Efficient All-Polymer Solar Cells with Sequentially Processed Active Layers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Equipment and Facilities

2.3. Analysis and Characterization

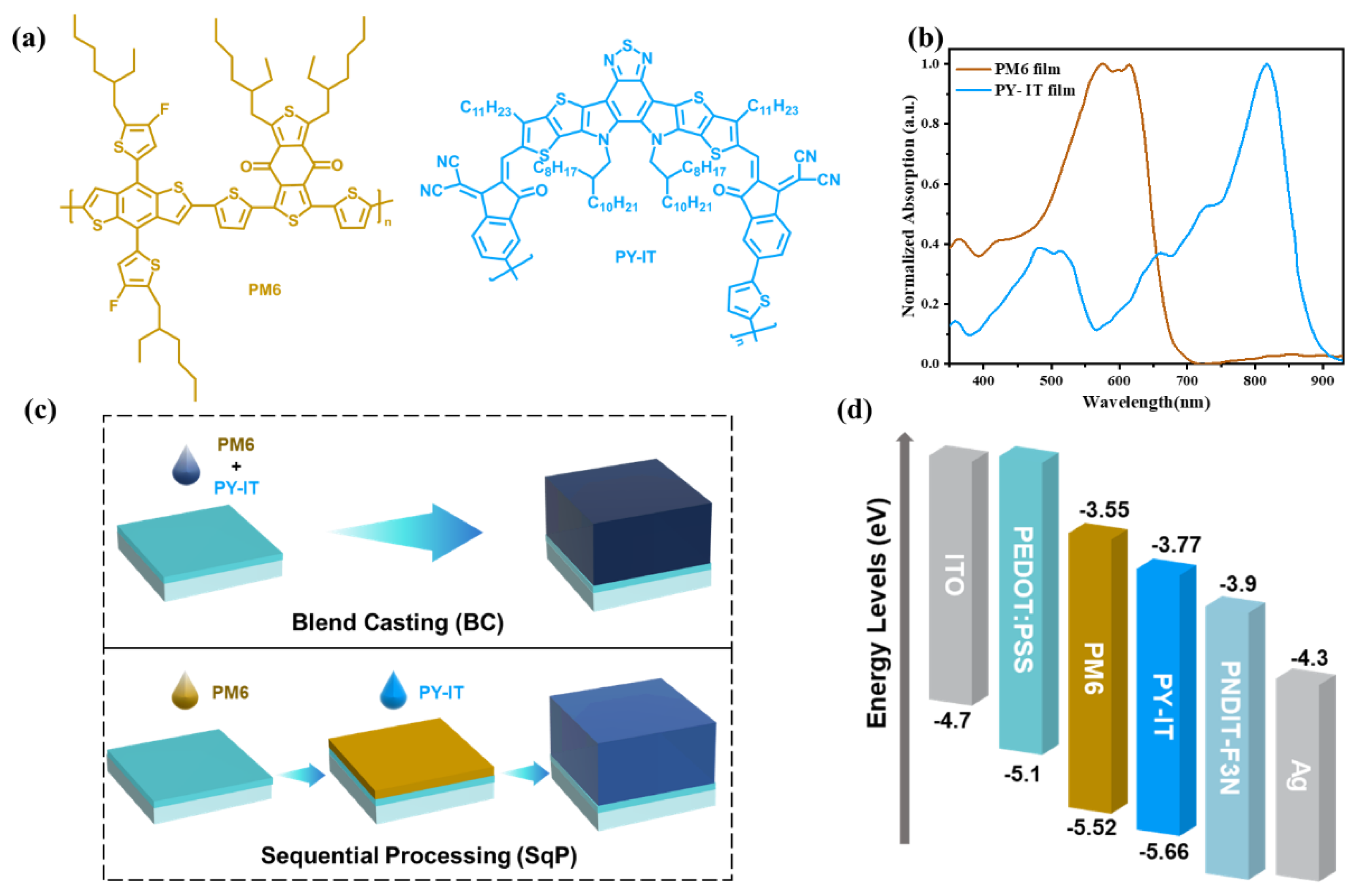

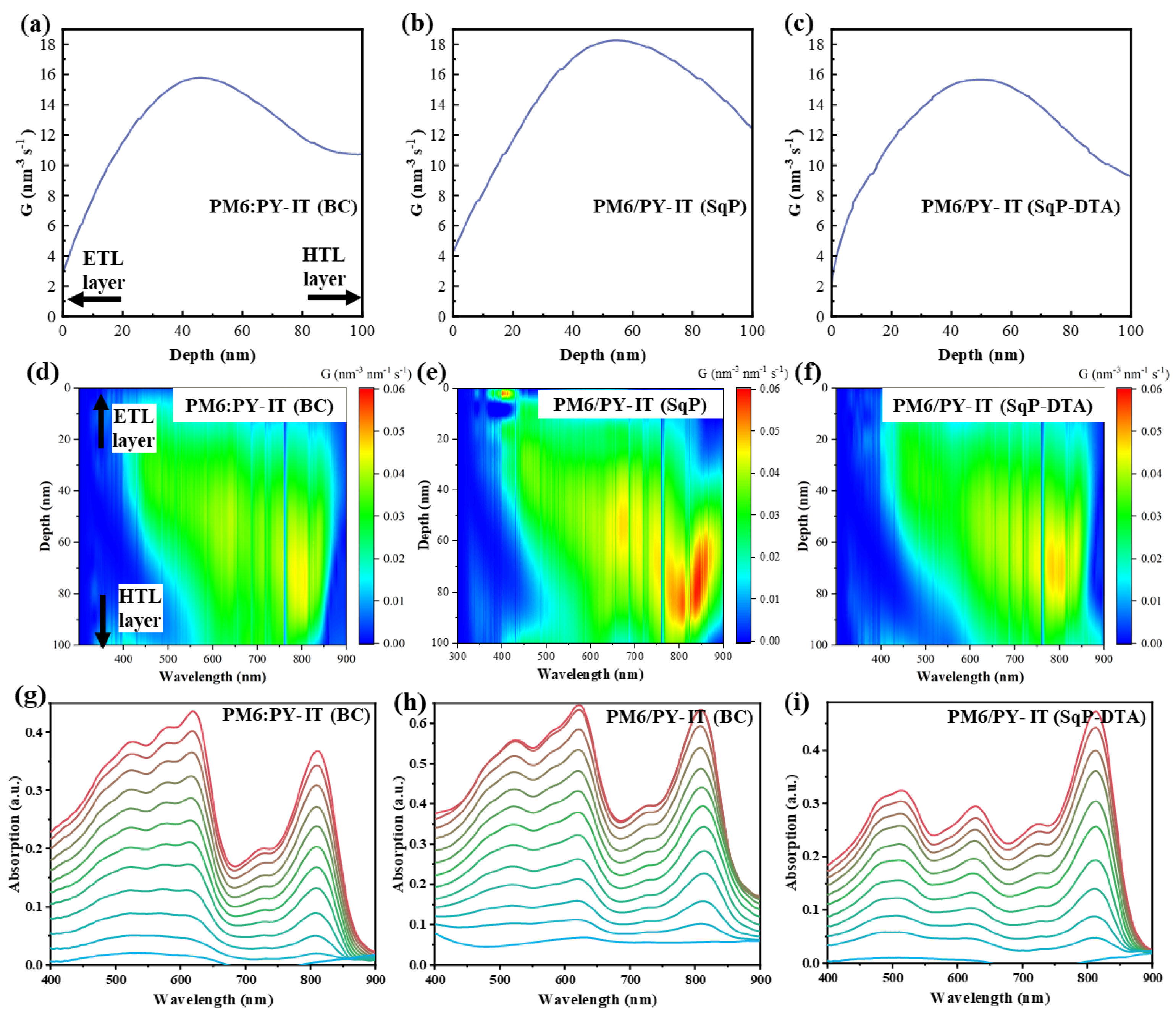

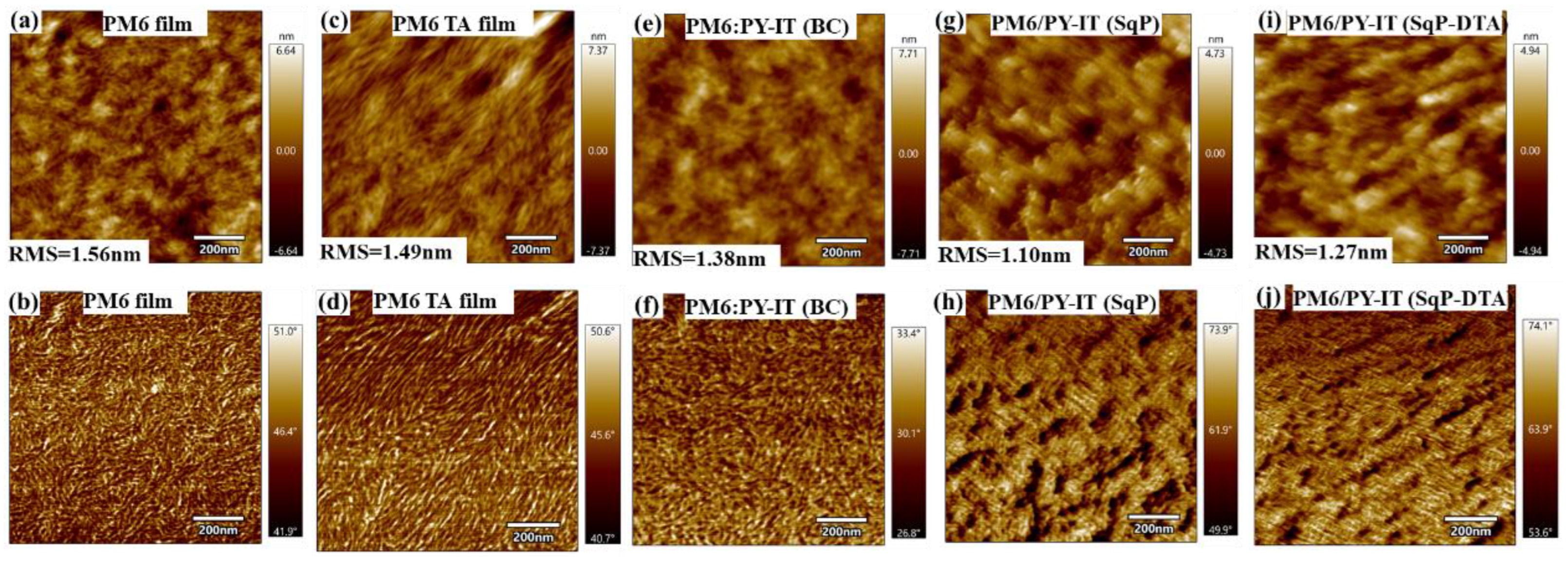

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, X.; Li, Y.; Peng, Q. Ternary Blend Organic Solar Cells: Understanding the Morphology from Recent Progress. Adv. Mater. 2022, 2107476. [Google Scholar] [CrossRef] [PubMed]

- Kan, B.; Ershad, F.; Rao, Z.; Yu, C. Flexible organic solar cells for biomedical devices. Nano Res. 2021, 14, 2891–2903. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, B.; Ma, C.-Q.; Huang, F.; Feng, G.; Chen, H.; Hou, J.; Yan, L.; Wei, Q.; Luo, Q.; et al. Recent progress in organic solar cells (Part I material science). Sci. China Chem. 2021, 65, 224–268. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, K.; Dong, S.; Xia, R.; Huang, F.; Cao, Y. Semitransparent Organic Solar Cells Enabled by a Sequentially Deposited Bilayer Structure. ACS Appl. Mater. Interfaces 2020, 12, 18473–18481. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Feng, E.; Li, H.; Shen, Z.; Liu, W.; Guo, J.; Luo, Q.; Zhang, J.; Lu, G.; Ma, C.; et al. Layer-by-layer slot-die coated high-efficiency organic solar cells processed using twin boiling point solvents under ambient condition. Nano Res. 2021, 14, 4236–4242. [Google Scholar] [CrossRef]

- Gharahcheshmeh, M.H.; Tavakoli, M.M.; Gleason, E.F.; Robinson, M.T.; Kong, J.; Gleason, K.K. Tuning, optimization, and perovskite solar cell device integration of ultrathin poly(3,4-ethylene dioxythiophene) films via a single-step all-dry process. Sci. Adv. 2019, 5, eaay0414. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Ishwara, T.; Gong, W.; Campoy-Quiles, M.; Nelson, J.; Bradley, D.D.C. High-Performance Metal-Free Solar Cells Using Stamp Transfer Printed Vapor Phase Polymerized Poly(3,4-Ethylenedioxythiophene) Top Anodes. Adv. Funct. Mater. 2012, 22, 1454–1460. [Google Scholar] [CrossRef]

- Sun, R.; Wu, Y.; Yang, X.; Gao, Y.; Chen, Z.; Li, K.; Qiao, J.; Wang, T.; Guo, J.; Liu, C.; et al. Single-Junction Organic Solar Cells with 19.17% Efficiency Enabled by Introducing One Asymmetric Guest Acceptor. Adv. Mater. 2022, 2110147. [Google Scholar] [CrossRef]

- Zhou, K.; Zhou, X.; Xu, X.; Musumeci, C.; Wang, C.; Xu, W.; Meng, X.; Ma, W.; Inganas, O. pi-pi Stacking Distance and Phase Separation Controlled Efficiency in Stable All-Polymer Solar Cells. Polymers 2019, 11, 1665. [Google Scholar] [CrossRef] [Green Version]

- Han, Y.W.; Jeon, S.J.; Lee, H.S.; Park, H.; Kim, K.S.; Lee, H.W.; Moon, D.K. Evaporation-Free Nonfullerene Flexible Organic Solar Cell Modules Manufactured by An All—Solution Process. Adv. Energy Mater. 2019, 9, 1902065. [Google Scholar] [CrossRef]

- Kim, T.; Kim, J.H.; Kang, T.E.; Lee, C.; Kang, H.; Shin, M.; Wang, C.; Ma, B.; Jeong, U.; Kim, T.S.; et al. Flexible, highly efficient all-polymer solar cells. Nat. Commun. 2015, 6, 8547. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, L.; Jia, T.; Pan, L.; Wu, B.; Wang, Z.; Gao, K.; Liu, F.; Duan, C.; Huang, F.; Cao, Y. 15.4% Efficiency all-polymer solar cells. Sci. China Chem. 2021, 64, 408–412. [Google Scholar] [CrossRef]

- Fu, H.T.; Li, Y.X.; Yu, J.W.; Wu, Z.A.; Fan, Q.P.; Lin, F.; Woo, H.Y.; Gao, F.; Zhu, Z.L.; Jen, A.K.Y. High Efficiency (15.8%) All-Polymer Solar Cells Enabled by a Regioregular Narrow Bandgap Polymer Acceptor. J. Am. Chem. Soc. 2021, 143, 2665–2670. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Wang, W.; Wu, Y.; Chen, Z.; Guo, J.; Sun, R.; Guo, J.; Yang, Y.; Min, J. High-Performance All-Polymer Solar Cells with a Pseudo-Bilayer Configuration Enabled by a Stepwise Optimization Strategy. Adv. Funct. Mater. 2021, 31, 2010411. [Google Scholar] [CrossRef]

- Ma, R.; Tao, Y.; Chen, Y.; Liu, T.; Luo, Z.; Guo, Y.; Xiao, Y.; Fang, J.; Zhang, G.; Li, X.; et al. Achieving 16.68% efficiency ternary as-cast organic solar cells. Sci. China Chem. 2021, 64, 581–589. [Google Scholar] [CrossRef]

- Yu, H.; Wang, Y.; Kim, H.K.; Wu, X.; Li, Y.; Yao, Z.; Pan, M.; Zou, X.; Zhang, J.; Chen, S.; et al. A Vinylene-Linker-Based Polymer Acceptor Featuring Co-planar and Rigid Molecular Conformation Enables High-Performance All-Polymer Solar Cells. Adv. Mater. 2022, 2200361. [Google Scholar] [CrossRef]

- Yu, H.; Luo, S.; Sun, R.; Angunawela, I.; Qi, Z.; Peng, Z.; Zhou, W.; Han, H.; Wei, R.; Pan, M.; et al. A Difluoro-Monobromo End Group Enables High-Performance Polymer Acceptor and Efficient All-Polymer Solar Cells Processable with Green Solvent under Ambient Condition. Adv. Funct. Mater. 2021, 31, 2100791. [Google Scholar] [CrossRef]

- Peng, W.; Lin, Y.; Jeong, S.Y.; Genene, Z.; Magomedov, A.; Woo, H.Y.; Chen, C.; Wahyudi, W.; Tao, Q.; Deng, J.; et al. Over 18% ternary polymer solar cells enabled by a terpolymer as the third component. Nano Energy 2022, 92. [Google Scholar] [CrossRef]

- Wang, W.; Wu, Q.; Sun, R.; Guo, J.; Wu, Y.; Shi, M.; Yang, W.; Li, H.; Min, J. Controlling Molecular Mass of Low-Band-Gap Polymer Acceptors for High-Performance All-Polymer Solar Cells. Joule 2020, 4, 1070–1086. [Google Scholar] [CrossRef]

- Zhan, T.; Yang, M.; Cai, P.; Oh, J.; Yuan, X.; Wu, B.; Pan, L.; Zhao, Y.; Yang, C.; Duan, C.; et al. Sequentially Deposited Active Layer with Bulk-Heterojunction-like Morphology for Efficient Conventional and Inverted All-Polymer Solar Cells. ACS Appl. Energy Mater. 2021, 4, 13307–13315. [Google Scholar] [CrossRef]

- Xu, Y.; Yuan, J.; Liang, S.; Chen, J.-D.; Xia, Y.; Larson, B.W.; Wang, Y.; Su, G.M.; Zhang, Y.; Cui, C.; et al. Simultaneously Improved Efficiency and Stability in All-Polymer Solar Cells by a P–i–N Architecture. ACS Energy Lett. 2019, 4, 2277–2286. [Google Scholar] [CrossRef]

- Zhan, L.; Li, S.; Xia, X.; Li, Y.; Lu, X.; Zuo, L.; Shi, M.; Chen, H. Layer-by-Layer Processed Ternary Organic Photovoltaics with Efficiency over 18%. Adv. Mater. 2021, 33, 2007231. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhang, L.; Hu, L.; Xie, Z.; Mao, H.; Tan, L.; Zhang, Y.; Chen, Y. High-Efficiency (16.93%) Pseudo-Planar Heterojunction Organic Solar Cells Enabled by Binary Additives Strategy. Adv. Funct. Mater. 2021, 31, 2102291. [Google Scholar] [CrossRef]

- Weng, K.; Ye, L.; Zhu, L.; Xu, J.; Zhou, J.; Feng, X.; Lu, G.; Tan, S.; Liu, F.; Sun, Y. Optimized active layer morphology toward efficient and polymer batch insensitive organic solar cells. Nat. Commun. 2020, 11, 2855. [Google Scholar] [CrossRef] [PubMed]

- Hong, L.; Yao, H.; Cui, Y.; Bi, P.; Zhang, T.; Cheng, Y.; Zu, Y.; Qin, J.; Yu, R.; Ge, Z.; et al. 18.5% Efficiency Organic Solar Cells with a Hybrid Planar/Bulk Heterojunction. Adv. Mater. 2021, 33, 2103091. [Google Scholar] [CrossRef]

- Sun, R.; Guo, J.; Wu, Q.; Zhang, Z.; Yang, W.; Guo, J.; Shi, M.; Zhang, Y.; Kahmann, S.; Ye, L.; et al. A multi-objective optimization-based layer-by-layer blade-coating approach for organic solar cells: Rational control of vertical stratification for high performance. Energy Environ. Sci. 2019, 12, 3118–3132. [Google Scholar] [CrossRef]

- Jiang, K.; Zhang, J.; Peng, Z.; Lin, F.; Wu, S.; Li, Z.; Chen, Y.; Yan, H.; Ade, H.; Zhu, Z.; et al. Pseudo-bilayer architecture enables high-performance organic solar cells with enhanced exciton diffusion length. Nat. Commun. 2021, 12, 468. [Google Scholar] [CrossRef]

- Ko, J.; Kim, J.; Song, H.J.; Park, Y.; Kwak, J.; Lee, C.; Char, K. Effect of Solvent on the Interfacial Crystallinity in Sequentially Processed Organic Solar Cells. Adv. Mater. Interfaces 2021, 8, 2100029. [Google Scholar] [CrossRef]

- Arunagiri, L.; Zhang, G.; Hu, H.; Yao, H.; Zhang, K.; Li, Y.; Chow, P.C.Y.; Ade, H.; Yan, H. Temperature-Dependent Aggregation Donor Polymers Enable Highly Efficient Sequentially Processed Organic Photovoltaics Without the Need of Orthogonal Solvents. Adv. Funct. Mater. 2019, 29, 1902478. [Google Scholar] [CrossRef]

- Hawks, S.A.; Aguirre, J.C.; Schelhas, L.T.; Thompson, R.J.; Huber, R.C.; Ferreira, A.S.; Zhang, G.Y.; Herzing, A.A.; Tolbert, S.H.; Schwartz, B.J. Comparing Matched Polymer:Fullerene Solar Cells Made by Solution-Sequential Processing and Traditional Blend Casting: Nanoscale Structure and Device Performance. J. Phys. Chem. C 2014, 118, 17413–17425. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Deng, D.; Wang, Z.; Wang, Y.; Zhang, J.; Fang, J.; Yang, Y.; Lu, G.; Ma, W.; Wei, Z. Enhancing the Photovoltaic Performance via Vertical Phase Distribution Optimization in Small Molecule:PC71BM Blends. Adv. Energy Mater. 2017, 7, 1701548. [Google Scholar] [CrossRef]

- Bu, L.; Gao, S.; Wang, W.; Zhou, L.; Feng, S.; Chen, X.; Yu, D.; Li, S.; Lu, G. Film-Depth-Dependent Light Absorption and Charge Transport for Polymer Electronics: A Case Study on Semiconductor/Insulator Blends by Plasma Etching. Adv. Electron. Mater. 2016, 2, 1600359. [Google Scholar] [CrossRef]

- Yu, H.; Pan, M.; Sun, R.; Agunawela, I.; Zhang, J.; Li, Y.; Qi, Z.; Han, H.; Zou, X.; Zhou, W.; et al. Regio-Regular Polymer Acceptors Enabled by Determined Fluorination on End Groups for All-Polymer Solar Cells with 15.2 % Efficiency. Angew. Chem. Int. Ed. 2021, 60, 10137–10146. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Sun, C.; Angunawela, I.; Meng, L.; Qin, S.; Zhou, L.; Li, S.; Zhuo, H.; Yang, G.; Zhang, Z.G.; et al. 16.52% Efficiency All-Polymer Solar Cells with High Tolerance of the Photoactive Layer Thickness. Adv. Mater. 2022, 2108749. [Google Scholar] [CrossRef]

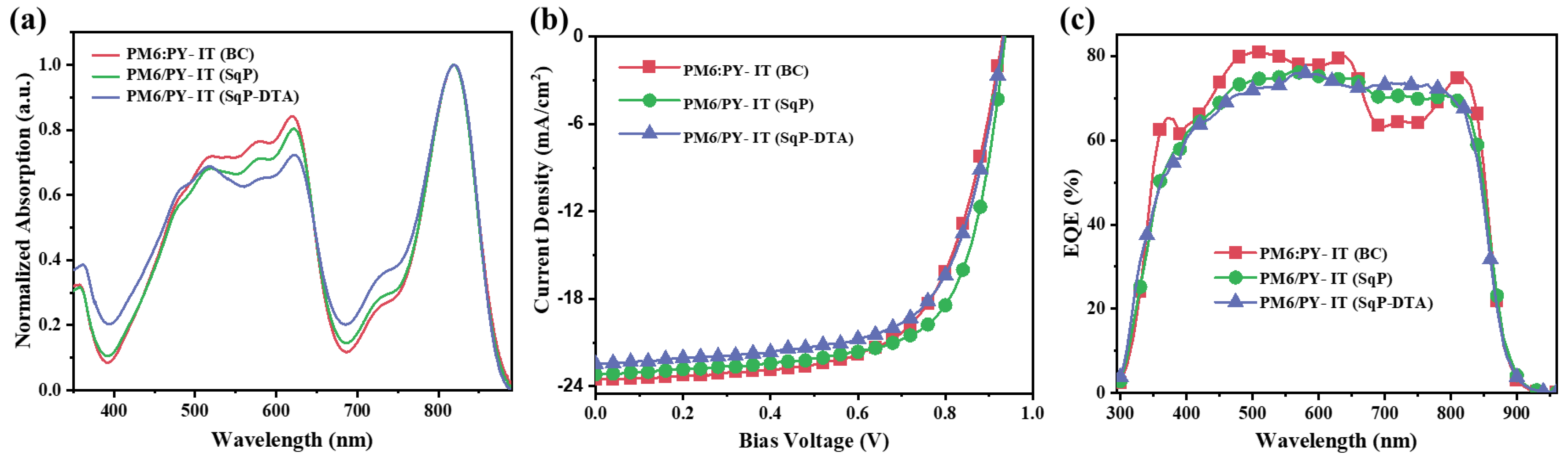

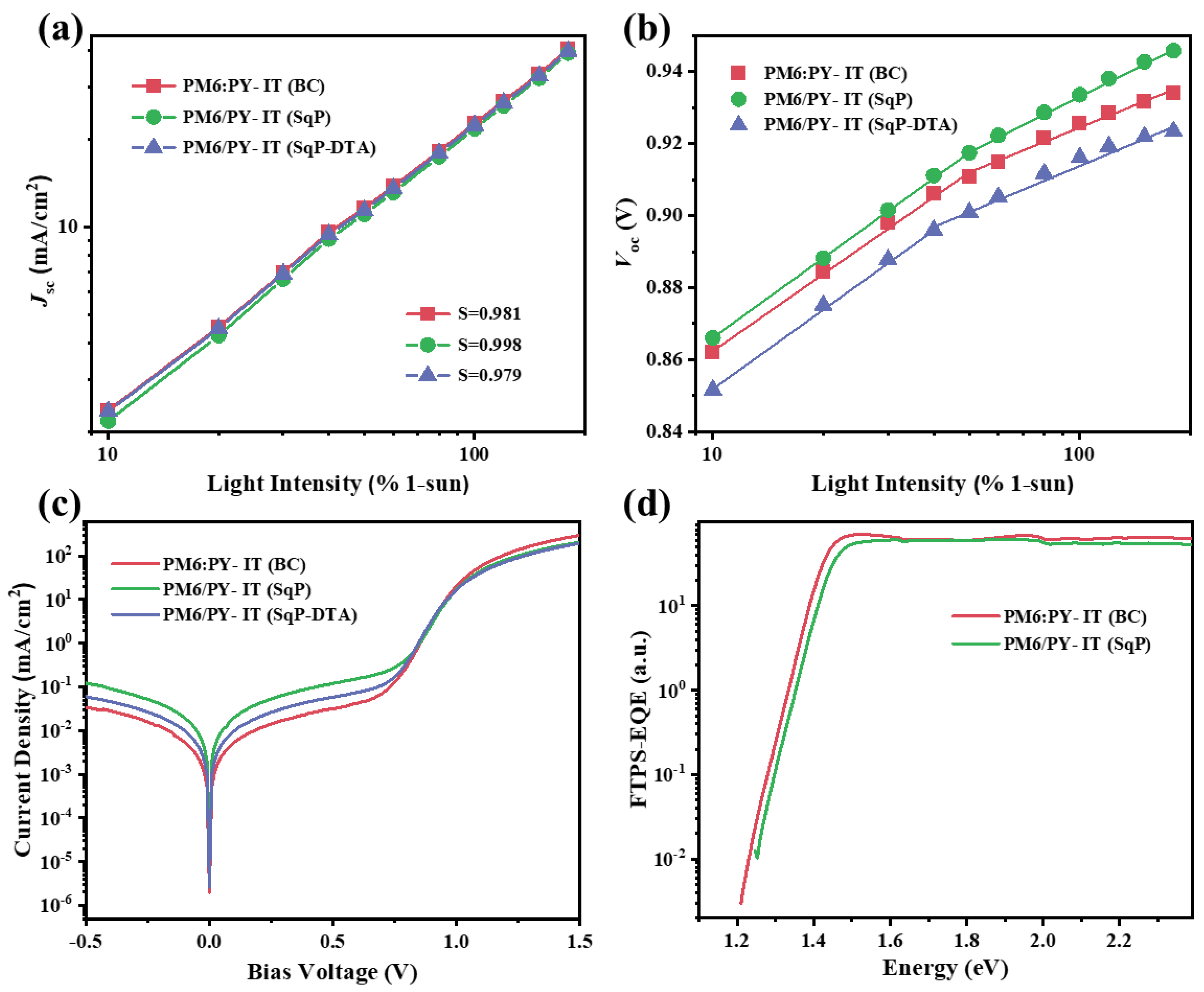

| Active Layer | VOC (V) | JSC (mA/cm2) | FF | PCE (a) (%) | nid,d(b) | nid,l(c) | S (d) | Rs(e) | Rsh(e) | μh/μe (f) | Ratio (g) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PM6:PY-IT (BC) | 0.934 ± 0.005 (0.937) | 23.78 ± 0.25 (23.90) | 0.654 ± 0.021 (0.677) | 14.49 ± 0.59 (15.15) | 1.474 | 1.248 | 0.981 | 1.1 | 1.0 | 3.5/2.3 | 1.54 |

| PM6/PY-IT (SqP) | 0.936 ± 0.002 (0.936) | 22.90 ± 0.26 (23.19) | 0.685 ± 0.011 (0.691) | 14.70 ± 0.28 (15.00) | 1.449 | 1.254 | 0.998 | 1.1 | 1.3 | 4.1/4.2 | 0.98 |

| PM6/PY-IT (SqP-DTA) | 0.930 ± 0.003 (0.932) | 22.45 ± 0.45 (22.36) | 0.644 ± 0.014 (0.657) | 13.44 ± 0.16 (13.69) | 1.496 | 1.272 | 0.979 | 1.8 | 1.0 | 5.8/2.2 | 2.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, C.; Huang, H.; Wang, L.; Zhang, G.; Lu, G.; Yu, H.; Lu, G.; Han, Y.; Qiu, M.; Li, S.; et al. Efficient All-Polymer Solar Cells with Sequentially Processed Active Layers. Polymers 2022, 14, 2058. https://doi.org/10.3390/polym14102058

Zhao C, Huang H, Wang L, Zhang G, Lu G, Yu H, Lu G, Han Y, Qiu M, Li S, et al. Efficient All-Polymer Solar Cells with Sequentially Processed Active Layers. Polymers. 2022; 14(10):2058. https://doi.org/10.3390/polym14102058

Chicago/Turabian StyleZhao, Chaoyue, Hui Huang, Lihong Wang, Guoping Zhang, Guanyu Lu, Han Yu, Guanghao Lu, Yulai Han, Mingxia Qiu, Shunpu Li, and et al. 2022. "Efficient All-Polymer Solar Cells with Sequentially Processed Active Layers" Polymers 14, no. 10: 2058. https://doi.org/10.3390/polym14102058

APA StyleZhao, C., Huang, H., Wang, L., Zhang, G., Lu, G., Yu, H., Lu, G., Han, Y., Qiu, M., Li, S., & Zhang, G. (2022). Efficient All-Polymer Solar Cells with Sequentially Processed Active Layers. Polymers, 14(10), 2058. https://doi.org/10.3390/polym14102058