Evaluation of Particleboards Made from Giant Reed (Arundo donax L.) Bonded with Cement and Potato Starch

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Manufacturing Process

2.3. Methods

3. Results

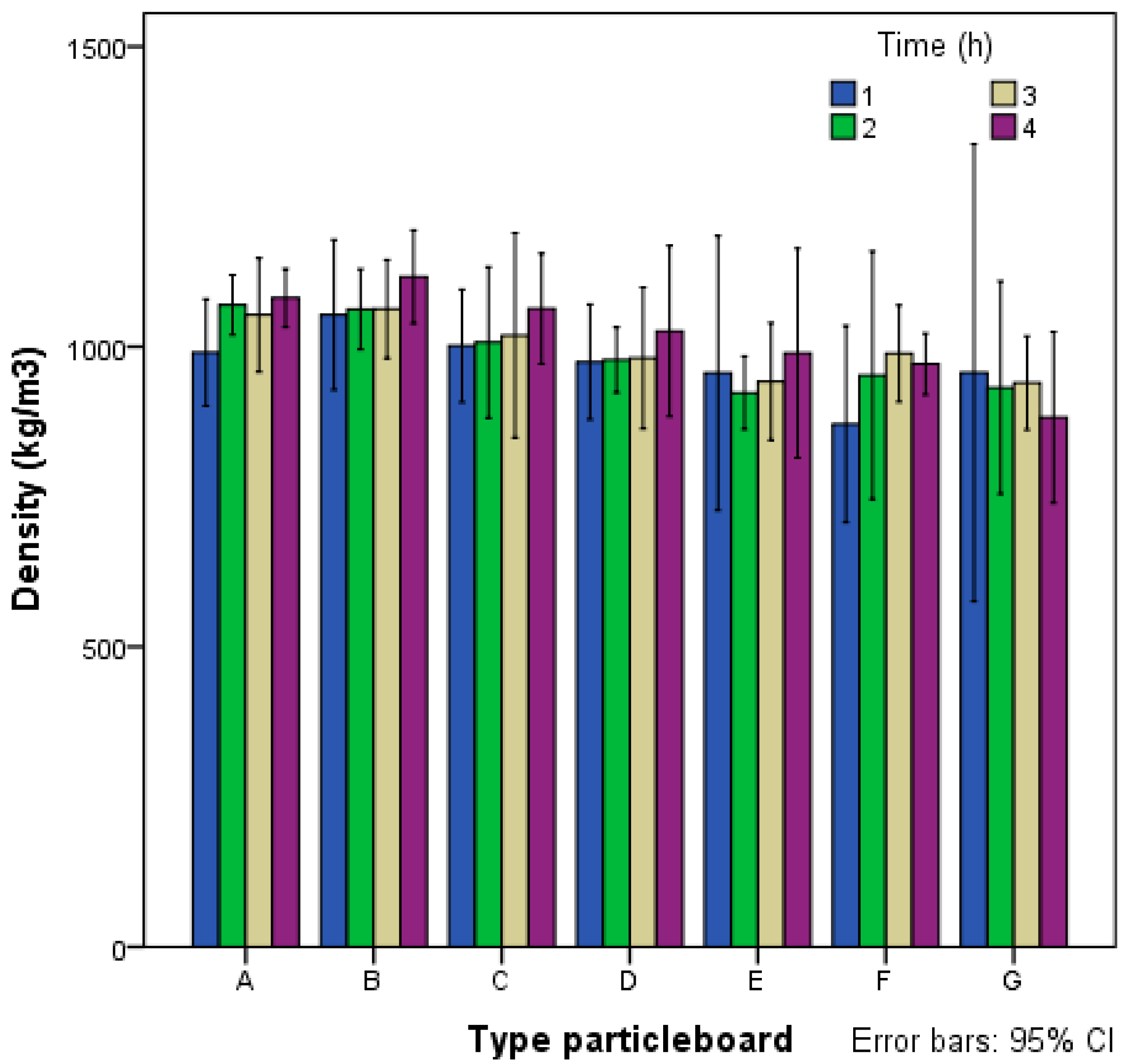

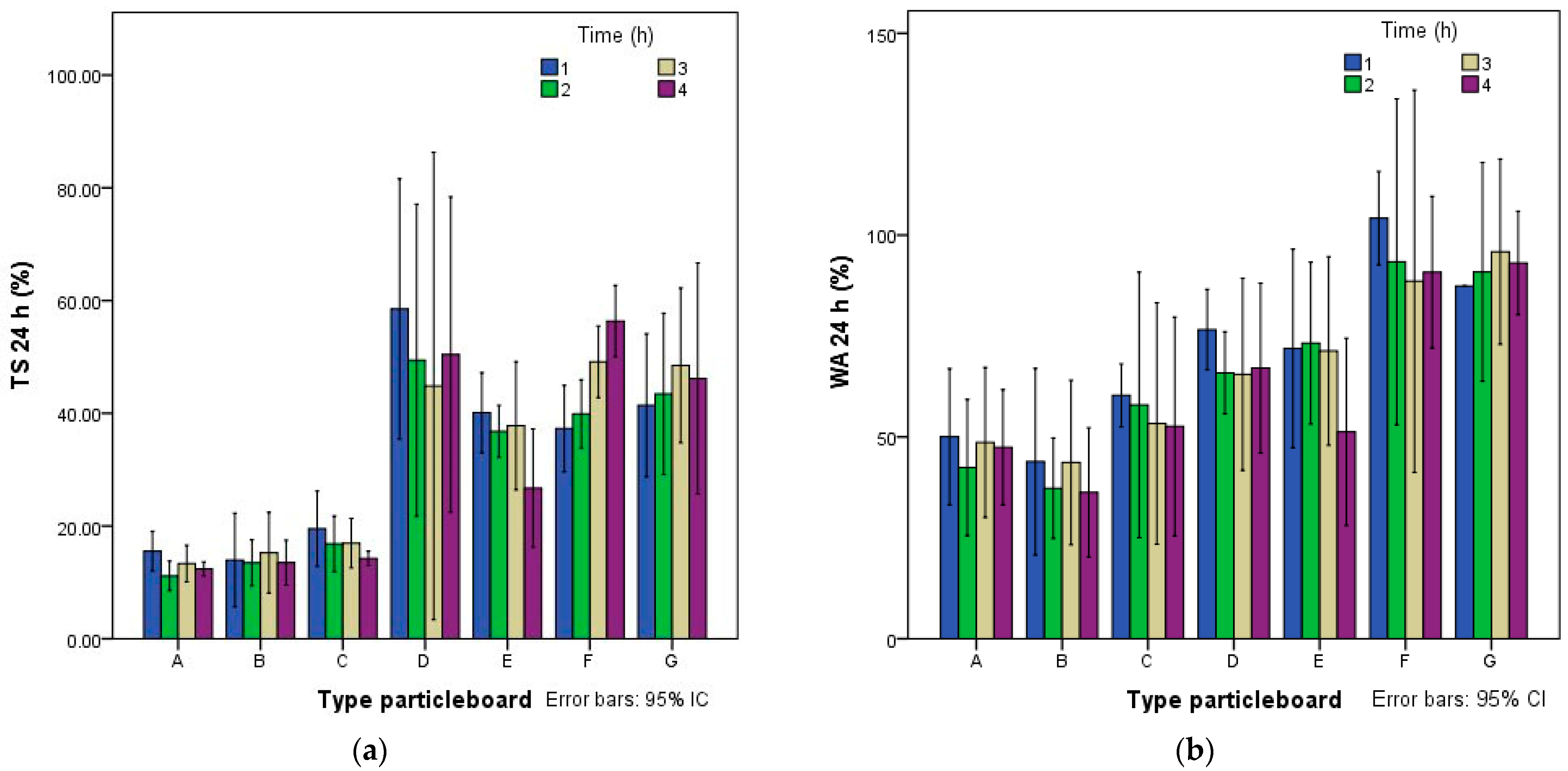

3.1. Physical Properties

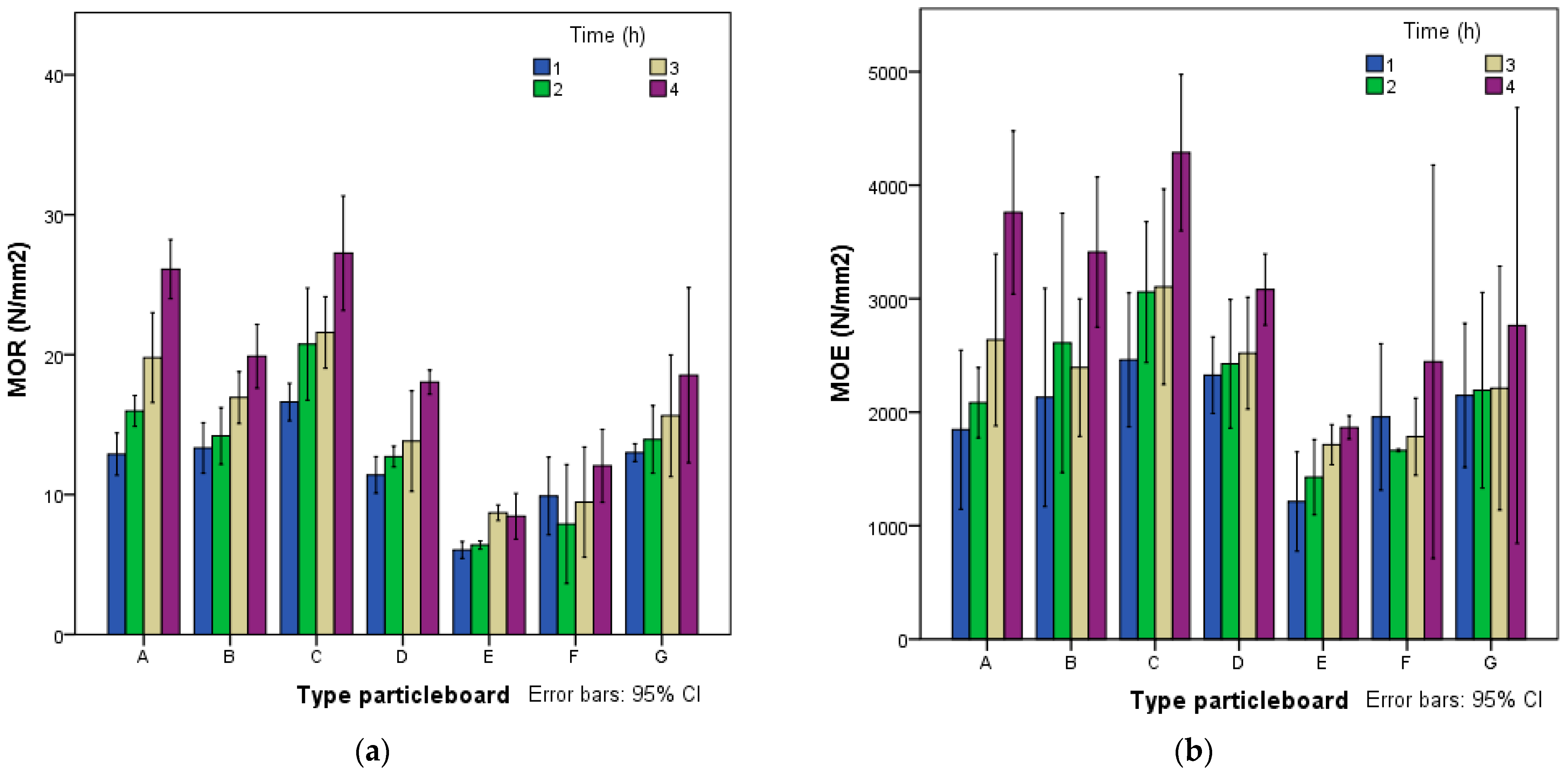

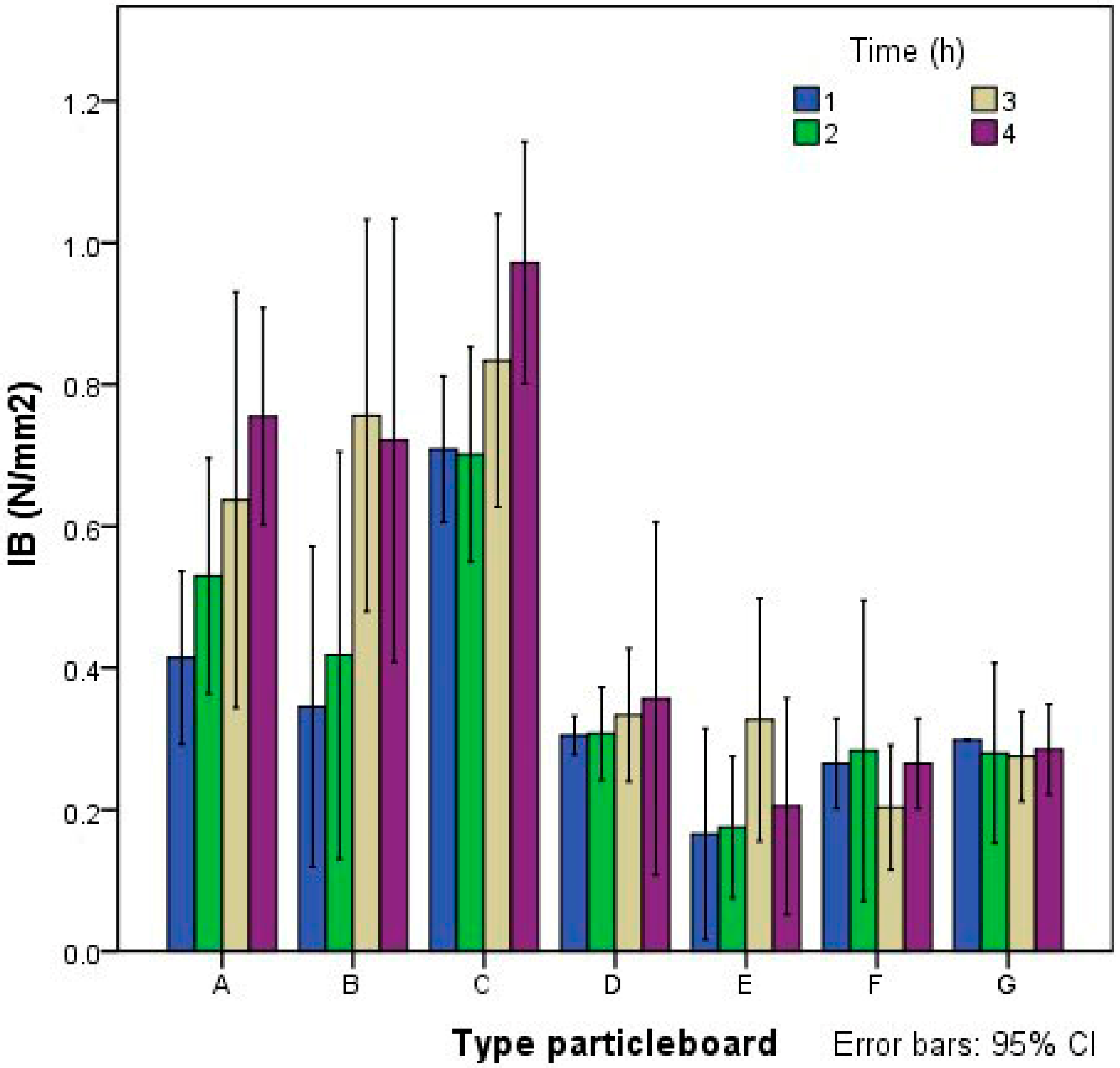

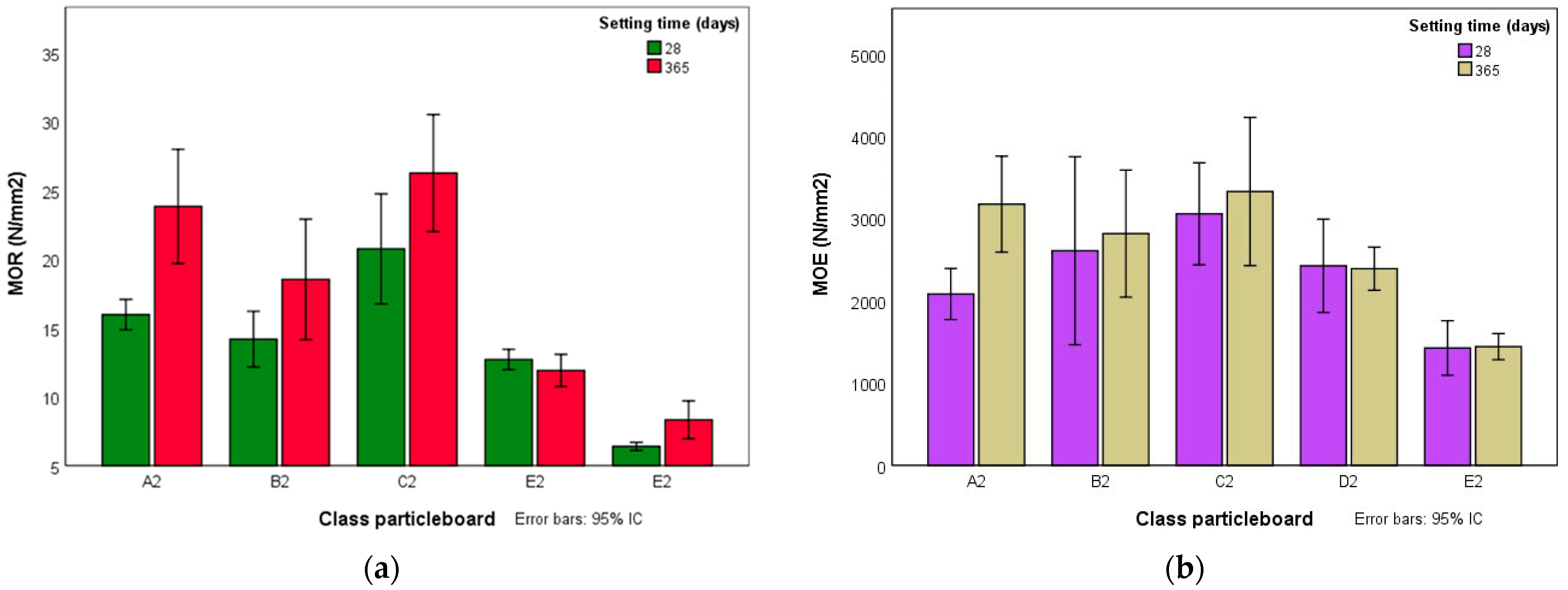

3.2. Mechanical Properties

3.3. Assessment of the Durability of the Fibers

3.4. Statistical Analysis

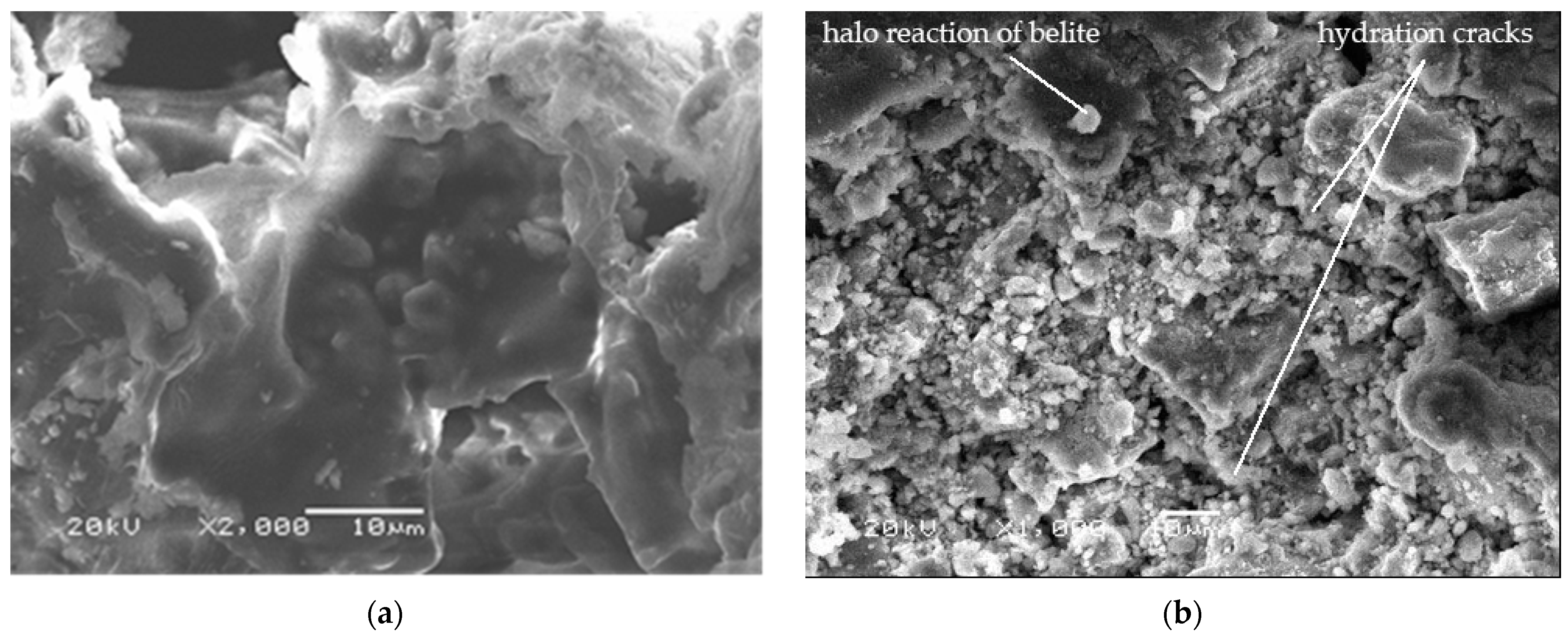

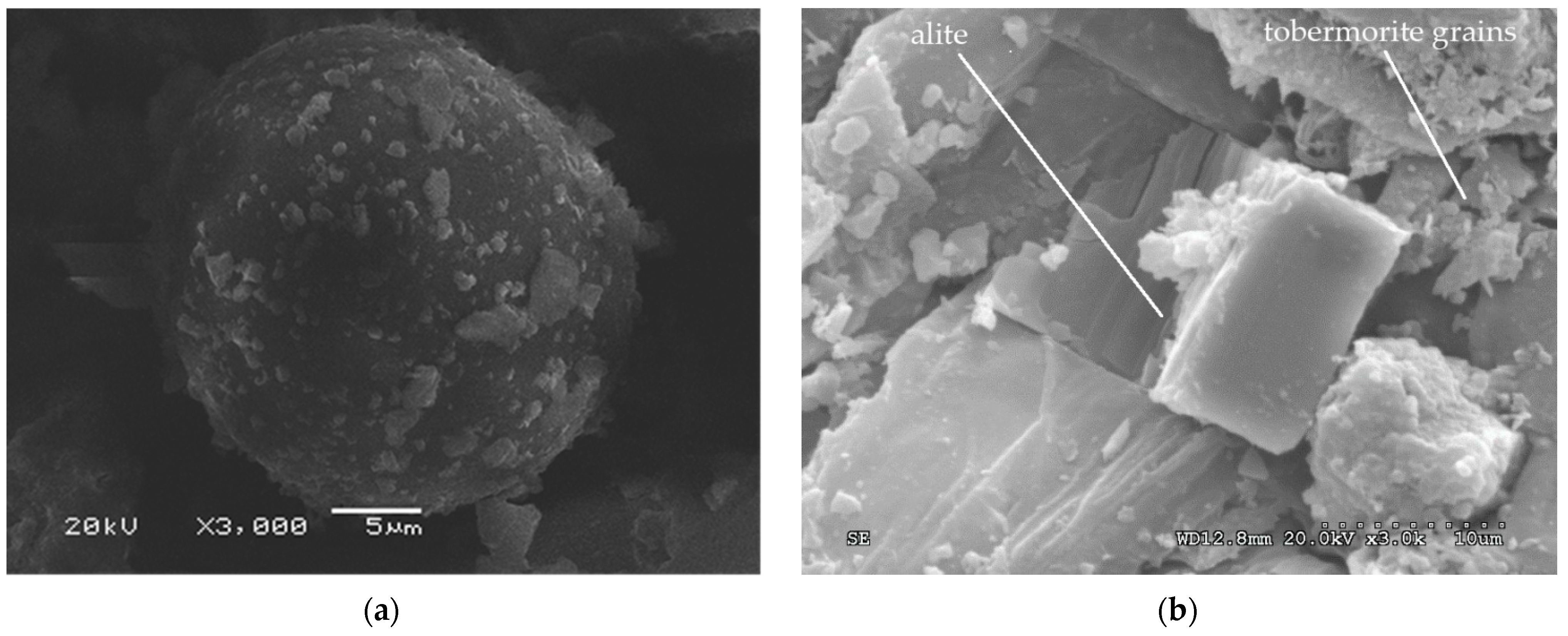

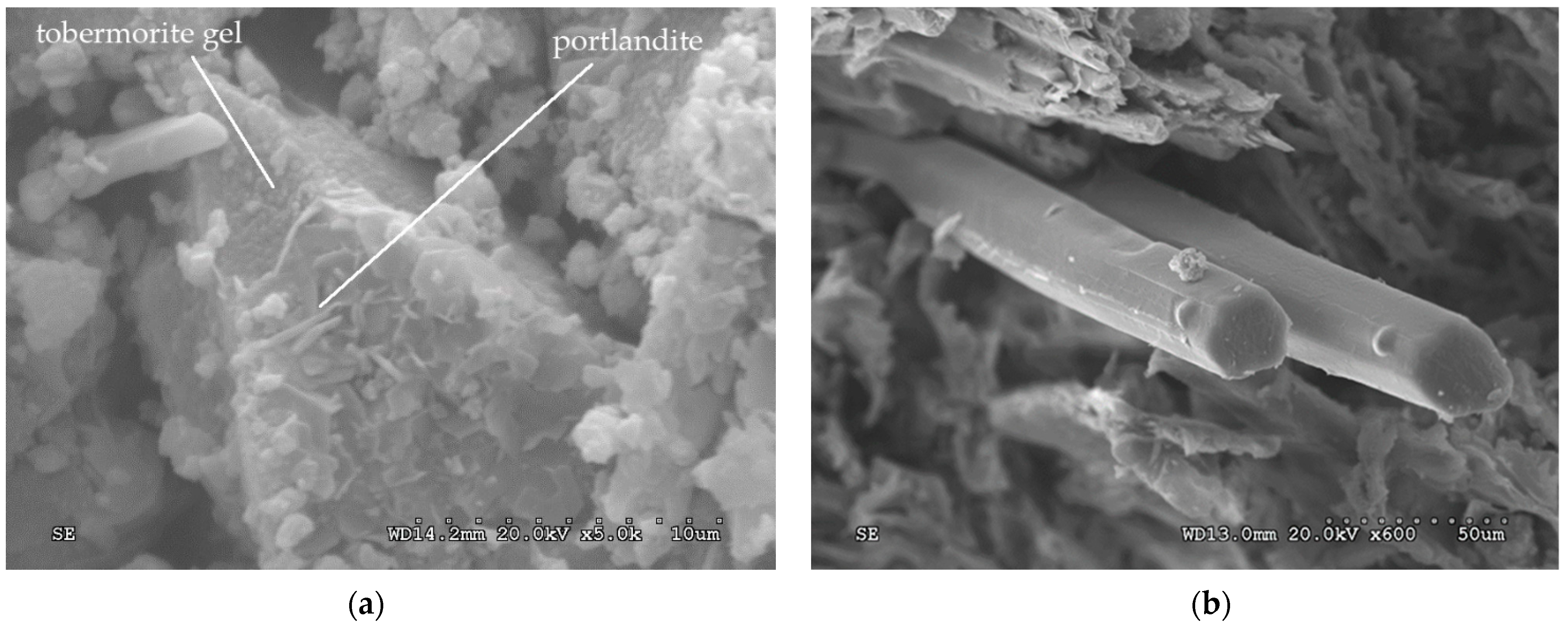

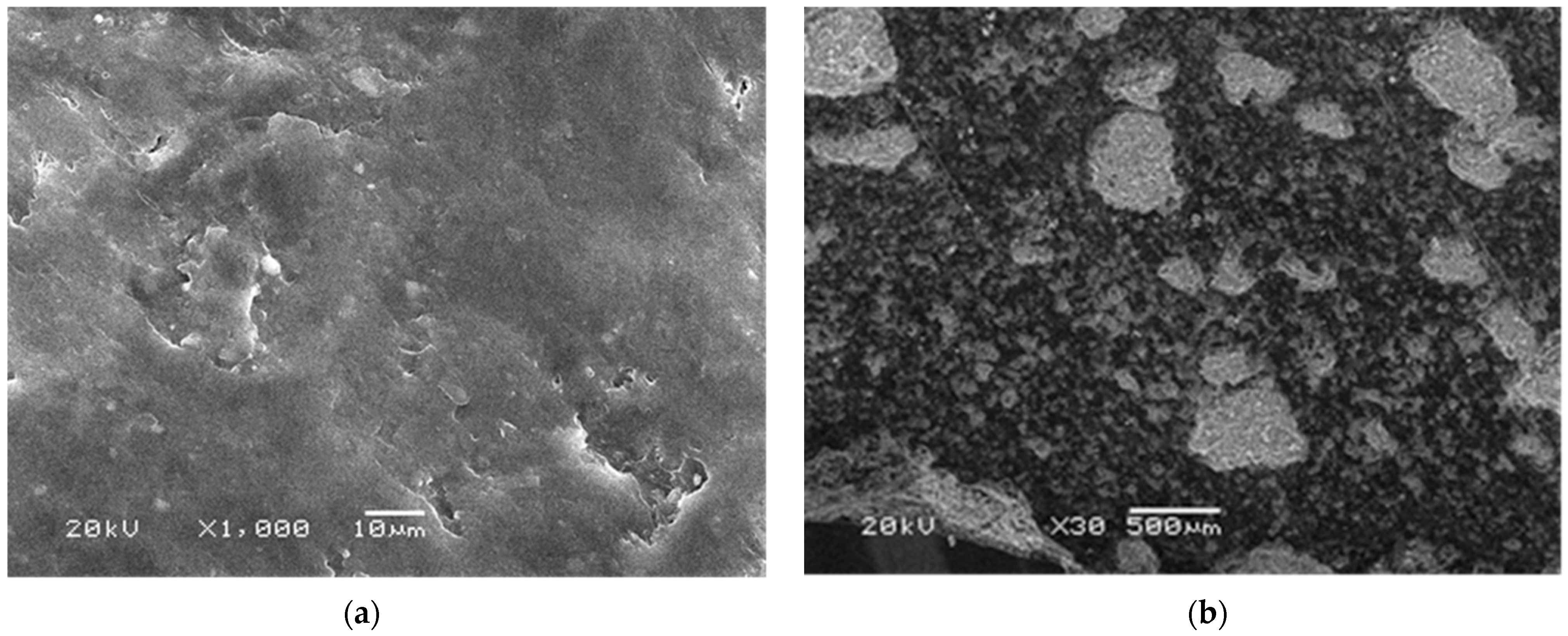

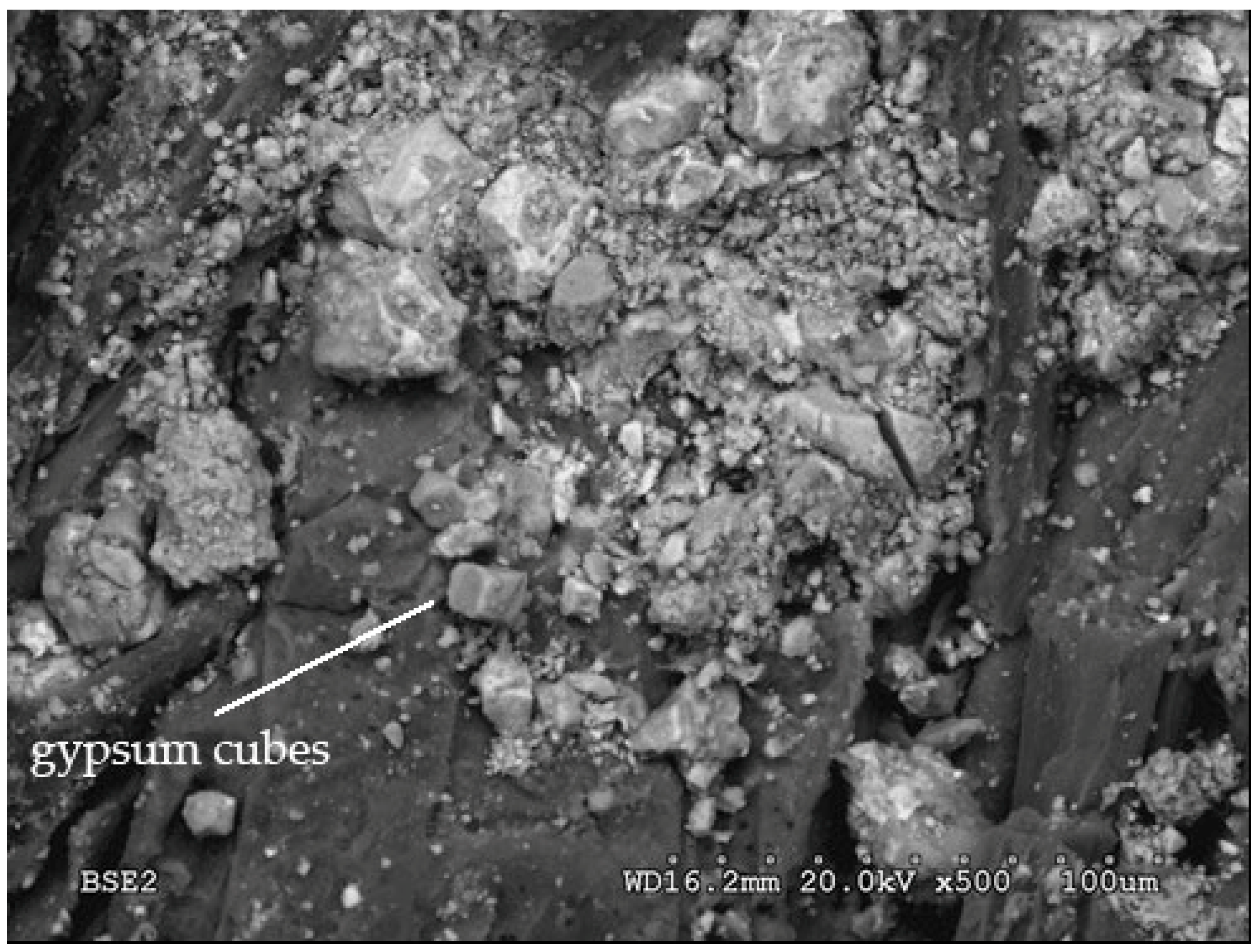

3.5. SEM Observations

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Directive 2008/98/EC of The European Parliament and of The Council on Waste and Repealing Certain Directives. Off. J. Eur. Union 2008, L312, 3–30, Current consolidated version: 5 July 2018.

- Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on industrial emissions (integrated pollution prevention and control). Off. J. Eur. Union 2010, L334, 159–261, Current consolidated version: 6 January 2011.

- Directive (EU) 2018/850 of the European Parliament and of the Council of 30 May 2018 amending Directive 1999/31/EC on the landfill of waste. Off. J. Eur. Union 2018, L150, 100–108.

- Regulation (EU) 2018/841 of the European Parliament and of the Council of 30 May 2018 on the inclusion of greenhouse gas emissions and removals from land use, land use change and forestry in the 2030 climate and energy framework, and amending Regulation (EU) No 525/2013 and Decision No 529/2013/EU. Off. J. Eur. Union 2018, L156, 1–25.

- Moslemi, A.A.; Pfister, S.C. The influence of cement/wood ratio and cement type on bending strength and dimensional stability of wood-cement composite panels. Wood Fiber Sci. 1987, 19, 165–175. [Google Scholar]

- Ferrier, E.; Agbossou, A.; Michel, L. Mechanical behaviour of ultra-high-performance fibrous-concrete wood panels reinforced by FRP bars. Compos. Part B Eng. 2014, 60, 663–672. [Google Scholar] [CrossRef]

- Li, M.; Khelifa, M.; Khennane, A.; El Ganaoui, M. Structural response of cement-bonded wood composite panels as permanent formwork. Compos. Struct. 2019, 209, 13–22. [Google Scholar] [CrossRef]

- Brahmia, F.Z.; Horváth, P.G.; Alpár, T.L. Effect of pre-treatments and additives on the improvement of cement wood composite: A review. BioResources 2020, 15, 7288–7308. [Google Scholar] [CrossRef]

- Okino, E.Y.; De Souza, M.R.; Santana, M.A.; da S Alves, M.V.; de Sousa, M.E.; Teixeira, D.E. Cement-bonded wood particleboard with a mixture of eucalypt and rubberwood. Cem. Concr. Compos. 2004, 26, 729–734. [Google Scholar] [CrossRef]

- Tittelein, P.; Cloutier, A.; Bissonnette, B. Design of a low-density wood-cement particleboard for interior wall finish. Cem. Concr. Compos. 2012, 34, 218–222. [Google Scholar] [CrossRef]

- Fuwape, J.A.; Oyagade, A.O. Bending strength and dimensional stability of tropical wood-cement particleboard. Bioresour. Technol. 1993, 44, 77–79. [Google Scholar] [CrossRef]

- Karade, S.R. Cement-bonded composites from lignocellulosic wastes. Constr. Build. Mater. 2010, 24, 1323–1330. [Google Scholar] [CrossRef]

- Ashori, A.; Tabarsa, T.; Valizadeh, I. Fiber reinforced cement boards made from recycled newsprint paper. Mater. Sci. Eng. A 2011, 528, 7801–7804. [Google Scholar] [CrossRef]

- Olorunnisola, A.O.; Adefisan, O.O. Trial production and testing of cement-bonded particleboard from rattan furniture waste. Wood Fiber Sci. 2002, 34, 116–124. [Google Scholar]

- Sudin, R.; Swamy, N. Bamboo and wood fibre cement composites for sustainable infrastructure regeneration. J. Mater. Sci. 2006, 41, 6917–6924. [Google Scholar] [CrossRef]

- Torkaman, J.; Ashori, A.; Momtazi, A.S. Using wood fiber waste, rice husk ash, and limestone powder waste as cement replacement materials for lightweight concrete blocks. Constr. Build. Mater. 2014, 50, 432–436. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Sisal fiber-reinforced cement composite with Portland cement substitution by a combination of metakaolin and nanoclay. J. Mater. Sci. 2014, 49, 7604–7619. [Google Scholar] [CrossRef]

- Frazão, C.; Barros, J.; Toledo Filho, R.; Ferreira, S.; Gonçalves, D. Development of sandwich panels combining sisal fiber-cement composites and fiber-reinforced lightweight. Concr. Cem. Concr. Comp. 2018, 86, 206–223. [Google Scholar] [CrossRef]

- Thomas, B.C.; Jose, Y.S. Impact of sisal fiber reinforced concrete and its performance analysis: A review. Evolut. Intell. 2019, 1–11. [Google Scholar] [CrossRef]

- Aggarwal, L.K. Studies on cement bonded coir fibre boards. Cem. Concr. Compos. 1992, 14, 63–69. [Google Scholar] [CrossRef]

- Asasutjarit, C.; Hirunlabh, J.; Khedari, J.; Charoenvai, S.; Zeghmati, B.; Cheul Shin, U. Development of coconut coir-based lightweight cement board. Constr. Build. Mater. 2007, 21, 277–288. [Google Scholar] [CrossRef]

- Silva, F.A.; Toledo Filho, R.D.; Melo Filho, J.A.; Fairbairn, E.M.R. Physical and mechanical properties of durable sisal fiber-cement composites. Constr. Build. Mater. 2010, 24, 777–785. [Google Scholar] [CrossRef]

- Wang, W.; Chouw, N. The behaviour of coconut fibre reinforced concrete (CFRC) under impact loading. Constr. Build. Mater. 2017, 134, 452–461. [Google Scholar] [CrossRef]

- Da Silva, E.J.; Marques, M.L.; Velasco, F.G.; Junior, C.F.; Luzardo, F.M.; Tashima, M.M. A new treatment for coconut fibers to improve the properties of cement-based composites—Combined effect of natural latex/pozzolanic materials. Sustain. Mater. Technol. 2017, 12, 44–51. [Google Scholar] [CrossRef] [Green Version]

- Sathiparan, N.; Rupasinghe, M.N.; Pavithra, B.H. Performance of coconut coir reinforced hydraulic cement mortar for surface plastering application. Constr. Build. Mater. 2017, 142, 23–30. [Google Scholar] [CrossRef]

- Farias Machado, N.A.; Barros Furtado, M.; Parra-Serrano, L.J.; de Oliveira Maia Parente, M.; Fiorelli, J.; Savastano Júnior, H. Agglomerated panels made from babaçu coconut residues. Rev. Bras. Cienc. Agrár. 2017, 12, 202–209. [Google Scholar] [CrossRef] [Green Version]

- Aggarwal, L.K. Bagasse-reinforced cement composites. Cem. Concr. Compos. 1995, 17, 107–112. [Google Scholar] [CrossRef]

- Bilba, K.; Arsène, M.A.; Ouensanga, A. Sugar cane bagasse fibre reinforcedcement composites. Part, I. Influence of the botanical components of bagasse on the setting of bagasse/cement composite. Cem. Concr. Compos. 2003, 25, 91–96. [Google Scholar] [CrossRef]

- Cabral, M.R.; Nakanishi, E.Y.; Dos Santos, V.; Palacios, J.H.; Godbout, S.; Junior, H.S.; Fiorelli, J. Evaluation of pre-treatment efficiency on sugarcane bagasse fibers for the production of cement composites. Arch. Civ. Mech. Eng. 2018, 18, 1092–1102. [Google Scholar] [CrossRef]

- Almeida, R.R.; Del Menezzi, C.H.S.; Teixeira, D.E. Utilization of the coconut shell of babaçu (Orbignya sp.) to produce cement-bonded particleboard. Bioresour. Technol. 2002, 85, 159–163. [Google Scholar] [CrossRef]

- Savastano, H., Jr.; Warden, P.G.; Coutts, R.S. Potential of alternative fibre cements as building materials for developing areas. Cem. Concr. Compos. 2003, 25, 585–592. [Google Scholar] [CrossRef]

- Teixeira, J.N.; Silva, D.W.; Vilela, A.P.; Junior, H.S.; de Siqueira Brandão, L.E.V.; Mendes, R.F. Lignocellulosic materials for fiber cement production. Waste Biomass Valoriz. 2020, 11, 2193–2200. [Google Scholar] [CrossRef]

- Cabalo, V.B. Utilization of coconut coir and abaca stripping waste fibers for cement bonded board. J. Sci. Eng. Technol. 2015, 3, 183–188. [Google Scholar]

- Basri, H.B.; Mannan, M.A.; Zain, M.F.M. Concrete using waste oil palm shells as aggregate. Cem. Concr. Res. 1999, 29, 619–622. [Google Scholar] [CrossRef]

- Hermawan, D.; Subiyanto, B.; Kawai, S. Manufacture and properties of oil palm frond cement-bonded board. J. Wood Sci. 2001, 47, 208–213. [Google Scholar] [CrossRef]

- Mannan, M.A.; Alexander, J.; Ganapathy, C.; Teo, D.C.L. Quality improvement of oil palm shell (OPS) as coarse aggregate in lightweight concrete. Build. Environ. 2006, 41, 1239–1242. [Google Scholar] [CrossRef]

- Ferrandez-Villena, M.; Ferrandez-Garcia, C.E.; Garcia-Ortuño, T.; Ferrandez-Garcia, A.; Ferrandez-Garcia, M.T. Properties of cement-bonded particleboards made from Canary Islands palm (Phoenix canariensis Ch.) trunks and different amounts of potato starch. Forests 2020, 11, 560. [Google Scholar] [CrossRef]

- Aggarwal, L.K.; Agrawal, S.P.; Thapliyal, P.C.; Karade, S.R. Cement-bonded composite boards with arhar stalks. Cem. Concr. Compos. 2008, 30, 44–51. [Google Scholar] [CrossRef]

- Juarez, C.; Duran, A.; Valdez, P.; Fajardo, G. Performance of “Agave lecheguilla” natural fiber in Portland cement composites exposed to severe environment conditions. Build. Environ. 2007, 42, 1151–1157. [Google Scholar] [CrossRef]

- Kriker, A.; Bali, A.; Debicki, G.; Bouziane, M.; Chabannet, M. Durability of date palm fibres and their use as reinforcement in hot dry climates. Cem. Concr. Compos. 2008, 30, 639–648. [Google Scholar] [CrossRef]

- Sedan, D.; Pagnoux, C.; Smith, A.; Chotard, T. Mechanical properties of hemp fibre reinforced cement: Influence of the fibre/matrix interaction. J. Eur. Ceram. Soc. 2008, 28, 183–192. [Google Scholar] [CrossRef]

- Diquélou, Y.; Gourlay, E.; Arnaud, L.; Kurek, B. Impact of hemp shiv on cement setting and hardening: Influence of the extracted components from the aggregates and study of the interfaces with the inorganic matrix. Cem. Concr. Compos. 2015, 55, 112–121. [Google Scholar] [CrossRef]

- Çomak, B.; Bideci, A.; Bideci, Ö.S. Effects of hemp fibers on characteristics of cement based mortar. Constr. Build. Mater. 2018, 169, 794–799. [Google Scholar] [CrossRef]

- Nguyen-Sy, T.; Tran-Le, A.D.; Nguyen-Thoi, T.; Langlet, T. A multi-scale homogenization approach for the effective thermal conductivity of dry lime–hemp concrete. J. Build. Perform. Simul. 2018, 11, 179–189. [Google Scholar] [CrossRef]

- Fernea, R.; Manea, D.L.; Plesa, L.; Iernuțan, R.; Dumitran, M. Acoustic and thermal properties of hemp-cement building materials. Procedia Manuf. 2019, 32, 208–215. [Google Scholar] [CrossRef]

- Mahjoub, R.; Yatim, J.M.; Mohd Sam, A.R.; Hashemi, S.H. Tensile properties of kenaf fiber due to various conditions of chemical fiber surface modifications. Constr. Build. Mater. 2014, 55, 103–113. [Google Scholar] [CrossRef]

- Ferrández-García, C.E.; García-Ortuño, T.; Andreu-Rodríguez, J.; Ferrández-Villena, M.; Ferrández-García, M.T. Mechanical properties of a cement mortar reinforced with Arundo donax L. reeds. Int. J. Civ. Eng. 2015, 2, 305–308. [Google Scholar]

- Demirbas, A.; Aslan, A. Effects of ground hazelnut shell, wood and tea waste on the mechanical properties of cement. Cem. Concr. Res. 1998, 28, 1101–1104. [Google Scholar] [CrossRef]

- Karade, S.R.; Irle, M.A.; Maher, K. Influence of granule properties and concentration on cork–cement compatibility. HolzRohWerkst 2006, 64, 281–286. [Google Scholar] [CrossRef]

- Ferrandez-García, M.T.; Ferrandez-Garcia, C.E.; Garcia-Ortuño, T.; Ferrandez-Garcia, A.; Ferrandez-Villena, M. Study of waste jute fibre panels (corchorus capsularis L.) agglomerated with Portland cement and starch. Polymers 2020, 12, 599. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, S.R.; Pepe, M.; Martinelli, E.; de Andrade Silva, F.; Toledo Filho, R.D. Influence of natural fibers characteristics on the interface mechanics with cement based matrices. Compos. Part B Eng. 2018, 140, 183–196. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B.; Oderji, S.Y.; Mohsan, M. Development of a new bio-composite for building insulation and structural purpose using corn stalk and magnesium phosphate cement. Energy Build. 2018, 173, 719–733. [Google Scholar] [CrossRef]

- Zadorecki, P.; Flodin, P. Surface modification of cellulose fibers. I. Spectroscopic characterization of surface-modified cellulose fibers and their copolymerization with styrene. J. Appl. Polym. Sci. 1985, 30, 2419–2429. [Google Scholar] [CrossRef]

- Zadorecki, P.; Flodin, P. Surface modification of cellulose fibers. II. The effect of cellulose fiber treatment on the performance of cellulose-polyester composites. J. Appl. Polym. Sci. 1985, 30, 3971–3983. [Google Scholar] [CrossRef]

- Bilba, K.; Arsene, M.A. Silane treatment of bagasse fiber for reinforcement of cementitious composites. Compos. Part A 2008, 39, 1488–1495. [Google Scholar] [CrossRef]

- Chakraborty, S.; Kundu, S.P.; Roy, A.; Adhikari, B.; Majumder, S.B. Polymer modified jute fibre as reinforcing agent controlling the physical and mechanical characteristics of cement mortar. Constr. Build. Mater. 2013, 49, 214–222. [Google Scholar] [CrossRef]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Vo, L.T.; Navard, P. Treatments of plant biomass for cementitious building materials. Constr. Build. Mater. 2016, 12, 161–176. [Google Scholar] [CrossRef] [Green Version]

- Peschard, A.; Govin, A.; Grosseau, P.; Guilhot, B.; Guyonnet, R. Effect of polysaccharides on the hydration of cement paste at early ages. Cem. Concr. Res. 2004, 34, 2153–2158. [Google Scholar] [CrossRef] [Green Version]

- Peschard, A.; Govina, A.; Pourchez, J.; Fredon, E.; Bertrand, L.; Maximilien, S.; Guilhot, B. Effect of polysaccharides on the hydration of cement suspension. J. Eur. Ceram. Soc. 2006, 26, 1439–1445. [Google Scholar] [CrossRef] [Green Version]

- Dewacker, D.R.; Mcad, B. Cement Mortar Systems Using Blends of Polysaccharides and Cold-Water-Soluble Unmodified Starches. U.S. Patent 5575840, 19 November 1996. [Google Scholar]

- Zhang, D.F.; Ju, B.Z.; Zhang, S.F.; He, L.; Yang, J.Z. The study on the dispersing mechanism of starch sulfonate as a water-reducing agent for cement. Carbohydr. Polym. 2007, 70, 363–368. [Google Scholar] [CrossRef]

- Ferrández-García, M.T.; García-Ortuño, T.; Ferrández-Villena, M.; Andreu-Rodríguez, J.; Ferrández-García, C.E. Study of the properties of cement boards improved with starch. In Proceedings of the 8th Iberian Congress of Agroengineering, Libro de Actas: Retos de la Nueva Agricultura Mediterránea, Orihuela, Spain, 1–3 June 2015; Universidad Miguel Hernández de Elche: Elche, Spain, 2015; pp. 387–392, ISBN 978-84-16024-30-8. [Google Scholar]

- Islam, M.R.; Rahman, F.; Islam, M.N.; Rana, M.N.; Nath, S.K.; Ashaduzzaman, M.; Shams, M.I. Cement-bonded lignocellulosic panel (CLP): A promising environmental friendly construction material for conservation of forest resources. In Handbook of Ecomaterials; Springer: New York, NY, USA, 2018; pp. 1–13. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Compos. 2016, 68, 96–108. [Google Scholar] [CrossRef]

- Deltoro Torró, V.; Jiménez Ruiz, J.; Vilán Fragueiro, X.M. Bases para el Manejo y Control de Arundo donax L. (Caña común). Colección Manuales Técnicos de Biodiversidad; Conselleria d’Infraestructures, Territori i Medi Ambient. Generalitat Valenciana: Valencia, Spain, 2012; ISBN 978-84-482-5777-4. [Google Scholar]

- Ferrández García, M.T. Análisis y Desarrollo de Tableros Multicapa de Caña Común (Arundo donax L.). Ph.D. Thesis, Universidad Miguel Hernández, Elche, Spain, 28 July 2008. [Google Scholar]

- EN 312. In Particleboards—Specifications; European Committee for Standardization: Brussels, Belgium, 2010.

- García-Ortuño, T.; Rodríguez, J.; Ferrández-García, M.T.; Ferrández-Villena, M.; Ferrández-García, C.E. Evaluation of the physical and mechanical properties of particleboard made from giant reed (Arundo donax L.). BioResources 2011, 6, 477–486. [Google Scholar] [CrossRef]

- Ferrández-García, C.E.; Andreu-Rodríguez, J.; Ferrández-García, M.T.; Ferrández-Villena, M.; García-Ortuño, T. Panels made from giant reed bonded with non-modified starches. BioResources 2012, 7, 5904–5916. [Google Scholar] [CrossRef] [Green Version]

- Shon, C.S.; Mukashev, T.; Lee, D.; Zhang, D.; Kim, J.R. Can common reed fiber become an effective construction material? Physical, mechanical, and thermal properties of mortar mixture containing common reed fiber. Sustainability 2019, 11, 903. [Google Scholar] [CrossRef] [Green Version]

- EN 326: Wood-based panels, Cutting and Inspection. In Part 1: Sampling and Cutting of Test Pieces and Expression of Test; European Committee for Standardization: Brussels, Belgium, 1994.

- EN 309: Particleboards. In Definitions and Classification; European Committee for Standardization: Brussels, Belgium, 2005.

- EN 323: Wood-based panels. In Determination of Density; European Committee for Standardization: Brussels, Belgium, 1993.

- EN 317: Particleboards and fiberboards. In Determination of Swelling in Thickness after Immersion in Water; European Committee for Standardization: Brussels, Belgium, 1993.

- EN 319: Particleboards and fiberboards. In Determination of Tensile Strength Perpendicular to the Plane of de Board; European Committee for Standardization: Brussels, Belgium, 1993.

- EN 310: Wood-based panels. In Determination of Modulus of Elasticity in Bending and of Bending Strength; European Committee for Standardization: Brussels, Belgium, 1993.

- Giraldo, M.A.; Tobón, J.I. Mineralogical evolution of Portland cement during hydratation process. Dyna 2006, 73, 69–81. [Google Scholar]

- Fan, M.; Ndikontar, M.K.; Zhou, X.; Ngamveng, J.N. Cement-bonded composites made from tropical woods: Compatibility of wood and cement. Constr. Build. Mater. 2012, 36, 135–140. [Google Scholar] [CrossRef]

| Type | Number of Panels | Weight Dosage (%) | |

|---|---|---|---|

| Starch | Cement | ||

| A | 20 | 10 | 20 |

| B | 20 | 5 | 20 |

| C | 20 | 10 | 10 |

| D | 20 | - | 10 |

| E | 20 | - | 20 |

| F | 16 | 5 | - |

| G | 16 | 10 | - |

| Pressing Time (h) | Class | Number of Panels |

|---|---|---|

| 1 | 1 | 4 |

| 2 | 2 | 8 1 |

| 3 | 3 | 4 |

| 4 | 4 | 4 |

| Test | N of Replicates (Per Panel) | N of Replicates (Total) | Size of the Specimens | Equipment Used |

|---|---|---|---|---|

| Relative Humidity | 3 | 396 | 20 g | Model UM2000, Imal s.r.l. |

| Density | 6 | 792 | 50 mm × 50 mm | Model IB700, Imal s.r.l. |

| Thickness Swelling (TS) | 3 | 396 | 50 mm × 50 mm | Model 76-B0066/B Water Bath, Controls S.A. Model UM2000, Imal s.r.l. |

| Water Absorption (WA) | 3 | 396 | 50 mm × 50 mm | Model 76-B0066/B Water Bath, Controls S.A. Model UM2000, Imal s.r.l. |

| Modulus of Rupture (MOR) | 6 | 792 | 150 mm × 50 mm | Model UM2000, Imal s.r.l. |

| Modulus of Elasticity (MOE) | 6 | 792 | 150 mm × 50 mm | Model UM2000, Imal s.r.l. |

| Internal Bonding Strength (IB) | 3 | 396 | 50 mm × 50 mm | Model UM2000, Imal s.r.l. |

| Factor | Properties | Sum of Squares | d.f. | Half Quadratic | F | Sig |

|---|---|---|---|---|---|---|

| Type of panel | Density (kg/m3) | 246,938.733 | 6 | 41,156.455 | 8.851 | 0.000 |

| TS 24 h (%) | 24,117.087 | 6 | 4019.514 | 79.859 | 0.000 | |

| WA 24 h (%) | 30,972.016 | 6 | 5162.003 | 24.673 | 0.000 | |

| MOR (N/mm2) | 2203.595 | 6 | 367.266 | 22.757 | 0.000 | |

| MOE (N/mm2) | 2.572 × 107 | 6 | 4.286 × 106 | 8290 | 0.000 | |

| IB (N/mm2) | 3.947 | 6 | 0.658 | 10.880 | 0.000 | |

| Pressing time | Density (kg/m3) | 44,648.253 | 3 | 14,882.751 | 2.285 | 0.083 |

| TS 24 h (%) | 421.488 | 3 | 140.496 | 0.496 | 0.686 | |

| WA 24 h (%) | 1060.883 | 3 | 353.628 | 0.708 | 0.549 | |

| MOR (N/mm2) | 1081.134 | 3 | 360.378 | 13.461 | 0.000 | |

| MOE (N/mm2) | 2.348 × 107 | 3 | 7.827 × 106 | 14.943 | 0.000 | |

| IB (N/mm2) | 0.995 | 3 | 0.332 | 3.771 | 0.013 | |

| Starch (%) | Density (kg/m3) | 225,752.148 | 2 | 112,876.074 | 24.920 | 0.000 |

| TS 24 h (%) | 22,366.496 | 2 | 11,183.248 | 170.680 | 0.000 | |

| WA 24 h (%) | 28,956.715 | 2 | 14,478.357 | 71.060 | 0.000 | |

| MOR (N/mm2) | 1686.149 | 2 | 843.074 | 40.973 | 0.000 | |

| MOE (N/mm2) | 14,861,771.141 | 2 | 7,430,885.571 | 12.256 | 0.000 | |

| IB (N/mm2) | 3.682 | 2 | 1.841 | 50.932 | 0.000 | |

| Cement (%) | Density (kg/m3) | 7589.261 | 1 | 7589.261 | 1.391 | 0.243 |

| TS 24 h (%) | 80.590 | 1 | 80.590 | 7.165 | 0.010 | |

| WA 24 h (%) | 1418.878 | 1 | 1418.878 | 5.653 | 0.021 | |

| MOR (N/mm2) | 307.374 | 1 | 307.374 | 15.118 | 0.000 | |

| MOE (N/mm2) | 8,513,888.803 | 1 | 8,513,888.803 | 12.613 | 0.001 | |

| IB (N/mm2) | 0.773 | 1 | 0.773 | 16.647 | 0.000 |

| Grade | Definition |

|---|---|

| P1 | Boards for general use in dry conditions |

| P2 | Boards for indoor application (including furniture) in dry conditions |

| P3 | Non-structural boards for use in humid conditions |

| P4 | Structural boards for use in dry conditions |

| P5 | Structural boards for use in humid conditions |

| P6 | High performance structural boards for use in dry conditions |

| P7 | High performance structural boards for use in humid conditions |

| Type of Panel | Classification EN 312 [68] | MOR (N/mm2) | MOE (N/mm2) | IB (N/mm2) | TS 24 h (%) |

|---|---|---|---|---|---|

| A1 | P2 | 12.89 (1.44) | 1846.04 (368.20) | 0.41 (0.13) | 15.54 (3.37) |

| A2 | P3 | 15.98 (1.19) | 2083.50 (335.15) | 0.53 (0.22) | 11.12 (2.85) |

| A3 | P4 | 19.79 (3.06) | 2636.88 (521.43) | 0.66 (0.27) | 13.33 (3.08) |

| A4 | P6 | 26.11 (2.28) | 3759.76 (377.99) | 0.76 (0.21) | 12.38 (1.35) |

| B1 | P1 | 13.33 (1.13) | 2130.78 (304.21) | 0.34 (0.15) | 13.96 (5.22) |

| B2 | P2 | 14.19 (1.63) | 2610.01 (520.34) | 0.42 (0.23) | 13.48 (3.28) |

| B3 | P4 | 16.94 (1.49) | 2392.63 (488.00) | 0.79 (0.21) | 15.25 (5.77) |

| B4 | P4 | 19.88 (0.91) | 3076.93 (431.62) | 0.74 (0.14) | 13.49 (1.59) |

| C1 | P2 | 12.56 (6.07) | 2021.89 (461.01) | 0.54 (0.19) | 24.22 (8.13) |

| C2 | P3 | 20.76 (2.51) | 3058.56 (389.95) | 0.71 (0.09) | 16.83 (3.09) |

| C3 | P3 | 21.60 (1.60) | 3104.68 (541.19) | 0.84 (0.24) | 16.95 (2.75) |

| C4 | P6 | 27.26 (3.29) | 4287.44 (554.31) | 0.95 (0.33) | 14.04 (1.03) |

| D1 | P1 | 11.41 (0.81) | 2325.87 (211.76) | 0.31 (0.01) | 58.50 (14.50) |

| D2 | P1 | 12.72 (0.46) | 2426.60 (356.39) | 0.31 (0.04) | 49.42 (0.17) |

| D3 | P1 | 13.82 (1.44) | 2519.48 (198.45) | 0.34 (0.03) | 44.83 (16.6) |

| D4 | P1 | 18.04 (0.35) | 3080.12 (126.14) | 0.36 (0.10) | 50.41 (11.20) |

| E1 | - | 6.22 (0.22) | 1234.77 (131.71) | 0.16 (0.11) | 42.24 (1.56) |

| E2 | - | 6.40 (0.24) | 1426.89 (167.47) | 0.16 (0.06) | 36.79 (3.71) |

| E3 | - | 8.71 (0.34) | 1713.74 (11.04) | 0.33 (0.10) | 37.79 (7.15) |

| E4 | - | 9.45 (1.02) | 1865.42 (64.53) | 0.21 (0.09) | 26.73 (6.59) |

| F1 | - | 9.90 (0.30) | 1958.16 (71.76) | 0.27 (0.01) | 37.28 (1.85) |

| F2 | - | 7.90 (0.47) | 1663.29 (1.38) | 0.28 (0.02) | 39.89 (0.67) |

| F3 | - | 9.46 (0.43) | 1784.03 (37.78) | 0.21 (0.01) | 49.11 (0.71) |

| F4 | - | 12.06 (0.29) | 2443.87 (51.51) | 0.27 (0.01) | 56.34 (0.71) |

| G1 | P1 | 13.00 (0.07) | 2148.25 (70.71) | 0.30 (0.01) | 41.41 (1.41) |

| G2 | P1 | 14.04 (0.27) | 2192.85 (95.95) | 0.28 (0.01) | 43.44 (1.59) |

| G3 | P1 | 15.63 (0.48) | 2211.76 (119.50) | 0.28 (0.01) | 48.49 (1.52) |

| G4 | P1 | 18.53 (0.69) | 2763.68 (72.18) | 0.29 (0.01) | 46.18 (2.28) |

| Thickness 6–13 mm [68] | P1 | 10.50 | - | 0.28 | - |

| P2 | 11.00 | 1800.00 | 0.40 | - | |

| P3 | 15.00 | 2050.00 | 0.45 | 17.00 | |

| Thickness 6–10 mm [68] | P4 | 16.00 | 2300.00 | 0.40 | 16.00 |

| P5 | 18.00 | 2550.00 | 0.45 | 13.00 | |

| P6 | 20.00 | 3150.00 | 0.60 | 16.00 | |

| P7 | 22.00 | 3350.00 | 0.75 | 10.00 |

| Source | Material | Ratio Cement/Material | MOR (N/mm2) | MOE (N/mm2) | IB (N/mm2) | TS 24 h (%) |

|---|---|---|---|---|---|---|

| [5] | Pine | 3/1 | 15.8 | 5495 | - | 18.5 |

| [9] | 50% Eucalypt and 50% rubberwood | 8/1 | 6.40 | 4090 | 0.34 | 1.80 |

| [21] | Coconut coir | 2/1 | 19.94 | 5315 | 0.73 | 3.64 |

| [37] | Canary palm | 1/5 | 15.76 | 1872 | 0.68 | 26.70 |

| This work (C4) | Giant reed | 1/10 | 27.26 | 4287.44 | 0.95 | 14.04 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrandez-García, A.A.; Ortuño, T.G.; Ferrandez-Villena, M.; Ferrandez-Garcia, A.; Ferrandez-García, M.T. Evaluation of Particleboards Made from Giant Reed (Arundo donax L.) Bonded with Cement and Potato Starch. Polymers 2022, 14, 111. https://doi.org/10.3390/polym14010111

Ferrandez-García AA, Ortuño TG, Ferrandez-Villena M, Ferrandez-Garcia A, Ferrandez-García MT. Evaluation of Particleboards Made from Giant Reed (Arundo donax L.) Bonded with Cement and Potato Starch. Polymers. 2022; 14(1):111. https://doi.org/10.3390/polym14010111

Chicago/Turabian StyleFerrandez-García, Aranzazu Alejandra, Teresa Garcia Ortuño, Manuel Ferrandez-Villena, Antonio Ferrandez-Garcia, and Maria Teresa Ferrandez-García. 2022. "Evaluation of Particleboards Made from Giant Reed (Arundo donax L.) Bonded with Cement and Potato Starch" Polymers 14, no. 1: 111. https://doi.org/10.3390/polym14010111

APA StyleFerrandez-García, A. A., Ortuño, T. G., Ferrandez-Villena, M., Ferrandez-Garcia, A., & Ferrandez-García, M. T. (2022). Evaluation of Particleboards Made from Giant Reed (Arundo donax L.) Bonded with Cement and Potato Starch. Polymers, 14(1), 111. https://doi.org/10.3390/polym14010111