Influence of Multiple Thermomechanical Processing of 3D Filaments Based on Polylactic Acid and Polyhydroxybutyrate on Their Rheological and Utility Properties

Abstract

:1. Introduction

2. Experimental Methods

2.1. Materials and Methods of Samples’ Preparation

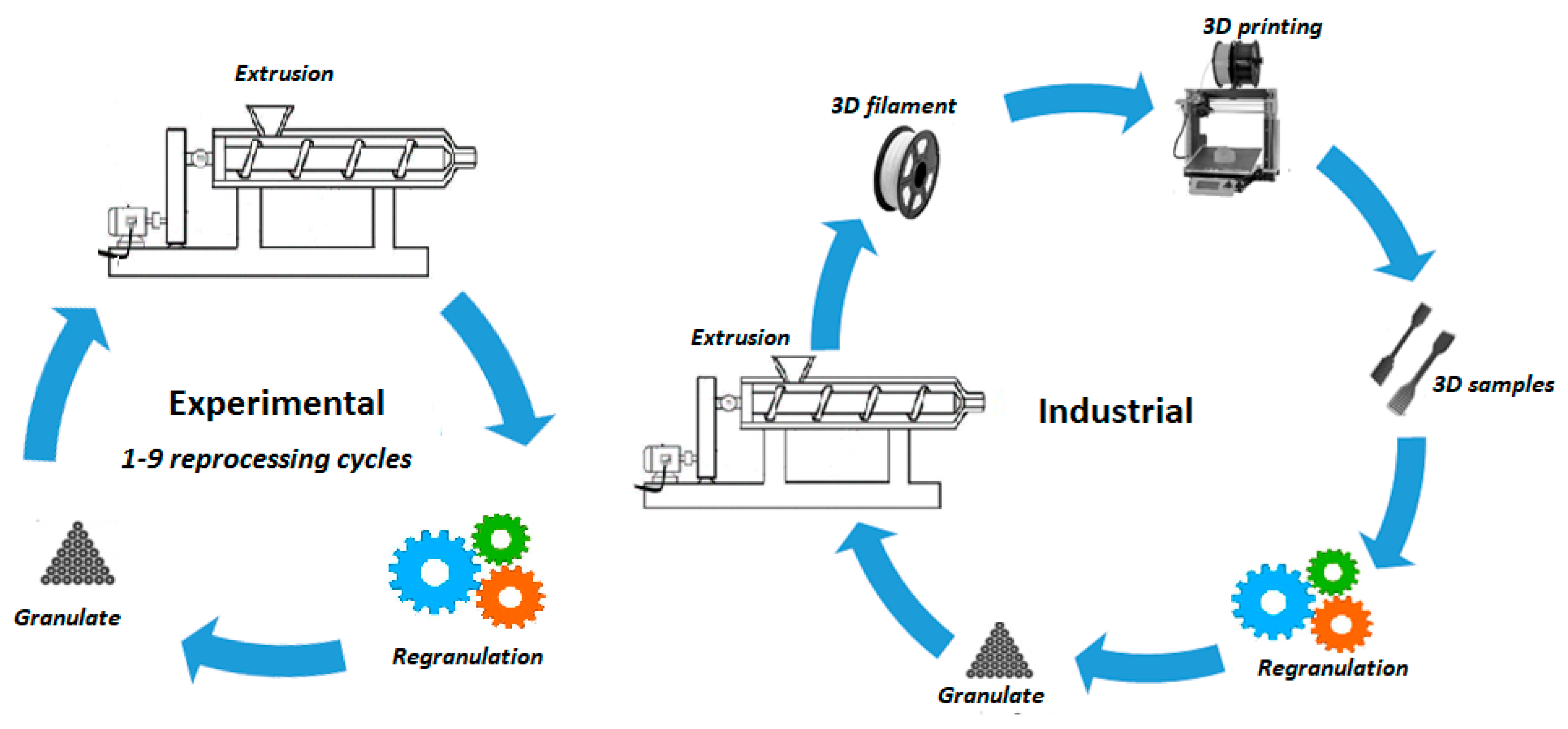

2.1.1. Polymer Blend Preparation for the Study of Experimental Recycling

2.1.2. Multiple Extrusion of the NONOILEN® 3D 3056-2 Experimental Samples

2.1.3. Study of Industrial Material Recycling (in Real Conditions)

2.1.4. Polymer Blend Preparation for the Study of Material Recycling in Industrial Conditions

2.2. Multiple Extrusion of the NONOILEN® 3D 3056-2 Industrial Samples

2.3. Preparation of the Samples by 3D Printing from Industrial Samples of NONOILEN® 3D 3056-2

3. Experiments

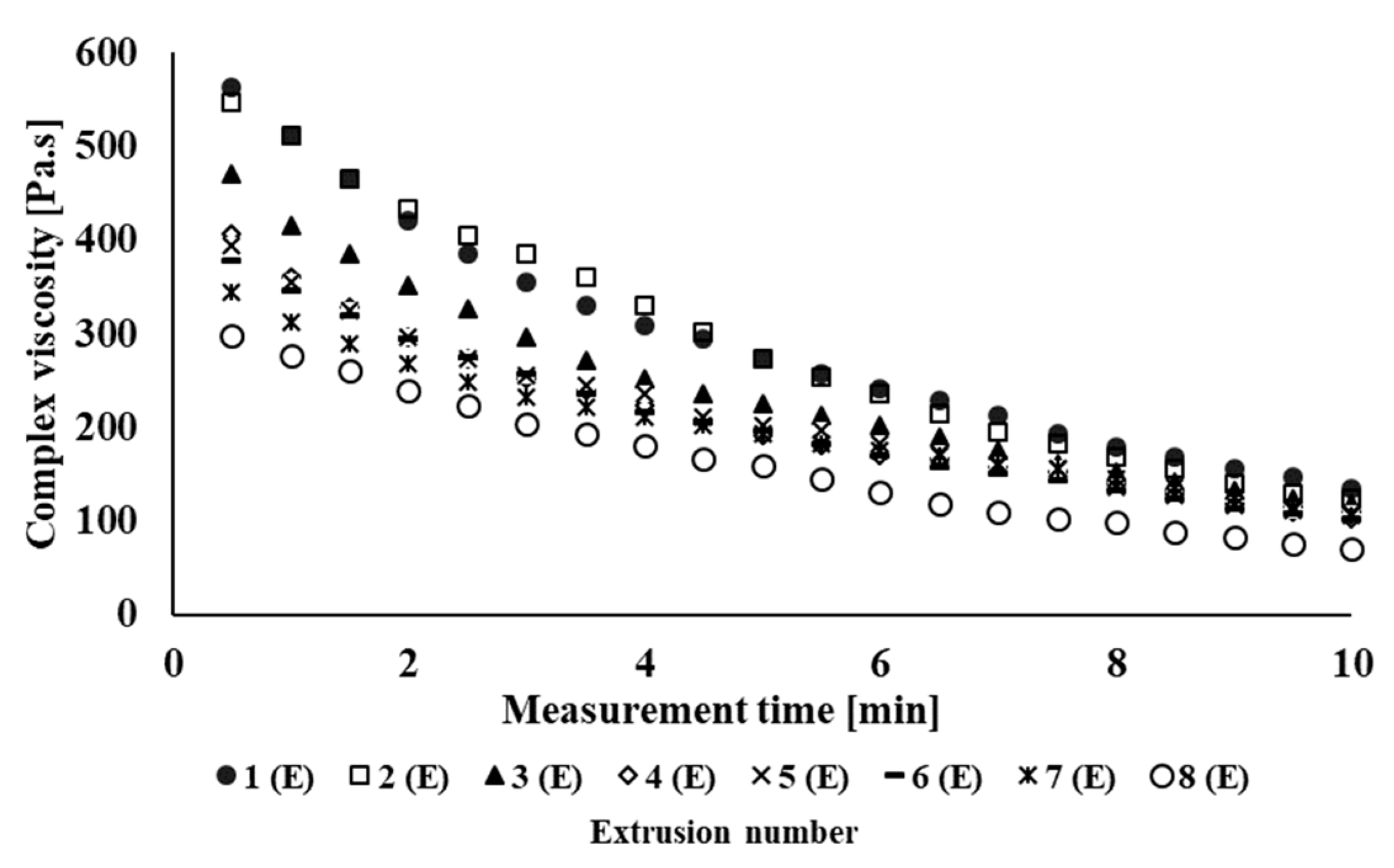

3.1. Processing (Thermomechanical) Stability

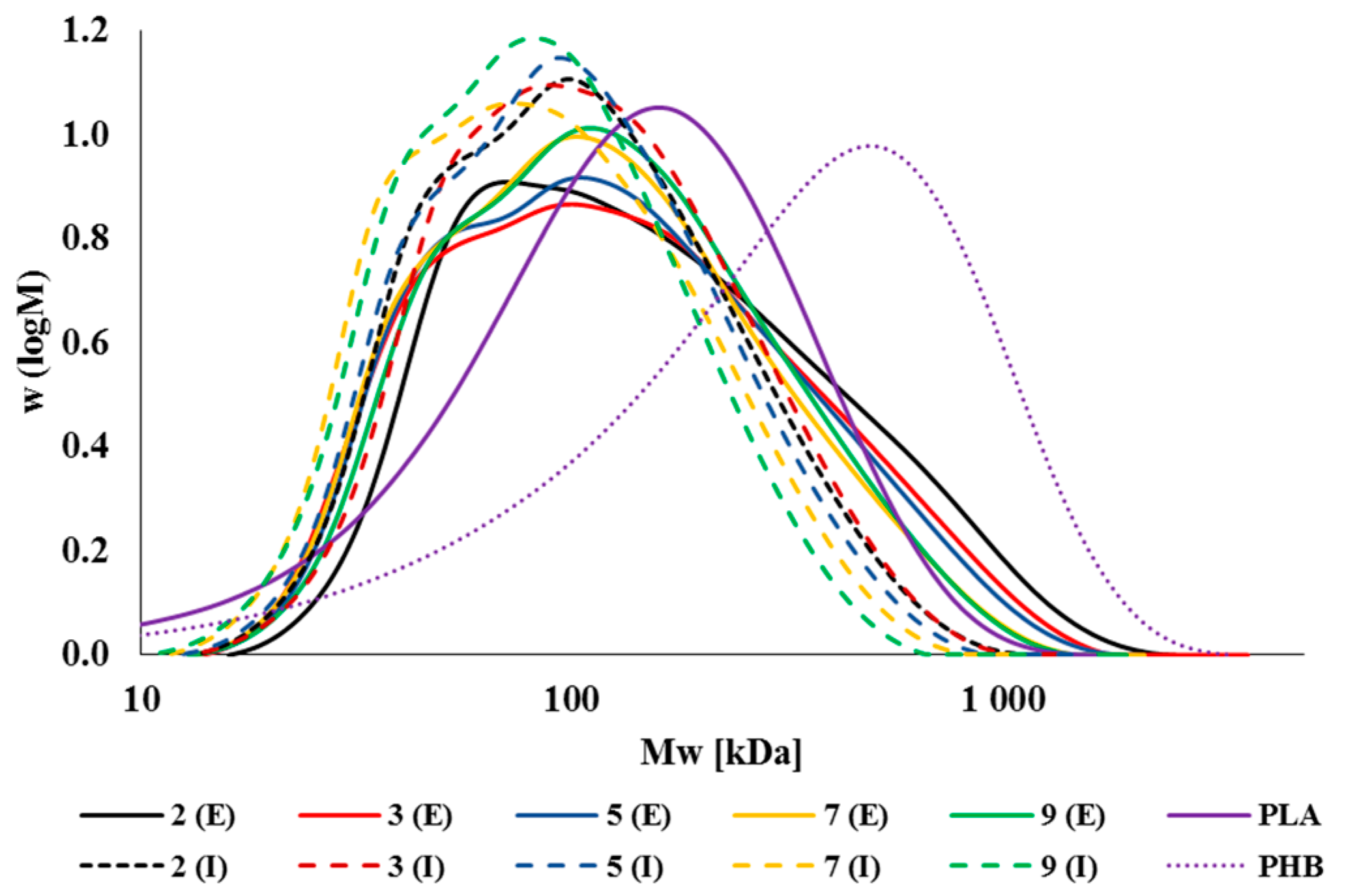

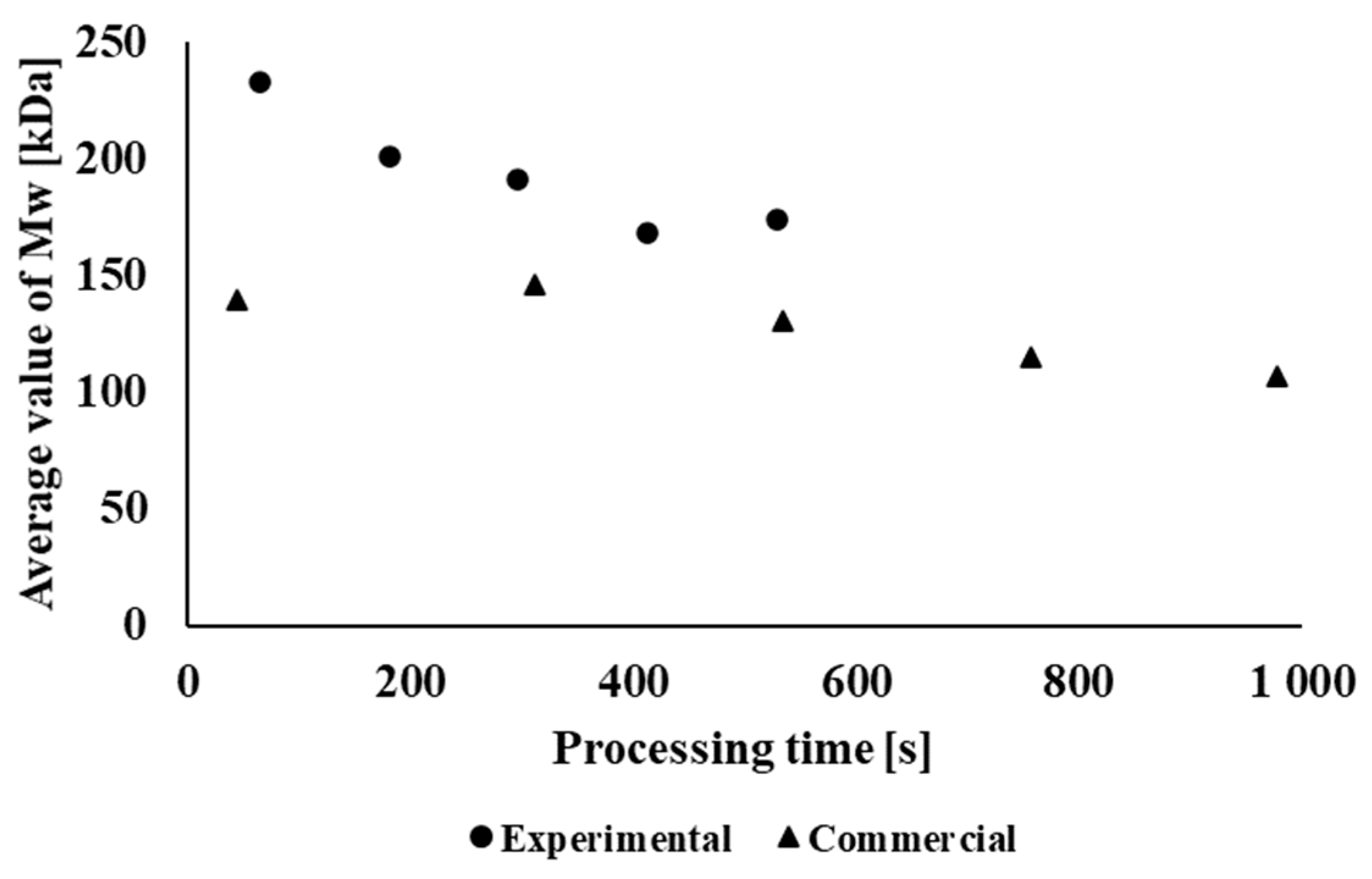

3.2. Molecular Characteristics

3.3. Color Changes Measurement

3.4. Measurement of Thermal Properties

3.5. Measurement of Mechanical Properties

3.6. Flexural Test

4. Results

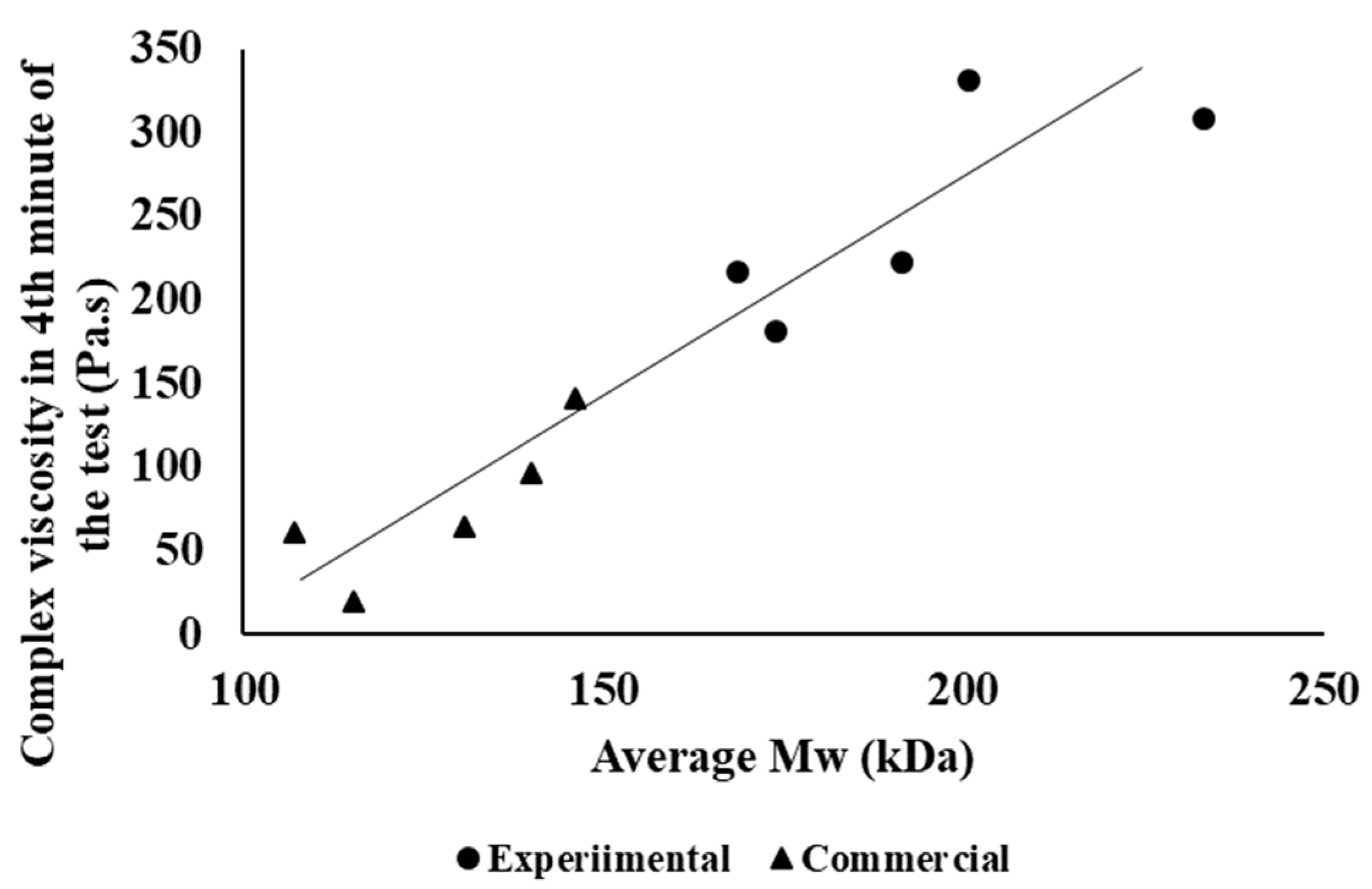

4.1. Processing Stability

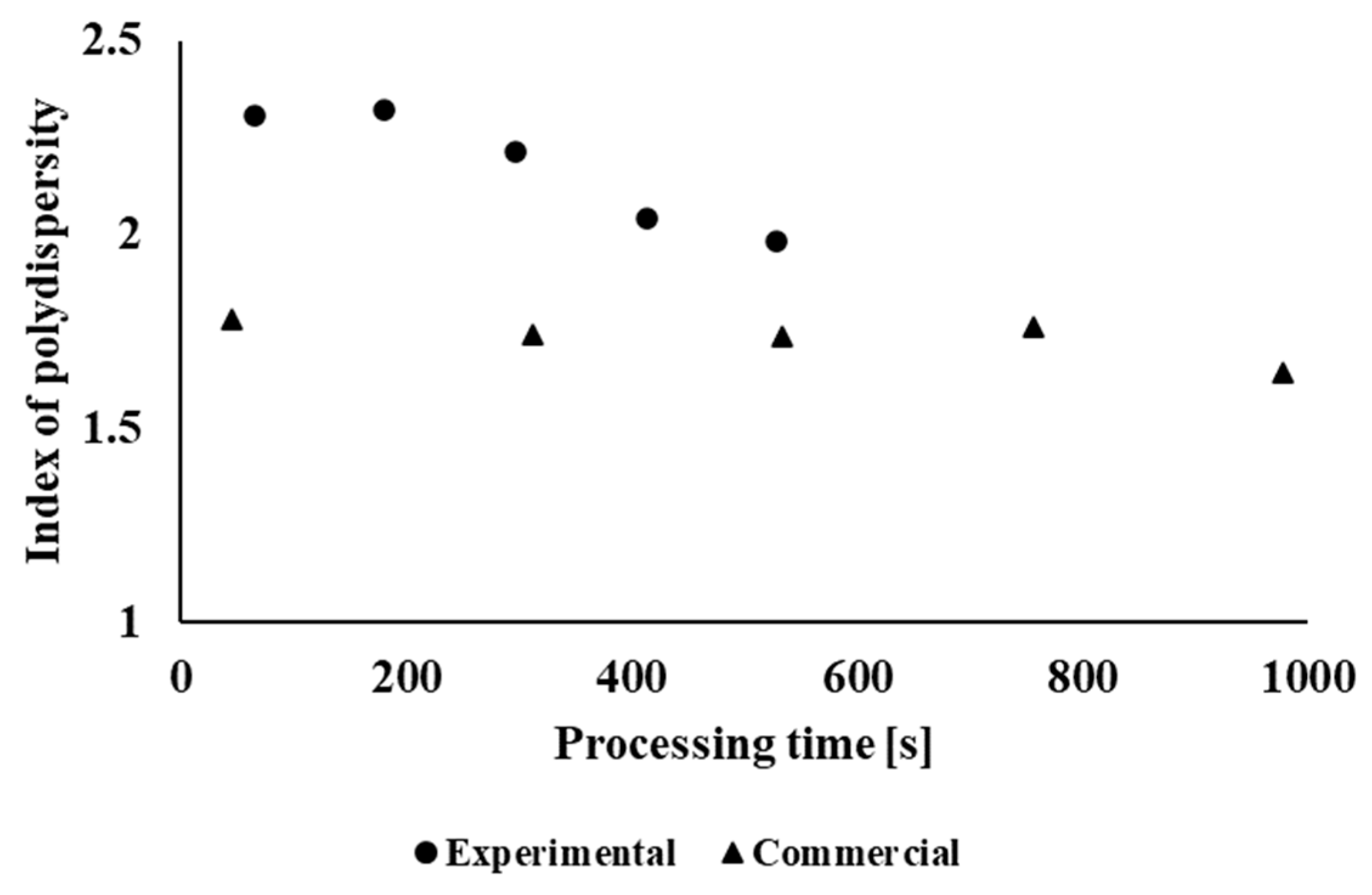

4.2. Molecular Characteristics

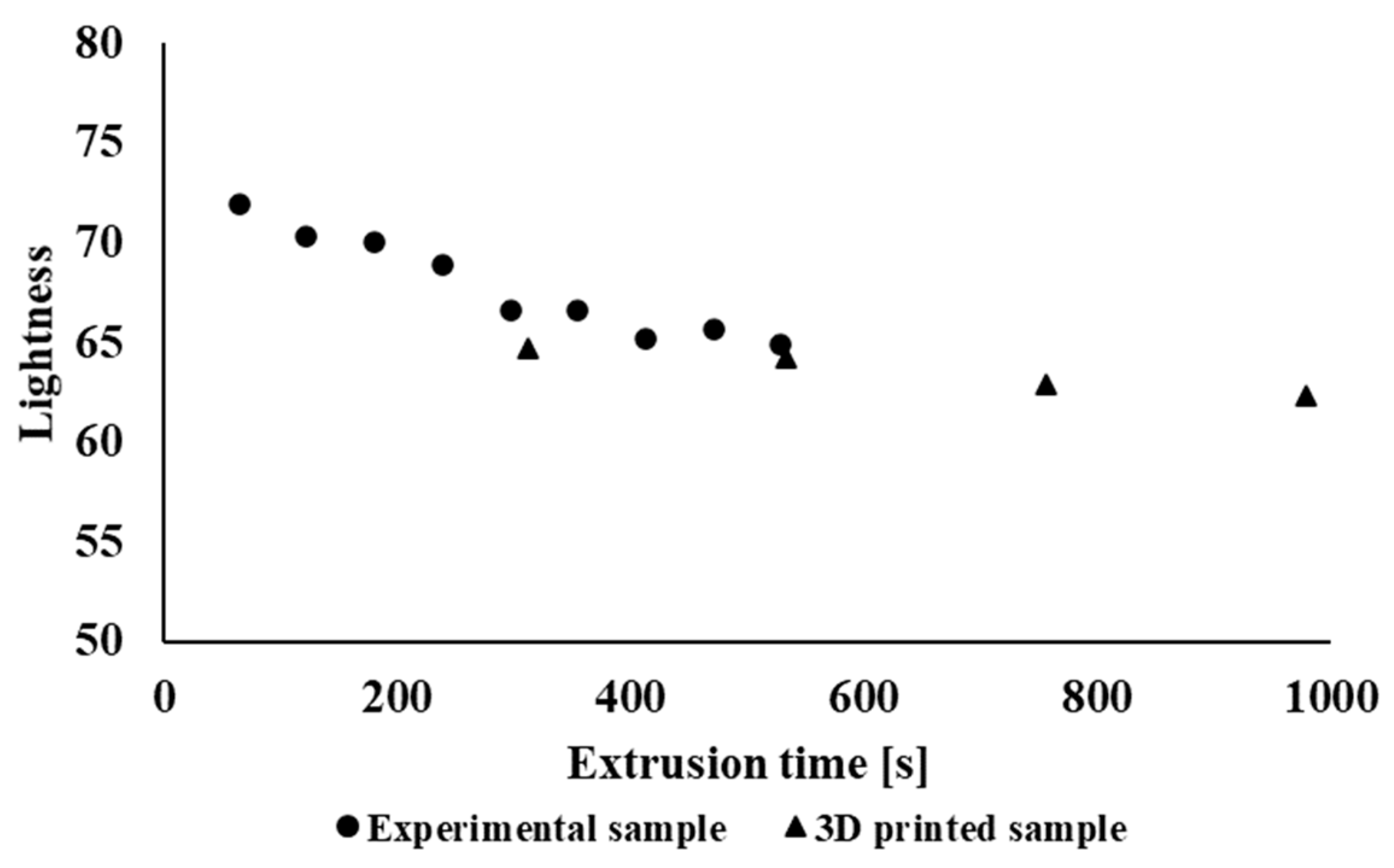

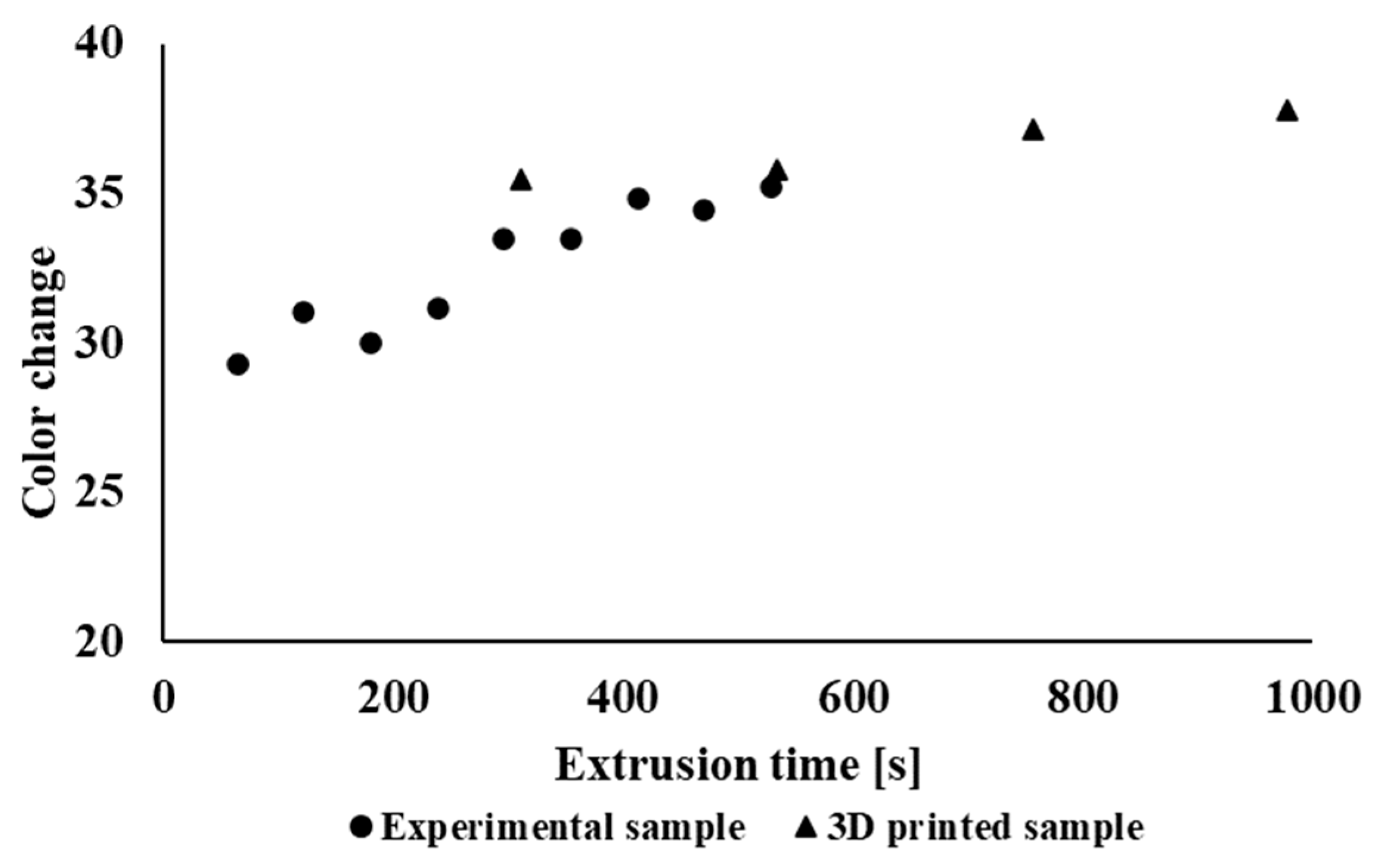

4.3. Color Changes

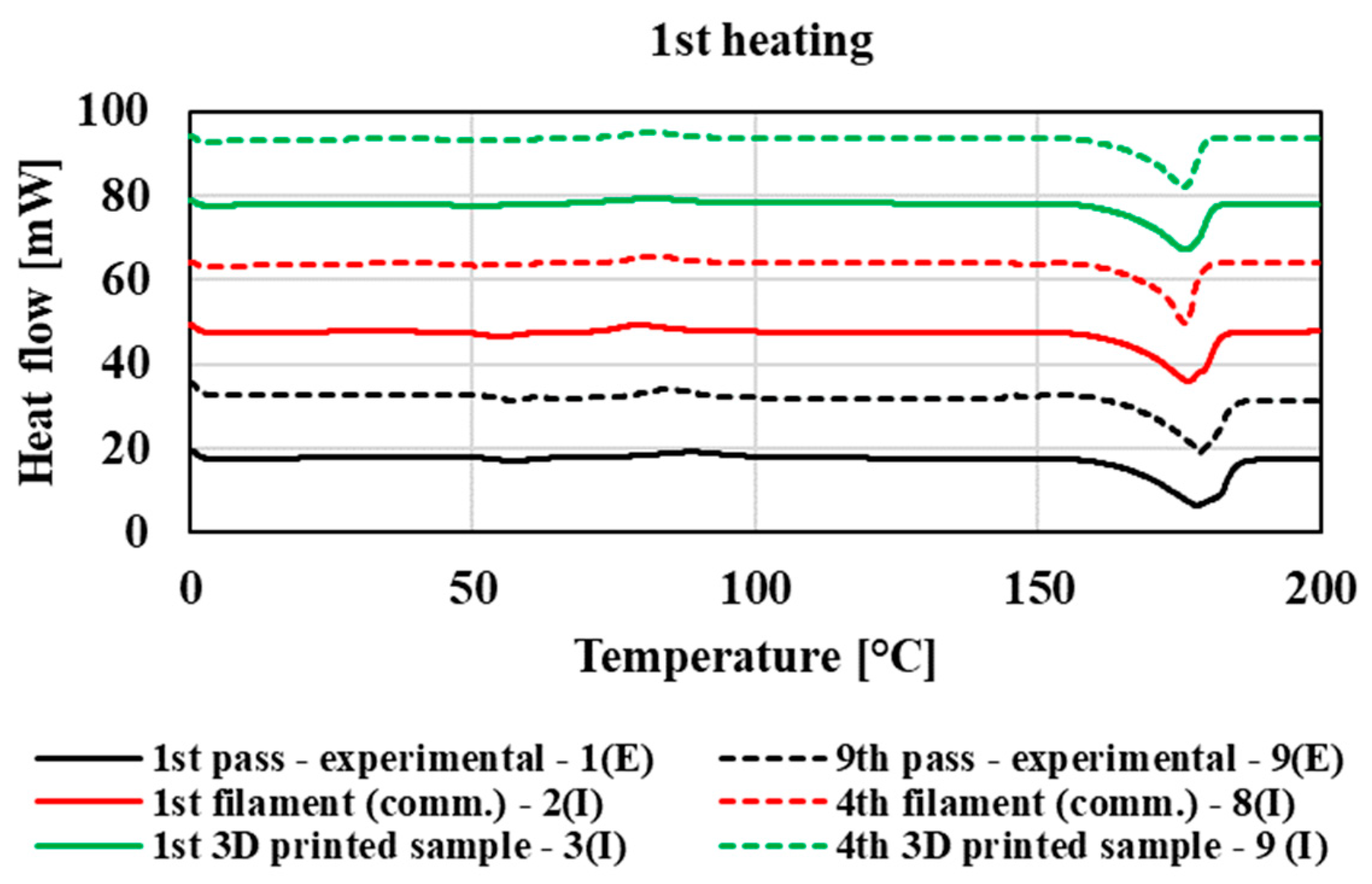

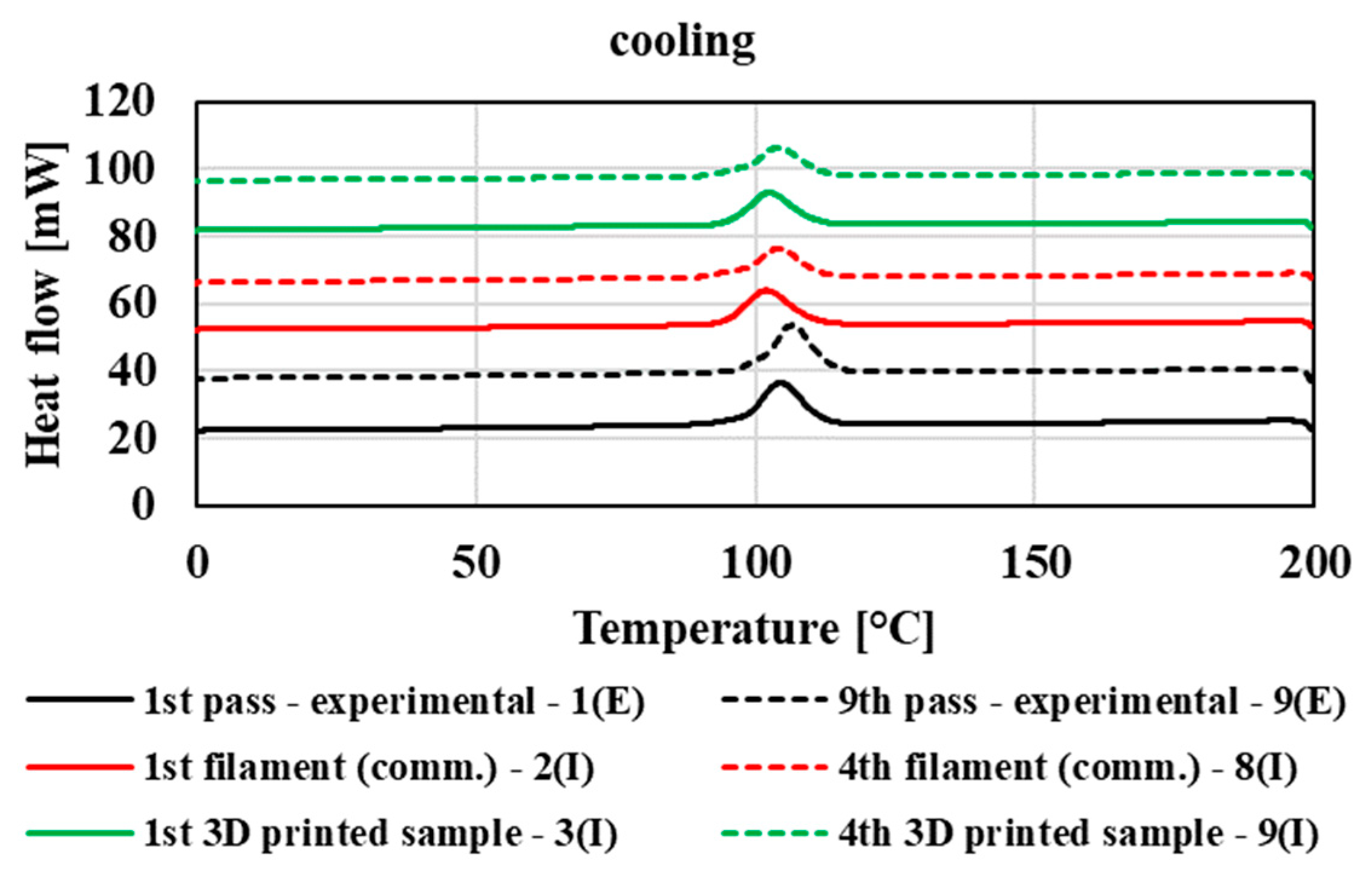

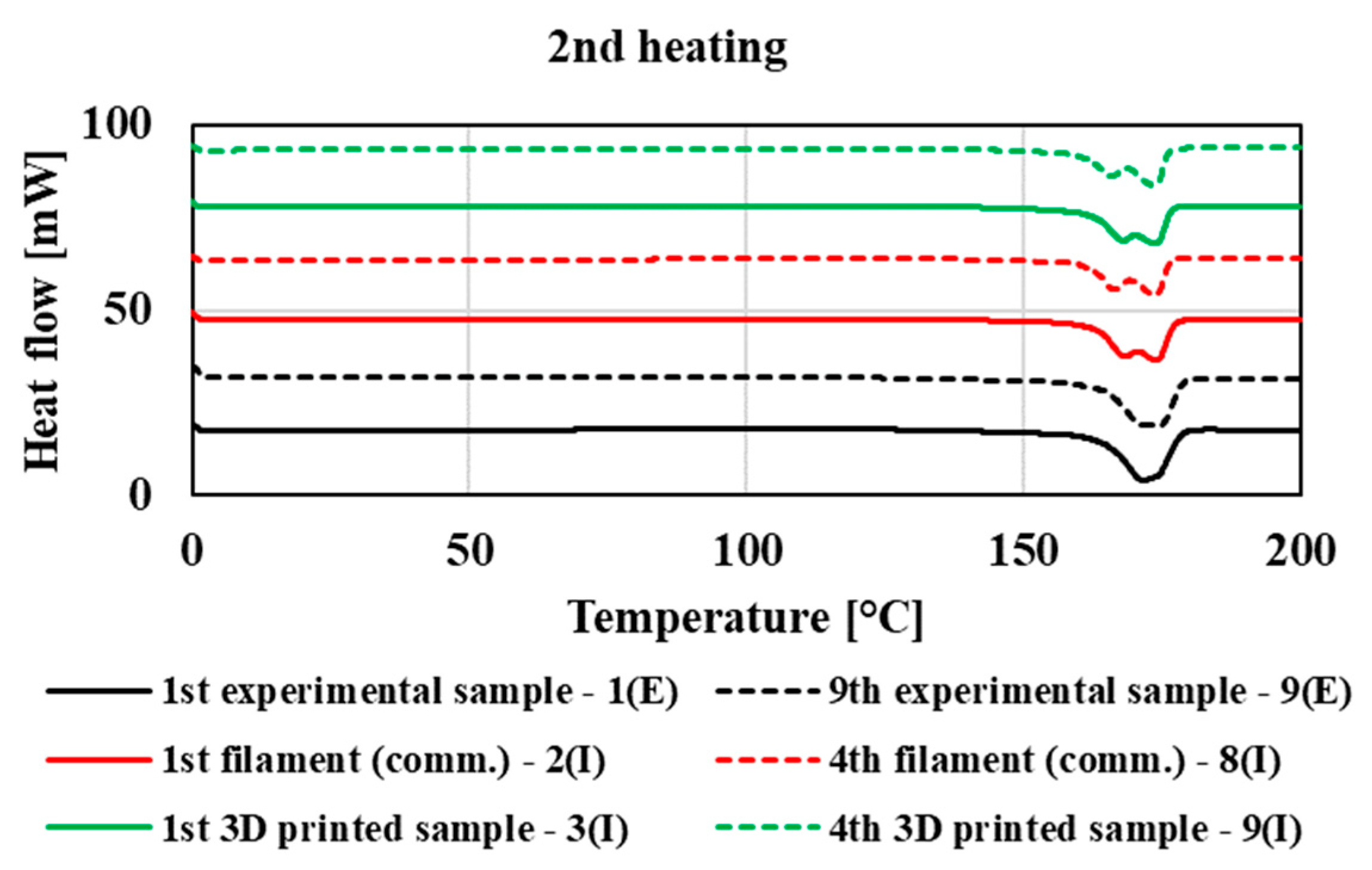

4.4. Thermophysical Properties

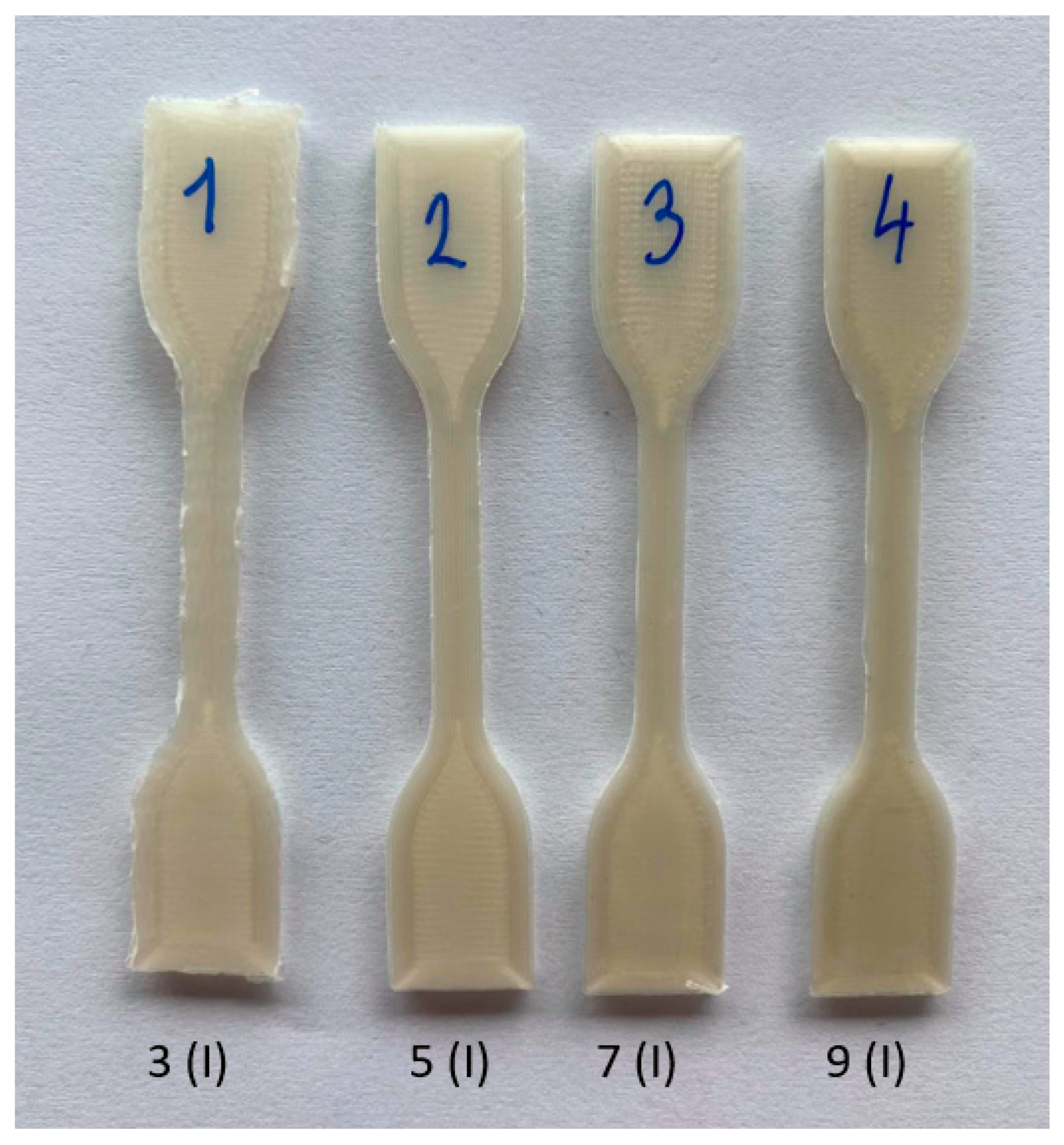

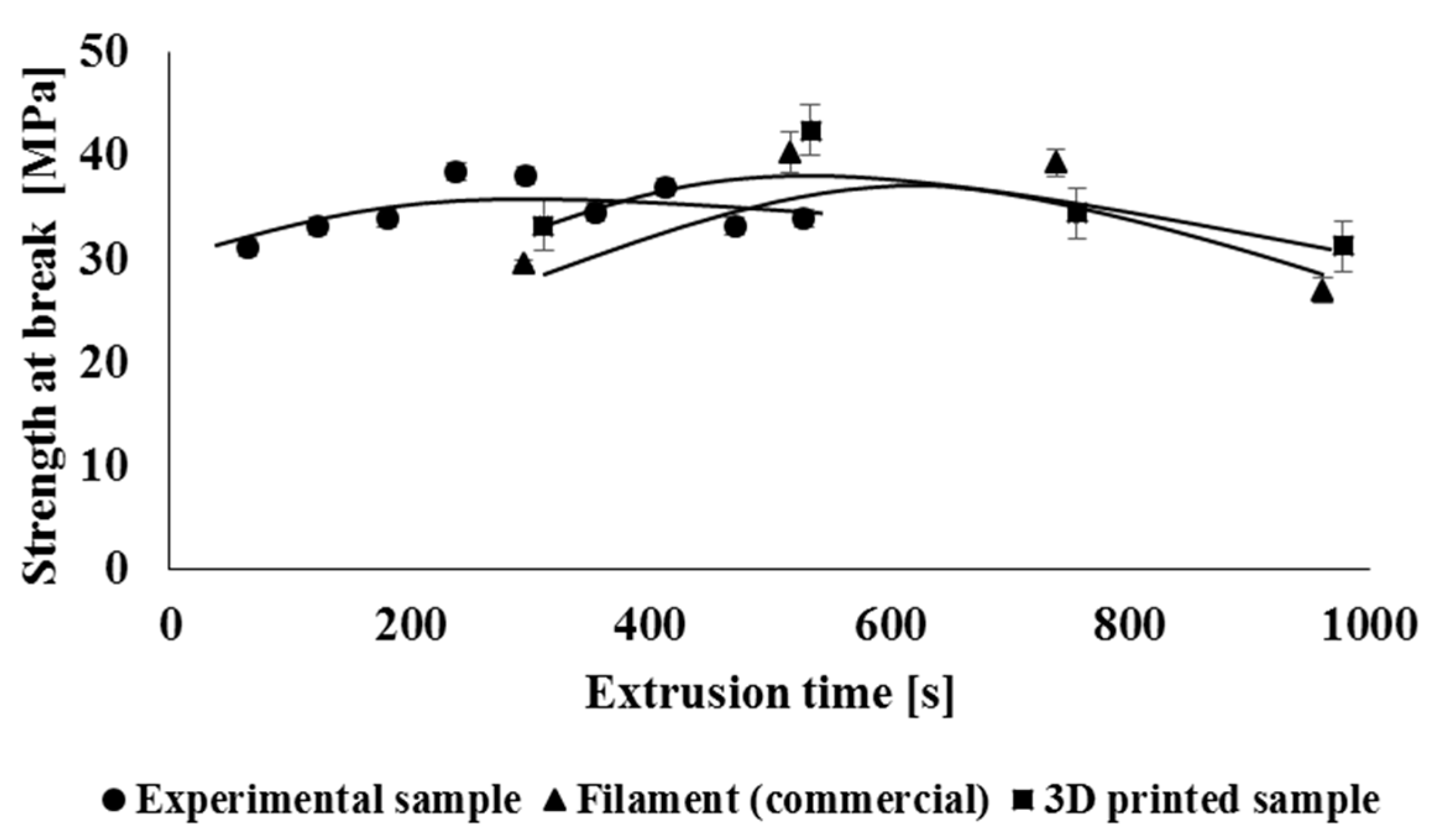

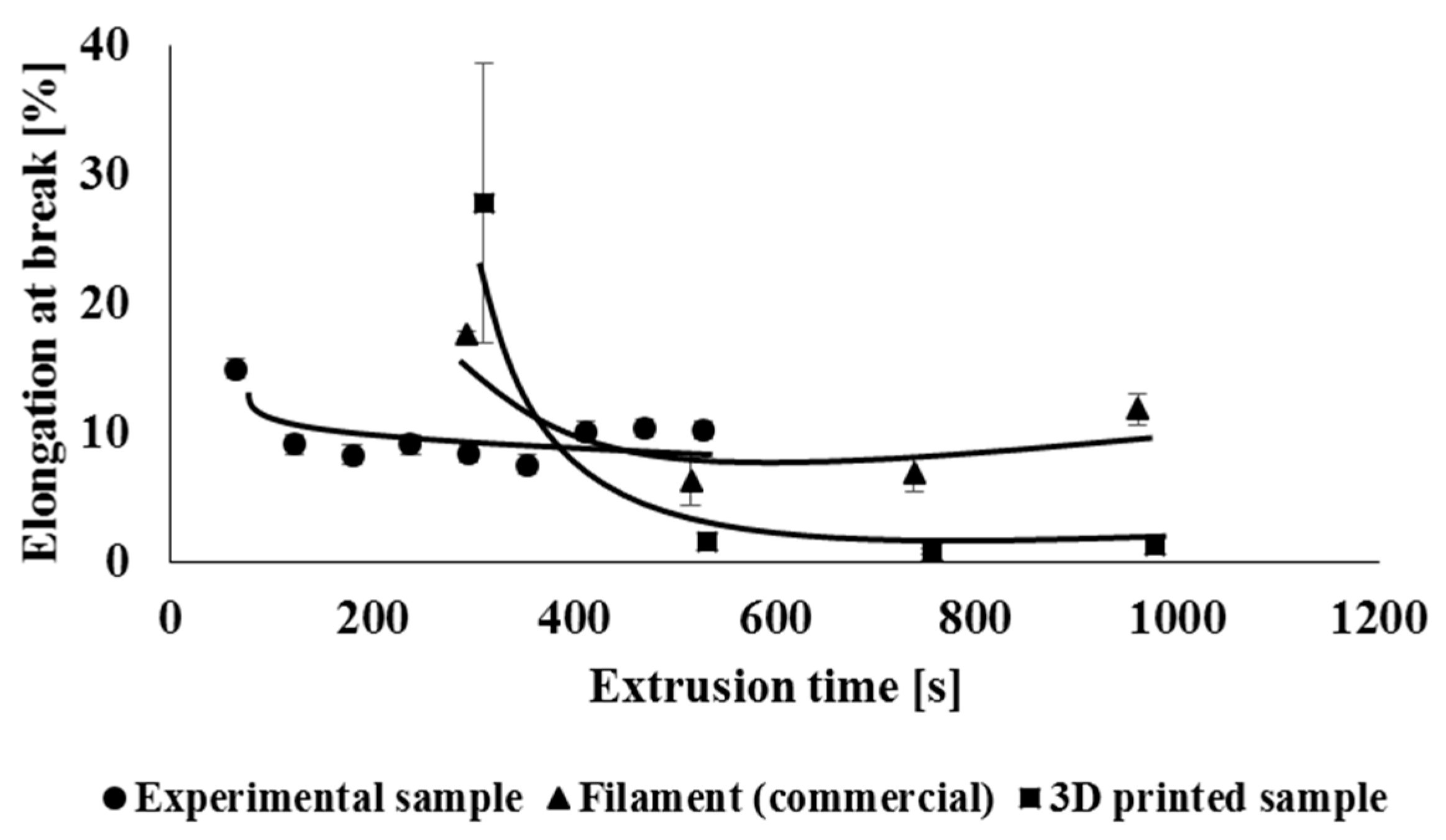

4.5. Mechanical Properties

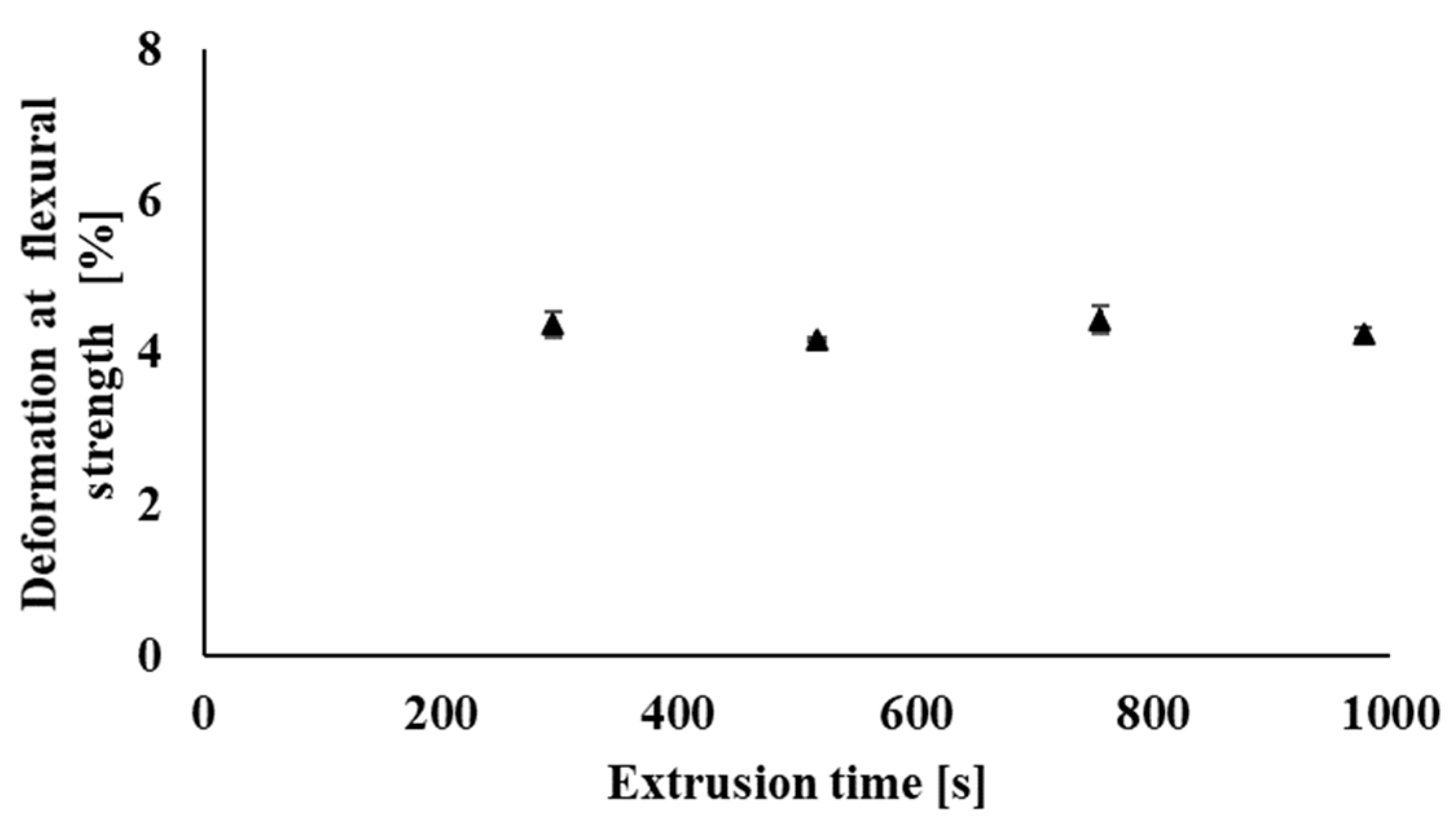

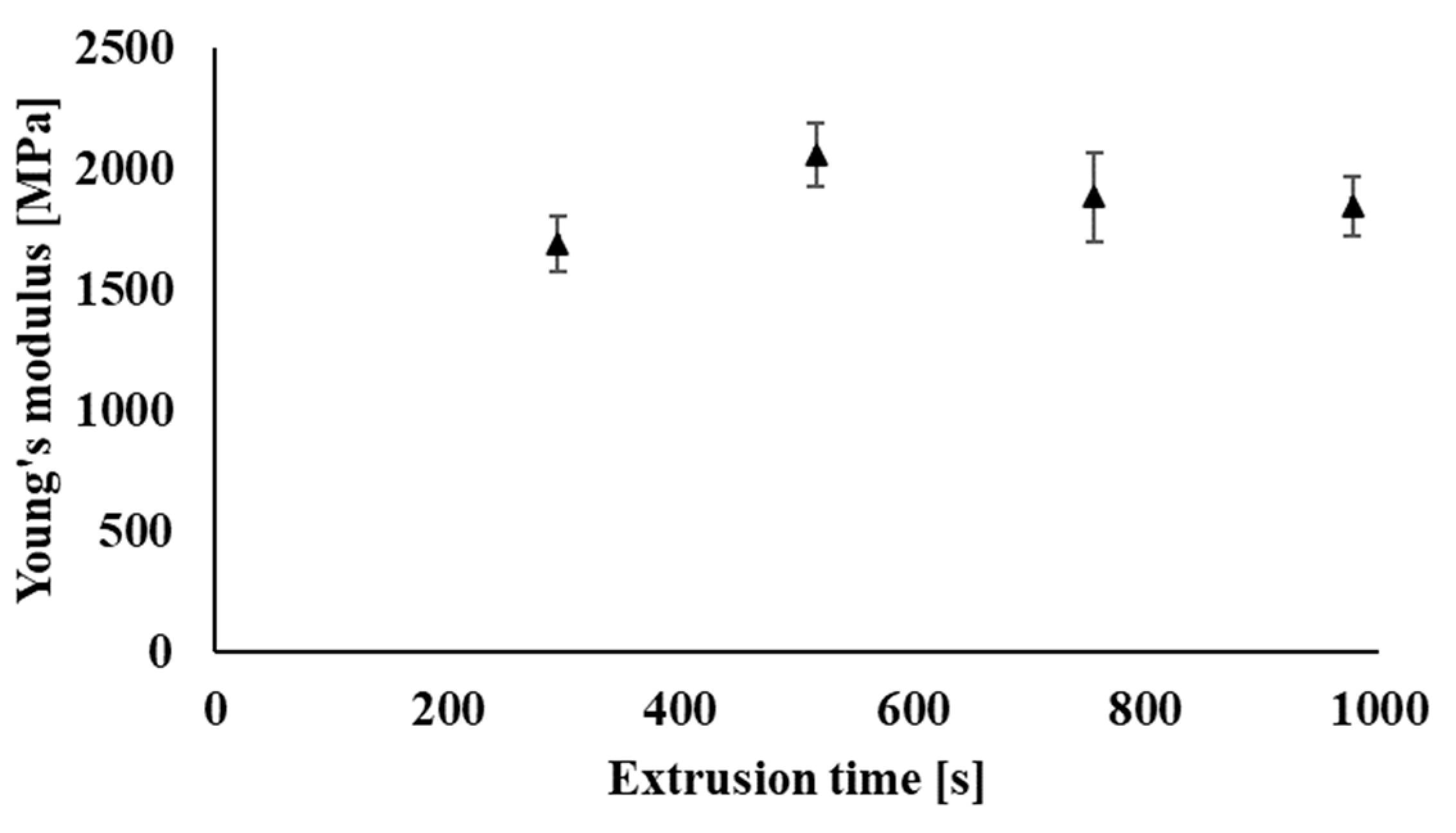

4.6. Flexural Test

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Plastics Europe. Plastics-the Facts. 2020. Available online: https://www.plasticseurope.org/en/resources/publications/4312-plastics-facts-2020 (accessed on 7 March 2022).

- Plavec, R.; Hlaváčiková, S.; Omaníková, L.; Feranc, J.; Vanovčanová, Z.; Tomanová, K.; Bočkaj, J.; Kruželák, J.; Medlenová, E.; Gálisová, I.; et al. Recycling possibilities of bioplastics based on PLA/PHB blends. Polym. Test. 2020, 92, 106880. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Deri, F. Recycling of waste from polymer materials: An overview of the recent works. Polym. Degrad. Stab. 2013, 98, 2801–2812. [Google Scholar] [CrossRef]

- Parliament, Directive 2018/852 of the European. Packaging and Packaging Waste. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32018L0852&from=EN (accessed on 7 March 2022).

- Li, J.; Wu, C.; Chu, P.K.; Gelinsky, M. 3D printing of hydrogels: Rational design strategies and emerging biomedical applications. Mater. Sci. Eng. R Rep. 2020, 140, 100543. [Google Scholar] [CrossRef]

- Cicala, G.; Latteri, A.; Del Curto, B.; Russo, A.L.; Recca, G.; Farè, S. Engineering Thermoplastics for Additive Manufacturing: A Critical Perspective with Experimental Evidence to Support Functional Applications. J. Appl. Biomater. Funct. Mater. 2017, 15, 10–18. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kleinfehn, A.P.; Lindemann, J.A.L.; Razvi, A.; Philip, P.; Richardson, K.; Nettleton, K.; Becker, M.L.; Dean, D. Modulating Bioglass Concentration in 3D Printed Poly(propylene fumarate) Scaffolds for Post-Printing Functionalization with Bioactive Functional Groups. Biomacromolecules 2019, 20, 4345–4352. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.; Xin, A.; Du, H.; Li, Y.; Wang, Q. Additive manufacturing of self-healing elastomers. NPG Asia Mater. 2019, 11, 7. [Google Scholar] [CrossRef] [Green Version]

- Ramiah, P.; Du Toit, L.C.; Choonara, Y.E.; Kondiah, P.P.D.; Pillay, V. Hydrogel-Based Bioinks for 3D Bioprinting in Tissue Regeneration. Front. Mater. 2020, 7, 76. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, Q.; Feng, J. 3D printing of tunable shape memory polymer blends. J. Mater. Chem. C 2017, 5, 8361–8365. [Google Scholar] [CrossRef]

- Shin, D.-Y.; Lee, J.S.; Koo, B.-R.; Ahn, H.-J. Hierarchical hybrid nanostructure of 1T-tungsten disulfide quantum dots/multihollow capillary bundle-type mesoporous carbon for ultrafast and ultrastable lithium storage. Chem. Eng. J. 2021, 412, 15. [Google Scholar] [CrossRef]

- Munaz, A.; Vadivelu, R.K.; John, J.S.; Barton, M.; Kamble, H.; Nguyen, N.-T. Three-dimensional printing of biological matters. J. Sci. Adv. Mater. Devices 2016, 1, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Gibson, I.; Rosen, D.W.; Stucker, B. The Use of Multiple Materials in Additive Manufacturing. Addit. Manuf. Technol. 2010, 436–449. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [Green Version]

- Sanatgar, R.H.; Campagne, C.H.; Nierstrasz, V. Investigation of the adhesion properties of direct 3D printing of polymers and nanocomposites on textiles: Effect of FDM printing process parameters. Appl. Surf. Sci. 2017, 403, 551–563. [Google Scholar] [CrossRef]

- Gupta, N.; Weber, C.; Newsome, S. Additive Manufacturing: Status and Opportunities; Science and Technology Policy Institute: Washington, DC, USA, 2012; pp. 1–35. [Google Scholar]

- Yao, T.; Ye, J.; Deng, Z.; Zhang, K.; Ma, Y.; Ouyang, H. Tensile failure strength and separation angle of FDM 3D printing PLA material: Experimental and theoretical analyses. Compos. Part B Eng. 2020, 188, 107894. [Google Scholar] [CrossRef]

- Chua, C.K.; Leong, K.F.; Lim, C.S. Rapid Prototyping: Principles and Applications, 3rd ed.; World Scientific Publishing Company: Singapore, 2010. [Google Scholar]

- Pham, D.; Dimov, S.S. Rapid Manufacturing: The Technologies and Applications of Rapid Prototyping and Rapid Tooling; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Wurm, M.C.; Möst, T.; Bergauer, B.; Rietzel, D.; Neukam, F.W.; Cifuentes, S.C.; Von Wilmowsky, C. In-vitro evaluation of Polylactic acid (PLA) manufactured by fused deposition modeling. J. Biol. Eng. 2017, 11, 29. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bose, S.; Vahabzadeh, S.; Bandyopadhyay, A. Bone Tissue Engineering Using 3D Printing. Mater. Today 2013, 16, 496–504. [Google Scholar] [CrossRef]

- Chia, H.N.; Wu, B.M. Recent advances in 3D printing of biomaterials. J. Biol. Eng. 2015, 9, 4. [Google Scholar] [CrossRef] [Green Version]

- Abouzaid, K.; Guessasma, S.; Belhabib, S.; Bassir, D.; Chouaf, A. Printability of co-polyester using fused deposition modelling and related mechanical performance. Eur. Polym. J. 2018, 108, 262–273. [Google Scholar] [CrossRef]

- Gebler, M.; Schoot Uiterkamp, A.J.M.; Visser, C. A global sustainability perspective on 3D printing technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Yadav, D.; Garg, R.K.; Ahlawat, A.; Chhabra, D. 3D printable biomaterials for orthopedic implants: Solution for sustainable and circular economy. Resour. Policy 2020, 68, 101767. [Google Scholar] [CrossRef]

- Pinho, A.C.; Amaro, A.M.; Piedade, A.P. 3D printing goes greener: Study of the properties of post-consumer recycled polymers for the manufacturing of engineering components. Waste Manag. 2020, 118, 426–434. [Google Scholar] [CrossRef] [PubMed]

- Youngjae, B.; Young, T.K. Chapter 14—Bioplastics for Food Packaging: Chemistry and Physics. In Innovations in Food Packaging, 2nd ed.; Han, J.H., Ed.; Academic Press: Cambridge, MA, USA, 2014; pp. 353–368. [Google Scholar]

- Koller, M. Advances in Polyhydroxyalkanoate (PHA) Production. Bioengineering 2017, 4, 88. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abdelwahab, M.A.; Flynn, A.; Chiou, B.S.; Imam, S.; Orts, W.; Chiellini, E. Thermal, mechanical and morphological characterization of plasticized PLA–PHB blends. Polym. Degrad. Stab. 2012, 97, 1822–1828. [Google Scholar] [CrossRef]

- Imre, B.; Pukánszky, B. Compatibilization in bio-based and biodegradable polymer blends. Eur. Polym. J. 2013, 49, 1215–1233. [Google Scholar] [CrossRef] [Green Version]

- Bastioli, C. Handbook of Biodegradable Polymers; Walter de Gruyter GmbH & Co. KG: Berlin, Germany, 2020. [Google Scholar]

- Van de Velde, K.; Kiekens, P. Biopolymers: Overview of several properties and consequences on their applications. Polym. Test. 2002, 21, 433–442. [Google Scholar] [CrossRef]

- van Wijk, A.J.M.; van Wijk, I. 3D Printing with Biomaterials: Towards a Sustainable and Circular Economy; IOS Press: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Cisneros-López, E.O.; Pal, A.K.; Rodriguez, A.U.; Wu, F.; Misra, M.; Mielewski, D.K.; Kiziltas, A.; Mohanty, A.K. Recycled poly(lactic acid)–based 3D printed sustainable biocomposites: A comparative study with injection molding. Mater. Today Sustain. 2020, 7, 100027. [Google Scholar] [CrossRef]

- Haro, F.B.; Burgo, J.M.D.A.D.; D’Amato, R.; Islán, M.; Heras, E.S.; Alonso, J.M.G.; Mendez, J.A.J. Monitoring an Analysis of Perturbations in Fusion Deposition Modelling (FDM) Processes for the Use of Biomaterials. J. Med. Syst. 2019, 43, 109. [Google Scholar] [CrossRef]

- Corcione, C.E.; Gervaso, F.; Scalera, F.; Padmanabhan, S.K.; Madaghiele, M.; Montagna, F.; Sannino, A.; Licciulli, A.; Maffezzoli, A. Highly loaded hydroxyapatite microsphere/PLA porous scaffolds obtained by fused deposition modelling. Ceram. Int. 2018, 45, 2803–2810. [Google Scholar] [CrossRef]

- Tellis, B.; Szivek, J.; Bliss, C.; Margolis, D.; Vaidyanathan, R.; Calvert, P. Trabecular scaffolds created using micro CT guided fused deposition modeling. Mater. Sci. Eng. C 2008, 28, 171–178. [Google Scholar] [CrossRef] [Green Version]

- Rimington, R.P.; Capel, A.J.; Christie, S.D.; Lewi, M.P. Biocompatible 3D printed polymers via fused deposition modelling direct C 2 C 12 cellular phenotype in vitro. Lab Chip 2017, 17, 2982–2993. [Google Scholar] [CrossRef] [Green Version]

- Singh, B.N.; Panda, N.N.; Mund, R.; Pramanik, K. Carboxymethyl cellulose enables silk fibroin nanofibrous scaffold with enhanced biomimetic potential for bone tissue engineering application. Carbohydr. Polym. 2016, 151, 335–347. [Google Scholar] [CrossRef] [PubMed]

- Jammalamadaka, U.; Tappa, K. Recent Advances in Biomaterials for 3D Printing and and tissue engineering. J. Funct. Biomater. 2018, 9, 22. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rojas-Martínez, L.; Flores-Hernandez, C.; López-Marín, L.; Martinez-Hernandez, A.; Thorat, S.; Vasquez, C.R.; Del Rio-Castillo, A.; Velasco-Santos, C. 3D printing of PLA composites scaffolds reinforced with keratin and chitosan: Effect of geometry and structure. Eur. Polym. J. 2020, 141, 110088. [Google Scholar] [CrossRef]

- Zhang, M.; Thomas, N.L. Blending polylactic acid with polyhydroxybutyrate: The effect on thermal, mechanical, and biodegradation properties. Adv. Polym. Technol. 2011, 30, 67–79. [Google Scholar] [CrossRef]

- Chiulan, I.; Frone, A.N.; Brandabur, C.; Panaitescu, D.M. Recent Advances in 3D Printing of Aliphatic Polyesters. Bioengineering 2017, 5, 2. [Google Scholar] [CrossRef] [Green Version]

- Xiao, L.; Wang, B.; Yang, G.; Gauthier, M. Poly (lactic acid)-based biomaterials: Synthesis, modification and applications. Biomed. Sci. Eng. Technol. 2012, 11, 247–282. [Google Scholar]

- Kontárová, S.; Přikryl, R.; Melčová, V.; Menčík, P.; Horálek, M.; Figalla, S.; Plavec, R.; Feranc, J.; Sadílek, J.; Pospíšilová, A. Printability, Mechanical and Thermal Properties of Poly(3-Hydroxybutyrate)-Poly(Lactic Acid)-Plasticizer Blends for Three-Dimensional (3D) Printing. Materials 2020, 13, 4736. [Google Scholar] [CrossRef]

- Upadhyay, R.K.; Mishra, A.K.; Kumar, A. Mechanical Degradation of 3D Printed PLA in Simulated Marine Environment. Surf. Interfaces 2020, 21, 100778. [Google Scholar] [CrossRef]

- Scaffaro, R.; Botta, L.; Passaglia, E.; Oberhauser, W.; Frediani, M.; Di Landro, L. Comparison of different processing methods to prepare poly(lactid acid)-hydrotalcite composites. Polym. Eng. Sci. 2013, 54, 1804–1810. [Google Scholar] [CrossRef]

- Le Marec, P.E.; Ferry, L.; Quantin, J.-C.; Bénézet, J.-C.; Bonfils, F.; Guilbert, S.; Bergeret, A. Influence of melt processing conditions on poly(lactic acid) degradation: Molar mass distribution and crystallization. Polym. Degrad. Stab. 2014, 110, 353–363. [Google Scholar] [CrossRef]

- Tuna, B.; Ozkoc, G. Effects of Diisocyanate and Polymeric Epoxidized Chain Extenders on the Properties of Recycled Poly(Lactic Acid). J. Polym. Environ. 2016, 25, 983–993. [Google Scholar] [CrossRef]

- Lim, J.; You, M.; Li, J.; Li, Z. Emerging bone tissue engineering via Polyhydroxyalkanoate (PHA)-based scaffolds. Mater. Sci. Eng. C 2017, 79, 917–929. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.-Q.; Wu, Q. The application of polyhydroxyalkanoates as tissue engineering materials. Biomaterials 2005, 26, 6565–6578. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Capoen, L.; D’hooge, D.R.; Cardon, L. Can the melt flow index be used to predict the success of fused deposition modelling of commercial poly(lactic acid) filaments into 3D printed materials? Plast. Rubber Compos. 2018, 47, 9–16. [Google Scholar] [CrossRef]

- Soroudi, A.; Jakubowicz, I. Recycling of bioplastics, their blends and biocomposites: A review. Eur. Polym. J. 2013, 49, 2839–2858. [Google Scholar] [CrossRef]

- Armentano, I.; Fortunati, E.; Burgos, N.; Dominici, F.; Luzi, F.; Fiori, S.; Jiménez, A.; Yoon, K.; Ahn, J.; Kang, S.; et al. Bio-based PLA_PHB plasticized blend films: Processing and structural characterization. LWT 2015, 64, 980–988. [Google Scholar] [CrossRef] [Green Version]

- Jost, V.; Kopitzky, R. Blending of polyhydroxybutyrate-co-valerate with polylactic acid for packaging applications-reflections on miscibility and effects on the mechanical and barrier properties. Chem. Biochem. Eng. Q. 2015, 29, 221–246. [Google Scholar] [CrossRef]

- Ma, Y.; Li, L.; Wang, Y. Development of PLA-PHB-based biodegradable active packaging and its application to salmon. Packag. Technol. Sci. 2018, 31, 739–746. [Google Scholar] [CrossRef]

- Blumm, E.; Owen, A.J. Miscibility, crystallization and melting of poly(3-hydroxybutyrate)/poly(L-lactide) blends. Polymer 1995, 36, 4077–4081. [Google Scholar] [CrossRef]

- Koyama, N.; Doi, Y. Miscibility of binary blends of poly[(R)-3-hydroxybutyric acid] and poly[(S)-lactic acid]. Polymer 1997, 38, 1589–1593. [Google Scholar] [CrossRef]

- Ohkoshi, I.; Abe, H.; Doi, Y. Miscibility and solid-state structures for blends of poly[(S)-lactide] with atactic poly[(R,S)-3-hydroxybutyrate]. Polymer 2000, 41, 5985–5992. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Lopez, J.; Hernandez, A.; Rayon, E. Ternary PLA-PHB-Limonene blends intended for biodegradable food packaging applications. Eur. Polym. J. 2014, 50, 255–270. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Lopez, J.; Jiménez, A. Combined Effect of Poly(hydroxybutyrate) and Plasticizers on Polylactic acid Properties for Film Intended for Food Packaging. J. Polym. Environ. 2014, 22, 460–470. [Google Scholar] [CrossRef]

- Arrieta, M.; Fortunati, E.; Dominici, F.; López, J.; Kenny, J. Bionanocomposite films based on plasticized PLA–PHB/cellulose nanocrystal blends. Carbohydr. Polym. 2015, 121, 265–275. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, S.; Ma, P.; Wang, R.; Zhang, Y. Mechanical, thermal and degradation properties of poly(D, L-lactide)/poly(hydroxybutyrate-co-hydroxyvalerate)/poly(ethylene glycol) blend. Polym. Degrad. Stab. 2008, 93, 1364–1369. [Google Scholar] [CrossRef]

- Alexy, P.; Chodák, I.; Bakoš, D.; Bugaj, P.; Pavlacková, M.; Tomanová, K.; Benovic, F.; Plavec, R.; Mihalik, M. Biologically Degradable Polymeric Composition with High Deformability. WO2012141660A1, 11 April 2012. Available online: https://patents.google.com/patent/WO2012141660A1/ (accessed on 7 March 2022).

- Menčík, P.; Přikryl, R.; Stehnová, I.; Melčová, V.; Kontárová, S.; Figalla, S.; Alexy, P.; Bočkaj, J. Effect of Selected Commercial Plasticizers on Mechanical, Thermal, and Morphological Properties of Poly(3-hydroxybutyrate)/Poly(lactic acid)/Plasticizer Biodegradable Blends for Three-Dimensional (3D) Print. Materials 2018, 11, 1893. [Google Scholar] [CrossRef] [Green Version]

- Fuentes, M.A.V.; Thakur, S.; Wu, F.; Misra, M.; Gregori, S.; Mohanty, A.K. Study on the 3D printability of poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/poly(lactic acid) blends with chain extender using fused filament fabrication. Sci. Rep. 2020, 1, 10. [Google Scholar]

- Ausejo, J.G.; Rydz, J.; Musioł, M.; Sikorska, W.; Janeczek, H.; Sobota, M.; Wlodarczyk, J.; Szeluga, U.; Hercog, A.; Kowalczuk, M. Three-dimensional printing of PLA and PLA/PHA dumbbell-shaped specimens of crisscross and transverse patterns as promising materials in emerging application areas: Prediction study. Polym. Degrad. Stab. 2018, 156, 100–110. [Google Scholar] [CrossRef] [Green Version]

- Lazarevic, D.; Aoustin, E.; Buclet, N.; Brandt, N. Plastic waste management in the context of a European recycling society: Comparing results and uncertainties in a life cycle perspective. Resour. Conserv. Recycl. 2010, 2, 246–259. [Google Scholar] [CrossRef]

- Perugini, F.; Mastellone, M.L.; Arena, U. A life cycle assessment of mechanical and feedstock recycling options for management of plastic packaging wastes. Environ. Prog. 2005, 2, 246–259. [Google Scholar] [CrossRef]

- Piemonte, V. Bioplastic Wastes: The Best Final Disposition for Energy Saving. J. Polym. Environ. 2011, 19, 988–994. [Google Scholar] [CrossRef]

- Arena, U.; Mastellone, M.L.; Perugini, F. Life Cycle assessment of a plastic packaging recycling system. Int. J. Life Cycle Assess. 2003, 8, 92–98. [Google Scholar] [CrossRef]

- Fisher, M. Plastics recycling. In Plastics and the Environment; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery rotes of plastic solid waste: A review. Waste Manag. 2009, 10, 2625–2643. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hatti-Kaul, R.; Nilsson, L.J.; Zhang, B.; Lundmark, S. Designing Biobased Recyclable Polymers for Plastics: A Review. Trends Biotechnol. 2020, 1, 50–67. [Google Scholar] [CrossRef] [PubMed]

- Mantia, F.L.A. Handbook of Plastics Recycling; iSmithers Rapra Publishing, Rapra Technology Limited: Shropshire, UK, 2002. [Google Scholar]

- Żenkiewicz, M.; Kurcok, M. Effects of compatibilizers and electron radiation on thermomechanical properties of composites consisting of five recycled polymers. Polym. Test. 2008, 27, 420–427. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions A European Strategy for Plastics in a Circular Economy; COM/2018/028; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Hinsken, H.; Moss, S.; Pauquet, J.-R.; Zweifel, H. Degradation of polyolefins during melt processing. Polym. Degrad. Stab. 1991, 34, 279–293. [Google Scholar] [CrossRef]

- Kometani, H.; Matsumura, T.; Suga, T.; Kanai, T. Quantitative Analysis for Polymer Degradation in the Extrusion Process. Int. Polym. Process. 2006, 21, 24–31. [Google Scholar] [CrossRef]

- Hu, H.; Zhang, R.; Kong, Z.; Wang, K.; Ying, W.B.; Wang, J.; Zhu, J. Bio-based poly(butylene furandicarboxylate)-b-poly(ethylene glycol) copolymers: The effect of poly(ethylene glycol) molecular weight on thermal properties and hydrolysis degradation behavior. Adv. Ind. Eng. Polym. Res. 2019, 2, 167–177. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Sasaki, D.; Takamura, A. On the entanglement-based mechanism in thermal degradation of vinyl polymers. Polym. Degrad. Stab. 2019, 169, 108990. [Google Scholar] [CrossRef]

- FBeltrán, R.; Lorenzo, V.; Acosta, J.; de la Orden, M.U.; Urreaga, J.M. Effect of simulated mechanical recycling processes on the structure and properties of poly(lactic acid). J. Environ. Manag. 2018, 216, 25–31. [Google Scholar] [CrossRef] [Green Version]

- Beltrán, F.R.; Infante, C.; de la Orden, M.U.; Urreaga, J.M. Mechanical recycling of poly(lactic acid): Evaluation of a chain extender and a peroxide as additives for upgrading the recycled plastic. J. Clean. Prod. 2019, 219, 46–56. [Google Scholar] [CrossRef]

- Żenkiewicz, M.; Richert, J.; Rytlewski, P.; Moraczewski, K.; Stepczyńska, M.; Karasiewicz, T. Characterisation of multi-extruded poly(lactic acid). Polym. Test. 2009, 28, 412–418. [Google Scholar] [CrossRef]

- Pillin, I.; Montrelay, N.; Bourmaud, A.; Grohens, Y. Effect of thermo-mechanical cycles on the physico-chemical properties of poly(lactic acid). Polym. Degrad. Stab. 2008, 93, 321–328. [Google Scholar] [CrossRef]

- Badia, J.D.; Strömberg, E.; Karlsson, S.; Ribes-Greus, A. Material valorisation of amorphous polylactide. Influence of thermo-mechanical degradation on the morphology, segmental dynamics, thermal and mechanical performance. Polym. Degrad. Stab. 2012, 97, 670–678. [Google Scholar] [CrossRef]

- Agüero, A.; Morcillo, M.d.C.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Lascano, D.; Torres-Giner, S.; Fenollar, O. Study of the Influence of the Reprocessing Cycles on the Final Properties of Polylactide Pieces Obtained by Injection Molding. Polymers 2019, 11, 1908. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rivas, L.F.; Casarin, S.A.; Cavalcante, N.; Alencar, M.I.; Agnelli, J.A.M.; de Medeiros, E.S.; de Oliveira Wanderley Neto, A.; de Oliveira, M.P.; de Medeiros, A.M.; Ferreira e Santos, A.S. Reprocessability of PHB in extrusion: ATR-FTIR, tensile tests and thermal studies. Polímeros 2017, 27, 122–128. [Google Scholar] [CrossRef] [Green Version]

- Mikušová, M.; Mihalík, M.; Alexy, P.; Tomanová, K.; Plavec, R.; Bočkaj, J.; Vanovčanová, Z. Method for Testing of Processing Stability of Biodegradable Polyesters Based on Oscillation Rheometry; Kautschuk Gummi Kunstoffe: Heidelberg, Germany, 2014; Volume 67, pp. 51–54. [Google Scholar]

- Ma, Y.; Zhang, W.; Wang, Z.; Wang, Z.; Xie, Q.; Niu, H.; Guo, H.; Yuan, Y.; Liu, C. PEGylated poly(glycerol sebacate)-modified calcium phosphate scaffolds with desirable mechanical behavior and enhanced osteogenic capacity. Acta Biomater. 2016, 44, 110–124. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, A.; Wang, Y.X.; Liu, Y.; Chen, K.; Wu, K.; Yu, S.; Yuan, Y.; Liu, C. Urethane-based low-temperature curing, highly-customized and multifunctional poly (glycerol sebacate)-co-poly (ethylene glycol) copolymers. Acta Biomater. 2018, 71, 279–292. [Google Scholar] [CrossRef]

| Experimental Recycling | |||

| Extrusion Number/Sample Name | Processing Equipment | Processing Time (Seconds) | |

| 1 (E) | Twin-screw extruder (blending) | 65 | |

| 2 (E) | Single-screw extruder | 123 | |

| 3 (E) | Single-screw extruder | 181 | |

| 4 (E) | Single-screw extruder | 239 | |

| 5 (E) | Single-screw extruder | 297 | |

| 6 (E) | Single-screw extruder | 355 | |

| 7 (E) | Single-screw extruder | 413 | |

| 8 (E) | Single-screw extruder | 471 | |

| 9 (E) | Single-screw extruder | 529 | |

| Industrial Recycling | |||

| Extrusion Number/Sample Name | Processing Equipment | Processing Time (Seconds) | Product |

| 1 (I) | Twin-screw extruder (blending) * | 45 | Polymer blend |

| 2 (I) | Single-screw extruder * | 295 | 1st Filament |

| 3 (I) | 3D printer | 312 | 1st 3D sample |

| 4 (I) | Single-screw extruder | 517 | 2nd Filament |

| 5 (I) | 3D printer | 534 | 2nd 3D sample |

| 6 (I) | Single-screw extruder | 739 | 3rd Filament |

| 7 (I) | 3D printer | 756 | 3rd 3D sample |

| 8 (I) | Single-screw extruder | 961 | 4th Filament |

| 9 (I) | 3D printer | 978 | 4th 3D sample |

| Ramp | Set Temperature (°C) | Time (min) | |

|---|---|---|---|

| Conditioning | isothermal | 0 | 1 |

| 1st Heating | 10 °C/min | 200 | 20 |

| Conditioning | isothermal | 200 | 3 |

| Cooling | 10 °C/min | 0 | 20 |

| Conditioning | isothermal | 0 | 3 |

| 2nd Heating | 10 °C/min | 200 | 20 |

| Sample | Experimental Samples | Industrial Samples | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 (E) | 3 (E) | 5 (E) | 7 (E) | 9 (E) | 1 (I) | 3 (I) | 5 (I) | 7 (I) | 9 (I) | |

| Tg [°C] | 53.76 | 54.75 | 54.67 | 54.73 | 54.74 | 48.58 | 46.75 | 47.76 | 49.11 | 48.28 |

| Tcc [°C] | 88.80 | 84.80 | 84.00 | 84.33 | 84.99 | 79.31 | 82.47 | 83.15 | 83.67 | 82.00 |

| ΔHcc [J/g] | 6.46 | 9.56 | 9.38 | 8.16 | 8.70 | 5.90 | 4.95 | 7.03 | 6.20 | 6.65 |

| Tm [°C] | 177.36 | 177.09 | 178.26 | 177.60 | 179.78 | 175.84 | 176.08 | 177.38 | 175.09 | 175.06 |

| ΔHm [J/g] | 56.75 | 53.93 | 53.57 | 53.30 | 50.28 | 57.70 | 55.46 | 55.17 | 53.99 | 53.92 |

| Tcc [°C] | 105.12 | 106.26 | 107.19 | 107.50 | 107.36 | 102.52 | 102.65 | 104.01 | 105.32 | 104.36 |

| ΔHc [J/g] | 46.06 | 45.45 | 47.23 | 45.52 | 46.69 | 46.57 | 43.33 | 44.53 | 41.31 | 42.83 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Plavec, R.; Horváth, V.; Hlaváčiková, S.; Omaníková, L.; Repiská, M.; Medlenová, E.; Feranc, J.; Kruželák, J.; Přikryl, R.; Figalla, S.; et al. Influence of Multiple Thermomechanical Processing of 3D Filaments Based on Polylactic Acid and Polyhydroxybutyrate on Their Rheological and Utility Properties. Polymers 2022, 14, 1947. https://doi.org/10.3390/polym14101947

Plavec R, Horváth V, Hlaváčiková S, Omaníková L, Repiská M, Medlenová E, Feranc J, Kruželák J, Přikryl R, Figalla S, et al. Influence of Multiple Thermomechanical Processing of 3D Filaments Based on Polylactic Acid and Polyhydroxybutyrate on Their Rheological and Utility Properties. Polymers. 2022; 14(10):1947. https://doi.org/10.3390/polym14101947

Chicago/Turabian StylePlavec, Roderik, Vojtech Horváth, Slávka Hlaváčiková, Leona Omaníková, Martina Repiská, Elena Medlenová, Jozef Feranc, Ján Kruželák, Radek Přikryl, Silvestr Figalla, and et al. 2022. "Influence of Multiple Thermomechanical Processing of 3D Filaments Based on Polylactic Acid and Polyhydroxybutyrate on Their Rheological and Utility Properties" Polymers 14, no. 10: 1947. https://doi.org/10.3390/polym14101947

APA StylePlavec, R., Horváth, V., Hlaváčiková, S., Omaníková, L., Repiská, M., Medlenová, E., Feranc, J., Kruželák, J., Přikryl, R., Figalla, S., Kontárová, S., Baco, A., Danišová, L., Vanovčanová, Z., & Alexy, P. (2022). Influence of Multiple Thermomechanical Processing of 3D Filaments Based on Polylactic Acid and Polyhydroxybutyrate on Their Rheological and Utility Properties. Polymers, 14(10), 1947. https://doi.org/10.3390/polym14101947