Development of Trans-1,4-Polyisoprene Shape-Memory Polymer Composites Reinforced with Carbon Nanotubes Modified by Polydopamine

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

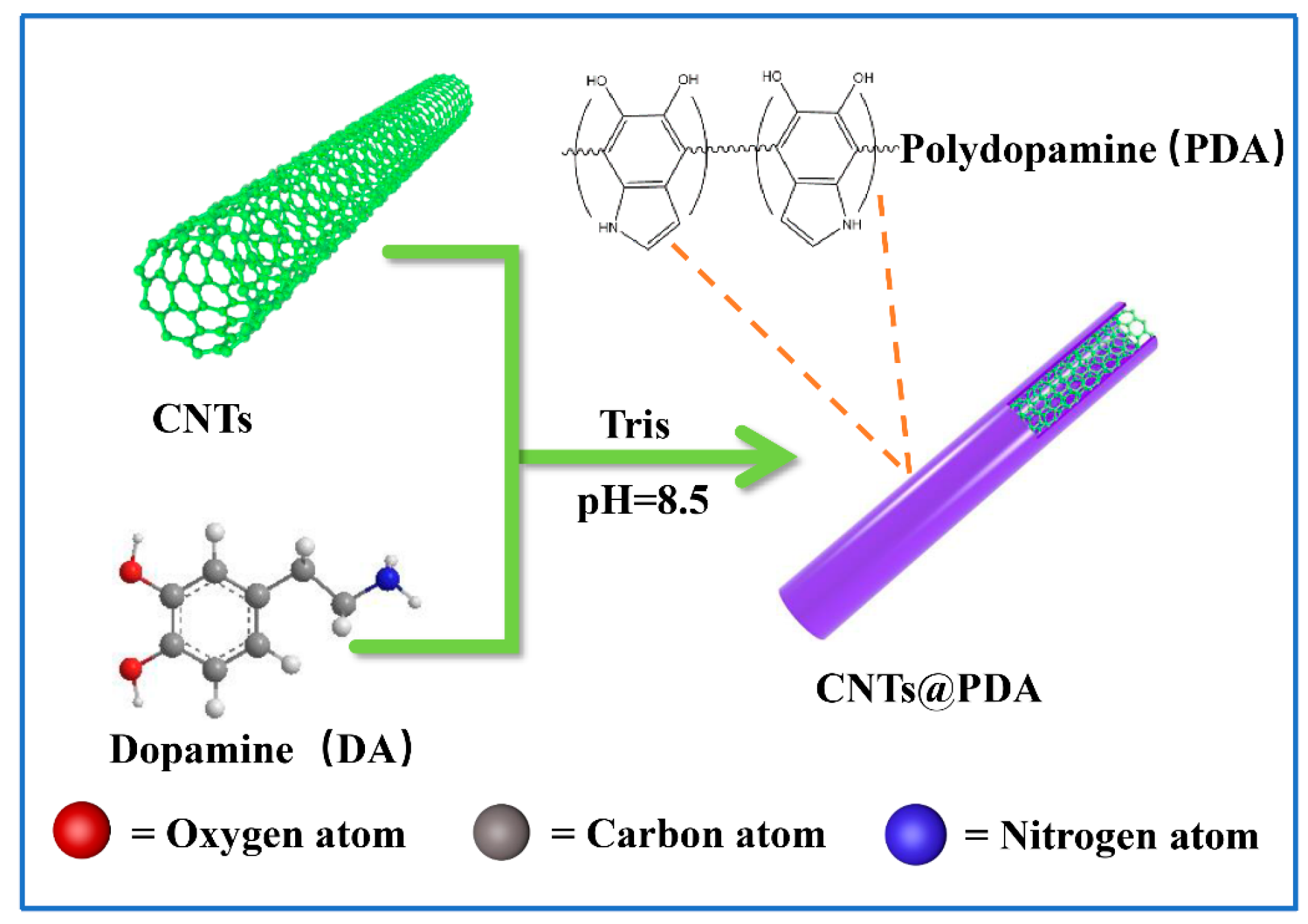

2.2. Preparation of TPI/CNTs@PDA Composites

2.3. Characterizations

3. Results and Discussion

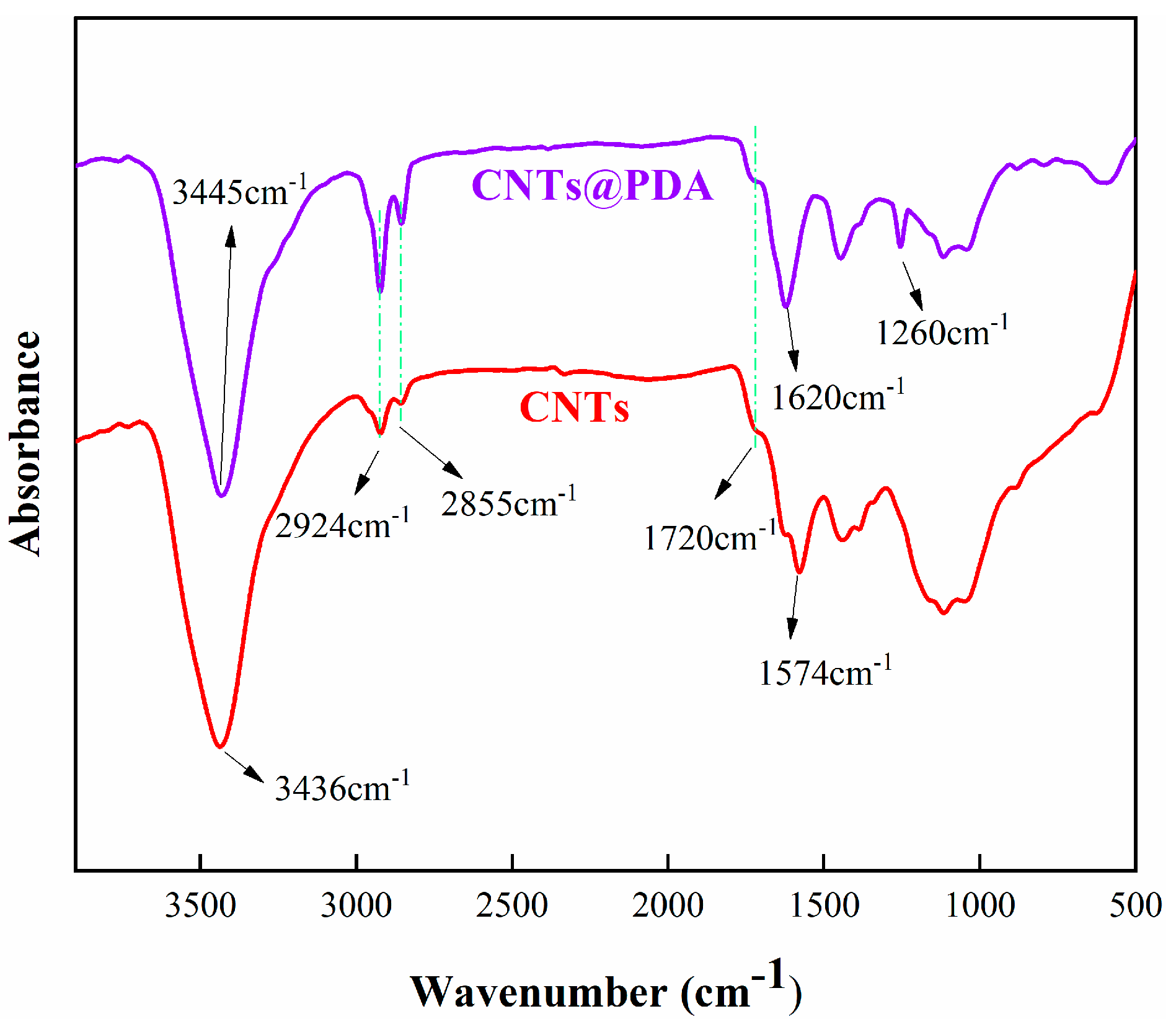

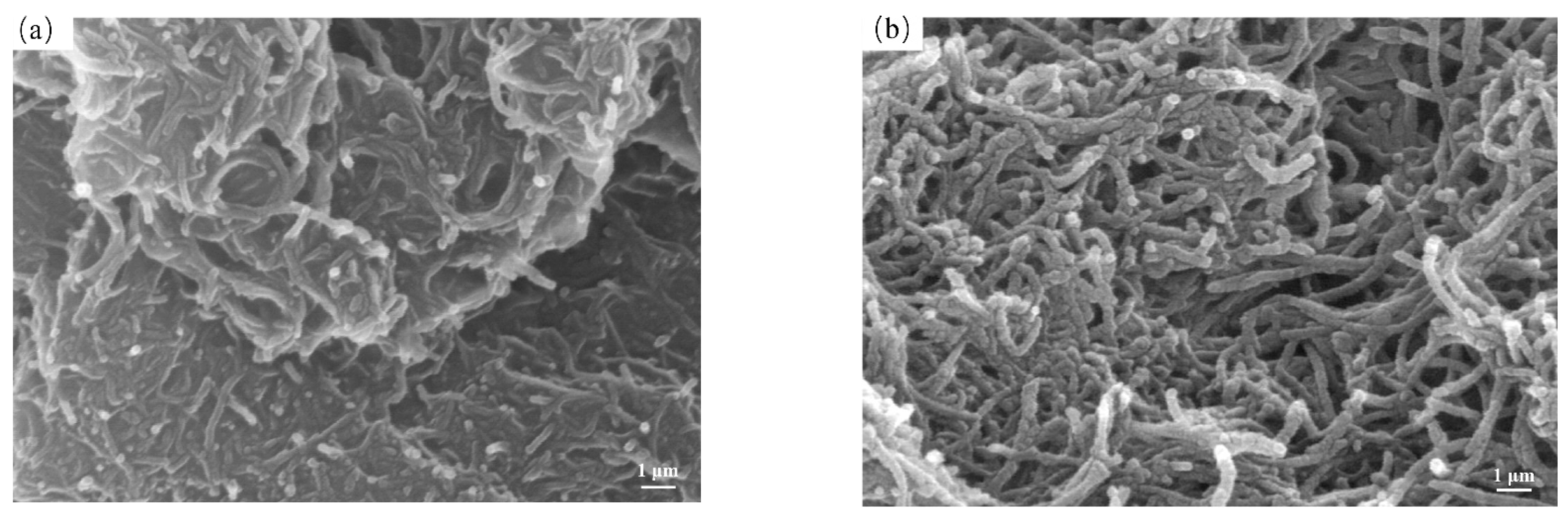

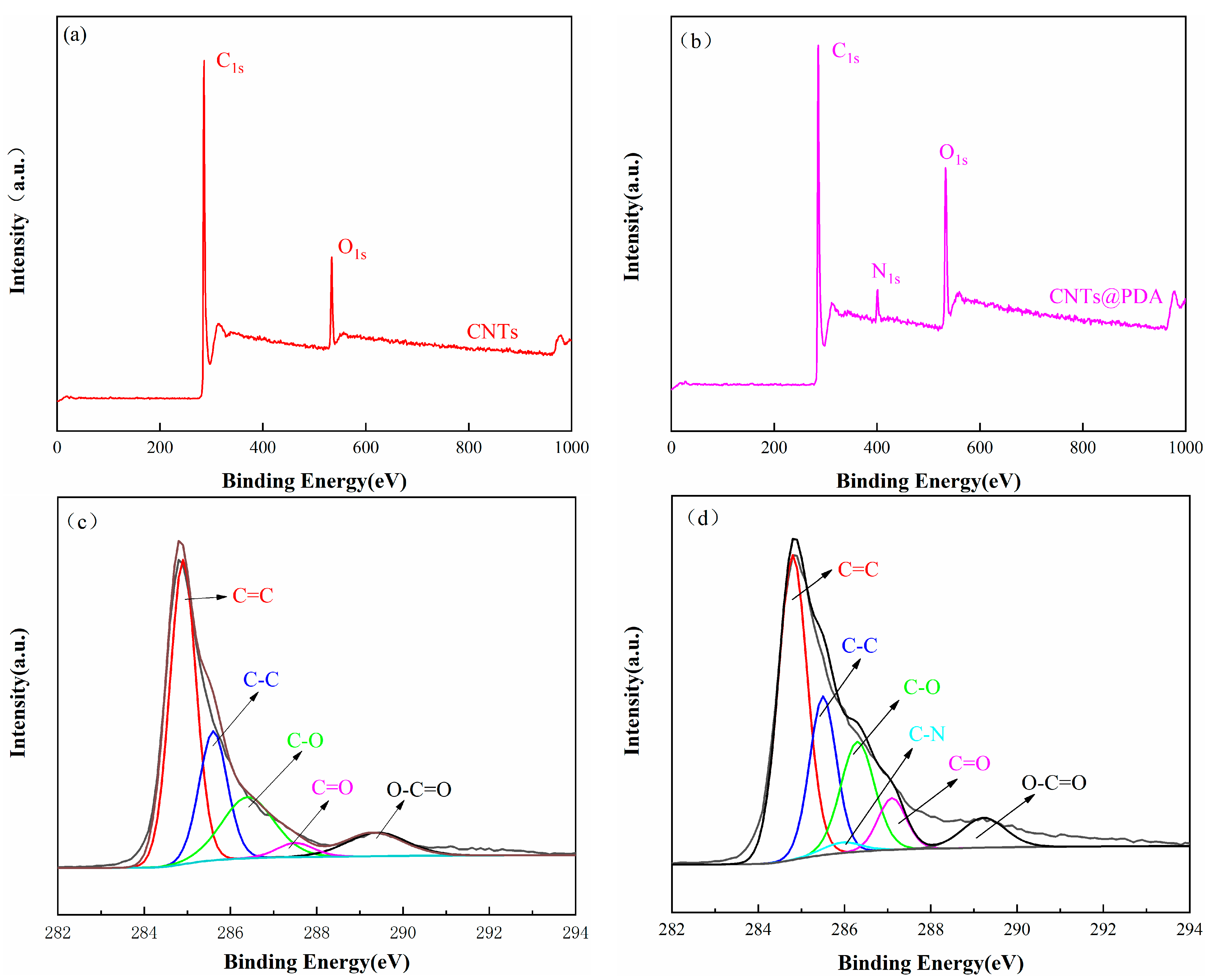

3.1. Characterization of CNTs and CNTs@PDA

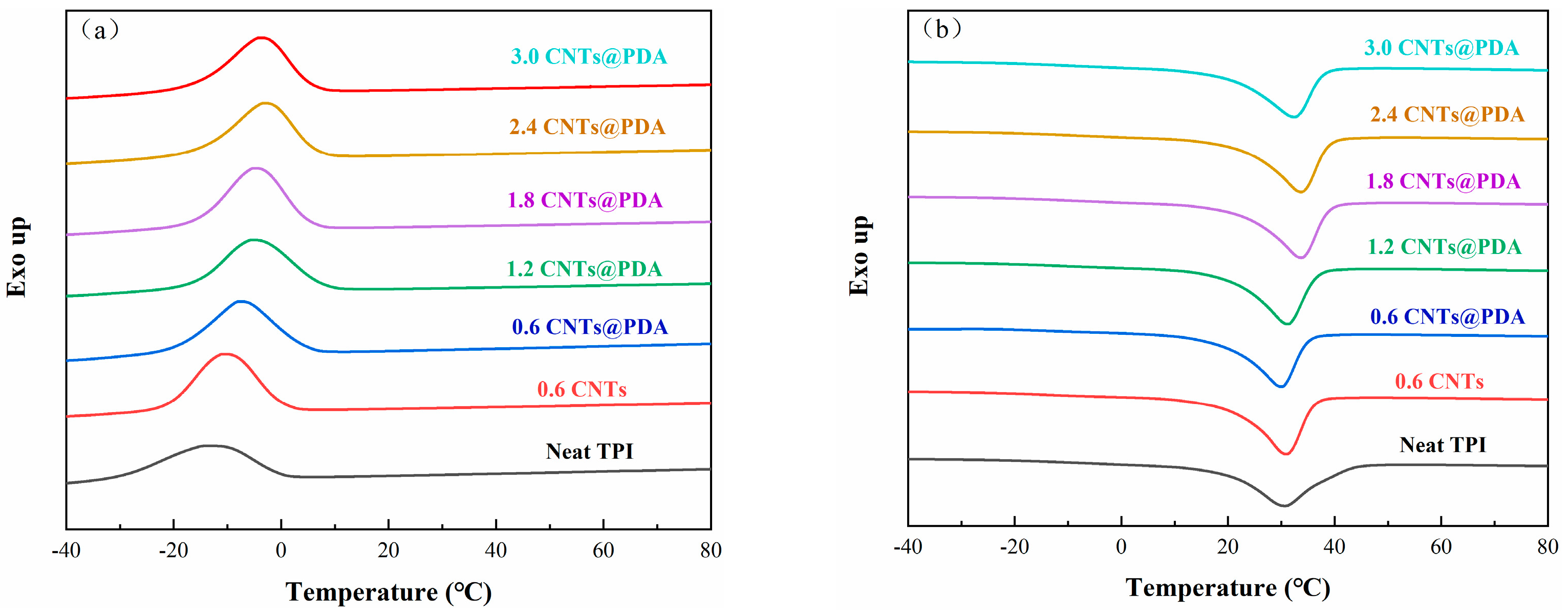

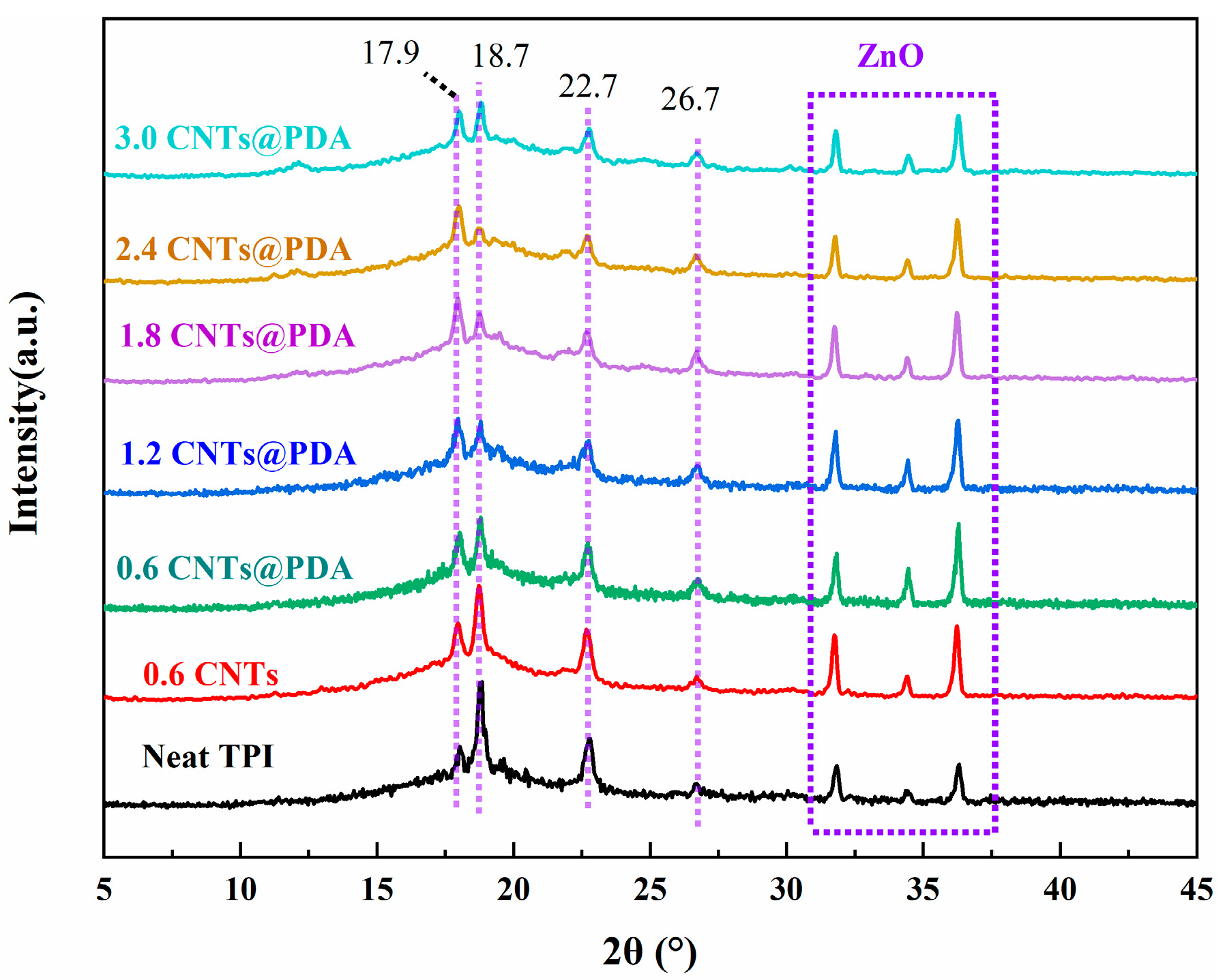

3.2. Crystallization Properties

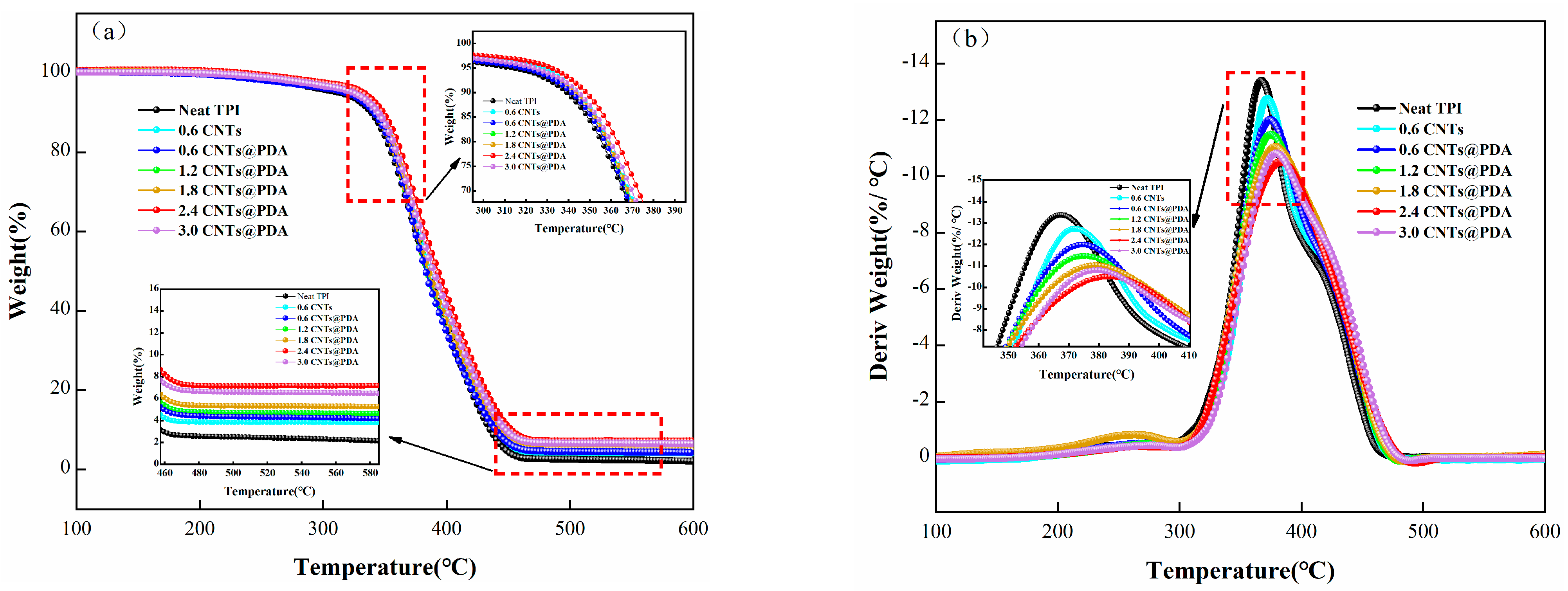

3.3. Thermal Properties

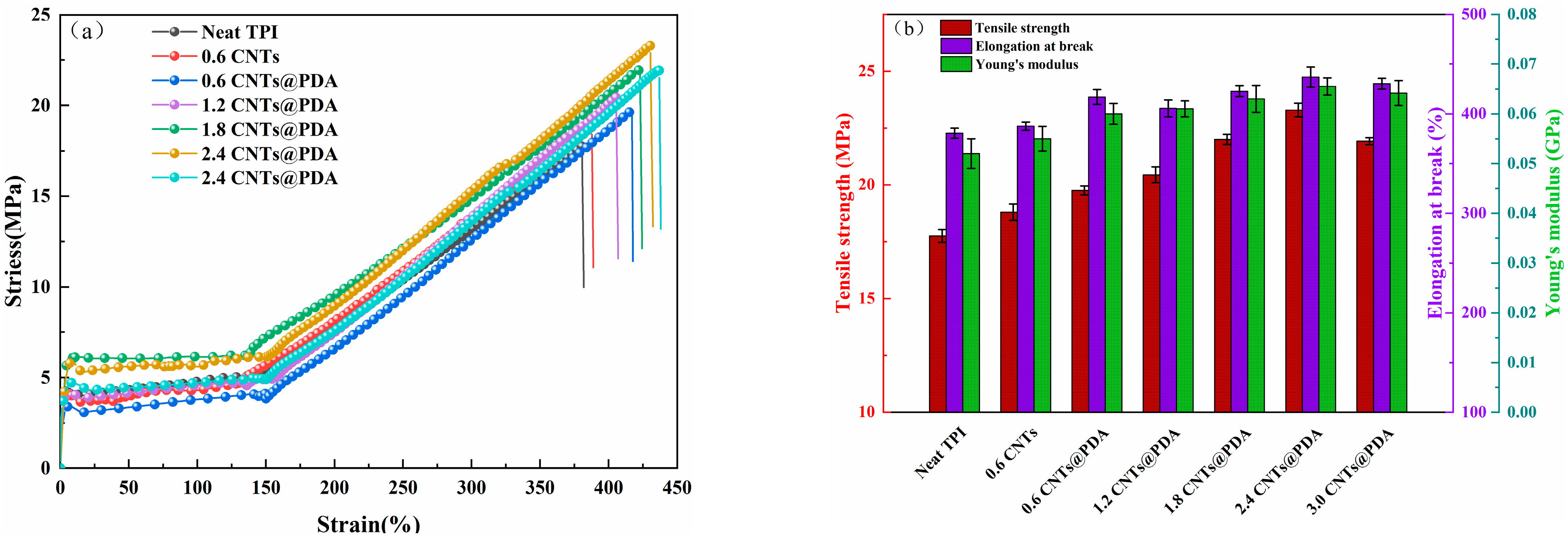

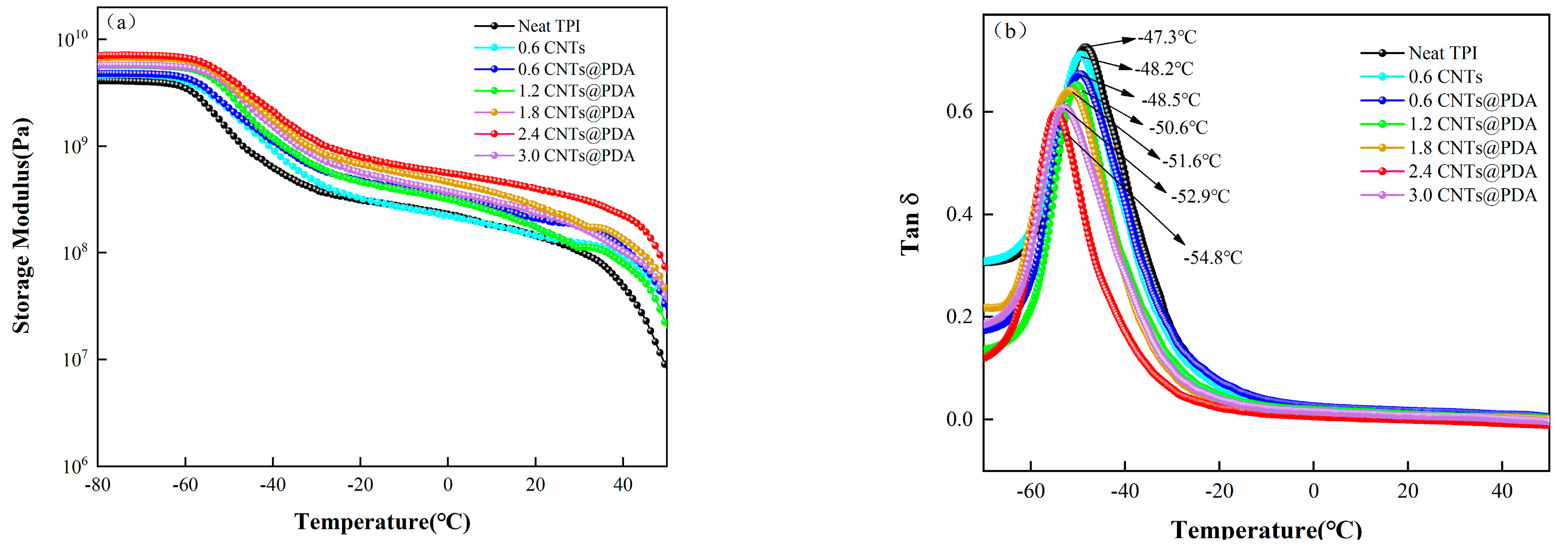

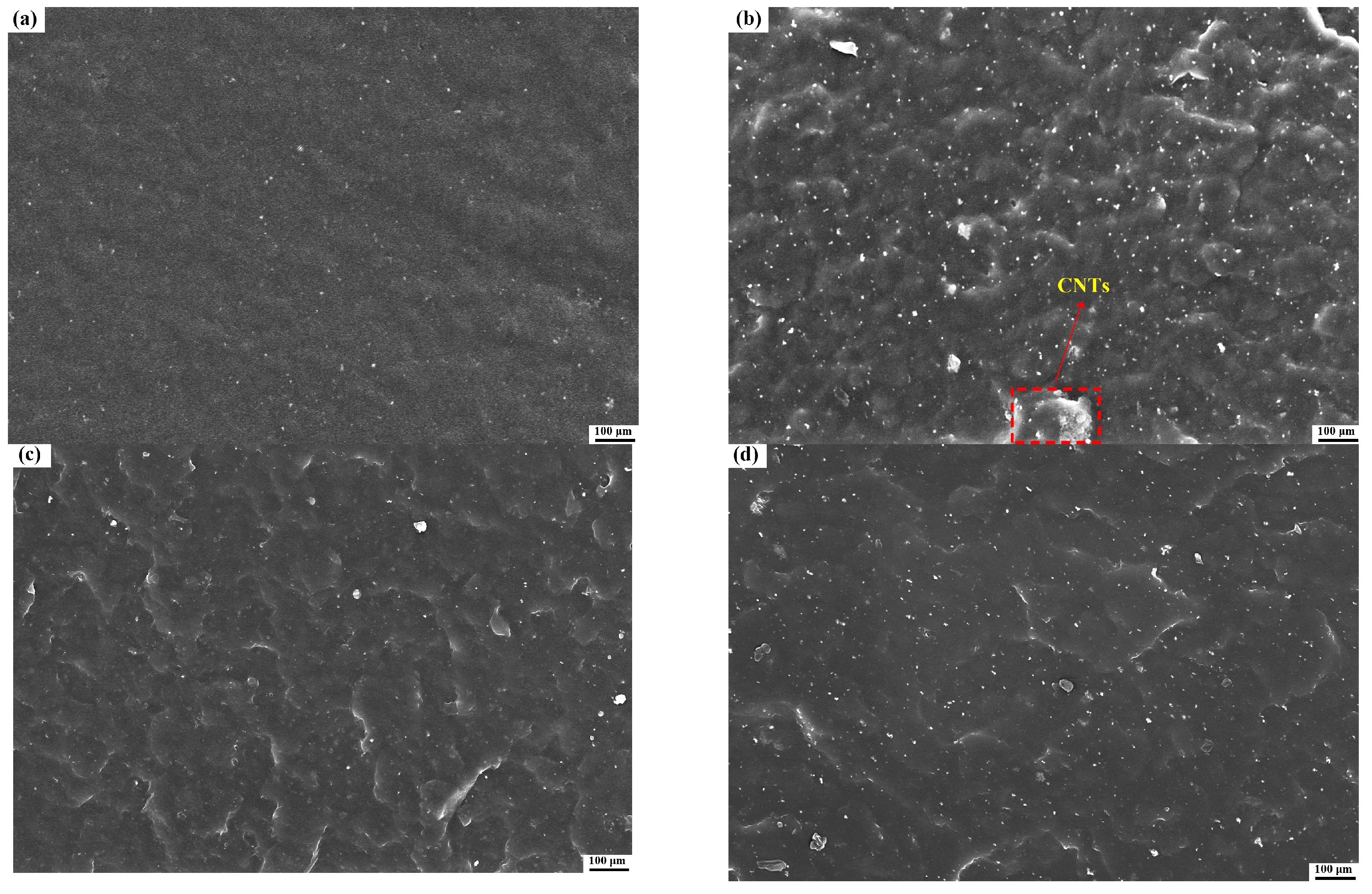

3.4. Mechanical Properties

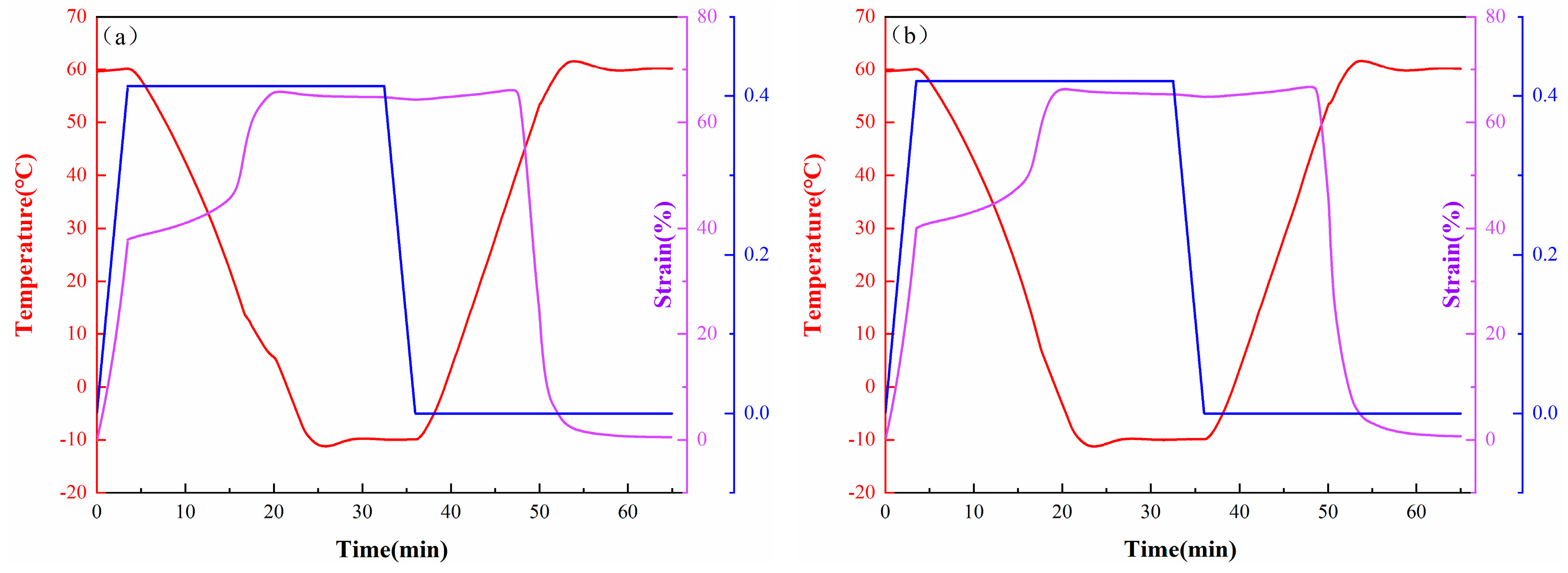

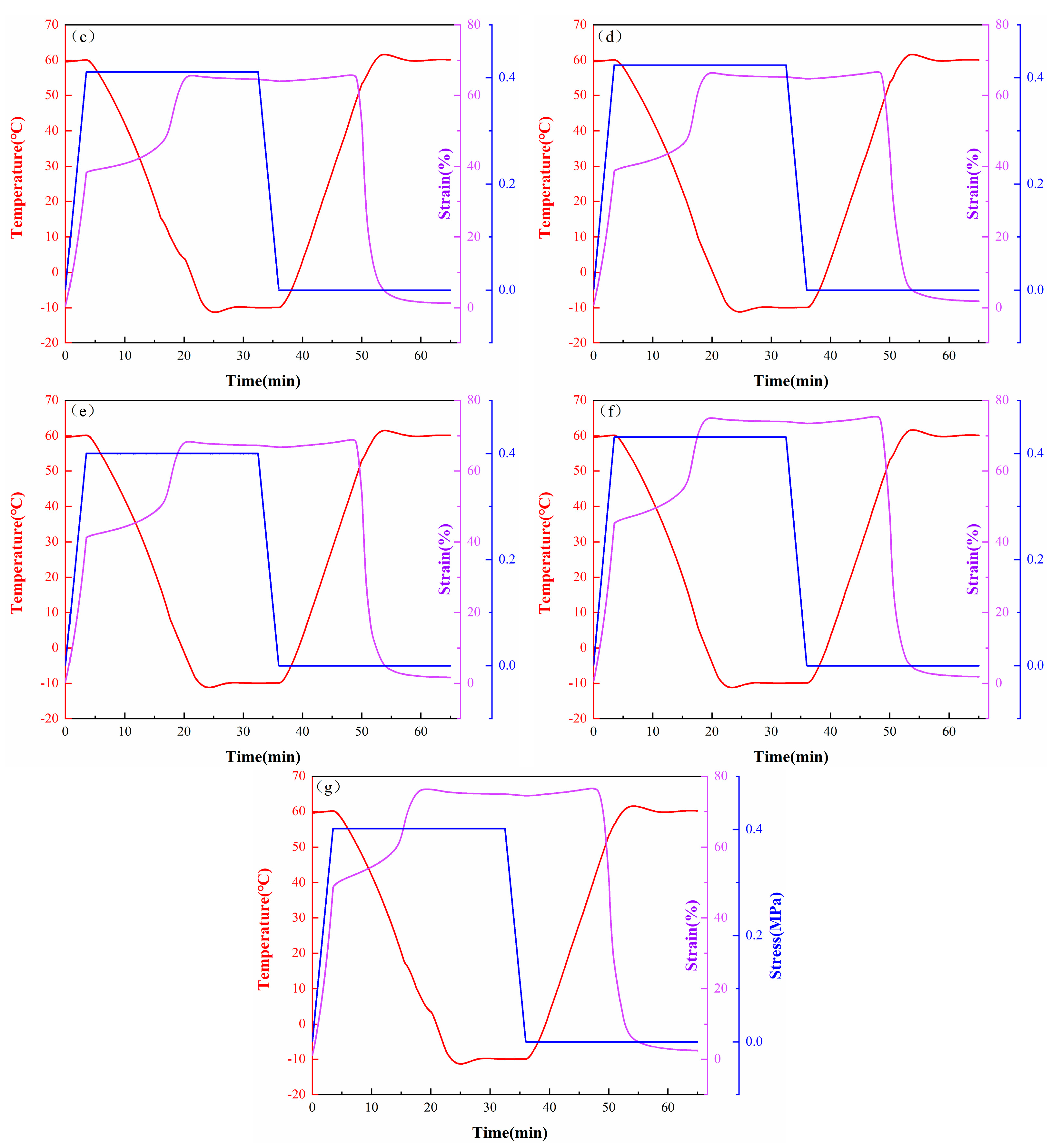

3.5. Shape-Memory Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, F.; Xia, Y.; Liu, Y.; Leng, J. Nano/microstructures of shape memory polymers: From materials to applications. Nanoscale Horiz. 2020, 5, 1155–1173. [Google Scholar] [CrossRef]

- Yu, X.; Wen, C.; Zeng, W.; Zhao, S.; Wang, L.; Wan, G.; Huang, S.; Grover, H.; Chen, Z. Mechanical behaviors and biomedical applications of shape memory materials: A review. AIMS Mater. Sci. 2018, 5, 559–590. [Google Scholar]

- Xia, Y.; He, Y.; Zhang, F.; Liu, Y.; Leng, J. A review of shape memory polymers and composites: Mechanisms, materials, and applications. Adv. Mater. 2021, 33, e2000713. [Google Scholar] [CrossRef] [PubMed]

- Peng, K.; Zhao, Y.; Shahab, S.; Mirzaeifar, R. Ductile shape-memory polymer composite with enhanced shape recovery ability. ACS Appl. Mater. Interfaces 2020, 12, 58295–58300. [Google Scholar] [CrossRef]

- Lendlein, A.; Gould, O.E.C. Reprogrammable recovery and actuation behaviour of shape-memory polymers. Nat. Rev. Mater. 2019, 4, 116–133. [Google Scholar] [CrossRef]

- D’Elia, E.; Ahmed, H.S.; Feilden, E.; Saiz, E. Electrically-responsive graphene-based shape-memory composites. Appl. Mater. Today 2019, 15, 185–191. [Google Scholar] [CrossRef]

- Maiti, B.; Abramov, A.; Franco, L.; Puiggalí, J.; Enshaei, H.; Alemán, C.; Díaz, D.D. Thermoresponsive shape-memory hydrogel actuators made by phototriggered click chemistry. Adv. Funct. Mater. 2020, 30, 2001683. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.-M.; Wang, L.; Zhou, S.-B. Recent progress in shape memory polymers for biomedical applications. Chin. J. Polym. Sci. 2018, 36, 905–917. [Google Scholar] [CrossRef]

- Diaz Lantada, A. Systematic development strategy for smart devices based on shape-memory polymers. Polymers 2017, 9, 496. [Google Scholar] [CrossRef] [PubMed]

- Xian, J.; Geng, J.; Wang, Y.; Xia, L. Quadruple-shape-memory effect of TPI/LDPE/HDPE composites. Polym. Adv. Technol. 2018, 29, 982–988. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, Z.; Li, H.; Teng, J.; Xu, L. Shape memory epoxy polymer (SMEP) composite mechanical properties enhanced by introducing graphene oxide (GO) into the matrix. Materials 2019, 12, 1107. [Google Scholar] [CrossRef] [Green Version]

- Miaudet, P.; Derre, A.; Maugey, M.; Zakri, C.; Piccione, P.M.; Inoubli, R.; Poulin, P. Shape and temperature memory of nanocomposites with broadened glass transition. Science 2007, 318, 1294–1296. [Google Scholar] [CrossRef]

- Meng, Q.; Hu, J. A review of shape memory polymer composites and blends. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1661–1672. [Google Scholar] [CrossRef]

- Pras, M.; Gerard, J.F.; Golanski, L.; Quintard, G.; Duchet-Rumeau, J. Key role of the dispersion of carbon nanotubes (CNTs) within epoxy networks on their ability to release. Polymers 2020, 12, 2530. [Google Scholar] [CrossRef] [PubMed]

- Zare, Y.; Rhee, K.Y. Analysis of the connecting effectiveness of the interphase zone on the tensile properties of carbon nanotubes (CNT) reinforced nanocomposite. Polymers 2020, 12, 896. [Google Scholar] [CrossRef] [Green Version]

- Sakharova, N.A.; Pereira, A.F.G.; Antunes, J.M.; Fernandes, J.V. Mechanical characterization of multiwalled carbon nanotubes: Numerical simulation study. Materials 2020, 13, 4283. [Google Scholar] [CrossRef] [PubMed]

- Kuroda, C.; Haniu, H.; Ajima, K.; Tanaka, M.; Sobajima, A.; Ishida, H.; Tsukahara, T.; Matsuda, Y.; Aoki, K.; Kato, H.; et al. The dispersion state of tangled multi-walled carbon nanotubes affects their cytotoxicity. Nanomaterials 2016, 6, 219. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gravely, A.A.; Cutting, A.; Nugent, S.; Grill, J.; Carlson, K.; Spoont, M. Validity of PTSD diagnoses in VA administrative data: Comparison of VA administrative PTSD diagnoses to self-reported PTSD Checklist scores. J. Rehabil. Res. Dev. 2011, 48, 21–30. [Google Scholar] [CrossRef] [PubMed]

- El-Mageed, A.I.A.A.; Ogawa, T. Metal ion effect on the supramolecular structures of metalloporphyrins on single-walled carbon nanotube surface. Appl. Surf. Sci. 2018, 462, 904–912. [Google Scholar] [CrossRef]

- Hirsch, A. Functionalization of single-walled carbon nanotubes. Angew. Chem. Int. Ed. 2002, 41, 1853–1859. [Google Scholar] [CrossRef]

- Abd El-Mageed, A.I.A.; Ogawa, T. Supramolecular structures of terbium(iii) porphyrin double-decker complexes on a single-walled carbon nanotube surface. RSC Adv. 2019, 9, 28135–28145. [Google Scholar] [CrossRef] [Green Version]

- Abd El-Mageed, A.I.A.; Handayani, M.; Chen, Z.; Inose, T.; Ogawa, T. Assignment of the absolute-handedness chirality of single-walled carbon nanotubes using organic molecule supramolecular structures. Chemistry 2019, 25, 1941–1948. [Google Scholar] [CrossRef]

- Kawamoto, M.; He, P.; Ito, Y. Green processing of carbon nanomaterials. Adv. Mater. 2017, 29, 1602423. [Google Scholar] [CrossRef]

- Song, X.; Zhang, Y.; Wang, Y.; Huang, M.; Gul, S.; Jiang, H. Nanocomposite membranes embedded with dopamine-melanin nanospheres for enhanced interfacial compatibility and nanofiltration performance. Sep. Purif. Technol. 2020, 242, 116816. [Google Scholar] [CrossRef]

- Liu, L. Organic modification of carbon nanotubes. Chin. Sci. Bull. 2002, 47, 441–447. [Google Scholar] [CrossRef]

- Nejatian, T.; Nathwani, N.; Taylor, L.; Sefat, F. Denture base composites: Effect of surface modified nano- and micro-particulates on mechanical properties of polymethyl methacrylate. Materials 2020, 13, 307. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yao, D.; Yin, G.; Bi, Q.; Yin, X.; Wang, N.; Wang, D.Y. Basalt fiber modified ethylene vinyl acetate/magnesium hydroxide composites with balanced flame retardancy and improved mechanical properties. Polymers 2020, 12, 2107. [Google Scholar] [CrossRef]

- Lin, Q.; Gourdon, D.; Sun, C.; Holten-Andersen, N.; Anderson, T.H.; Waite, J.H.; Israelachvili, J.N. Adhesion mechanisms of the mussel foot proteins mfp-1 and mfp-3. Proc. Natl. Acad. Sci. USA 2007, 104, 3782–3786. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nguyen, D.N.; Sim, U.; Kim, J.K. Biopolymer-inspired n-doped nanocarbon using carbonized polydopamine: A high-performance electrocatalyst for hydrogen-evolution reaction. Polymers 2020, 12, 912. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Dellatore, S.M.; Miller, W.M.; Messersmith, P.B. Mussel-inspired surface chemistry for multifunctional coatings. Science 2007, 318, 426–430. [Google Scholar] [CrossRef] [Green Version]

- Lee, B.P.; Messersmith, P.B.; Israelachvili, J.N.; Waite, J.H. Mussel-inspired adhesives and coatings. Annu. Rev. Mater. Res. 2011, 41, 99–132. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yan, B.; Zhou, Q.; Xing, T.; Chen, G. Dopamine-dyed and functionally finished silk with rapid oxidation polymerization. Polymers 2018, 10, 728. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bi, Q.; Yao, D.; Yin, G.-Z.; You, J.; Liu, X.-Q.; Wang, N.; Wang, D.-Y. Surface engineering of magnesium hydroxide via bioinspired iron-loaded polydopamine as green and efficient strategy to epoxy composites with improved flame retardancy and reduced smoke release. React. Funct. Polym. 2020, 155, 104690. [Google Scholar] [CrossRef]

- Koh, K.L.; Ji, X.; Dasari, A.; Lu, X.; Lau, S.K.; Chen, Z. Fracture toughness and elastic modulus of epoxy-based nanocomposites with dopamine-modified nano-fillers. Materials 2017, 10, 776. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, C.; Gong, F.; Yang, Z.; Zhao, X.; Li, Y.; Zeng, C.; Li, J.; Guo, S. Core-shell structured hmx@polydopamine energetic microspheres: Synergistically enhanced mechanical, thermal, and safety performances. Polymers 2019, 11, 568. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, H.; Wang, Z.; Yang, J.; Jia, X.; Zhang, Z. Facile synthesis of copper/polydopamine functionalized graphene oxide nanocomposites with enhanced tribological performance. Chem. Eng. J. 2017, 324, 51–62. [Google Scholar] [CrossRef]

- Huan, X.; Shi, K.; Yan, J.; Lin, S.; Li, Y.; Jia, X.; Yang, X. High performance epoxy composites prepared using recycled short carbon fiber with enhanced dispersibility and interfacial bonding through polydopamine surface-modification. Compos. Part B Eng. 2020, 193, 107987. [Google Scholar] [CrossRef]

- Xia, L.; Gao, H.; Geng, J.T. Facile fabrication of foamed natural Eucommia ulmoides gum composites with heat-triggered shape memory behavior. Polym. Compos. 2019, 40, 3075–3083. [Google Scholar] [CrossRef]

- Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S.; Cancado, L.G.; Jorio, A.; Saito, R. Studying disorder in graphite-based systems by Raman spectroscopy. Phys. Chem. Chem. Phys. 2007, 9, 1276–1291. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Chen, C.; Feng, Y.; Liao, Y.; Ye, Y.; Xie, X.; Mai, Y.W. Ultralow-carbon nanotube-toughened epoxy: The critical role of a double-layer interface. ACS Appl. Mater. Interfaces 2018, 10, 1204–1216. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Li, G.; Gao, Y.; Xiao, Z.; Zhang, J.; Wang, Q.; Zhang, X.; Wang, L. Doping carbon nanotubes with N, S, and B for electrocatalytic oxygen reduction: A systematic investigation on single, double, and triple doped modes. Catal. Sci. Technol. 2017, 7, 4007–4016. [Google Scholar] [CrossRef]

- Xia, L.; Wu, H.; Qiu, G. Shape memory behavior of carbon nanotube-reinforced trans-1,4-polyisoprene and low-density polyethylene composites. Polym. Adv. Technol. 2019, 31, 107–113. [Google Scholar] [CrossRef]

- Niu, Q.; Jiang, X.; He, A. Synthesis of spherical trans-1,4-polyisoprene/trans-1,4-poly(butadiene-co-isoprene) rubber alloys within reactor. Polymer 2014, 55, 2146–2152. [Google Scholar] [CrossRef]

- Li, Q.; Kumar, V.; Li, Y.; Zhang, H.; Marks, T.J.; Chang, R.P.H. Fabrication of ZnO nanorods and nanotubes in aqueous solutions. Chem. Mater. 2005, 17, 1001–1006. [Google Scholar] [CrossRef]

- Zanjanijam, A.R.; Bahrami, M.; Hajian, M. Poly(vinyl chloride)/single wall carbon nanotubes composites: Investigation of mechanical and thermal characteristics. J. Vinyl. Addit. Technol. 2016, 22, 128–133. [Google Scholar] [CrossRef]

- Zanjanijam, A.R.; Hajian, M.; Koohmareh, G.A. Improving the thermal and mechanical properties of poly(vinyl butyral) through the incorporation of acid-treated single-walled carbon nanotubes. J. Appl. Polym. Sci. 2014, 131, 40481. [Google Scholar] [CrossRef]

- Ling, Y.; Li, W.; Wang, B.; Gan, W.; Zhu, C.; Brady, M.A.; Wang, C. Epoxy resin reinforced with nanothin polydopamine-coated carbon nanotubes: A study of the interfacial polymer layer thickness. RSC Adv. 2016, 6, 31037–31045. [Google Scholar] [CrossRef] [Green Version]

| O 1s (at.%) | N 1s (at.%) | C 1s (at.%) | |

|---|---|---|---|

| CNTs | 10.92 | / | 89.08 |

| CNTs@PDA | 16.38 | 4.24 | 79.38 |

| Sample | Xc (%) | Tc (°C) | Tm (°C) | ∆Hm (J/g) |

|---|---|---|---|---|

| Neat TPI | 21.47 | −13.22 | 30.68 | 40.11 |

| TPI/0.6 CNTs | 21.28 | −10.68 | 29.97 | 39.76 |

| TPI/0.6 CNTs@PDA | 22.39 | −7.69 | 30.92 | 41.83 |

| TPI/1.2 CNTs@PDA | 22.66 | −5.55 | 31.12 | 42.32 |

| TPI/1.8 CNTs@PDA | 25.28 | −4.96 | 33.69 | 47.23 |

| TPI/2.4 CNTs@PDA | 25.62 | −3.28 | 34.12 | 47.86 |

| TPI/3.0 CNTs@PDA | 21.69 | −3.88 | 32.43 | 42.53 |

| Sample | T5% (℃) | Tmax (°C) | Weight 600 °C (wt%) |

|---|---|---|---|

| Neat TPI | 318.7 | 380.2 | 2.5 |

| TPI/0.6CNT | 322.1 | 381.8 | 4.1 |

| TPI/0.6CNTs@PDA | 324.3 | 382.5 | 4.2 |

| TPI/1.2CNTs@PDA | 326.5 | 387.6 | 4.4 |

| TPI/1.8CNTs@PDA | 329.5 | 389.6 | 4.9 |

| TPI/2.4CNTs@PDA | 331.1 | 392.5 | 6.8 |

| TPI/3.0CNTs@PDA | 326.6 | 384.8 | 6.5 |

| Samples | Rf (%) | Rr (%) |

|---|---|---|

| Neat TPI | 97.6 | 99.8 |

| TPI/0.6CNTs | 97.3 | 98.2 |

| TPI/0.6CNTs@PDA | 97.5 | 97.9 |

| TPI/1.2CNTs@PDA | 97.5 | 97.7 |

| TPI/1.8CNTs@PDA | 97.7 | 97.5 |

| TPI/2.4CNTs@PDA | 97. 3 | 97.4 |

| TPI/3.0CNTs@PDA | 97.6 | 96.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Li, L.; Xin, Y.; You, J.; Zhang, J.; Fu, W.; Wang, N. Development of Trans-1,4-Polyisoprene Shape-Memory Polymer Composites Reinforced with Carbon Nanotubes Modified by Polydopamine. Polymers 2022, 14, 110. https://doi.org/10.3390/polym14010110

Zhang C, Li L, Xin Y, You J, Zhang J, Fu W, Wang N. Development of Trans-1,4-Polyisoprene Shape-Memory Polymer Composites Reinforced with Carbon Nanotubes Modified by Polydopamine. Polymers. 2022; 14(1):110. https://doi.org/10.3390/polym14010110

Chicago/Turabian StyleZhang, Chuang, Long Li, Yuanhang Xin, Jiaqi You, Jing Zhang, Wanlu Fu, and Na Wang. 2022. "Development of Trans-1,4-Polyisoprene Shape-Memory Polymer Composites Reinforced with Carbon Nanotubes Modified by Polydopamine" Polymers 14, no. 1: 110. https://doi.org/10.3390/polym14010110

APA StyleZhang, C., Li, L., Xin, Y., You, J., Zhang, J., Fu, W., & Wang, N. (2022). Development of Trans-1,4-Polyisoprene Shape-Memory Polymer Composites Reinforced with Carbon Nanotubes Modified by Polydopamine. Polymers, 14(1), 110. https://doi.org/10.3390/polym14010110