A Highly Sensitive and Flexible Strain Sensor Based on Dopamine-Modified Electrospun Styrene-Ethylene-Butylene-Styrene Block Copolymer Yarns and Multi Walled Carbon Nanotubes

Abstract

:1. Introduction

2. Experimental Procedures

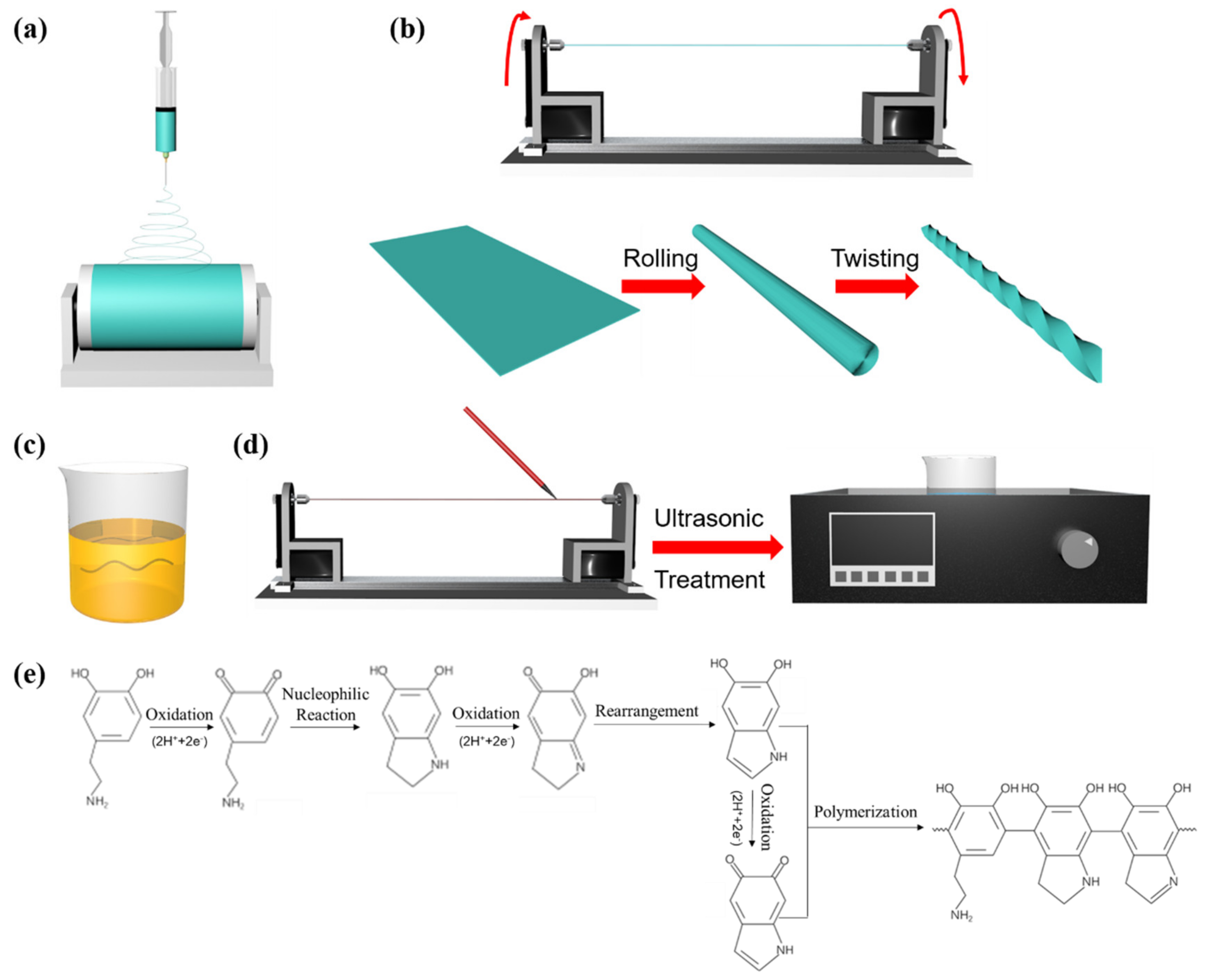

2.1. Preparation of Yarn-Based Strain Sensors

2.1.1. Preparation of Electrospun SEBS Yarn

2.1.2. Dopamine Modification of the Electrospun SEBS Yarn

2.1.3. Preparation of MWCNTs Coated Composite Yarn

2.2. Characterization

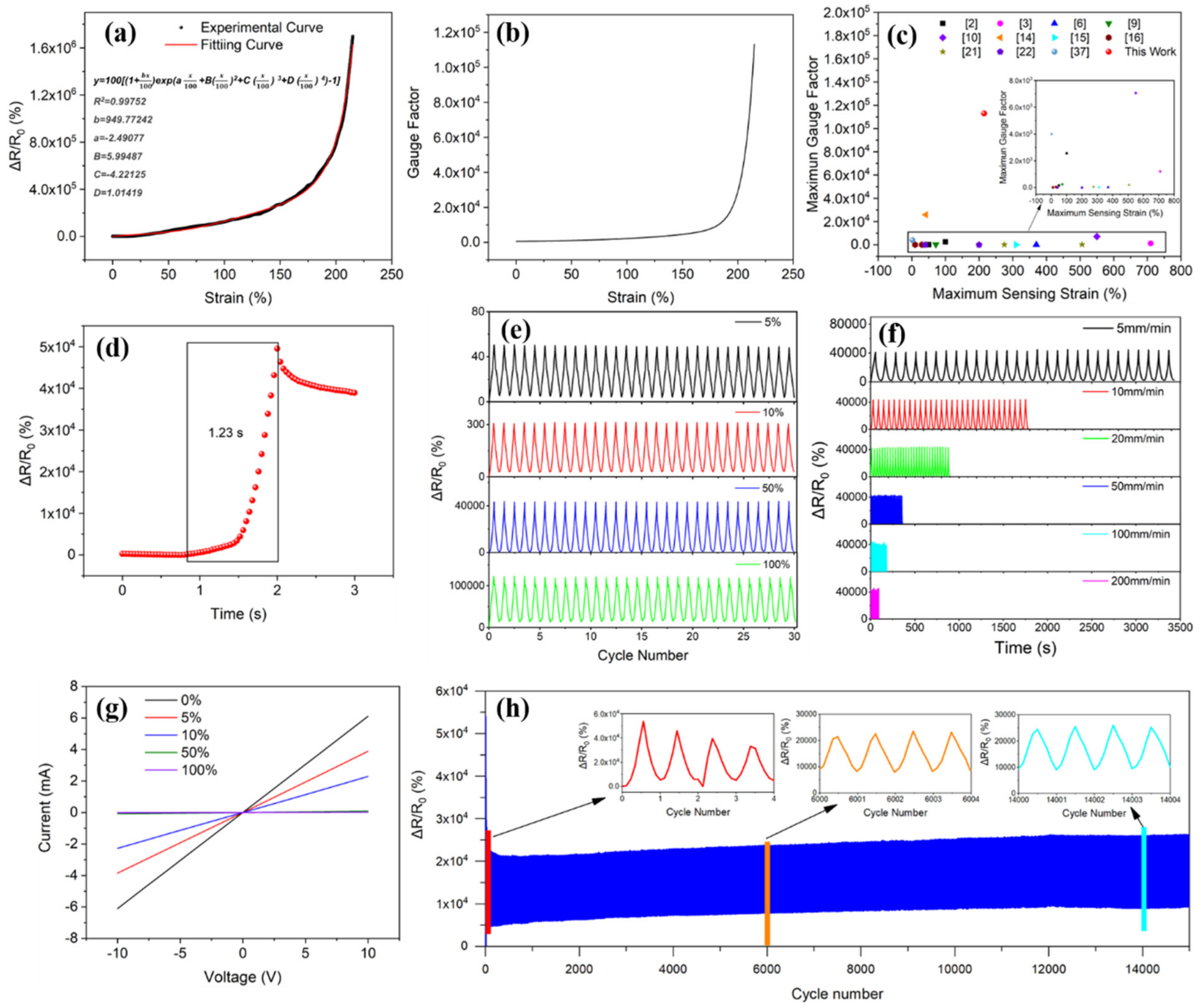

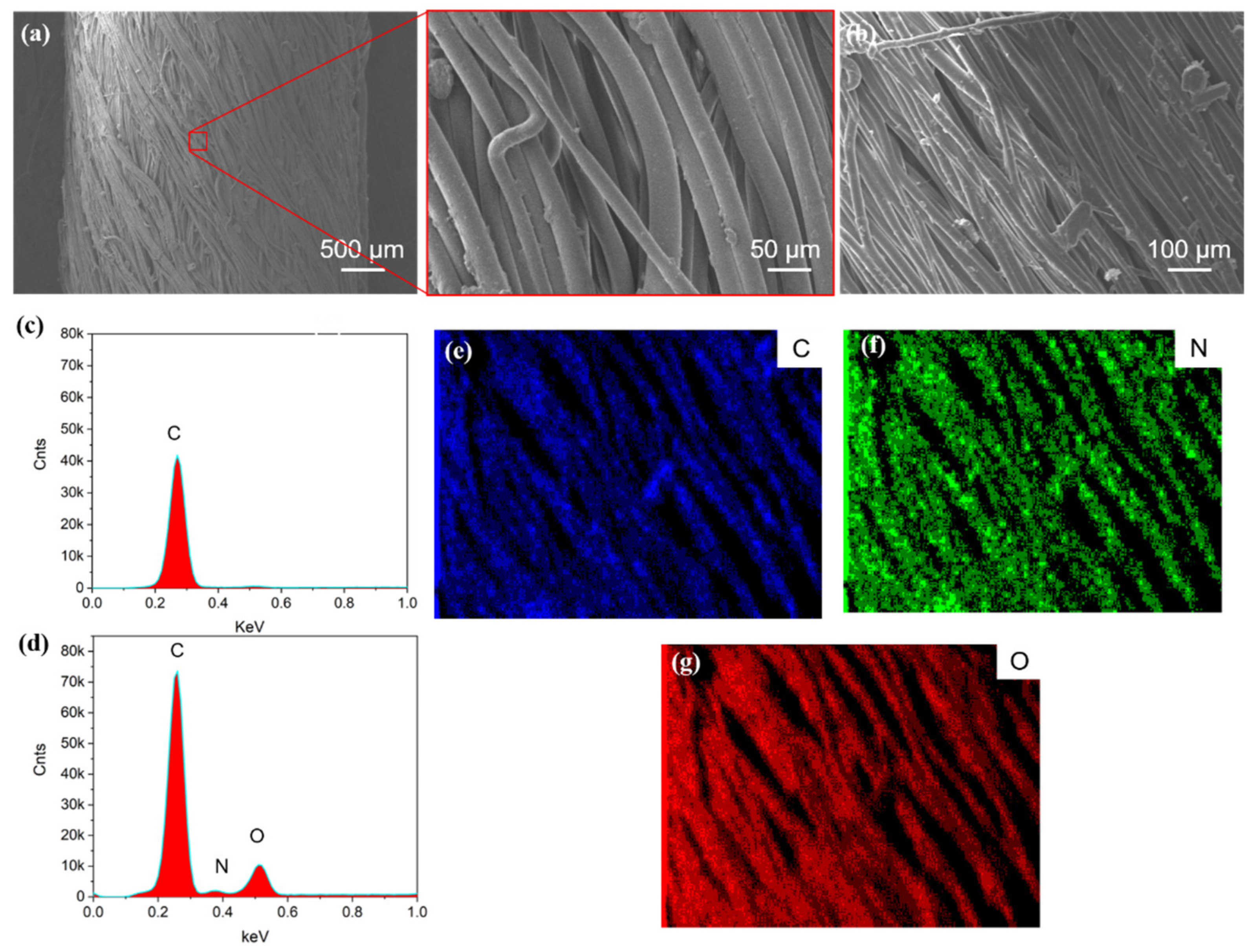

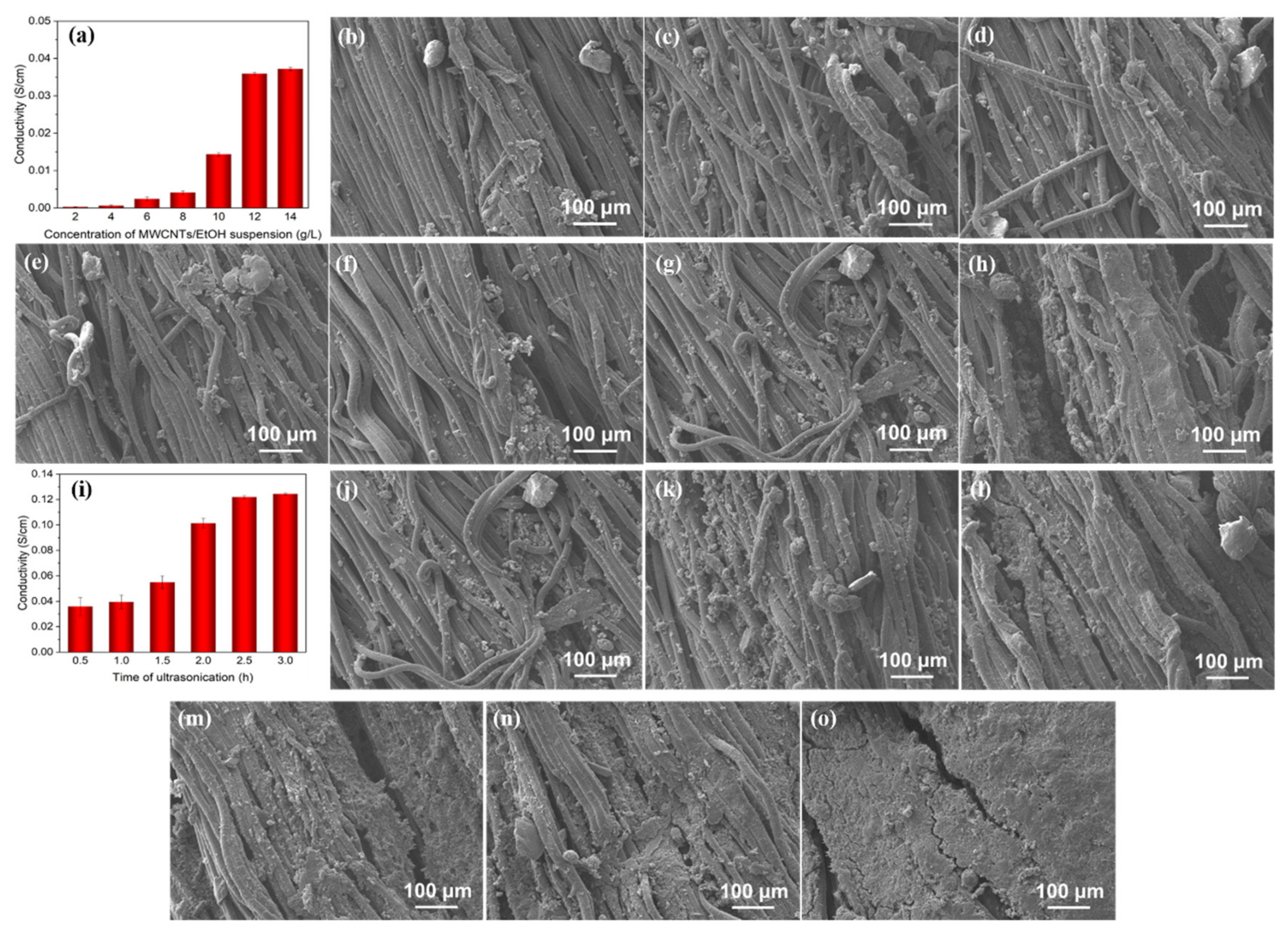

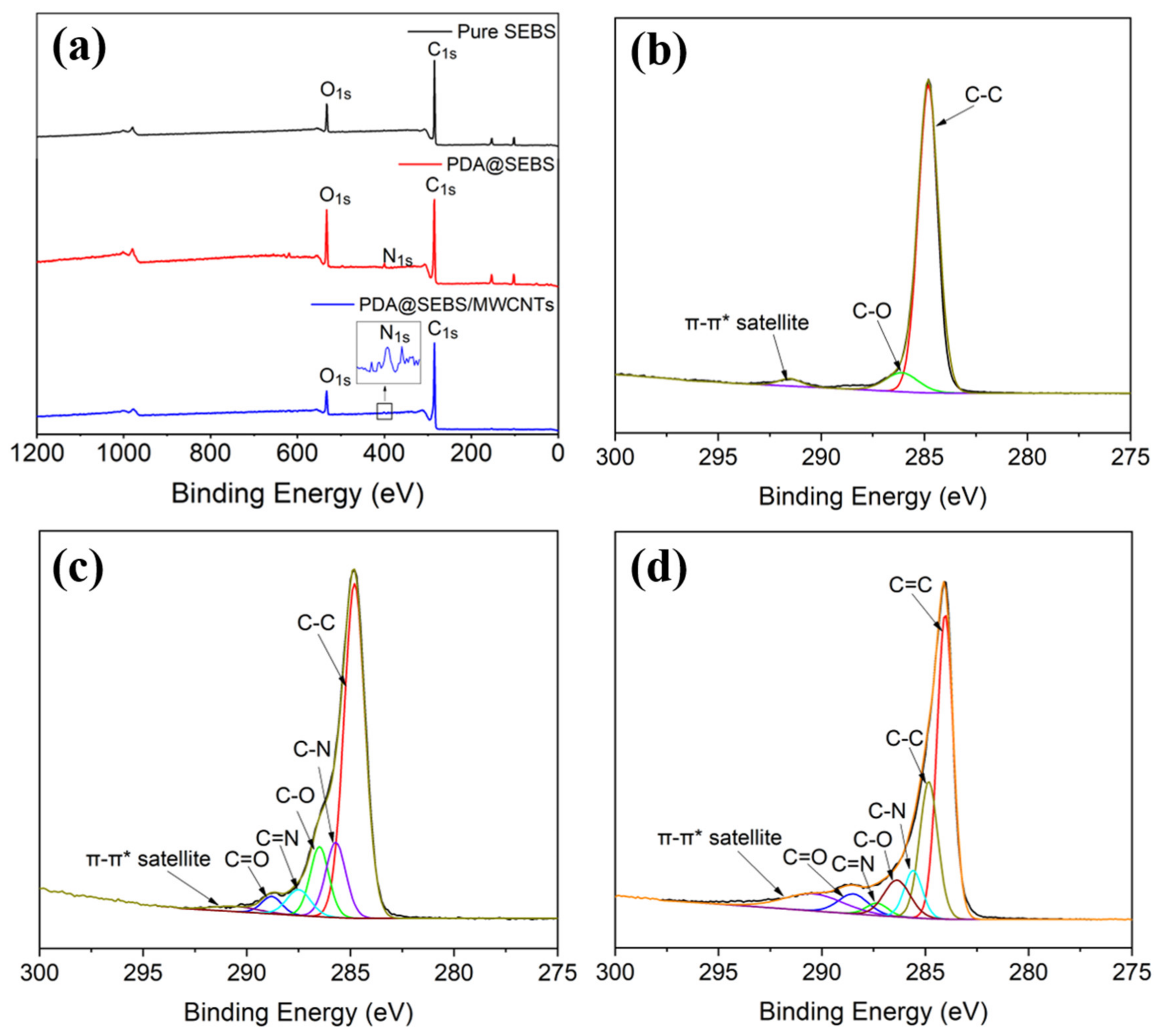

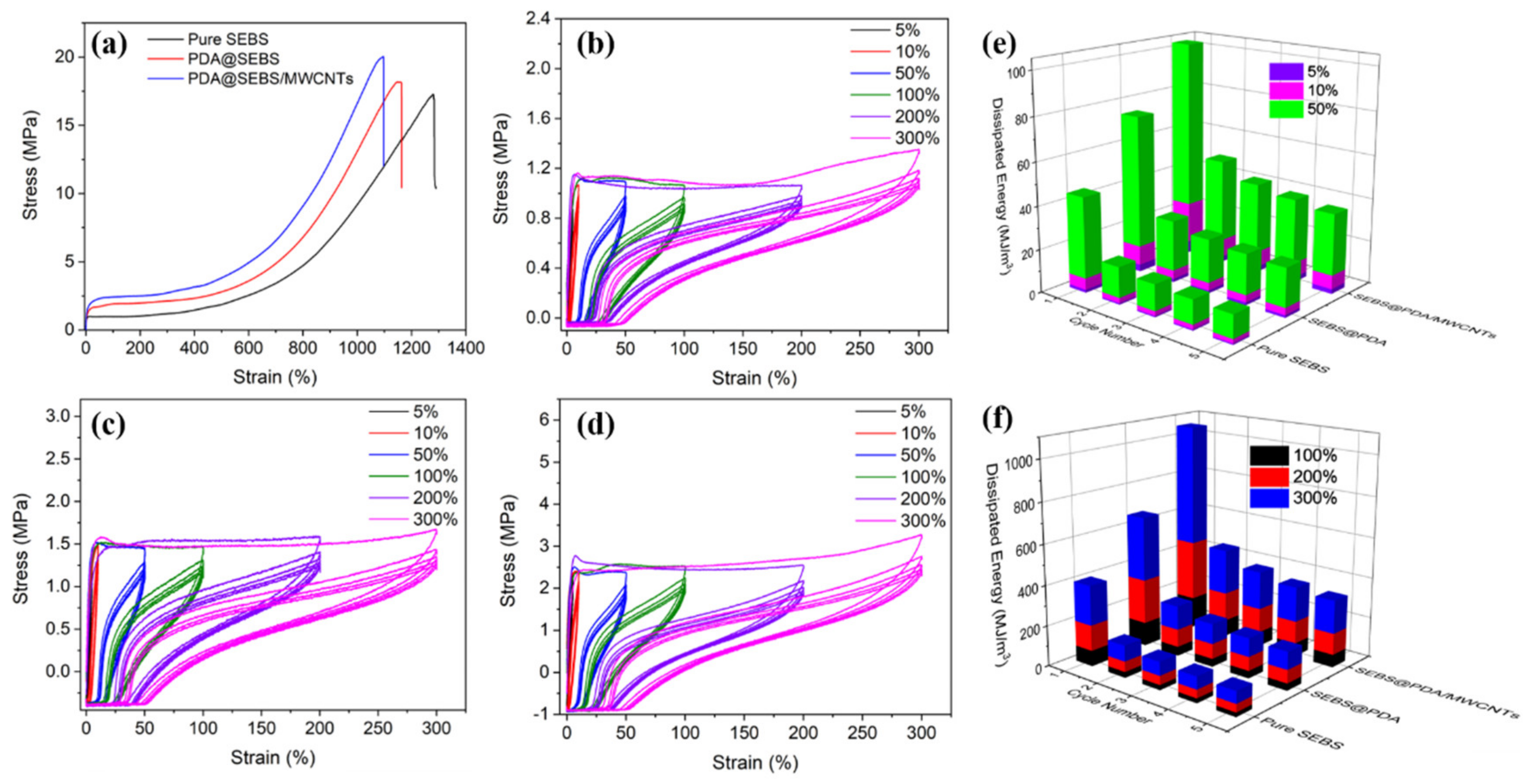

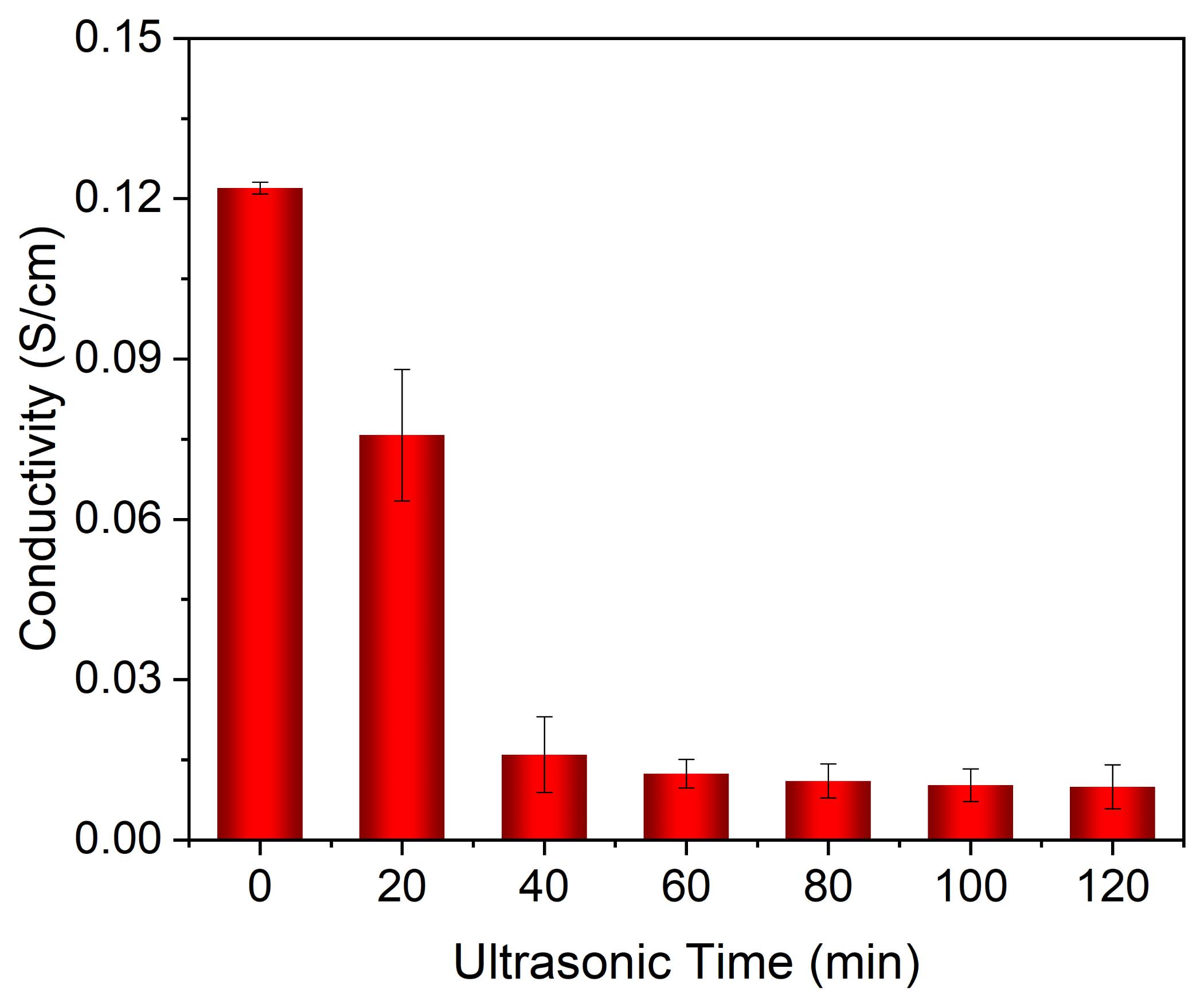

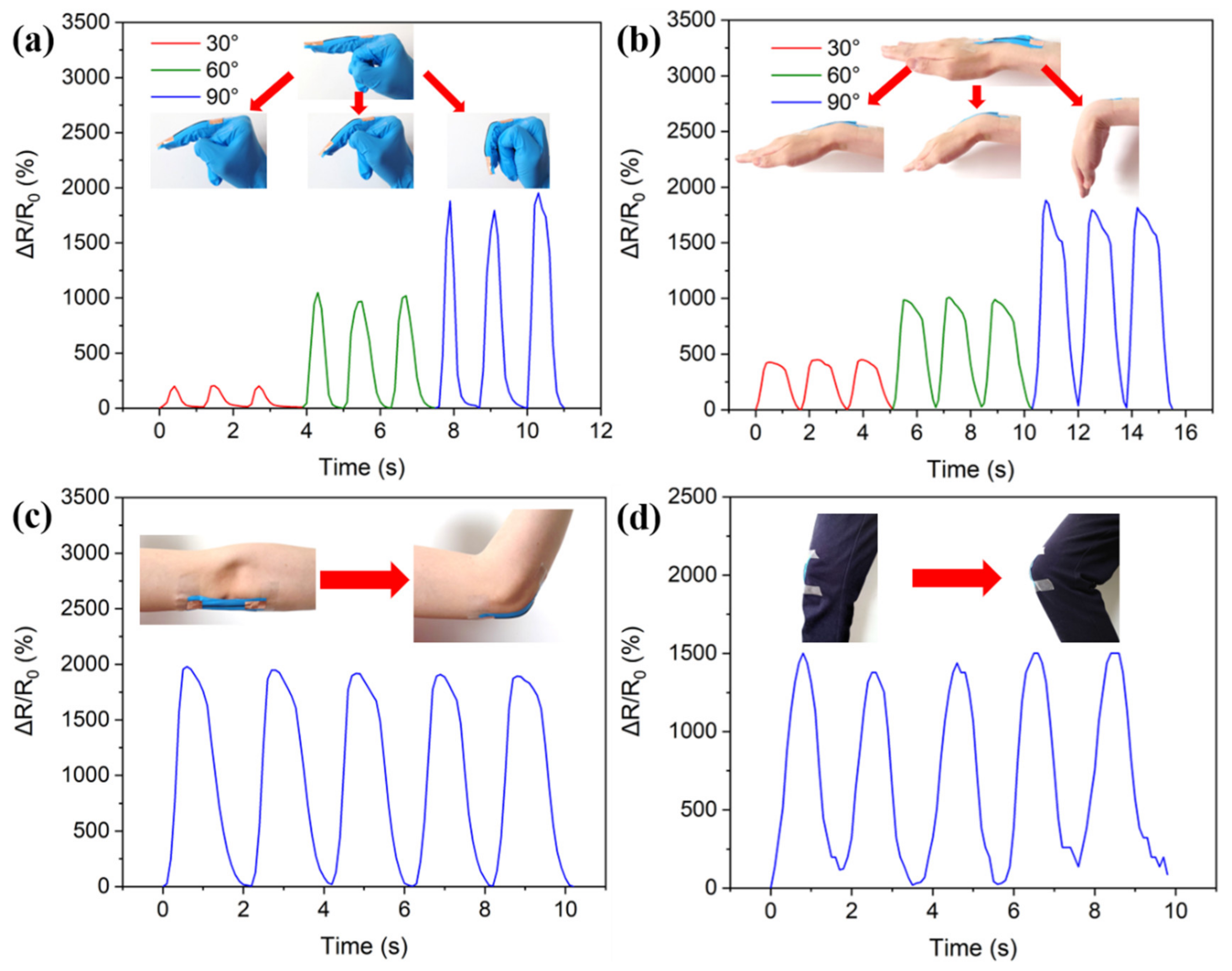

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and mechanics for stretchable electronics. Science 2010, 327, 1603–1607. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, X.; Meng, S.; Tebyetekerwa, M.; Li, Y.; Pionteck, J.; Sun, B.; Qin, Z.; Zhu, M. Highly sensitive and stretchable piezoresistive strain sensor based on conductive poly(styrene-butadiene-styrene)/few layer graphene composite fiber. Compos. Part A Appl. Sci. Manuf. 2018, 105, 291–299. [Google Scholar] [CrossRef]

- Huang, J.; Li, D.; Zhao, M.; Mensah, A.; Lv, P.; Tian, X.; Huang, F.; Ke, H.; Wei, Q. Highly Sensitive and Stretchable CNT-Bridged AgNP Strain Sensor Based on TPU Electrospun Membrane for Human Motion Detection. Adv. Electron. Mater. 2019, 5, 1900241. [Google Scholar] [CrossRef]

- Wang, J.; Lou, Y.; Wang, B.; Sun, Q.; Zhou, M.; Li, X. Highly Sensitive, Breathable, and Flexible Pressure Sensor Based on Electrospun Membrane with Assistance of AgNW/TPU as Composite Dielectric Layer. Sensors 2020, 20, 2459. [Google Scholar] [CrossRef]

- Li, W.Y.; Zhou, Y.F.; Wang, Y.H.; Li, Y.; Jiang, L.; Ma, J.W.; Chen, S.J. Highly Stretchable and Sensitive SBS/Graphene Composite Fiber for Strain Sensors. Macromol. Mater. Eng. 2020, 305, 1900736. [Google Scholar] [CrossRef]

- Li, W.; Zhou, Y.; Wang, Y.; Jiang, L.; Ma, J.; Chen, S.; Zhou, F.L. Core–Sheath Fiber-Based Wearable Strain Sensor with High Stretchability and Sensitivity for Detecting Human Motion. Adv. Electron. Mater. 2020, 7, 2000865. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Y.; Lin, L.W.; Wang, H.; Huang, X.W.; Xue, H.G.; Gao, J.F. Highly stretchable, anti-corrosive and wearable strain sensors based on the PDMS/CNTs decorated elastomer nanofiber composite. Chem. Eng. J. 2019, 362, 89–98. [Google Scholar] [CrossRef]

- Jin, C.C.; Liu, D.M.; Li, M.; Wang, Y. Application of highly stretchy PDMS-based sensing fibers for sensitive weavable strain sensors. J. Mater. Sci. Mater. Electron. 2020, 31, 4788–4796. [Google Scholar] [CrossRef]

- Son, W.; Kim, K.B.; Lee, S.; Hyeon, G.; Hwang, K.G.; Park, W. Ecoflex-Passivated Graphene-Yarn Composite for a Highly Conductive and Stretchable Strain Sensor. J. Nanosci. Nanotechnol. 2019, 19, 6690–6695. [Google Scholar] [CrossRef]

- Shen, Z.M.; Feng, J.C. Mass-produced SEBS/graphite nanoplatelet composites with a segregated structure for highly stretchable and recyclable strain sensors. J. Mater. Chem. C 2019, 7, 9423–9429. [Google Scholar] [CrossRef]

- Zhou, B.Z.; Liu, Z.X.; Li, C.C.; Liu, M.S.; Jiang, L.; Zhou, Y.F.; Zhou, F.L.; Chen, S.J.; Jerrams, S.; Yu, J.Y. A Highly Stretchable and Sensitive Strain Sensor Based on Dopamine Modified Electrospun SEBS Fibers and MWCNTs with Carboxylation. Adv. Electron. Mater. 2021, 7, 2100233. [Google Scholar] [CrossRef]

- Chossat, J.B.; Park, Y.L.; Wood, R.J.; Duchaine, V. A Soft Strain Sensor Based on Ionic and Metal Liquids. IEEE Sens. J. 2013, 13, 3405–3414. [Google Scholar] [CrossRef]

- Gullapalli, H.; Vemuru, V.S.; Kumar, A.; Botello-Mendez, A.; Vajtai, R.; Terrones, M.; Nagarajaiah, S.; Ajayan, P.M. Flexible piezoelectric ZnO-paper nanocomposite strain sensor. Small 2010, 6, 1641–1646. [Google Scholar] [CrossRef]

- Wang, Y.H.; Li, W.Y.; Li, C.C.; Zhou, B.Z.; Zhou, Y.F.; Jiang, L.; Wen, S.P.; Zhou, F.L. Fabrication of ultra-high working range strain sensor using carboxyl CNTs coated electrospun TPU assisted with dopamine. Appl. Surf. Sci. 2021, 566, 150705. [Google Scholar] [CrossRef]

- Wang, Y.H.; Li, W.Y.; Zhou, Y.F.; Jiang, L.; Ma, J.W.; Chen, S.J.; Jerrams, S.; Zhou, F.L. Fabrication of high-performance wearable strain sensors by using CNTs-coated electrospun polyurethane nanofibers. J. Mater. Sci. 2020, 55, 12592–12606. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, L.; Wu, Z.F.; Luo, J.C.; Li, B.; Huang, X.W.; Xue, H.G.; Gao, J.F. Super-hydrophobic, durable and cost-effective carbon black/rubber composites for high performance strain sensors. Compos. Part B Eng. 2019, 176, 107358. [Google Scholar] [CrossRef]

- Xu, M.; Qi, J.; Li, F.; Zhang, Y. Highly stretchable strain sensors with reduced graphene oxide sensing liquids for wearable electronics. Nanoscale 2018, 10, 5264–5271. [Google Scholar] [CrossRef]

- Baptista, F.R.; Belhout, S.A.; Giordani, S.; Quinn, S.J. Recent developments in carbon nanomaterial sensors. Chem. Soc. Rev. 2015, 44, 4433–4453. [Google Scholar] [CrossRef]

- Zhou, B.; Li, C.; Zhou, Y.; Liu, Z.; Gao, X.; Wang, X.; Jiang, L.; Tian, M.; Zhou, F.-L.; Jerrams, S.; et al. A flexible dual-mode pressure sensor with ultra-high sensitivity based on BTO@MWCNTs core-shell nanofibers. Compos. Sci. Technol. 2022, 224, 109478. [Google Scholar] [CrossRef]

- Hu, S.; Shi, Z.; Zhao, W.; Wang, L.; Yang, G. Multifunctional piezoelectric elastomer composites for smart biomedical or wearable electronics. Compos. B Eng. 2019, 160, 595–604. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, Y.; Sun, J.; Huang, Y.; Hu, H.; Jiang, R.; Gai, W.; Li, G.; Zhi, C. Polyurethane/Cotton/Carbon Nanotubes Core-Spun Yarn as High Reliability Stretchable Strain Sensor for Human Motion Detection. ACS Appl. Mater. Interfaces 2016, 8, 24837–24843. [Google Scholar] [CrossRef]

- Lee, T.; Choi, Y.W.; Lee, G.; Pikhitsa, P.V.; Kang, D.; Kim, S.M.; Choi, M. Transparent ITO mechanical crack-based pressure and strain sensor. J. Mater. Chem. C 2016, 4, 9947–9953. [Google Scholar] [CrossRef]

- Li, X.; Huang, K.; Wang, X.; Li, H.; Shen, W.; Zhou, X.; Xu, J.; Wang, X. Effect of montmorillonite on morphology, rheology, and properties of a poly[styrene–(ethylene-co-butylene)–styrene]/poly(ε-caprolactone) nanocomposite. J. Mater. Sci. 2017, 53, 1191–1203. [Google Scholar] [CrossRef]

- Kuester, S.; Barra, G.M.O.; Ferreira, J.C.; Soares, B.G.; Demarquette, N.R. Electromagnetic interference shielding and electrical properties of nanocomposites based on poly (styrene-b-ethylene-ran-butylene-b-styrene) and carbon nanotubes. Eur. Polym. J. 2016, 77, 43–53. [Google Scholar] [CrossRef]

- Shin, M.; Oh, J.Y.; Byun, K.E.; Lee, Y.J.; Kim, B.; Baik, H.K.; Park, J.J.; Jeong, U. Polythiophene nanofibril bundles surface-embedded in elastomer: A route to a highly stretchable active channel layer. Adv. Mater. 2015, 27, 1255–1261. [Google Scholar] [CrossRef]

- Xu, J.; Wang, S.; Wang, G.N.; Zhu, C.; Luo, S.; Jin, L.; Gu, X.; Chen, S.; Feig, V.R.; To, J.W.; et al. Highly stretchable polymer semiconductor films through the nanoconfinement effect. Science 2017, 355, 59–64. [Google Scholar] [CrossRef]

- Wei, W.; Liang, H.; Parvez, K.; Zhuang, X.; Feng, X.; Mullen, K. Nitrogen-doped carbon nanosheets with size-defined mesopores as highly efficient metal-free catalyst for the oxygen reduction reaction. Angew. Chem. Int. Ed. 2014, 53, 1570–1574. [Google Scholar] [CrossRef]

- Caliskan, S.; Karihaloo, B.L. Effect of surface roughness, type and size of model aggregates on the bond strength of aggregate/mortar interface. Interface Sci. 2004, 12, 361–374. [Google Scholar] [CrossRef]

- Seager, C.H.; Pike, G.E. Percolation and conductivity: A computer study. II. Phys. Rev. B 1974, 10, 1435–1446. [Google Scholar] [CrossRef]

- Yu, S.L.; Wang, X.P.; Xiang, H.X.; Zhu, L.P.; Tebyetekerwa, M.; Zhu, M.F. Superior piezoresistive strain sensing behaviors of carbon nanotubes in one-dimensional polymer fiber structure. Carbon 2018, 140, 1–9. [Google Scholar] [CrossRef]

- Gao, J.F.; Li, W.; Shi, H.C.; Hu, M.J.; Li, R.K.Y. Preparation, morphology, and mechanical properties of carbon nanotube anchored polymer nanofiber composite. Compos. Sci. Technol. 2014, 92, 95–102. [Google Scholar] [CrossRef]

- Cai, M.; He, H.; Zhang, X.; Yan, X.; Li, J.; Chen, F.; Yuan, D.; Ning, X. Efficient Synthesis of PVDF/PI Side-by-Side Bicomponent Nanofiber Membrane with Enhanced Mechanical Strength and Good Thermal Stability. Nanomaterials 2018, 9, 39. [Google Scholar] [CrossRef] [Green Version]

- Sang, Z.; Ke, K.; Manas-Zloczower, I. Effect of carbon nanotube morphology on properties in thermoplastic elastomer composites for strain sensors. Compos. Part A Appl. Sci. Manuf. 2019, 121, 207–212. [Google Scholar] [CrossRef]

- Wang, N.; Xu, Z.Y.; Zhan, P.F.; Dai, K.; Zheng, G.Q.; Liu, C.T.; Shen, C.Y. A tunable strain sensor based on a carbon nanotubes/electrospun polyamide 6 conductive nanofibrous network embedded into poly(vinyl alcohol) with self-diagnosis capabilities. J. Mater. Chem. C 2017, 5, 4408–4418. [Google Scholar] [CrossRef]

- Ogden, R.W.; Roxburgh, D.G. A pseudo–elastic model for the Mullins effect in filled rubber. Proc. R. Soc. Lond. Ser. A 1999, 455, 2861–2877. [Google Scholar] [CrossRef]

- Simmons, J.G. Generalized Formula for the Electric Tunnel Effect between Similar Electrodes Separated by a Thin Insulating Film. J. Appl. Phys. 1963, 34, 1793–1803. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Du, Z.; Sun, B.; Li, W.; Jiang, L.; Zhou, Y.; Ma, J.; Chen, S.; Zhou, F.-L. Fabrication of electrically conductive poly(styrene-b-ethylene-ran-butylene-b-styrene)/multi-walled carbon nanotubes composite fiber and its application in ultra-stretchable strain sensor. Eur. Polym. J. 2022, 169, 111121. [Google Scholar] [CrossRef]

- Liu, H.; Gao, J.; Huang, W.; Dai, K.; Zheng, G.; Liu, C.; Shen, C.; Yan, X.; Guo, J.; Guo, Z. Electrically conductive strain sensing polyurethane nanocomposites with synergistic carbon nanotubes and graphene bifillers. Nanoscale 2016, 8, 12977–12989. [Google Scholar] [CrossRef]

- Li, T.; Sun, M.; Wu, S. State-of-the-Art Review of Electrospun Gelatin-Based Nanofiber Dressings for Wound Healing Applications. Nanomaterials 2022, 12, 784. [Google Scholar] [CrossRef]

- Liu, J.; Li, T.; Zhang, H.; Zhao, W.; Qu, L.; Chen, S.; Wu, S. Electrospun strong, bioactive, and bioabsorbable silk fibroin/poly (L-lactic-acid) nanoyarns for constructing advanced nanotextile tissue scaffolds. Mater. Today Bio 2022, 14, 100243. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, Y.; Wang, X.; Ning, F.; Wen, S.; Zhou, Y.; Chen, S.; Betts, A.; Jerrams, S.; Zhou, F.-L. Electrohydrodynamic printing of a dielectric elastomer actuator and its application in tunable lenses. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106461. [Google Scholar] [CrossRef]

- Li, C.; Zhou, B.; Zhou, Y.; Ma, J.; Zhou, F.; Chen, S.; Jerrams, S.; Jiang, L. Carbon Nanotube Coated Fibrous Tubes for Highly Stretchable Strain Sensors Having High Linearity. Nanomaterials 2022, 12, 2458. [Google Scholar] [CrossRef]

- Liu, Z.; Li, C.; Zhang, X.; Zhou, B.; Wen, S.; Zhou, Y.; Chen, S.; Jiang, L.; Jerrams, S.; Zhou, F. Biodegradable Polyurethane Fiber-Based Strain Sensor with a Broad Sensing Range and High Sensitivity for Human Motion Monitoring. ACS Sustain. Chem. Eng. 2022, 10, 8788–8798. [Google Scholar] [CrossRef]

| Yarn | σ (MPa) | εat break (%) |

|---|---|---|

| SEBS | 17.1 ± 0.45 | 1270.96 ± 100.15 |

| PDA@SEBS | 18.17 ± 0.42 | 1158.4 ± 97.75 |

| PDA@SEBS/MWCNTs | 20.03 ± 0.51 | 1095.8 ± 91.43 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, B.; Li, C.; Liu, Z.; Zhang, X.; Li, Q.; He, H.; Zhou, Y.; Jiang, L. A Highly Sensitive and Flexible Strain Sensor Based on Dopamine-Modified Electrospun Styrene-Ethylene-Butylene-Styrene Block Copolymer Yarns and Multi Walled Carbon Nanotubes. Polymers 2022, 14, 3030. https://doi.org/10.3390/polym14153030

Zhou B, Li C, Liu Z, Zhang X, Li Q, He H, Zhou Y, Jiang L. A Highly Sensitive and Flexible Strain Sensor Based on Dopamine-Modified Electrospun Styrene-Ethylene-Butylene-Styrene Block Copolymer Yarns and Multi Walled Carbon Nanotubes. Polymers. 2022; 14(15):3030. https://doi.org/10.3390/polym14153030

Chicago/Turabian StyleZhou, Bangze, Chenchen Li, Zhanxu Liu, Xiaofeng Zhang, Qi Li, Haotian He, Yanfen Zhou, and Liang Jiang. 2022. "A Highly Sensitive and Flexible Strain Sensor Based on Dopamine-Modified Electrospun Styrene-Ethylene-Butylene-Styrene Block Copolymer Yarns and Multi Walled Carbon Nanotubes" Polymers 14, no. 15: 3030. https://doi.org/10.3390/polym14153030

APA StyleZhou, B., Li, C., Liu, Z., Zhang, X., Li, Q., He, H., Zhou, Y., & Jiang, L. (2022). A Highly Sensitive and Flexible Strain Sensor Based on Dopamine-Modified Electrospun Styrene-Ethylene-Butylene-Styrene Block Copolymer Yarns and Multi Walled Carbon Nanotubes. Polymers, 14(15), 3030. https://doi.org/10.3390/polym14153030