Bio-Based Rigid Polyurethane Foams Modified with Phosphorus Flame Retardants

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Polyurethane Foams

2.3. Test Method

3. Results and Discussion

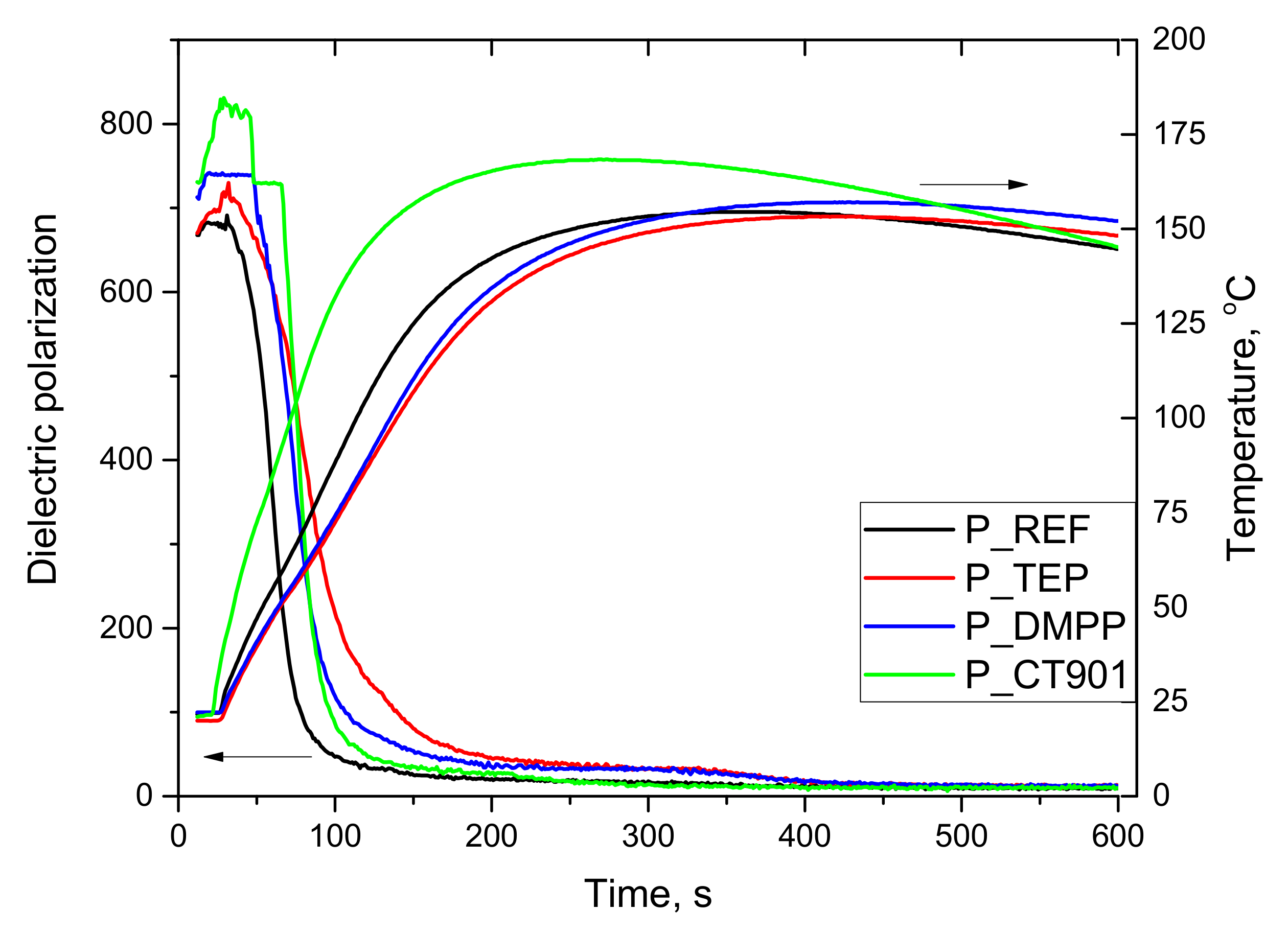

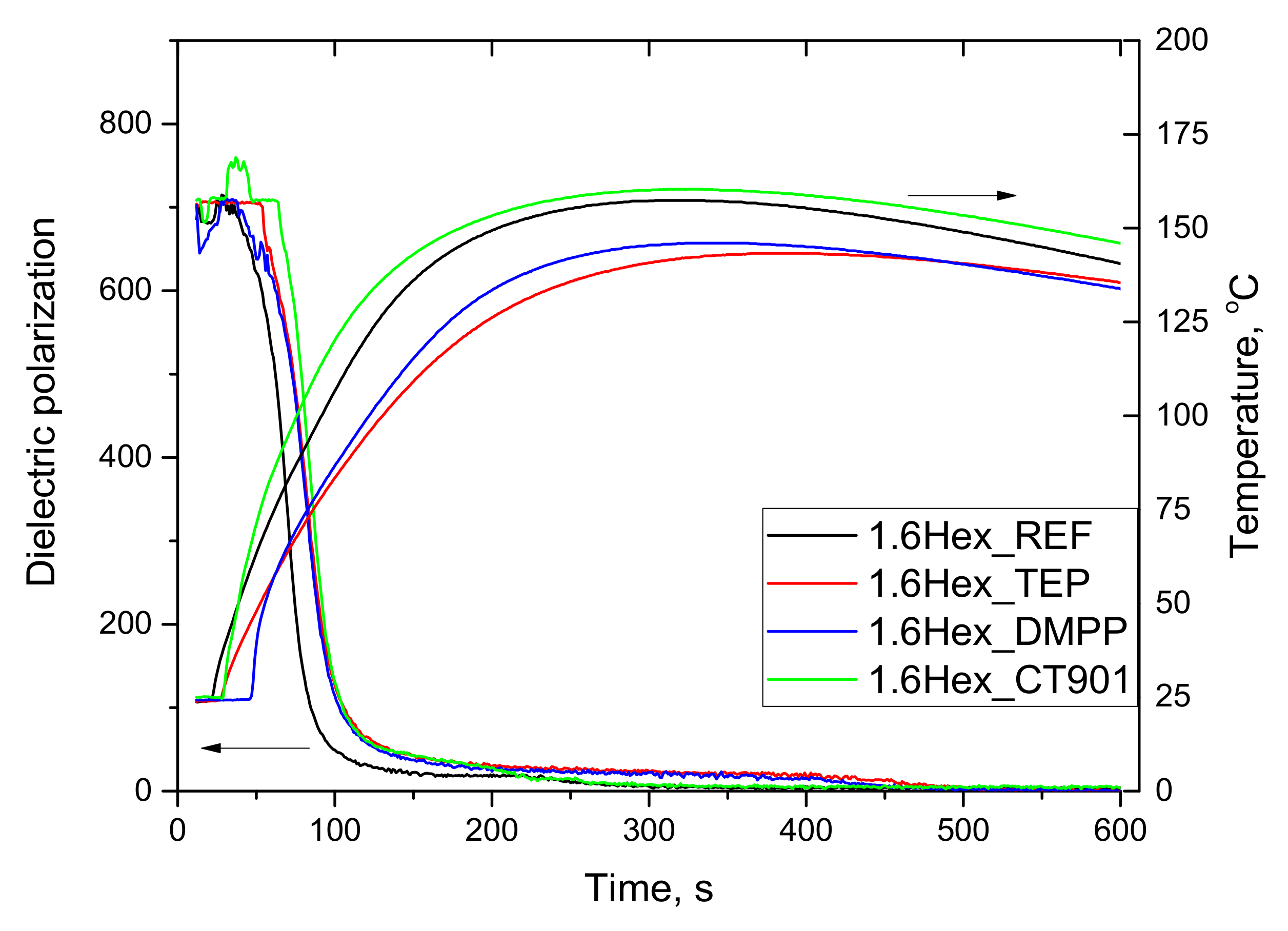

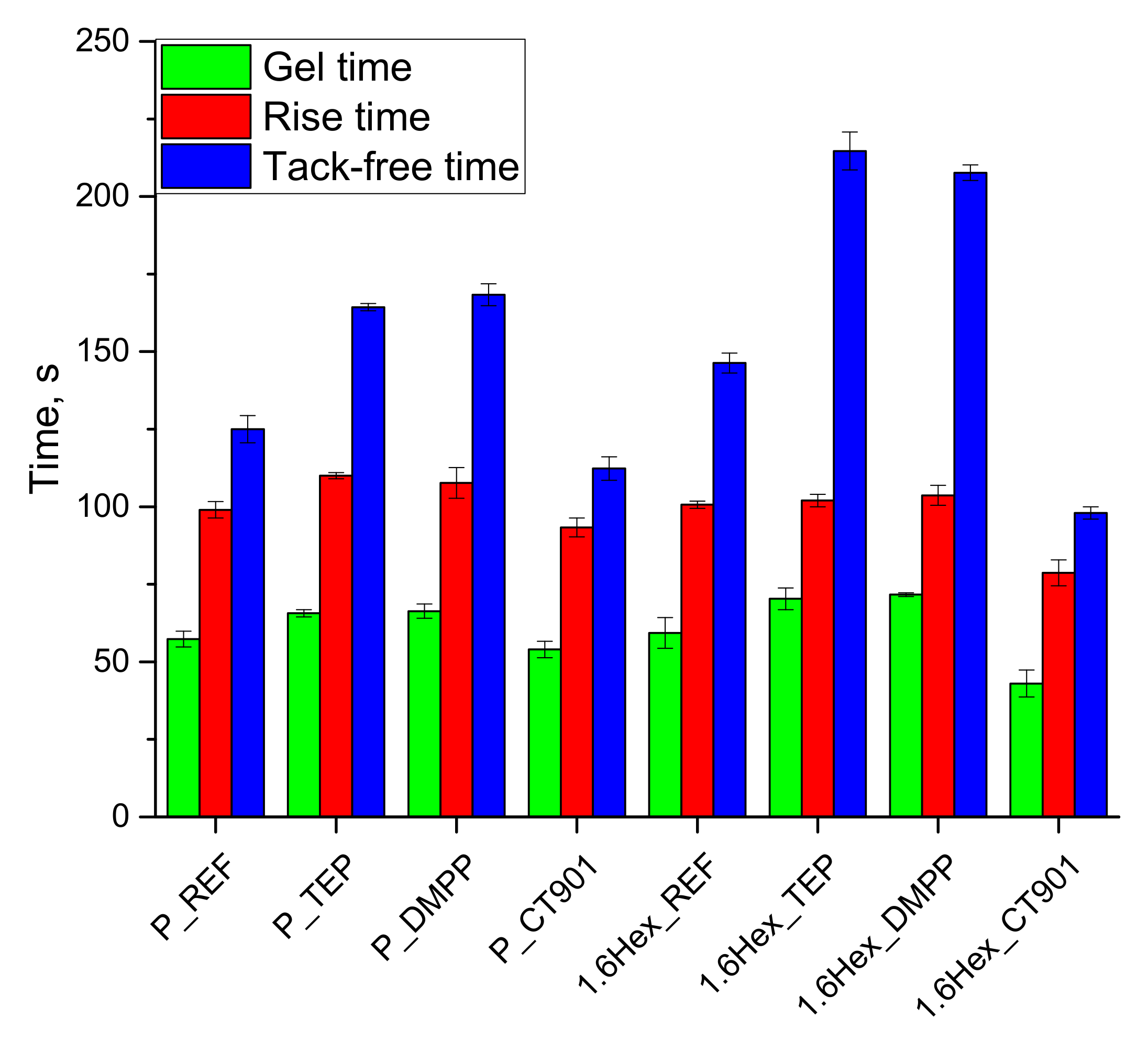

3.1. Foaming Process

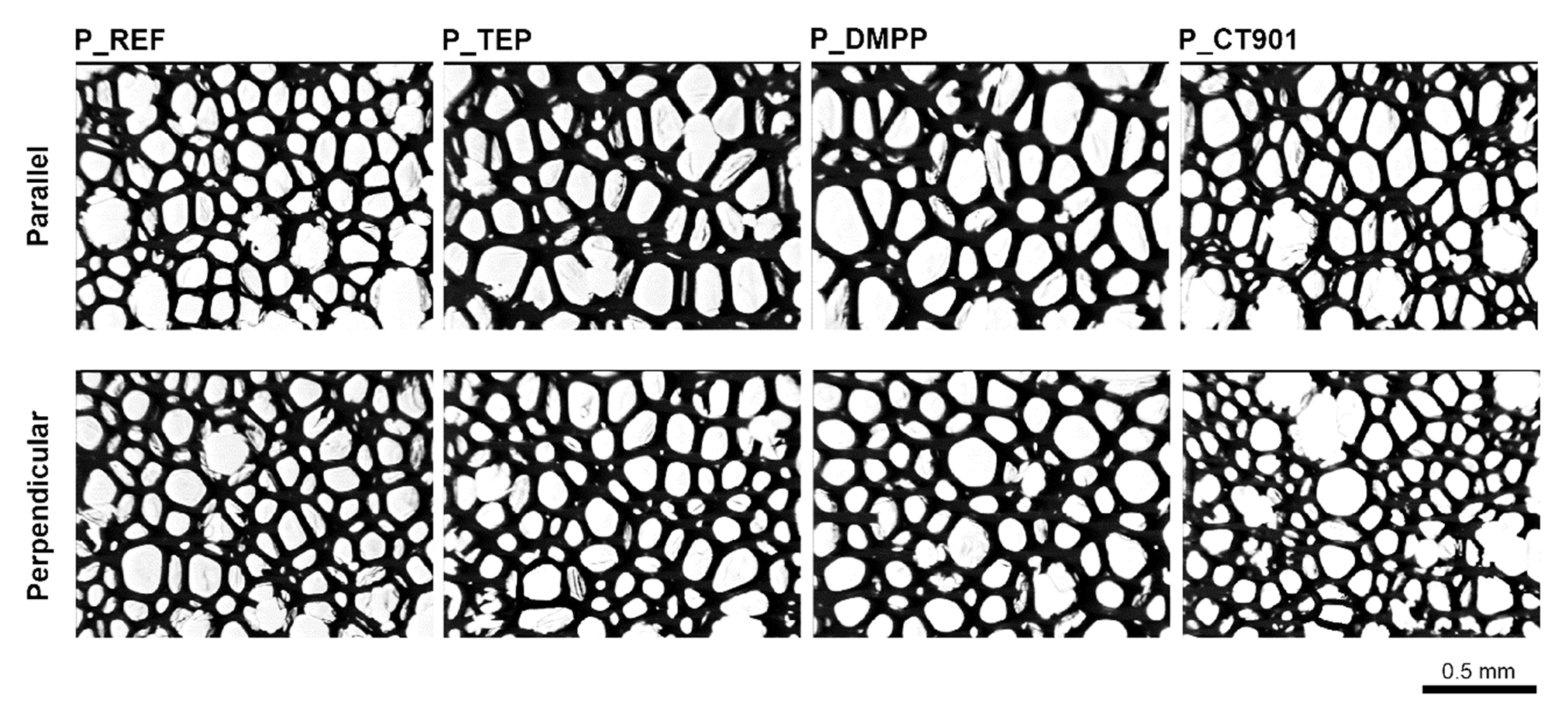

3.2. Cell Structure

3.3. Physical and Mechanical Properties

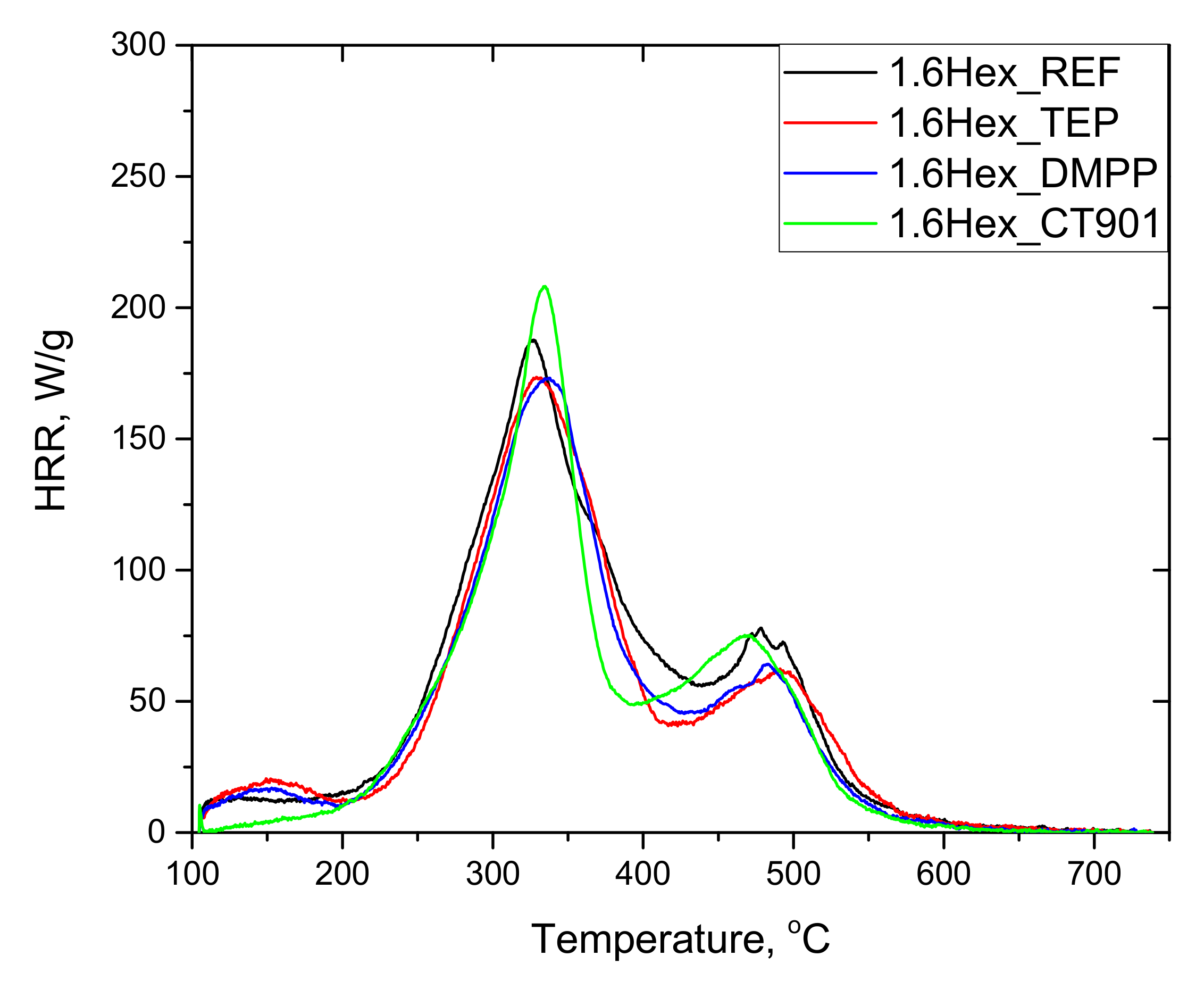

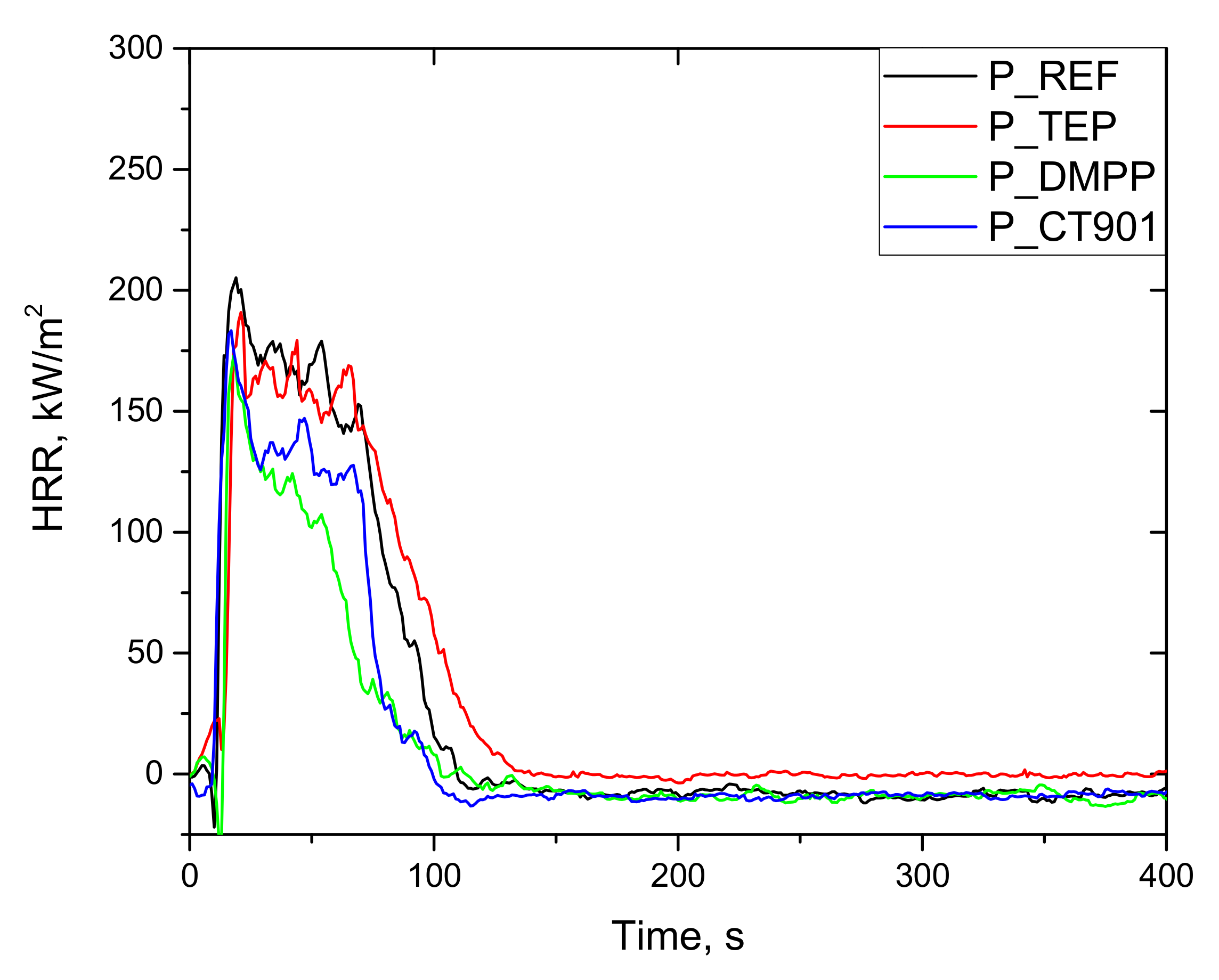

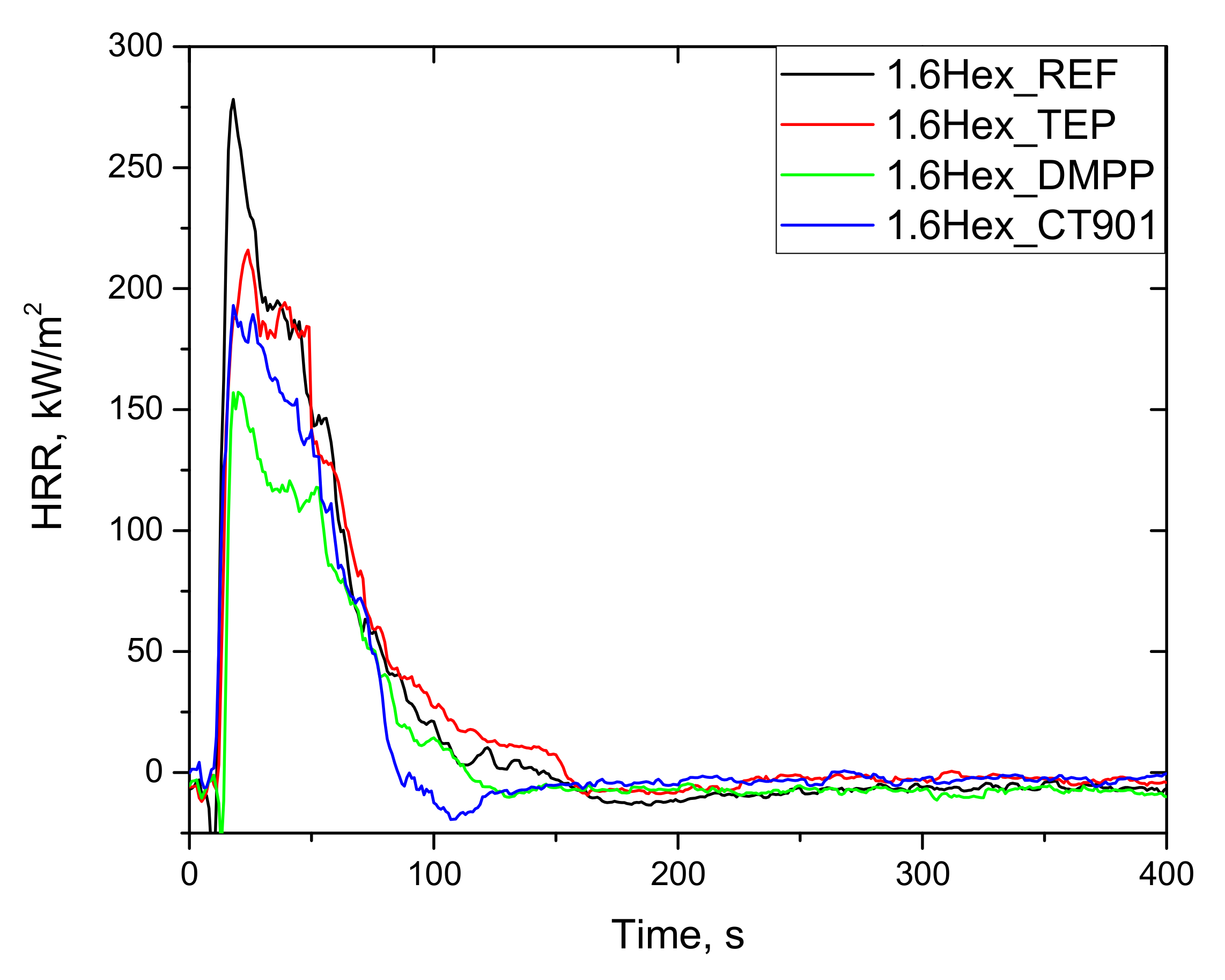

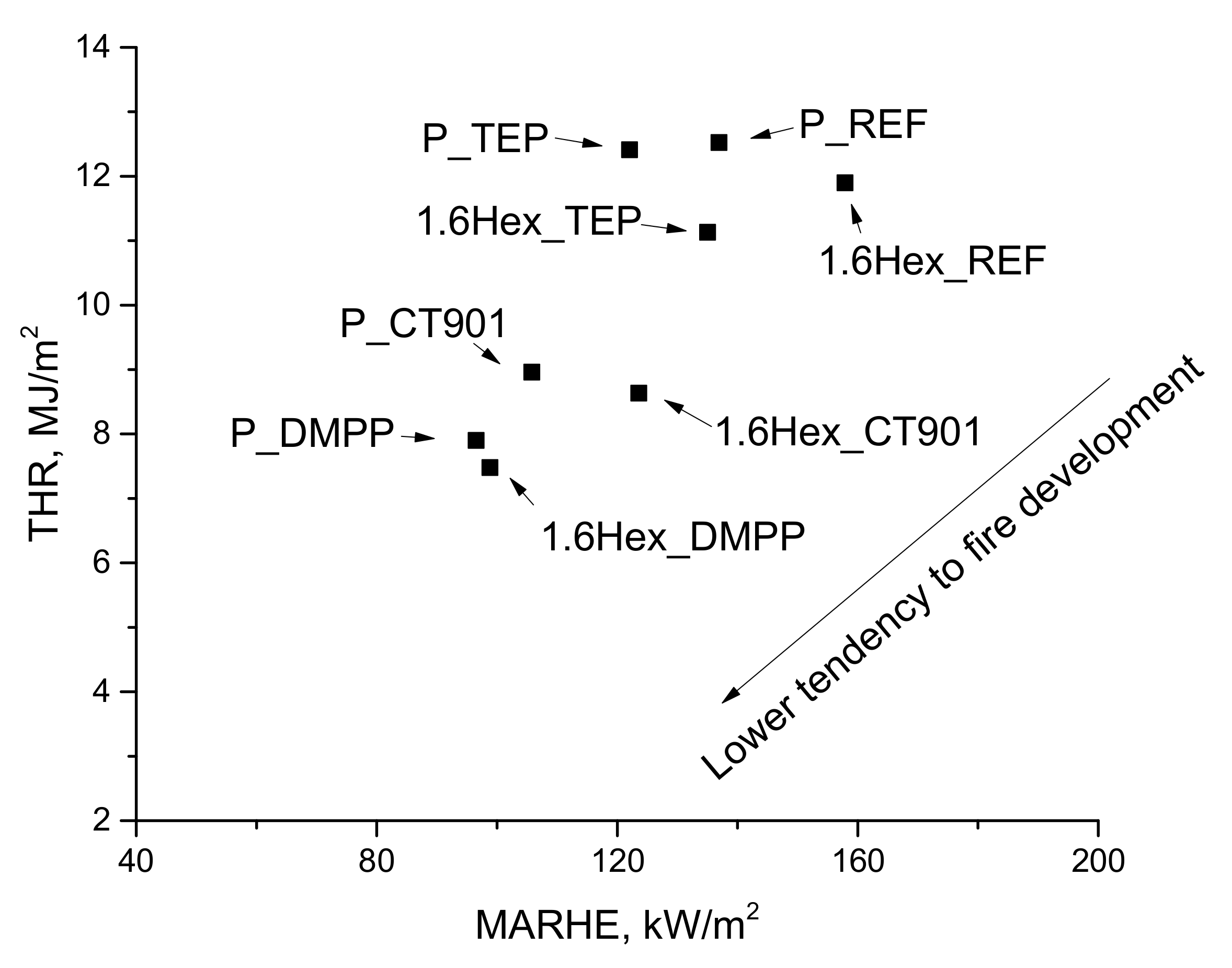

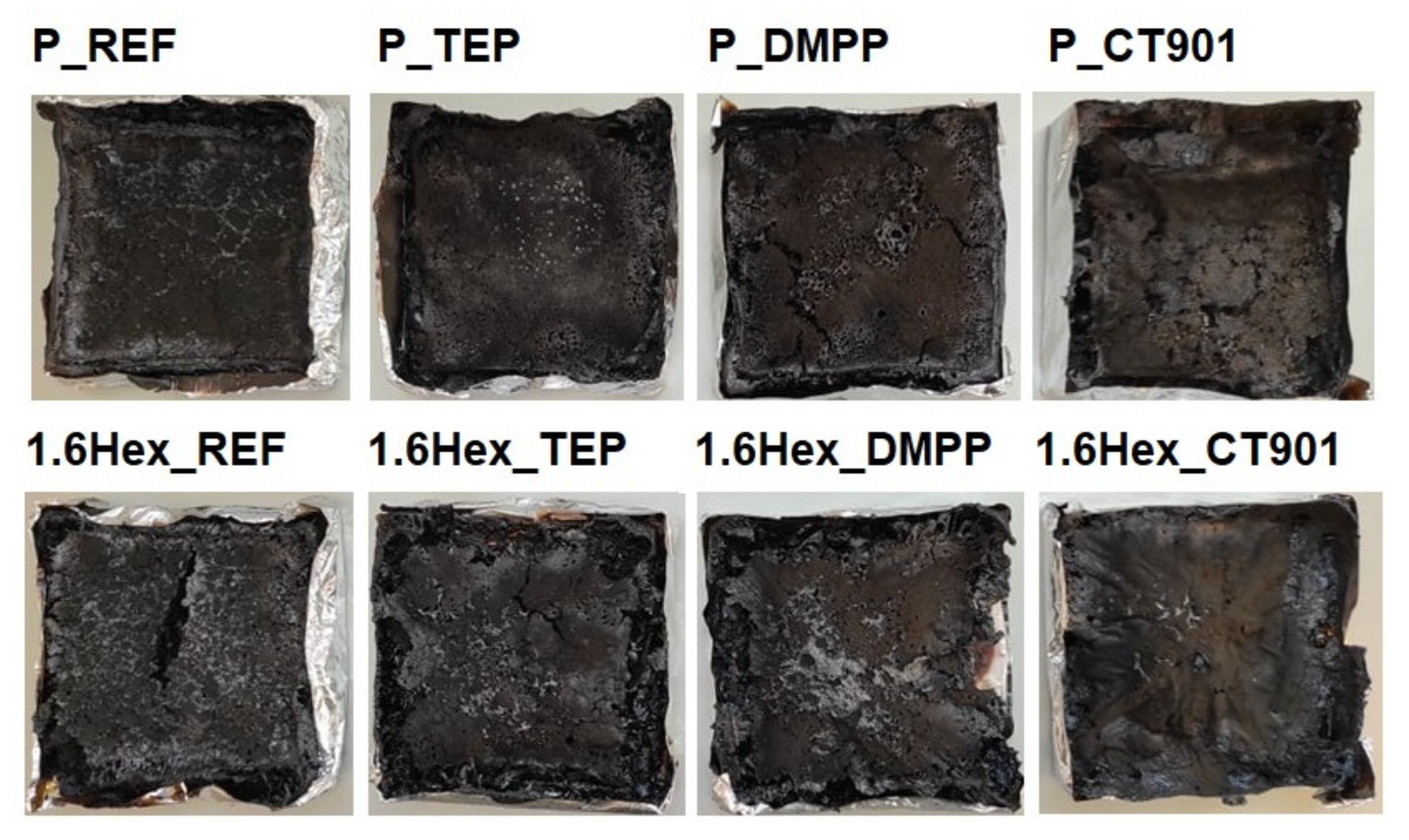

3.4. Flammability Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohammadpour, R.; Mir Mohamad Sadeghi, G. Effect of Liquefied Lignin Content on Synthesis of Bio-based Polyurethane Foam for Oil Adsorption Application. J. Polym. Environ. 2020, 28, 892–905. [Google Scholar] [CrossRef]

- Hu, Y.; Zhou, Z.; Li, S.; Yang, D.; Zhang, S.; Hou, Y. Flame Retarded Rigid Polyurethane Foams Composites Modified by Aluminum Diethylphosphinate and Expanded Graphite. Front. Mater. 2021, 7, 629284. [Google Scholar] [CrossRef]

- Andersons, J.; Kirpluks, M.; Stiebra, L.; Cabulis, U. Anisotropy of the stiffness and strength of rigid low-density closed-cell polyisocyanurate foams. Mater. Des. 2016, 92, 836–845. [Google Scholar] [CrossRef]

- Li, L.; Chen, Y.; Wu, X.; Xu, B.; Qian, L. Bi-phase flame-retardant effect of dimethyl methylphosphonate and modified ammonium polyphosphate on rigid polyurethane foam. Polym. Adv. Technol. 2019, 30, 2721–2728. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, Z.; Lei, Y. Flame retardant and smoke-suppressant rigid polyurethane foam based on sodium alginate and aluminum diethylphosphite. Des. Monomers Polym. 2021, 24, 46–52. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Xu, B.; Wang, X.; Liu, Y. A phosphorous-based bi-functional flame retardant for rigid polyurethane foam. Polym. Degrad. Stab. 2021, 186, 109516. [Google Scholar] [CrossRef]

- Jia, D.; Yang, J.; He, J.; Li, X.; Yang, R. Melamine-based polyol containing phosphonate and alkynyl groups and its application in rigid polyurethane foam. J. Mater. Sci. 2021, 56, 870–885. [Google Scholar] [CrossRef]

- Wang, L.; Tawiah, B.; Shi, Y.; Cai, S.; Rao, X.; Liu, C.; Yang, Y.; Yang, F.; Yu, B.; Liang, Y.; et al. Highly effective flame-retardant rigid polyurethane foams: Fabrication and applications in inhibition of coal combustion. Polymers 2019, 11, 1776. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Wu, Y.; Zhang, B.; Zhang, G. Synthesis and synergistic flame-retardant effects of rigid polyurethane foams used reactive DOPO-based polyols combination with expandable graphite. J. Appl. Polym. Sci. 2021, 138, 50223. [Google Scholar] [CrossRef]

- Li, X.; Yu, Z.; Zhang, L. Synthesis of a green reactive flame-retardant polyether polyol and its application. J. Appl. Polym. Sci. 2021, 138, 50154. [Google Scholar] [CrossRef]

- Luo, Y.; Miao, Z.; Sun, T.; Zou, H.; Liang, M.; Zhou, S.; Chen, Y. Preparation and mechanism study of intrinsic hard segment flame-retardant polyurethane foam. J. Appl. Polym. Sci. 2021, 138, 49920. [Google Scholar] [CrossRef]

- Liu, Q.; Gao, S.; Zhao, Y.; Tao, W.; Yu, X.; Zhi, M. Review of layer-by-layer self-assembly technology for fire protection of flexible polyurethane foam. J. Mater. Sci. 2021, 56, 9605–9643. [Google Scholar] [CrossRef]

- Vahabi, H.; Rastin, H.; Movahedifar, E.; Antoun, K.; Brosse, N.; Saeb, M.R. Flame retardancy of bio-based polyurethanes: Opportunities and challenges. Polymers 2020, 12, 1234. [Google Scholar] [CrossRef] [PubMed]

- Lorenzetti, A.; Modesti, M.; Besco, S.; Hrelja, D.; Donadi, S. Influence of phosphorus valency on thermal behaviour of flame retarded polyurethane foams. Polym. Degrad. Stab. 2011, 96, 1455–1461. [Google Scholar] [CrossRef]

- Liang, S.; Neisius, M.; Mispreuve, H.; Naescher, R.; Gaan, S. Flame retardancy and thermal decomposition of flexible polyurethane foams: Structural influence of organophosphorus compounds. Polym. Degrad. Stab. 2012, 97, 2428–2440. [Google Scholar] [CrossRef]

- Liu, X.; Hao, J.; Gaan, S. Recent studies on the decomposition and strategies of smoke and toxicity suppression for polyurethane based materials. RSC Adv. 2016, 6, 74742–74756. [Google Scholar] [CrossRef] [Green Version]

- Kurańska, M.; Cabulis, U.; Auguścik, M.; Prociak, A.; Ryszkowska, J.; Kirpluks, M. Bio-based polyurethane-polyisocyanurate composites with an intumescent flame retardant. Polym. Degrad. Stab. 2016, 127, 11–19. [Google Scholar] [CrossRef]

- Wrześniewska-Tosik, K.; Ryszkowska, J.; Mik, T.; Wesołowska, E.; Kowalewski, T.; Pałczyńska, M.; Sałasińska, K.; Walisiak, D.; Czajka, A. Composites of semi-rigid polyurethane foams with keratin fibers derived from poultry feathers and flame retardant additives. Polymers 2020, 12, 2943. [Google Scholar] [CrossRef]

- Ali, M.H.M.; Rahman, H.A.; Amirnordin, S.H.; Khan, N.A. Eco-friendly flame-retardant additives for polyurethane foams: A short review. Key Eng. Mater. 2018, 791, 19–28. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, W.; Liu, M.; Zhu, Q.; Liu, X.; Zhang, B.; Chen, D.; Liu, X.; Zhang, K.; Tang, G. Flame retarded rigid polyurethane foam composites based on gel-silica microencapsulated ammonium polyphosphate. J. Sol-Gel Sci. Technol. 2021, 98, 212–223. [Google Scholar] [CrossRef]

- Morgan, A.B. The Future of Flame Retardant Polymers–Unmet Needs and Likely New Approaches. Polym. Rev. 2019, 59, 25–54. [Google Scholar] [CrossRef]

- Zhao, Q.; Chen, C.; Fan, R.; Yuan, Y.; Xing, Y.; Ma, X. Halogen-free flame-retardant rigid polyurethane foam with a nitrogen-phosphorus flame retardant. J. Fire Sci. 2017, 35, 99–117. [Google Scholar] [CrossRef]

- Sałasińska, K.; Leszczyńska, M.; Celiński, M.; Kozikowski, P.; Kowiorski, K.; Lipińska, L. Burning behaviour of rigid polyurethane foams with histidine and modified graphene oxide. Materials 2021, 14, 1184. [Google Scholar] [CrossRef]

- Chen, M.J.; Chen, C.R.; Tan, Y.; Huang, J.Q.; Wang, X.L.; Chen, L.; Wang, Y.Z. Inherently flame-retardant flexible polyurethane foam with low content of phosphorus-containing cross-linking agent. Ind. Eng. Chem. Res. 2014, 53, 1160–1171. [Google Scholar] [CrossRef]

- Prociak, A.; Szczepkowski, L.; Ryszkowska, J.; Kurańska, M.; Auguścik, M.; Malewska, E.; Gloc, M.; Michałowski, S. Influence of Chemical Structure of Petrochemical Polyol on Properties of Bio-polyurethane Foams. J. Polym. Environ. 2019, 27, 2360–2368. [Google Scholar] [CrossRef] [Green Version]

- Ramanujam, S.; Zequine, C.; Bhoyate, S.; Neria, B.; Kahol, P.; Gupta, R. Novel Biobased Polyol Using Corn Oil for Highly Flame-Retardant Polyurethane Foams. C 2019, 5, 13. [Google Scholar] [CrossRef] [Green Version]

- Uram, K.; Prociak, A.; Kuranska, M. Influence of the chemical structure of rapeseed oil-based polyols on selected properties of polyurethane foams. Polimery 2020, 65, 698–707. [Google Scholar] [CrossRef]

- Kurańska, M.; Prociak, A.; Cabulis, U.; Kirpluks, M.; Ryszkowska, J.; Auguścik, M. Innovative porous polyurethane-polyisocyanurate foams based on rapeseed oil and modified with expandable graphite. Ind. Crops Prod. 2017, 95, 316–323. [Google Scholar] [CrossRef]

- Zhang, K.; Hong, Y.; Wang, N.; Wang, Y. Flame retardant polyurethane foam prepared from compatible blends of soybean oil-based polyol and phosphorus containing polyol. J. Appl. Polym. Sci. 2018, 135, 45779. [Google Scholar] [CrossRef]

- Marcovich, N.E.; Kurańska, M.; Prociak, A.; Malewska, E.; Bujok, S. The effect of different palm oil-based bio-polyols on foaming process and selected properties of porous polyurethanes. Polym. Int. 2017, 66, 1522–1529. [Google Scholar] [CrossRef]

- Kirpluks, M.; Vanags, E.; Abolins, A.; Michalowski, S.; Fridrihsone, A.; Cabulis, U. High functionality bio-polyols from tall oil and rigid polyurethane foams formulated solely using bio-polyols. Materials 2020, 13, 1985. [Google Scholar] [CrossRef] [PubMed]

- Ding, H.; Huang, K.; Li, S.; Xu, L.; Xia, J.; Li, M. Flame retardancy and thermal degradation of halogen-free flame-retardant biobased polyurethane composites based on ammonium polyphosphate and aluminium hypophosphite. Polym. Test. 2017, 62, 325–334. [Google Scholar] [CrossRef]

- Kurańska, M.; Prociak, A. Environmentally friendly polyurethane-polyisocyanurate foamsfor applications in the construction industry. Czas. Tech. 2015, 2014, 149–152. [Google Scholar] [CrossRef]

- Prociak, A.; Kurańska, M.; Malewska, E. Porous polyurethane plastics synthetized using bio-polyols from renewable raw materials. Polimery 2017, 62, 353–363. [Google Scholar] [CrossRef]

- Paruzel, A.; Michałowski, S.; Hodan, J.; Horák, P.; Prociak, A.; Beneš, H. Rigid Polyurethane Foam Fabrication Using Medium Chain Glycerides of Coconut Oil and Plastics from End-of-Life Vehicles. ACS Sustain. Chem. Eng. 2017, 5, 6237–6246. [Google Scholar] [CrossRef]

- Kurańska, M.; Barczewski, M.; Uram, K.; Lewandowski, K.; Prociak, A.; Michałowski, S. Basalt waste management in the production of highly effective porous polyurethane composites for thermal insulating applications. Polym. Test. 2019, 76, 90–100. [Google Scholar] [CrossRef]

- Kurańska, M.; Leszczyńska, M.; Kubacka, J.; Prociak, A.; Ryszkowska, J. Effects of Modified Used Cooking Oil on Structure and Properties of Closed-Cell Polyurethane foams. J. Polym. Environ. 2020, 28, 2780–2788. [Google Scholar] [CrossRef]

- Borowicz, M.; Paciorek-Sadowska, J.; Lubczak, J.; Czupryński, B. Biodegradable, flame-retardant, and bio-based rigid polyurethane/polyisocyanurate foams for thermal insulation application. Polymers 2019, 11, 1816. [Google Scholar] [CrossRef] [Green Version]

- Tang, G.; Zhou, L.; Zhang, P.; Han, Z.; Chen, D.; Liu, X.; Zhou, Z. Effect of aluminum diethylphosphinate on flame retardant and thermal properties of rigid polyurethane foam composites. J. Therm. Anal. Calorim. 2020, 140, 625–636. [Google Scholar] [CrossRef]

- Liu, X.; Salmeia, K.A.; Rentsch, D.; Hao, J.; Gaan, S. Thermal decomposition and flammability of rigid PU foams containing some DOPO derivatives and other phosphorus compounds. J. Anal. Appl. Pyrolysis 2017, 124, 219–229. [Google Scholar] [CrossRef] [Green Version]

- Wolska, A.; Goździkiewicz, M.; Ryszkowska, J. Influence of graphite and wood-based fillers on the flammability of flexible polyurethane foams. J. Mater. Sci. 2012, 47, 5693–5700. [Google Scholar] [CrossRef] [Green Version]

- Wolska, A.; Goździkiewicz, M.; Ryszkowska, J. Thermal and mechanical behaviour of flexible polyurethane foams modified with graphite and phosphorous fillers. J. Mater. Sci. 2012, 47, 5627–5634. [Google Scholar] [CrossRef] [Green Version]

- Schartel, B.; Wilkie, C.A.; Camino, G. Recommendations on the scientific approach to polymer flame retardancy: Part 2—Concepts. J. Fire Sci. 2017, 35, 3–20. [Google Scholar] [CrossRef]

- Zhao, B.; Liu, D.Y.; Liang, W.J.; Li, F.; Wang, J.S.; Liu, Y.Q. Bi-phase flame-retardant actions of water-blown rigid polyurethane foam containing diethyl-N,N-bis(2-hydroxyethyl) phosphoramide and expandable graphite. J. Anal. Appl. Pyrolysis 2017, 124, 247–255. [Google Scholar] [CrossRef]

- Li, L.; Chen, Y.; Qian, L.; Xu, B.; Xi, W. Addition flame-retardant effect of nonreactive phosphonate and expandable graphite in rigid polyurethane foams. J. Appl. Polym. Sci. 2018, 135, 45960. [Google Scholar] [CrossRef]

- Xi, W.; Qian, L.; Chen, Y.; Wang, J.; Liu, X. Addition flame-retardant behaviors of expandable graphite and [bis(2-hydroxyethyl)amino]-methyl-phosphonic acid dimethyl ester in rigid polyurethane foams. Polym. Degrad. Stab. 2015, 122, 36–43. [Google Scholar] [CrossRef]

- Kurańska, M.; Benes, H.; Sałasińska, K.; Prociak, A.; Malewska, E.; Polaczek, K. Development and Characterization of “Green Open-Cell Polyurethane Foams” with Reduced Flammability. Materials 2020, 13, 5459. [Google Scholar] [CrossRef]

- Makhlouf, G.; Hassan, M.; Nour, M.; Abdelmonem, Y.; Abdelkhalik, A. A Novel Intumescent Flame Retardant: Synthesis and Its Application for Linear Low-Density Polyethylene. Arab. J. Sci. Eng. 2017, 42, 4339–4349. [Google Scholar] [CrossRef]

- John, M.J. Flammability performance of biocomposites. In Green Composites for Automotive Applications; Koronis, G., Silva, A., Eds.; Elsevier Ltd.: New York, NY, USA, 2019; pp. 43–58. ISBN 9780081021774. [Google Scholar]

| Foam Symbol | RF-551 Polyol, g | 1.6Hex Bio-Polyol, g | Polycat® 218 Catalyst, g | L-6915 Surfactant, g | Total Water, g | PMDI Isocyanate, g | Flame Retardant, g |

|---|---|---|---|---|---|---|---|

| P_REF | 100 | 0 | 1.5 | 1.5 | 3.40 | 169.6 | 0 |

| P_TEP | 20 | ||||||

| P_DMPP | 20 | ||||||

| P_CT901 | 20 | ||||||

| 1.6Hex_REF | 60 | 40 | 1.5 | 1.5 | 3.23 | 148.0 | 0 |

| 1.6Hex_TEP | 20 | ||||||

| 1.6Hex_DMPP | 20 | ||||||

| 1.6Hex_CT901 | 20 |

| Foam Symbol | Number of Cells/1 mm2 | Average Cross-Sectional Area of Cells, mm2 ·103 | Anisotropy Index |

|---|---|---|---|

| P_REF | 40 ± 2 | 11.95 ± 0.89 | 1.23 ± 0.05 |

| P_TEP | 33 ± 3 | 12.22 ± 0.92 | 1.18 ± 0.03 |

| P_DMPP | 31 ± 2 | 15.29 ± 0.75 | 1.28 ± 0.06 |

| P_CT901 | 44 ± 4 | 10.98 ± 1.04 | 1.28 ± 0.07 |

| 1.6Hex_REF | 39 ± 2 | 12.89 ± 0.93 | 1.24 ± 0.05 |

| 1.6Hex_TEP | 39 ± 2 | 10.82 ± 0.73 | 1.04 ± 0.04 |

| 1.6Hex_DMPP | 34 ± 2 | 13.45 ± 0.64 | 1.10 ± 0.04 |

| 1.6Hex_CT901 | 57 ± 2 | 8.45 ± 0.84 | 1.18 ± 0.05 |

| Foam Symbol | Number of Cells/1 mm2 | Average Cross-Sectional Area of Cells, mm2 ·103 | Anisotropy Index |

|---|---|---|---|

| P_REF | 36 ± 2 | 14.19 ± 0.72 | 1.11 ± 0.03 |

| P_TEP | 40 ± 2 | 10.86 ± 0.84 | 1.07 ± 0.03 |

| P_DMPP | 38 ± 3 | 11.20 ± 0.85 | 1.00 ± 0.03 |

| P_CT901 | 58 ± 2 | 8.20 ± 0.74 | 1.04 ± 0.04 |

| 1.6Hex_REF | 50 ± 2 | 9.95 ± 0.86 | 1.04 ± 0.06 |

| 1.6Hex_TEP | 49 ± 3 | 8.32 ± 0.76 | 0.88 ± 0.02 |

| 1.6Hex_DMPP | 46 ± 2 | 9.02 ± 0.54 | 0.90 ± 0.03 |

| 1.6Hex_CT901 | 74 ± 2 | 5.98 ± 0.22 | 0.91 ± 0.02 |

| Foam Symbol | Apparent Density, kg/m3 | Content of Closed Cells, % | Water Absorption, vol% | Conductivity Coefficient, mW/m·K | Brittleness, % | Compression Strength, kPa | |

|---|---|---|---|---|---|---|---|

| Parallel | Perpendicular | ||||||

| P_REF | 39.8 ± 0.3 | 92.3 ± 1.3 | 5.9 ± 0.6 | 24.55 ± 0.33 | 3.89 ± 0.35 | 221.7 ± 7.8 | 174.8 ± 4.9 |

| P_TEP | 41.9 ± 0.1 | 90.8 ± 2.0 | 4.4 ± 0.2 | 25.51 ± 0.24 | 5.04 ± 0.15 | 216.5 ± 7.9 | 184.8 ± 4.9 |

| P_DMPP | 40.3 ± 1.3 | 91.3 ± 1.8 | 5.3 ± 0.4 | 25.69 ± 0.40 | 5.40 ± 0.56 | 211.0 ± 5.6 | 148.3 ± 3.5 |

| P_CT901 | 40.7 ± 1.0 | 93.5 ± 2.3 | 7.1 ± 0.9 | 25.15 ± 0.04 | 4.94 ± 0.12 | 241.0 ± 10.6 | 149.3 ± 6.2 |

| 1.6Hex_REF | 38.3 ± 0.3 | 93.1 ± 0.6 | 5.8 ± 0.1 | 25.35 ± 0.21 | 3.29 ± 0.38 | 210.3 ± 1.0 | 143.8 ± 9.8 |

| 1.6Hex_TEP | 41.6 ± 0.7 | 89.0 ± 2.0 | 5.6 ± 0.2 | 26.02 ± 0.17 | 4.28 ± 0.05 | 203.8 ± 5.9 | 153.5 ± 4.9 |

| 1.6Hex_DMPP | 41.1 ± 1.4 | 89.1 ± 2.1 | 6.8 ± 0.1 | 25.78 ± 0.27 | 4.35 ± 0.54 | 186.8 ± 9.5 | 131.0 ± 6.7 |

| 1.6Hex_CT901 | 38.8 ± 0.4 | 91.2 ± 1.2 | 9.6 ± 0.5 | 25.32 ± 0.27 | 5.05 ± 0.17 | 187.8 ± 6.4 | 87.6 ± 7.0 |

| Foam Symbol | THR, kJ/g | HRC, J/g·K | Temp. (1), °C a | Time (1), s b | PHRR (1), W/g c | Temp. (2), °C d | Time (2), s e | PHRR (2), W/g f |

|---|---|---|---|---|---|---|---|---|

| P_REF | 27.0 ± 0.5 | 251 ± 9 | 343 ± 8 | 304 ± 6 | 225.6 ± 9.5 | 496 ± 2 | 454 ± 7 | 36.0 ± 2.6 |

| P_TEP | 24.9 ± 0.6 | 209 ± 10 | 347 ± 5 | 309 ± 9 | 188.8 ± 9.8 | 501 ± 1 | 460 ± 6 | 50.8 ± 2.9 |

| P_DMPP | 25.7 ± 0.3 | 232 ± 6 | 347 ± 5 | 306 ± 2 | 211.7 ± 5.7 | 491 ± 4 | 442 ± 4 | 45.1 ± 5.7 |

| P_CT901 | 26.9 ± 0.5 | 281 ± 1 | 326 ± 1 | 289 ± 1 | 251.7 ± 0.9 | 495 ± 1 | 455 ± 1 | 56.3 ± 0.4 |

| 1.6Hex_REF | 29.7 ± 0.3 | 206 ± 6 | 327 ± 4 | 283 ± 7 | 187.5 ± 5.0 | 478 ± 1 | 431 ± 6 | 71.8 ± 9.5 |

| 1.6Hex_TEP | 27.3 ± 0.3 | 197 ± 9 | 332 ± 2 | 285 ± 6 | 185.6 ± 0.1 | 472 ± 6 | 441 ± 4 | 59.4 ± 3.6 |

| 1.6Hex_DMPP | 26.6 ± 0.6 | 189 ± 4 | 332 ± 6 | 287 ± 9 | 170.9 ± 2.5 | 483 ± 2 | 436 ± 3 | 67.8 ± 5.8 |

| 1.6Hex_CT901 | 25.8 ± 0.9 | 236 ± 6 | 330 ± 5 | 290 ± 9 | 212.8 ± 8.0 | 489 ± 1 | 436 ± 8 | 80.6 ± 8.1 |

| Foam Symbol | TTI, s | THR, MJ/m2 | PHRR, kW/m2 | Av-HRR, kW/m2 | MARHE, kW/m2 | Av-EHC, MJ/kg |

|---|---|---|---|---|---|---|

| P_REF | 5 ± 1 | 12.5 ± 0.7 | 206.5 ± 3.9 | 36.4 ± 0.6 | 137 ± 4 | 13.8 ± 0.8 |

| P_TEP | 5 ± 1 | 12.4 ± 0.5 | 203.3 ± 16.6 | 39.9 ± 3.7 | 122 ± 9 | 12.2 ± 0.5 |

| P_DMPP | 5 ± 1 | 7.9 ± 1.1 | 177.0 ± 6.3 | 20.4 ± 1.6 | 97 ± 4 | 7.3 ± 0.4 |

| P_CT901 | 4 ± 1 | 9.0 ± 0.2 | 171.2 ± 14.3 | 24.9 ± 1.3 | 106 ± 9 | 8.2 ± 0.6 |

| 1.6Hex_REF | 4 ± 1 | 11.9 ± 0.7 | 278.3 ± 16.8 | 35.3 ± 2.1 | 158 ± 3 | 13.6 ± 0.7 |

| 1.6Hex_TEP | 4 ± 1 | 11.1 ± 1.8 | 222.0 ± 21.4 | 35.0 ± 7.1 | 135 ± 10 | 11.4 ± 0.7 |

| 1.6Hex_DMPP | 4 ± 1 | 7.5 ± 0.4 | 173.2 ± 14.5 | 21.2 ± 1.6 | 99 ± 7 | 7.5 ± 0.4 |

| 1.6Hex_CT901 | 4 ± 1 | 8.6 ± 0.5 | 186.2 ± 9.6 | 25.4 ± 2.2 | 124 ± 8 | 8.4 ± 0.3 |

| Foam Symbol | TSR, m2/m2 | TSP, m2 | Av-COY, kg/kg | Av-CO2Y, kg/kg | CO/CO2 Weight Ratio | Residue, % |

|---|---|---|---|---|---|---|

| P_REF | 541 ± 44 | 4.78 ± 0.39 | 0.39 ± 0.02 | 3.46 ± 0.13 | 0.113 ± 0.006 | 22.2 ± 3.9 |

| P_TEP | 965 ± 43 | 8.53 ± 0.38 | 0.77 ± 0.06 | 2.68 ± 0.10 | 0.287 ± 0.027 | 14.6 ± 2.1 |

| P_DMPP | 796 ± 24 | 7.04 ± 0.21 | 0.86 ± 0.03 | 2.59 ± 0.10 | 0.332 ± 0.022 | 20.6 ± 2.0 |

| P_CT901 | 894 ± 61 | 7.90 ± 0.54 | 0.76 ± 0.03 | 2.55 ± 0.08 | 0.300 ± 0.011 | 18.6 ± 1.6 |

| 1.6Hex_REF | 547 ± 49 | 4.84 ± 0.44 | 0.40 ± 0.03 | 3.47 ± 0.12 | 0.116 ± 0.006 | 25.1 ± 1.4 |

| 1.6Hex_TEP | 849 ± 48 | 7.51 ± 0.43 | 0.69 ± 0.04 | 2.85 ± 0.14 | 0.242 ± 0.006 | 18.2 ± 1.3 |

| 1.6Hex_DMPP | 791 ± 39 | 6.99 ± 0.34 | 0.81 ± 0.02 | 2.46 ± 0.12 | 0.330 ± 0.008 | 22.7 ± 1.1 |

| 1.6Hex_CT901 | 811 ± 21 | 7.17 ± 0.19 | 0.73 ± 0.05 | 2.62 ± 0.12 | 0.279 ± 0.011 | 18.7 ± 2.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zemła, M.; Prociak, A.; Michałowski, S. Bio-Based Rigid Polyurethane Foams Modified with Phosphorus Flame Retardants. Polymers 2022, 14, 102. https://doi.org/10.3390/polym14010102

Zemła M, Prociak A, Michałowski S. Bio-Based Rigid Polyurethane Foams Modified with Phosphorus Flame Retardants. Polymers. 2022; 14(1):102. https://doi.org/10.3390/polym14010102

Chicago/Turabian StyleZemła, Marcin, Aleksander Prociak, and Sławomir Michałowski. 2022. "Bio-Based Rigid Polyurethane Foams Modified with Phosphorus Flame Retardants" Polymers 14, no. 1: 102. https://doi.org/10.3390/polym14010102

APA StyleZemła, M., Prociak, A., & Michałowski, S. (2022). Bio-Based Rigid Polyurethane Foams Modified with Phosphorus Flame Retardants. Polymers, 14(1), 102. https://doi.org/10.3390/polym14010102