Effect of Cu Ions Implantation on Structural, Electronic, Optical and Dielectric Properties of Polymethyl Methacrylate (PMMA)

Abstract

1. Introduction

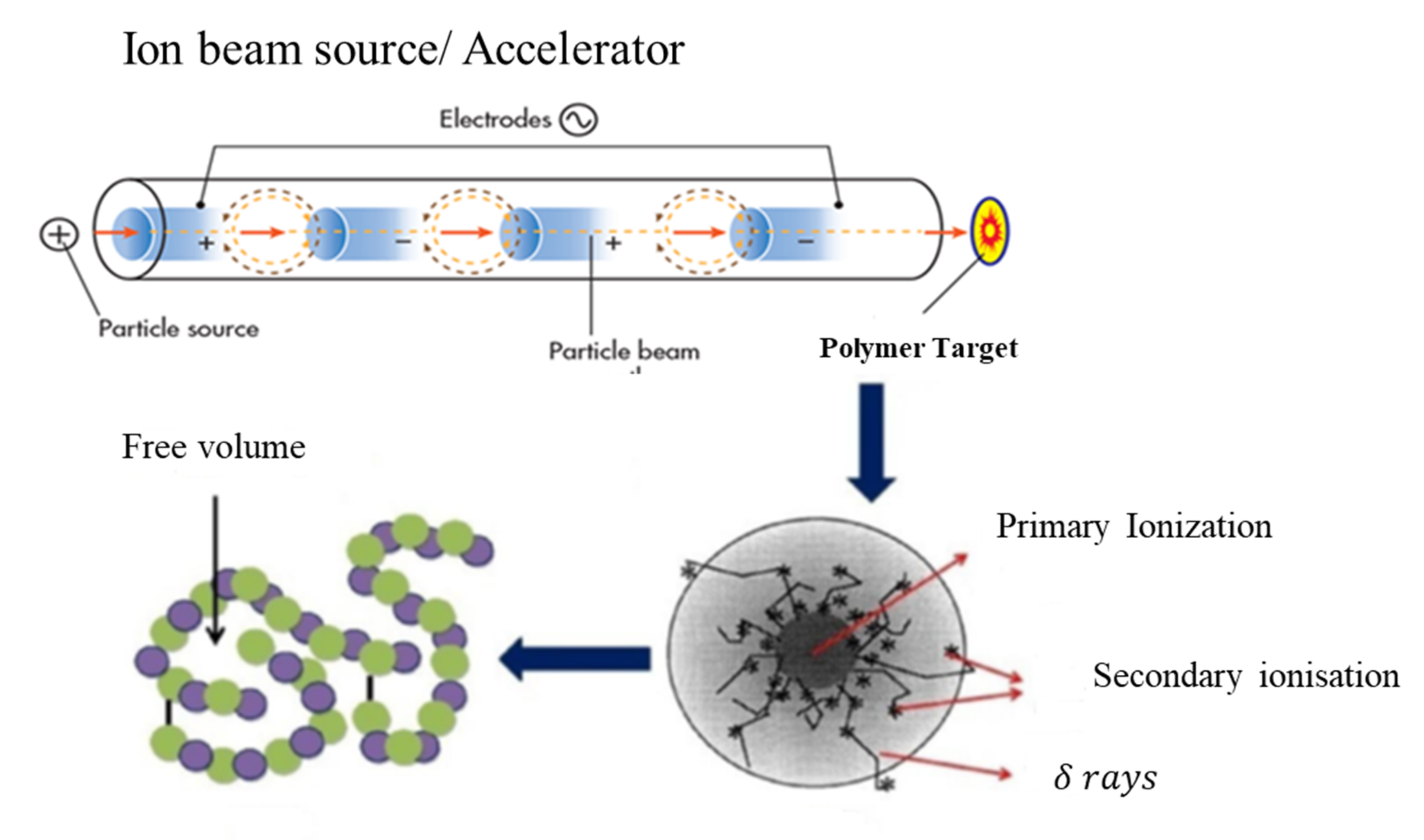

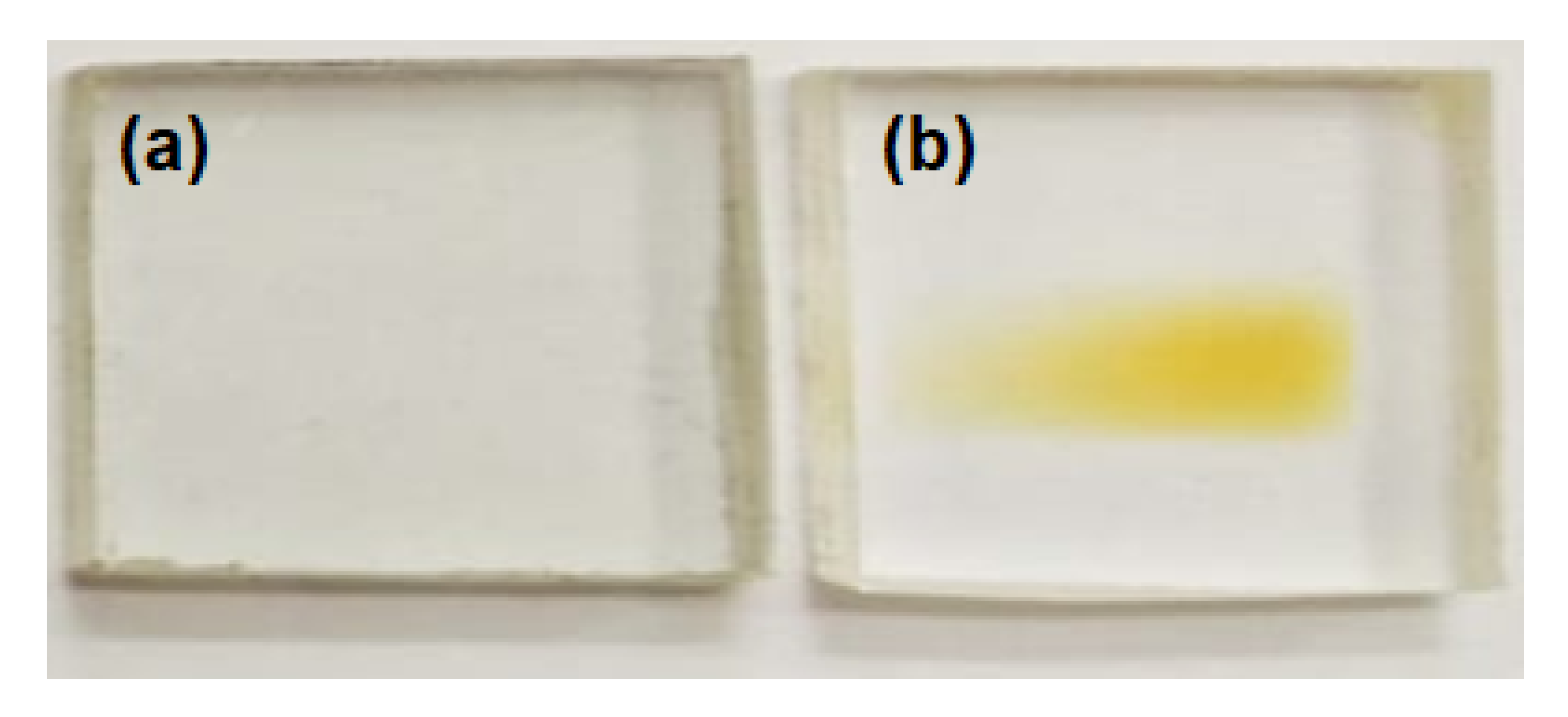

2. Experimental Setup

Characterization

3. Results and Discussion

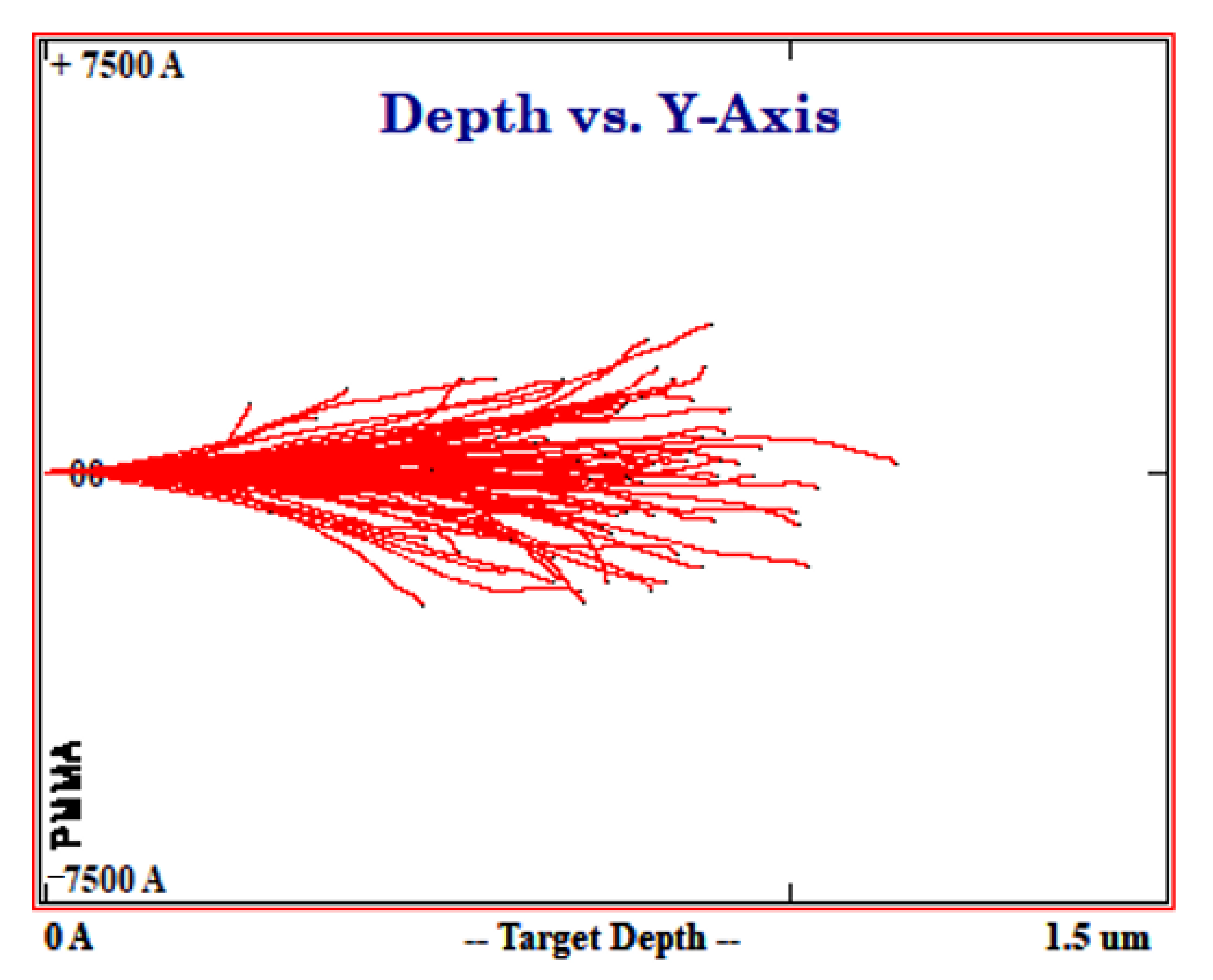

3.1. SRIM Analysis

3.2. X-ray Diffractometer Analysis

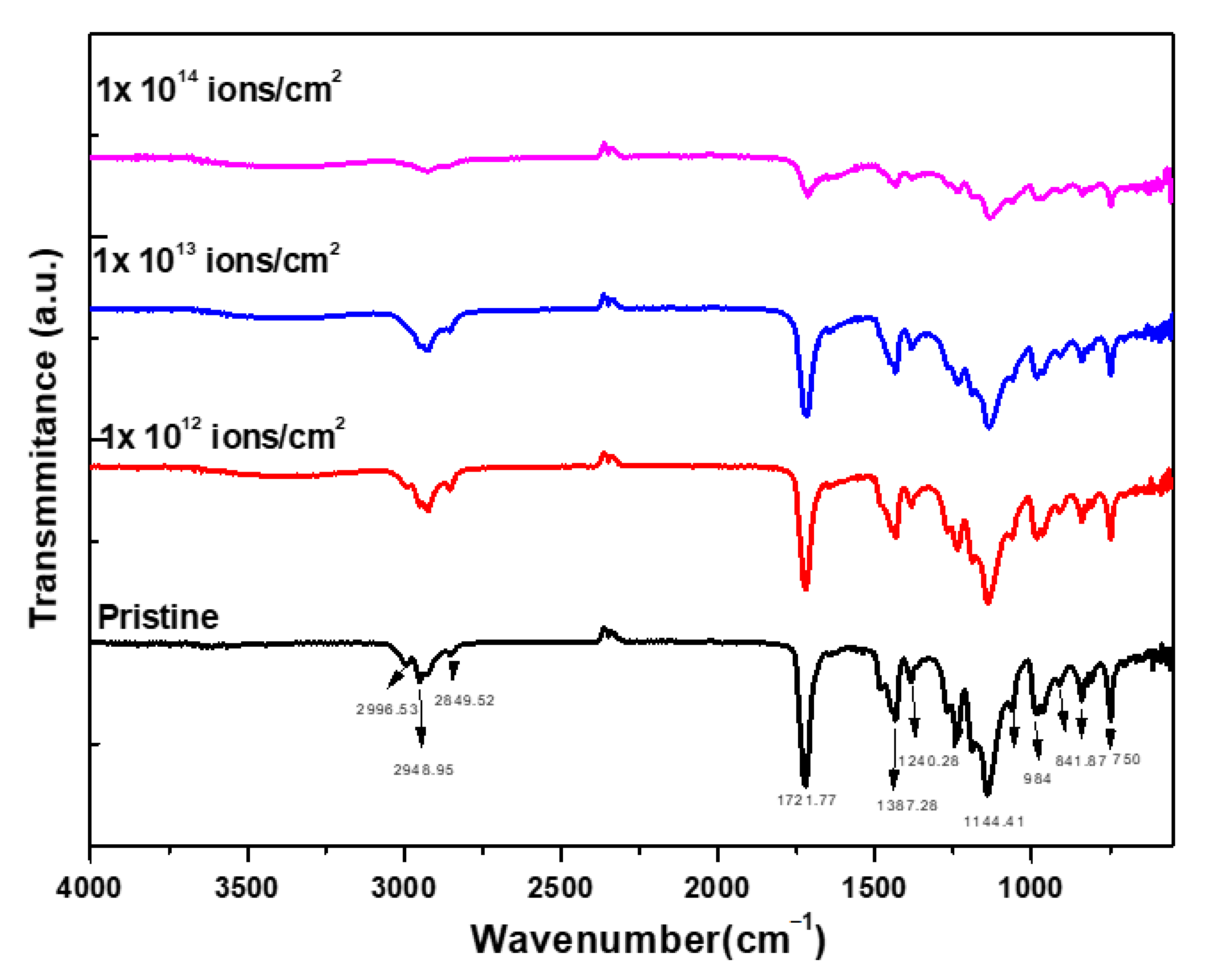

3.3. FTIR Analysis

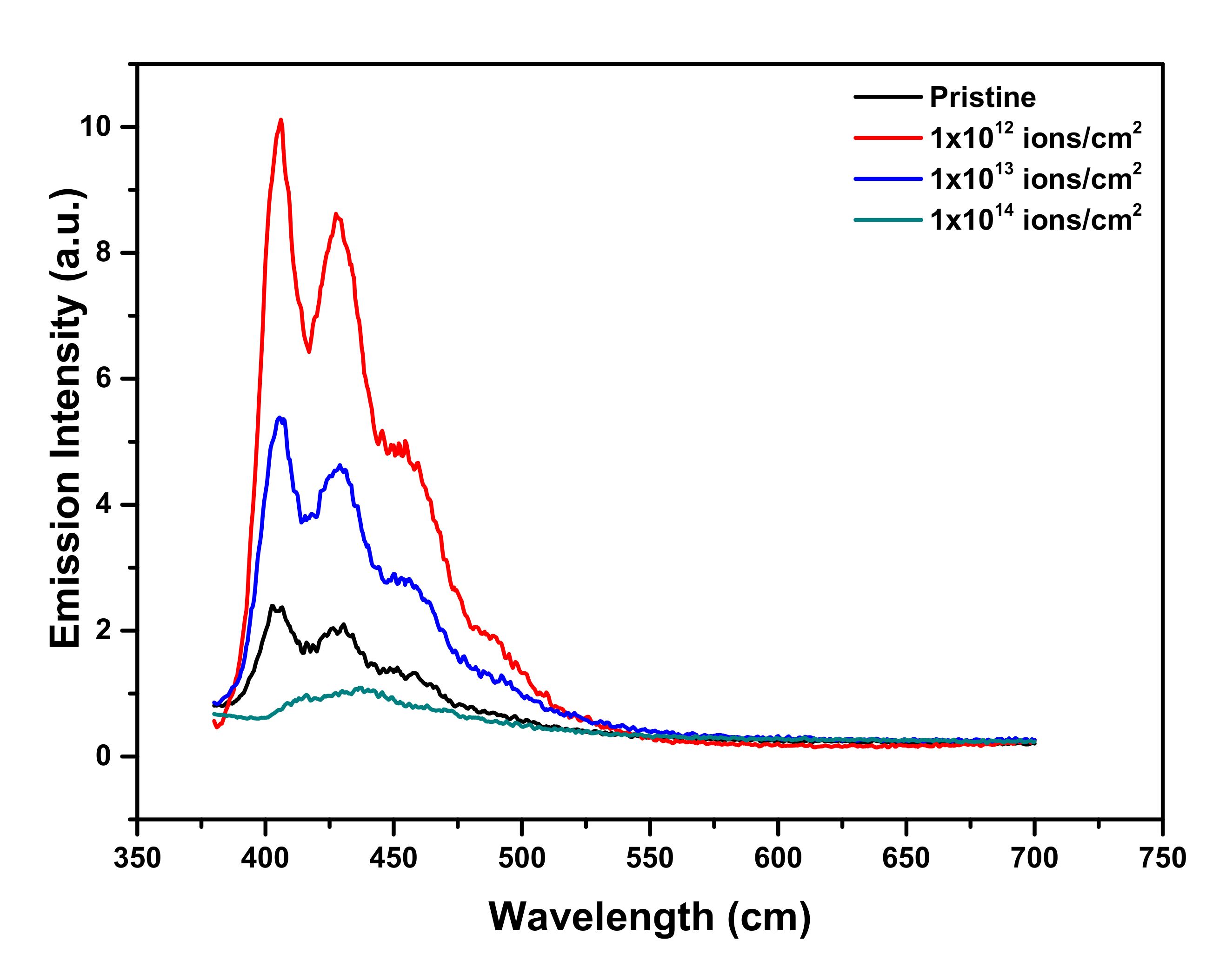

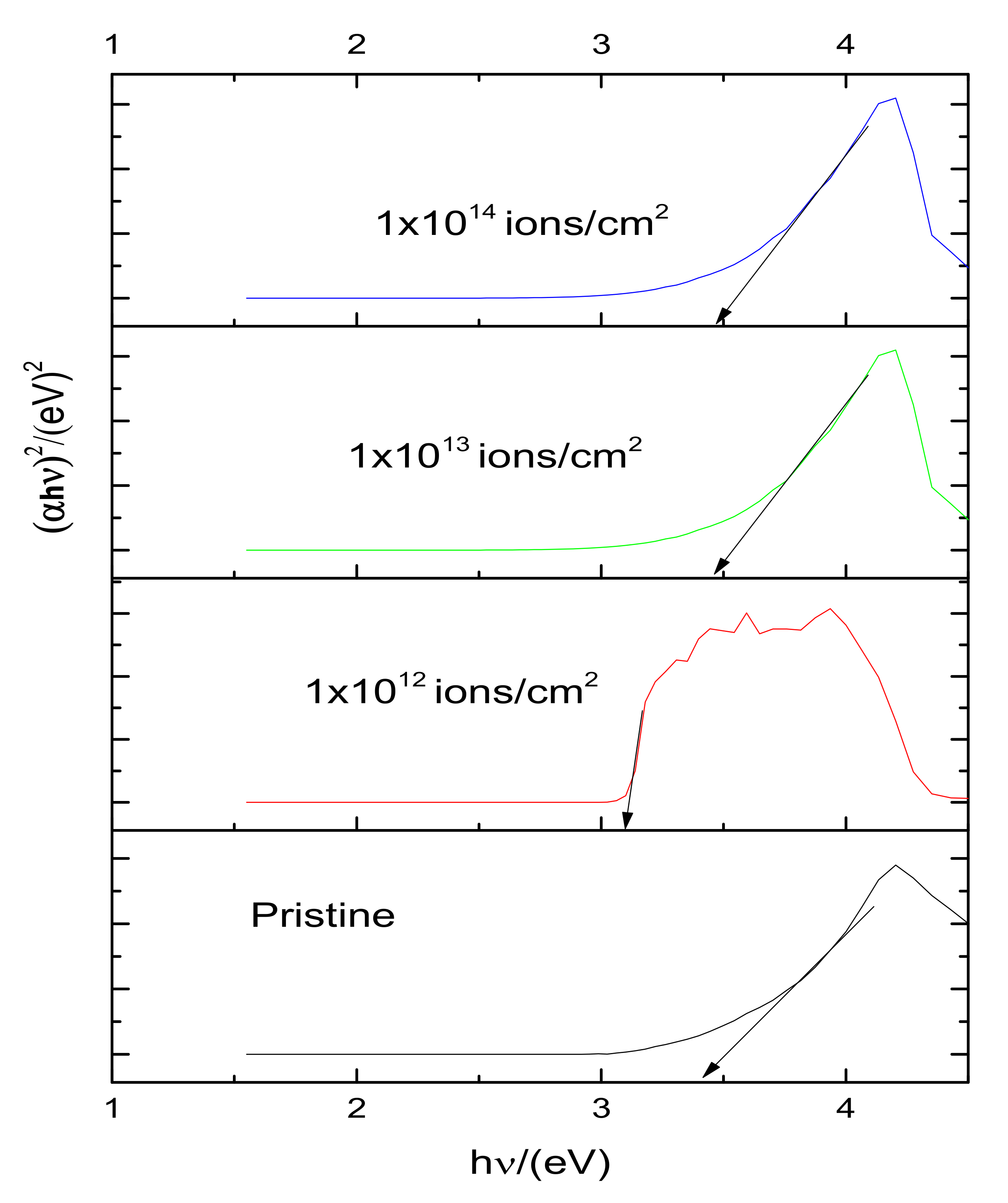

3.4. Photoluminescence and UV-Vis Analysis

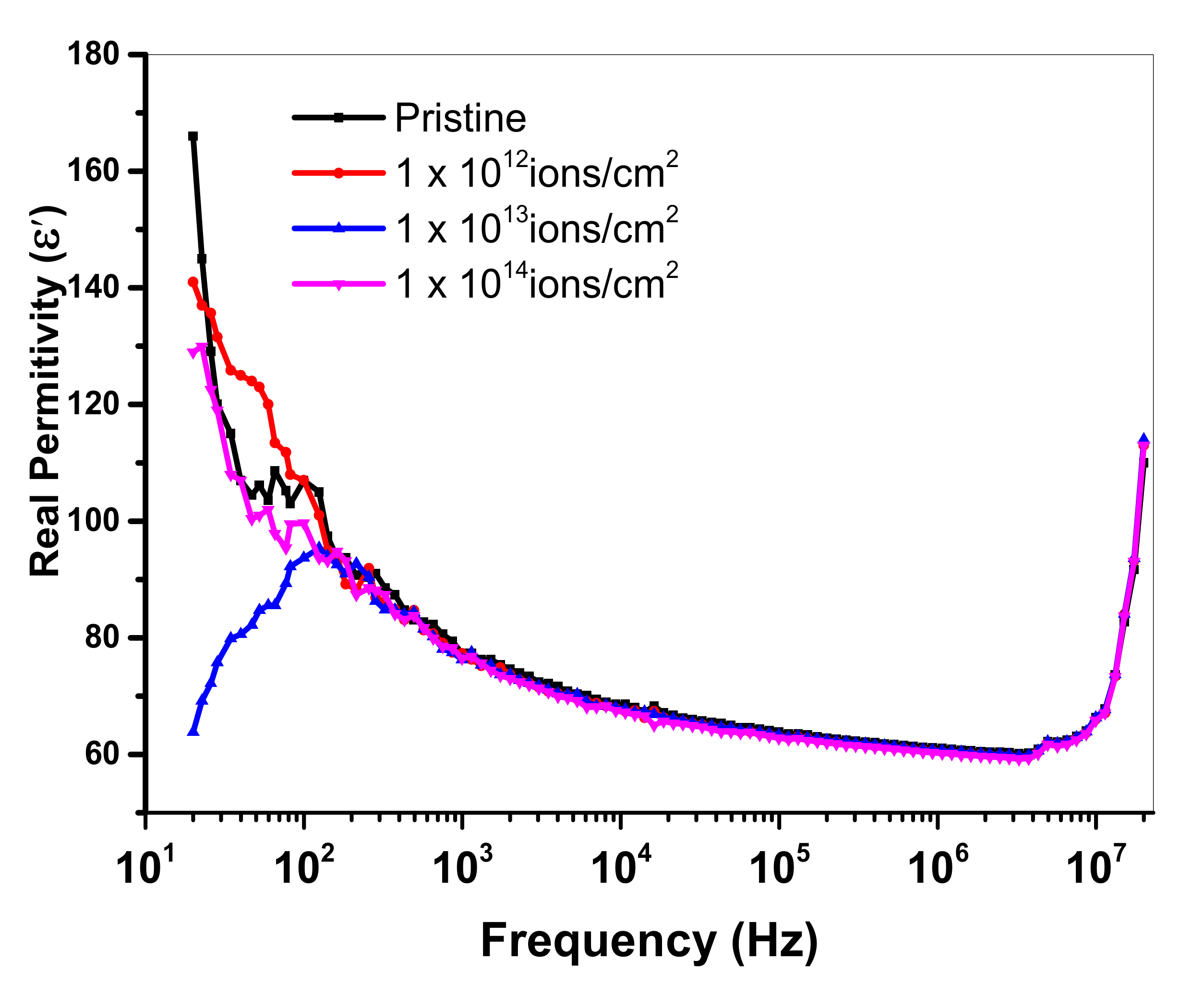

3.5. Dielectric Measurements

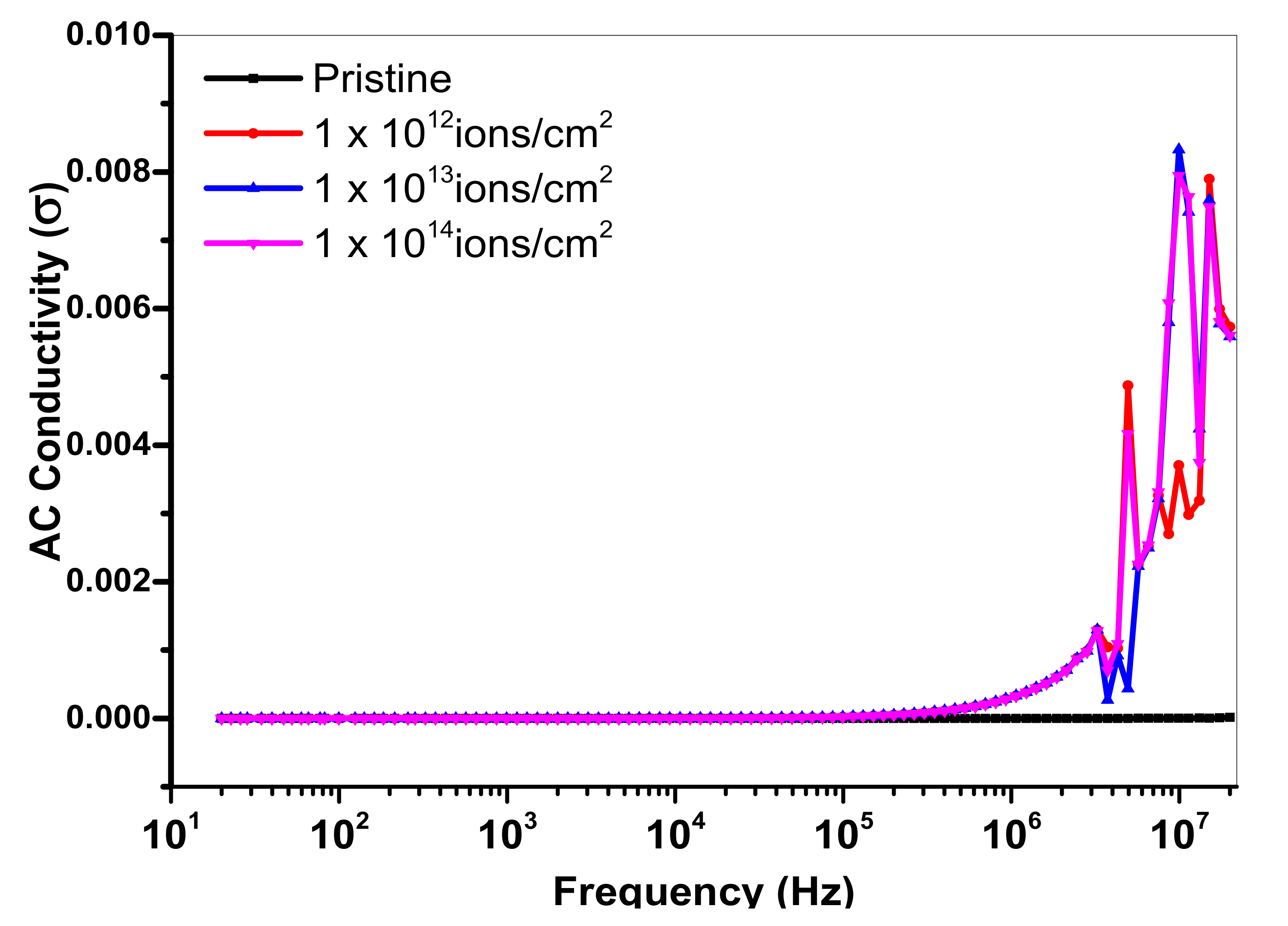

3.6. AC Conductivity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- El-Badry, B.A.; Zaki, M.; Abdul-Kader, A.; Hegazy, T.M.; Morsy, A.A. Ion bombardment of poly-allyl-diglycol-carbonate (CR-39). Vacuum 2009, 83, 1138–1142. [Google Scholar] [CrossRef]

- Charrier, J.-M. Polymeric Materials and Processing: Plastics, Elastomers, and Composites; Carl Hanser Verlag GmbH & Co: Munich, Germany, 1991. [Google Scholar]

- Popok, V. Ion implantation of polymers: Formation of nanoparticulate materials. Rev. Adv. Mater. Sci. 2012, 30, 1. [Google Scholar]

- Du, W.; Slaný, M.; Wang, X.; Chen, G.; Zhang, J. The inhibition property and mechanism of a novel low molecular weight zwitterionic copolymer for improving wellbore stability. Polymers 2020, 12, 708. [Google Scholar] [CrossRef] [PubMed]

- Shah, S.; Qureshi, A.; Singh, N.L.; Kulriya, P.K.; Singh, K.P.; Avasthi, D.K. Structural and chemical modification of polymer composite by proton irradiation. Surf. Coat. Technol. 2009, 203, 2595. [Google Scholar] [CrossRef]

- Kosobrodova, E.; Kondyurin, A.; Chrzanowski, W.; McCulloch, D.G.; McKenzie, D.R.; Bilek, M.M. Optical properties and oxidation of carbonized and cross-linked structures formed in polycarbonate by plasma immersion ion implantation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2014, 329, 52–63. [Google Scholar] [CrossRef]

- Mondal, S.; Das, S.; Nandi, A.K. A review on recent advances in polymer and peptide hydrogels. Soft Matter 2020, 16, 1404. [Google Scholar] [CrossRef] [PubMed]

- Nathawat, R.; Kumar, A.; Kulshrestha, V.; Vijay, Y.K.; Kobayashi, T.; Kanjilal, D. Study of surface activation of PET by low energy (keV) Ni+ and N+ ion implantation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2008, 266, 4749–4756. [Google Scholar] [CrossRef]

- Allayarov, S.R.; Olkhov, Y.A.; Dixon, D.A.; Allayarov, R.S. Influence of Accelerated Protons on the Molecular–Topological Structure of Polyethylene. High Energy Chem. 2020, 54, 368. [Google Scholar] [CrossRef]

- Pirker, L.; Krajnc, A.P.; Malec, J.; Radulović, V.; Gradišek, A.; Jelen, A.; Remškar, M.; Mekjavić, I.B.; Kovač, J.; Mozetič, M.; et al. Sterilization of polypropylene membranes of facepiece respirators by ionizing radiation. J. Membr. Sci. 2020, 619, 118756. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Ali, S.A.; Singh, P.; De, U.; Virk, H.S.; Prasad, R. Physical and chemical response of 145 MeV Ne6+ ion irradiated polymethylmethacrylate (PMMA) polymer. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2011, 269, 1755–1759. [Google Scholar] [CrossRef]

- Hadjichristov, G.B.; Ivanov, V.; Faulques, E. Reflectivity modification of polymethylmethacrylate by silicon ion implantation. Appl. Surf. Sci. 2008, 254, 4820. [Google Scholar] [CrossRef]

- Ueda, M.; Kostov, K.G.; Beloto, A.F.; Leite, N.F.; Grigorov, K.G. Surface modification of polyethylene terephthalate by plasma immersion ion implantation. Surf. Coat. Technol. 2004, 186, 295. [Google Scholar] [CrossRef]

- Shekhawat, N.; Aggarwal, S.; Sharma, A.; Sharma, S.K.; Deshpande, S.K.; Nair, K.G. Surface disordering and its correlations with properties in argon implanted CR-39 polymer. J. Appl. Phys. 2011, 109, 083513. [Google Scholar] [CrossRef]

- Zhang, Q.; Yoon, S.; Ahn, J.; Rusli; Yang, H.; Yang, C.; Watt, F.; Teo, E.; Osipowice, T. Effects of high energetic He+ ion irradiation on the structure of polymeric hydrogenated amorphous carbon. Microelectron. J. 1999, 30, 801. [Google Scholar] [CrossRef]

- Ma, L.; Zhu, Y.; Feng, P.; Song, G.; Huang, Y.; Liu, H.; Zhang, J.; Fan, J.; Hou, H.; Guo, Z. Reinforcing carbon fiber epoxy composites with triazine derivatives functionalized graphene oxide modified sizing agent. Compos. Part B Eng. 2019, 176, 107078. [Google Scholar] [CrossRef]

- Dhillon, R.K.; Singh, P.; Gupta, S.K.; Singh, S.; Kumar, R. Study of high energy (MeV) N6+ ion and gamma radiation induced modifications in low density polyethylene (LDPE) polymer. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2013, 301, 12. [Google Scholar] [CrossRef]

- Rai, V.; Mukherjee, C.; Jain, B. UV-Vis and FTIR spectroscopy of gamma irradiated polymethyl methacrylate. Indian J. Pure Appl. Phys. 2017, 55, 775. [Google Scholar]

- Öchsner, R.; Kluge, A.; Zechel-Malonn, S.; Gong, L.; Ryssel, H. Improvement of surface properties of polymers by ion implantation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 1993, 80, 1050. [Google Scholar] [CrossRef]

- Stepanov, A.L.; Popok, V.N.; Khaibullin, I.B.; Kreibig, U. Optical properties of polymethylmethacrilate with implanted silver nanoparticles. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2002, 191, 473. [Google Scholar] [CrossRef]

- Boldyryeva, H.; Umeda, N.; Plaksin, O.A.; Takeda, Y.; Kishimoto, N. High-fluence implantation of negative metal ions into polymers for surface modification and nanoparticle formation. Surf. Coat. Technol. 2005, 196, 373. [Google Scholar] [CrossRef]

- Umeda, N.; Bandourko, V.V.; Vasilets, V.N.; Kishimoto, N. Metal precipitation process in polymers induced by ion implantation of 60 keV Cu−. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2003, 206, 657. [Google Scholar] [CrossRef]

- Sangeetha, R.; Madheswari, D.; Priya, G. Fabrication of poly (methyl methacrylate)/Ce/Cu substituted apatite/Egg white (Ovalbumin) biocomposite owning adjustable properties: Towards bone tissue rejuvenation. J. Photochem. Photobiol. B Biol. 2018, 187, 162. [Google Scholar] [CrossRef]

- Kumar, V.; Sonkawade, R.G.; Dhaliwal, A.S. High electronic excitation induced modifications by 100 MeV O7+ and 150 MeV Ni11+ ions in Makrofol KG polycarbonate film. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2012, 287, 4. [Google Scholar] [CrossRef]

- Mikšová, R.; Macková, A.; Pupikova, H.; Malinský, P.; Slepička, P.; Švorčík, V. Compositional, structural, and optical changes of polyimide implanted by 1.0 MeV Ni+ ions. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2017, 406, 199. [Google Scholar] [CrossRef]

- Goyal, P.K.; Kumar, V.; Gupta, R.; Mahendia, S.; Kumar, S. Modification of polycarbonate surface by Ar+ ion implantation for various opto-electronic applications. Vacuum 2012, 86, 1087. [Google Scholar] [CrossRef]

- Popok, V.N.; Azarko, I.I.; Odzhaev, V.B.; Tóth, A.; Khaibullin, R.I. High fluence ion beam modification of polymer surfaces: EPR and XPS studies. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2001, 178, 305. [Google Scholar] [CrossRef]

- Arif, S.; Rafique, M.S.; Saleemi, F.; Naab, F.; Toader, O.; Sagheer, R.; Bashir, S.; Zia, R.; Siraj, K.; Iqbal, S. Surface topographical and structural analysis of Ag+-implanted polymethylmethacrylate. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2016, 381, 114. [Google Scholar] [CrossRef]

- Sharma, A.; Chawla, M.; Gupta, D.; Bura, M.; Shekhawat, N.; Aggarwal, S. Low energy B+ implantation induced optical and structural characteristics of aliphatic and aromatic polymers. Vacuum 2019, 159, 306. [Google Scholar] [CrossRef]

- Popok, V.N.; Nuzhdin, V.I.; Valeev, V.F.; Stepanov, A.L. Copper nanoparticles synthesized in polymers by ion implantation: Surface morphology and optical properties of the nanocomposites. J. Mater. Res. 2015, 30, 86. [Google Scholar] [CrossRef]

- Banerjee, S.; Deka, M.; Kumar, A.; De, U. Ion Irradiation Effects in some Electro-Active and Engineering Polymers Studies by Conventional and Novel Techniques. Defect Diffus. Forum 2013, 341, 1. [Google Scholar] [CrossRef]

- Tuleushev, A.Z.; Harrison, F.E.; Kozlovskiy, A.L.; Zdorovets, M.V. Assessment of the Irradiation Exposure of PET Film with Swift Heavy Ions Using the Interference-Free Transmission UV-Vis Transmission Spectra. Polymers 2021, 3, 358. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Biersack, J.P.; Ziegler, M.D. The Stopping and Range of Ions in Solids, SRIM Software. 2008. Available online: http://www.srim.org/ (accessed on 1 January 2008).

- Lovell, R.; Windle, A.H. Determination of the local conformation of PMMA from wide-angle X-ray scattering. Polymer 1981, 22, 175. [Google Scholar] [CrossRef]

- Ravindrachary, V.; Bhajantri, R.F.; Praveena, S.D.; Poojary, B.; Dutta, D.; Pujari, P.K. Optical and microstructural studies on electron irradiated PMMA: A positron annihilation study. Polym. Degrad. Stab. 2010, 95, 1083. [Google Scholar]

- Slany, M.; Jankovic, L.; Madejova, J. Structural characterization of organo-montmorillonites prepared from a series of primary alkylamines salts: Mid-IR and near-IR study. Appl. Clay Sci. 2019, 176, 11. [Google Scholar] [CrossRef]

- Sugitani, M. Ion implantation technology and ion sources. Rev. Sci. Instrum. 2014, 85, C315. [Google Scholar] [CrossRef] [PubMed]

- Rajesh, K.; Crasta, V.; Kumar, N.R.; Shetty, G.; Rekha, P.D. Structural, optical, mechanical and dielectric properties of titanium dioxide doped PVA/PVP nanocomposite. J. Polym. Res. 2019, 26, 1. [Google Scholar] [CrossRef]

- Mahendia, S.; Tomar, A.K.; Kumar, S. Nano-Ag doping induced changes in optical and electrical behaviour of PVA films. Mater. Sci. Eng. B 2011, 176, 530. [Google Scholar] [CrossRef]

- Bhajantri, R.F.; Ravindrachary, V.; Harisha, A.; Crasta, V.; Nayak, S.P.; Poojary, B. Microstructural studies on BaCl2 doped poly (vinyl alcohol). Polymer 2006, 47, 3591. [Google Scholar] [CrossRef]

- Kumar, N.R.; Crasta, V.; Praveen, B.M. Dielectric and electric conductivity studies of PVA (Mowiol 10-98) doped with MWCNTs and WO3 nanocomposites films. Mater. Res. Express 2016, 3, 055012. [Google Scholar] [CrossRef]

- Blout, E.R.; Fields, M. Absorption Spectra. V. The Ultraviolet and Visible Spectra of Certain Polyene Aldehydes and Polyene Azines1. J. Am. Chem. Soc. 1948, 70, 189. [Google Scholar] [CrossRef]

- Hesse, M.; Meier, H.; Zeeh, B.; Hesse, M.; Meier, H.; Zeeh, B. Spectroscopic Methods in Organic Chemistry; Thieme Publishing Group: Stuttgart, Germany, 2007. [Google Scholar]

- Phang, S.W.; Tadokoro, M.; Watanabe, J.; Kuramoto, N. Synthesis, characterization and microwave absorption property of doped polyaniline nanocomposites containing TiO2 nanoparticles and carbon nanotubes. Synth. Met. 2008, 158, 251. [Google Scholar] [CrossRef]

| PMMA Samples | Fluence (ions/cm2) |

|---|---|

| PMMA 1 | 0 |

| PMMA 2 | 1 × 1012 |

| PMMA 3 | 1 × 1013 |

| PMMA 4 | 1 × 1014 |

| Band Position | Wave Number (cm−1) |

|---|---|

| C-H asymmetric stretching | 2996.53 |

| C-H symmetric stretching | 2948.95 |

| CH2 stretching vibration | 2853.07 |

| C=O stretching vibration | 1721.77 |

| C-H bending vibration | 1387.28 |

| C-O stretching vibration | 1240.28 |

| C-O-CH3 | 9984.00 |

| O-CH3 | 901.53 |

| CH2 | 841.87 |

| C-C | 750.26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akhtar, A.N.; Murtaza, G.; Shafique, M.A.; Haidyrah, A.S. Effect of Cu Ions Implantation on Structural, Electronic, Optical and Dielectric Properties of Polymethyl Methacrylate (PMMA). Polymers 2021, 13, 973. https://doi.org/10.3390/polym13060973

Akhtar AN, Murtaza G, Shafique MA, Haidyrah AS. Effect of Cu Ions Implantation on Structural, Electronic, Optical and Dielectric Properties of Polymethyl Methacrylate (PMMA). Polymers. 2021; 13(6):973. https://doi.org/10.3390/polym13060973

Chicago/Turabian StyleAkhtar, Athar N., G. Murtaza, M. Ahsan Shafique, and Ahmed S. Haidyrah. 2021. "Effect of Cu Ions Implantation on Structural, Electronic, Optical and Dielectric Properties of Polymethyl Methacrylate (PMMA)" Polymers 13, no. 6: 973. https://doi.org/10.3390/polym13060973

APA StyleAkhtar, A. N., Murtaza, G., Shafique, M. A., & Haidyrah, A. S. (2021). Effect of Cu Ions Implantation on Structural, Electronic, Optical and Dielectric Properties of Polymethyl Methacrylate (PMMA). Polymers, 13(6), 973. https://doi.org/10.3390/polym13060973