On the Mechanical Performance of Polylactic Material Reinforced by Ceramic in Fused Filament Fabrication

Abstract

:1. Introduction

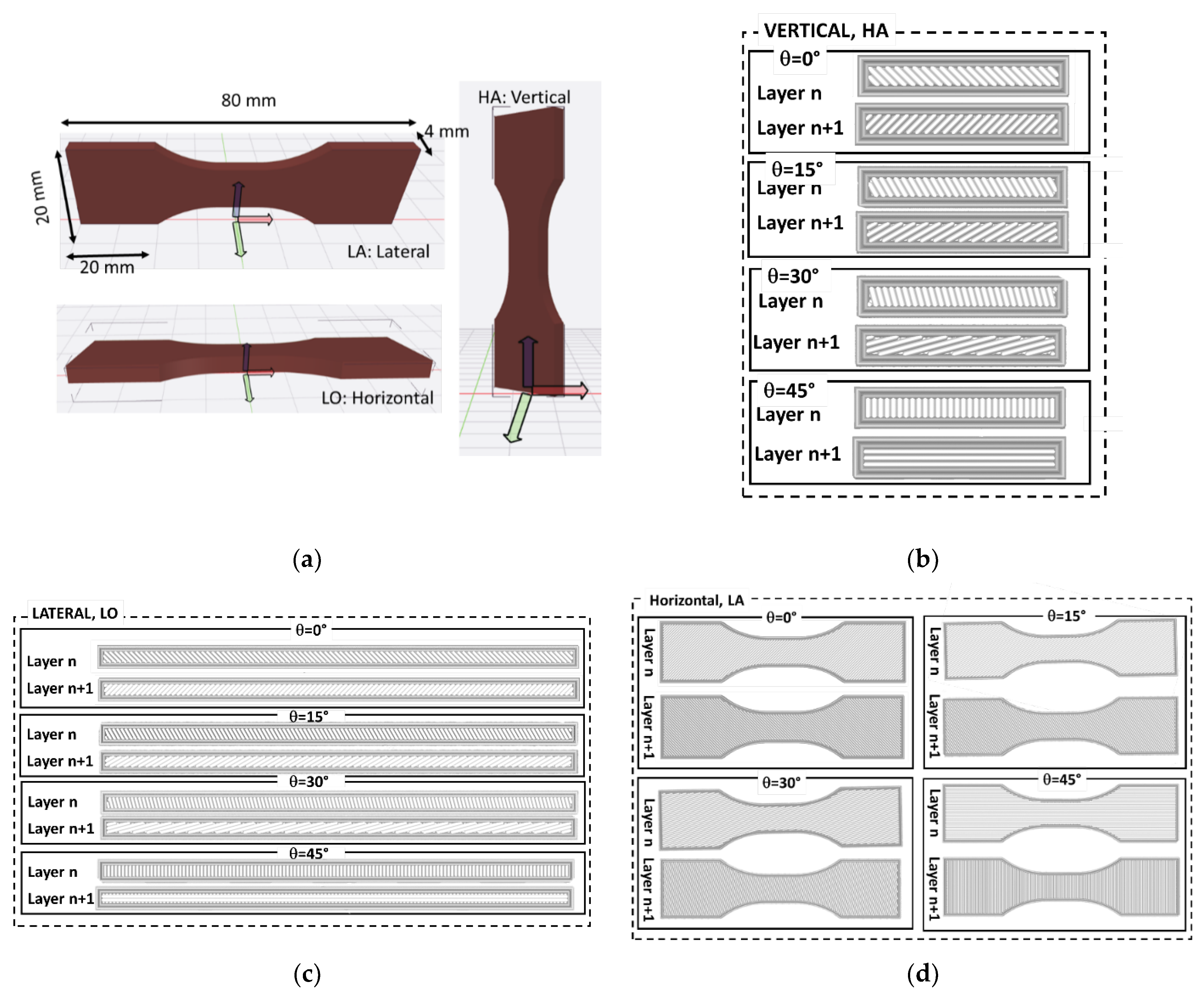

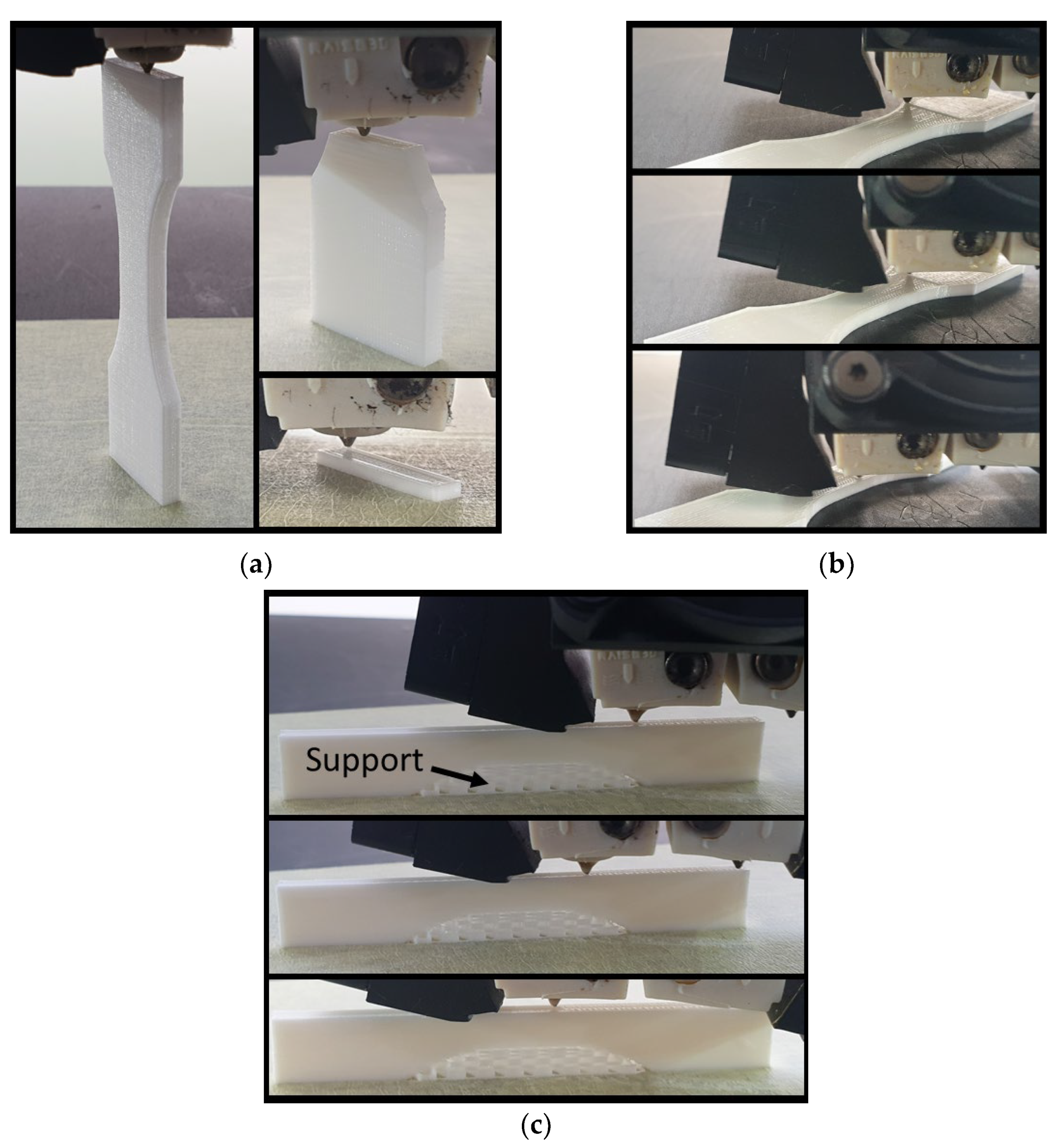

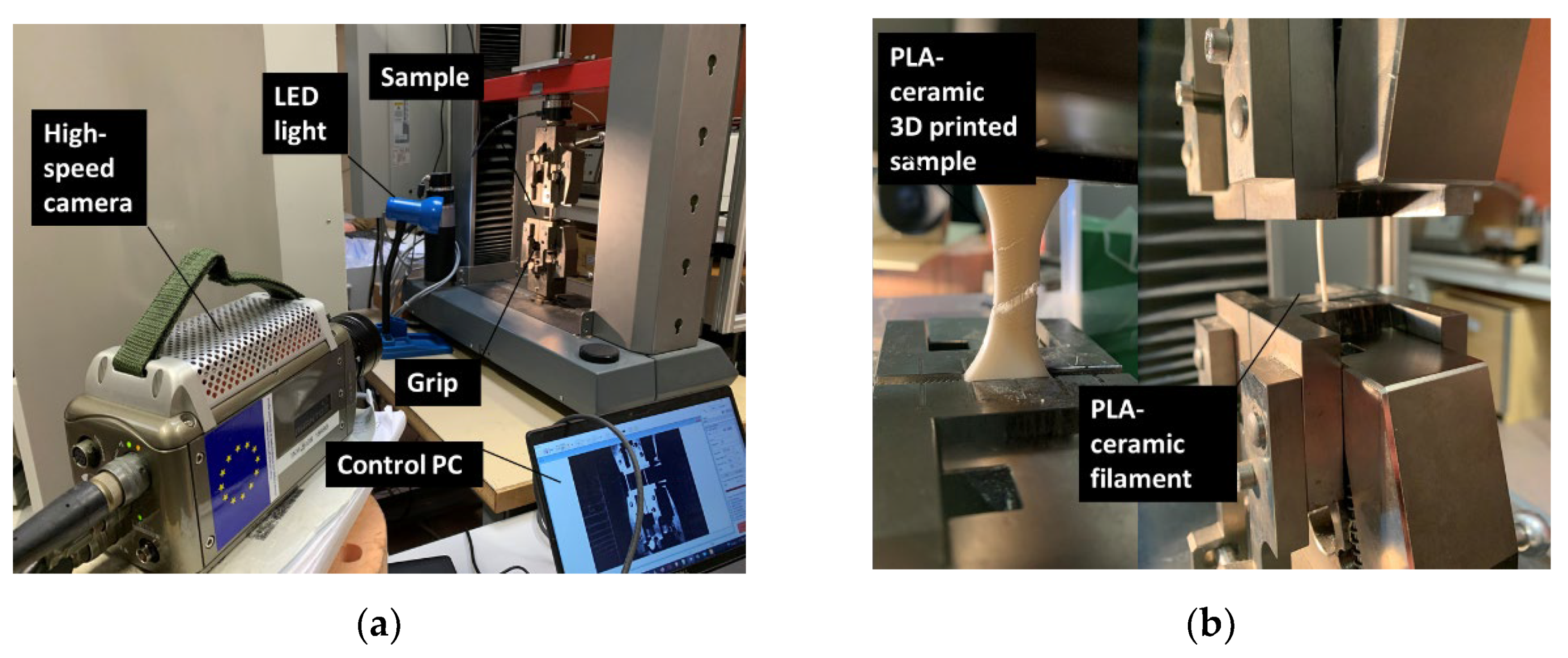

2. Materials and Methods

3. Results and Discussion

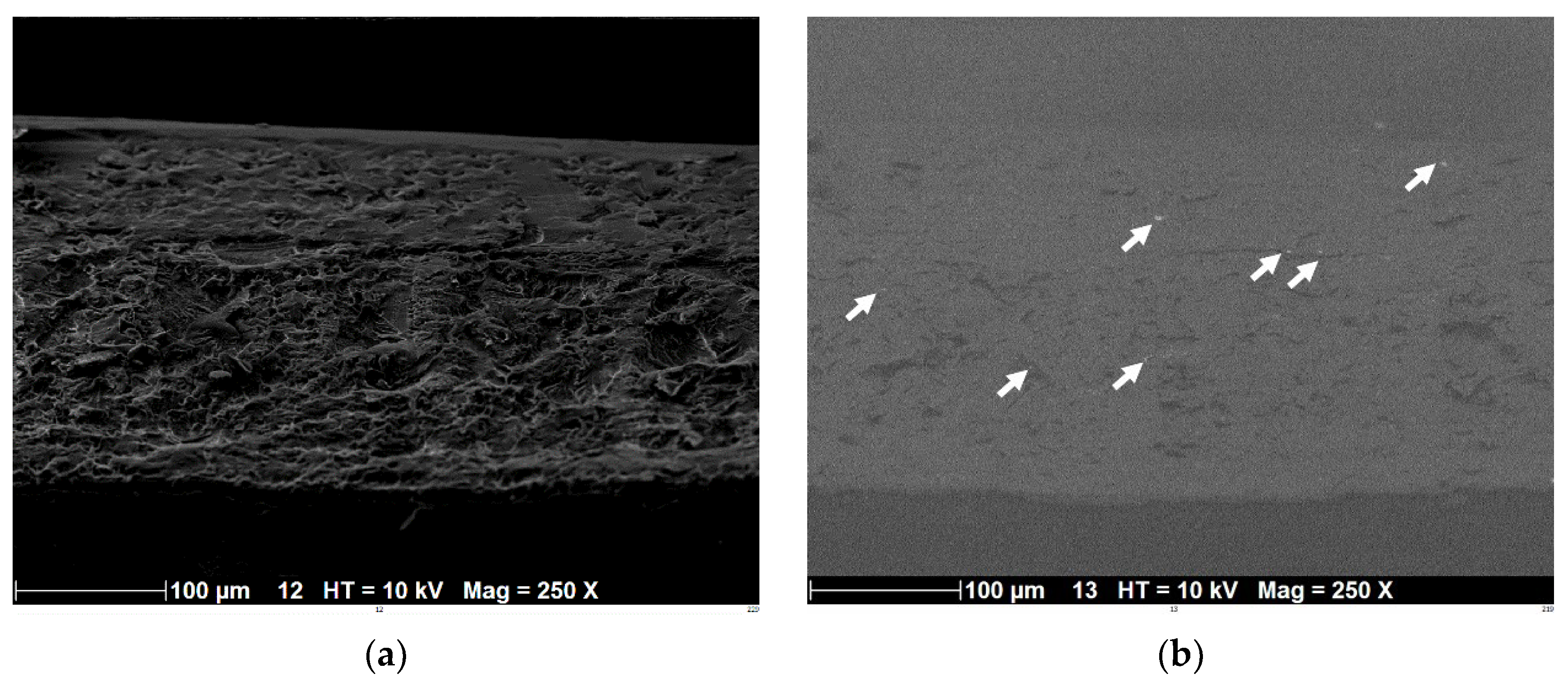

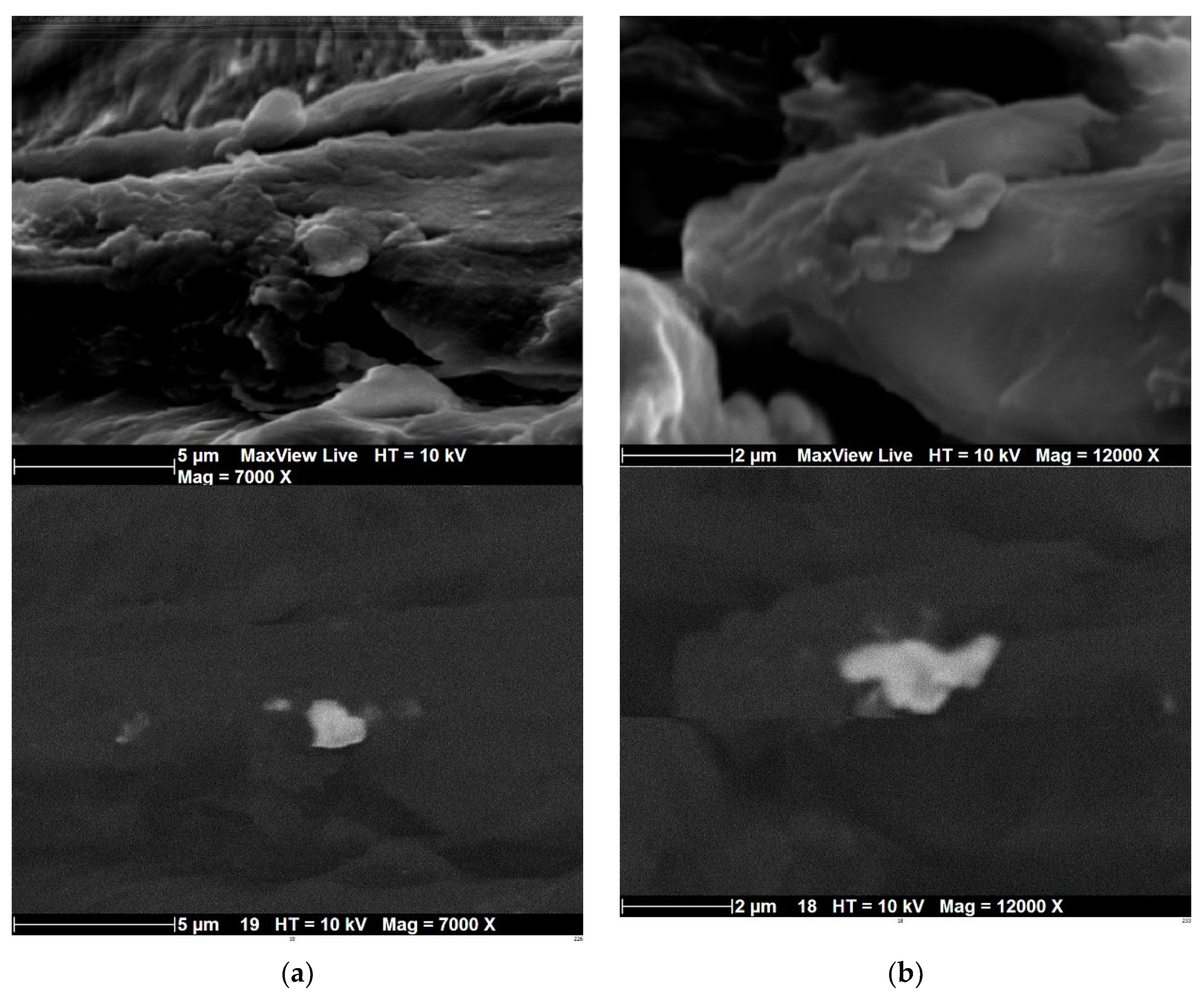

3.1. Properties of As-Received PLC Filament

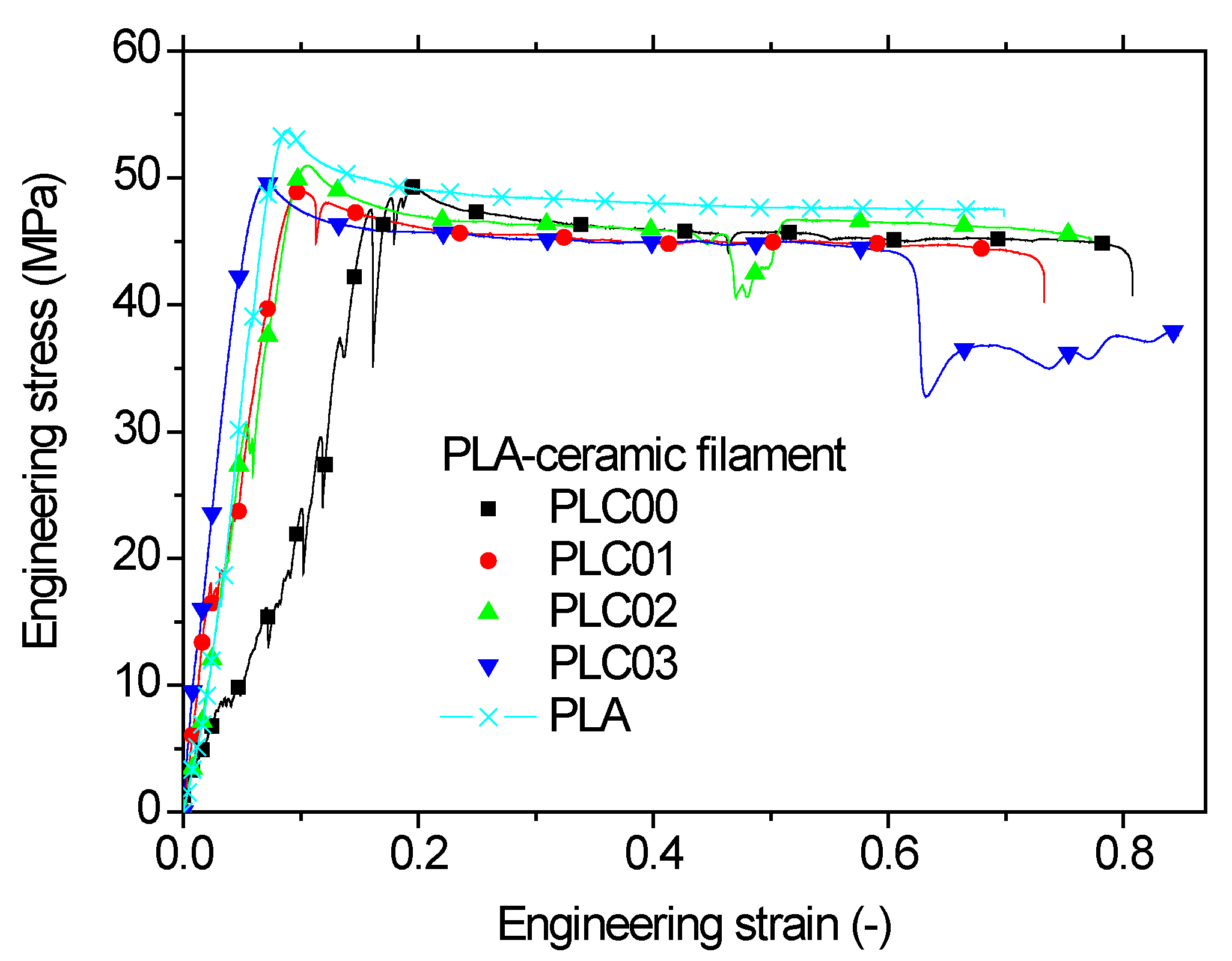

3.2. Tensile Behaviour of PLC Filament

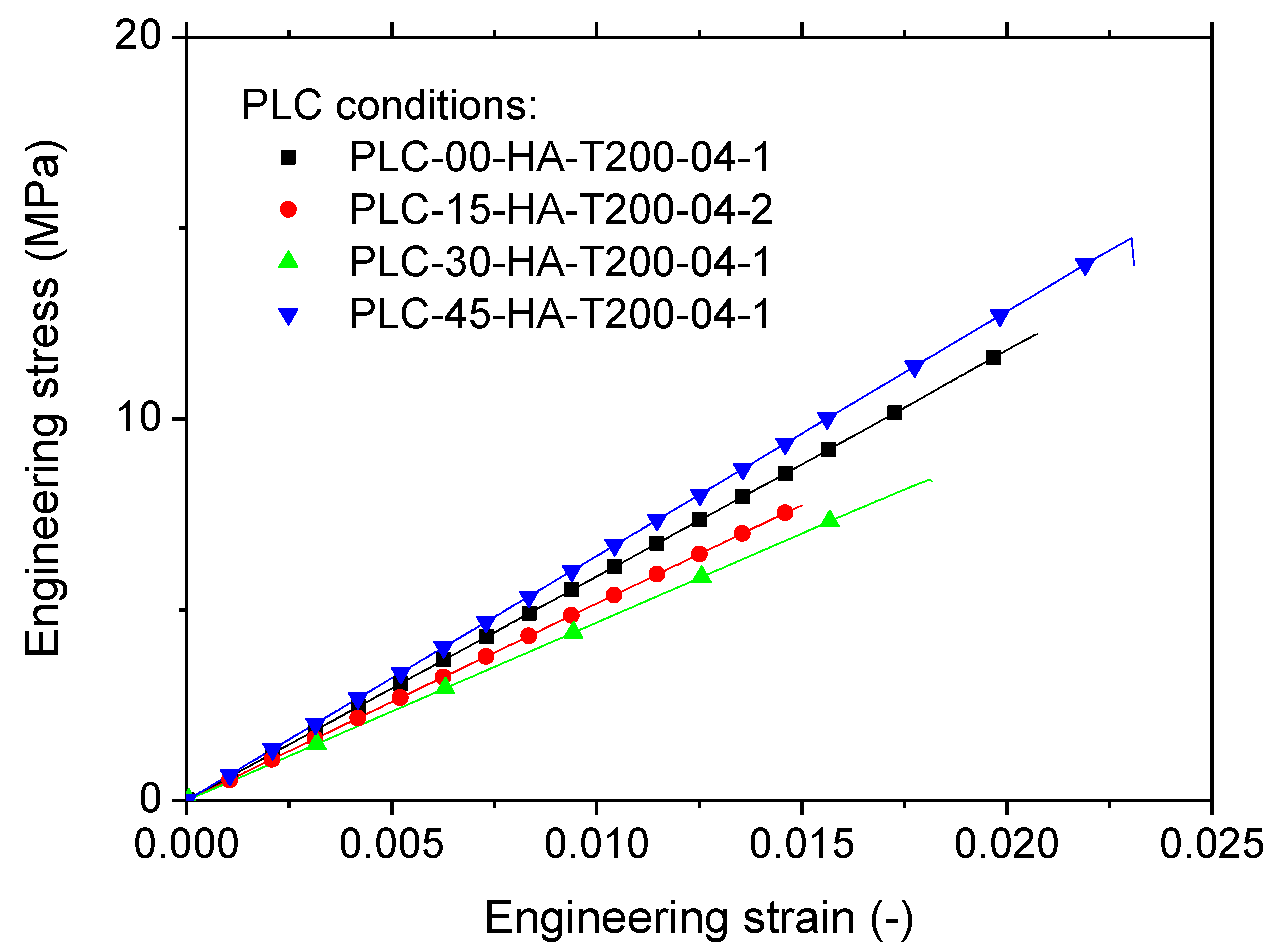

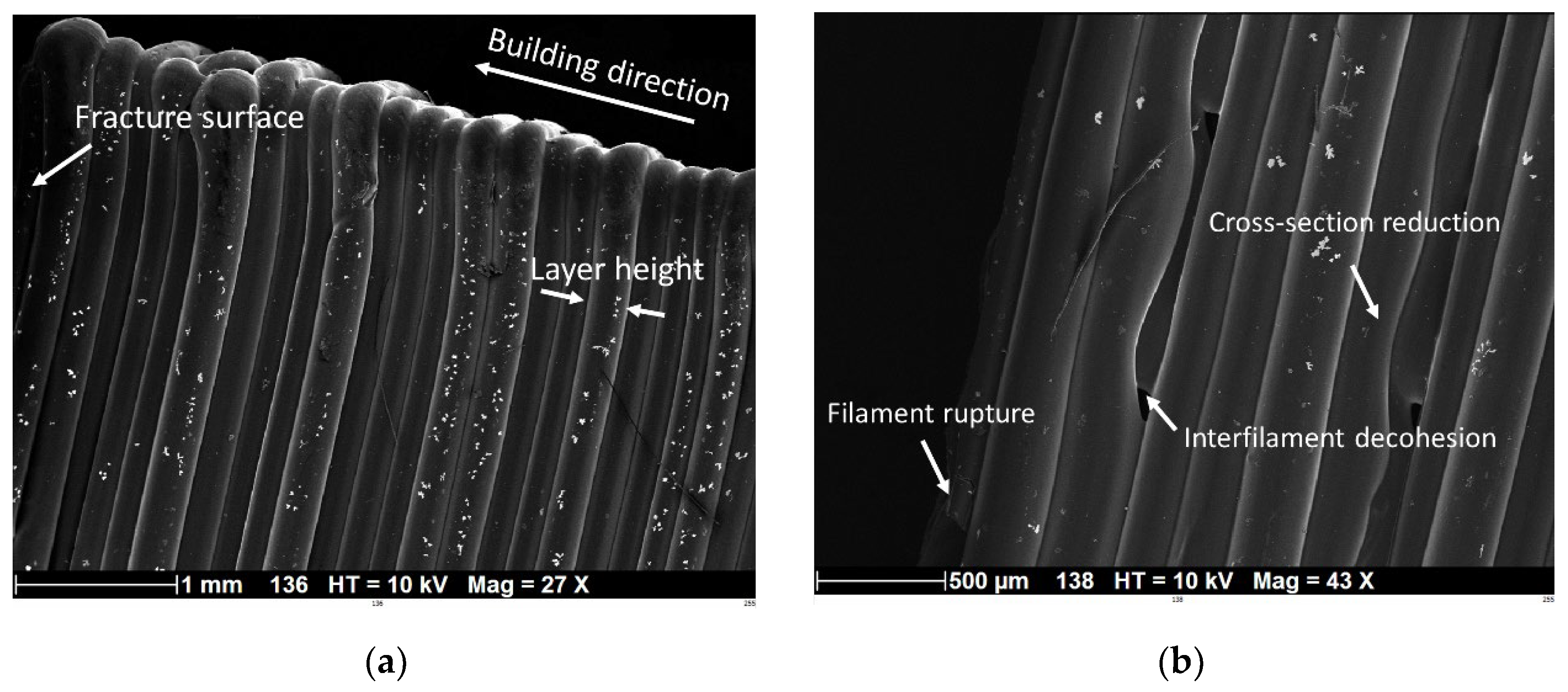

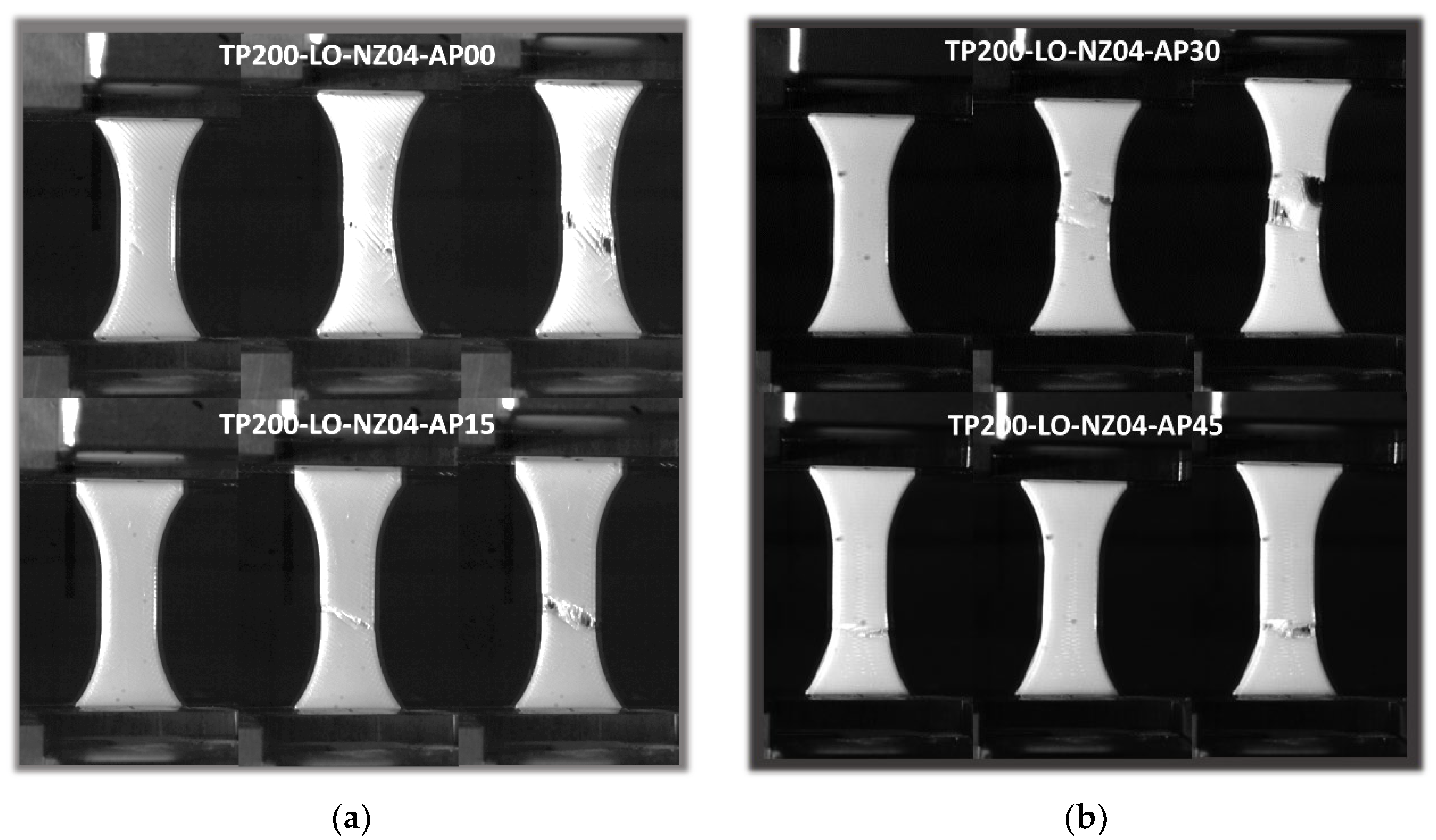

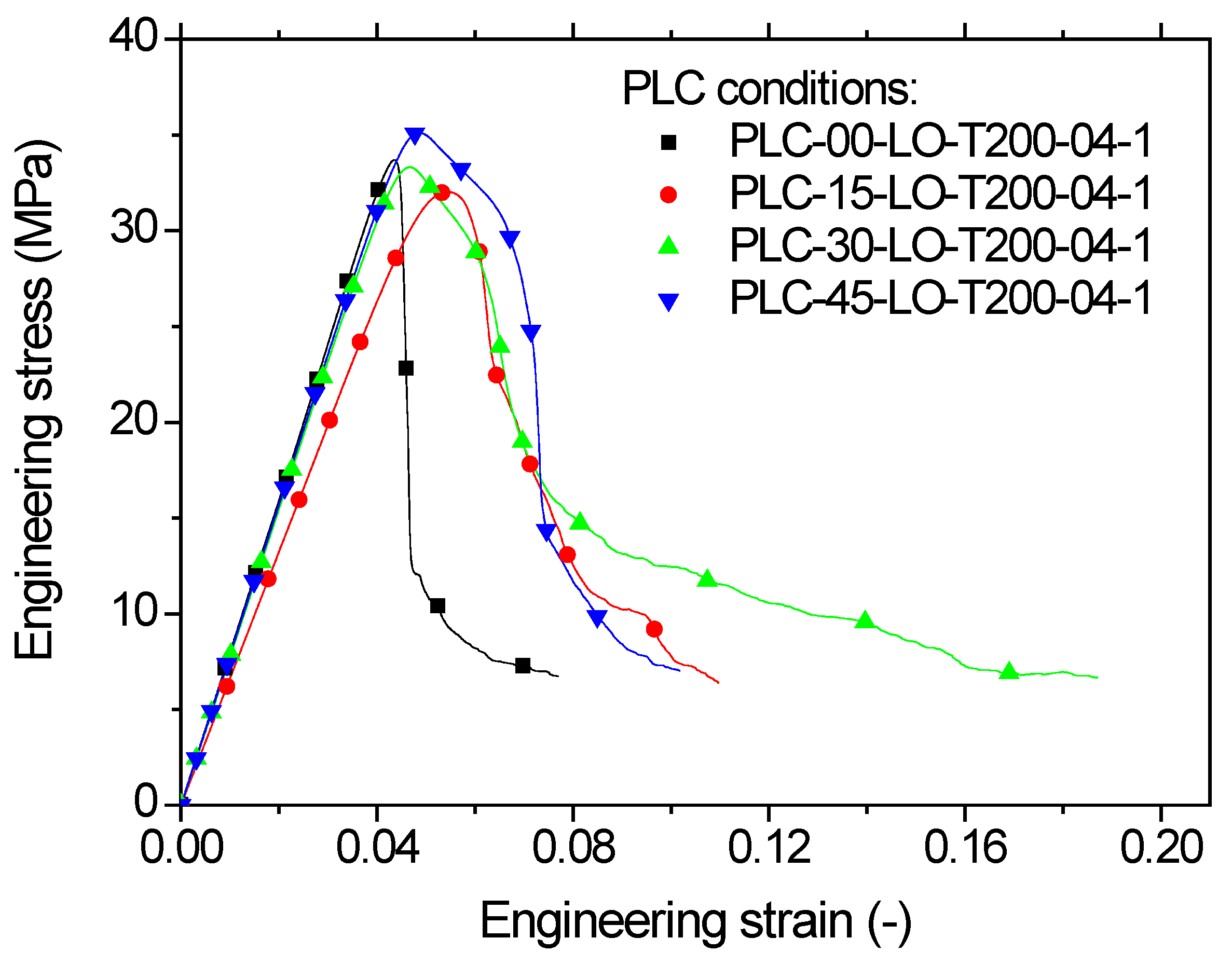

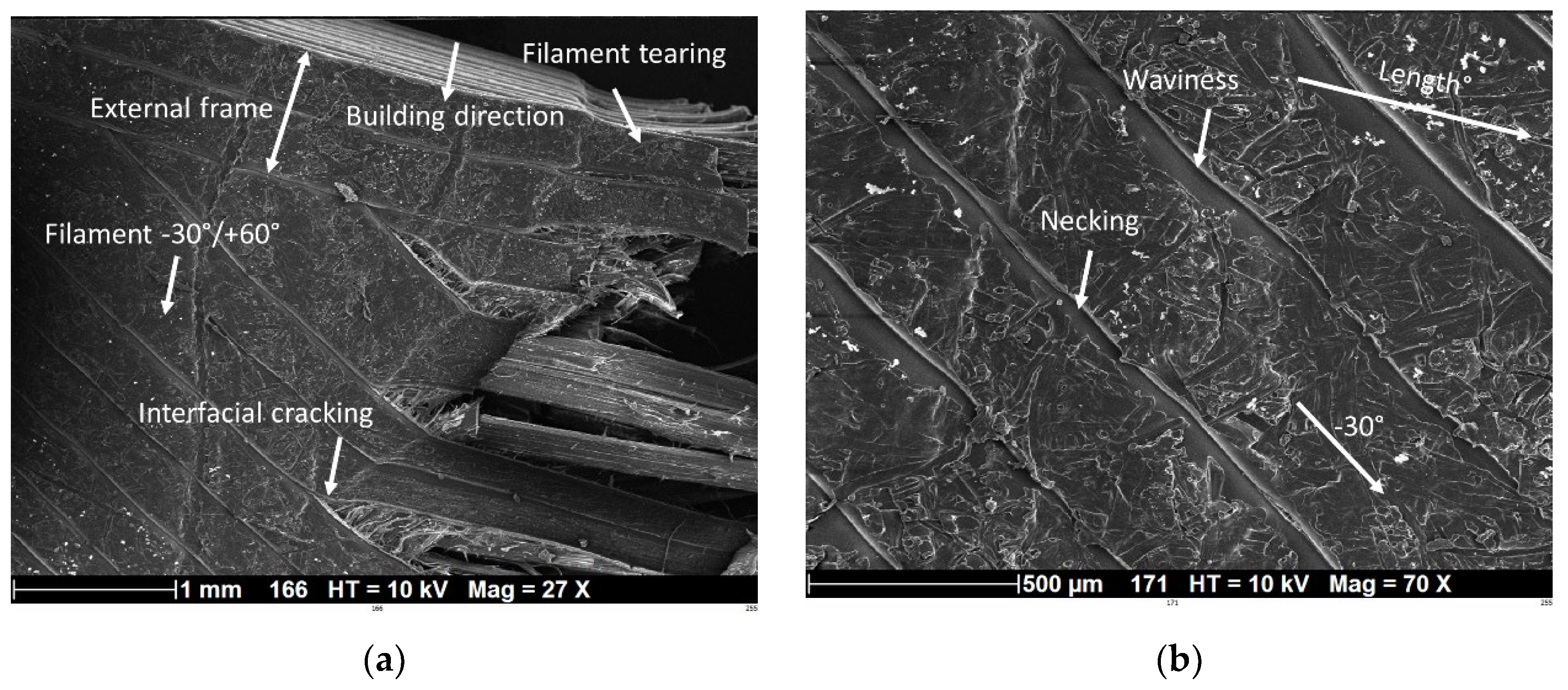

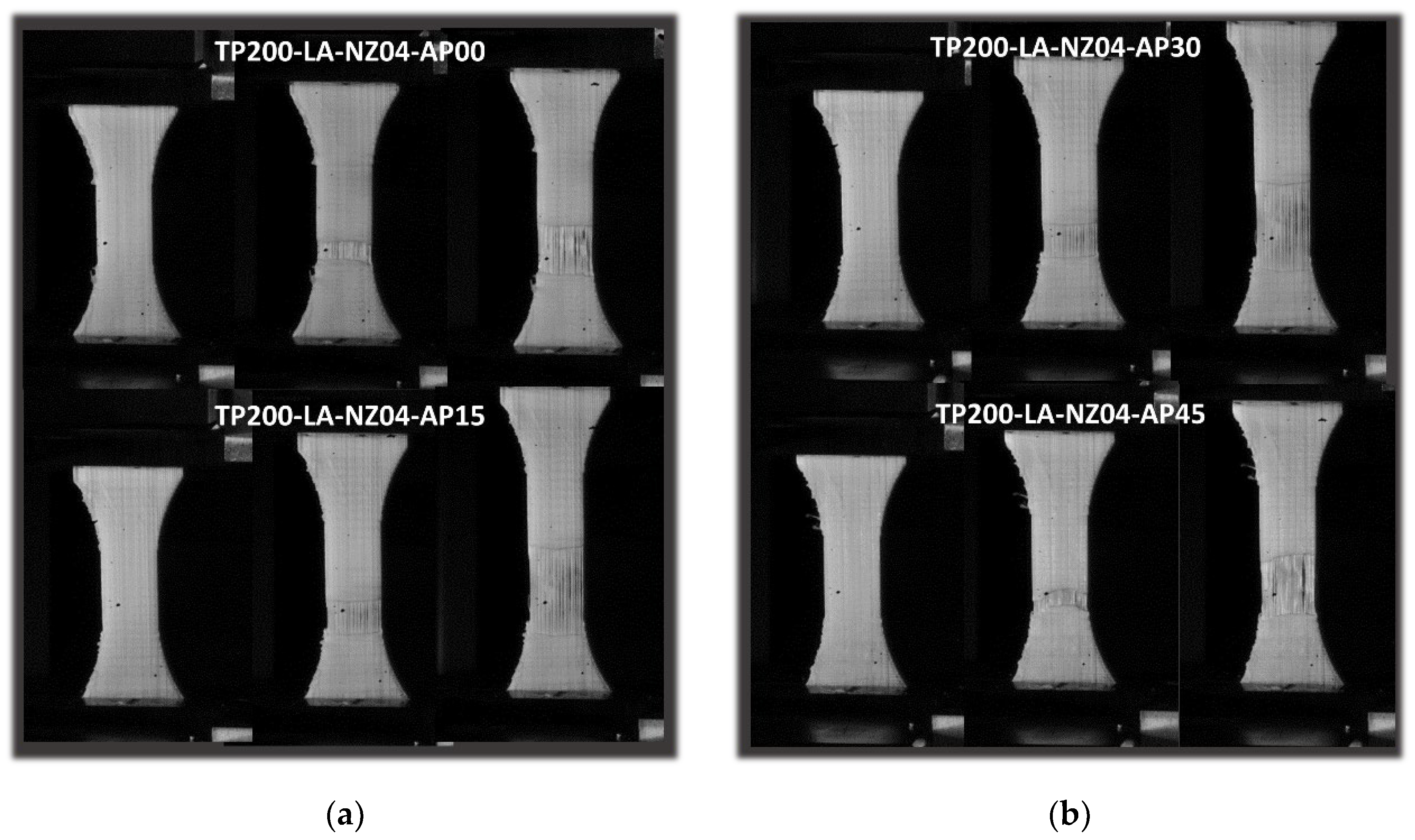

3.3. Effect of Part Orientation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qian, X.; Ostwal, M.; Asatekin, A.; Geise, G.M.; Smith, Z.P.; Phillip, W.A.; Lively, R.P.; McCutcheon, J.R. A critical review and commentary on recent progress of additive manufacturing and its impact on membrane technology. J. Membr. Sci. 2022, 645, 120041. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Kirchheim, A.; Dennig, H.-J.; Zumofen, L. Why Education and Training in the Field of Additive Manufacturing is a Necessity. Industrializing Additive Manufacturing. In Proceedings of the Additive Manufacturing in Products and Applications—AMPA2017; Springer: Berlin/Heidelberg, Germany, 2018; pp. 329–336. [Google Scholar]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Lacroix, R.; Seifert, R.W.; Timonina-Farkas, A. Benefiting from additive manufacturing for mass customization across the product life cycle. Oper. Res. Perspect. 2021, 8, 100201. [Google Scholar] [CrossRef]

- Li, S.; Waheed, U.; Bahshwan, M.; Wang, L.Z.; Kalossaka, L.M.; Choi, J.; Kundrak, F.; Lattas, A.; Ploumpis, S.; Zafeiriou, S.; et al. A scalable mass customisation design process for 3D-printed respirator mask to combat COVID-19. Rapid Prototyp. J. 2021, 27, 1302–1317. [Google Scholar] [CrossRef]

- Rezaie, R.; Badrossamay, M.; Ghaie, A.; Moosavi, H. Topology Optimization for Fused Deposition Modeling Process. Procedia CIRP 2013, 6, 521–526. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Feng, Z.; Hao, L.; Huang, L.; Xin, C.; Wang, Y.; Bilotti, E.; Essa, K.; Zhang, H.; Li, Z.; et al. A Review on Functionally Graded Materials and Structures via Additive Manufacturing: From Multi-Scale Design to Versatile Functional Properties. Adv. Mater. Technol. 2020, 5, 1900981. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive manufacturing of functionally graded materials: A review. Mater. Sci. Eng. A 2019, 764, 138209–138273. [Google Scholar] [CrossRef]

- Czyżewski, P.; Marciniak, D.; Nowinka, B.; Borowiak, M.; Bieliński, M. Influence of Extruder’s Nozzle Diameter on the Improvement of Functional Properties of 3D-Printed PLA Products. Polymers 2022, 14, 356. [Google Scholar] [CrossRef]

- Dhinakaran, V.; Manoj Kumar, K.P.; Bupathi Ram, P.M.; Ravichandran, M.; Vinayagamoorthy, M. A review on recent advancements in fused deposition modeling. Mater. Today Proc. 2020, 27, 752–756. [Google Scholar] [CrossRef]

- Al-Ghamdi, K.A. Sustainable FDM additive manufacturing of ABS components with emphasis on energy minimized and time efficient lightweight construction. Int. J. Lightweight Mater. Manuf. 2019, 2, 338–345. [Google Scholar] [CrossRef]

- Subramaniam, S.R.; Samykano, M.; Selvamani, S.K.; Ngui, W.K.; Kadirgama, K.; Sudhakar, K.; Idris, M.S. 3D printing: Overview of PLA Progress; AIP Publishing LLC: Melville, NY, USA, 2019. [Google Scholar]

- Ahn, S.H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef] [Green Version]

- Samykano, M.; Selvamani, S.K.; Kadirgama, K.; Ngui, W.K.; Kanagaraj, G.; Sudhakar, K. Mechanical property of FDM printed ABS: Influence of printing parameters. Int. J. Adv. Manuf. Technol. 2019, 102, 2779–2796. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Liu, C.-Y. The influence of forced-air cooling on a 3D printed PLA part manufactured by fused filament fabrication. Addit. Manuf. 2019, 25, 196–203. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Liu, Z.; Lei, Q.; Xing, S. Mechanical characteristics of wood, ceramic, metal and carbon fiber-based PLA composites fabricated by FDM. J. Mater. Res. Technol. 2019, 8, 3741–3751. [Google Scholar] [CrossRef]

- Cuan-Urquizo, E.; Álvarez-Trejo, A.; Robles Gil, A.; Tejada-Ortigoza, V.; Camposeco-Negrete, C.; Uribe-Lam, E.; Treviño-Quintanilla, C.D. Effective Stiffness of Fused Deposition Modeling Infill Lattice Patterns Made of PLA-Wood Material. Polymers 2022, 14, 337. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Printability and Tensile Performance of 3D Printed Polyethylene Terephthalate Glycol Using Fused Deposition Modelling. Polymers 2019, 11, 1220. [Google Scholar] [CrossRef] [Green Version]

- Alizadeh-Osgouei, M.; Li, Y.; Wen, C. A comprehensive review of biodegradable synthetic polymer-ceramic composites and their manufacture for biomedical applications. Bioact. Mater. 2019, 4, 22–36. [Google Scholar] [CrossRef]

- Bouamer, A.; Benrekaa, N.; Younes, A. Characterization of polylactic acid ceramic composites synthesized by casting method. Mater. Today Proc. 2021, 42, 2959–2962. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116, 100736–100750. [Google Scholar] [CrossRef]

- Windsheimer, H.; Travitzky, N.; Hofenauer, A.; Greil, P. Laminated Object Manufacturing of Preceramic-Paper-Derived Si?SiC Composites. Adv. Mater. 2007, 19, 4515–4519. [Google Scholar] [CrossRef]

- Eckel, Z.C.; Zhou, C.; Martin, J.H.; Jacobsen, A.J.; Carter, W.B.; Schaedler, T.A. Additive manufacturing of polymer-derived ceramics. Science 2016, 351, 58–62. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. 3D Printing PLA Waste to Produce Ceramic Based Particulate Reinforced Composite Using Abundant Silica-Sand: Mechanical Properties Characterization. Polymers 2020, 12, 2579. [Google Scholar] [CrossRef]

- Onagoruwa, S.; Bose, S.; Bandyopadhyay, A. Fused Deposition of Ceramics (FDC) and composites. In Proceedings of the 2001 International Solid Freeform Fabrication Symposium; University of Texas: Austin, TX, USA, 2001; pp. 224–231. [Google Scholar]

- Rangarajan, S.; Qi, G.; Venkataraman, N.; Safari, A.; Danforth, S.C. Powder Processing, Rheology, and Mechanical Properties of Feedstock for Fused Deposition of Si3N4 Ceramics. J. Am. Ceram. Soc. 2004, 83, 1663–1669. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H.; Ben Hassana, O. Anisotropic damage inferred to 3D printed polymers using fused deposition modelling and subject to severe compression. Eur. Polym. J. 2016, 85, 324–340. [Google Scholar] [CrossRef]

- Bhagia, S.; Bornani, K.; Agrawal, R.; Satlewal, A.; Ďurkovič, J.; Lagaňa, R.; Bhagia, M.; Yoo, C.G.; Zhao, X.; Kunc, V.; et al. Critical review of FDM 3D printing of PLA biocomposites filled with biomass resources, characterization, biodegradability, upcycling and opportunities for biorefineries. Appl. Mater. Today 2021, 24, 10107–10129. [Google Scholar] [CrossRef]

- Kariz, M.; Sernek, M.; Obućina, M.; Kuzman, M.K. Effect of wood content in FDM filament on properties of 3D printed parts. Mater. Today Commun. 2018, 14, 135–140. [Google Scholar] [CrossRef]

- Zohdi, N.; Yang, R. Material Anisotropy in Additively Manufactured Polymers and Polymer Composites: A Review. Polymers 2021, 13, 3368. [Google Scholar] [CrossRef] [PubMed]

- Guessasma, S.; Belhabib, S.; Altin, A. On the Tensile Behaviour of Bio-Sourced 3D-Printed Structures from a Microstructural Perspective. Polymers 2020, 12, 1060. [Google Scholar] [CrossRef] [PubMed]

- Guessasma, S.; Belhabib, S.; Nouri, H. Thermal cycling, microstructure and tensile performance of PLA-PHA polymer printed using fused deposition modelling technique. Rapid Prototyp. J. 2020, 26, 122–133. [Google Scholar] [CrossRef]

| Property | Level |

|---|---|

| Orientation, OR (-) | Vertical (HA), Horizontal (LO), Lateral (LA) |

| Printing angle, AP (°) | 0, 15, 30, 45 |

| Property | Level |

|---|---|

| Infill, IF (%) | 100 |

| Nozzle diameter, DN (mm) | 0.4 |

| Layer height (mm) | 0.2 |

| Printing temperature, TP(°C) | 200 |

| Bed temperature, TB (°C) | 60 |

| Printing speed, VP (mm/s) | 50 |

| Support density, SPD (%) | 10 |

| Frame width, WF (mm) | 0.6, 0.8 |

| Material * | EY (MPa) | σY (MPa) | σM (MPa) | σR (MPa) | εR (%) |

|---|---|---|---|---|---|

| PLC wire | 792 ± 167 | 37 ± 2 | 50 ± 1 | 41 ± 4 | 78 ± 5 |

| PLC-00-HA-T200-04 | 596 ± 13 | 12 ± 1 | 12 ± 1 | 12 ± 1 | 2 ± 0 |

| PLC-15-HA-T200-04 | 517 ± 11 | 8 ± 1 | 8 ± 1 | 8 ± 1 | 2 ± 0 |

| PLC-30-HA-T200-04 | 487 ± 29 | 8 ± 1 | 8 ± 1 | 8 ± 1 | 2 ± 0 |

| PLC-45-HA-T200-04 | 597 ± 62 | 13 ± 3 | 13 ± 3 | 12 ± 2 | 2 ± 0 |

| PLC-00-LO-T200-04 | 706 ± 128 | 30 ± 5 | 32 ± 3 | 6 ± 1 | 16 ± 12 |

| PLC-15-LO-T200-04 | 650 ± 16 | 31 ± 4 | 34 ± 2 | 7 ± 0 | 12 ± 1 |

| PLC-30-LO-T200-04 | 735 ± 54 | 31 ± 1 | 33 ± 1 | 7 ± 0 | 17 ± 3 |

| PLC-45-LO-T200-04 | 781 ± 5 | 32 ± 1 | 35 ± 1 | 7 ± 0 | 9 ± 1 |

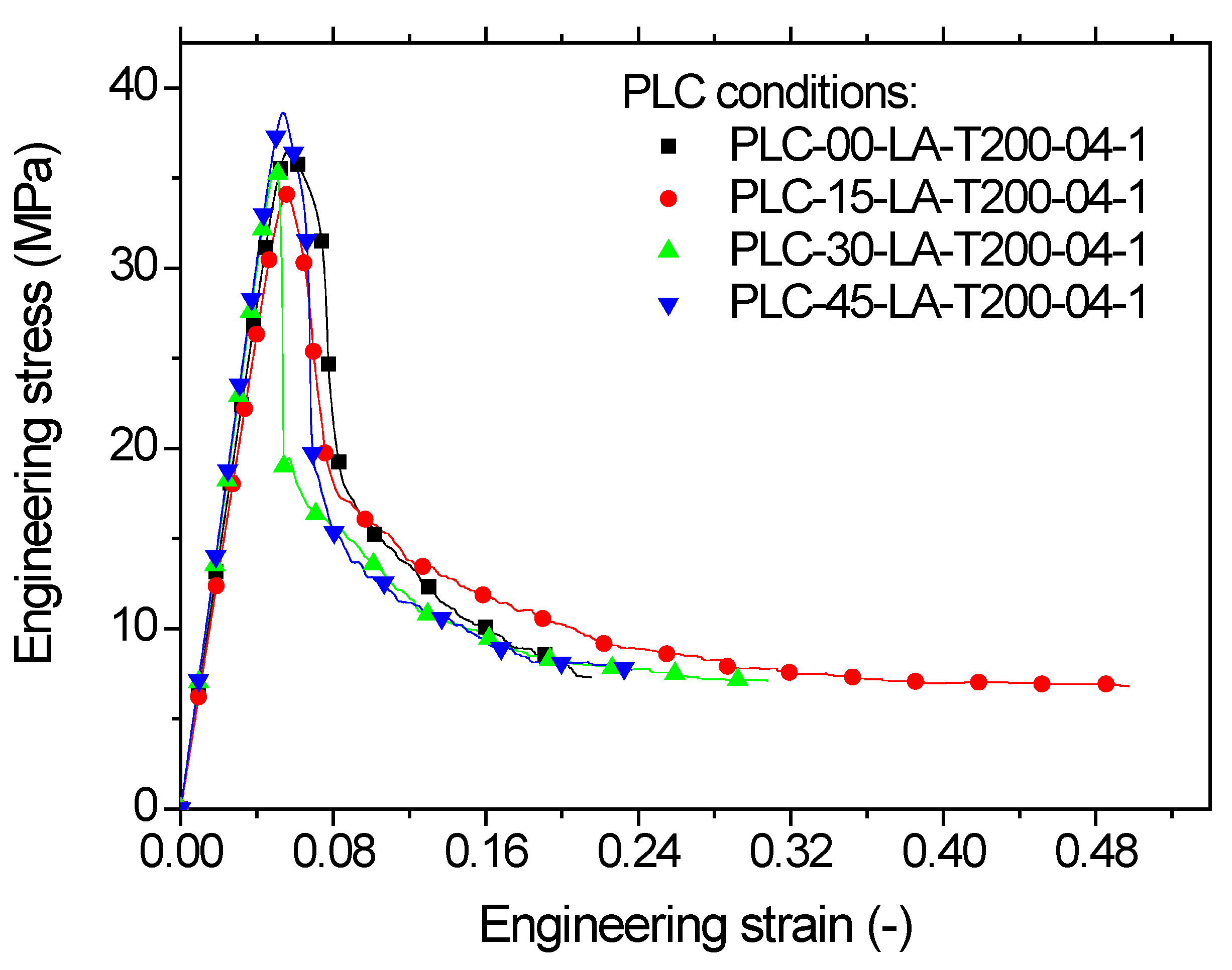

| PLC-00-LA-T200-04 | 699 ± 0 | 35 ± 1 | 37 ± 0 | 7 ± 0 | 24 ± 3 |

| PLC-15-LA-T200-04 | 657 ± 3 | 32 ± 0 | 34 ± 0 | 7 ± 0 | 40 ± 14 |

| PLC-30-LA-T200-04 | 735 ± 22 | 34 ± 0 | 35 ± 1 | 7 ± 0 | 30 ± 1 |

| PLC-45-LA-T200-04 | 766 ± 9 | 38 ± 1 | 39 ± 1 | 8 ± 0 | 23 ± 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hedjazi, L.; Guessasma, S.; Belhabib, S.; Stephant, N. On the Mechanical Performance of Polylactic Material Reinforced by Ceramic in Fused Filament Fabrication. Polymers 2022, 14, 2924. https://doi.org/10.3390/polym14142924

Hedjazi L, Guessasma S, Belhabib S, Stephant N. On the Mechanical Performance of Polylactic Material Reinforced by Ceramic in Fused Filament Fabrication. Polymers. 2022; 14(14):2924. https://doi.org/10.3390/polym14142924

Chicago/Turabian StyleHedjazi, Lotfi, Sofiane Guessasma, Sofiane Belhabib, and Nicolas Stephant. 2022. "On the Mechanical Performance of Polylactic Material Reinforced by Ceramic in Fused Filament Fabrication" Polymers 14, no. 14: 2924. https://doi.org/10.3390/polym14142924

APA StyleHedjazi, L., Guessasma, S., Belhabib, S., & Stephant, N. (2022). On the Mechanical Performance of Polylactic Material Reinforced by Ceramic in Fused Filament Fabrication. Polymers, 14(14), 2924. https://doi.org/10.3390/polym14142924