High-Precision Thin Wall Bipolar Plates for Fuel Cell Applications via Injection Compression Molding with Dynamic Mold Temperature Control

Abstract

:1. Introduction

2. Materials, Specimen and Methods

2.1. Materials

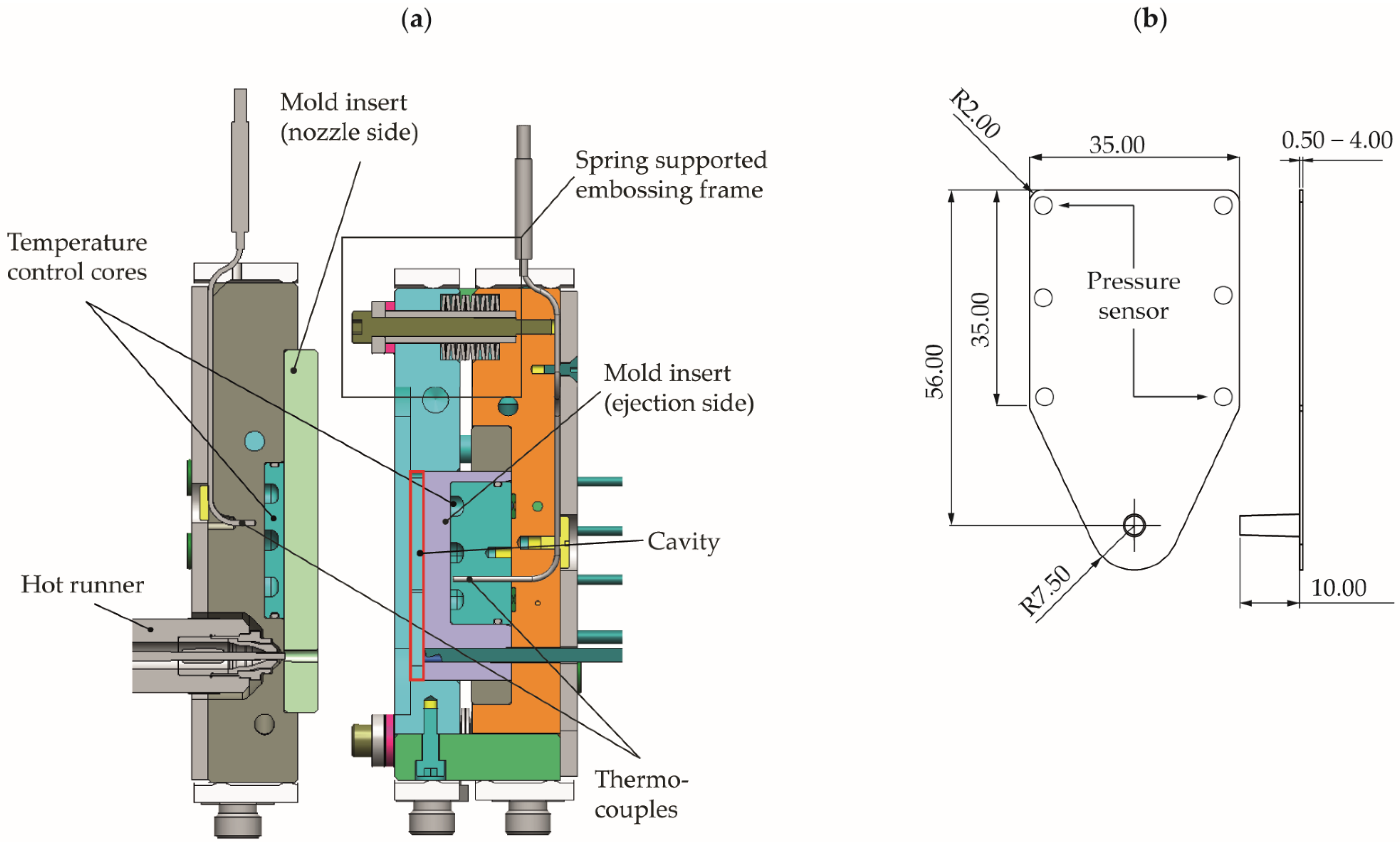

2.2. Specimen

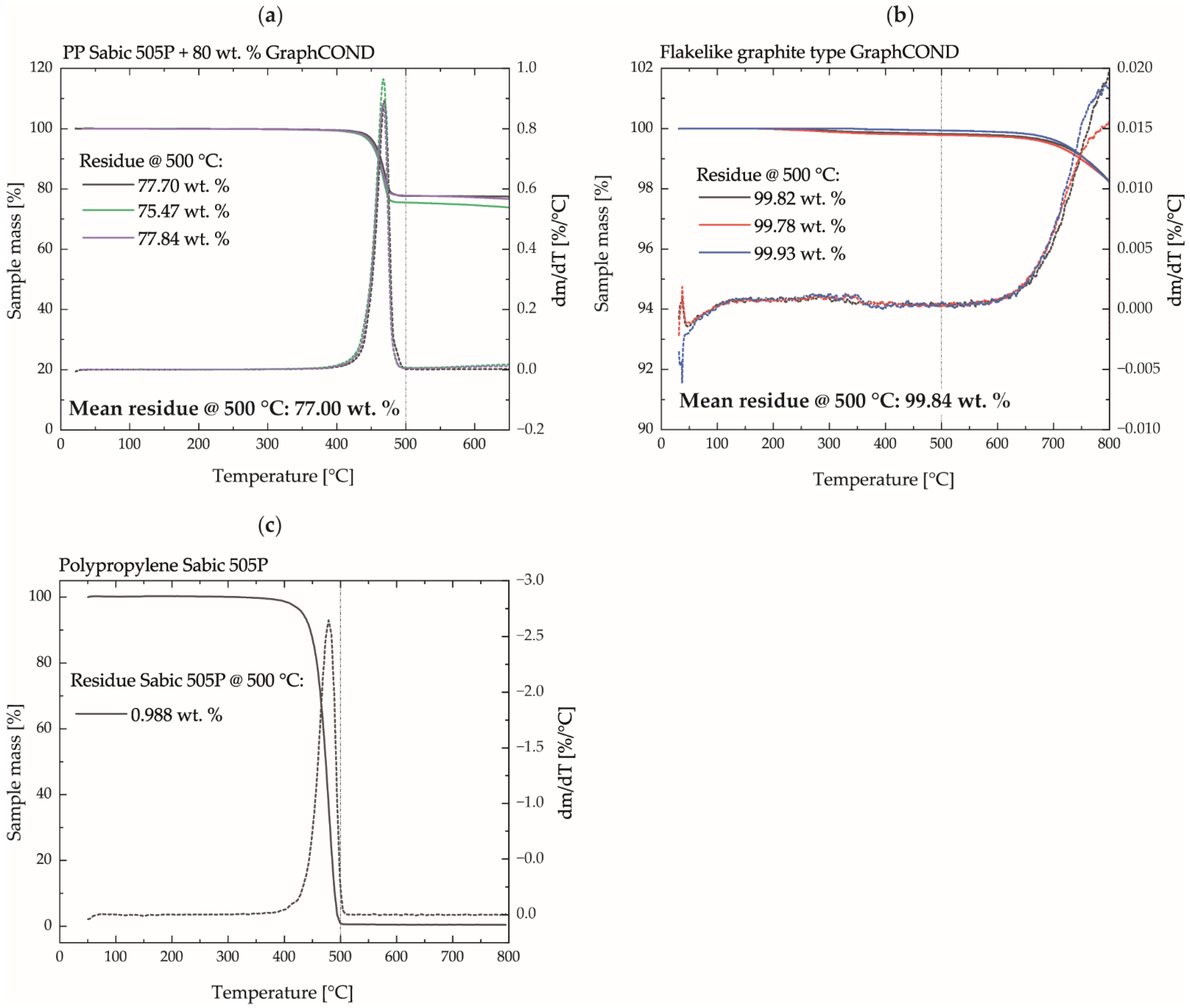

2.3. Thermogravimetric Analysis

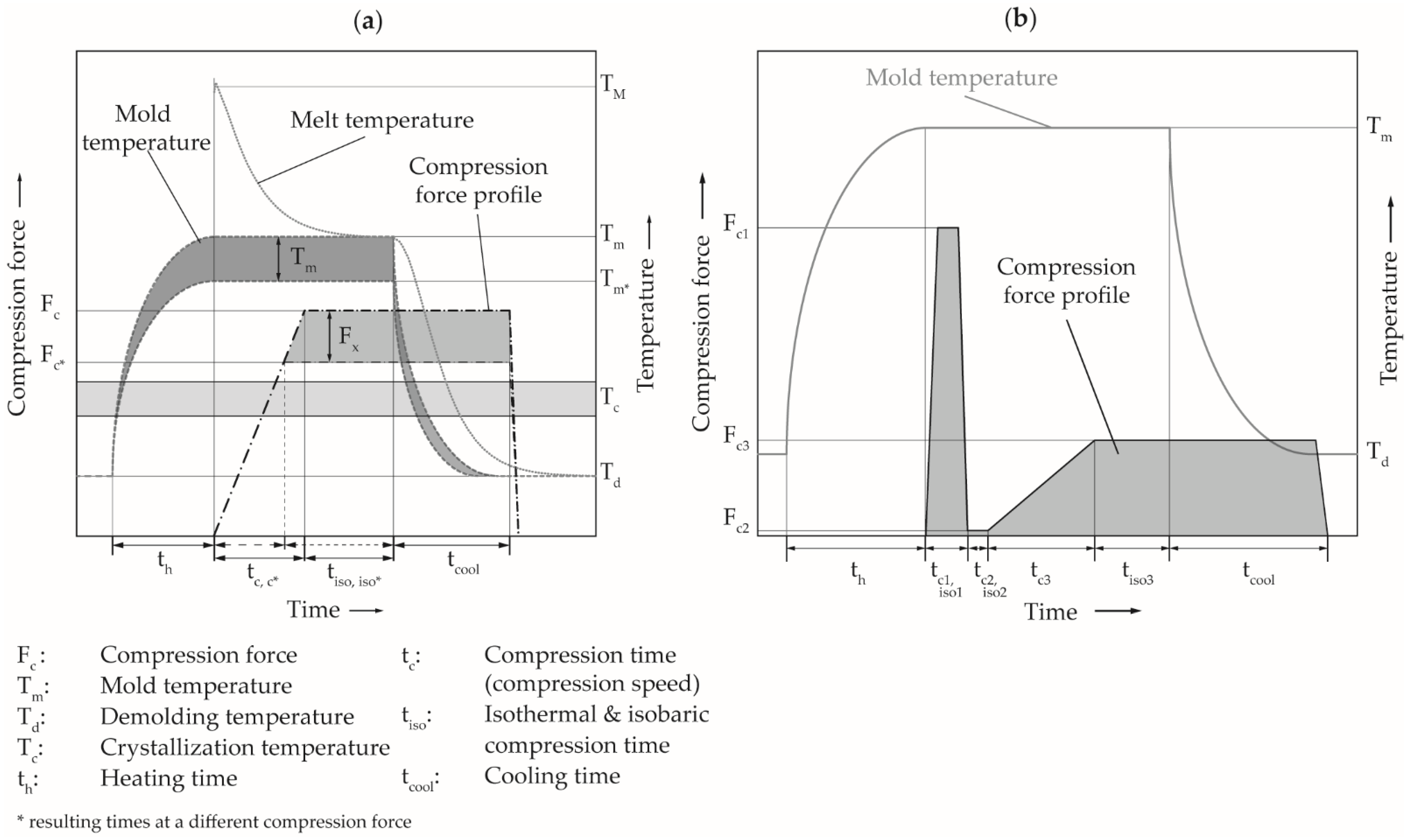

2.4. Analytical Process Characterization

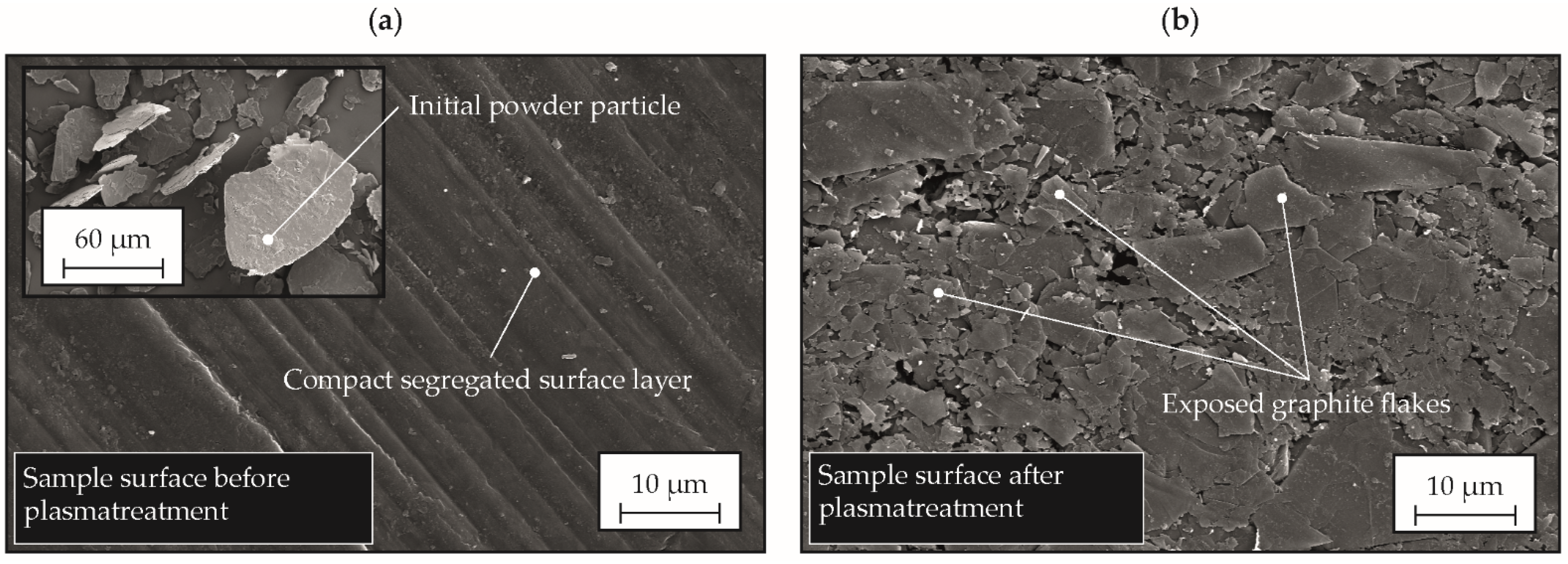

2.5. Electrical Conductivity

2.6. Plate Aspect Ratio and Dimensional Accuracy

3. Results and Discussion

3.1. Filling Content

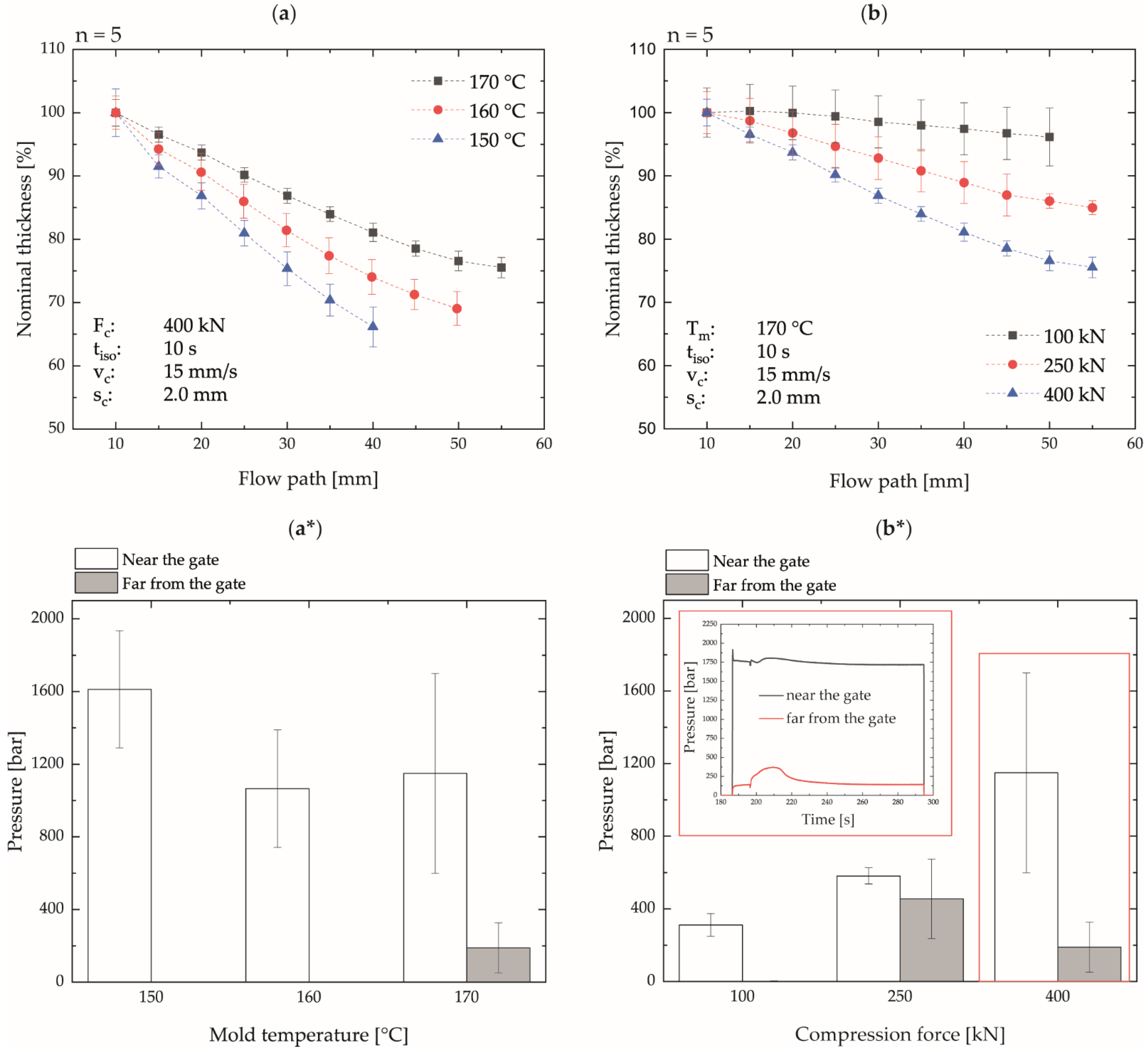

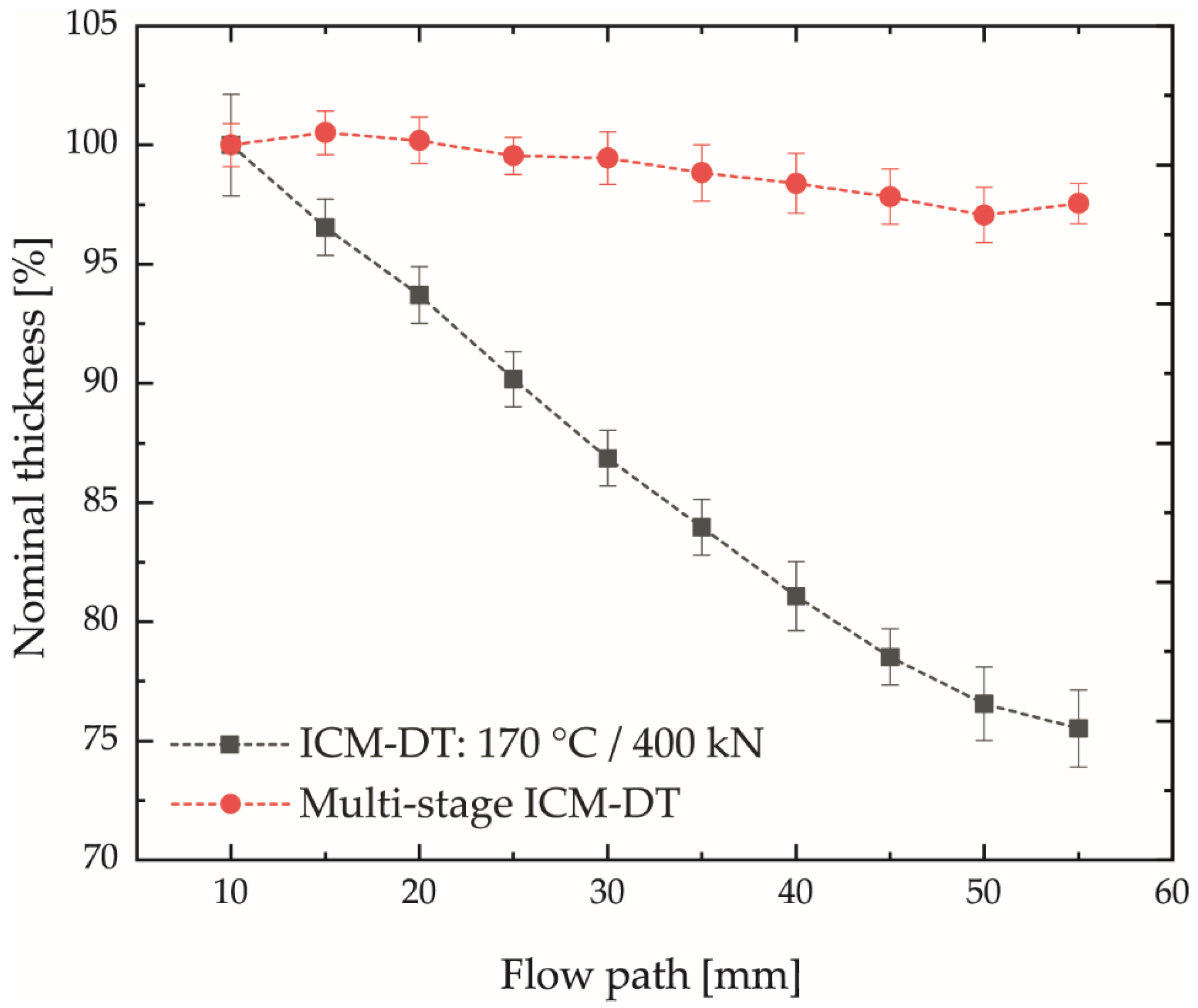

3.2. Analytical Process Characterization

3.3. Electrical Conductivity

3.4. Plate Aspect Ratio and Dimensional Accuracy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviation

| PEMFC | Polymer electrolyte membrane fuel cell |

| CNT | Carbon nanotubes |

| PPS | Polyphenylene sulfide |

| PP | Polypropylene |

| PA6 | Polyamide 6 |

| S/V | Surface to Volume ratio |

| ICM-DT | Injection compression molding with dynamic mold temperature control |

| IM-DT | Injection molding with dynamic mold temperature control |

| DSC | Dynamic differential calorimetry |

| pvT | Pressure–volume–temperature measurement |

| R | Electrical resistance |

| RL,x | Line resistance |

| A | Cross sectional area of the current passage |

| d | Plate thickness |

| Specific resistivity | |

| Specific conductivity | |

| Tm | Mold temperature |

| Td | Demolding temperature |

| Tc | Crystallization temperature |

| Tc,b | Temperature of crystallization onset |

| Tc,m | Temperature of crystallization peak |

| Tc,e | Temperature of crystallization offset |

| Fc,x | Compression force in stage x |

| vc,x | Compression speed in stage x |

| Tiso,x | Isothermal and isobaric compression time in stage x |

| th | Heating time |

| TM | Melt temperature |

| sc | Compression gap |

| vi | Injection flowrate |

| tcool | Cooling time |

| fc | Filling content |

| mc/pp/g,res | Residual mass of the compound/polypropylene/graphite |

References

- Daud, W.; Rosli, R.; Majlan, E.; Hamid, S.; Mohamed, R.; Husaini, T. PEM fuel cell system control: A review. Renew. Energy 2017, 113, 620–638. [Google Scholar] [CrossRef]

- Benjamin, T.; Borup, R.; Garland, N.; Gittleman, C.; Habibzadeh, B.; Hirano, S. Fuel Cell Technical Team Roadmap. Energy Gov. (Off. Energy Effic. Renew. Energy) 2017. [Google Scholar]

- Kim, J.; Luo, G.; Wang, C.-Y. Modeling two-phase flow in three-dimensional complex flow-fields of proton exchange membrane fuel cells. J. Power Sources 2017, 365, 419–429. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, C.; Ling, C.-Y.; Han, M.; Yong, R.-Y.; Sun, D.; Chen, J. Review on current research of materials, fabrication and application for bipolar plate in proton exchange membrane fuel cell. Int. J. Hydrogen Energy 2020, 45, 29832–29847. [Google Scholar] [CrossRef]

- Pollet, B.G.; Kocha, S.S.; Staffell, I. Current status of automotive fuel cells for sustainable transport. Curr. Opin. Electrochem. 2019, 16, 90–95. [Google Scholar] [CrossRef]

- Serban, D.; Lamanna, G.; Opran, C.G. Mixing, Conveying and Injection Molding Hybrid System for Conductive Polymer Composites. Procedia CIRP 2019, 81, 677–682. [Google Scholar] [CrossRef]

- Shimpalee, S.; Lilavivat, V.; McCrabb, H.; Khunatorn, Y.; Lee, H.-K.; Lee, W.-K.; Weidner, J. Investigation of bipolar plate materials for proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2016, 41, 13688–13696. [Google Scholar] [CrossRef] [Green Version]

- Zhang, R.; Lan, S.; Xu, Z.; Qiu, D.; Peng, L. Investigation and optimization of the ultra-thin metallic bipolar plate multi-stage forming for proton exchange membrane fuel cell. J. Power Sources 2021, 484, 229298. [Google Scholar] [CrossRef]

- Papadias, D.D.; Ahluwalia, R.K.; Thomson, J.K.; Meyer, H.M., III; Brady, M.P.; Wang, H.; Turner, J.A.; Mukundan, R.; Borup, R. Degradation of SS316L bipolar plates in simulated fuel cell environment: Corrosion rate, barrier film formation kinetics and contact resistance. J. Power Sources 2015, 273, 1237–1249. [Google Scholar] [CrossRef]

- Porstmann, S.; Wannemacher, T.; Drossel, W.-G. A comprehensive comparison of state-of-the-art manufacturing methods for fuel cell bipolar plates including anticipated future industry trends. J. Manuf. Process. 2020, 60, 366–383. [Google Scholar] [CrossRef]

- Alo, O.A.; Otunniyi, I.O.; Pienaar, H. Manufacturing methods for metallic bipolar plates for polymer electrolyte membrane fuel cell. Mater. Manuf. Process. 2019, 34, 927–955. [Google Scholar] [CrossRef]

- Lan, S.; Xu, Z.; Jiang, T.; Peng, L. Thin metallic wave-like channel bipolar plates for proton exchange membrane fuel cells: Deformation behavior, formability analysis and process design. J. Power Sources 2019, 444, 227217. [Google Scholar]

- Stübler, N.; Meiners, D.; Ziegmann, G.; Hickmann, T. Investigation of the properties of polymer composite bipolar plates in fuel cells. J. Plast. Technol. 2014, 3, 69–89. [Google Scholar]

- Boyaci San, F.G.; Tekin, G. A review of thermoplastic composites for bipolar plate applications. Int. J. Energy Res. 2013, 37, 283–309. [Google Scholar] [CrossRef]

- Menges, G.; Haberstroh, E.; Michaeli, W.; Schmachtenberg, E. Menges Werkstoffkunde Kunststoffe; Carl Hanser Verlag GmbH Co KG: München, Germany, 2014. [Google Scholar]

- Kim, N.H.; Kuila, T.; Kim, K.M.; Nahm, S.H.; Lee, J.H. Material selection windows for hybrid carbons/poly (phenylene sulfide) composite for bipolar plates of fuel cell. Polym. Test. 2012, 31, 537–545. [Google Scholar] [CrossRef]

- Yang, T.; Shi, P. Study on the mesocarbon microbeads/polyphenylene sulfide composite bipolar plates applied for proton exchange membrane fuel cells. J. Power Sources 2008, 175, 390–396. [Google Scholar] [CrossRef]

- Rzeczkowski, P.; Krause, B.; Pötschke, P. Characterization of highly filled PP/graphite composites for adhesive joining in fuel cell applications. Polymers 2019, 11, 462. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ehrenstein, G.W. Polymeric Materials: Structure, Properties, Applications; Carl Hanser Verlag: München, Germany, 2012. [Google Scholar]

- Mighri, F.; Huneault, M.A.; Champagne, M.F. Electrically conductive thermoplastic blends for injection and compression molding of bipolar plates in the fuel cell application. Polym. Eng. Sci. 2004, 44, 1755–1765. [Google Scholar] [CrossRef]

- Planes, E.; Flandin, L.; Alberola, N. Polymer composites bipolar plates for PEMFCs. Energy Procedia 2012, 20, 311–323. [Google Scholar] [CrossRef] [Green Version]

- Zarmehri, E.; Sadeghi, M.; Mehrabani-Zeinabad, A. Construction of composite polymer bipolar plate for Pem fuel cell. Iran. J. Energy Env. 2013, 4, 357–360. [Google Scholar] [CrossRef]

- Sandler, J.; Kirk, J.; Kinloch, I.; Shaffer, M.; Windle, A. Ultra-low electrical percolation threshold in carbon-nanotube-epoxy composites. Polymer 2003, 44, 5893–5899. [Google Scholar] [CrossRef]

- Seo, M.-K.; Park, S.-J. Electrical resistivity and rheological behaviors of carbon nanotubes-filled polypropylene composites. Chem. Phys. Letters 2004, 395, 44–48. [Google Scholar] [CrossRef]

- Derieth, T.; Bandlamudi, G.; Beckhaus, P.; Kreuz, C.; Mahlendorf, F.; Heinzel, A. Development of highly filled graphite compounds as bipolar plate materials for low and high temperature PEM fuel cells. J. New Mater. Electrochem. Syst. 2008, 11, 21. [Google Scholar]

- Rudolph, N.M.; Agudelo, A.C.; Granada, J.C.; Park, H.E.; Osswald, T.A. WLF model for the pressure dependence of zero shear viscosity of polycarbonate. Rheol. Acta 2016, 55, 673–681. [Google Scholar] [CrossRef]

- Schröder, T. Rheologie Der Kunststoffe: Theorie Und Praxis; Carl Hanser Verlag GmbH Co KG: München, Germany, 2020. [Google Scholar]

- Starov, V.; Zhdanov, V.; Meireles, M.; Molle, C. Viscosity of concentrated suspensions: Influence of cluster formation. Adv. Colloid Interface Sci. 2002, 96, 279–293. [Google Scholar] [CrossRef] [Green Version]

- Gleissle, W. Rheologie hochgefüllter Kunststoffe. In Hochgefüllte Kunststoffe mit Definierten Magnetischen, Thermischen und Elektrischen Eigenschaften; Springer-VDI-Verlag: Düsseldorf, Germany, 2002. [Google Scholar]

- Rudolph, N.; Osswald, T.A. Polymer Rheology: Fundamentals and Applications; Carl Hanser Verlag: München, Germany, 2014. [Google Scholar]

- Markov, A. Rheologisches verhalten hochgefüllter kunststoffe. einfluss der füllstoffe. Mater. Werkst. Entwickl. Fert. Prüf. Eig. Anwend. Technischer Werkst. 2008, 39, 227–233. [Google Scholar] [CrossRef]

- Chen, H.; Ginzburg, V.V.; Yang, J.; Yang, Y.; Liu, W.; Huang, Y.; Du, L.; Chen, B. Thermal conductivity of polymer-based composites: Fundamentals and applications. Prog. Polym. Sci. 2016, 59, 41–85. [Google Scholar] [CrossRef]

- Fischer, C. Zum Einfluss Der Werkzeugtemperatur Beim Dynamisch Temperierten Spritzgießen von Teilkristallinen Mikro-Und Dünnwandbauteilen; Lehrstuhl f. Kunststofftechnik Universität Erlangen-Nürnberg: Erlangen, Germany, 2019. [Google Scholar]

- Meister, S.; Seefried, A.; Drummer, D. Replication quality of micro structures in injection moulded thin wall parts using rapid tooling moulds. Microsyst. Technol. 2016, 22, 687–698. [Google Scholar] [CrossRef]

- Meister, S.; Drummer, D. Influence of mold temperature on mold filling behavior and part properties in micro injection molding. Int. Polym. Process. 2013, 28, 550–557. [Google Scholar] [CrossRef]

- Yu, F.; Deng, H.; Zhang, Q.; Wang, K.; Zhang, C.; Chen, F.; Fu, Q. Anisotropic multilayer conductive networks in carbon nanotubes filled polyethylene/polypropylene blends obtained through high speed thin wall injection molding. Polymer 2013, 54, 6425–6436. [Google Scholar] [CrossRef]

- Xu, G.; Yu, L.; Lee, L.J.; Koelling, K.W. Experimental and numerical studies of injection molding with microfeatures. Polym. Eng. Sci. 2005, 45, 866–875. [Google Scholar] [CrossRef]

- Yokoi, H.; Han, X.; Takahashi, T.; Kim, W. Effects of molding conditions on transcription molding of microscale prism patterns using ultra-high-speed injection molding. Polym. Eng. Sci. 2006, 46, 1140–1146. [Google Scholar] [CrossRef]

- Greener, J. Pressure-Induced densification in injection molding. Polym. Eng. Sci. 1986, 26, 534–542. [Google Scholar] [CrossRef]

- Hong, S.; Min, I.; Yoon, K.; Kang, J. Effects of adding injection–compression to rapid heat cycle molding on the structure of a light guide plate. J. Micromechanics Microengineering 2013, 24, 015009. [Google Scholar] [CrossRef]

- Wimberger-Friedl, R. The assessment of orientation, stress and density distributions in injection-molded amorphous polymers by optical techniques. Prog. Polym. Sci. 1995, 20, 369–401. [Google Scholar] [CrossRef]

- Kadijk, S.; Van Den Brule, B. On the pressure dependency of the viscosity of molten polymers. Polym. Eng. Sci. 1994, 34, 1535–1546. [Google Scholar] [CrossRef]

- Huang, J.; Fu, X.; Shao, C.; Ma, Z.; Wang, Y.; Liu, C.; Shen, C. High-pressure induced formation of isotactic polypropylene mesophase: Synergistic effect of pressure and pressurization rate. Polym. Eng. Sci. 2019, 59, 439–446. [Google Scholar] [CrossRef]

- Toll, S.; Andersson, P.O. Microstructure of long-and short-fiber reinforced injection molded polyamide. Polym. Compos. 1993, 14, 116–125. [Google Scholar] [CrossRef]

- Fischer, C.D.D. Micro Components with Locally Different Properties Realized by Segmented Tempered Injection Molding. In Proceedings of the SPE Antec 2017, Anaheim, CA, USA, 8 May 2017. [Google Scholar]

- Li, Y.; Tjong, S. Nonlinear current–voltage characteristics in polymer nanocomposites. In Physical Properties and Applications of Polymer Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2010; pp. 862–890. [Google Scholar]

- Brokamp, S.; Heinzel, A.; Birkholz, A.; Wortberg, J. Final Report on the IGF Research Project 455 ZN: Verfahrensentwicklung Eines Variothermen Spritzgießprozesses zur Herstellung Großdimensionierter Bipolarplatten für den Einsatz in Hochtemperatur PEM-Brennstoffzellen; Duisburg-Essen: Duisburg, Germany, 2013. [Google Scholar]

| Calculated Graphite Content (wt.%) | Dosing Speed PP Sabic 505 P (kg·h−1) | Dosing Speed GraphCOND (kg·h−1) | Nozzle Temperature (°C) | Screw Speed (min−1) |

|---|---|---|---|---|

| 50 | 2.5 | 2.5 | 270 | 150 |

| 60 | 2.0 | 3.0 | ||

| 70 | 1.5 | 3.5 | ||

| 80 | 1.0 | 4.0 |

| Parameter (Unit) | Value |

|---|---|

| Mold temperature Tm (°C) | 150/160/170 |

| Heating time th (s) | 180 |

| Melt temperature TM (°C) | 270 |

| Compression gap sc (mm) | 2.0 |

| Injection flowrate vi (cm3·s−1) | 25.4 |

| Compression speed vc (mm·s−1) | 15.0 |

| Compression force Fc (kN) | 100/250/400 |

| Isothermal und isobaric compression time tiso (s) | 10 |

| Cooling time tcool (s) | 80 |

| Demolding temperature Td (°C) | 60 |

| Parameter (SI-Unit) | Value |

|---|---|

| Compression speed stage 1 vc1 (mm·s−1) (tc1) | 15.0 |

| Compression force stage 1 Fc1 (kN) | 400 |

| Isothermal und isobaric compression time stage 1 tiso1 (s) | 5 |

| Compression speed stage 2 vc2 (mm·s−1) (tc2) | 15.0 |

| Compression force stage 2 Fc1 (kN) | 10 |

| Isothermal und isobaric compression time stage 1 tiso2 (s) | 5 |

| Compression speed stage 3 vc3 (mm·s−1) (tc3) | 1.0 |

| Compression force stage 3 Fc3 (kN) | 100 |

| Isothermal und isobaric compression time stage 3 tiso3 (s) | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roth, B.; Frank, R.; Kleffel, T.; Schneider, K.; Drummer, D. High-Precision Thin Wall Bipolar Plates for Fuel Cell Applications via Injection Compression Molding with Dynamic Mold Temperature Control. Polymers 2022, 14, 2799. https://doi.org/10.3390/polym14142799

Roth B, Frank R, Kleffel T, Schneider K, Drummer D. High-Precision Thin Wall Bipolar Plates for Fuel Cell Applications via Injection Compression Molding with Dynamic Mold Temperature Control. Polymers. 2022; 14(14):2799. https://doi.org/10.3390/polym14142799

Chicago/Turabian StyleRoth, Benedikt, Rainer Frank, Tobias Kleffel, Kevin Schneider, and Dietmar Drummer. 2022. "High-Precision Thin Wall Bipolar Plates for Fuel Cell Applications via Injection Compression Molding with Dynamic Mold Temperature Control" Polymers 14, no. 14: 2799. https://doi.org/10.3390/polym14142799

APA StyleRoth, B., Frank, R., Kleffel, T., Schneider, K., & Drummer, D. (2022). High-Precision Thin Wall Bipolar Plates for Fuel Cell Applications via Injection Compression Molding with Dynamic Mold Temperature Control. Polymers, 14(14), 2799. https://doi.org/10.3390/polym14142799