Abstract

Recently, designers of electronic equipment have paid special attention to the issue of electromagnetic compatibility (EMC) of devices with their own components and assemblies. This is due to the high sensitivity of semiconductor microcircuits to electromagnetic interference. This interference can be caused either by natural phenomena, such as lightning strikes, or by technical processes, such as transients in circuits during fast periodic or random switching. Either way, interference implies a sudden change in voltage or current in a circuit, which is undesirable, whether it propagates along a cable or is transmitted as an electromagnetic wave. The purpose of this article is to review the works devoted to the development, creation, and investigation of modern polymeric nanocomposite materials used for shielding electromagnetic radiation and their effective application for solving problems of electromagnetic compatibility. Additionally, the approach to design EMI shielding complex media with predetermined parameters based on investigation of various properties of possible components is shown. In the review, all polymer composites are classified according to the type of filler. The issues of the interaction of a polymer with conductive fillers, the influence of the concentration of fillers and their location inside the matrix, and the structure of the nanocomposite on the mechanisms of electromagnetic interaction are considered. Particular attention is paid to a new generation of nanocomposite materials with widely adjustable electrical and magnetic properties. A wide class of modern filled polymeric materials with dielectric and magneto-dielectric losses is considered. These materials make it possible to create effective absorbers of electromagnetic waves that provide a low level of reflection coefficient in the microwave range. The model mechanisms for shielding electromagnetic radiation are considered in the paper. A detailed review of the electro-physical properties of polymer nanocomposites is provided. Multilayer electrodynamic media containing combinations of layers of filled polymer composite materials with nanoparticles of different compositions and manufactured using a single technology will make it possible to create electrodynamic media and coatings with the required electro-physical characteristics of absorption, transmission, and reflection. Within the framework of the two-layer coating model, the difference in the effects of the interaction of electromagnetic radiation with conductive layers located on a dielectric and metal substrate is demonstrated. It is shown that in order to achieve optimal (maximum) values of reflection and absorption of electromagnetic radiation in the appropriate frequency range, it is necessary to fit the appropriate layer thicknesses, specific conductivity, and permittivity. Such approach allows designers to create new shielding materials that can effectively vary the shielding, absorbing, and matching characteristics of coatings over a wide frequency band. In general, it can be said that the development of innovative polymer composite materials for shielding electronic devices from electromagnetic interference and excessive electromagnetic background is still an important task. Its solution will ensure the safe and uninterrupted operation of modern digital electronics and can be used for other applications.

1. Introduction

The intensive development of telecommunication systems in the last 30 years has led to qualitative changes in the use of the radio frequency spectrum (RFS). During this time, the RFS load with radio emissions has increased many times over. At the same time, the air is not only filled with useful signals necessary for radio transmission but is also literally clogged with unwanted emissions from radio-electronic and electrical equipment, which create unintentional interference to receiving devices and reduce the efficiency of using RFS. At the same time, the proportion of radio emissions of artificial origin constantly increases. It is necessary to note that the RFS loading is not the same in frequency bands. In recent years, it has especially increased in the ranges of meter and decimeter waves. These ranges are widely used in telecommunication systems now [1]. Since the number of users of such systems in cities is in the millions, their operation even at relatively low transmitter powers (as a rule, not higher than 60 W for base and mobile subscriber stations and a fraction of a Watt for subscriber portable stations) led to a significant increase in RFS load. At the same time, with the development of electric and automobile transport and the widespread use of electrical and high-frequency equipment for various purposes, the RFS load in cities and industrial centers grew due to radio emissions that create industrial and contact interference. As a result, the field strength levels of only the background load component in some areas can reach 15–20 μV/m or more. At the same time, the sensitivity of modern receivers that characterizes the minimum levels of received signals converted to a receiving antenna is calculated in units and even fractions of μV/m. Under operating radio-electronic systems (RES), it is necessary to find ways to ensure the joint operation of RES with the required quality in conditions of limited frequency, time, and territorial resources. Electromagnetic compatibility of devices is its ability to simultaneously function in real operating conditions with the required quality under the effect of unintentional electromagnetic interference and not create unacceptable electromagnetic interference to other devices.

In order to prevent the unintentional release of electromagnetic radiation (EMR) generated in various electronic devices into the external space as well as to exclude the influence of radiation on individual sensitive elements inside radio engineering devices, it is necessary to solve problems of electromagnetic compatibility. It is known that metals reflect almost all electromagnetic radiation incident on them; therefore, metal screens are not used in many devices since the reflected radiation causes interference and disables radiation-sensitive devices. The radiation reflected from metal screens can be significantly reduced by using radio-absorbing materials (RAM) and coatings that attenuate EMR [2].

Electromagnetic shielding is the primary method for achieving electromagnetic compatibility (EMC) in terms of immunity to electromagnetic fields as well as compliance with the requirements for the level of radiated interference. Installing screens on noise-emitting elements ensures the separation of signals necessary for the operation of radio-electronic equipment and increases the selectivity of receivers, the noise immunity of sensitive equipment, the purity of the generator signal, and the accuracy of the devices. The correct choice of shielding method, shield material, and its design is very important at the initial design stage since it will determine the possibility of successfully passing EMC tests and the high-quality functioning of the developed equipment.

The meaning of shielding is to weaken the electric, magnetic, and electromagnetic fields in the space where these fields cause a negative effect. Screen performance depends on configuration, geometric dimensions of the screen, frequency or rate of field change, dielectric and magnetic permeability, and electrical conductivity of the screen material.

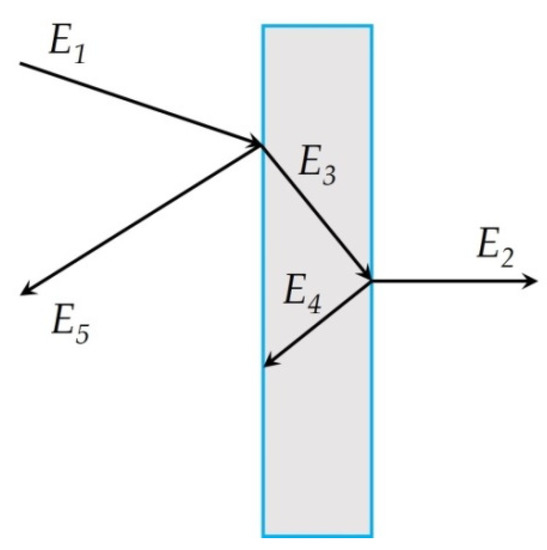

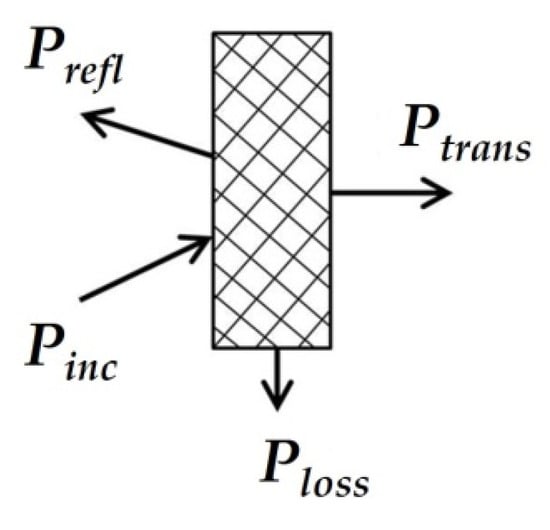

The model of interaction of an electromagnetic wave with a screen is shown in Figure 1. The main characteristic of the screen is the screening factor. An electromagnetic wave is reflected from each interface between the media, and absorption occurs in the thickness of the material.

Figure 1.

Interaction of an electromagnetic wave with a screen.

In the general case, the screening factor Ke (dB) is the ratio of the intensity of the electromagnetic field measured before the installation of a continuous endless screen and after its installation. The resulting shielding factor is the sum of the reflection and absorption losses. The shielding factor is:

where Ei are the intensities of the corresponding electromagnetic waves: E1 is the incident wave; E2 is the transmitted wave; E3 is the absorbed wave; E4 is the re-reflected wave; E5 is the reflected wave.

Ke = 20 × log(E1/E2),

E2 = E1 − E3 − E4 − E5

For shielding permanent magnetic fields and low-frequency electromagnetic fields, where the magnetic component predominates, materials with high magnetic permeability are needed. It is known that the higher the magnetic permeability of the material, the higher the shielding factor. For shielding over a wide frequency range, multilayer materials are best suited. A promising method for creating broadband absorbing materials is the use of materials with special dispersion laws for the dielectric and magnetic permeability.

Therefore, to create an effective screen, it is necessary to fit the material, its structure, and thickness depending on the component of the electromagnetic field that needs to be screened.

Recently, fundamentally new classes of materials have appeared, such as filled polymers, conductive polymers, nanostructured polymer composites, magnetic composites, and products filled with carbon-containing materials [3]. It should be noted that the development of polymeric materials with specific properties, in particular, with special electrical and magnetic characteristics, namely antistatic, electrically conductive, radio absorbing, electret, piezo-, and pyroelectric, is currently one of the most important areas in materials science [4].

One of the important aspects of the development of electronic equipment is the issue of EMC of devices with their own components and assemblies. This is due to the high sensitivity of semiconductor microcircuits to electromagnetic interference. This interference can be caused either by natural phenomena, such as lightning strikes, or by technical processes, such as transients in circuits during fast periodic or random switching. Either way, interference implies a sudden change in voltage or current in a circuit, which is undesirable, whether it propagates along a cable or is transmitted as an electromagnetic wave.

The aim of this paper is to review the works devoted to the development, creation, and investigation of modern polymeric nanocomposite materials used for shielding electromagnetic radiation and their effective application for solving problems of electromagnetic compatibility. In the review, all polymer composites are classified according to the type of filler. The process of their manufacture is explained in detail. The issues of the interaction of a polymer with conductive fillers, the influence of the concentration of fillers and their location inside the matrix, and the structure of the nanocomposite on the mechanisms of electromagnetic interaction are considered. Particular attention is paid to a new generation of nanocomposite materials with widely adjustable electrical and magnetic properties. The model mechanisms for shielding electromagnetic radiation are considered in the paper. The review ends with consideration of some practical solutions in the development of multilayer coatings, which illustrate the possibility of obtaining almost any relationship between the coefficients of reflection, transmission, and absorption of an electromagnetic wave when interacting with such a coating. Such approach allows designers to create new effective shielding materials that can effectively vary the shielding, absorbing, and matching characteristics of coatings over a wide frequency band.

2. Radio-Absorbing Materials and Technologies for Their Production

Radio waves cover a fairly wide spectrum of the frequency range (the range of waves used is from ultra-long to millimeter; the range is from centimeters and meters to thousands of kilometers) and are harmonic signals modulated in amplitude and frequency. The main source of powerful electromagnetic radiation is an antenna that radiates a flow of electromagnetic energy in a directionally or non-directionally into the surrounding space [5].

RAMs are widely used in special-purpose equipment. These materials are designed to ensure the electromagnetic compatibility of radio-electronic equipment and antenna systems [6,7]. The main radio engineering parameters that characterize the RAM are: the values of the real and imaginary parts of the dielectric and magnetic permeability as well as the reflection coefficients (R) and/or transmission coefficients (T) in the frequency ranges of the microwave spectrum.

It is known that an ideal single-layer absorber of electromagnetic waves (EMW) is a material with equal dielectric and magnetic permeability. In this case, the reflections from the front boundary of the material will tend to zero [8].

2.1. RAM Classification

In real conditions, obtaining RAM with the same values of dielectric and magnetic permeability in the frequency range is an extremely difficult task due to differences in the physical processes that determine these parameters.

RAM can be classified according to various criteria, for example, according to the operating range of effective action: (i) broadband-, when the R values do not exceed a given value in the frequency range λmax/λmin ≥ 10; (ii) narrow-range-; (iii) tunable-; and (iv) selective-type RAM.

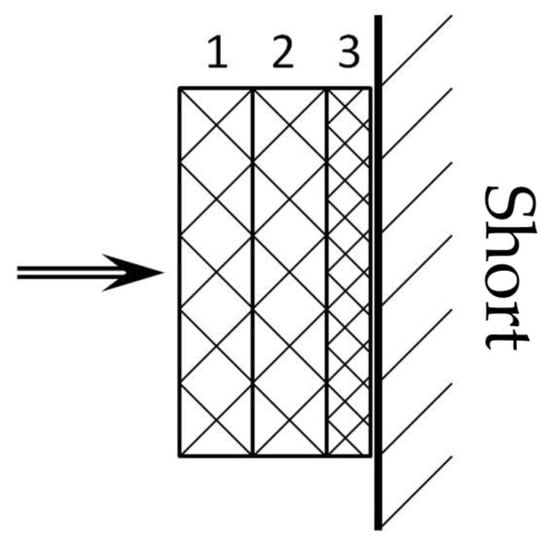

According to the structure of RAM, they are divided into (i) single-layer constant composition, (ii) gradient-type (multilayer materials with a stepwise change in electrodynamic characteristics from the front boundary to the rear), (iii) interference-type, (iv) geometrically inhomogeneous (for example, spike-like materials), and (v) combined, i.e., materials with a possible combination of gradient and interference structures.

Most of the existing interference-type RAMs depending on their structure can be divided into the following groups: (i) Salisbury screen based on an outer layer of a thin-layer conductive film located on a dielectric layer screened from the back side, (ii) Dallenbach screen based on absorbing layers placed on a conductive shielding substrate, and (iii) Jaumann screen based on multilayer alternating structures of dielectric and conductive layers [9,10]. As a rule, gradient-type RAMs have more broadband EMR absorption compared to similar single-layer absorbers [11]. A special case of such RAMs are materials with an unfilled input layer with respect to external electromagnetic effects (“soft input”). The values of dielectric permittivity ε of such a layer are as close as possible to ε of the external environment at magnetic permeability μ = 1. The subsequent layer or layers are distinguished by higher values of ε and μ that increase as one approach to the reflective substrate [12]. The thickness of the outer input layer is usually greater than the thicknesses of subsequent layers.

RAMs can be divided into materials of (i) magnetic-type, (ii) non-magnetic-type, and (iii) combined materials depending on the functional filler used. Materials of the magnetic type interact with the H-component of the electromagnetic field and have magnetic losses. Non-magnetic materials interact with the E-component of the electromagnetic field and have only dielectric losses. Combined-type materials contain both magnetic and non-magnetic conductive fillers.

RAMs classification can be carried out according to a number of other features technological, matrix composition, etc. Currently, smart coatings, including active (controlled) radio-absorbing structures, are becoming increasingly important [13]. The principle of operation of such structures is based on the use of external sensors that capture the effective EMR on the object and controlled layers designed to process and restructure the parameters of incoming signals in order to reduce them. In this connection, a new classification of RAM appears: (i) active and (ii) passive. Active RAMs are able to provide values of R of EMR from the boundary of the medium and free space, which is close to zero at any polarizations and angles of incidence [14]. Any elements capable of changing the electrodynamic parameters of the material, for example, frequency selective gratings with pin diodes, can be used as active structures for such RAMs and radio-absorbing coatings (RAC). The main preference is given to pin diodes due to their low weight and ease of control by changing the values of the applied external voltage [15].

At present, active RAMs are already used in the fifth-generation Japanese fighter X-2 [16]. Active RAMs and RACs are prone to self-excitation, i.e., generation of their own EMR, which is an unmasking factor. To match the intelligent sensors of active RAMs and RACs, in some cases, it is necessary to use passive radio engineering materials. These materials could be composites with functional fillers. In most cases, obtaining passive RAMs is characterized by ease of manufacture and lower economic costs compared to active structures. In this connection, the works aimed at creating and improving traditional (passive) RAMs do not lose their relevance.

The vast majority of traditional passive RAMs and RACs are composites based on matrices with low dielectric constants and functional fillers. Ceramic [17], polymeric [18], textile [19], mineral materials [20], etc., can be used as matrices.

2.2. RAM’s Matrixes and Fillers

The choice of matrix and filler is determined by the purpose and operating conditions of the RAM. The main disadvantages of RAMs based on magnetic fillers are high values of bulk density as well as a low operating temperature range. One of the common advantages of such materials is to achieve lower values of R of EMR in thinner layers compared to non-magnetic type materials as well as to reduce the contribution to backscattering associated with edge diffraction and surface waves.

In this connection, in most cases, magnetic-type composites are used as coatings. Ferrites and powders of ferromagnetic metals are among the most characteristic magnetic fillers used in the creation of RAMs [21]. To ensure a wider operating temperature range of RPM, as a rule, non-magnetic type fillers are used, which are various electrically conductive functional particles: carbon black, graphite, carbon-containing fibers, powders of diamagnetic metals and their compounds, carbon nanotubes (CNT), graphene, etc. [22]. The microwave and electrophysical properties of RAM depend on the composition, thickness, and number of layers as well as on the concentration of functional fillers. By varying these parameters, it is possible to give composite materials (CM) the necessary radio characteristics.

Soot-filled RAMs possess low values of bulk density; however, to achieve low values of R in the ranges of the microwave spectrum, thicknesses of more than 10 mm are required [23]. There are a large number of RAMs made using carbon fiber fillers. It is known that such fillers can be used both in materials for anechoic chambers [24] and for structural reinforced plastics [25,26].

2.3. RAM with Magnetic Fillers

Of greater interest are RAMs with high values of high-frequency dynamic magnetic permeability [27]. Such materials include CMs based on powders of ferromagnetic metals and hexagonal ferrites [28]. There is a known RAM based on nickel-zinc ferrite [29]. It provides efficient EMR absorption in the frequency range from 30 MHz to 1000 MHz. RAMs based on ferromagnetic metals; for example, metals of the iron triad (Fe, Ni, Co) as well as their various alloys and compounds have become widespread [30]. Carbonyl iron powders are of great interest for radio engineering applications and research [31]. For the antennas, developing the RACs based on an epoxy elastomer and carbonyl iron powder is used [32].

The shape and size of the functional filler has a significant impact on the radio-absorbing properties of the RAM [33]. A classic example of varying the electrodynamic properties of RAM based on carbon-containing fibers is a change not only in the concentration of the filler but also in its linear dimensions, for example, by cutting the fiber into lengths from tenths of mm to tens of mm [34].

It is known that powders of ferromagnetic metals and their compounds in the form of flakes and plates significantly increase the values of the dielectric and magnetic permeability of composites based on them compared with materials containing similar spherical ferromagnetic particles [35,36]. This is explained by the higher values of the average polarizability of composites with lamellar inclusions due to the small values of the form factors in the particle planes compared with composites containing spherical inclusions. As a rule, plates and flakes of ferromagnetic powders are produced by high-energy grinding in a closed-circuit bead mill in various organic media, for example, in ethanol and heptane [37]. Commercially available spherical ferromagnetic powders are usually used as the initial raw material for obtaining lamellar particles [38].

The disadvantage of RAM based on lamellar particles at their concentration above 40–50 vol. % is an increase in the values of the dielectric constant (more than a hundred).

The magnetic characteristics of powders of the LaxNd2−xFe17 (x = 0.0, 0.2, 0.4, 0.6) alloy of various morphologies and the electrodynamic properties of corresponding RAMs were studied. The shape changing of the powders was carried out by high-energy grinding. The obtained powders of the investigated flake-shaped alloys provided the R of EMR for RAM samples less than −10 dB in a wide frequency range at a thickness of 2 mm. It has been found that the minimum values of the R of EMR amounted to −32.5 dB at 9.8 GHz [39].

Among the known magnetic materials for microwave applications, a special place is occupied by ferromagnetic films and CMs (laminates). CMs (laminates) based on ferromagnetic and polymeric films have high magnetic losses in the LF region and have a bulk density not exceeding 2–3 g/cm3.

As a rule, obtaining a thin layer of a ferromagnetic metal or other material, such as hydrogenated carbon, is achieved using methods of ion-plasma magnetron sputtering on a substrate. The substrates can be polymer films, woven, non-woven materials, etc. The granular films of hydrogenated carbon with nanoparticles of ferromagnetic metals (Co, Ni) and corresponding RACs were developed [40]. The value of R of EMR for obtained RAMs did not exceed −10 dB in the frequency range from 7 to 70 GHz. RAMs were multilayer structures based on aramid fabric coated with films of hydrogenated carbon with different concentrations of ferromagnetic metals from layer to layer and, consequently, varying values of dielectric and magnetic permeability [40]. The films were deposited on the fabric surface by the method of ion-plasma magnetron sputtering. The RAM based on thin films of amorphous hydrogenated carbon with ferromagnetic nanoparticles deposited on a flexible substrate of aramid fabric by ion-plasma magnetron sputtering was developed [41]. According to the results obtained, such RAMs provide a high level of EMR absorption with R is in the range of −10 to −30 dB in the microwave frequency range. These materials are characterized by ultra-wideband.

A material that consists of two layers of polymer nanofibers bonded with a radio-transparent material is presented in [42]. A film of hydrogenated carbon with embedded ferromagnetic or ferrimagnetic particles is deposited on each layer of polymer nanofibers by vacuum sputtering. This material provides effective EMW absorption in the frequency range from 5 to 70 GHz at small thicknesses (no more than 2 mm). However, in real conditions, the application of such materials to the surface of a number of objects is an extremely difficult task due to low manufacturability and the need to create additional protective coatings and materials that can improve the physical, mechanical, and tribological properties, for example, erosion resistance. The RAMs described are also characterized by high cost. RAMs based on magnetic fibers have attracted the attention of many researchers. Micro wires can be referred to such magnetic materials [43]. The cores of micro wires are characterized by high values of magnetic permeability. The high value of the dynamic magnetic permeability of fibrous ferromagnetic materials is manifested in the direction along the axis of their fibers; however, the disadvantage is the high dielectric response, which exceeds the magnetic one.

Recently, RAMs based on nanosized fillers and powders with a nanosized crystalline structure have become increasingly important [44,45]. It is known that crystalline ferromagnetic powders have a large domain size, and therefore, the process of rotation of the magnetization vectors is hindered [46]. Such shortcomings are absent in nanocrystalline soft magnetic alloys with a set of α-Fe or α-(Fe,Si) nanocrystals in the superparamagnetic state and located in the residual amorphous matrix [47].

2.4. RAM with Nanocarbon Fillers

Nanosized electrically conductive fillers, for example, fullerenes, graphene [48], and CNTs [49], have a wide prospect for creating appropriate RAMs due to their small size and high electrical conductivity. The presence of thin fibrous inclusions in the composition of the CM makes a more significant contribution to the dielectric losses. Inclusions with large linear dimensions limit the technical applications, such RAMs. For example, sheet materials based on carbon fibers of millimeter size are characterized by anisotropy of the permittivity along and across the sheet plane. The clusters can appear in CNT-based RAMs. Its presence as well as their shape and geometric sizes, the value of their capacitances, and conductivities are affected by the frequency dispersion of the permittivity of the material and the expansion of the frequency range. It should be noted that the electrical resistance of contacts between particles and clusters can be much higher than the ohmic resistances inside the particles themselves. In some cases, this effect can make the main contribution to the electrodynamic properties of the material [50,51].

It is known RAMs based on BaFe12O19 (BHF) /MWCNTs/PANi nanocomposite [52]. As it was observed due to the presence of PANi, the absorption increased extraordinarily. The absorber exhibited a maximum reflection loss of −24.2 dB at 11.6 GHz.

The manufacturing method and properties of structural RAM based a polyurethane composition with CNTs deposited on walls of honeycomb plastics are described in [53]. By varying the content of CNTs in the compositions, the possibility of tuning the radio technical characteristics of the RAM was shown. The best characteristics on a single-layer composite were obtained at a CNT concentration of 5.6 wt. % (the minimum EC value of R was −24 dB at the resonant frequency of the operating frequency range of 2–18 GHz). With an increase in the number of layers of the functionalized honeycomb, a further decrease in the values of R was noted.

The methods for regulating the electromagnetic parameters of RAMs based on polyurethane with multiwalled CNTs introduced into its volume are described in [54]. The characteristics of both CNTs and composites were changed by modifying the CNT surface with ferromagnetic metal oxides of various concentrations.

In a number of cases, in order to achieve lower values of the R of EMR and expand the operating RPM range, groups of various functional fillers are used. These fillers are introduced as a mixture into the volume of matrices. Both mixtures of magnetic powders and non-magnetic particles in combination with magnetic inclusions can be used as such fillers [55,56,57].

It is known multilayered RAMs with varying values of parts of the magnetic and dielectric permittivity from layer to layer are made on the basis of ferrite and carbonyl iron powders [58,59,60]. Another example of the technical implementation of RAM based on groups of functional fillers is the material described in [61,62]. Here, to ensure the absorption of EMR in the sub-bands of the range from 2 to 60 GHz, powders of hexagonal barium and strontium ferrites were introduced in combination with ultrafine powders of spinel ferrites and iron carbide.

A material based on latexes with functional fillers as combinations of fullerenes with powders of carbonyl iron and ferrites is described in [63]. The resulting composite ensures efficient absorption of the incident EMR energy in the frequency range from 2 to 20 GHz. The aim to broadening the operating frequency range of the RAM is solved through the use of groups and mixtures of various functional fillers. It was shown that at CNTs combining with nanosized magnesium-zinc ferrite powders (Mn1−xZnxFe2O4 (x = 0.0 и 1.0)) the value of the R of EMR obtained in the frequency range from 8 to 12 GHz did not exceed −10 dB [64]. The RAMs based on CNTs and magnetite nanoparticles, providing the values of the R of EMR of no more than −15 dB in the frequency range from 10.2 to 18 GHz and with a thickness of no more than 3.0 mm, is described in [65].

The RAMs based on nanostructured graphene oxide and magnetite powder with various concentrations are presented in [66]. It was found that the joint introduction of the investigated functional fillers allow to control the values of the dielectric and magnetic permeability in the microwave range. For samples containing a mixture of magnetite powder and graphene oxide (at a concentration of up to 3 wt. %), lower values of the R of EMR in the frequency range from 2 to 18 GHz are provided compared with RAM samples based on magnetite powder alone. With a sample thickness of 1.7 mm, the values of the R of EMR were no more than −10 dB in the studied frequency region.

It is necessary to note that the choice of matrix material during RAM design is very important due to the need to ensure the required performance depending on the application. It is also necessary to take into account manufacturability and economic indicators.

Currently, there are promising works aimed at creating structural RAMs for various purposes [67,68]. Reinforced composites are known, which are fiberglass based on an epoxy binder containing resistive carbon fibers [69]. Another example of the implementation of a structural RAM is a laminated composite consisting of layers of fiberglass in combination with a lamellar porous structure [70]. Modern methods for modeling and obtaining structural RAMs, including those with a gradient structure, are 3D-printing technologies [8,71]. It should be noted that materials with a large number of air-filled cavities and cells in its volume have lower values of dielectric permittivity compared to similar close-packed matrices. Classical examples are porous-cellular (foam plastics [72,73], spheroplastics [74]), and porous-fibrous (non-woven fabrics [75,76] and mats [77]) materials.

A lightweight covering RAM based on polyacrylonitrile fibers and nickel with cobalt materials introduced into its volume and applied to its surface at the manufacturing stage is described in [78]. According to the authors’ results, the described RPM provides values of the R of EMR that do not exceed −20 dB in the operating frequency range.

2.5. RAM Based on Elastomers

A method for synthesizing a functionalized nickel–carbon porous material where the formation of Ni and carbon nanoparticles occurred simultaneously at the material formation stage is presented in [79]. The density of the obtained RAM was 0.1 g/cm3, the value of the R of EMR at a thickness of 2 mm at a frequency of 4.5 GHz was no more than −10 dB, and at a frequency of 13.3 GHz, it was −45 dB.

Increasing the operating temperature range of CM greatly expands the possibilities of their application. Organosilicon materials are among the most heat-resistant (workable up to 300–400 °C) polymer binders and compositions, including those resistant to UV radiation and water. These elastomers are widely used in the creation of RAMs with such fillers as iron nanoparticles, pyrite ash, and carbonil iron particles [80,81,82].

Taking into account the wide range of RAMs and functional fillers of various types, there are a large number of methods for their production and technologies for their manufacture. Questions on the development of promising technologies for the manufacture of RAMs with improved properties still do not lose their relevance.

The following most common manufacturing methods depending on the matrices used in composites can be distinguished. Sintering technologies of raw materials at various temperatures and holding times are usually used to create RAMs based on ceramic matrices [83,84]. For RAMs based on textile and fibrous structures, impregnation methods and needle-punched fabrication methods are used [85,86].

There are a large number ways to produce the RAMs based on polymer matrices. An important role in the choice of processing technology is played the chemical composition, rheology, thermal properties of the binder, the type of curing used, and the composition and concentration of the filling. For RAM based on thermoplastic matrices, the following processing methods are widely used: (i) molding under pressure in a press or autoclave [87], (ii) extrusion methods [88], and (iii) additive technologies [89,90]. Such methods as pouring compositions [91], pressing [92,93] and autoclave molding [94], paint and varnish application methods [95,96], technologies for manufacturing porous structures [97], and impregnation technologies [98,99] are used for production the RAMs based on fiber-reinforced polymer composites. In some cases, to expand the operating radio frequency range and ensure a set of requirements for performance characteristics (physical, mechanical, thermal, resistance to external factors, etc.), RAMs based on combinations of different materials manufactured according to their technology are used [100].

3. Composite Materials Based on Filled Polymers

The term “composite materials” or “composites” appeared when a most capacious name was required for a new class of materials consisting of a reinforcing component and a binder. Composite materials were also called reinforced or filled with plastics (plastic masses). Currently, the term “filled polymers” is widely used to refer to heterophase composite materials with a continuous polymer phase (matrix). In such matrices, solid, liquid, or gaseous fillers are distributed randomly or in a certain order. These substances fill part of the volume of the matrix while either reducing the consumption of scarce or expensive raw materials, or the composition is modified, obtaining the desired qualities corresponding to the purpose, technological features of production and processing, as well as the operating conditions of the products. Filled polymers are the vast majority of plastics, rubbers, paints and varnishes, polymer compounds, adhesives, and other polymer composite materials [101]. Depending on the type of polymer matrix, filled thermoplastics, thermoplastics, and rubbers are distinguished. The most common binders are: polyesters, phenols, epoxy compounds, silicones, alkyds, melamines, polyamides, polyimides, fluorocarbons, polycarbonate, acrylics, acetals, polypropylene, acrylonitrile butadiene styrene copolymer (ABS), polyethylene, and polystyrene. Fillers can be incorporated into plastics to modify the properties of thermoplastics or thermosets. The modern industry of composite materials widely varies different combinations of reinforcing components and binders. The choice of the appropriate components is determined both by technical parameters and by price. Most of the properties of the filled polymers turn out to be higher than the properties of the original components. A material whose structural purpose is the same as one of its components may also be referred to as a composite. Such materials are, for example, products covered with a polyvinyl film used in aircraft, laminated metal-plastic facings, etc. [102]. The range and applications of the filled polymers are constantly expanding.

The composites are divided into particulate-filled plastics that based on dispersed particles of various shapes, including crushed fiber, reinforced plastics that consist of reinforcing filler with a continuous fibrous structure, gas-filled plastics, and oil-filled rubbers. This dividing is independent on the filler type.

As the fillers’ various fibers, powders, microspheres, crystals and whiskers from organic, inorganic, metallic materials, or ceramics can be used. Most often, solid fillers are used to obtain filled polymers finely dispersed with particles of granular (carbon black, wood flour, SiO2, chalk, etc.) or lamellar (talc, mica, graphite, kaolin, etc.) forms as well as various fibrous materials in the form of threads, strands, bundles, canvases, mats, fabrics, paper, and nets.

Besides using dispersed fillers and chopped fiber, the main production method is mechanical mixing of the filler with a melt or solution of a polymer, prepolymer, oligomer, or monomer. For this purpose, mixers of various designs and rollers are used. Continuous fibrous preforms are impregnated with a polymeric binder. The various methods of modifying the surface of the fillers as well as the method of polymerization on fillers are used to improve the impregnation of fibrous fillers with a binder, to increase the degree of dispersion of filler particles in the matrix, and to increase the strength of the adhesive contact at the filler–matrix interface. Gas-filled materials are obtained by foaming with the help of special agents (porogens) or by mechanical foaming of liquid compositions, such as latexes. The foamy structure of the polymeric material is fixed by cooling the composition below the glass transition temperature of the polymer, curing, or vulcanization. Liquid fillers are mechanically emulsified in a binder. The subsequent transformation of it into a filled polymer matrix occurs without destroying the original emulsion structure.

The properties of composite materials are determined by the properties of the polymer matrix and filler, their ratio, the nature of the filler distribution in the matrix, and the nature of the interaction at the polymer–filler interface. By improving any characteristic of the composition, the filler can simultaneously worsen its other properties. For example, most types of carbon black increase not only strength but also the elastic modulus (hardness) of rubber and the latter is undesirable in many cases. Therefore, in each specific case, during selection of the type, concentration, and method of surface modification of the filler, it is necessary to carefully balance the effects caused by the presence of the filler and matrix in the composite.

Composite materials based on filled polymers are widely used for the development of radio engineering materials. The composites are based on dielectric carbon-chain polymers obtained by polymerization (polystyrene, polyethylene, polyvinyl chloride, polytetrafluoroethylene) or polycondensation (resole, novolac and epoxy resins, lavsan, polyimides) methods. The most popular polymer-based composites used in electrical and radio engineering are layered plastics, gas-filled plastics, and magneto-dielectrics [49,103,104,105,106,107,108,109,110,111,112,113].

Various methods can be used to synthesize composites based on filled polymers. It could be mechanical mixing of components with subsequent processing into finished products, treatment of polymer films with metal vapors, chemical reactions of metal salts in polymer solutions with subsequent isolation of the corresponding polymer, polymerization of metal-containing monomer systems, etc. [114,115,116,117,118,119].

The development of nanotechnology opens up new approaches to the creation of radio engineering materials, including materials for ensuring electromagnetic compatibility. The task of nanotechnology is to develop economically and environmentally efficient technologies for obtaining new practically important nanostructured materials and highly dispersed systems, films and coatings, functional nanostructures, and elements of nanoelectronic devices that are promising for practical applications in various fields from information and telecommunication systems, nanomechanics, nanoelectronics, optoelectronics, and catalytic systems to bionanotechnology and nanomedicine.

The creation of nanomaterials is the most promising for a number of reasons. First of all, this is due to the recently opened possibilities of an infinite variety of sizes, shapes, compositions, and structures of nanoparticles that affect the unique physicochemical properties of nanocomposites obtained by “chemical” (solution) methods. This, in turn, makes it possible to predetermine and vary the physical properties of nanoparticles before using them as “building blocks” to create nanomaterials.

Particles with sizes less than 10 nm fundamentally differ in their physicochemical properties from macro-objects since the surface/volume ratio sharply increases with decreasing particle size. In highly dispersed and highly porous materials, the surface area increases significantly, and consequently, the chemical reactivity of such objects increases, too. In addition, in bulk materials, a decrease in the size of crystallites leads to an increase its mechanical characteristics. More important is that quantum mechanical effects begin to appear in the behavior of nano-objects. This is attributed with the fact that electrons cannot be in continuous energy bands in nanoparticles, but they occupy only a few narrow energy levels, the structure of which is determined by the particle size. Such a limitation drastically changes the mechanism of the electrical conductivity of nanomaterials since the conductivity becomes a quantized quantity; i.e., it begins to depend on the level population that varies discretely itself. At the smallest change in the particle size, the collective motion of electrons along the ballistic mode begins. This movement occurs almost without scattering and is characterized by low ohmic losses and high potential, resulting in very high current densities and switching speeds in devices. Electronic energy levels determine the optical and magnetic properties of substance. The changing the particle size makes it possible to control absorption in a wide range of wavelengths. An important aspect of the problem under consideration is also the existence of collective excitations of the states of surface plasmons. All of these effects play an important role in the absorption of electromagnetic energy inside composites.

Stabilization of metal-containing nanoparticles by polymer matrices makes it possible to create composite materials with unique electrical and operational properties [104,120,121,122,123,124,125,126,127,128,129,130]. The development of the science of materials based on metal-containing nanoparticles, including matrix-stabilized polymers, is stimulated by the ever-growing interest in this problem in many areas of chemistry, physics, and materials science. The possibility of combining the properties of a polymer and a metal in one material as well as the regulation of these properties by means of concentration changes has been discussed for a long time. It is known that most metal-containing nanoparticles are thermodynamically unstable. Various polymers can be used to stabilize them, such as polyethylene, polypropylene, polytetrafluoroethylene, and others. These polymers have a relatively high thermal stability, unique rheological properties, and high dielectric strength. They are chemically inert and technologically advanced, which makes it possible to manufacture products of the required shape and size. It is also important that the methods for obtaining these polymers are well-developed.

For the most part, polymeric materials are good dielectrics with stable physical and chemical properties. The chemical stability of polymers allows their use under hard conditions; however, the main application of polymers is as insulating materials. It should be noted that the mechanical properties of polymers can be changed by modifying them with various inorganic fillers. The modification of polymers with specific dielectric properties by carbon nanotubes and metal-containing fillers leads to the creation of composites with increased electrical conductivity compared to the original polymer matrix. The electrical properties of composites depend on the composition, shape, size, and concentration of the filler [120,123].

Various methods are used for the synthesis of metal-polymer composites, such as treatment of polymer films with metal vapors, chemical reactions of metal salts in polymer solutions with subsequent isolation of the corresponding polymer, polymerization of various metal-containing monomer systems, etc. Along with this, the introduction of inorganic fillers into polymers makes it possible to create materials that are characterized by properties of both filler and matrix.

High-pressure polyethylene (HPPE) is most suitable for use as a dielectric matrix for the development of composite materials. The reasons are as follows: the cost of HPPE is not high, the production technology is well-developed, it easy to mix with organic and inorganic fillers, and it belongs to thermoplastic polymers that makes it possible to manufacture products of the required shape and size under mild conditions. All of the above properties of polyethylene have contributed to its intensive use in the electrical industry.

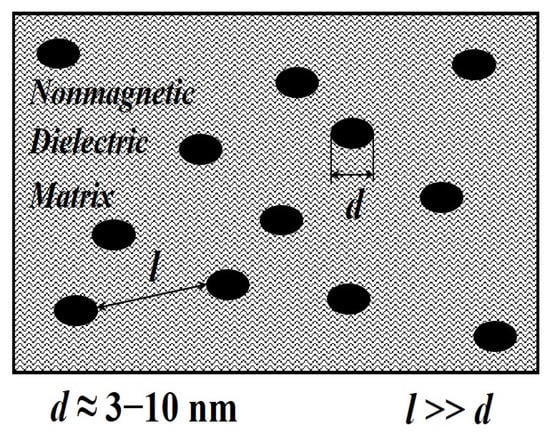

One of the most promising methods of stabilization is the stabilization of nanoparticles in the solid phase, i.e., the introduction of nanoparticles into matrices of various types. This method is indispensable for obtaining materials whose properties must remain unchanged for a long time. For example, the stabilization of nanosized particles in matrices can find wide application in the production of magnetic materials that can be used as potential devices for recording and storing information or radio-absorbing materials. The general scheme for stabilizing nanoparticles in the volume of stabilizing matrices is shown in Figure 2.

Figure 2.

Scheme of nanoparticles stabilization inside a matrix stabilizer.

The method of stabilization of nanoparticles with organic polymer matrices was historically the first method for creating nanomaterials [130,131]. Information about the stabilization of metal nanoparticles by various polymer matrices and the approaches used in this case are described in detail in monograph [132]. Note that this method of stabilization is the most developed, and the widespread use of polymeric materials is due to the existence of natural voids in them with sizes necessary for the incorporation and stabilization of nanoparticles of various compositions [133,134].

There are two fundamentally different ways to stabilize nanoparticles using polymer matrices. According to the first method, a polymer suspension or melt is added to the finished dispersion of particles [132]. The second approach is to prepare the dispersion in a polymer medium. The resulting materials differ not only in the most uniform distribution of metal particles in the volume of the polymer but also in the strength of the chemical interaction between the metal-containing nanoparticle and the polymer.

4. Electrical and Magnetic Properties of Composite Materials

Of all the variety of physical properties, the most important ones characterizing a substance as a dielectric are electrical properties. These include polarization, electrical conductivity, permittivity, and polarizability of the dielectric. The classification of dielectric substances is based on their most important properties for practice and related functional purposes. Among these substances, there are, for example, piezo- and ferroelectrics, pyroelectrics, electrets, and magneto-dielectrics [135,136].

This section describes the methods used in the study of the electrophysical and magnetic properties of RAM materials and also presents the results of the research:

- Specific volumetric resistance;

- Dielectric permittivity in the low-frequency range and in the microwave range;

- Demagnetization curves by the vibromagnetometer method;

- Magnetization curves by the Faraday’s method.

4.1. Specific Volume Resistance of Composite Materials

4.1.1. Measurement Methodology

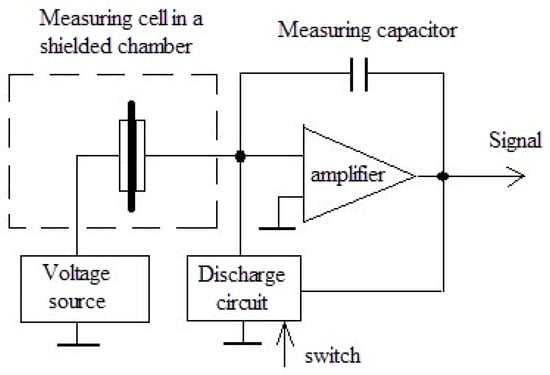

Measurement of the specific volume resistance ρv of synthesized composites was performed by the voltmeter-ammeter method [129,137]. The essence of the method is to measure the currents passing through the sample when a constant electric voltage is applied to it. In this work, the ρv measurements of composite materials were carried out according to the two-electrode scheme shown in Figure 3.

Figure 3.

Scheme of a circuit for resistivity measurement. Adapted from [129] with permission.

The measuring cell is a clamping device with polished brass electrodes with a diameter of 10, 15, 20, and 25 mm and a thickness of 1 mm. The electrodes are isolated from a clamping device by polytetrafluoroethylene insulators. The diameter of the electrode was selected in accordance with the size of the sample in such a way that the possible surface conductivity ρv was lower than the measured volume.

The samples under study were disks with a diameter of 20–30 mm and a thickness of 1–3 mm. They had no cracks, dents, chips, burrs, dirt, or scratches visible to the naked eye, and the planes of the samples were parallel. The thickness of the tested samples L was determined as the arithmetic mean of measurements at five points evenly spaced over the surface in the intended area of the measuring electrode. The measurements were carried out with a micrometer with an accuracy of 0.01 mm.

The measurement of the resistance R of the measuring cell with the sample placed in it was carried out using an electrometric voltmeter, which has a source of measuring voltages in its composition. The cell was placed in a shielded measuring chamber included in the voltmeter kit. The device allowed measuring resistances in the range of 103–1018 Ohms at values of measuring voltages 0.1–1000 V.

The measurement process consisted in automatic recording of the readings of the electrometric voltmeter for 20 min with an interval of 1 min. The specific volume resistance of the sample ρv (Ohm × m) was calculated by means:

where R is the resistance of the sample 20 min after starting measurements (Ohm); S is the surface area of the sample covered by the electrode (m2); L is the thickness of the sample (m).

ρv = R × S/L

4.1.2. Experimental Data

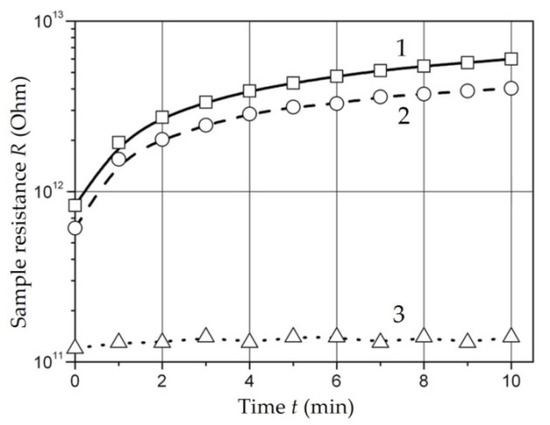

Figure 4 shows a typical view of the dependence of the resistance on the exposure time under stress for a sample Fe-03 with an iron concentration of CFe = 20 wt. % synthesized from iron (III) formate [129].

Figure 4.

Dependence of the sample Fe-03 resistance on time at various operating voltages: 1—10 V; 2—100 V; 3—1000 V. Adapted from [129] with permission.

Such dependence of the resistance on the exposure time under voltage is characteristic of polymer dielectrics with ionic electrical conductivity. An increase in the resistance over time can be caused by such reasons as dipole polarization, polarization of the displacement of ions in the sample volume (macro-displacement of ions), and electrical cleaning, which is a decrease in the content of conduction ions in the sample as a result of electrolysis.

Iron- and Cobalt-Containing Nanocomposites [129,138,139,140]. The results of measuring the ρV of composite materials based on Fe- and Co-containing nanoparticles are shown in Table 1 [129].

Table 1.

Results of measurement of ρv composite materials based on Fe- and Co-containing nanoparticles.

The order of magnitude and the nature of the time dependences of ρV allows us to conclude that the electrical conductivity of samples is mainly due to the same mechanisms of ionic and hopping as the electrical conductivity of unfilled polyethylene. The difference between the ρv values of unfilled polyethylene and standard values (1016–1018 Ohm × m) may be due to the increased content of impurities as a result of technological processing.

The resistivity of samples with a filling of 5 and 10 wt. % (samples Fe-01 and Fe-02) as well as that of unfilled polyethylene weakly depends on the magnitude of the applied field and decreases linearly over the entire range of operating voltages with an increase in the content of nanoparticles.

With an increase in the content of nanoparticles up to 20 wt. % dependence of the specific volume resistance on the applied voltage becomes more pronounced. Thus, in the samples Fe-04 and Co-01, the specific volume resistance decreases three times and in the sample Fe-03 by more than an order of magnitude, with an increase in the applied voltage from 100 to 1000 V.

A decrease in the specific volume resistance of samples when nanoparticles are introduced into the polymer matrix may be the result of a change in the structure of polyethylene towards an increase in amorphousness and porosity, which leads to an increase in molecular mobility and a decrease in the dissociation energy of ions in the polymer. An additional contribution to the conduction current can be made by polarization phenomena caused by the polarizability of nanoparticles: polarization of macro-displacement (within the sample) and micro-displacement (within some areas) as well as slow-forming dipole polarization.

The presence of a tunneling mechanism of electrical conductivity in composites based on metal-containing nanoparticles in a polymer matrix is substantiated [141,142,143]. The presence of this type of electrical conductivity in the material can be determined by the type of current-voltage characteristic (CVC) of the sample. When implementing the tunnel mechanism, the VAC has the form [144]:

where J is the current density, V is the voltage, and A and B are the constants.

J = A × V2 × exp(−B/V)

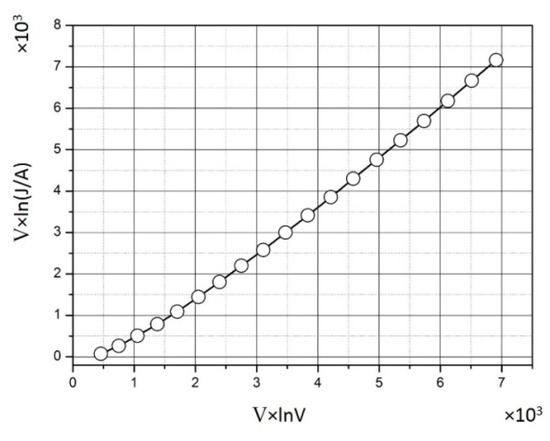

The CVC should have the form of a straight line in Fowler–Nordheim coordinates (V × ln(J/A); V × lnV). The sample Fe-03 synthesized from Fe(HCOO)3 with CFe = 20 mass.% is characterized by the lowest value of ρV among the studied samples. For this sample, CVC at a voltage of 100–1000 V was constructed (Figure 5) [129].

Figure 5.

Current-voltage characteristic of a metal polymer based on a polyethylene matrix with iron nanoparticles (about 20 wt. %).

According to the type of the obtained CVC, it can be concluded that a tunneling mechanism of electrical conductivity is implemented in the sample Fe-03, which contributes to the conduction current.

The electrical conductivity of the filled HPPE is affected in a complex way by both the composition and the average size of the nanoparticles dav. This is well-illustrated by the lower ρv of the sample Fe-03 (dav ≈ 11.5 nm) at a voltage of 1000 V compared with the ρv of the sample Fe-04 (dav ≈ 2.4 nm).

The block samples of composites based on iron- and cobalt-containing nanoparticles were obtained by thermal decomposition of formates with CFe= CCo = 30 wt. % [139]. These samples are characterized by a relatively large particle size (dcp ≈ 8 nm), the presence of a pronounced metallic core, and low values of specific volume resistance (ρv ≈ 102 Ohm × m). Such values of electrical conductivity are characteristic of materials having a granular structure with poor contact between granules having their own electronic conductivity, which can also occur in polyethylene containing Fe and Co nanoparticles with a relatively high concentration of metal. The mechanism of electrical conductivity can also be tunnel-like. Such materials, as will be found below, attenuate (shield) the microwave radiation well and, due to the tunneling mechanism of electrical conductivity, can also be used as nonlinear elements of the microwave range [145].

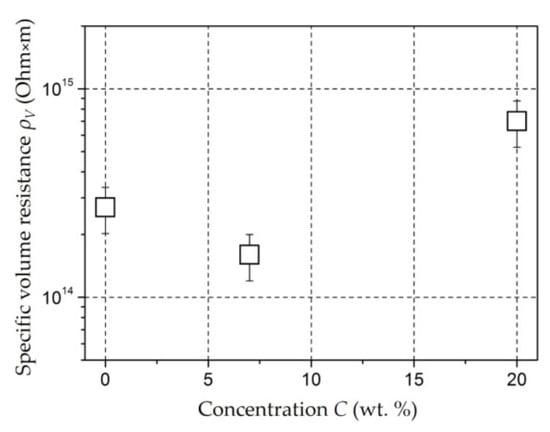

Molybdenum-Containing Nanocomposites [146,147]. The specific volume resistance ρv of a composite nanomaterial based on polyethylene containing molybdenum nanoparticles is comparable in order of magnitude (1014 Ohm × m) with the value for unfilled polyethylene that has undergone reaction treatment (Figure 6).

Figure 6.

Dependence of resistivity on molybdenum particle concentration CMo in a polyethylene matrix.

This means that no additional electrical conductivity mechanisms arise within the obtained concentrations of the CMo filler. Since ionic electrical conductivity is the main mechanism for polyethylene, an increase in the resistivity can be caused by an increase in the dissociation energy of ions under the influence of molybdenum nanoparticles.

Lead-Containing Nanocomposites [148,149,150]. Table 2 presents the results of measurements of specific volume resistance ρv composite materials based on Pb-containing nanoparticles.

Table 2.

Results of measurement of ρv composite materials based on Pb-containing nanoparticles (author’s results).

The ρv values of lead-containing nanocomposites in order of magnitude (1014 Ohm × m) coincide with the ρv of unfilled HPPE that has undergone reaction treatment. Lead-containing nanocomposites in the order of magnitude (1014 Ohm × m) coincide with the ρv of unfilled HPPE that has undergone reaction treatment. A slight increase in ρv compared to an unfilled matrix may be caused by a decrease in the mobility of charge carriers (molecular ions) when nanoparticles are introduced into the HPPE matrix. In the studied range of filler concentrations, the composite retains the properties of polyethylene as a good dielectric [142].

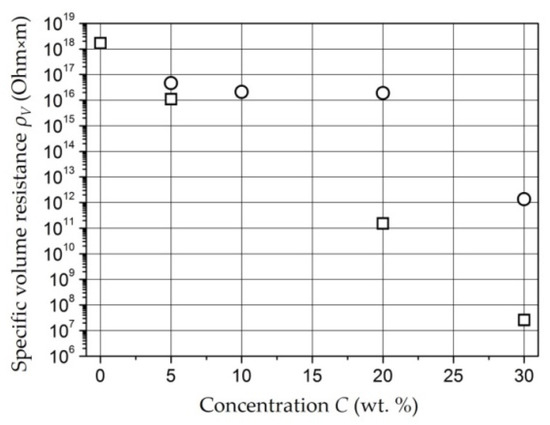

Composites with NiFe2O4 Nanoparticles [151,152,153]. With concentration increases, the ρv of the samples decrease, but up to a concentration of 20 wt. %, it remains comparable with the ρv of unfilled polyethylene (1014–1016 Ohm × m) (Figure 7) [151]. A noticeable decrease in ρv (1012 Ohm × m) is observed at concentration of 30 wt. % for a tablet 1.5 mm thick (circles in Figure 7). In a film sample 0.25 mm thick (squares in Figure 7) with concentration of 30 wt. %, an even more noticeable level of conductivity is achieved: 3 × 107 Ohm × m.

Figure 7.

Dependence of resistivity on concentration of NiFe2O4 nanoparticles for tablets 0.25 mm thick (squares) and 1.5 mm thick (circles) [151].

The dependence of ρv composites based on Fe- and Co-containing nanoparticles as well as NiFe2O4 nanoparticles on the concentration of the metal-containing component is percolation [141,154]. Figure 7 shows that a significant decrease in the resistance of the material occurs at concentrations of 20–30 wt. %.

Rhenium-Containing Nanocomposites [124,155,156]. The specific volume resistance of the samples Re-02–Re-05 in order of magnitude (1013 Ohm × m) corresponds to unfilled polyethylene. The exception is the sample Re-01, whose specific volume resistance is an order of magnitude lower (1012 Ohm × m). This may be a consequence of a higher proportion of components with a low degree of oxidation in rhenium-containing nanoparticles of this sample as well as additional injection of electrons from nanoparticles under the influence of applied voltage (taking into account the fact that the size of Re-containing nanoparticles in composites is relatively large at 15 nm) [155].

The studies performed with samples of polymeric composites based on Bi, CeO2, and CdS nanoparticles have shown that such composites also retain high values of specific volume resistance for all synthesized concentrations [157,158,159].

4.2. Dielectric Permittivity of Composite Materials at Low Frequencies

4.2.1. Measurement Methodology

The determination of the relative permittivity ε is based on the dependence of the capacitance of a flat capacitor Cε on the permittivity of the material filling the space between the electrodes:

where S is the area of the electrodes of a flat capacitor, d is the distance between the electrodes (working gap), ε is the relative permittivity of the material filling the working gap of the capacitor, and εo is the vacuum electrical constant.

Cε = ε × εo × S/d

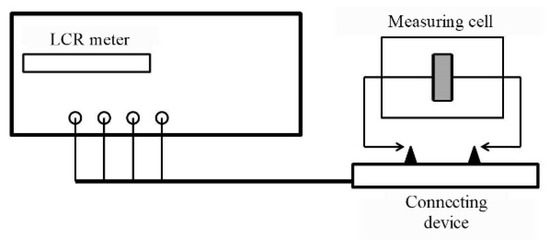

The measuring cell, a clamping device with polished brass electrodes with a diameter of 10, 15, 20, and 25 mm and a thickness of 1 mm, is a flat capacitor. The measurement of the cell capacity and the tangent of the loss angle (active conductivity) was performed by the bridge method using digital LCR meters E7–8 and E7–12 with operating frequencies fop = 1 kHz and fop = 1 MHz, respectively. The measurement error of the capacitance of about 10 pF is 0.3% for both devices. A two-electrode circuit with round electrodes of different diameters was used at the measurements. The block diagram of the measuring unit is shown in Figure 8.

Figure 8.

Scheme of the setup for permittivity ε measurement.

In according with the measured capacity of the sample cell:

where Cx is measured capacitance, Cp is correction consisting of the sum of the parasitic capacitance and the lateral capacitance of the measuring capacitor, and the geometric capacitance of a flat capacitor Cε filled with the material under study was calculated.

Cx = Cε + Cp,

The correction Cp was preliminarily calculated from the measured values of the capacitance of the measuring capacitor with air filling or by formulas that take into account the geometry of the measuring capacitor [160].

The value of the dielectric constant ε is calculated by the formula:

where d, Cp, Cx, and S= πd2/4 are the measured values.

ε = Cε × d/(ε0 × S) = (Cx− Cp) × d/(ε0 × S),

The tangent of the loss angle of the material under study is calculated by the formula:

where tanh(δx) = Gx/(ω × Cx) is the measured value of the tangent of the loss angle of the measuring capacitor.

The samples under study are similar to those described in Section 4.1 of this work.

The dielectric permittivity of various samples of composite materials based on metal-containing nanoparticles stabilized in a HPPE matrix was measured using the above method. The results of these measurements and their interpretation are presented below.

4.2.2. Experimental Data

Iron- and Cobalt-Containing Nanocomposites [129,138,139,140]. The results of the dielectric permittivity measurement are presented in Table 3 [129]. The samples based on cobalt-containing particles with CCo = 30 wt. % were synthesized from cobalt formate, and the samples were pressed at different temperatures: Co-02 at 230 °C and Co-03 at 280 °C.

Table 3.

Measurement results for composite nanomaterials.

The monotonic increase in ε with increasing CFe is due to the contribution to the total polarization of the polarization of Fe- and Co-containing nanoparticles, whose polarizability is higher than the polarizability of the matrix due to the higher mobility of the electron shells. The difference in the values of the dielectric permittivity of the Fe-03 and Fe-04 samples with the same concentration of iron-containing nanoparticles is associated with a higher susceptibility of large nanoparticles. The high dielectric permittivity of the Co-02 and Co-03 samples may be associated with a percolation transition in a granular nanocomposite [142].

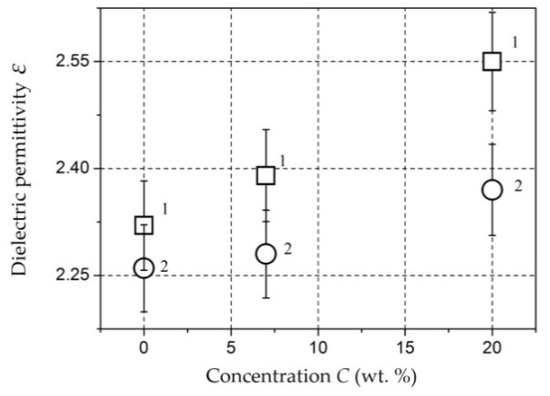

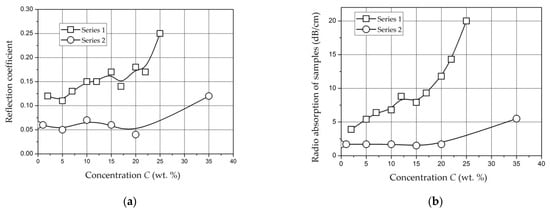

Molybdenum-Containing Nanocomposites [146,147]. The results of measuring the permittivity of composite materials based on Mo-containing nanoparticles are shown in Figure 9 [146]. The monotonous increase in the permittivity ε is caused by an increase in the contribution of the polarization of nanoparticles to the total polarization of the composite with an increase in the mass fraction of the filler [146]. However, for molybdenum-containing composite materials, an increase in the dielectric constant relative to unfilled polyethylene at C up to 20 wt. % is insignificant.

Figure 9.

The dependence of the permittivity ε of composite nanomaterial on the mass concentration of Mo in HPPE: 1, at a frequency of 1 kHz; 2, at a frequency of 1 MHz. Adapted from [146] with permission.

Lead-Containing Nanocomposites [148,149,150]. The results of the measurements of ε of Pb-containing composites at frequencies of 1 kHz and 1 MHz are presented in Table 4 [150].

Table 4.

Results of measurements of ε Pb-containing composites at frequencies of 1 kHz and 1 MHz.

The nonmonotonic behavior of the dielectric permittivity with an increase in the mass content of nanoparticles looks unexpected. The contribution from the polarization of nanoparticles usually leads to an increase in ε [129]. The weak polarizability of lead-containing nanoparticles may be related to the peculiarities of their phase state (liquid–solid) and requires additional study [150].

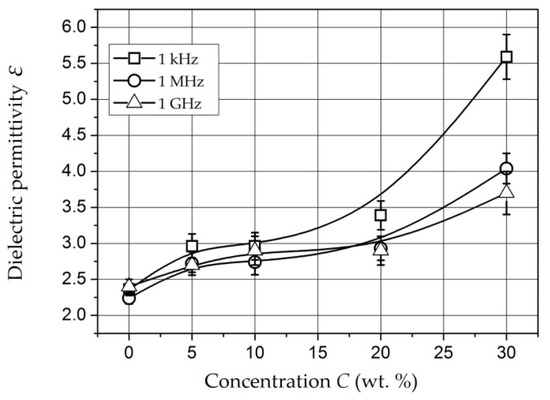

Composites with NiFe2O4 nanoparticles [151,152,153]. The dependencies of dielectric permittivity of samples on NiFe2O4 nanoparticlesare presented in Figure 10.

Figure 10.

Dependence of dielectric permittivity ε on concentration of NiFe2O4 nanoparticlesat a frequency of 1 kHz (squares), 1 MHz (circles), and 1 GHz (triangles) [151].

The samples under study were tablets of 1.5 mm thick. The dependencies were measured at a frequency of 1 kHz (squares), 1 MHz (circles), and 1 GHz (triangles). It can be seen that permittivity increases with increasing concentration and, changes relatively weakly at C = 5–20 wt. % (ε = 2.7–3.4). At C = 30 wt. %, it reaches values of 5.6 (for 1 kHz) and 4 (for 1 MHz). This dependence of ε(C) may also indicate the presence of a percolation transition in composites based on NiFe2O4 nanoparticles in the concentration range of 20–30 wt. % [151].

Rhenium-Containing Nanocomposites [124,155,156]. The results of measuring the dielectric permittivity of Re-containing composites are presented in Table 5 [124].

Table 5.

Results of measurements of ε of rhenium-containing composites at frequencies of 1 kHz and 1 MHz.

The difference between the ε of composites with Re-containing nanoparticles from the corresponding values for unfilled polyethylene that has undergone reaction treatment may be caused by differences in the component composition of nanoparticles. A higher content of rhenium compounds with a low degree of oxidation (Re, ReO2, ReO3) leads to higher mobility of electron shells and polarizability of nanoparticles. The consequence of this is higher values of ε for samples Re-01 and Re-04. Conversely, the predominance of compounds with a high degree of oxidation (Re2O7) does not give a noticeable additional contribution to the polarization of the composite and dielectric losses. Therefore, the values of ε for the Re-02 sample differ slightly from the ε of unfilled polyethylene [155,156].

4.3. Investigation of the Properties of Composite Materials Using a Measuring Line

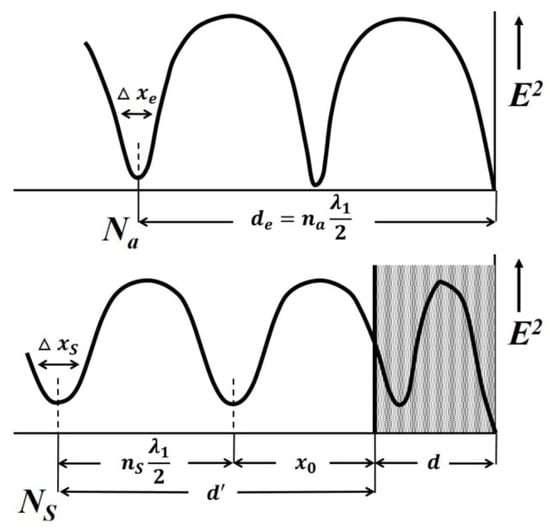

The dielectric permittivity measurement by means of the closed-loop line method is based on observing the pattern of standing waves in the waveguide path containing the sample under study (Figure 11).

Figure 11.

Standing waves in a short-circuited waveguide (upper) and in a short-circuited waveguide with a sample located in it (lower). Adapted from [129] with permission.

This method is most common when measuring the dielectric properties of materials since, in comparison with other methods in many practical cases it turns out to be relatively simpler and more universal in terms of the technique of preparing and conducting the experiment. Its disadvantage should include more cumbersome calculations to obtain the final results. The test sample of the material is placed in a segment of a rectangular waveguide attached to the measuring line. The sample must completely fill the section of the waveguide and fit snugly to the short-circuiting flange. In principle, the length of the sample can be arbitrary [160].

The measurements were carried out in the frequency band 20–53 GHz. This range was overlapped by three bands. For each band, special standard measuring equipment is used (Table 6) [129].

Table 6.

Characteristics of measurement ranges.

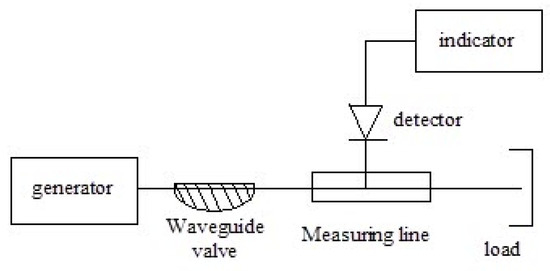

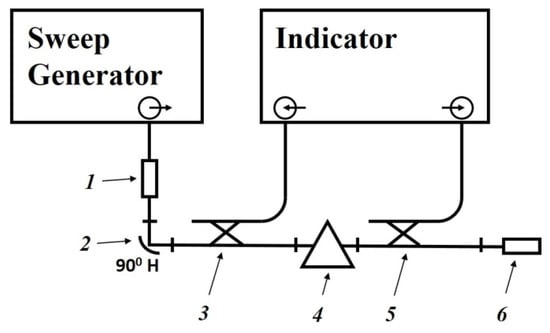

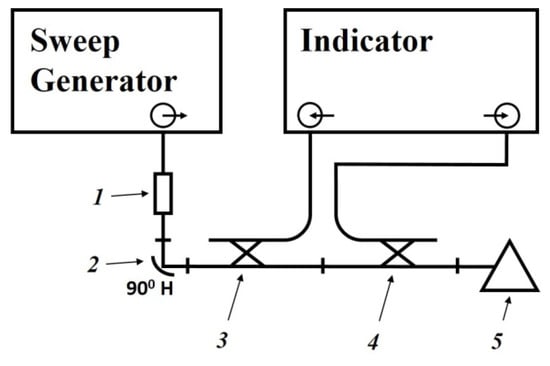

The scheme of the setup used is shown in Figure 12. The generator signal is modulated by a 1 kHz meander and, after quadratic detection enters the input of a selective microvoltmeter B6–9. The output of it is connected with a digital voltmeter, B7–38. The measuring line has a precise movement mechanism that allows one to determine the position of the probe with an error of 0.01 mm.

Figure 12.

Scheme of the setup for the study of dielectrics in the microwave range using a measuring line. Adapted from [129] with permission.

The measurement principle is based on determining the reflection coefficient (or impedance) at the input of a short-circuited line segment filled with the sample under study.

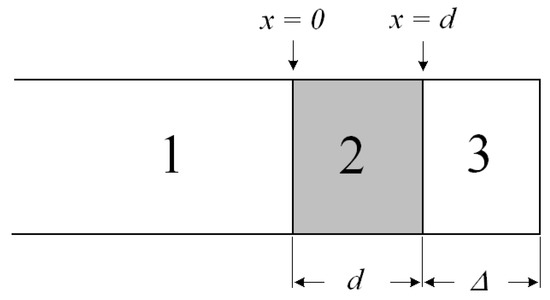

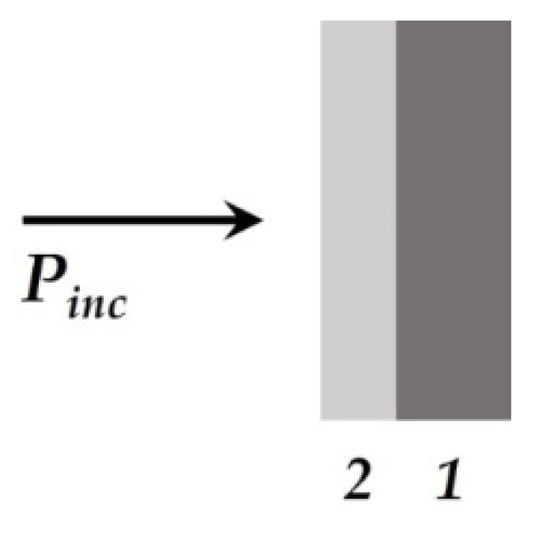

The scheme of inclusion of a sample with thickness d in the waveguide path and the picture of standing waves are shown in Figure 13.

Figure 13.

The scheme of inclusion of the sample.

An electromagnetic wave falls on the interface with the sample 2 from medium 1 (empty waveguide). The standing wave in medium 1 is the result of the interference of the incident wave and the waves obtained as a result of reflection from the interface (x = 0) and the short-circuit wall. The short-circuit wall can be in two positions: x = d (case of short circuit) or x = d + Δ (case of idling).

The use of a measuring line allows measurements to be made in two positions: short circuit and idle (open line). The equivalent of an open line is a quarter-wave section formed by a movable short-circuited load located behind the sample.

The total resistance in the cross section x = 0 from the medium 1 can be defined for each position aforementioned by measuring the wavelength in an unfilled waveguide λ1, the voltage standing wave coefficient (VSWC) KswU = Emax/Emin, and the distance from the boundary of the dielectric to the first node of the standing wave in the direction of the generator x0:

where is the wave resistance of an unfilled waveguide, a and b are the dimensions of the wide and narrow walls of the waveguide, respectively, i is imaginary unit.

The total resistance in cross-section x = 0 from the medium 2 are equal to:

- Z(0) = Z2 × tanh(γ2d), where Z2 and γ2 are the wave resistance and propagation constant of the waveguide filled with the material under study, respectively, in the case of a short circuit (Δ = 0);

- Z(0) = Z2 × cth(γ2d) in the case of idling (Δ = λ1/4).

As a result, complex equations are obtained for determination of the parameters of the waveguide filled with the material under study, Z2 and γ2:

Hence, the measured values of the VSWC and x0 for cases of short circuit and idling will be different.

The samples Fe-01 with 5 wt. % of Fe(CO)5, Fe-02 with 10 wt. % of Fe(CO)5, and Fe-03 with 20 wt. % of Fe(HCOO)3 were examined [129].

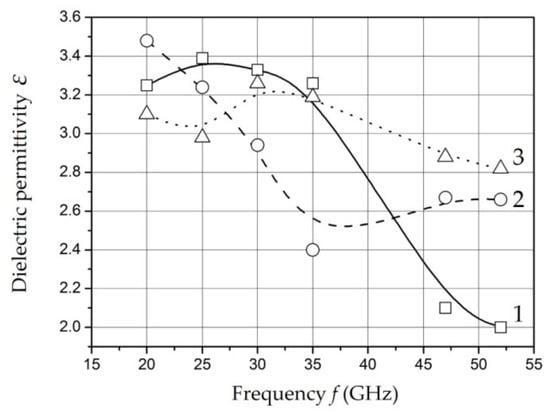

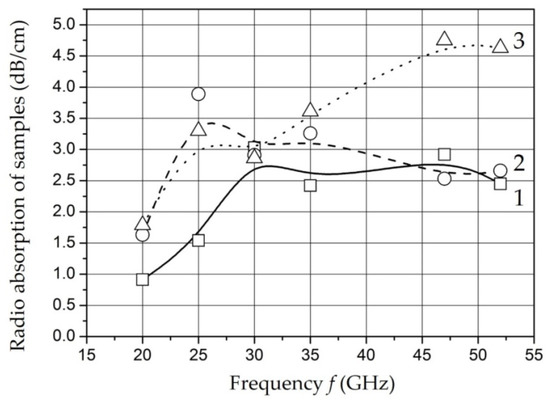

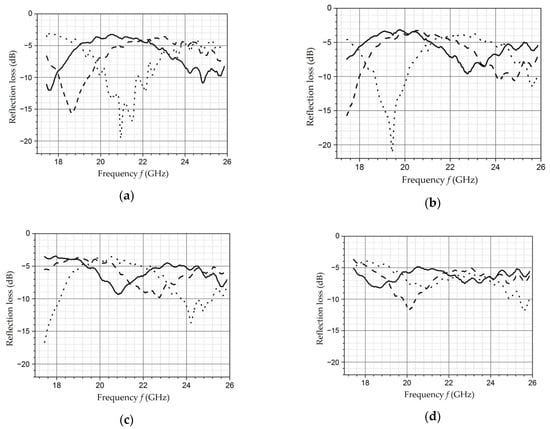

The results of measurements of the dielectric permittivity and water absorption of the samples with different mass filling in the microwave range are shown in Figure 14 and Figure 15 [129].

Figure 14.

The dependence of the dielectric permittivity of the samples Fe-01 (1), Fe-02 (2), and Fe-03 (3) on the operating frequency. Adapted from [129] with permission.

Figure 15.

The dependence of the radio absorption of the samples Fe-01 (1), Fe-02 (2), and Fe-03 (3) on the operating frequency. Adapted from [129] with permission.

The ratio of amplitude and time characteristics of relaxation processes can be estimated in according with measurements of the dielectric permittivity and radio absorption of samples in the microwave range. The decrease in dielectric permittivity with a relatively constant level of losses in the operating frequency range for the samples Fe-01 and Fe-02 can be explained by a decrease in the intensity of relaxation processes while maintaining relaxation time. An increase in the content of nanoparticles to 20 wt. % (sample Fe-03) is accompanied by a decrease in relaxation time at a relatively constant intensity.

It should be noted that there is a tendency to decrease the time and increase the intensity of the relaxation process of dipoles with an increase in the content of nanoparticles in the polymer. The obtained dependencies can be associated with the polarization of metal-containing nanoparticles as well as for low frequencies. It is known that its polarizability increases with size of nanoparticles increase [161]. The results of microwave measurements are characterized in the studied samples as materials having uniform absorption and dielectric permittivity parameters in a wide band of the studied frequency range.

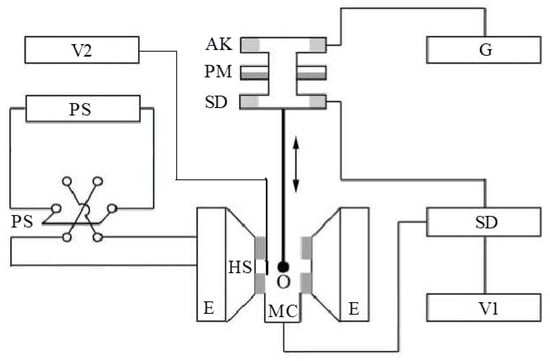

4.4. Investigation of the Properties of Composite Materials by the Resonance Method

The study of the properties of materials using coaxial resonators with an end gap is based on determination of the shift of the resonant frequency and the change in the quality factor of the resonator in the presence of a sample under study [162,163]. The method of placing the sample in the resonator depends on what characteristics of the material (permittivity, tangent of the dielectric loss angle, surface impedance, etc.) are going to be measured. The dielectric constant ε and the tangent of the dielectric loss angle tanδ of polymeric composite materials were studied [104,146,151,164,165,166,167,168].

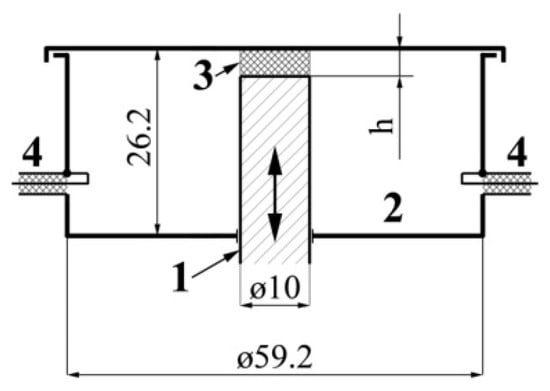

The scheme of an experimental setup based on a measuring coaxial resonator with an end gap is shown in Figure 16.

Figure 16.

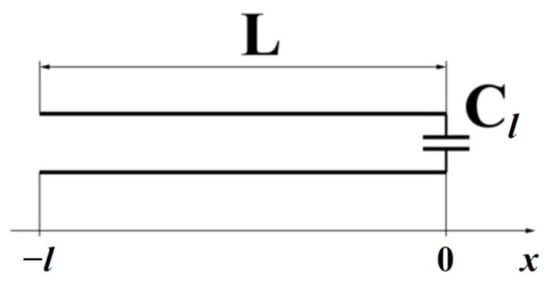

The scheme of a tunable coaxial resonator with an end capacitive gap.

The brass resonator is consisted of a movable central rod 1 with a closed cylindrical working volume 2 placed on the axis of 1. The rod is moved by a backlash-free micrometric mechanism equipped with a vernier position indicator. All surfaces inside the working volume are polished and have a silver coating. The capacitive gap 3 is designed for tuning into resonance and for placing samples under study inside it. Its height h can be changed by moving the movable central conductor. The resonator is connected to the signal generator and the spectrum analyzer by means of inductive communication loops 4. The dimensions of the resonator parts used in calculations are presented in Figure 16. An equivalent circuit of such a resonator is a long line with a capacitive load (Figure 17).

Figure 17.

An equivalent scheme of a resonator used.

The resonant frequency of such a circuit can be defined by means the total complex resistance of the long line at its input (in section with the coordinate x = −l:

where Zw and Zl are wave resistance of the line and resistance of the load, respectively, γ = α + iβ and is l = L are the electromagnetic wave propagation constant in the line and length of the line, respectively.

For a line with negligible attenuation (α = 0), the relation (10) has the form:

The zero input impedance of the line Zin(–l) = 0 is the resonance condition. Thus,

Zl + i × Zb × tanh(βl) = 0.

Taking into account that, for a capacitive load Zl = 1/(i × ωr × Cl), and also β = ωr/c for an air-filled coaxial line, a nonlinear equation for finding the resonant frequency of a coaxial resonator with an end gap can be obtained:

where c is the velocity of light in vacuum.

1/(ωr × Cl) = Zw × tanh(ωr × Cl/c)

The measurement method has the next algorithm. First, by varying the frequency of the generator, the system is tuned into resonance, and the resonant frequency fr and quality factor Q0 of the resonator are measured without a sample. Then, a sample is placed in the resonator, and the same measurements are carried out again. The resonance frequency fr’ and the quality factor Q’ of the resonator with the sample are obtained.

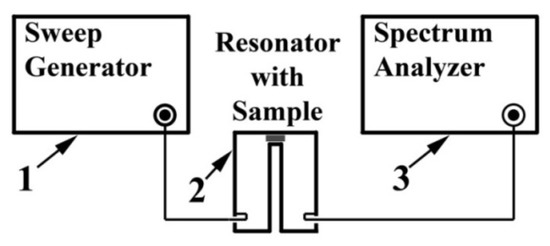

The scheme of the measuring unit is shown in Figure 18. A signal generator (SME06, Rohde&Schwartz) with operating frequency range of 10 kHz–6 GHz was used as a signal source 1. A spectrum analyzer (FSP7, Rohde&Schwartz) 3, with an upper limit frequency of 7 GHz together with generator 1, makes it possible to observe the resonant curve of the measuring resonator 2 on the screen and automatically perform frequency and amplitude measurements necessary to determine the resonant frequency and quality factor.

Figure 18.

The scheme of an experimental setup for measuring ε and tanh(δ) in a coaxial resonator with an end gap.

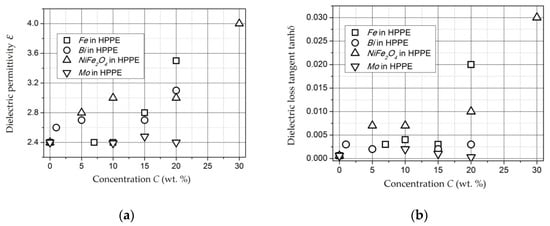

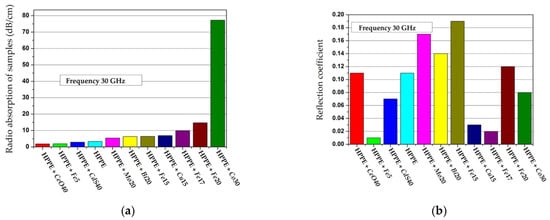

This method was used to study the concentration dependences of composite materials based on Fe-, Bi-, and Mo-containing nanoparticles as well as NiFe2O4 nanoparticles in a HPPE matrix [165]. The results of measurements of ε and tanh(δ) for samples with Fe, Bi, Mo, and NiFe2O4 nanoparticles in a HPPE matrix are presented in Figure 19. The analysis of concentration dependences allows us to conclude that there are percolation transitions in the concentration range of 15–20 wt. % for samples with Fe-containing nanoparticles and in the range of 20–30 wt. % for samples with NiFe2O4 nanoparticles. In the case of Fe-containing nanoparticles in the ultra-high-frequency range, a shift of the percolation transition to the region of lower concentrations is observed.

Figure 19.

Dependence of dielectric permittivity (a) and dielectric losses (b) of nanocomposites on concentration of the nanoparticles Fe, Bi, NiFe2O4, and Mo.

The dielectric permittivity of Bi-containing composites also monotonically increases with increasing concentration of the nanoparticles, while tanδ is slightly higher than that of unfilled polyethylene and remains constant up to CBi = 20 wt. %. ε and tanh(δ) of Mo-containing composites in the studied concentration range differ slightly from the values of ε and tanh(δ) of the unfilled matrix.

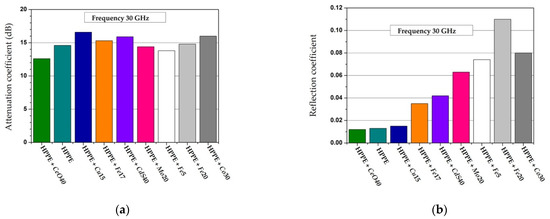

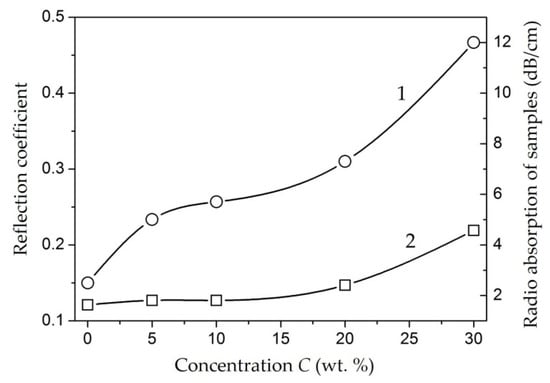

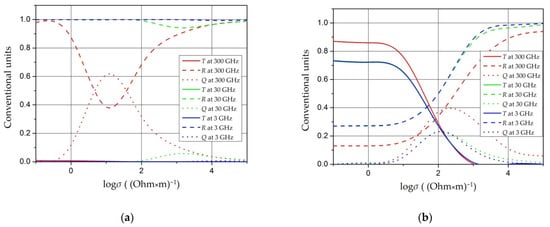

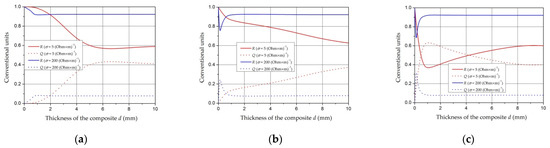

It should also be noted that the increased values of dielectric permittivity relative to unfilled polyethylene remain in the microwave range. This means that the value of ε of the composite materials based on a nonpolar polyethylene matrix is determined by electronic polarization.

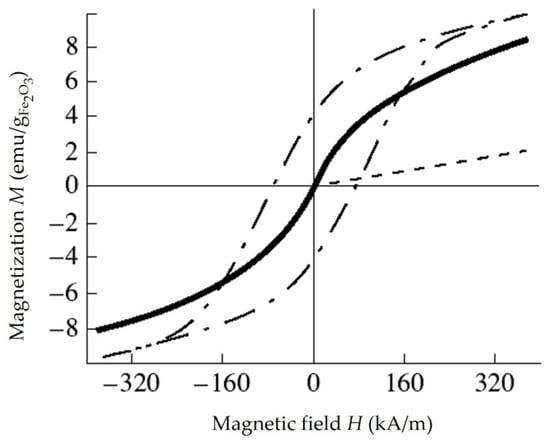

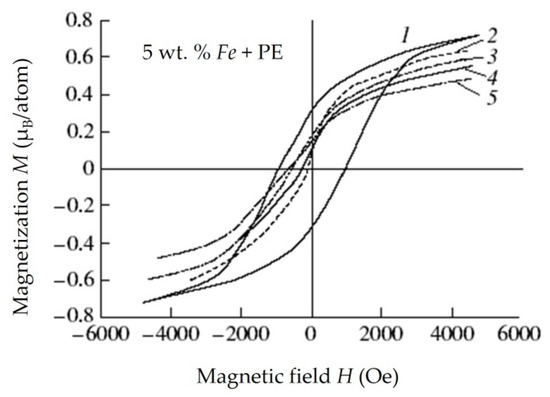

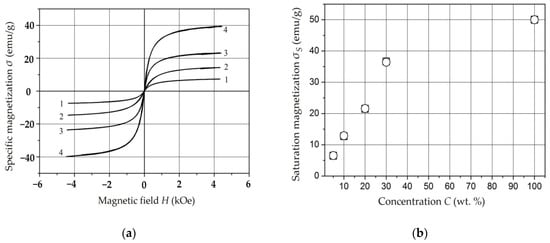

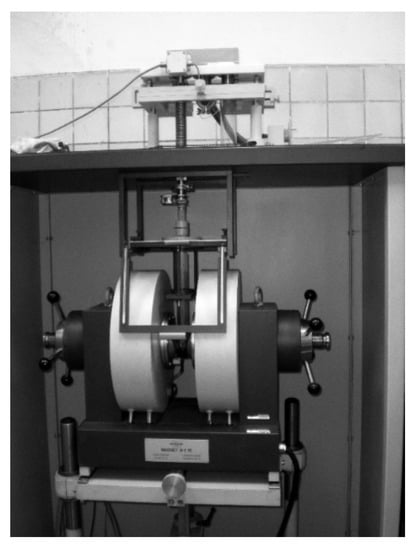

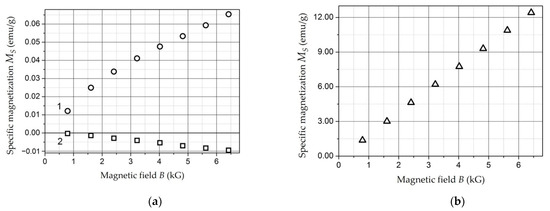

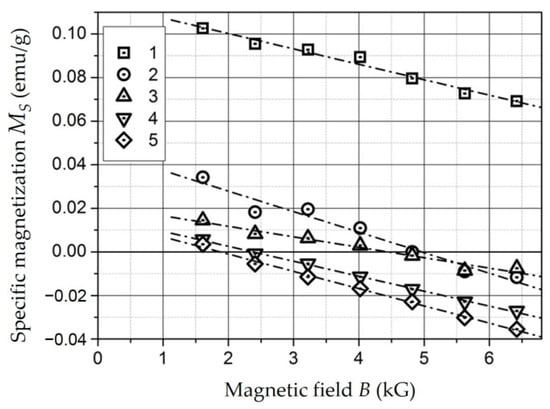

4.5. Magnetic Properties of Composite Materials with Ferromagnetic Nanoparticles