Facile Construction of Polypyrrole Microencapsulated Melamine-Coated Ammonium Polyphosphate to Simultaneously Reduce Flammability and Smoke Release of Epoxy Resin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

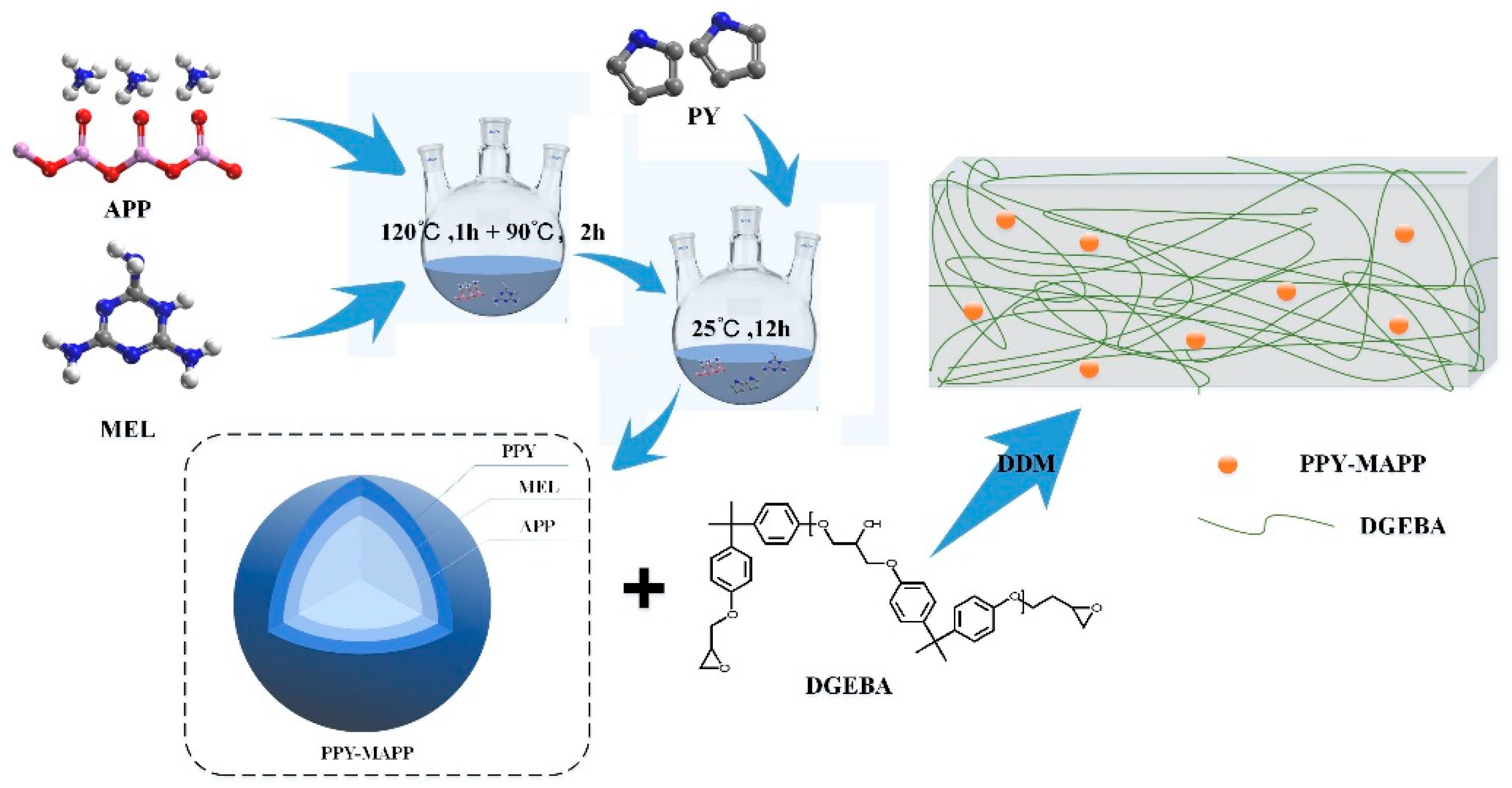

2.2. Synthesis of PPy-MAPP

2.3. Preparation of Pure EP and EP Composites

2.4. Characterization and Measurements

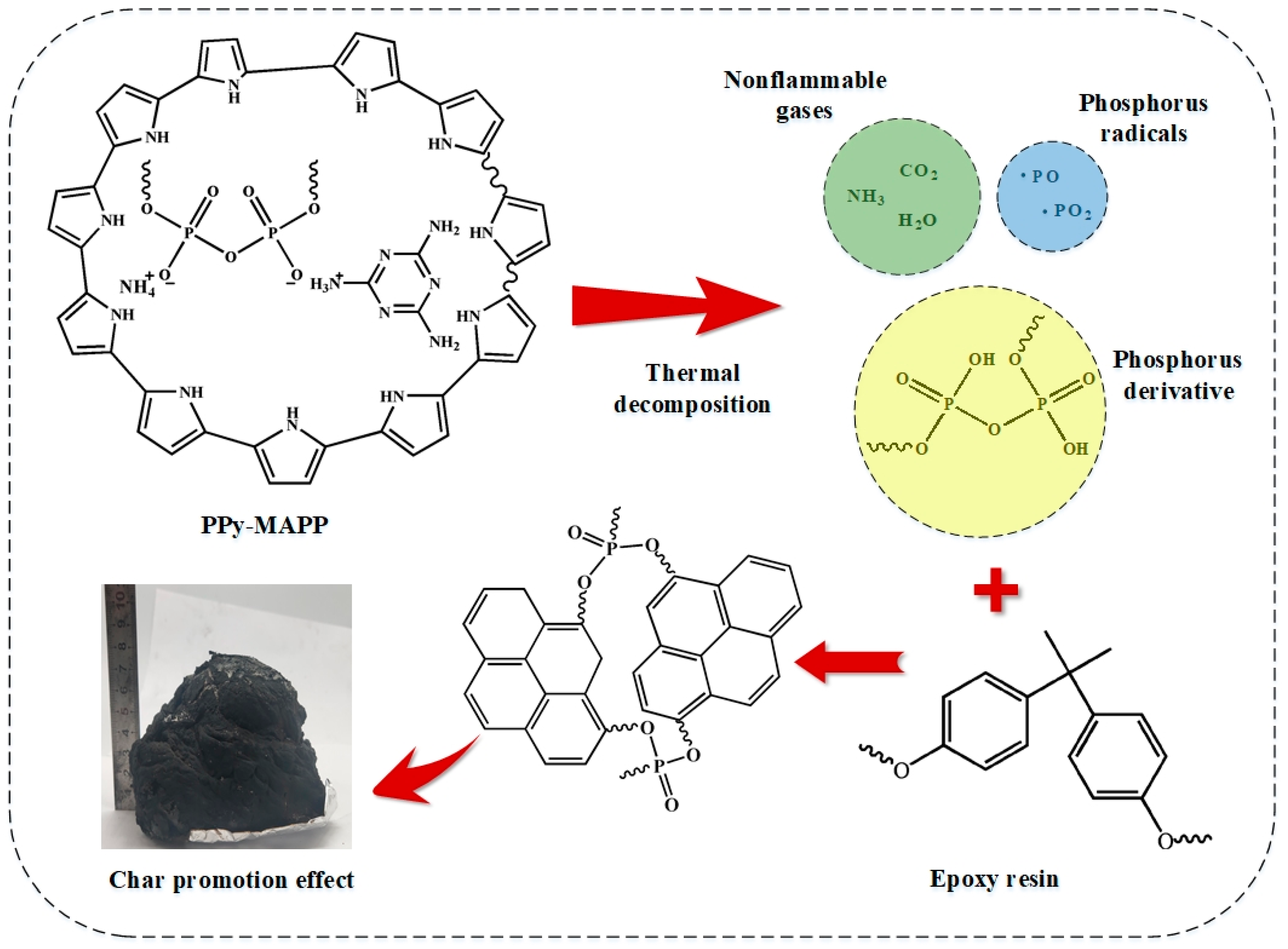

3. Results and Discussion

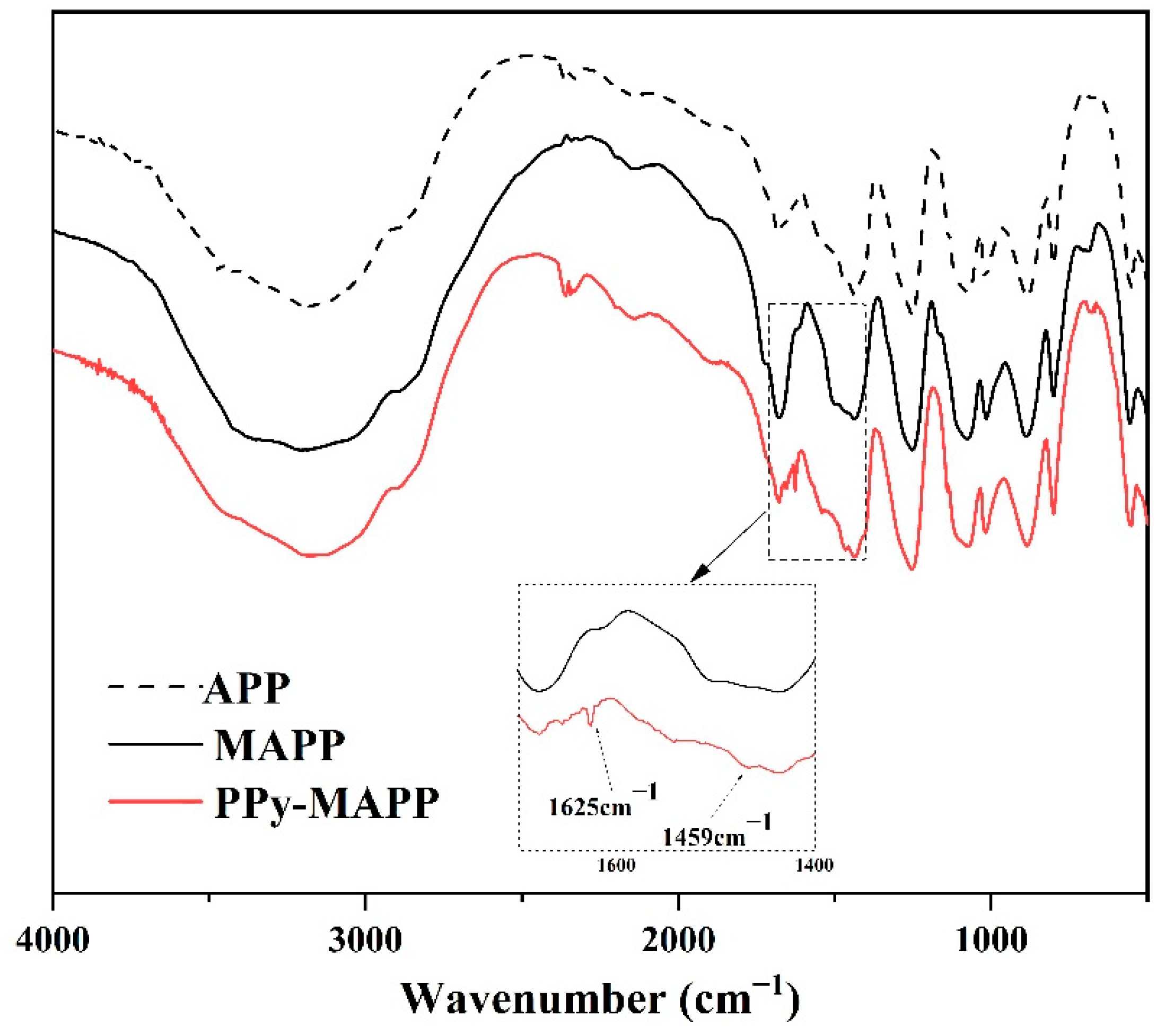

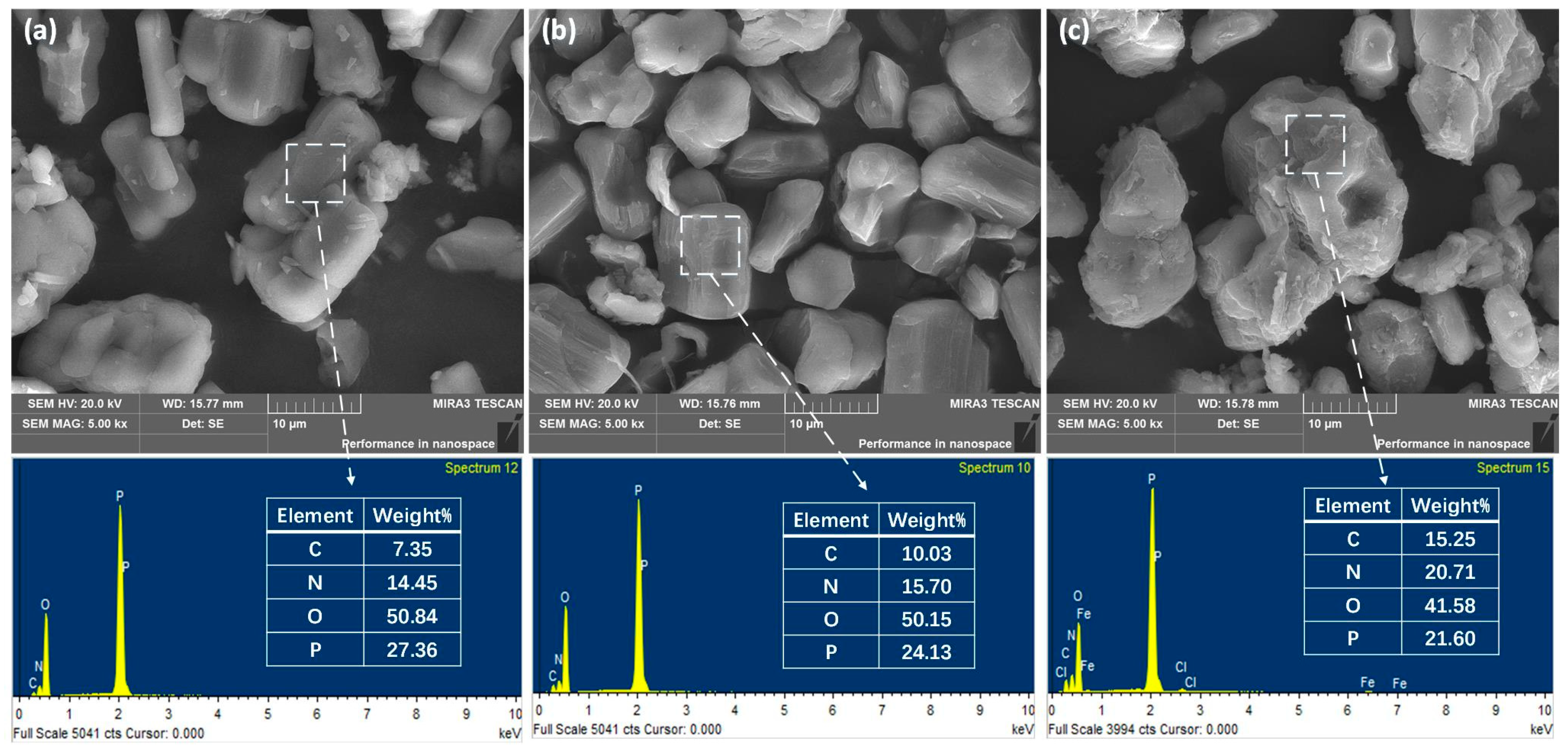

3.1. Characterization of PPy-MAPP

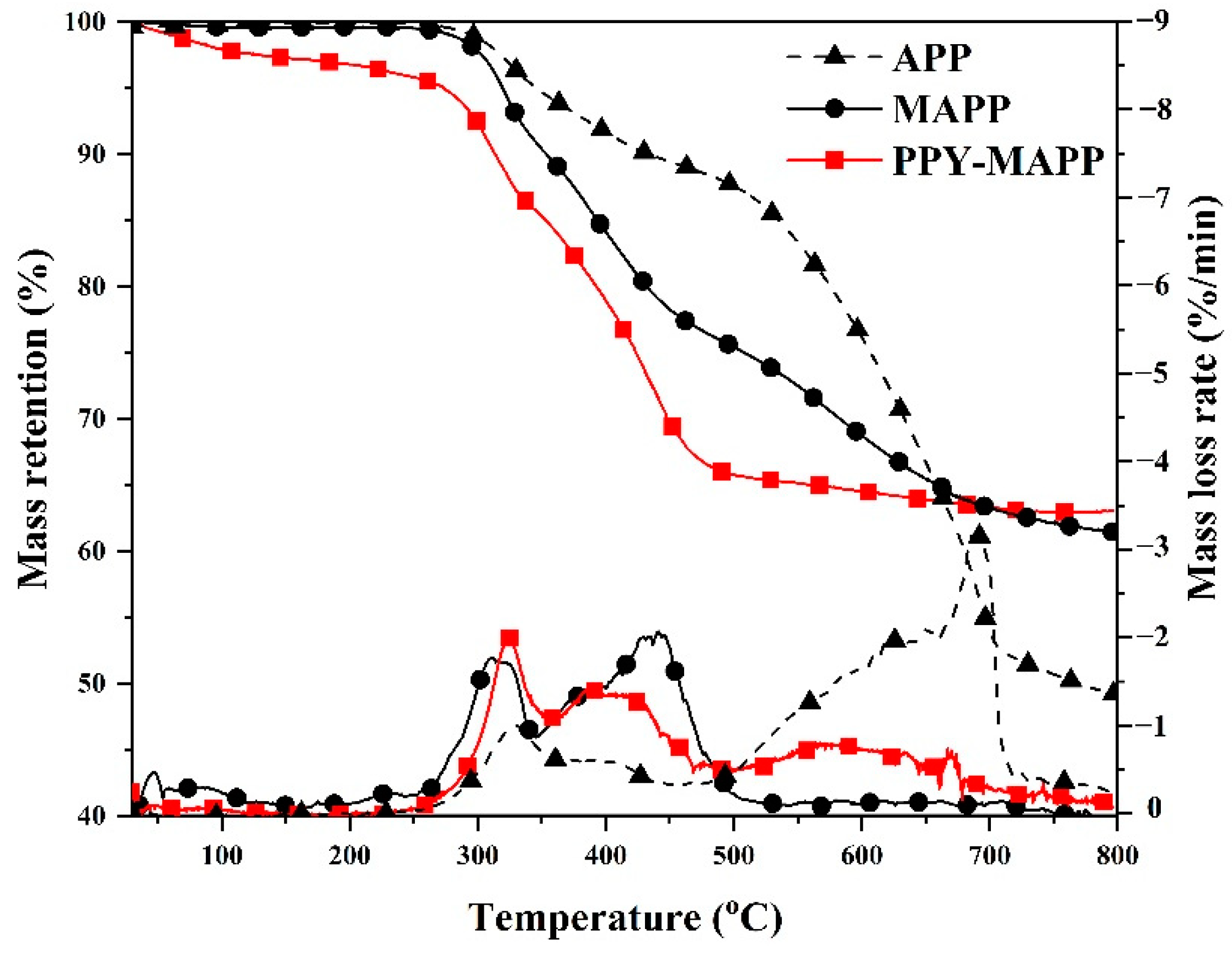

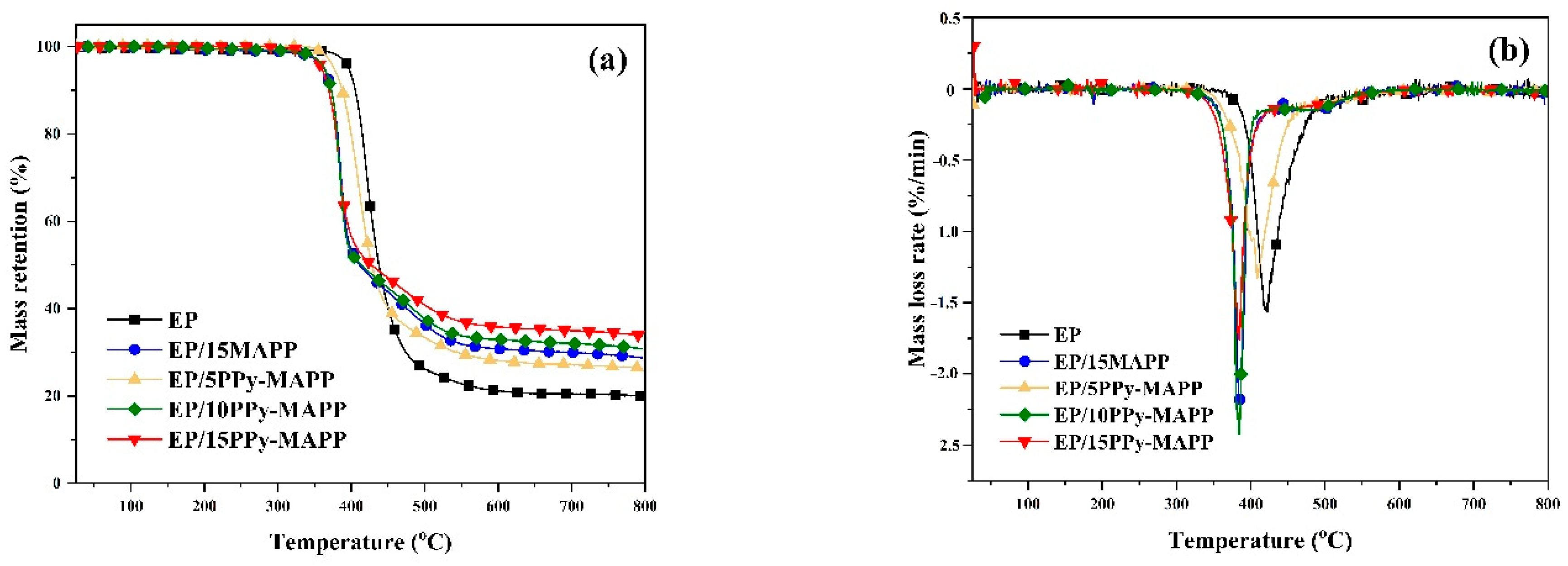

3.2. TG Analysis

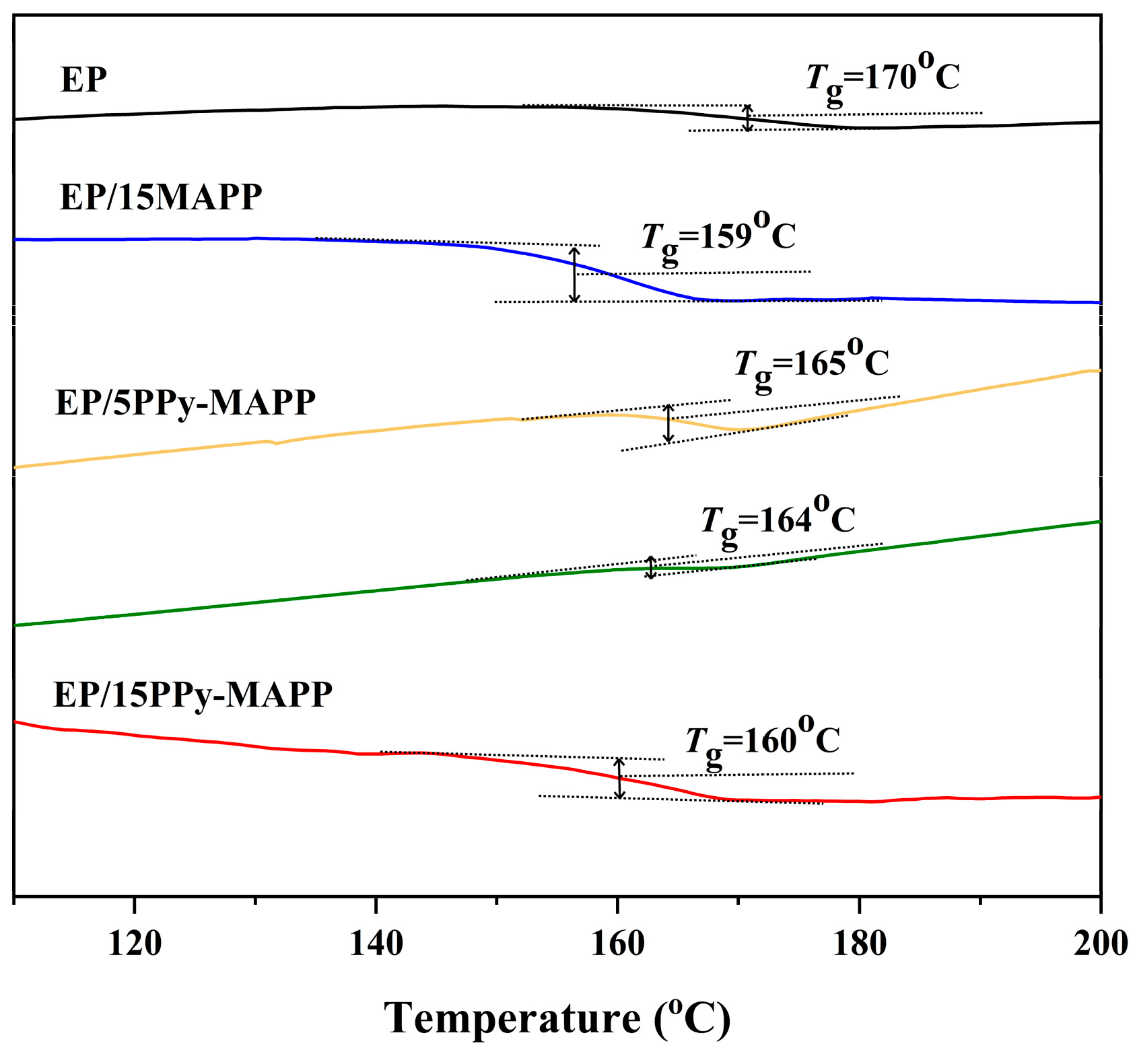

3.3. DSC Analysis

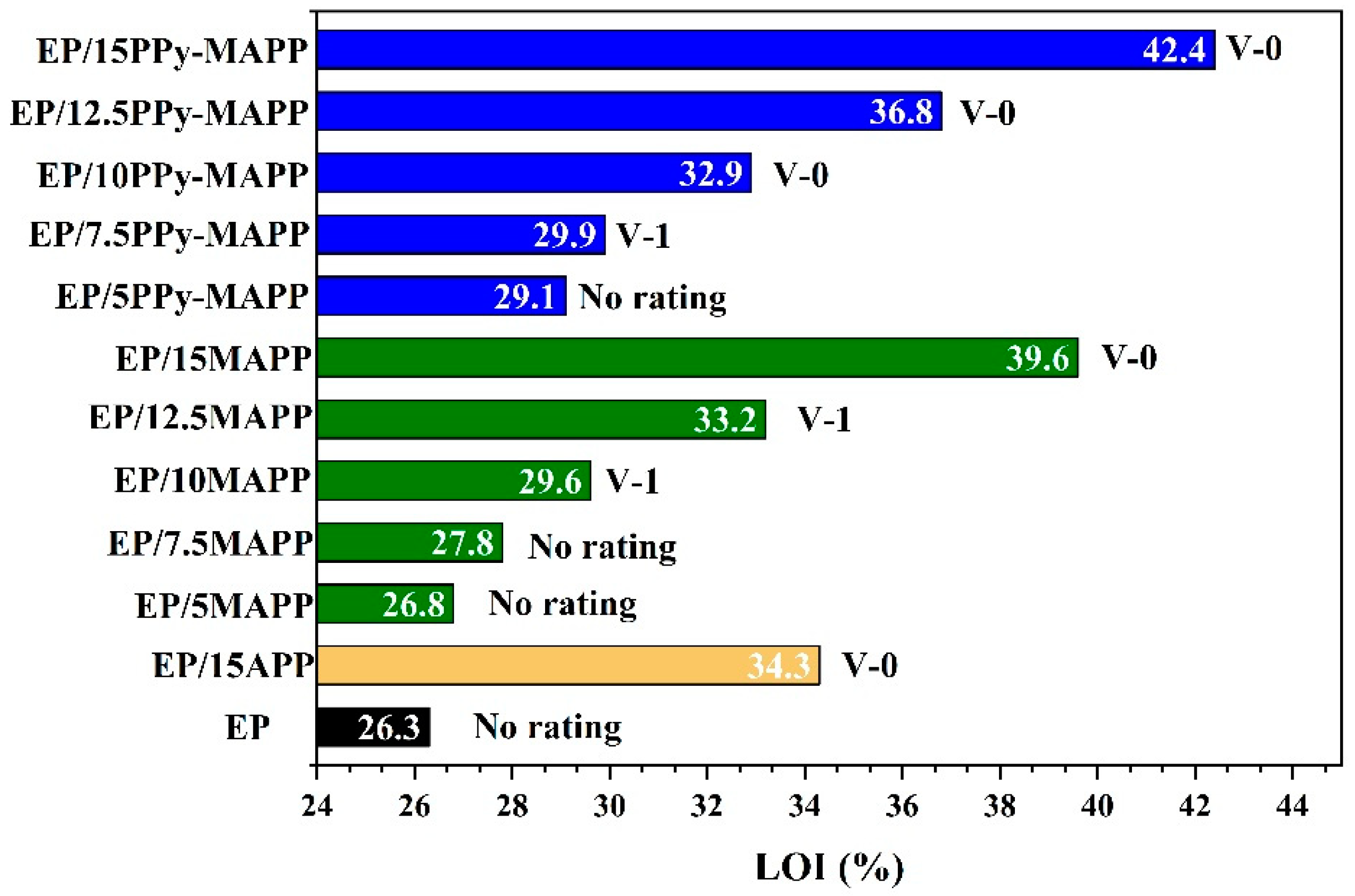

3.4. LOI and UL94 Tests

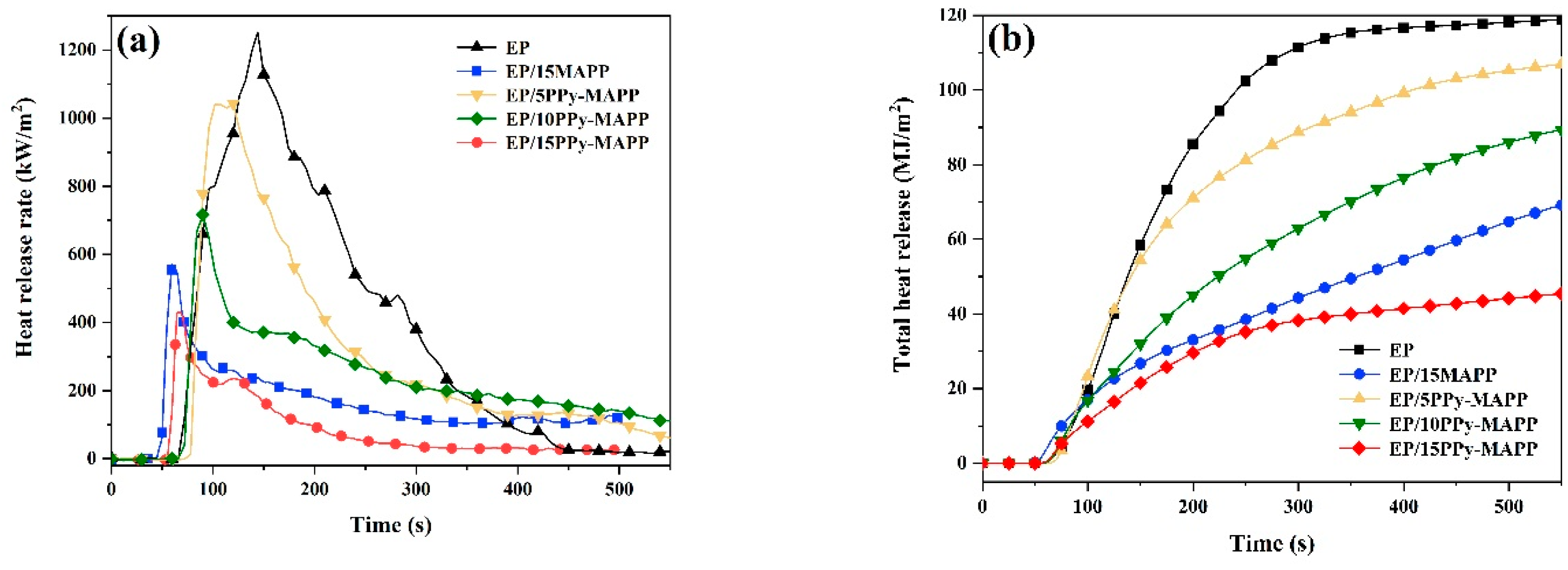

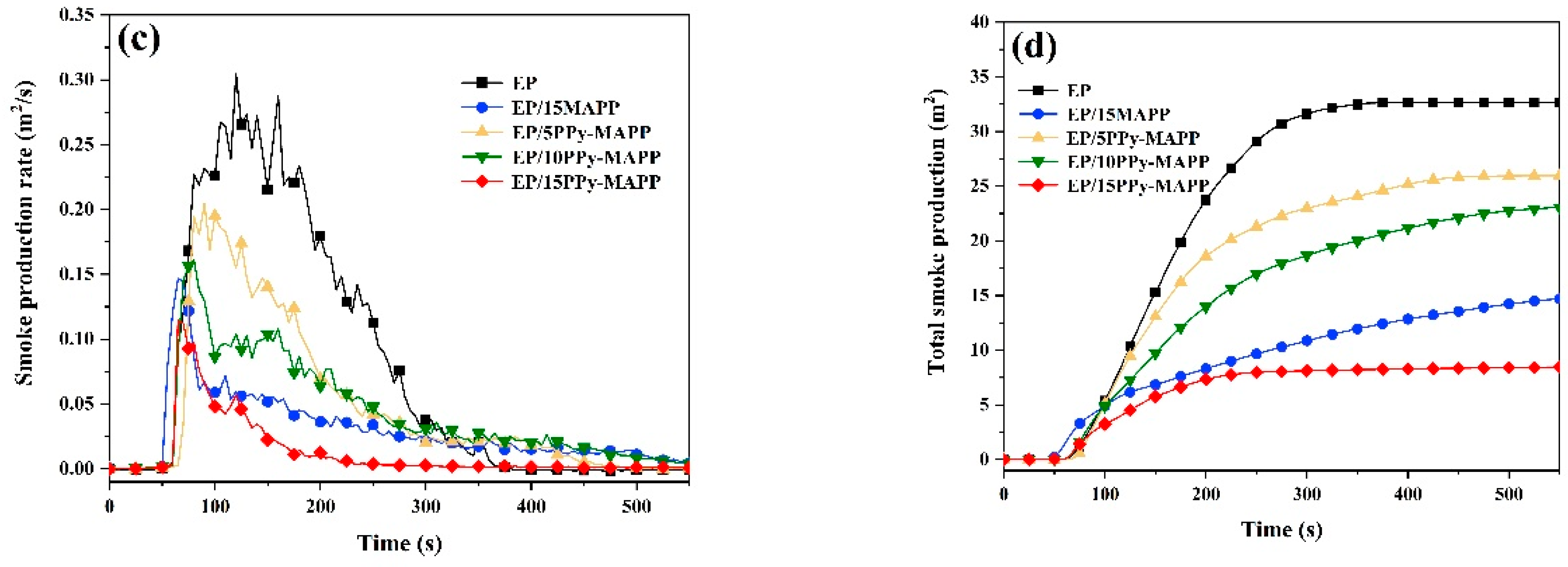

3.5. Cone Calorimeter Test

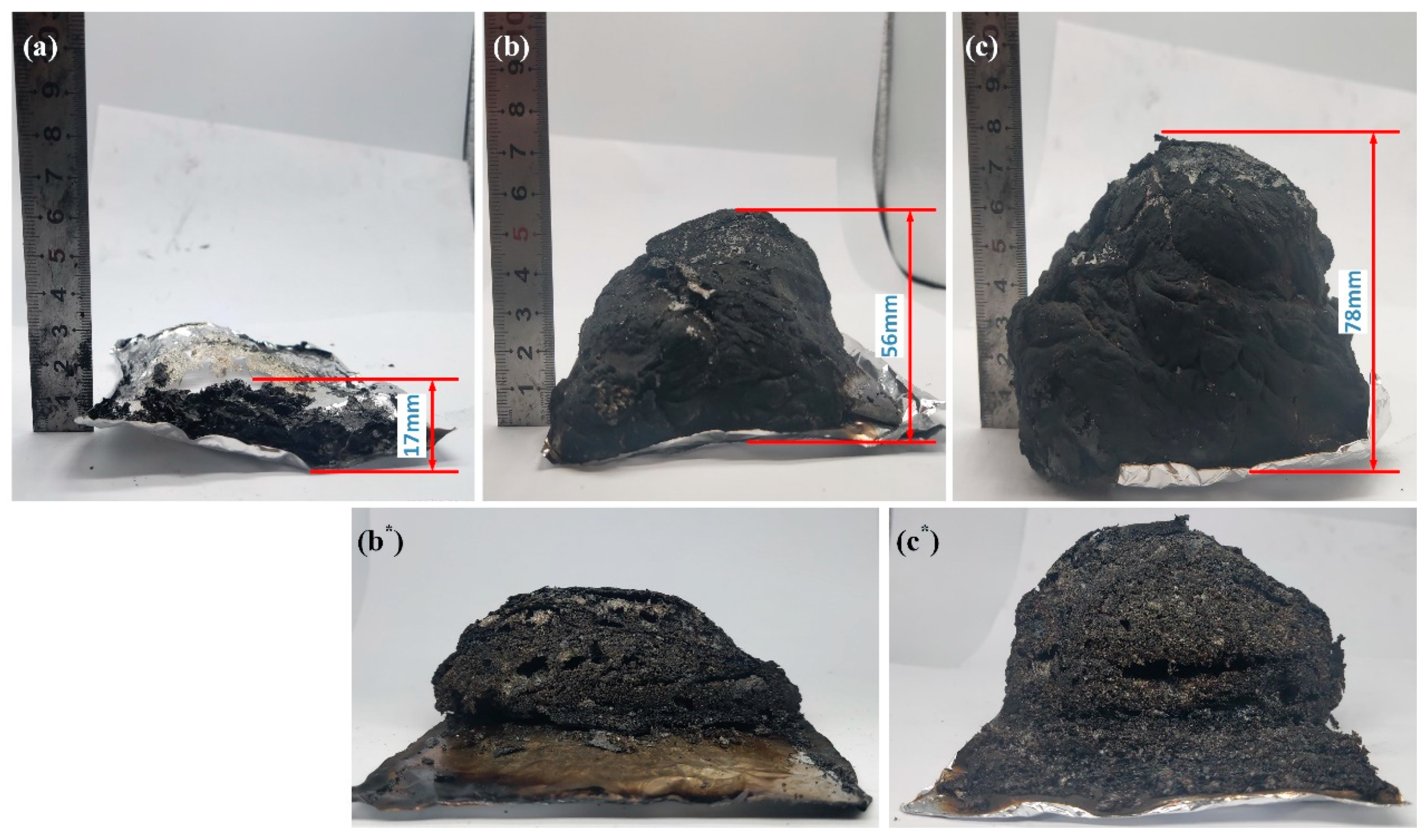

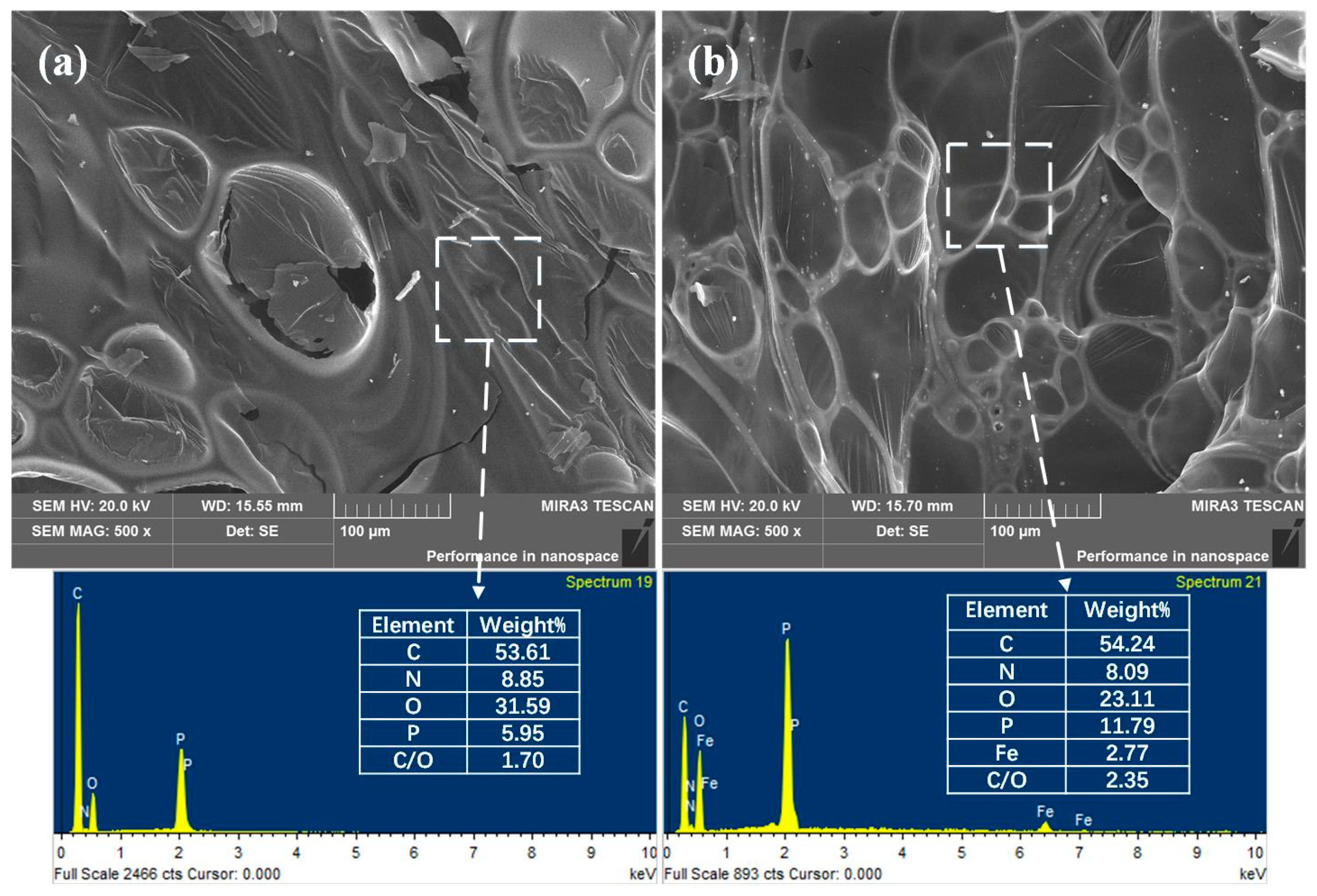

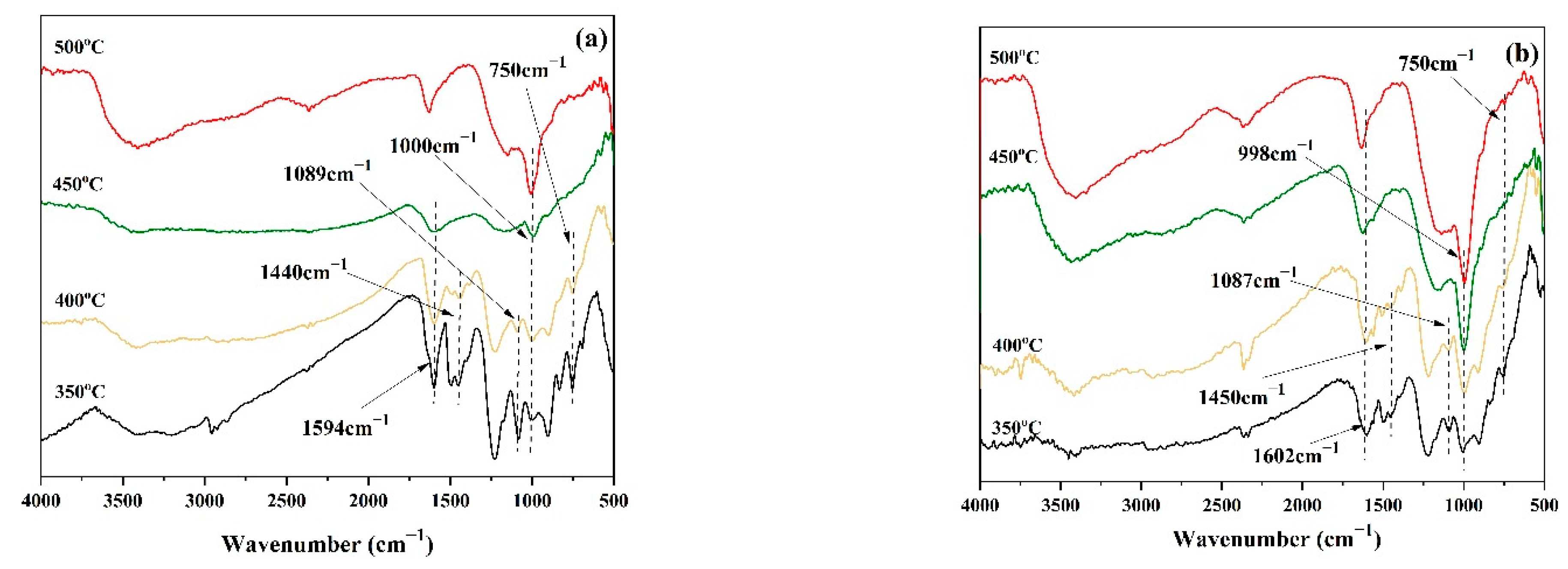

3.6. Char Residue Analysis

3.7. Tensile Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huo, S.; Yang, S.; Wang, J.; Cheng, J.; Zhang, Q.; Hu, Y.; Ding, G.; Zhang, Q.; Song, P. A liquid phosphorus-containing imidazole derivative as flame-retardant curing agent for epoxy resin with enhanced thermal latency, mechanical, and flame-retardant performances. J. Hazard. Mater. 2020, 386, 121984. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Yang, S.; Wang, J.; Cheng, J.; Zhang, Q.; Ding, G.; Hu, Y.; Huo, S. A DOPO based reactive flame retardant constructed by multiple heteroaromatic groups and its application on epoxy resin: Curing behavior, thermal degradation and flame retardancy. Polym. Degrad. Stab. 2019, 167, 10–20. [Google Scholar] [CrossRef]

- Wang, J.; Ma, C.; Wang, P.; Qiu, S.; Cai, W.; Hu, Y. Ultra-low phosphorus loading to achieve the superior flame retardancy of epoxy resin. Polym. Degrad. Stab. 2018, 149, 119–128. [Google Scholar] [CrossRef]

- Müller, P.; Schartel, B. Melamine poly(metal phosphates) as flame retardant in epoxy resin: Performance, modes of action, and synergy. J. Appl. Polym. Sci. 2016, 133, 43549. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, J.; Yang, S.; Cheng, J.; Ding, G.; Huo, S. Facile construction of one-component intrinsic flame-retardant epoxy resin system with fast curing ability using imidazole-blocked bismaleimide. Compos. Part B Eng. 2019, 177, 107380. [Google Scholar] [CrossRef]

- Shi, X.-H.; Xu, Y.-J.; Long, J.-W.; Zhao, Q.; Ding, X.-M.; Chen, L.; Wang, Y.-Z. Layer-by-layer assembled flame-retardant architecture toward high-performance carbon fiber composite. Chem. Eng. J. 2018, 353, 550–558. [Google Scholar] [CrossRef]

- Alongi, J.; Han, Z.; Bourbigot, S. Intumescence: Tradition versus novelty. A comprehensive review. Prog. Polym. Sci. 2015, 51, 28–73. [Google Scholar] [CrossRef]

- Mostovoy, A.S.; Nurtazina, A.S.; Burmistrov, I.N.; Kadykova, Y.A. Effect of Finely Dispersed Chromite on the Physicochemical and Mechanical Properties of Modified Epoxy Composites. Russ. J. Appl. Chem. 2018, 91, 1758–1766. [Google Scholar] [CrossRef]

- Moaseri, E.; Bazubandi, B.; Baniadam, M.; Maghrebi, M. Enhancement in mechanical properties of multiwalled carbon nanotube-reinforced epoxy composites: Crosslinking of the reinforcement with the matrix via diamines. Polym. Eng. Sci. 2019, 59, 1905–1910. [Google Scholar] [CrossRef]

- Ahmetli, G.; Kocak, N.; Dag, M.; Kurbanli, R. Mechanical and thermal studies on epoxy toluene oligomer-modified epoxy resin/marble waste composites. Polym. Compos. 2012, 33, 1455–1463. [Google Scholar] [CrossRef]

- Bekeshev, A.; Mostovoy, A.; Tastanova, L.; Kadykova, Y.; Kalganova, S.; Lopukhova, M. Reinforcement of epoxy composites with application of finely-ground ochre and electrophysical method of the composition modification. Polymers 2020, 12, 1437. [Google Scholar] [CrossRef] [PubMed]

- Bekeshev, A.; Mostovoy, A.; Kadykova, Y.; Akhmetova, M.; Tastanova, L.; Lopukhova, M. Development and Analysis of the Physicochemical and Mechanical Properties of Diorite-Reinforced Epoxy Composites. Polymers 2021, 13, 2421. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Kumar, K.; Sahoo, P.; Bhowmik, S. Study of Mechanical Properties of Wood Dust Reinforced Epoxy Composite. Procedia Mater. Sci. 2014, 6, 551–556. [Google Scholar] [CrossRef] [Green Version]

- Feng, L.; Zhao, H.; He, X.; Zhao, Y.; Gou, L.; Wang, Y. Synthesis and self-healing behavior of thermoreversible epoxy resins modified with nitrile butadiene rubber. Polym. Eng. Sci. 2019, 59, 1603–1610. [Google Scholar] [CrossRef]

- Kulkarni, S.M.; Kishore. Effect of filler–fiber interactions on compressive strength of fly ash and short-fiber epoxy composites. J. Appl. Polym. Sci. 2003, 87, 836–841. [Google Scholar] [CrossRef]

- Bao, X.; Wu, F.; Wang, J. Thermal Degradation Behavior of Epoxy Resin Containing Modified Carbon Nanotubes. Polymers 2021, 13, 3332. [Google Scholar] [CrossRef]

- Mostovoy, A.S.; Nurtazina, A.S.; Kadykova, Y.A.; Bekeshev, A.Z. Highly Efficient Plasticizers-Antipirenes for Epoxy Polymers. Inorg. Mater. Appl. Res. 2019, 10, 1135–1139. [Google Scholar] [CrossRef]

- Zhou, S.; Tao, R.; Dai, P.; Luo, Z.; He, M. Two-step fabrication of lignin-based flame retardant for enhancing the thermal and fire retardancy properties of epoxy resin composites. Polym. Compos. 2020, 41, 2025–2035. [Google Scholar] [CrossRef]

- Chen, X.L.; Wang, K.; Gu, Y.X.; Jiao, C.; Liang, H.; Li, S. Influence of nickel citrate in flame retardant thermoplastic polyurethane elastomer composites based on ammonium polyphosphate. Express Polym. Lett. 2021, 15, 445–458. [Google Scholar] [CrossRef]

- Shi, C.; Qian, X.; Jing, J.; Che, H. Influence of β-FeOOH nanorods and ammonium polyphosphate on reducing the fire hazard of epoxy resins composites. J. Ther. Anal. Calorim. 2021, 147, 3599–3607. [Google Scholar] [CrossRef]

- Kandola, B.K.; Magnoni, F.; Ebdon, J.R. Flame retardants for epoxy resins: Application-related challenges and solutions. J. Vinyl Addit. Technol. 2022, 28, 17. [Google Scholar] [CrossRef]

- Lin, H.; Yan, H.; Liu, B.; Wei, L.; Xu, B. The influence of KH-550 on properties of ammonium polyphosphate and polypropylene flame retardant composites. Polym. Degrad. Stab. 2011, 96, 1382–1388. [Google Scholar] [CrossRef]

- Zhou, L.; Guo, C.; Li, L. Influence of ammonium polyphosphate modified with 3-(methylacryloxyl) propyltrimethoxy silane on mechanical and thermal properties of wood flour–polypropylene composites. J. Appl. Polym. Sci. 2011, 122, 849–855. [Google Scholar] [CrossRef]

- Wang, N.; Mi, L.; Wu, Y.; Wang, X.; Fang, Q. Enhanced flame retardancy of natural rubber composite with addition of microencapsulated ammonium polyphosphate and MCM-41 fillers. Fire Saf. J. 2013, 62, 281–288. [Google Scholar] [CrossRef]

- Fukumura, C.; Iwata, M.; Narita, N.; Inoue, K.; Takahashi, R. Process for Producing a Melamine-Coated Ammonium Polyphosphate. U.S. Patent US5534291 A, 9 July 1996. [Google Scholar]

- Tian, F.; Liu, L.; Yang, Z.; Wang, X.; Chen, Q.; Wang, X. Electrochemical characterization of a LiV3O8–polypyrrole composite as a cathode material for lithium ion batteries. Mater. Chem. Phys. 2011, 127, 151–155. [Google Scholar] [CrossRef]

- Yue, B.; Wang, C.; Ding, X.; Wallace, G.G. Polypyrrole coated nylon lycra fabric as stretchable electrode for supercapacitor applications. Electrochim. Acta 2012, 68, 18–24. [Google Scholar] [CrossRef] [Green Version]

- Massafera, M.P.; Córdoba de Torresi, S.I. Evaluating the performance of polypyrrole nanowires on the electrochemical sensing of ammonia in solution. J. Electroanal. Chem. 2012, 669, 90–94. [Google Scholar] [CrossRef]

- Pethsangave, D.A.; Khose, R.V.; Wadekar, P.H.; Some, S. Novel Approach toward the Synthesis of a Phosphorus-Functionalized Polymer-Based Graphene Composite as an Efficient Flame Retardant. ACS Sustain. Chem. Eng. 2019, 7, 11745–11753. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, D.; Zhang, Y.; Cai, W.; Yao, C.; Hu, Y.; Hu, W. Construction of multifunctional boron nitride nanosheet towards reducing toxic volatiles (CO and HCN) generation and fire hazard of thermoplastic polyurethane. J. Hazard. Mater. 2019, 362, 482–494. [Google Scholar] [CrossRef]

- Rashidzadeh, A.; Olad, A.; Ahmadi, S. Preparation and characterization of polypyrrole/clinoptilolite nanocomposite with enhanced electrical conductivity by surface polymerization method. Polym. Eng. Sci. 2013, 53, 970–975. [Google Scholar] [CrossRef]

- Wang, F.; Liao, J.; Yan, L.; Liu, H. Fabrication of Diaminodiphenylmethane Modified Ammonium Polyphosphate to Remarkably Reduce the Fire Hazard of Epoxy Resins. Polymers 2021, 13, 3221. [Google Scholar] [CrossRef] [PubMed]

- Si, M.; Feng, J.; Hao, J.; Xu, L.; Du, J. Synergistic flame retardant effects and mechanisms of nano-Sb 2 O 3 in combination with aluminum phosphinate in poly (ethylene terephthalate). Polym. Degrad. Stab. 2014, 100, 70–78. [Google Scholar] [CrossRef]

- Jian, R.; Wang, P.; Duan, W.; Wang, J.; Zheng, X.; Weng, J. Synthesis of a Novel P/N/S-Containing Flame Retardant and Its Application in Epoxy Resin: Thermal Property, Flame Retardance, and Pyrolysis Behavior. Ind. Eng. Chem. Res. 2016, 55, 11520–11527. [Google Scholar] [CrossRef]

- Qu, H.; Wu, W.; Hao, J.; Wang, C.; Xu, J. Inorganic-organic hybrid coating-encapsulated ammonium polyphosphate and its flame retardancy and water resistance in epoxy resin. Fire Mater. 2013, 38, 312–322. [Google Scholar] [CrossRef]

- Hu, X.; Wang, G.; Huang, Y. Study on the preparation and properties of novel transparent fire-resistive coatings. J. Coat. Technol. Res. 2013, 10, 717–726. [Google Scholar] [CrossRef]

- Yan, L.; Xu, Z.; Wang, X. Influence of nano-silica on the flame retardancy and smoke suppression properties of transparent intumescent fire-retardant coatings. Prog. Org. Coat. 2017, 112, 319–329. [Google Scholar] [CrossRef]

- Zheng, Z.; Liu, Y.; Zhang, L.; Wang, H. Synergistic effect of expandable graphite and intumescent flame retardants on the flame retardancy and thermal stability of polypropylene. J. Mater. Sci. 2016, 51, 5857–5871. [Google Scholar] [CrossRef]

- Xu, Z.; Chu, Z.; Yan, L. Enhancing the flame-retardant and smoke suppression properties of transparent intumescent fire-retardant coatings by introducing boric acid as synergistic agent. J. Anal. Calorim. 2018, 133, 1241–1252. [Google Scholar] [CrossRef]

- Meili, D.; Baolin, W.; Shidong, X.; Po, H. The effect of organic-phosphorus flame retardant on the performance of epoxy resin. Australian Joumal of Chemidtry. Fire Sci. Technol. 2017, 36, 1698–1702. [Google Scholar]

| Samples | APP (wt%) | MAPP (wt%) | PPy-MAPP (wt%) | EP (wt%) | DDM (wt%) |

|---|---|---|---|---|---|

| EP | 0 | 0 | 0 | 80 | 20 |

| EP/15APP | 15 | 0 | 0 | 68 | 17 |

| EP/5MAPP | 0 | 5 | 0 | 76 | 19 |

| EP/7.5MAPP | 0 | 7.5 | 0 | 74 | 18.5 |

| EP/10MAPP | 0 | 10 | 0 | 72 | 18 |

| EP/12.5MAPP | 0 | 12.5 | 0 | 70 | 17.5 |

| EP/15MAPP | 0 | 15 | 0 | 68 | 17 |

| EP/5PPy-MAPP | 0 | 0 | 5 | 76 | 19 |

| EP/7.5PPy-MAPP | 0 | 0 | 7.5 | 74 | 18.5 |

| EP/10PPy-MAPP | 0 | 0 | 10 | 72 | 18 |

| EP/12.5PPy-MAPP | 0 | 0 | 12.5 | 70 | 17.5 |

| EP/15PPy-MAPP | 0 | 0 | 15 | 68 | 17 |

| Samples | T5% (°C) | Tmax (°C) | PMLR (% min−1) | Wexp (%) | Wcal | ΔW |

|---|---|---|---|---|---|---|

| EP | 396.1 | 421.4 | 1.56 | 19.9 | – | – |

| EP/15MAPP | 362.4 | 384.5 | 2.19 | 28.7 | 26.15 | 2.55 |

| EP/5PPY-MAPP | 376.5 | 408.5 | 1.33 | 26.4 | 21.95 | 4.45 |

| EP/10 PPy-MAPP | 363.3 | 384.5 | 2.42 | 30.8 | 24.30 | 6.50 |

| EP/15 PPy-MAPP | 359.5 | 384.2 | 1.76 | 33.8 | 26.45 | 7.35 |

| Samples | TTI (s) | THR (MJ/m2) | PHRR (KW/m2) | TSR (m2/m2) | TSP (m2) | PSPR (m2/s) | Residue (%) |

|---|---|---|---|---|---|---|---|

| EP | 58 | 118.8 | 1252.0 | 1186.7 | 32.6 | 0.304 | 6.8 |

| EP/15MAPP | 59 | 68.3 | 570.9 | 866.1 | 14.6 | 0.147 | 24.7 |

| EP/5PPy-MAPP | 59 | 106.1 | 1040.0 | 826.9 | 25.9 | 0.205 | 16.9 |

| EP/10PPy-MAPP | 61 | 89.0 | 896.7 | 753.4 | 23.0 | 0.161 | 17.1 |

| EP/15PPy-MAPP | 67 | 45.3 | 430.7 | 702.4 | 8.5 | 0.115 | 30.3 |

| Samples | Content (wt%) | LOI (%) | UL94 Rating | Reduction of PHRR (%) | Reduction of PSPR (%) | Char Residue Weight (%) | Refs. |

|---|---|---|---|---|---|---|---|

| EP/15PPy-MAPP | 15 | 42.4 | V-0 | 65.6 | 62.2 | 30.3 | this work |

| EP/DDS/PBI-1.0 | 14.3 | 33.5 | V-0 | 49.5 | – | 21.2 | [2] |

| EP/APP/Fe-3 | 9.5 | 30.0 | V-0 | 75.8 | – | 23.5 | [20] |

| EP/15DDP | 15 | 37.1 | V-0 | 40.8 | 47.8 | 34.0 | [32] |

| EP/12.5% DOPO-ABZ | 12.5 | 32.0 | V-0 | 43.0 | – | 20.1 | [34] |

| EPMAPP12 | 12 | 32.5 | V-0 | 84.6 | – | – | [35] |

| Samples | Elastic Modulus (MPa) | Tensile Strength (MPa) |

|---|---|---|

| EP | 5710.3 ± 10.2 | 51.2 ± 2.4 |

| EP/15MAPP | 7556.8 ± 23.1 | 33.2 ± 1.9 |

| EP/5PPy-MAPP | 5792.7 ± 16.4 | 46.0 ± 2.3 |

| EP/10PPy-MAPP | 5814.8 ± 8.9 | 39.2 ± 2.2 |

| EP/15PPy-MAPP | 7907.0 ± 22.0 | 34.0 ± 1.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Liao, J.; Yan, L.; Cai, M. Facile Construction of Polypyrrole Microencapsulated Melamine-Coated Ammonium Polyphosphate to Simultaneously Reduce Flammability and Smoke Release of Epoxy Resin. Polymers 2022, 14, 2375. https://doi.org/10.3390/polym14122375

Wang F, Liao J, Yan L, Cai M. Facile Construction of Polypyrrole Microencapsulated Melamine-Coated Ammonium Polyphosphate to Simultaneously Reduce Flammability and Smoke Release of Epoxy Resin. Polymers. 2022; 14(12):2375. https://doi.org/10.3390/polym14122375

Chicago/Turabian StyleWang, Feiyue, Jiahao Liao, Long Yan, and Mengtao Cai. 2022. "Facile Construction of Polypyrrole Microencapsulated Melamine-Coated Ammonium Polyphosphate to Simultaneously Reduce Flammability and Smoke Release of Epoxy Resin" Polymers 14, no. 12: 2375. https://doi.org/10.3390/polym14122375

APA StyleWang, F., Liao, J., Yan, L., & Cai, M. (2022). Facile Construction of Polypyrrole Microencapsulated Melamine-Coated Ammonium Polyphosphate to Simultaneously Reduce Flammability and Smoke Release of Epoxy Resin. Polymers, 14(12), 2375. https://doi.org/10.3390/polym14122375