham, A.; Cantwell, W. Autoclave cure simulation of composite structures applying implicit and explicit FE techniques. Int. J. Mech. Mater. Des. 2013, 9, 55–63. [Google Scholar] [CrossRef] [Green Version]

- Garstka, T.; Ersoy, N.; Potter, K.D.; Wisnom, M.R. In situ measurements of through-the-thickness strains during processing of AS4/8552 composite. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2517–2526. [Google Scholar] [CrossRef]

- Twigg, G.; Poursartip, A.; Fernlund, G. Tool–part interaction in composites processing. Part II: Numerical modelling. Compos. Part A Appl. Sci. Manuf. 2004, 35, 135–141. [Google Scholar] [CrossRef]

| Properties | AS4 Fiber | 8552 |

|---|---|---|

| E1 (GPa) | 207.0 | 4.67 |

| E2 = E3 (GPa) | 20.4 | - |

| G12 = G13 (GPa) | 27.6 | 1.7 |

| G23 (GPa) | 6.89 | - |

| = | 0.2 | 0.37 |

| 0.3 | - | |

| (με/°C) | −0.9 | 48.7 |

| = (με/°C) | 7.2 | - |

| Lay-Up | Maximum Curing Deformation | ||

|---|---|---|---|

| Present (mm) | FEM (mm) | Difference | |

| [06/906] | 9.31 | 8.81 | 5.37% |

| [09/903] | 2.47 | 2.66 | 7.69% |

| [03/90]2 | 1.30 | 1.32 | 1.54% |

| [03/90]s | 0.17 | 0.16 | 5.88% |

| [0/90]s | 0.29 | 0.30 | 3.44% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, X.; Xu, J.; Cheng, Y.; Zhang, L.; Yang, J.; Li, Y. An Analytical Model for Cure-Induced Deformation of Composite Laminates. Polymers 2022, 14, 2903. https://doi.org/10.3390/polym14142903

Peng X, Xu J, Cheng Y, Zhang L, Yang J, Li Y. An Analytical Model for Cure-Induced Deformation of Composite Laminates. Polymers. 2022; 14(14):2903. https://doi.org/10.3390/polym14142903

Chicago/Turabian StylePeng, Xiaobo, Jiang Xu, Yong Cheng, Long Zhang, Jie Yang, and Yinghui Li. 2022. "An Analytical Model for Cure-Induced Deformation of Composite Laminates" Polymers 14, no. 14: 2903. https://doi.org/10.3390/polym14142903

APA StylePeng, X., Xu, J., Cheng, Y., Zhang, L., Yang, J., & Li, Y. (2022). An Analytical Model for Cure-Induced Deformation of Composite Laminates. Polymers, 14(14), 2903. https://doi.org/10.3390/polym14142903