In-Built Fabrication of MOF Assimilated Porous Hollow Carbon from Pre-Hydrolysate for Supercapacitor

Abstract

:1. Introduction

2. Experimental Method

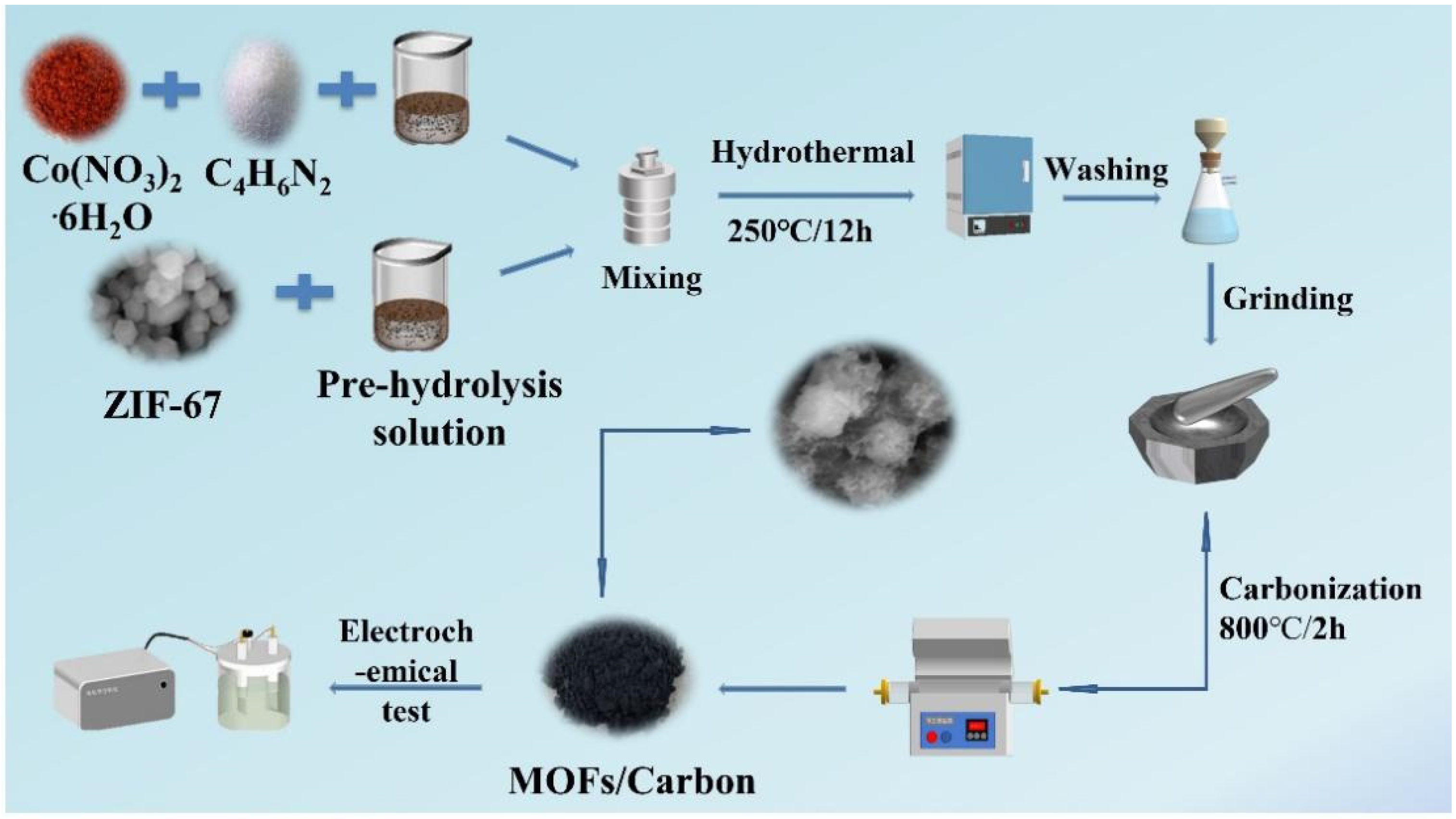

2.1. Materials Synthesis

2.1.1. Preparation of the Pre-Hydrolysate

2.1.2. Preparation of the ZIF-67 (Co-MOF)

2.1.3. Preparation of the ZIF-67/Carbon

2.2. Characterization

2.3. Electrochemical Test

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.; Zhang, J.; Liu, J.; Cao, Y.; Huang, C.; Ji, G.; Zhao, Z.; Ou, X.; Zhang, B. Environmentally phase-controlled stratagem for open framework pyrophosphate anode materials in battery energy storage. J. Mater. Chem. C 2021, 9, 9147–9157. [Google Scholar] [CrossRef]

- Jeong, J.H.; Lee, G.-W.; Kim, Y.H.; Choi, Y.J.; Roh, K.C.; Kim, K.-B. A holey graphene-based hybrid supercapacitor. Chem. Eng. J. 2019, 278, 115436. [Google Scholar] [CrossRef]

- Wang, C.; Yan, B.; Chen, Z.; You, B.; Liao, T.; Zhang, Q.; Lu, Y.; Jiang, S.; He, S. Recent advances in carbon substrate supported nonprecious nanoarrays for electrocatalytic oxygen evolution. J. Mater. Chem. A 2021, 9, 25773–25795. [Google Scholar] [CrossRef]

- Liu, S.; Wei, L.; Wang, H. Relationship between the N2O decomposition and NO formation in H2O/CO2/NH3/NO atmosphere under the conditions of simulated air-staged combustion in the temperature interval of 900–1600 °C. Appl. Energ. 2020, 278, 115436. [Google Scholar] [CrossRef]

- Cheng, F.; Yang, X.; Zhang, S.; Lu, W. Boosting the supercapacitor performances of activated carbon with carbon nanomaterials. J. Power Sources 2020, 450, 227678. [Google Scholar] [CrossRef]

- Wang, T.; Li, K.; An, S.; Song, C.; Guo, X. Facile and green synthesis of TiN/C as electrode materials for supercapacitors. Appl. Surf. Sci. 2018, 470, 241–249. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, W.; Wang, G.; Li, C. Electrophoresis-microwave synthesis of S,N-doped graphene foam for high-performance supercapacitors. J. Mater. Chem. A 2021, 9, 15766–15775. [Google Scholar] [CrossRef]

- Liu, C.-F.; Liu, Y.-C.; Yi, T.-Y.; Hu, C.-C. Carbon materials for high-voltage supercapacitors. Carbon 2018, 145, 529–548. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Hou, H.; Xu, W.; Duan, G.; He, S.; Liu, K.; Jiang, S. Recent progress in carbon-based materials for supercapacitor electrodes: A review. J. Mater Sci. 2021, 56, 173–200. [Google Scholar] [CrossRef]

- Yang, L.; Gu, B.; Chen, Z.; Yue, Y.; Wang, W.; Zhang, H.; Liu, X.; Ren, S.; Yang, W.; Li, Y. Synthetic Biopigment Supercapacitors. ACS Appl. Mater. Interfaces 2019, 11, 30360–30367. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X.; Li, Z.; Ma, Y.; Ma, L. Recent progress of biomass-derived carbon materials for supercapacitors. J. Power Sources 2020, 451, 227794. [Google Scholar] [CrossRef]

- Li, Z.; Su, J.; Wang, X. Atomic layer deposition in the development of supercapacitor and lithium-ion battery devices. Carbon 2021, 179, 299–326. [Google Scholar] [CrossRef]

- Xiong, S.; Jiang, S.; Wang, J.; Lin, H.; Lin, M.; Weng, S.; Liu, S.; Jiao, Y.; Xu, Y.; Chen, J. A high-performance hybrid supercapacitor with NiO derived NiO@Ni-MOF composite electrodes. Electrochim. Acta 2020, 340, 135956. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, A.; Zhong, M.; Zhang, Z.; Zhang, X.; Zhou, Z.; Bu, X.-H. Metal–Organic Frameworks (MOFs) and MOF-Derived Materials for Energy Storage and Conversion. Electrochem. Energy Rev. 2019, 2, 29–104. [Google Scholar] [CrossRef]

- Ma, X.; Xiong, Y.; Liu, Y.; Han, J.; Duan, G.; Chen, Y.; He, S.; Mei, C.; Jiang, S.; Zhang, K. When MOFs meet wood: From opportunities toward applications. Chem 2022, 8, 1–20. [Google Scholar] [CrossRef]

- Jian, S.; Ma, X.; Wang, Q.; Wu, J.; Wang, Y.; Jiang, S.; Xu, W.; Yang, W. Hierarchical porous Co3O4 nanocages with elaborate microstructures derived from ZIF-67 toward lithium storage. Vacuum 2021, 184, 109879. [Google Scholar] [CrossRef]

- Hou, S.; Lian, Y.; Bai, Y.; Zhou, Q.; Ban, C.; Wang, Z.; Zhao, J.; Zhang, H. Hollow dodecahedral Co3S4@NiO derived from ZIF-67 for supercapacitor. Electrochim. Acta 2020, 341, 136053. [Google Scholar] [CrossRef]

- Wang, J.; Sun, Y.; Zhao, X.; Chen, L.; Peng, S.; Ma, C.; Duan, G.; Liu, Z.; Wang, H.; Yuan, Y.; et al. A poly(amidoxime)-modified MOF macroporous membrane for high-efficient uranium extraction from seawater. e-Polymers 2022, 22, 399–410. [Google Scholar] [CrossRef]

- Yin, X.; Li, H.; Yuan, R.; Lu, J. NiCoLDH nanosheets grown on MOF-derived Co3O4 triangle nanosheet arrays for high-performance supercapacitor. J. Mater. Sci. Technol. 2020, 62, 60–69. [Google Scholar]

- Li, S.; Yang, K.; Ye, P.; Ma, K.; Zhang, Z.; Huang, Q. Three-dimensional porous carbon/Co3O4 composites derived from grapheme/Co-MOF for high performance supercapacitor electrodes. Appl. Surf. Sci. 2020, 503, 144090. [Google Scholar] [CrossRef]

- Andres-Garcia, E.; Oar-Arteta, L.; Gascon, J.; Kapteijn, F. ZIF-67 as silver-bullet in adsorptive propane/propylene separation. Chem. Eng. J. 2018, 360, 10–14. [Google Scholar] [CrossRef]

- Siwatch, P.; Sharma, K.; Tripathi, S. Facile synthesis of NiCo2O4 quantum dots for asymmetric supercapacitor. Electrochimica Acta 2020, 329, 135084. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, D.; Liu, T.; Jaroniec, M.; Yu, J. Nickel-based materials for supercapacitors. Mater. Today 2019, 25, 35–65. [Google Scholar] [CrossRef]

- Zheng, H.; Cao, Q.; Zhu, M.; Xu, D.; Guo, H.; Li, Y.; Zhou, J. Biomass-based flexible nanoscale carbon fibers: Effects of chemical structure on energy storage properties. J. Mater. Chem. A 2021, 9, 10120–10134. [Google Scholar] [CrossRef]

- Annamalai, J.; Murugan, P.; Ganapathy, D.; Nallaswamy, D.; Atchudan, R.; Arya, S.; Khosla, A.; Barathi, S.; Sundramoorthy, A.K. Synthesis of various dimensional metal organic frameworks (MOFs) and their hybrid composites for emerging applications—A review. Chemosphere 2022, 298, 134184. [Google Scholar] [CrossRef]

- Wang, X.; Feng, J.L.; Bai, Y.; Zhang, Q.; Yin, Y. Synthesis, Properties, and Applications of Hollow Micro-/Nanostructures. Chem. Rev. 2016, 116, 10983–11060. [Google Scholar] [CrossRef]

- Yu, L.; Hu, H.; BWu, H.B.; Lou, X.W.D. Complex Hollow Nanostructures: Synthesis and Energy-Related Applications. Adv. Mater. 2017, 29, 1604563. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, H.; Wang, S.; Shao, W.; Qin, W.; Zhao, X.; Kong, F. Kong Facile fabrication and structure control of SiO2/carbon via in situ doping from liquefied bio-based sawdust for supercapacitor. Ind. Crop. Pro. 2020, 148, 112306. [Google Scholar] [CrossRef]

- Jiang, G.; Cai, J.; Krishnamoorthy, M.; Senthil, R.A.; Sun, Y.; Li, X.; Pan, J. Controlling Morphologies and Structures of PANI@Carbon with Superior Rate Performance for Supercapacitors. ACS Appl. Energy Mater. 2022, 5, 4138–4148. [Google Scholar] [CrossRef]

- Zhou, H.; Wu, S.; Wang, H.; Li, Y.; Liu, X.; Zhou, Y. The preparation of porous carbon materials derived from bio-protic ionic liquid with application in flexible solid-state supercapacitors. J. Hazard. Mater. 2021, 402, 124023. [Google Scholar] [CrossRef]

- Jiang, G.; Osman, S.; Senthil, R.A.; Sun, Y.; Tan, X.; Pan, J. Hierarchically porous carbon derived from magnesium-based metal-organic frameworks as advanced active material for supercapacitor. J. Energy Storage 2022, 49, 104071. [Google Scholar] [CrossRef]

- Gu, J.; Sun, L.; Zhang, Y.; Zhang, Q.; Li, X.; Si, H.; Shi, Y.; Sun, C.; Gong, Y.; Zhang, Y. MOF-derived Ni-doped CoP@C grown on CNTs for high-performance supercapacitors. Chem. Eng. J. 2020, 385, 123454. [Google Scholar] [CrossRef]

- Zhang, Y.; Ding, J.; Xu, W.; Wang, M.; Shao, R.; Sun, Y.; Lin, B. Mesoporous LaFeO3 perovskite derived from MOF gel for all-solid-state symmetric supercapacitors. Chem. Eng. J. 2020, 386, 124030. [Google Scholar] [CrossRef]

- Eftekhari, A. Surface Diffusion and Adsorption in Supercapacitors. ACS Sustain. Chem. Eng. 2019, 7, 3692–3701. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Y.; Zhang, T.; Wang, Y.; Zhang, Q.; Li, T.; Han, Y. Electrochemical polymerization of polypyrrole on carbon cloth@ZIF67 using alizarin red S as redox dopant for flexible supercapacitors. Electrochim. Acta 2022, 407, 139869. [Google Scholar] [CrossRef]

- Dahal, B.; Mukhiya, T.; Prasad Ojha, G.; Muthurasu, A.; Chae, S.-H.; Kim, T.; Kang, D.; Kim, H.K. In-built fabrication of MOF assimilated B/N co-doped 3D porous carbon nanofiber network as a binder-free electrode for supercapacitors. Electrochim. Acta 2019, 301, 209–219. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, B.; She, W.; Gao, S.; Wang, J.; Wang, Y.; Wang, K.; Li, H.; Han, L. Simultaneously achieving high energy and power density for ultrafast-charging supercapacitor built by a semi-graphitic hierarchical porous carbon nanosheet and a high-voltage alkaline aqueous electrolyte. J. Power Sources 2021, 506, 230103. [Google Scholar] [CrossRef]

- Sheberla, D.; Bachman, J.C.; Elias, J.; Sun, C.-J.; Shao-Horn, Y.; Dincă, M. Conductive MOF electrodes for stable supercapacitors with high areal capacitance. Nat. Mater. 2016, 16, 220–224. [Google Scholar] [CrossRef]

- Yue, M.-L.; Yu, C.-Y.; Duan, H.-H.; Yang, B.-L.; Meng, X.-X.; Li, Z.-X. Six Isomorphous Window-Beam MOFs: Explore the Effects of Metal Ions on MOF-Derived Carbon for Supercapacitors. Chem. A Eur. J. 2018, 24, 16160–16169. [Google Scholar] [CrossRef]

- Li, Q.; Dai, Z.; Wu, J.; Liu, W.; Di, T.; Jiang, R.; Zheng, X.; Wang, W.; Ji, X.; Li, P.; et al. Fabrication of Ordered Macro-Microporous Single-Crystalline MOF and Its Derivative Carbon Material for Supercapacitor. Adv. Energy Mater. 2020, 10, 1903750. [Google Scholar] [CrossRef]

- Dai, E.; Xu, J.; Qiu, J.; Liu, S.; Shucheng, L.; Liu, Y. Co@Carbon and Co3O4@Carbon nanocomposites derived from a single MOF for supercapacitors. Sci. Rep. 2017, 7, 12588. [Google Scholar] [CrossRef] [PubMed]

- dos Reis, G.; de Oliveira, H.; Larsson, S.; Thyrel, M.; Lima, E.C. A Short Review on the Electrochemical Performance of Hierarchical and Nitrogen-Doped Activated Biocarbon-Based Electrodes for Supercapacitors. Nanomaterials 2021, 11, 424. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.; Xiang, R.; Lin, J.; Cheng, Y.; Lu, C. Lignocellulosic Biomass-Derived Carbon Electrodes for Flexible Supercapacitors: An Overview. Materials 2021, 14, 4571. [Google Scholar] [CrossRef] [PubMed]

- Jyothibasu, J.P.; Wang, R.-H.; Tien, Y.-C.; Kuo, C.-C.; Lee, R.-H. Lignin-Derived Quinone Redox Moieties for Bio-Based Supercapacitors. Polymers 2022, 14, 3106. [Google Scholar] [CrossRef]

- Wu, S.-C.; Chang, P.-H.; Chou, S.-H.; Huang, C.-Y.; Liu, T.-C.; Peng, C.-H. Waffle-Like Carbons Combined with Enriched Mesopores and Highly Heteroatom-Doped Derived from Sandwiched MOF/LDH/MOF for High-Rate Supercapacitor. Nanomaterials 2020, 10, 2388. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Wang, M.; Liu, Y.; Li, Y.; Lu, T.; Pan, L. In situ construction of carbon nanotubes/nitrogen-doped carbon polyhedra hybrids for supercapacitors. Energy Storage Mater. 2016, 5, 132–138. [Google Scholar] [CrossRef]

- Li, C.; Chen, H.; Zhang, L.; Jiao, S.; Zhang, H.; Zhang, J.; Li, P.; Tao, Y.; Zhao, X. Rice Hull-Derived Carbon for Supercapacitors: Towards Sustainable Silicon-Carbon Supercapacitors. Polymers 2021, 13, 4463. [Google Scholar] [CrossRef]

- Gao, Q.; Yuan, Z.; Yang, G.; Tian, Z.; Jiang, Z.; Zhang, K.; Wang, C.; Chen, J. Enhancement of lignin-based carbon quantum dots from poplar pre-hydrolysis liquor on photocatalytic CO2 reduction via TiO2 nanoshe. Ind. Crops Prod. 2021, 160, 113161. [Google Scholar] [CrossRef]

- Jiao, S.; Zhang, L.; Li, C.; Zhang, H.; Zhang, J.; Li, P.; Tao, Y.; Zhao, X.; Chen, H.; Jiang, J. Efficient construction of a carbon-based symmetric supercapacitor from soybean straw by coupling multi-stage carbonization and mild activation. Ind. Crop. Prod. 2022, 183, 114906. [Google Scholar] [CrossRef]

- Yang, H.; Liu, Y.; Sun, X.; Zhang, H.; Zhu, C.; Yin, X.; Li, Z.; Ma, X. MOFs assisted construction of Ni@NiOx/C nanosheets with tunable porous structure for high performance supercapacitors. J. Alloys Compd. 2022, 903, 163993. [Google Scholar] [CrossRef]

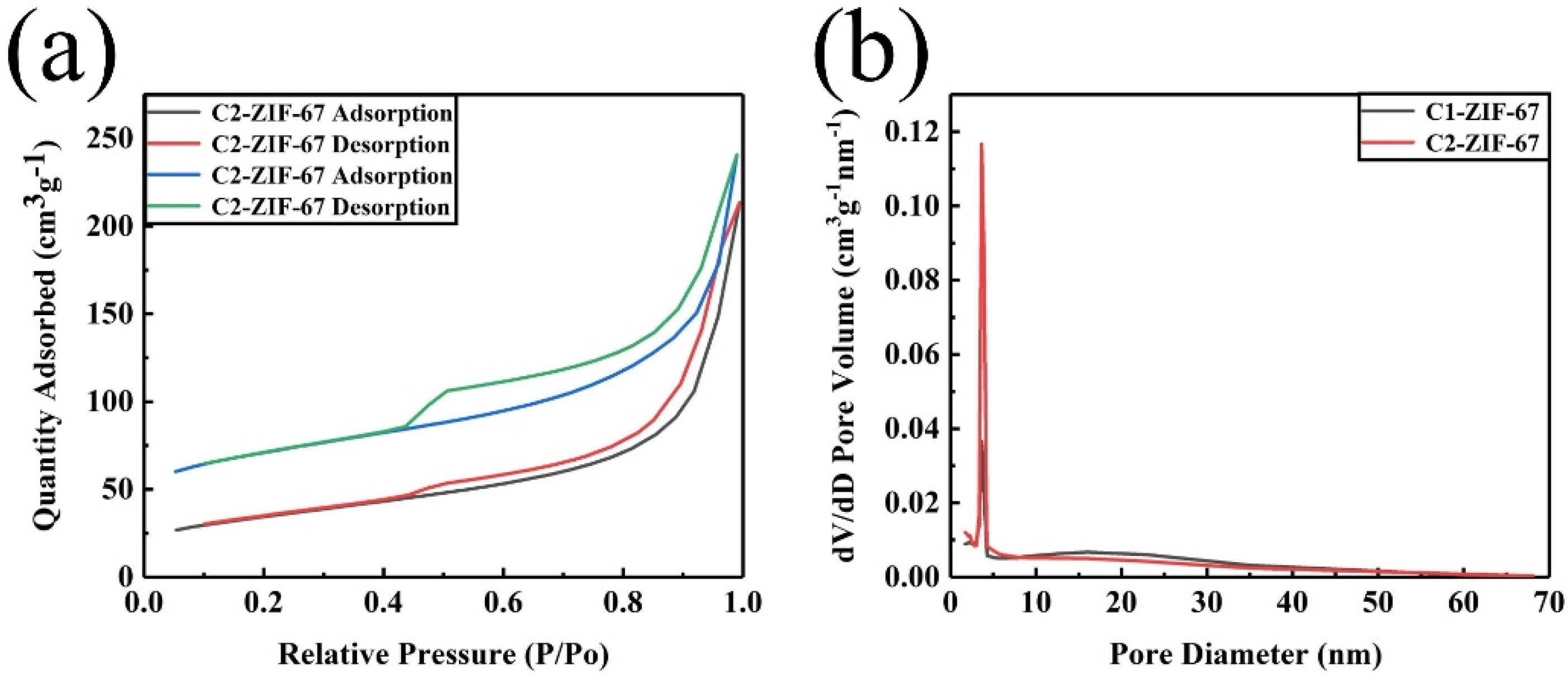

| Sample | SBET (m2 g−1) | Smicro/SBET (%) | Vtotal (cm3 g−1) | Average Pore Size (nm) |

|---|---|---|---|---|

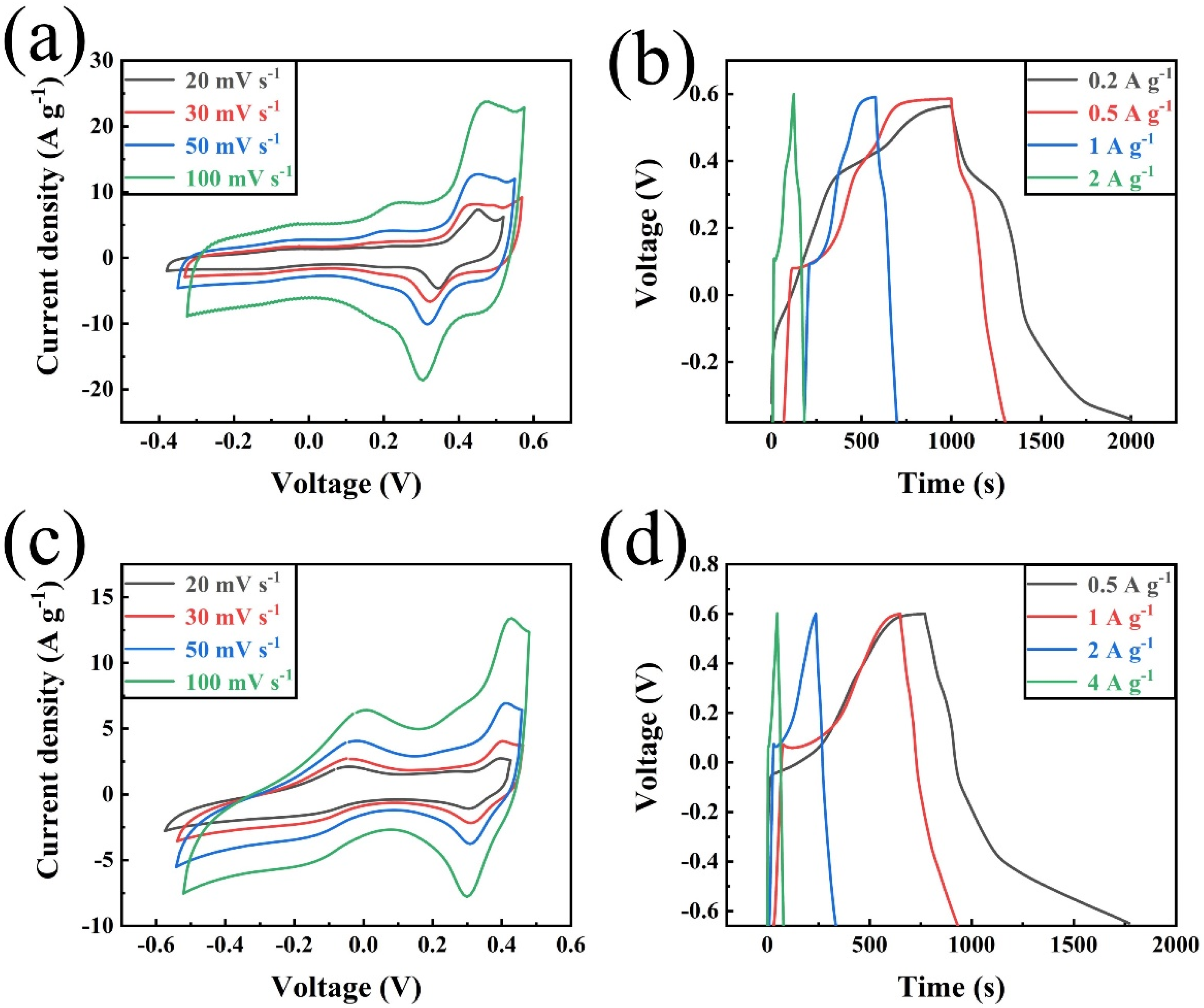

| C1-ZIF-67 | 121 | 11 | 0.209 | 11.9 |

| C2-ZIF-67 | 235 | 38 | 0.254 | 8.4 |

| Materials | Electrolyte | Current Density (A g−1) | Specific Capacitance (F g−1) | Ref. |

|---|---|---|---|---|

| Ni3(HITP)2 EDLC | TEABF4/ACN | 0.05 | 111 | [38] |

| PC-Zn | KOH | 0.5 | 138 | [39] |

| IM-HPC | H2SO4 | 0.5 | 236 | [40] |

| Co3O4@Carbon Peanut shells@FeCl3/MgCl2 | KOH Na2SO4 | 1 1 | 261 247 | [41] [42] |

| Cellulose paper @Ni Lignin/single walled CNT hydrogel Co-Al-LDH@Carbon | KOH Cellulose/Li2SO4 gel H2SO4 | 0.2 0.5 1 | 268 292 300.7 | [43] [44] [45] |

| CNTs/NCP | H2SO4 | 1 | 308 | [46] |

| C-ZIF-67 | KOH | 0.5 | 400 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Li, C.; Sha, L.; Yang, K.; Gao, M.; Chen, H.; Jiang, J. In-Built Fabrication of MOF Assimilated Porous Hollow Carbon from Pre-Hydrolysate for Supercapacitor. Polymers 2022, 14, 3377. https://doi.org/10.3390/polym14163377

Zhao X, Li C, Sha L, Yang K, Gao M, Chen H, Jiang J. In-Built Fabrication of MOF Assimilated Porous Hollow Carbon from Pre-Hydrolysate for Supercapacitor. Polymers. 2022; 14(16):3377. https://doi.org/10.3390/polym14163377

Chicago/Turabian StyleZhao, Xin, Changwei Li, Lei Sha, Kang Yang, Min Gao, Honglei Chen, and Jianchun Jiang. 2022. "In-Built Fabrication of MOF Assimilated Porous Hollow Carbon from Pre-Hydrolysate for Supercapacitor" Polymers 14, no. 16: 3377. https://doi.org/10.3390/polym14163377

APA StyleZhao, X., Li, C., Sha, L., Yang, K., Gao, M., Chen, H., & Jiang, J. (2022). In-Built Fabrication of MOF Assimilated Porous Hollow Carbon from Pre-Hydrolysate for Supercapacitor. Polymers, 14(16), 3377. https://doi.org/10.3390/polym14163377