A Review of Polymer Composites Based on Carbon Fillers for Thermal Management Applications: Design, Preparation, and Properties

Abstract

1. Introduction

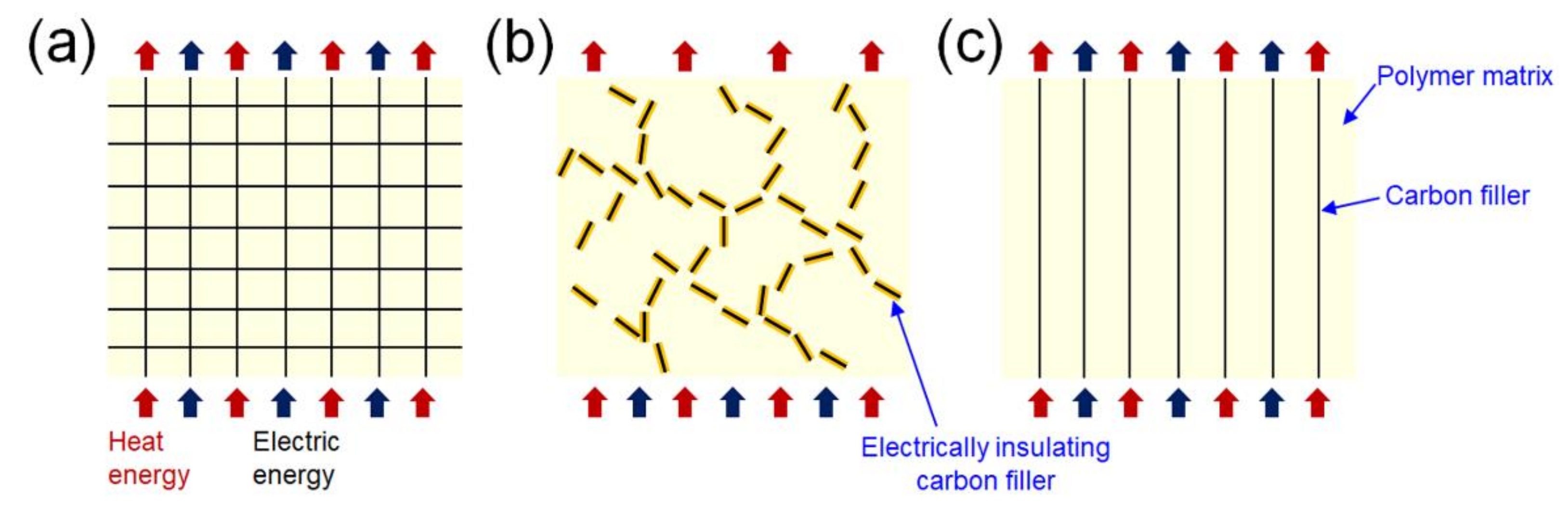

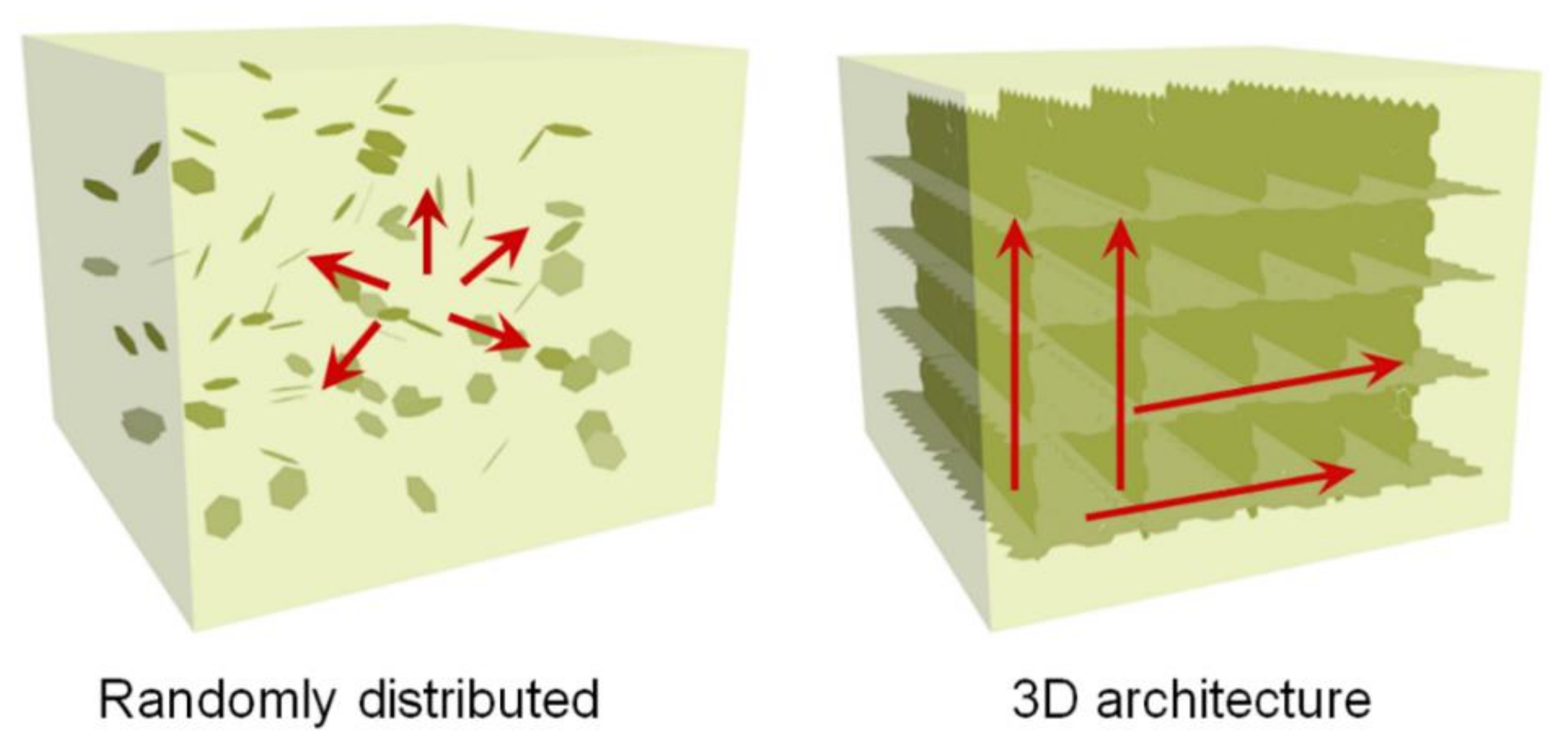

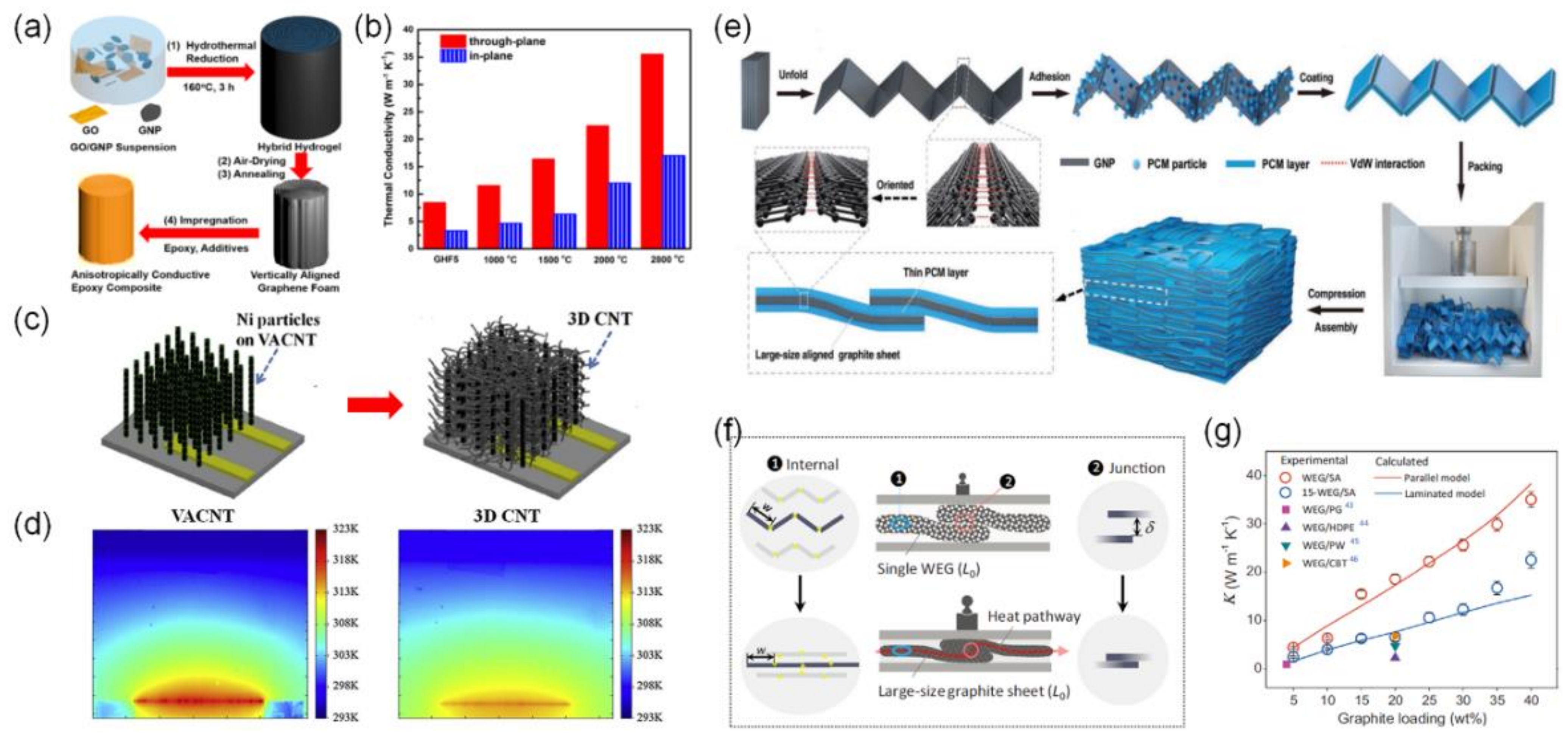

2. Polymer Composites with a Continuous 3D Architecture of Carbon Fillers

3. Polymer Composites with Thermally Conductive Yet Electrically Insulating Carbon Fillers

4. Polymer Composites with Vertically Aligned Carbon Fillers

5. Stability of the Thermal Conductivity Performance of Polymer Composites

6. Conclusions and Future Outlooks

- The construction of a continuous 3D networked structure with carbon fillers is a promising approach for the fabrication of thermally conductive polymer composites with a small amount of filler loading. To obtain the 3D networked carbon structures, graphene aerogels, CNT arrays, and expanded graphite have been developed. Many scientists mentioned that the most important factors for determining the thermal conductivity of a 3D carbon network-based composites are the quality and density of the carbon 3D network. To satisfy both requirements, new approaches for the hydrothermal reduction of 3D carbon frameworks in the presence of the thermally conductive carbon fillers in powder form have been proposed;

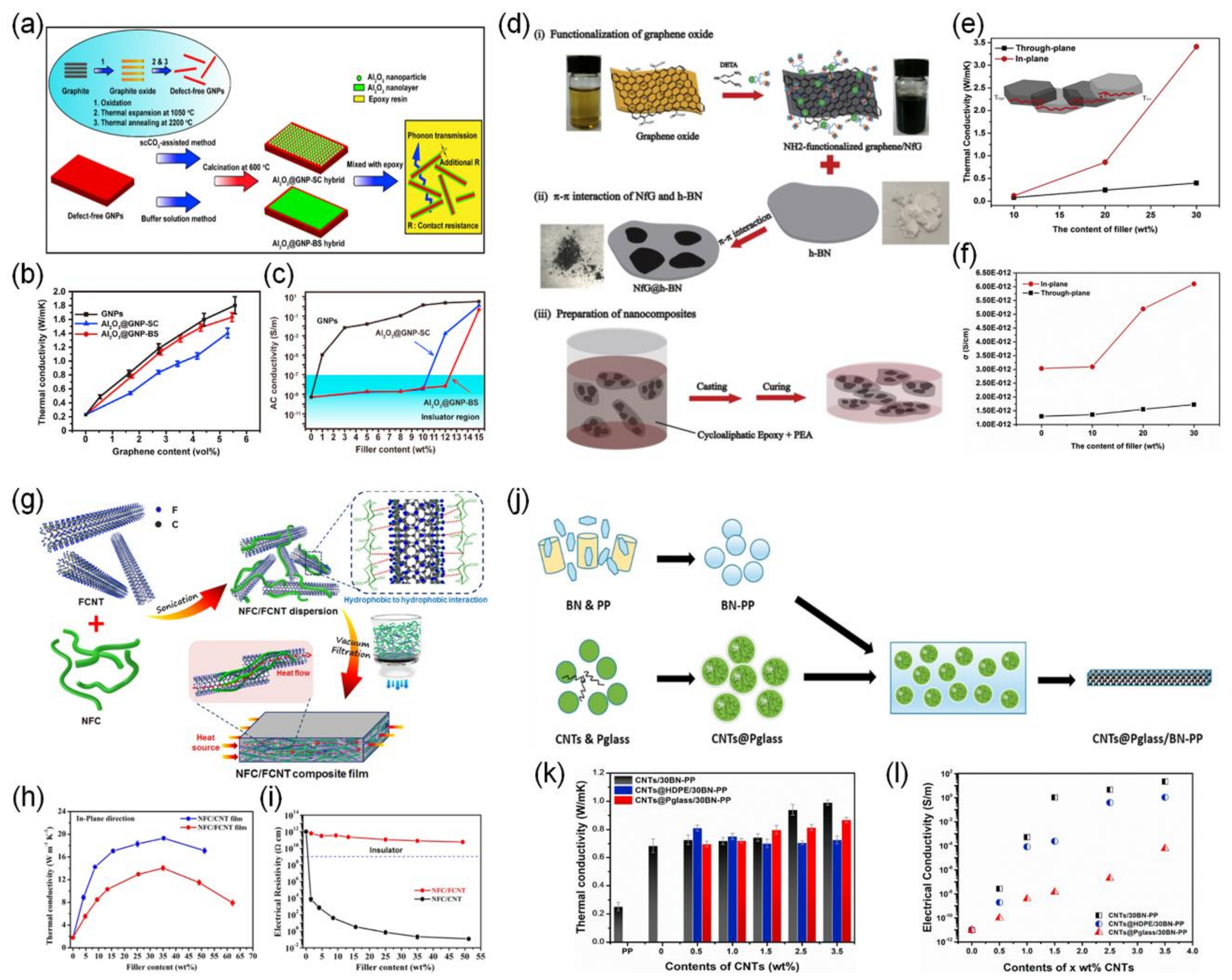

- Although nanocarbon fillers have ultrahigh thermal conductivity, they have been limited in use on various electronic parts because of their high electrical conductivity. We introduced some papers on the development of thermally conductive yet electrically insulating carbon fillers, including the coating and hybridization of carbon materials with other nanomaterials, band gap tuning, and the morphological control of carbon fillers in polymer composites. In general, nanocarbon fillers have been coated and hybridized with inorganic materials such as MgO, SiO2, Al2O3, and BN to prevent the formation of electrically conductive networks. Through these approaches, thermally conductive composite materials can be applied to various electronic parts requiring electrical insulation, such as electronic circuit boards;

- Some electronic parts request heat dissipation in the thickness direction rather than the surface direction, depending on the working mechanism and structure of the electronic product. However, in general, the thermally conductive polymer composites in the film formation have much lower through-plane thermal conductivities than the in-plane thermal conductivities. Therefore, we introduced research on the vertical alignment of carbon fillers in the polymer matrix. Although these studies have recently been started, some composite materials with high through-plane thermal conductivities were developed through various processing techniques, such as electrostatic flocking, 3D printing, and directional freeze drying of the nanocarbons;

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, Z.; Liu, G.; Khan, J.M.; Balandin, A.A. Graphene quilts for thermal management of high-power GaN transistors. Nat. Commun. 2012, 3, 1–8. [Google Scholar] [CrossRef] [PubMed]

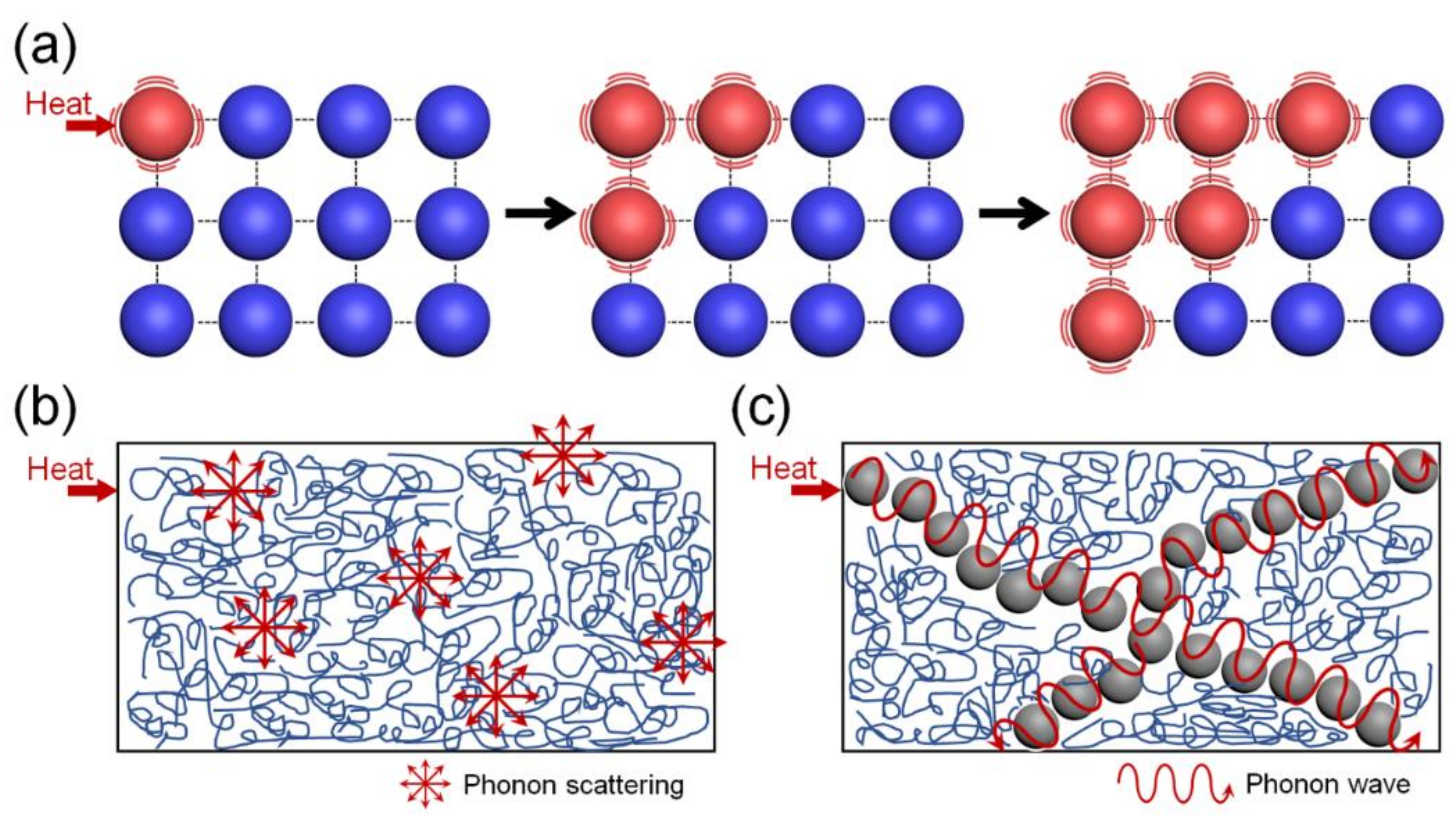

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Ma, D.; Arora, A.; Deng, S.; Xie, G.; Shiomi, J.; Yang, N. Quantifying phonon particle and wave transport in silicon nanophononic metamaterial with cross junction. Mater. Today Phys. 2019, 8, 56–61. [Google Scholar] [CrossRef]

- Kim, H.S.; Jang, J.-U.; Lee, H.; Kim, S.Y.; Kim, S.H.; Kim, J.; Jung, Y.C.; Yang, B.J. Thermal Management in Polymer Composites: A Review of Physical and Structural Parameters. Adv. Eng. Mater. 2018, 20, 1800204. [Google Scholar] [CrossRef]

- Zhang, F.; Feng, Y.; Feng, W. Three-dimensional interconnected networks for thermally conductive polymer composites: Design, preparation, properties, and mechanisms. Mater. Sci. Eng. R Rep. 2020, 142, 100580. [Google Scholar] [CrossRef]

- Li, T.-L.; Hsu, S.L.-C. Enhanced Thermal Conductivity of Polyimide Films via a Hybrid of Micro- and Nano-Sized Boron Nitride. J. Phys. Chem. B 2010, 114, 6825–6829. [Google Scholar] [CrossRef]

- Firdaus, S.M.; Mariatti, M. Fabrication and characterization of nano filler-filled epoxy composites for underfill application. J. Mater. Sci. Mater. Electron. 2012, 23, 1293–1299. [Google Scholar] [CrossRef]

- Liu, K.; Takagi, H.; Osugi, R.; Yang, Z. Effect of physicochemical structure of natural fiber on transverse thermal conductivity of unidirectional abaca/bamboo fiber composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1234–1241. [Google Scholar] [CrossRef]

- Chung, D.D.L. Materials for thermal conduction. Appl. Therm. Eng. 2001, 21, 1593–1605. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, H.L.; Wu, J.H.; Wang, X.T. Enhanced thermal conductivity in copper matrix composites reinforced with titanium-coated diamond particles. Scr. Mater. 2011, 65, 1097–1100. [Google Scholar] [CrossRef]

- Hammerstroem, D.W.; Burgers, M.A.; Chung, S.W.; Gulliants, E.A.; Bunker, C.E.; Wentz, K.M.; Hayes, S.E.; Buckner, S.W.; Jelliss, P.A. Aluminum Nanoparticles Capped by Polymerization of Alkyl-Substituted Epoxides: Ratio-Dependent Stability and Particle Size. Inorg. Chem. 2011, 50, 5054–5059. [Google Scholar] [CrossRef] [PubMed]

- Afanasov, I.M.; Savchenko, D.V.; Ionov, S.G.; Rusakov, D.A.; Seleznev, A.N.; Avdeev, V.V. Thermal conductivity and mechanical properties of expanded graphite. Inorg. Mater. 2009, 45, 486–490. [Google Scholar] [CrossRef]

- Wang, S.; Downes, R.; Young, C.; Haldane, D.; Hao, A.; Liang, R.; Wang, B.; Zhang, C.; Maskell, R. Carbon Fiber/Carbon Nanotube Buckypaper Interply Hybrid Composites: Manufacturing Process and Tensile Properties. Adv. Eng. Mater. 2015, 17, 1442–1453. [Google Scholar] [CrossRef]

- Yu, A.; Ramesh, P.; Sun, X.; Bekyarova, E.; Itkis, M.E.; Haddon, R.C. Enhanced Thermal Conductivity in a Hybrid Graphite Nanoplatelet—Carbon Nanotube Filler for Epoxy Composites. Adv. Mater. 2008, 20, 4740–4744. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior Thermal Conductivity of Single-Layer Graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Li, A.; Zhang, C.; Zhang, Y.-F. Thermal Conductivity of Graphene-Polymer Composites: Mechanisms, Properties, and Applications. Polymers 2017, 9, 437. [Google Scholar]

- Han, Z.; Fina, A. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: A review. Prog. Polym. Sci. 2011, 36, 914–944. [Google Scholar] [CrossRef]

- Shen, S.; Henry, A.; Tong, J.; Zheng, R.; Chen, G. Polyethylene nanofibres with very high thermal conductivities. Nat. Nanotechnol. 2010, 5, 251–255. [Google Scholar] [CrossRef]

- Wang, X.; Ho, V.; Segalman, R.A.; Cahill, D.G. Thermal Conductivity of High-Modulus Polymer Fibers. Macromolecules 2013, 46, 4937–4943. [Google Scholar] [CrossRef]

- Yang, J.; Li, X.; Han, S.; Yang, R.; Min, P.; Yu, Z.-Z. High-quality graphene aerogels for thermally conductive phase change composites with excellent shape stability. J. Mater. Chem. A 2018, 6, 5880–5886. [Google Scholar] [CrossRef]

- Yang, J.; Qi, G.-Q.; Liu, Y.; Bao, R.-Y.; Liu, Z.-Y.; Yang, W.; Xie, B.-H.; Yang, M.-B. Hybrid graphene aerogels/phase change material composites: Thermal conductivity, shape-stabilization and light-to-thermal energy storage. Carbon 2016, 100, 693–702. [Google Scholar] [CrossRef]

- Zhao, Y.-H.; Zhang, Y.-F.; Wu, Z.-K.; Bai, S.-L. Synergic enhancement of thermal properties of polymer composites by graphene foam and carbon black. Compos. Part B Eng. 2016, 84, 52–58. [Google Scholar] [CrossRef]

- An, F.; Li, X.; Min, P.; Liu, P.; Jiang, Z.-G.; Yu, Z.-Z. Vertically Aligned High-Quality Graphene Foams for Anisotropically Conductive Polymer Composites with Ultrahigh Through-Plane Thermal Conductivities. ACS Appl. Mater. Interfaces 2018, 10, 17383–17392. [Google Scholar] [CrossRef] [PubMed]

- Kong, Q.; Bodelot, L.; Lebental, B.; Lim, Y.D.; Shiau, L.L.; Gusarov, B.; Tan, C.W.; Liang, K.; Lu, C.; Tan, C.S.; et al. Novel three-dimensional carbon nanotube networks as high performance thermal interface materials. Carbon 2018, 132, 359–369. [Google Scholar] [CrossRef]

- Wu, S.; Li, T.; Tong, Z.; Chao, J.; Zhai, T.; Xu, J.; Yan, T.; Wu, M.; Xu, Z.; Bao, H.; et al. High-Performance Thermally Conductive Phase Change Composites by Large-Size Oriented Graphite Sheets for Scalable Thermal Energy Harvesting. Adv. Mater. 2019, 31, 1905099. [Google Scholar] [CrossRef]

- Chandu, B.; Kurmarayuni, C.M.; Kurapati, S.; Bollikolla, H.B. Green and economical synthesis of graphene–silver nanocomposite exhibiting excellent photocatalytic efficiency. Carbon Lett. 2020, 30, 225–233. [Google Scholar] [CrossRef]

- Ivanov, I.; Puretzky, A.; Eres, G.; Wang, H.; Pan, Z.; Cui, H.; Jin, R.; Howe, J.; Geohegan, D.B. Fast and highly anisotropic thermal transport through vertically aligned carbon nanotube arrays. Appl. Phys. Lett. 2006, 89, 223110. [Google Scholar] [CrossRef]

- Wang, Z.L.; Tang, D.W.; Zheng, X.H.; Zhang, W.G.; Zhu, Y.T. Length-dependent thermal conductivity of single-wall carbon nanotubes: Prediction and measurements. Nanotechnology 2007, 18, 475714. [Google Scholar] [CrossRef]

- Li, C.; Tan, L.-Y.; Zeng, X.-L.; Zhu, D.-L.; Sun, R.; Xu, J.-B.; Wong, C.-P. Polymer composites with high thermal conductivity optimized by polyline-folded graphite paper. Compos. Sci. Technol. 2020, 188, 107970. [Google Scholar] [CrossRef]

- Dai, W.; Ma, T.; Yan, Q.; Gao, J.; Tan, X.; Lv, L.; Hou, H.; Wei, Q.; Yu, J.; Wu, J.; et al. Metal-Level Thermally Conductive yet Soft Graphene Thermal Interface Materials. ACS Nano 2019, 13, 11561–11571. [Google Scholar] [CrossRef]

- Keshtkar, M.; Mehdipour, N.; Eslami, H. Thermal Conductivity of Polyamide-6,6/Carbon Nanotube Composites: Effects of Tube Diameter and Polymer Linkage between Tubes. Polymers 2019, 11, 1465. [Google Scholar] [CrossRef]

- Hu, T.; Song, Y.; Di, J.; Xie, D.; Teng, C. Highly thermally conductive layered polymer composite from solvent-exfoliated pristine graphene. Carbon 2018, 140, 596–602. [Google Scholar] [CrossRef]

- Zhang, J.; Du, Z.; Zou, W.; Li, H.; Zhang, C. MgO nanoparticles-decorated carbon fibers hybrid for improving thermal conductive and electrical insulating properties of Nylon 6 composite. Compos. Sci. Technol. 2017, 148, 1–8. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, M.; Seong, H.-G.; Jung, J.Y.; Baeck, S.-H.; Shim, S.E. Roles of silica-coated layer on graphite for thermal conductivity, heat dissipation, thermal stability, and electrical resistivity of polymer composites. Polymer 2018, 148, 295–302. [Google Scholar] [CrossRef]

- Sun, R.; Yao, H.; Zhang, H.-B.; Li, Y.; Mai, Y.-W.; Yu, Z.-Z. Decoration of defect-free graphene nanoplatelets with alumina for thermally conductive and electrically insulating epoxy composites. Compos. Sci. Technol. 2016, 137, 16–23. [Google Scholar] [CrossRef]

- Su, Z.; Wang, H.; Tian, K.; Huang, W.; Xiao, C.; Guo, Y.; He, J.; Tian, X. The combination of π-π interaction and covalent bonding can synergistically strengthen the flexible electrical insulating nanocomposites with well adhesive properties and thermal conductivity. Compos. Sci. Technol. 2018, 155, 1–10. [Google Scholar] [CrossRef]

- Shen, Z.; Feng, J. Highly in-Plane Thermally Conductive Composite Films from Hexagonal Boron Nitride Microplatelets Assembled with Graphene Oxide. ACS Appl. Nano Mater. 2018, 1, 94–100. [Google Scholar] [CrossRef]

- Wang, X.; Wu, P. Fluorinated Carbon Nanotube/Nanofibrillated Cellulose Composite Film with Enhanced Toughness, Superior Thermal Conductivity, and Electrical Insulation. ACS Appl. Mater. Interfaces 2018, 10, 34311–34321. [Google Scholar] [CrossRef]

- Vu, M.C.; Thieu, N.A.T.; Lim, J.-H.; Choi, W.-K.; Won, J.C.; AkhtarulIslam, M.; Kim, S.-R. Ultrathin thermally conductive yet electrically insulating exfoliated graphene fluoride film for high performance heat dissipation. Carbon 2020, 157, 741–749. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Deng, H.; Jing, Y.; Fu, Q. Enhanced thermal conductivity and electrical insulation properties of polymer composites via constructing Pglass/CNTs confined hybrid fillers. Compos. Part A Appl. Sci. Manuf. 2018, 115, 1–7. [Google Scholar] [CrossRef]

- Morishita, T.; Katagiri, Y.; Matsunaga, T.; Muraoka, Y.; Fukumori, K. Design and fabrication of morphologically controlled carbon nanotube/polyamide-6-based composites as electrically insulating materials having enhanced thermal conductivity and elastic modulus. Compos. Sci. Technol. 2017, 142, 41–49. [Google Scholar] [CrossRef]

- Feng, W.; Long, P.; Feng, Y.; Li, Y. Two-Dimensional Fluorinated Graphene: Synthesis, Structures, Properties and Applications. Adv. Sci. 2016, 3, 1500413. [Google Scholar] [CrossRef] [PubMed]

- Uetani, K.; Ata, S.; Tomonoh, S.; Yamada, T.; Yumura, M.; Hata, K. Elastomeric Thermal Interface Materials with High Through-Plane Thermal Conductivity from Carbon Fiber Fillers Vertically Aligned by Electrostatic Flocking. Adv. Mater. 2014, 26, 5857–5862. [Google Scholar] [CrossRef] [PubMed]

- Jung, H.; Yu, S.; Bae, N.-S.; Cho, S.M.; Kim, R.H.; Cho, S.H.; Hwang, I.; Jeong, B.; Ryu, J.S.; Hwang, J.; et al. High Through-Plane Thermal Conduction of Graphene Nanoflake Filled Polymer Composites Melt-Processed in an L-Shape Kinked Tube. ACS Appl. Mater. Interfaces 2015, 7, 15256–15262. [Google Scholar] [CrossRef] [PubMed]

- Han, D.; Zhao, Y.-H.; Zhang, Y.-F.; Bai, S.-L. Vertically and compactly rolled-up reduced graphene oxide film/epoxy composites: A two-stage reduction method for graphene-based thermal interfacial materials. RSC Adv. 2015, 5, 94426–94435. [Google Scholar] [CrossRef]

- Jia, Y.; He, H.; Geng, Y.; Huang, B.; Peng, X. High through-plane thermal conductivity of polymer based product with vertical alignment of graphite flakes achieved via 3D printing. Compos. Sci. Technol. 2017, 145, 55–61. [Google Scholar] [CrossRef]

- Zhang, Y.-F.; Ren, Y.-J.; Bai, S.-L. Vertically aligned graphene film/epoxy composites as heat dissipating materials. Int. J. Heat Mass Transf. 2018, 118, 510–517. [Google Scholar] [CrossRef]

- Lian, G.; Tuan, C.-C.; Li, L.; Jiao, S.; Wang, Q.; Moon, K.-S.; Cui, D.; Wong, C.-P. Vertically Aligned and Interconnected Graphene Networks for High Thermal Conductivity of Epoxy Composites with Ultralow Loading. Chem. Mater. 2016, 28, 6096–6104. [Google Scholar] [CrossRef]

- Li, X.-H.; Liu, P.; Li, X.; An, F.; Min, P.; Liao, K.-N.; Yu, Z.-Z. Vertically aligned, ultralight and highly compressive all-graphitized graphene aerogels for highly thermally conductive polymer composites. Carbon 2018, 140, 624–633. [Google Scholar] [CrossRef]

- Ha, Y.-M.; Kim, Y.N.; Kim, Y.-O.; So, C.; Lee, J.-S.; Kim, J.; Jung, Y.C. Enhanced mechanical properties and thermal conductivity of polyimide nanocomposites incorporating individualized boron-doped graphene. Carbon Lett. 2020, 30, 457–464. [Google Scholar] [CrossRef]

- Hou, X.; Chen, Y.; Dai, W.; Wang, Z.; Li, H.; Lin, C.-T.; Nishimura, K.; Jiang, N.; Yu, J. Highly thermal conductive polymer composites via constructing microphragmites communis structured carbon fibers. Chem. Eng. J. 2019, 375, 121921. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, Y.; Li, Y.; Dai, W.; Yan, Q.; Alam, F.E.; Du, S.; Wang, Z.; Nishimura, K.; Jiang, N.; et al. Graphene foam-embedded epoxy composites with significant thermal conductivity enhancement. Nanoscale 2019, 11, 17600–17606. [Google Scholar] [CrossRef]

| Fillers | Matrix | Filler Loading | k (W·m−1·K−1) | Enhancement in k (%) | References |

|---|---|---|---|---|---|

| Graphen eaerogel | 1-octadecanol | 5.0 wt% | 4.28 | 94.5% | [20] |

| GO/GNP hybrid aerogel | PEG | 0.45/1.8 wt% | 1.43 | 361% | [21] |

| CVD graphene network with CB | PDMS | 8 wt% | 0.686 | 222% | [22] |

| GO/GNP hybrid foam | Epoxy | 19.0 vol% | 35.5 | 884% | [23] |

| 3D CNT network | - | - | 5.40 | - | [24] |

| Expended graphite | Stearic acid | 40.0 wt% | 35.0 | - | [25] |

| Fillers | Matrix | Filler Loading | k (W·m−1·K−1) | Enhancement in k (%) | Refs |

|---|---|---|---|---|---|

| CF-MgO | Nylon 6 | 20 wt% | 0.748 | - | [33] |

| silica@graphite | TPEE | 30 vol% | 1.44 | - | [34] |

| Al2O3@GNP | epoxy | 12 wt% | 1.49 | 667% | [35] |

| NfG@h-BN | epoxy | 30 wt% | 3.409 | - | [36] |

| GO | BN | 50 wt% | 10.3 | - | [37] |

| FCNT | NFCs | 35 wt% | 14.1 | 729% | [38] |

| EGF | - | - | 242 | - | [39] |

| CNTs@Pglass/BN | PP | 3.5 wt% | 0.87 | - | [40] |

| MWCNT | PA6 | 1 vol% | 0.433 | - | [41] |

| Fillers | Matrix | Filler Loading | k (W·m−1·K−1) | Enhancement in k (%) | References |

|---|---|---|---|---|---|

| CF | Rubber | 13.2 wt% | 8.9 | 10,986% | [43] |

| GNF | PVDF | 25 vol% | 10.19 | - | [44] |

| GO | Epoxy | 15.79 wt% | 2.645 | 887% | [45] |

| Graphite | PA6/POE-g-MAH/PS | 10 wt% | 5.5 | - | [46] |

| Graphene | Epoxy | 44 vol% | 384.9 | 3570% | [47] |

| GO | Epoxy | 0.92 vol% | 2.13 | 1231% | [48] |

| GO | Epoxy | 1.5 wt% | 6.57 | 5890% | [49] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwon, Y.-J.; Park, J.-B.; Jeon, Y.-P.; Hong, J.-Y.; Park, H.-S.; Lee, J.-U. A Review of Polymer Composites Based on Carbon Fillers for Thermal Management Applications: Design, Preparation, and Properties. Polymers 2021, 13, 1312. https://doi.org/10.3390/polym13081312

Kwon Y-J, Park J-B, Jeon Y-P, Hong J-Y, Park H-S, Lee J-U. A Review of Polymer Composites Based on Carbon Fillers for Thermal Management Applications: Design, Preparation, and Properties. Polymers. 2021; 13(8):1312. https://doi.org/10.3390/polym13081312

Chicago/Turabian StyleKwon, Yeon-Ju, Jung-Bin Park, Young-Pyo Jeon, Jin-Yong Hong, Ho-Seok Park, and Jea-Uk Lee. 2021. "A Review of Polymer Composites Based on Carbon Fillers for Thermal Management Applications: Design, Preparation, and Properties" Polymers 13, no. 8: 1312. https://doi.org/10.3390/polym13081312

APA StyleKwon, Y.-J., Park, J.-B., Jeon, Y.-P., Hong, J.-Y., Park, H.-S., & Lee, J.-U. (2021). A Review of Polymer Composites Based on Carbon Fillers for Thermal Management Applications: Design, Preparation, and Properties. Polymers, 13(8), 1312. https://doi.org/10.3390/polym13081312