Abstract

There is an astonishing number of optoelectronic, photonic, biological, sensing, or storage media devices, just to name a few, that rely on a variety of extraordinary periodic surface relief miniaturized patterns fabricated on polymer-covered rigid or flexible substrates. Even more extraordinary is that these surface relief patterns can be further filled, in a more or less ordered fashion, with various functional nanomaterials and thus can lead to the realization of more complex structured architectures. These architectures can serve as multifunctional platforms for the design and the development of a multitude of novel, better performing nanotechnological applications. In this work, we aim to provide an extensive overview on how multifunctional structured platforms can be fabricated by outlining not only the main polymer patterning methodologies but also by emphasizing various deposition methods that can guide different structures of functional nanomaterials into periodic surface relief patterns. Our aim is to provide the readers with a toolbox of the most suitable patterning and deposition methodologies that could be easily identified and further combined when the fabrication of novel structured platforms exhibiting interesting properties is targeted.

1. Introduction

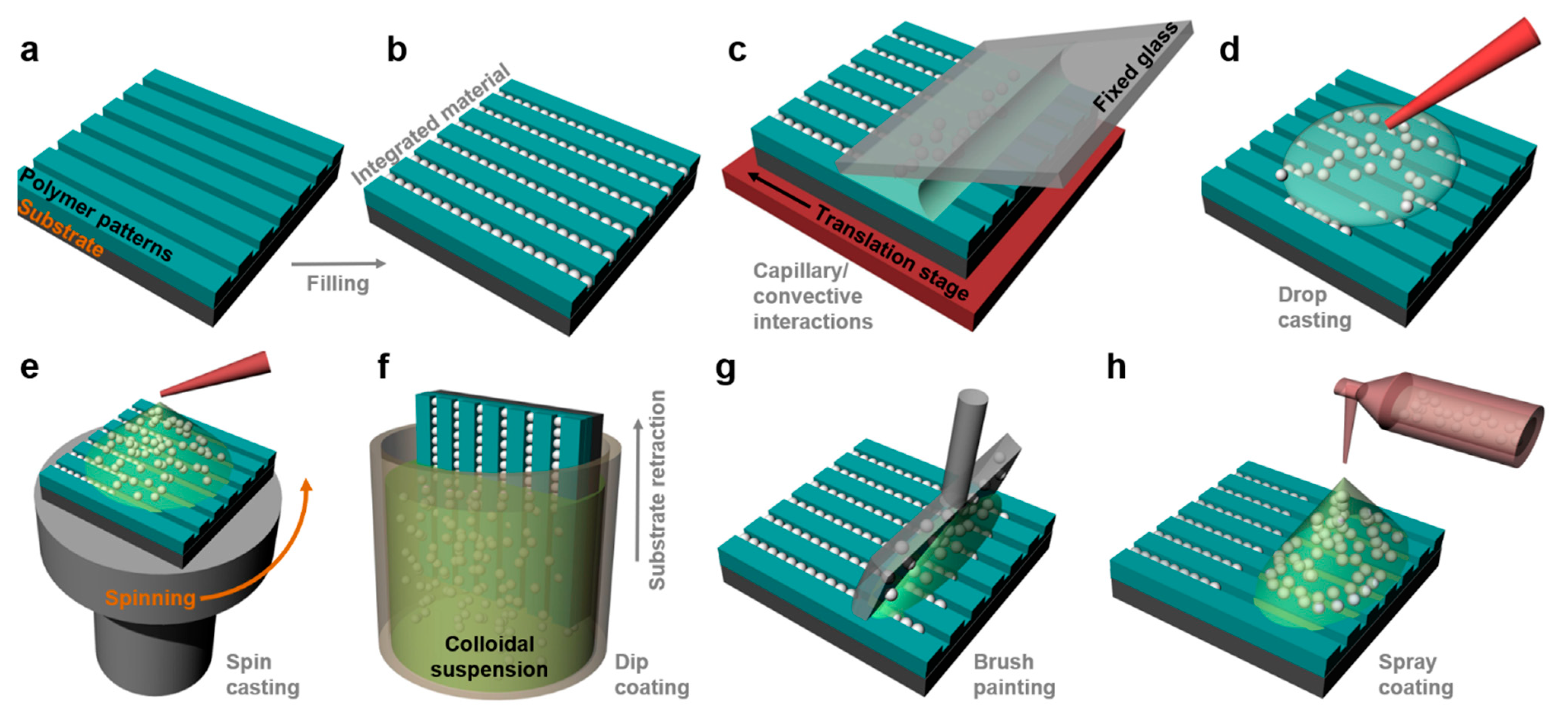

In the past years, a variety of conventional [1,2,3,4] and less conventional [5,6,7] micro- and nano-patterning methods have been used to generate periodic surface relief patterns. As a consequence, a huge diversity of patterned materials developed in time. These materials were shown to exhibit enhanced and/or novel properties and have been embedded in modern technological and engineering areas [8,9,10] in order to improve the quality and functionality of different devices. Nowadays, the number and diversity of such devices significantly increased inclusively due to the fact that the periodic surface relief patterns can be routinely fabricated on (polymer-covered) solid or flexible substrates and can be further filled with other (functional) materials by employing a variety of available deposition methodologies [11,12,13,14]. The resulting structured platforms (SPs), i.e., periodic surface relief patterns of certain shape and dimension that are filled in a disordered or (hierarchically) ordered manner with various materials of different size, shape, and function [15,16,17,18], are being currently used in a variety of optoelectronic [9,16,19], photonic [20], biological [17,21,22], sensing [13], or storage media [18] applications. Therefore, it is obvious that in order to further exploit such applications, we have to design and develop novel SPs with puzzling properties. This implies that we have to appropriately choose the most suitable methods and approaches related both to the patterning of polymer-covered substrates and to material deposition methodologies. To do this efficiently, we need to have at hand an overview of all the advantages and disadvantages of the above-mentioned methodologies.

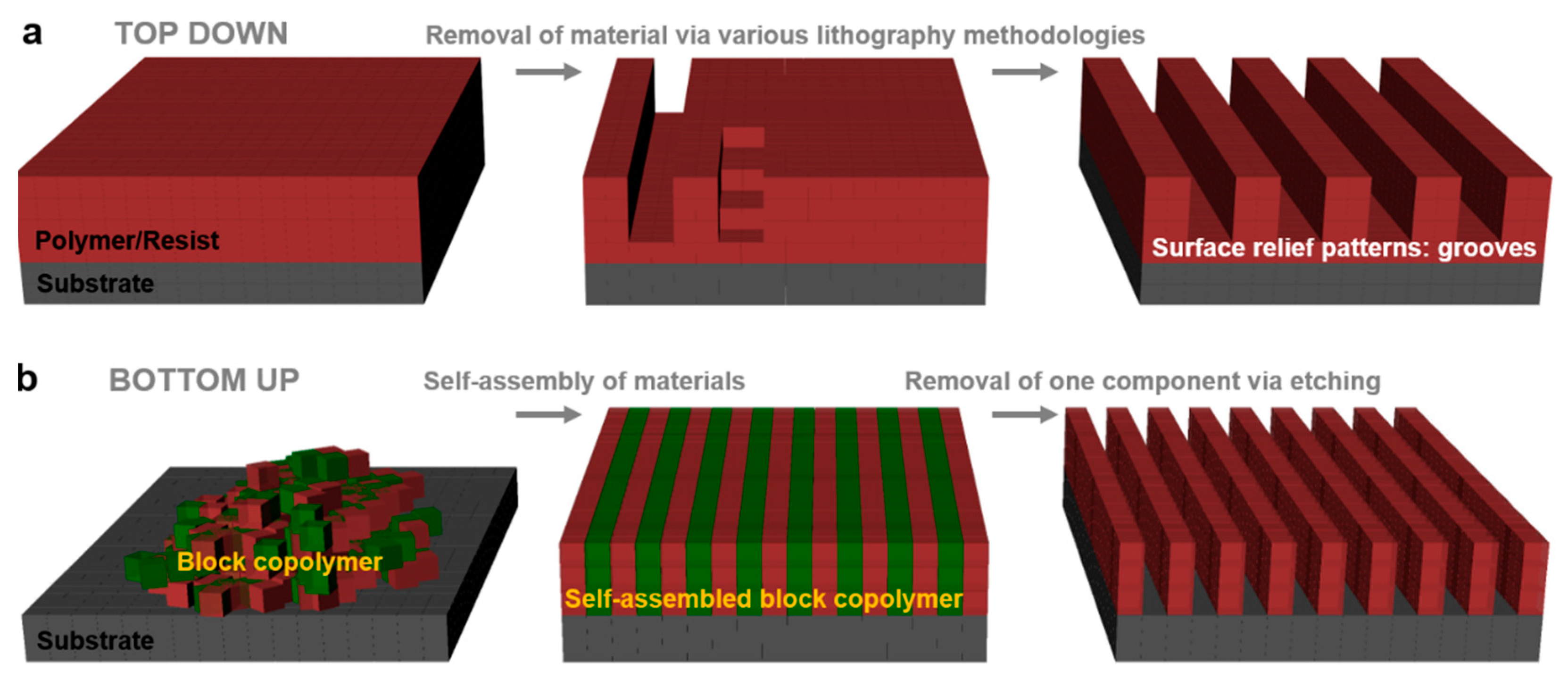

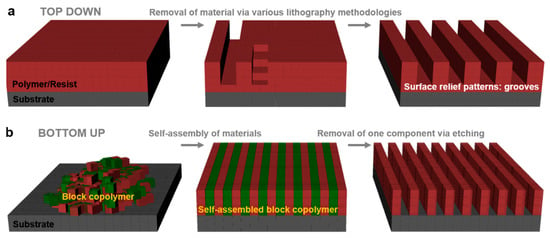

In general, periodic surface relief patterns of various dimensions and shapes can be fabricated using either top–down or bottom–up lithographic methodologies (Figure 1), although other methods might work as well [5,6,7]. These methodologies can be used separately [23,24,25,26] or combined [27,28]. The top–down methodology is breaking down the material system by removing molecules or atoms using electrons [29], ions [30], protons [31], light [32], etc. and leaving a clearer pattern on the surface of the material (Figure 1a), while the bottom–up methodology is based on building different blocks or stacking molecules on top of each other (Figure 1b). Both approaches have advantages and limitations and are equally important in nanotechnology and modern technological industry. The bottom–up method is supposed to be more advantageous because the resulting patterns can be of better miniature and show less defects, exhibiting a more homogenous chemical composition. Nonetheless, the top–down approach seems to display an overall better control in pattern formation on large surfaces.

Figure 1.

(a–b) Illustration of the top–down (a) and bottom–up (b) lithographic principles.

In this work, we aim to provide an overview on the current polymer-based SPs and their use in nanotechnological applications, with a direct emphasis on their fabrication methodology. To accomplish this aim, in the first part of the review, we are going to offer an extensive outline about the main (polymer film) patterning methodologies, including top–down and bottom–up approaches, while in the second part of the review, we will present and analyze various deposition methods used for the guided deposition of different structures (nanoparticles, nanorods, nanospheres, etc.) of functional materials into periodic surface relief patterns. At the end of this work, readers will have at hand a toolbox of the most suitable patterning and deposition methodologies that could be easily identified and further combined in order to fabricate interesting SPs possessing puzzling properties.

2. Top–Down Lithographic Methodologies

Many current nanotechnological advancements rely on the development of novel micro- and nanostructured materials exhibiting good mechanical properties, flexibility, and robustness. Within this category, patterned materials displaying no chemical defects or no mechanical deformations at edges are highly desirable. Their fabrication is performed by employing different top–down patterning methods (Figure 1a) that are being continuously developed and adapted and that include photolithography, electron, proton, as well as ion beam lithography, soft lithography, scanning lithography, particle lithography, or stencil lithography.

2.1. Photolithography

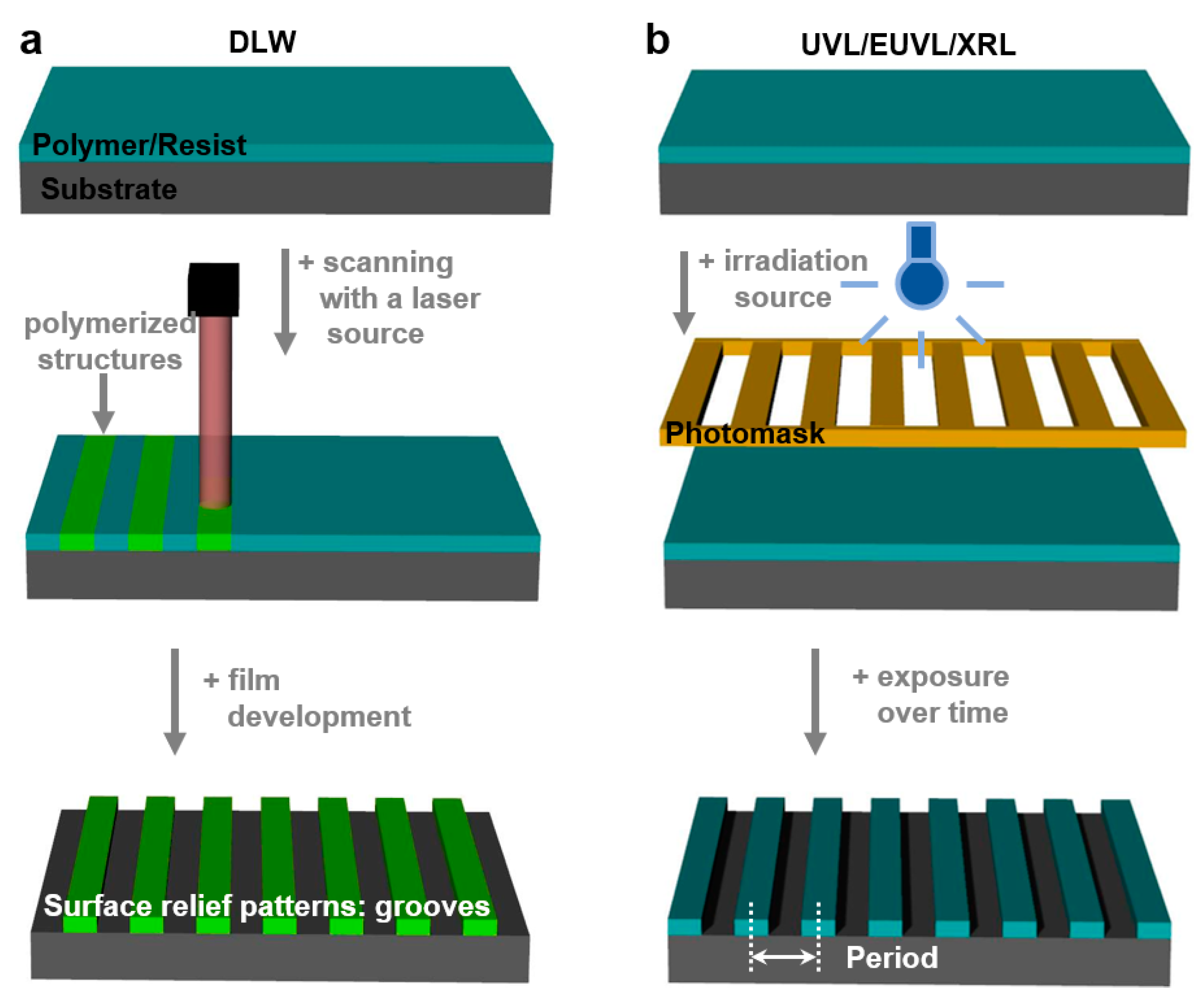

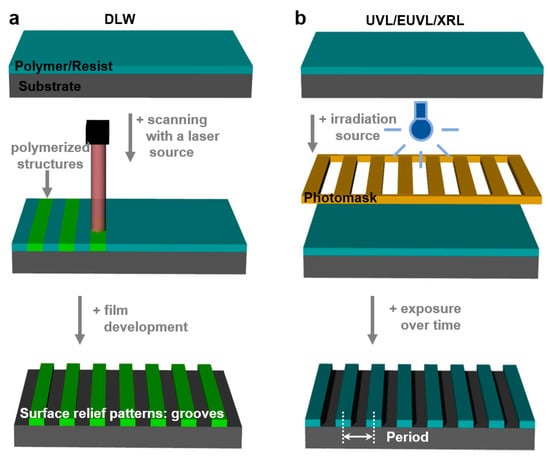

Photolithography has proved itself to be one of the key cost-effective fabrication processes that are being used to realize surface relief structures on micro- and nanoscale in polymer-based films. This method is employing light in order to transfer a specific geometric pattern to a chemical resist that is photosensitive. Generally, while the exposure to light induces chemical changes that allow the photoresist to be removed through various development processes based on etching chemicals, the transfer of specific patterns can be realized through direct laser writing (Figure 2a) or by employing a photomask as in the case of UV lithography and X-rays lithography (Figure 2b). Here, either positive (exposed regions are etched) or negative (unexposed regions are etched) photoresists can be utilized. However, photolithography can sometimes require multiple fabrication steps, and in some situations, it can compromise the chemical and the physical properties of the materials [33]. Moreover, using photolithographic techniques on unsuitable materials is not producing high-quality surface relief patterns due to thermal changes [34] that may induce the vaporization and melting of the material or due to surface degradation and carbonization [35].

Figure 2.

(a,b) Schematic representation of the photolithographic techniques: direct laser writing (a), UV, extreme UV and X-ray lithographies (b). Note that in (b), the case of patterning through the removal of material is presented.

In the past years, patterned surfaces fabricated using photolithography have been used in biomedical devices [36], cell growth [37], or organic optoelectronics [38,39], just to name a few examples, and it is clear that one of the main requirements for a “healthy” development of novel applications in diverse fields of nanotechnology consists of the production of small patterned features with tailored properties and high resolution over a large area. In order to achieve such patterns through photolithography, a top-quality photomask displaying extremely fine features can be held closely to the resist material for transferring the design on the polymeric substrate by breaking down the polymer chains. Alternatively, a high-intensity laser with a well-defined wavelength can be used as well, as it can deliver optical energy to the focal spot on the material prior to its development.

2.1.1. Direct Laser Writing

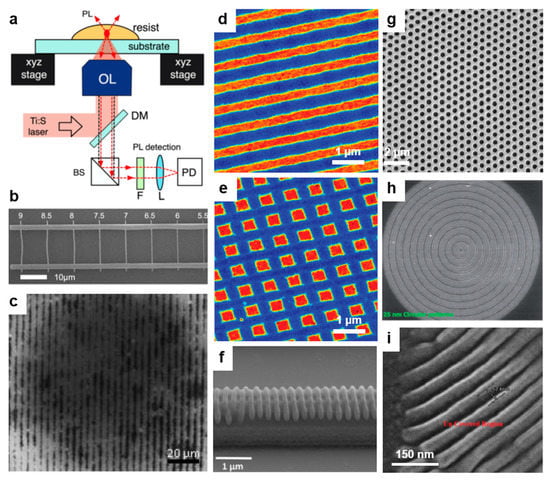

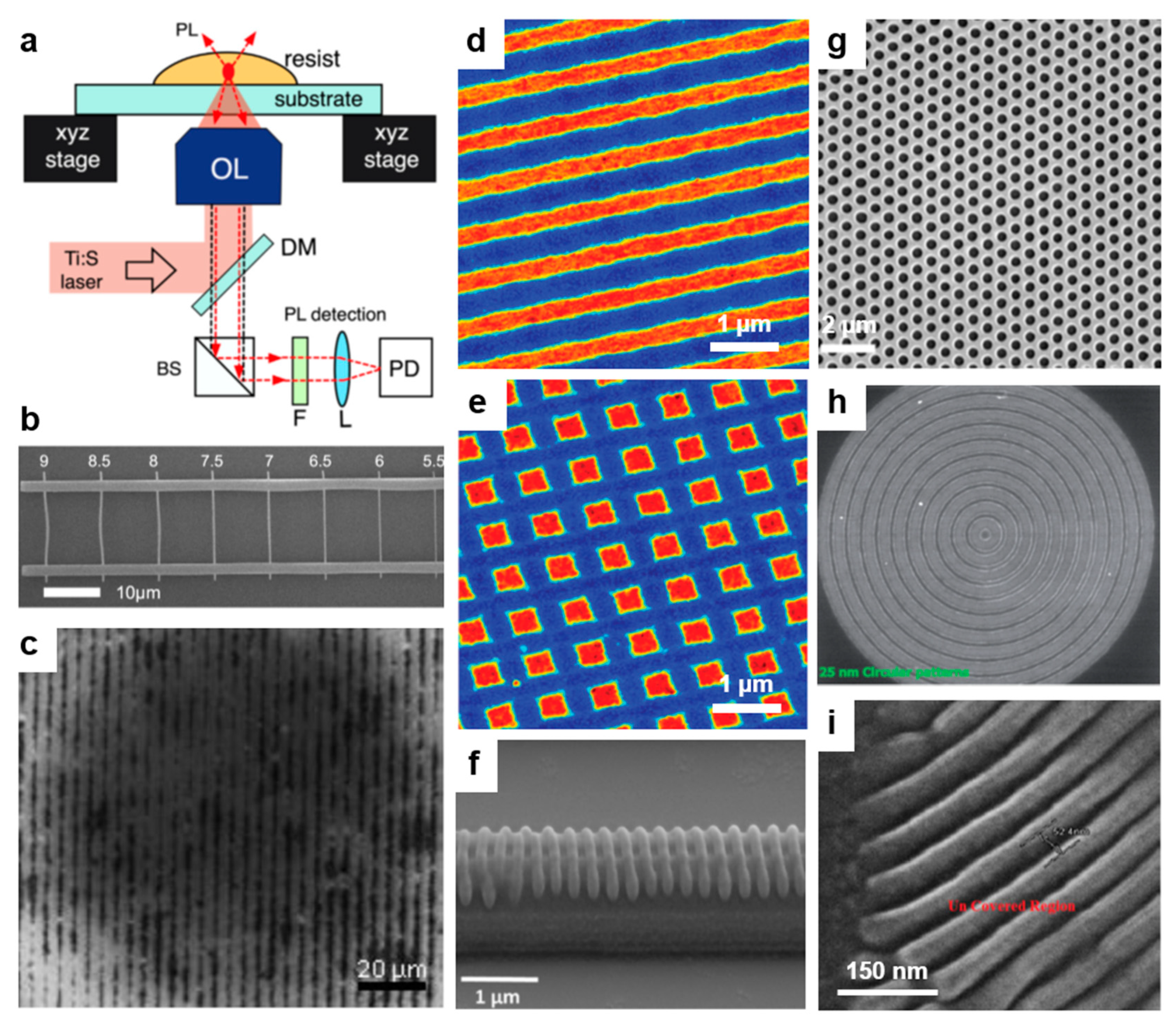

Direct laser writing (DLW) is a photolithographic technique that can create, on a photosensitive material, permanent micro- and nano-patterns with different (hierarchical) structures exhibiting high spatial resolution (Figure 2a). Based on the multiphoton absorption process in a photoresist (which is transparent at the wavelength of the laser), DLW is properly modulating the laser until a chemical change such as polymerization of the photoresist is initiated in a small focal volume on the surface [34,40] where the laser intensity is high enough. Scanning the laser over the photoresist surface changes its solubility in the exposed regions. This procedure may be followed by the film development and leads to high-quality (periodic) surface relief patterns. The shape and dimension of such patterns can be eventually improved by employing and controlling a number of laser beams and the angle between them [41]. In addition to the laser properties, the spot size, the photoresist material, and the acceptable writing speed are also important requirements for creating a high fidelity pattern [42]. Despite the fact that this method can achieve finely patterned structures [43,44], there are cases in which the relief model is different from the design, which is inclusively due to mechanical instabilities and deformations caused by the processes of chemical development and drying or by the mechanical drifting of the focal spot position with respect to the sample [45]. However, recently, Yulianto et al. have overcome some of these limitations by replacing the conventional live monitoring of patterns based on wide-field microscopy with a photoluminescence scanning method (Figure 3a). This new setup is capable of visualizing latent three-dimensional (3D) photoexposure patterns recorded in photoresist doped with photoinitiators and exhibits a spatial resolution comparable to that of two-photon microscopy [46]. As a result, 350 nm wide single lines supported by massive walls could be demonstrated (Figure 3b).

There are other significant variable parameters to be taken in consideration when performing DLW, including the exposure time, laser power and dose, as each of them can modify the desired surface pattern [47]. For instance, the laser power has to be kept between a range of values in order to avoid undesirable local heating of the sample, which may result in damaged photoresist material. Moreover, an inappropriate laser power can alter material composition by leading to irreversible chemical bonding during the irradiation of thermoplastic polymers [48]. Furthermore, when exposed to low laser fluences, the morphology of the polymer film can induce material expansion known as swelling [49].

Another challenge related to DLW is to keep newly obtained relief patterns non-colored on the surface, since the heating or degradation of the polymer/colorant blends can induce color changing in the irradiated area, especially after the etching. Recently, Lafleur et al. overcame this limitation by presenting an improved DLW method to create desired optical patterns [50]. In this case, the common DLW technique was used on a photothermal dye, a mixture of high-density polyethylene (HDPE) and 2-(2H-benzotriazol-2-yl)-4,6-ditertpentylphenol (BZT), and it was assisted by a pulsed UV laser that controlled the local UV irradiation dose. As a result, the bulk morphology of the polymer stayed unaffected during irradiation, while the newly obtained topographical patterns appeared white on the transparent tape [50].

In recent years, DLW has been widely used not only to miniaturize the dimensions of the surface relief patterns but also to extend patterning to other materials. For example, Mulko et al. have used poly(methacrylic acid) (PMAA) doped with fluorescent silver nanoclusters in order to create groove patterns displaying an average half-peak width of 1.2 µm [40] (Figure 3c). Here, they employed 10 laser pulses of 355 nm and of 10 ns duration with a fluence of 400 mJ/cm2. This is impressive because in PMAA, no patterns can be created employing this wavelength. Nonetheless, using silver nanoclusters increased the absorbance at 355 nm, and PMAA patterns could be realized [40]. Another example of a system on which patterning has been successfully employed is 2,3,5,6-tetrafluoro-7,7,8,8-tetracyanoquinodimethane (F4TCNQ) doped poly(3-hexylthiophene) (P3HT). In this case, Su et al. have used 405 nm and 532 nm continuous wave lasers to achieve micrometer wide grooves [38]. Moreover, using the same doped polymer system, Jacobs et al. have further shown that patterns of sub-diffraction limit down to 200 nm could be achieved with the DLW method based on a laser scanning confocal microscope combined with doping-induced solubility control [51]. Here, well-defined 1D (Figure 3d) and 2D (Figure 3e) P3HT-based gratings with a 640 nm pitch were demonstrated.

In addition to grooves and gratings, many other patterns can be fabricated with the DLW method, including hierarchical structures. Hierarchical micropillars based on polyether ether ketone enforced with carbon fibers can be fabricated with two-beam DLW based on either 263 nm or 1053 nm laser pulses at various laser fluences [23]. Other periodic surface structures can also be developed on micrometer-sized line pre-patterns previously fabricated in photoresist films by contact lithography [52] (Figure 3f). These surface structures display a period of 195 nm and were sculptured by a laser at very low laser fluences and high pulse numbers [52]. More types of structures that can be fabricated using DLW are summarized in Table 1.

Figure 3.

(a) Schematics of the direct laser writing (DLW) setup based on a photoluminescence scanning method along with its main components: an objective lens (OL), a short-pass filter (F), a dielectric mirror (DM), a focusing lens (L), and a Si photodetector (PD). (b) SEM image of the single lines developed by DLW. (c) Optical microscopy image of Ag@PMAA (poly(methacrylic acid)) obtained with 10 laser pulses. (d,e) Atomic force microscopy (AFM) images of 1D (d) and 2D (e) dedoped poly(3-hexylthiophene) (P3HT) gratings obtained by raster scanning of the patterning laser over the film. (f) SEM image depicting periodic surface structures sculptured by a laser on a line prepattern in photoresist. (g) SEM image of a nanohole pattern fabricated by UV lithography (UVL) using a 500/600 (diameter/pitch, nm) colloidal mask and an exposure time of 4 s. (h) SEM image of 25 nm wide circular patterns obtained via extreme UV lithography (EUVL) in non-chemically amplified hybrid (4-(methacryloyloxy)phenyl)dimethylsulfonium triflate (MAPDST)–ferrocenylmethyl methacrylate (FMMA) resist. (i) SEM micrograph of patterned imine-based monolayer on silicon wafers. Adapted with permission from ref. [46] (a,b), from ref. [40] (c), ref. [51] (d,e), ref. [52] (f), ref. [53] (g), ref. [54] (h) and ref. [55] (i). Copyright (2019, 2020) Elsevier, (2016, 2018) John Wiley and Sons and (2014) American Chemical Society. Ref. [54]—Published by The Royal Society of Chemistry.

Figure 3.

(a) Schematics of the direct laser writing (DLW) setup based on a photoluminescence scanning method along with its main components: an objective lens (OL), a short-pass filter (F), a dielectric mirror (DM), a focusing lens (L), and a Si photodetector (PD). (b) SEM image of the single lines developed by DLW. (c) Optical microscopy image of Ag@PMAA (poly(methacrylic acid)) obtained with 10 laser pulses. (d,e) Atomic force microscopy (AFM) images of 1D (d) and 2D (e) dedoped poly(3-hexylthiophene) (P3HT) gratings obtained by raster scanning of the patterning laser over the film. (f) SEM image depicting periodic surface structures sculptured by a laser on a line prepattern in photoresist. (g) SEM image of a nanohole pattern fabricated by UV lithography (UVL) using a 500/600 (diameter/pitch, nm) colloidal mask and an exposure time of 4 s. (h) SEM image of 25 nm wide circular patterns obtained via extreme UV lithography (EUVL) in non-chemically amplified hybrid (4-(methacryloyloxy)phenyl)dimethylsulfonium triflate (MAPDST)–ferrocenylmethyl methacrylate (FMMA) resist. (i) SEM micrograph of patterned imine-based monolayer on silicon wafers. Adapted with permission from ref. [46] (a,b), from ref. [40] (c), ref. [51] (d,e), ref. [52] (f), ref. [53] (g), ref. [54] (h) and ref. [55] (i). Copyright (2019, 2020) Elsevier, (2016, 2018) John Wiley and Sons and (2014) American Chemical Society. Ref. [54]—Published by The Royal Society of Chemistry.

2.1.2. UV and Extreme UV Lithography

UV lithography (UVL) is a patterning method widely used in engineering [1] and biotechnology [56]. It is based on the transfer of a diversity of patterns, through a positive or a negative tone, into polymer-based photoresists (most often SU-8) by employing a variety of photomasks (Figure 2b), including Cr [57] or soft [53] masks. The exposure of the photoresist to a pattern of intense UV light induces a chemical change and allows the removal of exposed or non-exposed photoresist regions with a certain solution. A significant advantage of photomasks is that they can generate sub-50 nm resolution patterns [57] when employing a UV light of 365 nm, as it was shown by Liu and co-workers. Unfortunately, most of the photomasks present a huge drawback as, very often, they can be utilized for only one patterning procedure. Fortunately, this issue can be fixed in the future either by circumventing the need for photomasks through the use of digital micromirrors [32,58] or by fabricating reusable and highly durable masks through cost-effective procedures [59]. For instance, polydimethylsiloxane (PDMS) masks are currently easy to fabricate and can create, on a large area, subwavelength patterns such as nanoholes [53] (Figure 3g).

Some very specific applications might require materials that need more energy in order to be transformed into periodic relief patterns via exposure to UV light. Therefore, UV light can be replaced with light coming from a coherent powerful source generating extreme UV wavelengths and leading to extreme UV lithography (EUVL; Figure 2b). This patterning technique is able to create periodic surface relief patterns with sub-30 nm resolution [57], including arrays of 25 nm wide grooves and circular patterns (Figure 3h) generated in a hybrid non-chemically amplified photoresist (n-CARs) based on a copolymer synthesized by reacting (4-(methacryloyloxy)phenyl)dimethylsulfonium triflate (MAPDST) and ferrocenylmethyl methacrylate (FMMA) monomers [54]. The subsequent incorporation of organometallic entities within resulting patterns was demonstrated to lead to the increased thermal profile of the hybrid material and its sensitivity toward radiation. Additional details on the patterns that can be obtained using UVL and EUVL are given in Table 1.

In both UVL and EUVL techniques, photomasks designed with different array dimensions and shape are used to transfer the desired pattern on the material by modifying the exposure time [58]. Generally, when long exposure times are needed, the patterning process becomes expensive and time consuming. In most cases, the masks cannot be reused, this being one of the disadvantages of the UVL and EUVL techniques, as already stated above. Therefore, scientists working in this field have to further focus their research on one hand toward photomask circumvention [32,58] and on the other hand to the development of reusable photomasks that do not encounter deformations and are still able to generate uniform surface relief patterns [53,59].

2.1.3. X-ray Lithography

X-ray lithography (XRL) comes as a complementary method to UVL and EUVL by using short wavelengths generated by a synchrotron source. The XRL setup consists of a substrate coated with a thin light-sensitive resist layer covered with a mask that is partially or completely removed by X-ray radiation passing through, leaving behind desired patterns (Figure 2b). By employing wavelengths below 1 nm, the advantages of this method consist of the depth of focus and in the high resolution of the resulting patterns [55,60]. Unfortunately, XRL needs expensive and complex instrumentation [60], and examples of patterning via XRL are rather scarce. Most recent examples of such examples (see Table 1) include resin materials based on polystyrenebenzaldimine (PSBA) [55] or bridged poly-silsesquioxanes (BPS) [60] that can lead, for instance, to groove-like features exhibiting periodicities around 50 nm [55] (Figure 3i). More information on photolithography can be further consulted in the literature [61,62].

2.2. Electron Beam Lithography

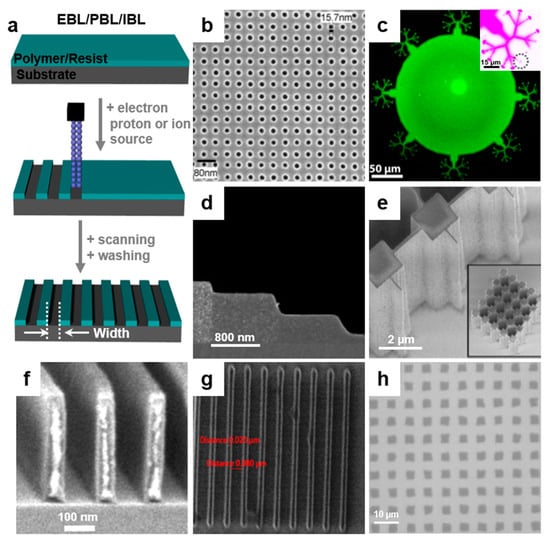

Electron beam lithography (EBL) is a direct surface writing technique that consists of creating high-resolution patterns through the use of focused beams of electrons onto a chemical photoresist, which is often of polymeric nature (Figure 4a). In this case too, the electrons in contact with the resist are modifying its solubility, permitting the selective removal of the exposed or non-exposed regions of the resist by subsequent etching in a solvent. The main advantage of this method relies on the maskless fabrication of sub-20 nm patterns in the horizontal plane [63] and of sub-10 nm patterns in the vertical plane [64] by employing a computer software that guides a finely focused beam of electrons over the patternable surface. Nonetheless, the best contrast and sensitivity of the material has to be considered when choosing the appropriate resist for high-aspect ratio patterns [65] and when aiming at sub-20 nm resolution on both positive and negative tones resists [66]. Sometimes, depending on the resist type, EBL can also induce unwanted competing chemistries including surface-grafting or cross-linking or changes in chemical functionality [67]. For the preparation and optimization of the right resist, we advise our readers to follow suggestive examples given in the literature by Pfirrmann, Takei, and Wieberger and their collaborators [68,69,70]. They have demonstrated (see Table 1) that cardioids structures, line and space, grating, or moth-eye patterns can be fabricated by EBL. This is possible when using optimized resists based either on organic sugar-based materials derived from biomass [69] or on various copolymers exhibiting different compositions [68] and synthesized from methyl adamantyl methacrylate, hydroxyl adamantyl methacrylate, and α-gamma butyrolactone methacrylate monomers [70]. Although these resists are generally deposited via spin casting on solid substrates, there are cases when a resist is deposited through the thermal evaporation on irregular surfaces [24].

Other factors to be considered when patterning with EBL include the energy of the electrons, the material of the substrate, or the post exposure temperature. Their inappropriate use may lead to unwanted irradiation defects, resist heating effects or charging effects. Such effects, which can be predicted inclusively through simulations [71], need to be eventually eliminated. For instance, when patterning fluoropolymers, the charging process during electron exposure becomes a serious issue as the insulator substrates covered with polymeric resists accumulate charges and degrade the EBL process. Nonetheless, performing EBL at variable pressure by employing an ambient reactive gas at subatmospheric pressure can mitigate charging [72]. Other anticharging schemes reported for the fabrication of arrays of dots of diameters of few tens of nm in the polymethylmethacrylate (PMMA) resist (Figure 4b) include the use of overlayers of either aluminum or water-soluble conducting polymers, as well as sandwiching of Al or Cr thin films between the substrate and the PMMA [73].

To emphasize the power of EBL in the fabrication of various well-defined and high-quality patterns, we present below several relevant examples. Although the sub-micrometer lateral patterning of conjugated polymers such as poly(9,9-di(2-ethylhexyl)-fluorenyl-2,7-diyl) (PF 2/6) was demonstrated a decade ago [74], EBL has been recently employed to pattern wires of conducting polymers with the aim to explore their electric conductivity and quantum effects [75]. The fabrication was performed by Mahmoodian et al. by utilizing a PMMA resist combined with the conducting polypyrrole (PPy) and PPy doped with anthraquinone-2-sulfonic acid sodium salt monohydrate/5-sulfosalicylic acid dehydrate (AQSANa/SSCA). Arrays of dots exhibiting each a diameter of 100 nm and arrays of long PPy wires exhibiting 130 nm in width were obtained [75]. Shorter organic molecules forming crystals such as quaterthiophenes are also good candidates for performing EBL. Grating patterns with a period of 80 nm and 20 nm wide lines can be designed and produced on such organic crystals when using a specific exposure dose [76].

Furthermore, EBL can be used to build 3D micro- or nanostructures that can become tools for modifying the cellular shape or for controlling cell migration [2]. Vinje et al. have carefully established control over the spatial resolution and fabrication process within films of SU-8 polymer-based resist and have obtained arrays of high-aspect ratio lines and pillars with a horizontal periodicity of ~100 nm [2]. Other more complex polymeric patterns for biological purposes can be sculptured by EBL [17]. For example, spherical patterns of few hundreds of micrometers in diameter containing many branches of a lateral size down to 50 nm were demonstrated in Teflon AF coatings (Figure 4c) and employed in experiments related to phospholipid monolayer spreading and behavior in ultraconfined spaces [17].

Finally, it is worth mentioning that EBL can also be employed to create vertical grayscale patterns down to sub-10 nm step height [64]. Recent examples include fabrication in PMMA of 6 nm multilevel grayscale patterns [64] (Figure 4d) as well as of 3D structures with several micrometers in height and exhibiting a pie-chart shape [29]. More details on the next generation of EBL resists [66] and on the evolution of EBL technique [77] can be further consulted in the literature.

Figure 4.

(a) Schematic illustration of electron, proton, and ion beam lithographies. (b) SEM image depicting an array of dots of a diameter below 16 nm and a pitch of 50 nm that were fabricated in a 70/90 nm thick conductive polymer/PMMA (polymethylmethacrylate) layer deposited on a fused silica substrate. Electrons of 30 keV at a dose of 125 µC/cm2 were employed in electron beam lithography (EBL), while a 5 nm thick anticharge layer of Cr was sputtered on top of the sample before the acquisition of the SEM image. (c) Confocal image of a complex spherical structure sculptured by EBL in a Teflon AF coating and filled with a fluorophore-doped lipid. Inset shows a confocal image of one of the multiple branches connected to the spherical structure. (d) SEM image emphasizing the cross-section through four-resist-level grayscale patterns fabricated in 2000 nm thick PMMA films. (e) SEM image depicting how pillars are connected to high aspect ratio walls of a width of 60 and 120 nm. Inset shows SEM image of 2 × 2 µm pillars written in a 10 µm thick SU-8 layer. The structures were written with a 1 MeV proton beam. (f) SEM image depicting parallel walls of a width of 50 nm written in a 350 nm thick PMMA layer by employing a focused 2 MeV proton beam. (g) He-ion exposed 20 nm wide lines written in a hybrid copolymer resist (100× magnification) at a dose of 120 µC/cm2. (h) Optical microscopic images showing arrays of holes obtained in PMMA films by masked ion beam lithography (IBL; irradiation was performed with 85 keV, 1 × 1014 ions/cm2 Ca+ ions). Adapted with permission from ref. [73] (b), ref. [17] (c), ref. [64] (d), ref. [31] (e–f), ref. [78] (g) and ref. [79] (h). Copyright (2011) American Vacuum Society, (2015) American Chemical Society, (2019) Robert Kirchner et al. published by De Gruyter, (2003, 2017) AIP Publishing and (2003, 2019) Elsevier.

Figure 4.

(a) Schematic illustration of electron, proton, and ion beam lithographies. (b) SEM image depicting an array of dots of a diameter below 16 nm and a pitch of 50 nm that were fabricated in a 70/90 nm thick conductive polymer/PMMA (polymethylmethacrylate) layer deposited on a fused silica substrate. Electrons of 30 keV at a dose of 125 µC/cm2 were employed in electron beam lithography (EBL), while a 5 nm thick anticharge layer of Cr was sputtered on top of the sample before the acquisition of the SEM image. (c) Confocal image of a complex spherical structure sculptured by EBL in a Teflon AF coating and filled with a fluorophore-doped lipid. Inset shows a confocal image of one of the multiple branches connected to the spherical structure. (d) SEM image emphasizing the cross-section through four-resist-level grayscale patterns fabricated in 2000 nm thick PMMA films. (e) SEM image depicting how pillars are connected to high aspect ratio walls of a width of 60 and 120 nm. Inset shows SEM image of 2 × 2 µm pillars written in a 10 µm thick SU-8 layer. The structures were written with a 1 MeV proton beam. (f) SEM image depicting parallel walls of a width of 50 nm written in a 350 nm thick PMMA layer by employing a focused 2 MeV proton beam. (g) He-ion exposed 20 nm wide lines written in a hybrid copolymer resist (100× magnification) at a dose of 120 µC/cm2. (h) Optical microscopic images showing arrays of holes obtained in PMMA films by masked ion beam lithography (IBL; irradiation was performed with 85 keV, 1 × 1014 ions/cm2 Ca+ ions). Adapted with permission from ref. [73] (b), ref. [17] (c), ref. [64] (d), ref. [31] (e–f), ref. [78] (g) and ref. [79] (h). Copyright (2011) American Vacuum Society, (2015) American Chemical Society, (2019) Robert Kirchner et al. published by De Gruyter, (2003, 2017) AIP Publishing and (2003, 2019) Elsevier.

2.3. Proton Beam Lithography

Although EBL is being effectively used for the fabrication of sub-100 nm patterns, often electrons scatter and create unwanted features on the surface and/or edges. This limitation can be eliminated by employing proton beam lithography (PBL). This technique is similar to EBL as it employs protons instead of electrons (Figure 4a). Although the penetration depth of the protons varies with their energy, the interaction of protons with the electrons of the material is rather low and represents an advantage of PBL when creating deep line patterns or holes and pillars in polymer films (Table 1). For instance, van Kan et al. have effectively demonstrated the use of proton writing in producing high-aspect ratio pillars and pillars connected with walls (Figure 4e) in both PMMA and SU-8 resists [31]. Moreover, mostly miniaturized walls (Figure 4f) and line patterns exhibited only 50 nm and 30 nm in width, respectively. This was possible due to the fact that secondary electrons of lower energy induced by the primary proton beam have limited range and produce minimal local effects. Moreover, Cutroneo et al. showed that by employing protons of energy varying between 2 and 2.6 MeV along with an optimized fluence (50–280 nC/mm2), sharp edges and smooth sidewalls can be developed in PMMA films, leading to arrays of micron-sized holes [80].

2.4. Ion Beam Lithography

Ion beam lithography (IBL) is similar to EBL and PBL techniques, but instead of electrons, respectively protons, it employs ions to remove parts of the resist films and to create high-quality periodic relief patterns (Figure 4a). IBL is used in different polymeric substrates where the proximity effect limitation that would be induced by EBL needs to be alleviated. IBL is capable of creating well-defined sub-10 nm features when employing high-density resists [81]. Compared to EBL, where primary electrons interact with the resist by transferring energy via elastic and inelastic collisions, IBL can reach sub-10 nm resolution due to less backscattering of ions coupled with their better penetration properties that can be adapted to higher resistance materials [82]. For example, taking into account the characteristics of the resist, Reddy et al. have fabricated sharp inner walls in a non-chemically amplified hybrid copolymer resist made through copolymerization of an organic monomer with another inorganic monomer. Using He ions, they have obtained 20 nm wide line patterns (Figure 4g) separated by different lateral distances [78].

The IBL method can further be employed to develop small structures at the surface of the poly(acrylic acid)-based bio-resists used in biomedical studies such as surface cell adhesion [83] (Table 1). In this case, the surface energy (i.e., hydrophobicity/hydrophilicity) is important, and it can be controlled by using a mask-based IBL approach. This was shown by He et al. who changed the surface property by implanting Ca+ and P+ ions in the as-spin cast PMMA film through the use of a mesh-like mask [79]. As a result, arrays of nanometer-deep and micrometer-wide PMMA holes (Figure 4h) were created and could be further used in biomedical research. Hole patterns can further be fabricated using focused IBL directly on silicon wafers by milling, with the final aim to transfer these patterns on polymeric substrates and thus to develop robust molds for nanoimprint lithography [84].

Finally, we would like to point out that each ion beam approach comes with advantages and limitations when fabricating high-quality sub-100 nm patterns. For instance, focused IBL employing slow ions of energy in the range of keV creates surface patterning resolution of sub-100 nm by modifying the surface structure, while fast ions with energy in the range of MeV produce deep penetration into a variety of substrates. Therefore, IBL can lead to a variety of patterns of desired dimensions, including sub-10 nm lines [82]. More details on IBL can be further found in the literature [30,85].

Table 1.

Summary of various surface relief patterns that can be fabricated using photolithography and different beam-based lithographic methodologies.

Table 1.

Summary of various surface relief patterns that can be fabricated using photolithography and different beam-based lithographic methodologies.

| Lithography | Type of Mask | Patterned Material | Resulting Pattern | Pattern Dimension | Ref. |

|---|---|---|---|---|---|

| DLW | NA | Doped P3HT | 1D, 2D gratings | 640 nm/pitch | [51] |

| DLW | NA | PMAA doped with Ag+ | Lines/grooves | 1.2 μm/half-width | [40] |

| DLW | NA | PI, PEEK, PEI, PC | Lines Microcavities | 6.2 μm/period 7.2 μm/diameter | [41] |

| DLW | NA | HDPE/BZT | Lines | hundreds of micrometers/width | [50] |

| DLW | NA | F4TCNQ-doped P3HT | Grooves | 2 μm/width | [38] |

| DLW | NA | PHEMA | Gratings | 2.6 μm/period | [49] |

| DLW | NA | PEEK/carbon fibers | Hierarchical structures | 1.5 μm/period | [23] |

| DLW | NA | PDY-132, P3HT | Lines | 17 μm/width | [39] |

| DLW | NA | Doped SZ2080 photoresist | Lines | 350 nm/width | [46] |

| DLW | NA | Pre-patterned photoresist | Surface structures | 195 nm/period | [52] |

| UVL | Photomask | Keratin photoresist | Various architectures | ≈3 μm/width | [1] |

| UVL | Photomask | Polydiacetylene | Square patches | 5 μm × 5 μm | [56] |

| UVL | PDMS colloidal mask | 5206E, ma-N photoresist | Nanoholes | 500 nm/diameter | [53] |

| UVL | Digital mirrors | Nucleic acid | Linear/branched structures | micrometer resolution | [32] |

| UVL | Digital mirrors | Polymer brush | Hypersurfaces | micrometer resolution | [58] |

| UVL | Cr photomask | Photoresist | Lines | 102 nm/period | [57] |

| EUVL | IMO228775 mask | n-CARs | Lines Circular patterns | 25 nm/width 25 nm/width | [54] |

| XRL | Photomask | PSBA | Groove lines | ≈52 nm/period | [55] |

| XRL | Si3N4 mask | BPS | Circular lines | ≈266 nm/width | [60] |

| EBL | NA | PMMA | Grayscale patterns Horizontal patterns | 6 nm/height step 32 nm/width | [64] |

| EBL | NA | PS evaporated resist | Lines, ratings | 30 nm/half-pitch | [24] |

| EBL | NA | Biotinylated PEG | Pads | 10 μm range | [67] |

| EBL | NA | Various star BCPs | Lines | 66 nm/width | [70] |

| EBL | NA | ZEP520A resist | L-shaped lines Rectangular mesh | 60 nm/pitch 80 nm/pitch | [86] |

| EBL | NA | SML resist | Dense gratings | 50 nm/half-pitch | [65] |

| EBL | NA | mr-PosEBR | Grating lines Grayscale patterns | 29 nm/width 240 nm/height step | [68] |

| EBL | NA | Teflon AF | L-shaped lines | 40 nm/half-pitch | [72] |

| EBL | NA | Ppy/AQSANa/SSCA | Wires Dots | 130 nm/width 100 nm/diameter | [75] |

| EBL | NA | Conjugated PF2/6 | Lines | 2 μm/width | [74] |

| EBL | NA | PMMA | Dots | 16–30 nm/diameter | [73] |

| EBL | NA | Quaterthiphene | Grating stripes | 20–500 nm/width | [76] |

| EBL | NA | SU-8 polymer resist | Lines Pillars | 100 nm/width 250 nm/pitch | [2] |

| EBL | NA | Teflon AF | Grooves | 50 nm/width | [17] |

| EBL | NA | Sugar-based polymer | Moth-eye patterns | 120 nm/period | [69] |

| EBL | NA | PMMA | Simulated lines | 2 nm/width | [71] |

| PBL | NA | PMMA, SU-8 polymer resists | Lines Walls Pillars | 30 nm/width 50–60 nm/width 2 µm × 2 µm | [31] |

| PBL | NA | PMMA | Holes | 1 µm × 1 µm | [80] |

| IBL | NA | PAA-patterned PS | Lines | 100 μm/width | [83] |

| IBL | Ni mesh mask | PMMA | Holes | micrometer/width | [79] |

| IBL | NA | Hybrid n-CAR | Lines | 20 nm/width | [78] |

2.5. Soft Lithography

Soft lithography is a family of patterning techniques used to fabricate or replicate various micro- and nanoscale periodic surface relief structures (Table 2) by employing soft, elastomeric (most notably PDMS) stamps, molds, or conformable photomasks. This methodology presents various advantages, starting from the dimension of patterns that can be fabricated (around 10 nm [87]) to the relatively large area that can be patterned [88], to the possibility of performing patterning on curved surfaces [89], to the use of automatized machinery at the industrial scale [90,91], etc.

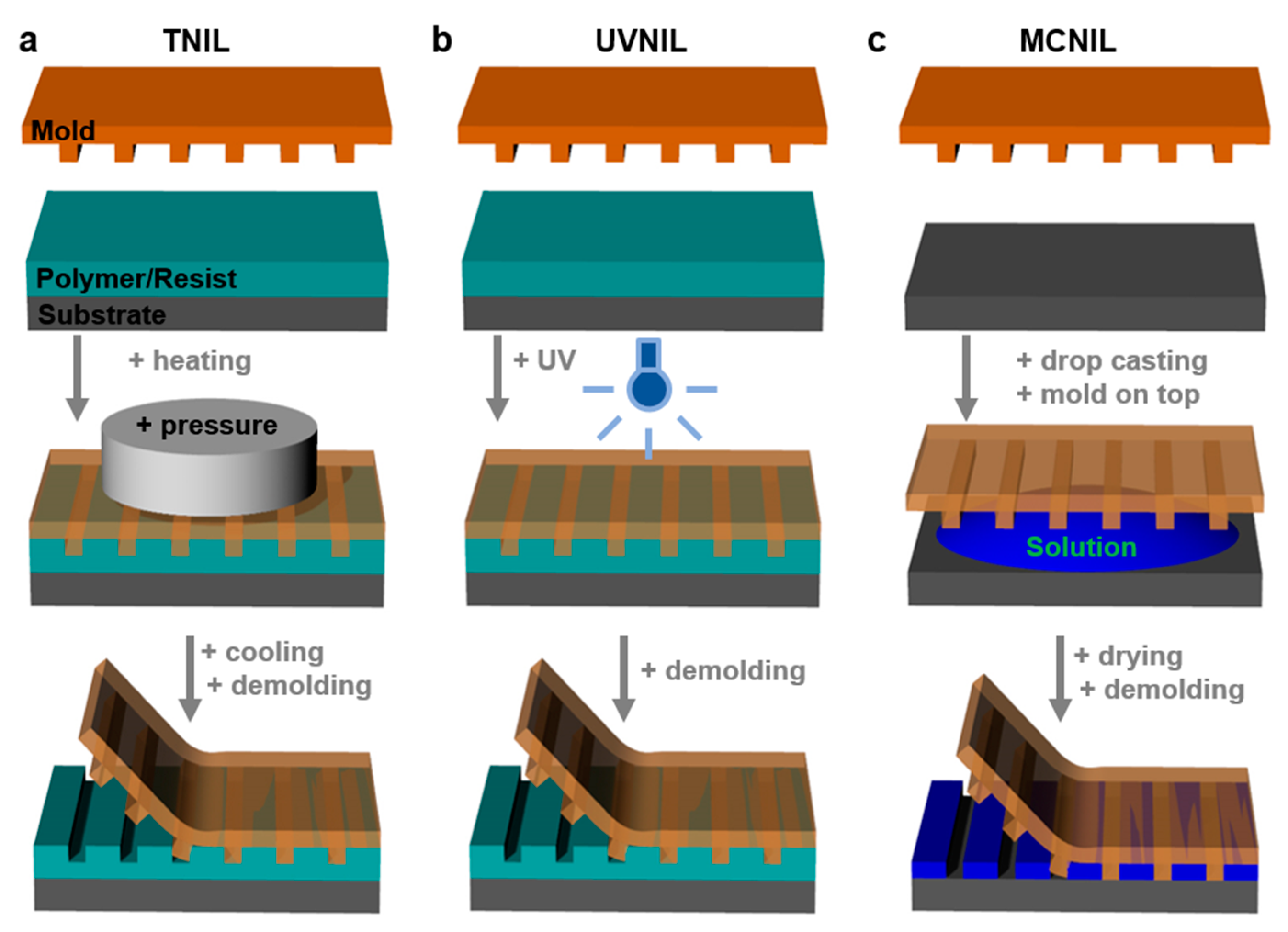

2.5.1. Nanoimprint Lithography

Nanoimprint lithography (NIL) is a soft lithography method consisting of a rapid, cost-effective transfer of a specific structure relief pattern from a master mold to an imprint (polymeric) resist via a variety of mechanisms, including mechano-thermal deformation (Figure 5). NIL has been widely utilized by many research groups for its high reproducibility in the realization of defect-free patterns over a large area [92] to be incorporated in sensors [93], organic solar cells [94], reverse osmosis membranes [95], and soft electrodes [96], or to develop applications in the biomedical field [97,98,99]. With NIL, different complex patterns such as elliptical hemisphere arrays [100], hole arrays [101], pillar structures [102,103], and nanogratings [104] can be achieved. Moreover, imprint molds [105] of different types have been designed, developed, and eventually improved in order to replicate high-resolution periodic patterns on various substrates with the help of various lithographic approaches derived from NIL that include thermal NIL, UV-based NIL, or molding capillaries NIL. Being a highly adaptable method, NIL can be continuously improved by considering the type of utilized resist/polymer, processing parameters, materials for molds, etc. in order to extend its productivity and applicability [106].

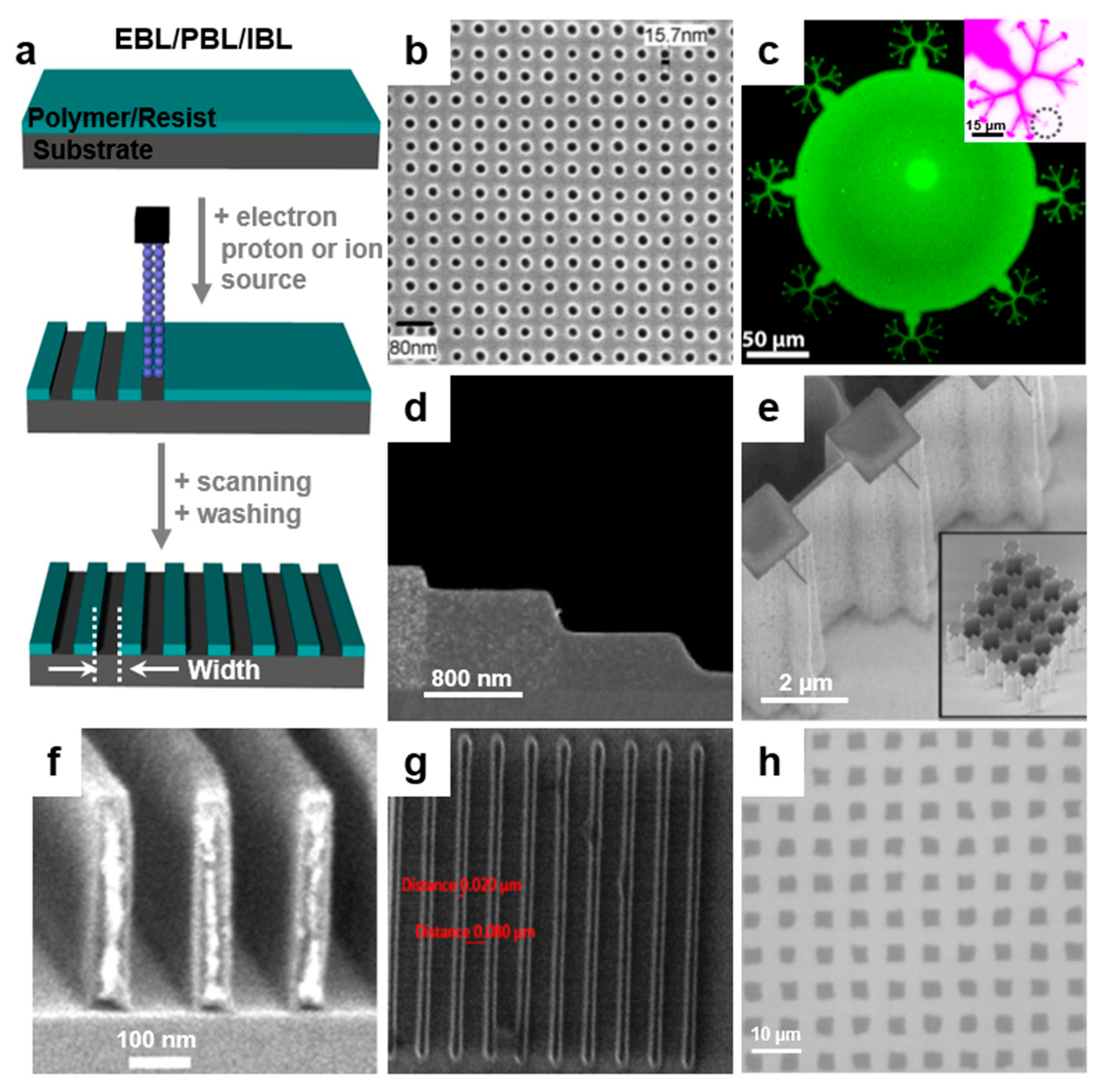

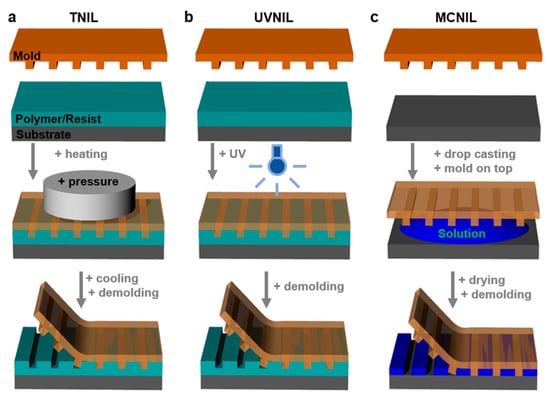

Figure 5.

(a–c) Illustrative representation of various types of nanoimprint lithography (NIL): thermal nanoimprint lithography (TNIL) (a), UV nanoimprint lithography (UVNIL) (b), and molding in capillaries NIL (MCNIL) (c).

Thermal nanoimprint lithography (TNIL) has become a popular choice because it allows rapid patterning at low cost, and it can achieve 10 nm pattern resolution on soft and hard substrates by using PDMS molds [87]. One advantage of TNIL is that various soft and rigid molds can be re-used for several patterning procedures due to their rather acceptable lifetime (that is nonetheless limited by the constant mechanical deformation under different thermal conditions). Generally, in order to transfer a pattern from the mold to polymeric films deposited on flexible [107], solid [108], or textile [3] substrates, molds are mechanically pressed against a polymer melt [109] or films while heating the latter to melting temperatures [110,111] (Figure 5a). For efficiency reasons, it is also possible to press the molds against films soaked with non-solvents to form surface “gels” [112], or against as drop-cast solutions [113] or even to poor solutions of interest directly on the mold [114] and heat afterwards.

There are also cases when TNIL occurs at room temperature with [104] or without [115] an additional solvent annealing procedure. When no heating is needed at all, NIL becomes athermal [116]. Solvent annealing can further be combined with TNIL when the spacing between the polymer patterns needs to be increased or decreased through stretching or heating [117]. Moreover, solvent-assisted TNIL can significantly reduce feature sizes as compared to the master by controlled swelling of the patterned molds with different solvents [117]. Furthermore, TNIL can take advantage of porous gas permeable molds that increase material fluidity and thus allow patterning of materials that show poor fluidity even after being heated, such as polylactide [118].

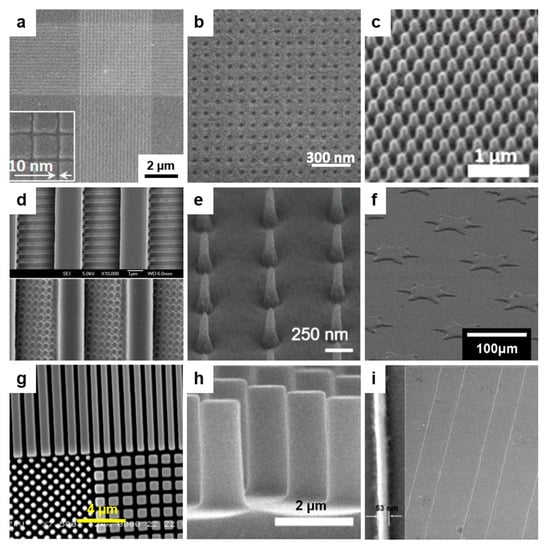

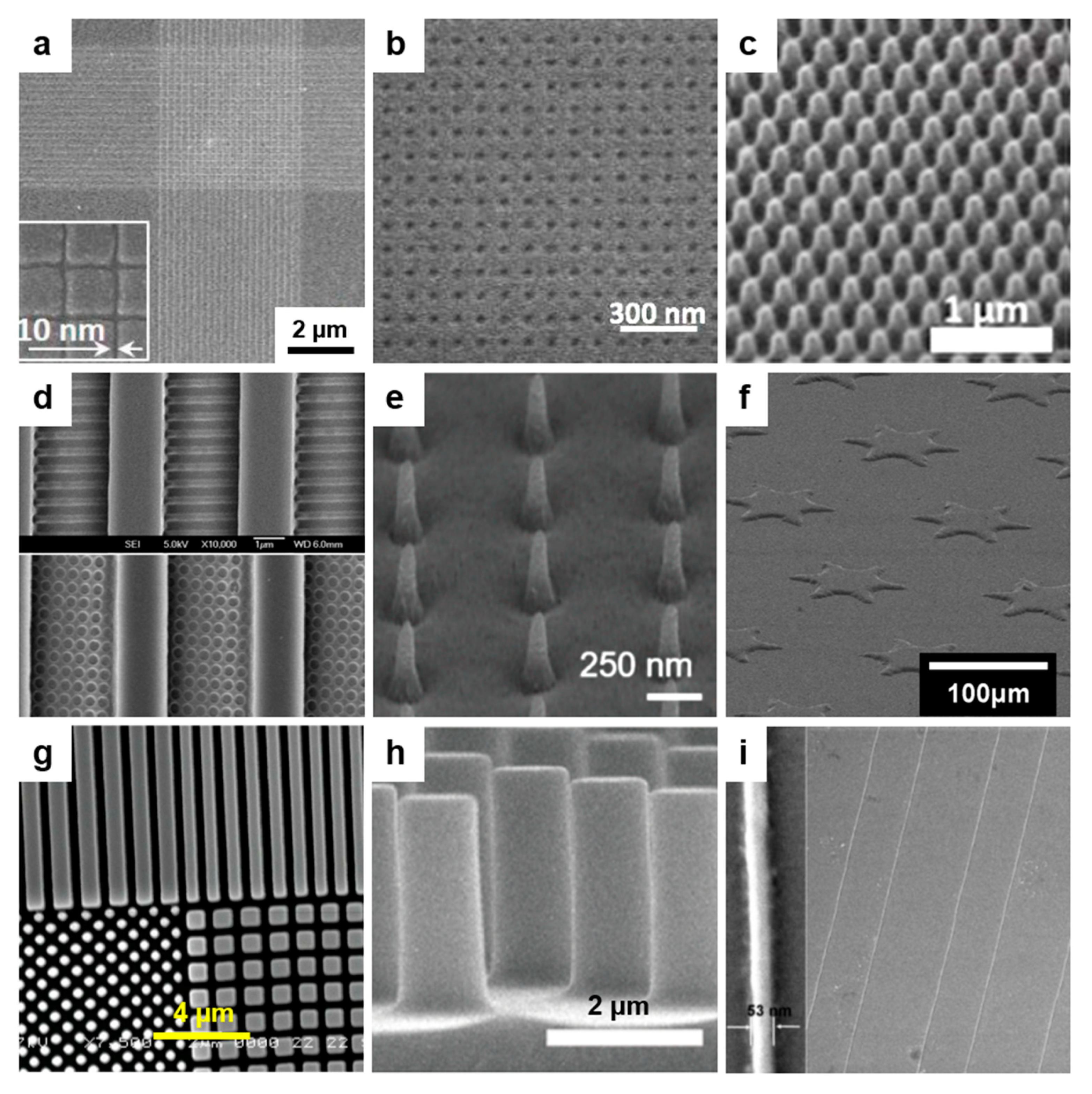

There is a variety of structures that can be obtained with TNIL (Table 2) and employed in different biological applications [111,113,114,119,120], organic photovoltaics [121], interfaces [122], superhydrophobic surfaces [107], memory elements [123], dental implants [124], etc. Miniaturized patterns obtained by TNIL and consisting in poly(benzyl methacrylate) (PBMA) lines/2D gratings and nanoholes were recently reported [87] (Figure 6a–b). The width of lines was measured to be 10 nm, while diameters of nanoholes were around 20 nm, respectively. Patterns that can be obtained using TNIL include lines of proteins [125], Nafion [126], poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate) (PEDOT:PSS) [122], PMMA [123], poly(vinyl pyrrolidone) (PVP) [123], poly(vinyl acetate) (PVAc) [123], P3HT [104], or fluorinated polymer gratings [121] or azopolimeric [113] and gelatin [124] pillars, or poly(d,l-lactide-co-caprolactone) (PLCL) [111] and polyacrylamide (PAM) [119] grooves, or gelatin holes [124], etc.

Furthermore, interesting moth-eye patterns of a periodicity of few hundreds of nanometers, sculptured in cyclo-olefin-based polymers by TNIL using a PDMS stamp, were reported as good antireflective coatings [127] (Figure 6c). In particular cases, the TNIL procedure can be consecutively repeated on the same sample, but using molds comprised of patterns of smaller dimensions compared to the initial molds. At this stage, TNIL, which may or may not involve a rotation at 90° of the molds, can lead to very interesting recessed patterned structures of multiple features in a particular polymer, including the presence of line/space patterns or holes in the recessed line/space patterns [128] (Figure 6d).

Figure 6.

(a,b) SEM images of 10 nm wide lines (a) and 20 nm sized nanoholes (b) transferred from the mold to the poly(benzyl methacrylate) (PBMA) thermal resist. (c) SEM image of a moth-eye antireflective coating imprinted by TNIL on the surface of a substrate covered with a cyclo-olefin-based polymer. (d) SEM images of patterns obtained from a direct recessed area imprint of SU-8 polymer resist with an ethylene tetrafluroethylene (ETFE) template by TNIL showing the presence of line and space features (top) and holes (bottom) in the recessed areas of the line and space patterns. (e) SEM image of the 2-methacryloyloxyethyl phosphorylcholine (MPC)-grafted PEGDMA nanoneedle arrays fabricated using UVNIL. (f) SEM micrograph depicting patterns produced within poly(β-hydroxyl thio-ether) by UVNIL using the PDMS mold. (g) Various structures with critical dimension of 200 nm done by roll-to-roll (R2R) UVNIL with polymer shim (i.e., a harder formulation of the multi component UV-curable JRcure resist that results in a stiff but flexible layer after UV curing) at 5 m/min in a polymer stamp material (JRstamp2 formulation). (h) Straight micrometer sized azopolymer pillars obtained by MCNIL. (i) SEM image depicting an array of 53 nm wide lines of a thermoplastic polymer fabricated on Si/SiO2 substrate by MCNIL using a 50 nm wide mold. Adapted with permission from ref. [87] (a,b), ref. [127] (c), ref. [128] (d), ref. [129] (e), ref. [130] (f), ref. [131] (g), ref. [103] (h) and ref. [132] (i). Ref. [87]—Published by The Royal Society of Chemistry. Copyright (2011) American Vacuum Society, (2016, 2019, 2020) American Chemical Society and (2010) John Wiley and Sons.

Figure 6.

(a,b) SEM images of 10 nm wide lines (a) and 20 nm sized nanoholes (b) transferred from the mold to the poly(benzyl methacrylate) (PBMA) thermal resist. (c) SEM image of a moth-eye antireflective coating imprinted by TNIL on the surface of a substrate covered with a cyclo-olefin-based polymer. (d) SEM images of patterns obtained from a direct recessed area imprint of SU-8 polymer resist with an ethylene tetrafluroethylene (ETFE) template by TNIL showing the presence of line and space features (top) and holes (bottom) in the recessed areas of the line and space patterns. (e) SEM image of the 2-methacryloyloxyethyl phosphorylcholine (MPC)-grafted PEGDMA nanoneedle arrays fabricated using UVNIL. (f) SEM micrograph depicting patterns produced within poly(β-hydroxyl thio-ether) by UVNIL using the PDMS mold. (g) Various structures with critical dimension of 200 nm done by roll-to-roll (R2R) UVNIL with polymer shim (i.e., a harder formulation of the multi component UV-curable JRcure resist that results in a stiff but flexible layer after UV curing) at 5 m/min in a polymer stamp material (JRstamp2 formulation). (h) Straight micrometer sized azopolymer pillars obtained by MCNIL. (i) SEM image depicting an array of 53 nm wide lines of a thermoplastic polymer fabricated on Si/SiO2 substrate by MCNIL using a 50 nm wide mold. Adapted with permission from ref. [87] (a,b), ref. [127] (c), ref. [128] (d), ref. [129] (e), ref. [130] (f), ref. [131] (g), ref. [103] (h) and ref. [132] (i). Ref. [87]—Published by The Royal Society of Chemistry. Copyright (2011) American Vacuum Society, (2016, 2019, 2020) American Chemical Society and (2010) John Wiley and Sons.

UV nanoimprint lithography (UVNIL) is applying transparent molds, mostly flexible PDMS, onto various UV-curable (polymeric) liquid resists covering solid substrates. Once the mold is pressed together with the substrate, the resist is cured through its exposure to UV light and turns into a solid material (Figure 5b). This process is followed by the mold separation, which leaves behind the resulting pattern transferred into the resist [133]. When needed, the pattern from the resists can be further transferred onto the underneath substrate by employing other processes such as etching [134]. The UVNIL technique has the advantage of reproducing cost-effective yet large area patterns that are highly stable under chemical, thermal, or biological stress [135]. Nonetheless, as in the case of TNIL, when using a mold for too many patterning procedures, the patterns on the mold get deformed due to pressure and exposure to UV, leading to defects in the final transferred patterns.

UVNIL is able to produce high-quality features that can be used in biofilm [129], vascular muscle cell function [99], cell stimulation [98], data storage [136], as well as in fluidic [137] applications. Periodic patterns that can be obtained by employing UVNIL are various (Table 2) and include arrays of grooves made of inorganic–organic polymer [137], of poly(urethane acrylate) (PUA) [99], and of poly(ethylene glycol) (PEG)-based hydrogel grooves [98]. Other relief patterns are represented by arrays of 2-methacryloyloxyethyl phosphorylcholine (MPC) grafted poly(ethylene glycol) dimethacrylate (PEGDMA) nanoneedles of a periodicity of few hundreds nanometers [129] (Figure 6e), arrays of metallopolymer nanodots and nanolines [136], or even arrays of poly(β-hydroxyl thio-ether) microlines, microstars (Figure 6f), microgrids, cylindrical cavities, and other micropatterns with acute angles [130]. Again, repetitive UVNIL combined with the use of two molds comprised of patterns of different dimensions can lead to a variety of hierarchical micro–nano recessed patterned polymer structures of high aspect ratio [138].

In addition to conventional UVNIL, nowadays, the scientific community along with industrial partners has designed and up-scaled UVNIL methodologies to be able to perform patterning of various materials at the industrial scale and large area platforms [88,139]. This is known as roll-to-roll (R2R) UVNIL patterning and requires flexible yet highly resistant molds. Moreover, in order to create high-quality periodic polymeric patterns with R2R UVNIL such as arrays of lines, dots, or rectangles with critical dimension down to 200 nm [131] (Figure 6g), it is important to start with a rapid and uniform coating of resist [139]. In this sense, Koo et al. have developed a coating method based on airbrushing that was able to conformally coat the UV-curable polymeric resist at high speed and in a continuous manner, and have obtained large-area uniform lines [139]. Further information related to details on UVNIL on large industrial platforms can be found in recent reports [88,131].

Molding in capillaries NIL (MCNIL) represents another version of the NIL technique in which soft polymeric (most often PDMS) molds are placed directly on a solid substrate covered with a small quantity of liquid solution containing the desired functional material that will fill the patterns through the capillary action. Once the solvent is fully evaporated, the mold is removed, leaving behind replicated periodic patterns on the substrate (Figure 5c). MCNIL is a cost-effective, simple, and robust patterning method capable of patterning proteins as well as thermoplastic and conductive polymers at the nanometer scale on large areas [132].

The eventual slow evaporation of specific solvents makes MCNIL slower, but a slight heating of the substrate, eventually in vacuum conditions, can further compensate this drawback [102]. Instead of liquid solutions, MCNIL can also be performed on thin films. For instance, this can be done by placing the Sylgard 184 mold over PEDOT:PSS films to ensure a complete conformal contact between the two. The subsequent exposure of PEDOT:PSS films to water vapor induces swelling of the films followed by pattern replication driven by the capillary forces [140]. An interesting example where MCNIL was employed to fabricate arrays of submicrometer azopolymer pillars for unidirectional wetting and directional adhesion surfaces [103] (Figure 6h) was recently reported by Jo et al. Other examples where MCNIL is employed include the fabrication of arrays of protein lines, squares, triangles, circles, or stars for selective anti-biofouling surfaces [141]. Yet other patterns obtained by MCNIL include protein dots perfectly aligned along grooves [132] or thermoplastic (Figure 6i) and conductive polymer wires [132]. For more details, see Table 2.

2.5.2. Micro and Nanocontact Printing Lithography

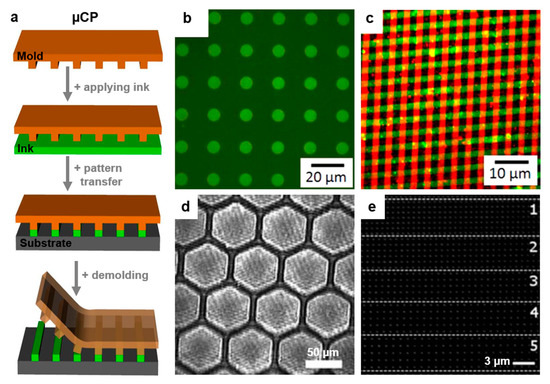

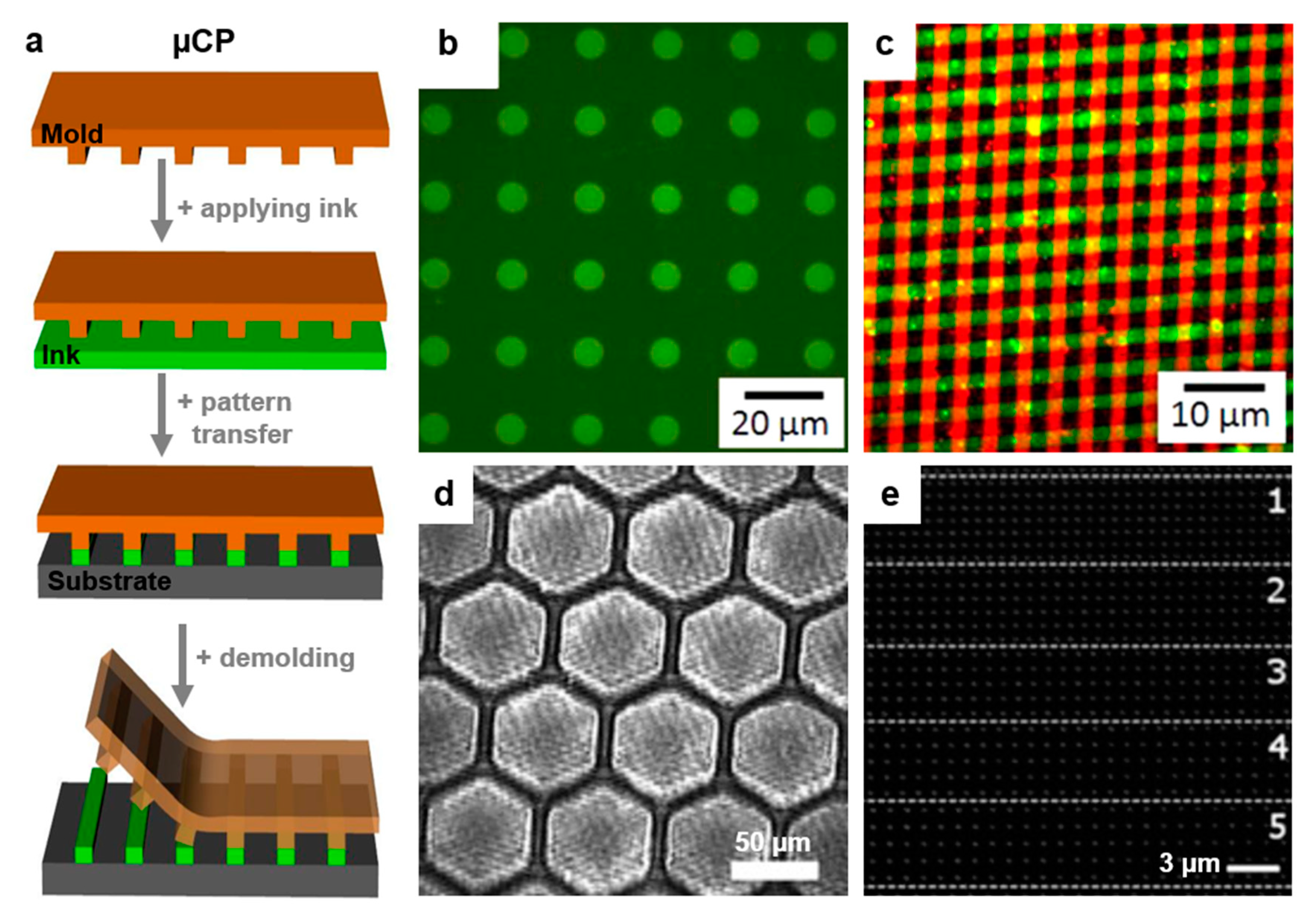

Microcontact printing (μCP) is a soft lithographic method that creates micrometer (or nanometer, e.g., nanocontact printing) surface relief patterns onto well-defined polymeric surfaces through the conformal contact of the latter with various patterns, of a PDMS master stamp, that are covered with polymer-based or self-assembled monolayer (SAM) inks (Figure 7a). Tips and tricks on how to explore the maximum potential of the μCP technique can be found in the literature [142]. This patterning technique is preponderantly used in biological applications, and it is accompanied by processes such as functionalization [143]. In order to increase interfacial adhesion across multiple materials [144] and thus create high-quality patterns of both nano and micrometer resolution, the μCP method needs adaptation through hydrophilic surface modification of the PDMS stamps via oxidation or coating [145]. Otherwise, the hydrophobic nature of the PDMS stamp can result in the denaturation or adsorption of protein-based inks; thus, the stamp would not be sufficiently/homogeneously covered, leading to an inefficient transfer of the pattern.

The extensive use of the μCP technique in materials science, especially biotechnology [46,146] and engineering [147] applications, is well-known. Examples of efficient employment of μCP include the fabrication of patterned amyloid material with high chemical and thermal stability [46,148], other proteins [149], viral membrane clusters [150], or polymer brushes [143]. Moreover, micrometer-sized patches of DNA can be enabled by μCP on poly(4-aminostyrene) (PAS) [147] (Figure 7b). PAS can further be employed as the base on which μCP can be utilized to realize more complex structures comprised of stripes of two different types of biomolecules micropatterned laterally and vertically (Figure 7c).

The μCP method is perfectible and offers place for a continuous design and improvement of new patterns inclusively by developing a universal PDMS-assisted nanoadhesive joining technique based on the adhesive nature of a PDMS oligomer layer [144]. This technique can lead to honeycomb patterns of PDMS oligomers (Figure 7d). Moreover, nanocontact printing can be utilized in biotechnology research when printing proteins on physiologically soft substrates for cell studies [151] is desired or when the production of nanodots [152] is needed. For instance, nanodots made of peptides mixed with antibodies and exhibiting a diameter of ≈200 nm can be patterned to form digital nanodot gradients (Figure 7e) for cell haptotaxis [152]. Furthermore, this method can pattern poly(pyrrole) (PPy) nanowires with a width below 800 nm [153]. The advantages of (nano/micro)contact printing techniques include their cost-effectiveness and the possibility to adapt to nanoparticle inks and to R2R processes [154] as well as to inkless contact printing assisted by the exposure to UV light and to the use of reactive resists [155].

Figure 7.

(a) Schematics depicting the microcontact printing (μCP) technique. (b,c) Fluorescence micrographs of micropatches of DNA (b) and of stripes of biomolecules (c) micropatterned via μCP on poly(4-aminostyrene) (PAS). (d) Optical image depicting polydimethylsiloxane (PDMS) micropatterns transferred to a solid silicon substrate. (e) Confocal fluorescence microscope image of a digital nanodot gradient patterned by nanocontact printing and comprised of grids of 200 nm dots of an “ink” made of a peptide that was mixed with an antibody. The image shows five rectangular boxes (labeled 1–5) of the digital nanodot gradient with a grid size of 1052, 1171, 1286, 1397, and 1504 nm. Adapted with permission from ref. [147] (b,c), from ref. [144] (d) and from ref. [152] (e). Copyright (2014) American Chemical Society and (2011, 2013) John Wiley and Sons.

Figure 7.

(a) Schematics depicting the microcontact printing (μCP) technique. (b,c) Fluorescence micrographs of micropatches of DNA (b) and of stripes of biomolecules (c) micropatterned via μCP on poly(4-aminostyrene) (PAS). (d) Optical image depicting polydimethylsiloxane (PDMS) micropatterns transferred to a solid silicon substrate. (e) Confocal fluorescence microscope image of a digital nanodot gradient patterned by nanocontact printing and comprised of grids of 200 nm dots of an “ink” made of a peptide that was mixed with an antibody. The image shows five rectangular boxes (labeled 1–5) of the digital nanodot gradient with a grid size of 1052, 1171, 1286, 1397, and 1504 nm. Adapted with permission from ref. [147] (b,c), from ref. [144] (d) and from ref. [152] (e). Copyright (2014) American Chemical Society and (2011, 2013) John Wiley and Sons.

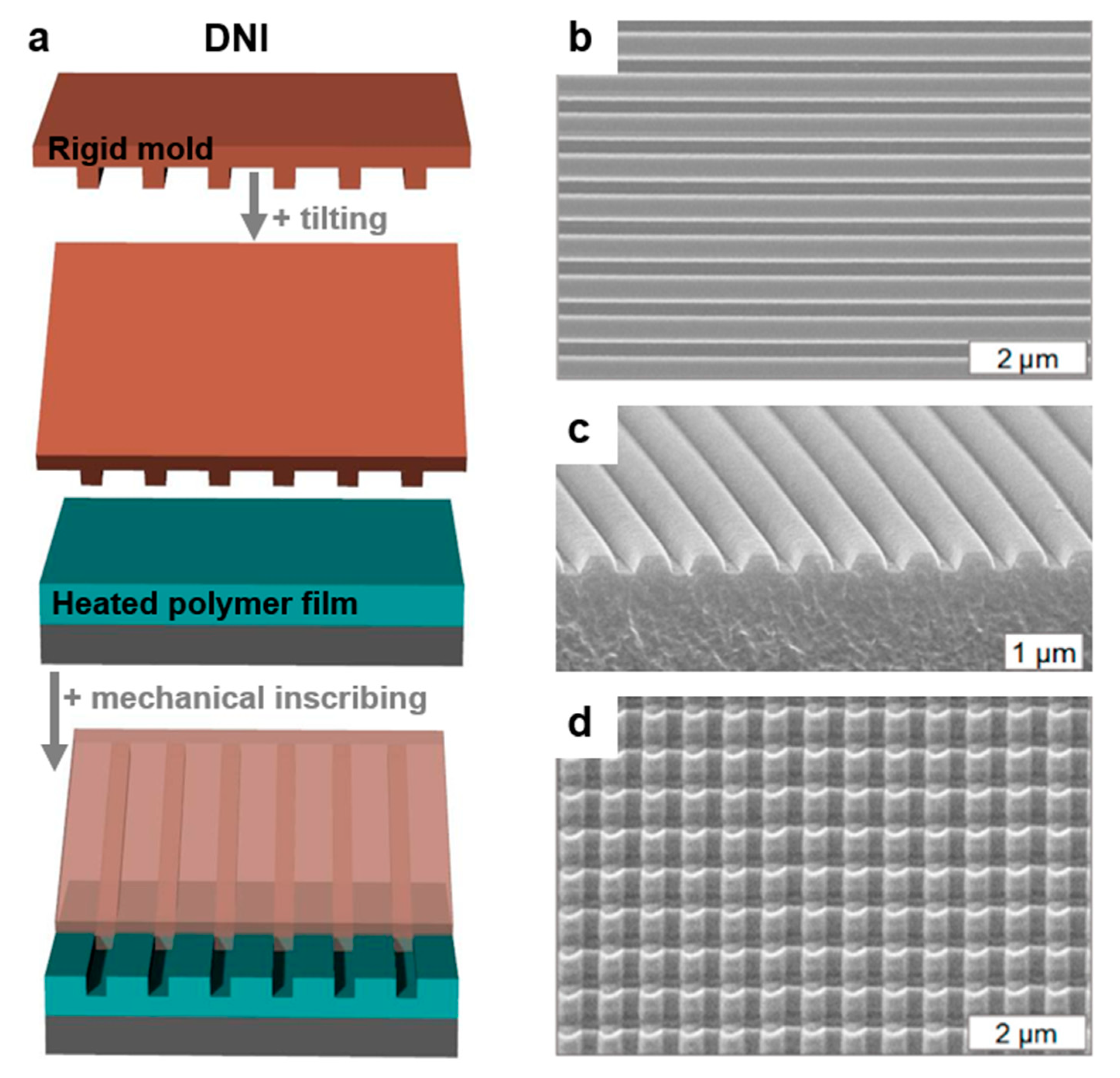

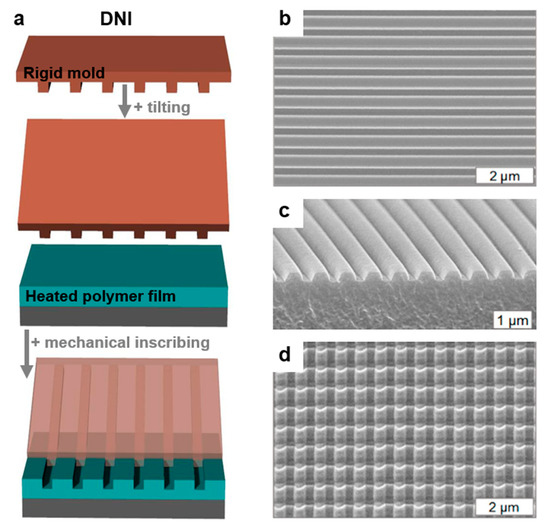

2.5.3. Dynamic Nanoinscribing

At the end of this soft lithography section, we would like to shortly include and describe the controlled dynamic nanoinscribing (DNI) technique, even though in this case, a sliced edge from a patterned rigid mold is used. DNI is based on the continuous mechanical inscribing of various flexible polymer substrates in order to replicate different bur-free patterns (Figure 8a) with a periodicity down to ≈50 nm [156]. At this value, the experimental limit is believed to be reached. The advantage of this techniques relies on the possibility to obtain gradient patterns or multidimensional profiles by modulating the angle between the sliced edge and the flexible substrate to be patterned. The disadvantages of DNI consist of the necessity to heat the polymer substrates around their glass transition temperature (Tg), while the patterns that can be obtained with DNI are rather limited to 1D arrays of lines (Figure 8b,c) or to 2D patterns obtained by multidimensional DNI [156] (in this case, DNI is performed at least two times along different directions; Figure 8d). Such patterns can be obtained on flexible polymer materials such as polycarbonate (PC), polyethylene terephthalate (PET), perfluoroalkoxy alkane (PFA), or polyimide (PI). Moreover, in order to determine the nanopattern depths and their specific profiles from rounded to angular shapes, DNI requires the precise control of several critical parameters such as the inscribing force, substrate temperature, or substrate feed rate [156].

Figure 8.

(a) Illustrative representation of the dynamic nanoinscribing (DNI) technique. (b,c) Top (b) and cross-sectional (c) SEM images depicting arrays of lines obtained by DNI on polymeric substrates. (d) SEM image depicting 2D patterns obtained by multidimensional DNI. Adapted with permission from ref. [156] (b–d). Copyright (2019) American Chemical Society.

Table 2.

Summary of various surface relief patterns that can be developed via soft lithography.

Table 2.

Summary of various surface relief patterns that can be developed via soft lithography.

| Lithography | Type of Mold | Patterned Material | Resulting Pattern | Pattern Dimension | Ref. |

|---|---|---|---|---|---|

| TNIL | PDMS | PLCL | Linear ridges/grooves | 3/3 μm/width | [111] |

| TNIL | PDMS | Anisotropic PAM | Linear ridges/grooves | 30/30 μm/width | [97] |

| TNIL | Silicon | P(VDF-TrFE) | Pillars | 65 nm/diameter | [110] |

| TNIL | PDMS | Proteins | Lines | 700 nm/period | [114] |

| TNIL | PDMS | Poly-DR1M | Pillars | 4 μm × 4 μm | [113] |

| TNIL | PDMS | Cyclo-olefin polymer, PC | Grooves Moth-eye | 20 nm/width 347 nm/period | [127] |

| TNIL | PDMS | PAM hydrogel | Grooves | 30 μm/width | [119] |

| TNIL | PDMS | Nafion resin | Grooves | 800 nm/width | [120] |

| TNIL | PDMS | Fluorinated polymer | Gratings | 760 nm/pitch | [121] |

| TNIL | PDMS | PEDOT:PSS | Lines | 87 nm/width | [122] |

| TNIL | Silicon | ETFE, PMMA, SU-8 | Recessed hierarchical gratings | ≈254 nm/width on ~2.18 μm/width | [128] |

| TNIL | PDMS | PVP, PVAc, PVDF/PMMA | Lines | ≥6 μm/width | [123] |

| TNIL | Silicon | PMMA | Gratings | 250 nm/width | [108] |

| TNIL | PDMS | PEDOT:PSS, P3HT:PCBM | Lines | 340 nm/period | [94] |

| TNIL | Silicon | P(VDF-TrFE-CFE) | Lines | 60–100 nm/width | [93] |

| TNIL | Silicon | FEP, PVDF, PDFE, PFA, PCTFE | Dots | 500 nm/diameter 800 nm/period | [107] |

| TNIL | PDMS | PS, PEDOT | Lines | 416 nm/width | [96] |

| TNIL | PDMS | PS | Elliptical hemispheres | 279 nm/width | [100] |

| TNIL | PDMS | Gelatin/genipin | Grooves Holes Pillars | 500 nm/width 500 nm/diameter 100 nm/diameter | [124] |

| TNIL | Cyclodextrin-based, porous | Polylactide | Lines | 150 nm/width | [118] |

| TNIL | PUA | HA | Lines Dots Holes | 200 nm/width 480 nm/diameter 265 nm/diameter | [3] |

| TNIL | PDMS | PBMA | Lines, 2D grids Nanoholes | 10 nm/width 20 nm/diameter | [87] |

| TNIL | PDMS | PLLA | Nanocups, nanocones | 750 nm/pitch | [115] |

| UVNIL | PDMS | Metallopolymers | Nanodots | 460 nm/diameter | [136] |

| UVNIL | Silicon | Hybrid polymer | Grooves | 30 nm/width | [137] |

| UVNIL | Silicon | PEGDMA | Nanoneedles | 50 nm/diameter (tip) | [129] |

| UVNIL | PUA | PUA | Ridges/grooves | 800/800 nm/width | [99] |

| UVNIL | Silicon | PEG | Ridges/grooves | 3/3 μm/width | [98] |

| UVNIL | PDMS | Poly(β-hydroxyl thio-ether) | Lines Stars Grids Pillars | ≈70 μm/width ≈38 μm/“diameter” 10 μm/width 200 nm/diameter | [130] |

| UVNIL | PDMS | UV-curable polymer | Recessed pillars | 300 nm/diameter | [138] |

| UVNIL | Bilayer h-PDMS/PDMS | Amonil/PMMA | Pillars Lines | 50 nm/diameter 50 nm/width | [134] |

| UVNIL | PDMS | Ormostamp/Amonil | Holes | 350 nm/diameter | [157] |

| UVNIL | Silicon | SSQ/PEG | Lines | 25 nm/width | [135] |

| MCNIL | PDMS | mr-7010 polymer PEDOT:PSS | Nanowires | 53 nm/width 100 nm/width | [132] |

| MCNIL | PDMS | Azopolymers | Pillars | 17 μm/diameter | [102] |

| MCNIL | PDMS | Azopolymers | Bent pillars | 1 μm/diameter | [103] |

| MCNIL | PDMS | PEG-PLA/PEL | Lines Squares Triangles Circles Stars | 590 nm/width 10 μm × 10 μm 30 μm/size 40 μm/diameter 40 μm/“diameter” | [141] |

| μCP | PDMS, PVA | Protein/Sylgard 527 | Nanodots | 200 nm × 200 nm | [151] |

| μCP | PDMS | Proteins/polymer | Nanodots | ≈200 nm/diameter | [152] |

| μCP | PDMS | Biomolecules/PAS | Stripes Pads | ≈2 μm/width ≈7 μm/diameter | [147] |

| μCP | PDMS | Proteins/PIPAAm | Lines | 20 μm/width | [149] |

| μCP | PDMS | Au nanorods/PLL | Grains | ≈290 nm/diameter | [146] |

| μCP | PDMS | PPy, PI, PEN, COC | Nanowires | ≈785 nm/width | [158] |

| μCP | PDMS | Neutravidin/PLL-g-PEG biotin | Spherical vesicles | ≈62 nm/diameter | [150] |

| μCP | Rigiflex/PET | Poly(4-vinyl phenol) | Lines | 400 nm/width | [155] |

| DNI | SiO2 | PC, PET, PFA, PI | Lines | 700 nm/period | [156] |

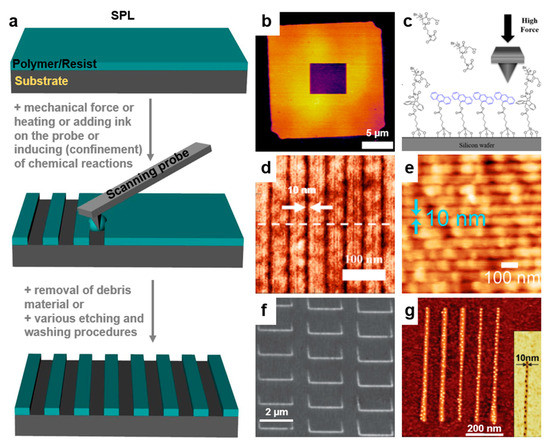

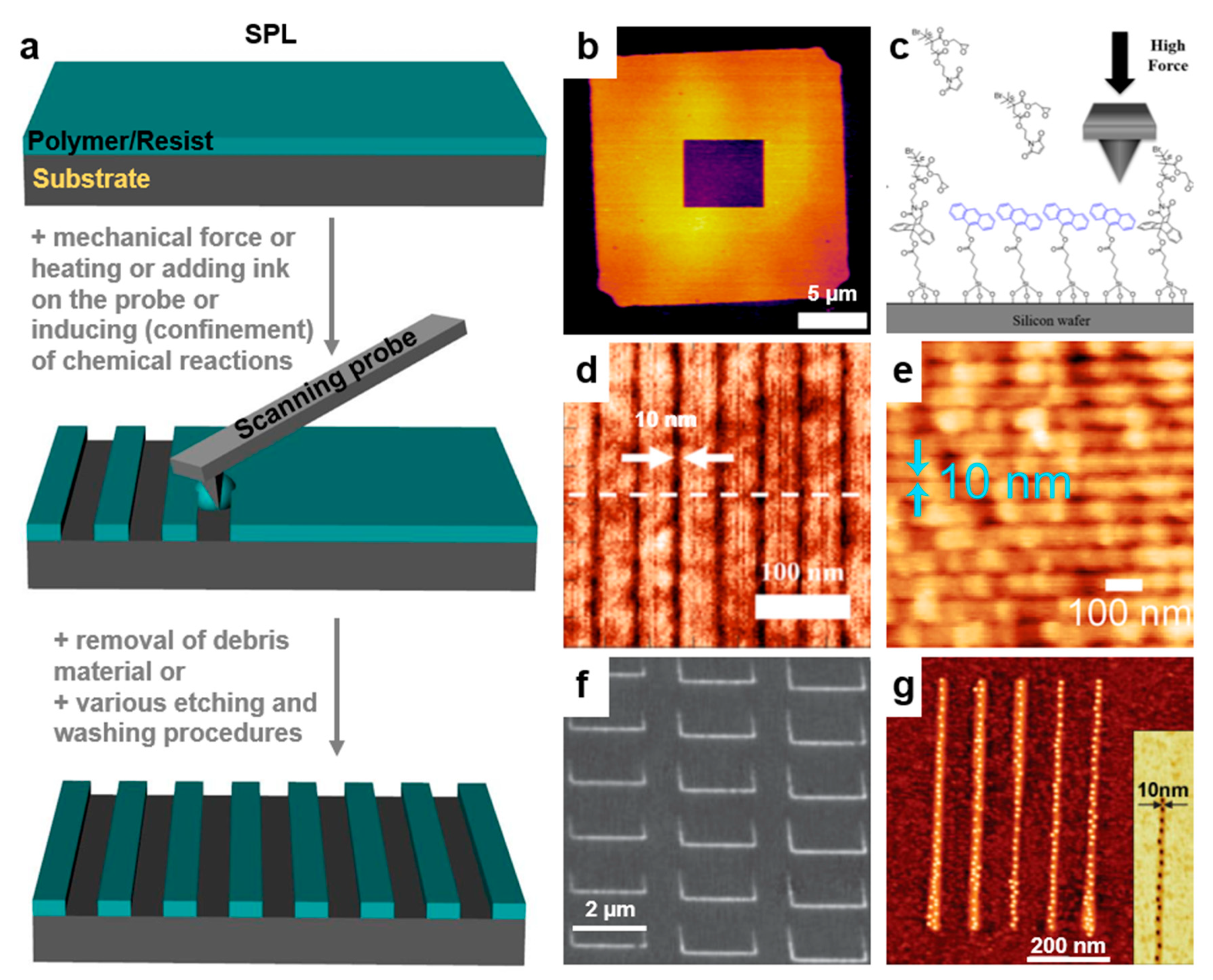

2.6. Scanning Probe Lithography

Scanning probe lithography (SPL) is a methodology used to pattern various materials down to the nanoscale and beyond, to individual atoms, without the need of masks, by employing various sharp scanning probes (Figure 9a). Such probes include the atomic force microscopy (AFM) tips controlled by high-precision piezoelectric scanners. Scanning probes are able to exert, on materials that need to be patterned, various stimuli including force, heat, or electric fields, just to name a few. There are many types of SPL, and they can be consulted in the literature [159]. Generally, SPL is used over EBL or IBL because it does not involve radiation which can, in some cases, damage the surface of thin films. Moreover, SPL is a user-friendly technique, with operation of the instrumentation being made through a computer software. Nonetheless, to create topographical patterns of nanoscale (see examples in Table 3), multiple parameters such as applied voltage, air humidity, and scanning speed have to be adapted [160]. SPL can be easily employed to create patterns at ambient heat and humidity, and it can be used on nonconductive polymers by exploiting their mechanical properties. Despite these advantages, and despite being capable to reach a sub-10 nm [161,162] patterning resolution, SPL is much slower compared to other lithographic techniques. This inconvenience can be mitigated at some extent by increasing the patterning speed through the employment of multi-tip lithographic systems [163].

2.6.1. Mechanical Scanning Probe Lithography

Mechanical SPL (MSPL) is based on the mechanical force exerted by a sharp tip on a (polymeric) material in order to induce the selective removal [164,165] or spatial activation [166] of the latter on the surface, with the aim to create desired surface relief patterns (Figure 9a). Obtained patterns may include PMMA ridges of a pitch varying from 30 to 100 nm [164] or large protein covered self-assembled monolayer (SAM) assays [165]. Other patterns such as squares of several micrometers developed in poly-(glycidyl methacrylate) (PGMA) brushes deposited on maleimide-anthracene mechanophores covered silicon wafers were also demonstrated [166] (Figure 9b). Here, the mechanophores were activated locally by applying high force on the AFM probes in order to deliver mechanical stimulation and to force the individual mechanophores to undergo a retro-[4 + 2] cycloaddition reaction, with the aim to form a surface-bound anthracene moiety and free PGMA [166] (Figure 9c).

Unfortunately, the limiting factor in creating sharp and yet reproducible patterns by MSPL is the stability of the tip itself, which is vulnerable to the contamination from the debris of the removed material [167] and to the deformation induced inclusively by the patterning speed. Often, to minimize such drawbacks, MSPL is coupled with additional thermal treatment of the tip [168], while the operation of contact mode AFM without active feedback increases the patterning speed in polymeric resists. As a result, high-quality patterns, including square wave patterns, or fractal carpet patterns with a pitch of 15 nm or even circle and triangle patterns with a pitch of 40 nm [168], can be fabricated.

2.6.2. Thermal and Thermochemical Scanning Probe Lithography

Thermal scanning probe lithography (TSPL) uses a scanning probe with a heated tip that can efficiently remove material from a surface without the need for significant mechanical forces. The advantage of TSPL consists in overall control over the patterning depth that leads to realization, in various polymer-based resists, of high-resolution surface relief structures at a half pitch down to 15 nm [169]. Moreover, the patterning resolution with TSPL can go further down, especially when patterns such as lines are targeted. This was demonstrated by Gottlieb et al. who have patterned ≈10 nm wide lines in thin films of poly(phthalaldehyde) (PPA) [170] (Figure 9d).

Instead, thermochemical scanning probe lithography (TCSPL) uses various scanning probes to induce thermally activated chemical reactions that are modifying chemical functionalities, inclusively in (conjugated) polymers covering solid surfaces [171]. The advantage of TCSPL is that it can generate miniaturized periodic patterns (squares, rectangles, dots) of enzymes on pre-patterned copolymers containing thermally labile tetrahydropyran carbamate-protecting groups [161]. These patterns, which also include sub-10 nm lines close to enzyme molecular dimension (Figure 9e), were proved to be ideal for various nano-biodevices [161,162]. Similarly, biodevices based on proteins covered polymeric patterns can further profit from TCSPL, as it was demonstrated by Albisetti et al. who realized streptavidin squared and triangular patterns in a methacrylate copolymer presenting functional amines protected by tetrahydropyran carbamate groups [172].

Figure 9.

(a) Illustration of the scanning probe lithography (SPL) principle. (b) AFM topographic image of a poly-(glycidyl methacrylate) (PGMA) brush acquired under 10 nN force that was then subjected in the central region (5.46 × 4.80 μm) to high-force (450 nN) scans. (c) Activation of mechanophores at the interface between PGMA and silicon surface using an AFM probe. (d) AFM image depicting a highly uniform pattern written by thermal scanning probe lithography (TSPL) in polyacrylic acid (PAA) exhibiting 10 nm lines at <47 nm pitch. (e) AFM topography image showing high-resolution single-line patterns made of an enzyme on a copolymer and exhibiting a width smaller than 10 nm. (f) AFM image of PMMA polymer brush lines fabricated by dip-pen scanning probe lithography (DPSPL) with different operating conditions. (g) Typical AFM topography image of lines of ferritin molecules deposited on the 10–15 nm local oxide lines. The inset shows the AFM phase image of a single oxide line containing individual dark spot ferritin molecules. Adapted with permission from ref. [166] (b,c), ref. [170] (d), ref. [161] (e), ref. [173] (f) and ref. [174] (g). Copyright (2019) American Chemical Society, (2017) IOP Publishing and (2010, 2014) John Wiley and Sons.

Figure 9.

(a) Illustration of the scanning probe lithography (SPL) principle. (b) AFM topographic image of a poly-(glycidyl methacrylate) (PGMA) brush acquired under 10 nN force that was then subjected in the central region (5.46 × 4.80 μm) to high-force (450 nN) scans. (c) Activation of mechanophores at the interface between PGMA and silicon surface using an AFM probe. (d) AFM image depicting a highly uniform pattern written by thermal scanning probe lithography (TSPL) in polyacrylic acid (PAA) exhibiting 10 nm lines at <47 nm pitch. (e) AFM topography image showing high-resolution single-line patterns made of an enzyme on a copolymer and exhibiting a width smaller than 10 nm. (f) AFM image of PMMA polymer brush lines fabricated by dip-pen scanning probe lithography (DPSPL) with different operating conditions. (g) Typical AFM topography image of lines of ferritin molecules deposited on the 10–15 nm local oxide lines. The inset shows the AFM phase image of a single oxide line containing individual dark spot ferritin molecules. Adapted with permission from ref. [166] (b,c), ref. [170] (d), ref. [161] (e), ref. [173] (f) and ref. [174] (g). Copyright (2019) American Chemical Society, (2017) IOP Publishing and (2010, 2014) John Wiley and Sons.

2.6.3. Dip-Pen Scanning Probe Lithography

Dip-pen scanning probe lithography (DPSPL) is a mask-free patterning method based on a diffusion process, i.e., on the transferring of various liquid inks from scanning probes to a range of surfaces. In this sense, DPSPL is different from the other SPL types because it adds material (ink) on top of a certain surface instead of removing material by force or by chemical reactions followed by etching. Additional capacity for thermal heating of the probe provides DPSPL with the possibility to also create patterns from solid inks. Once heated, such inks can be deposited in their liquid state, leading to advantages such as the uniformity of the resulting structures and the high reproducibility. Moreover, 2D arrays containing tens of thousands of probes can be tailored and further used to increase the patterning speed of DPSPL beyond that of EBL [27].

There are several interesting examples reported in the literature where DPSPL was successfully employed to create polymeric patterns. For instance, this method was shown to be able to rapidly create, over a rather large area, 3D brush structures such as 66 to 115 nm wide PMMA “elongated dots” and 80 to 115 nm wide PMMA nanolines [173] (Figure 9f). Furthermore, DPSPL can be used to transfer various hybrid inks based on block copolymer and metal ions in the form of ≥100 nm features on an underlying substrate. This enables a precise control over the growth and position of individual nanoparticles in situ [175]. When the polymer is removed and the metal ions are reduced through plasma etching, arrays of single crystal nanoparticles of less than 5 nm are obtained. Similarly, DPSPL can be used to pattern lipids on SAMs with the purpose to follow lipid microdomain formation [176]. Here, the obtained patterns are comprised of lipid dots displaying a diameter in the micrometer range. Further details about the recent developments on DPSPL and about the patterning strategies associated with this technique can be found in the literature [177,178].

2.6.4. Oxidation Scanning Probe Lithography

Oxidation scanning probe lithography (OSPL) is a versatile patterning method based on the spatial confinement of an oxidation reaction and can be used when sub-10 nm polymeric patterns are required [179]. The good dimensional quality of patterns is owed to impeccable close-loop correction of the AFM displacement in all three dimensions. By adapting parameters such as the tip dimension and shape, the applied voltage and the environmental humidity (usually, oxidation takes place in the presence of water adsorbed to the tip), OSPL can be used to pattern a broad range of materials, including block copolymers [179] or proteins [174] deposited on oxidized polymer brush layers [179] and octadecyltrichlorosilane (OTS) or on aminopropyltriethoxysilane (APTES) SAMs [174]. As a consequence, patterns such as narrower [179] or wider [174] than 10 nm lines (Figure 9g) or even erasable circles with a line width of ≈80 nm [180] can be fabricated. Again, to increase the patterning speed, multi-tip OSPL can be developed and used [163]. More details on the OSPL patterning technique can be further consulted in the literature [181].

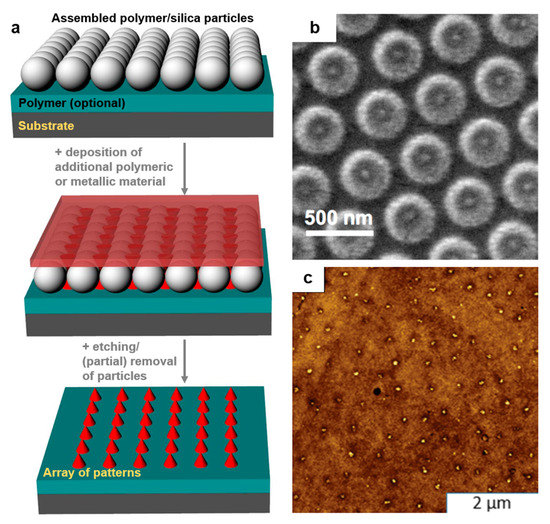

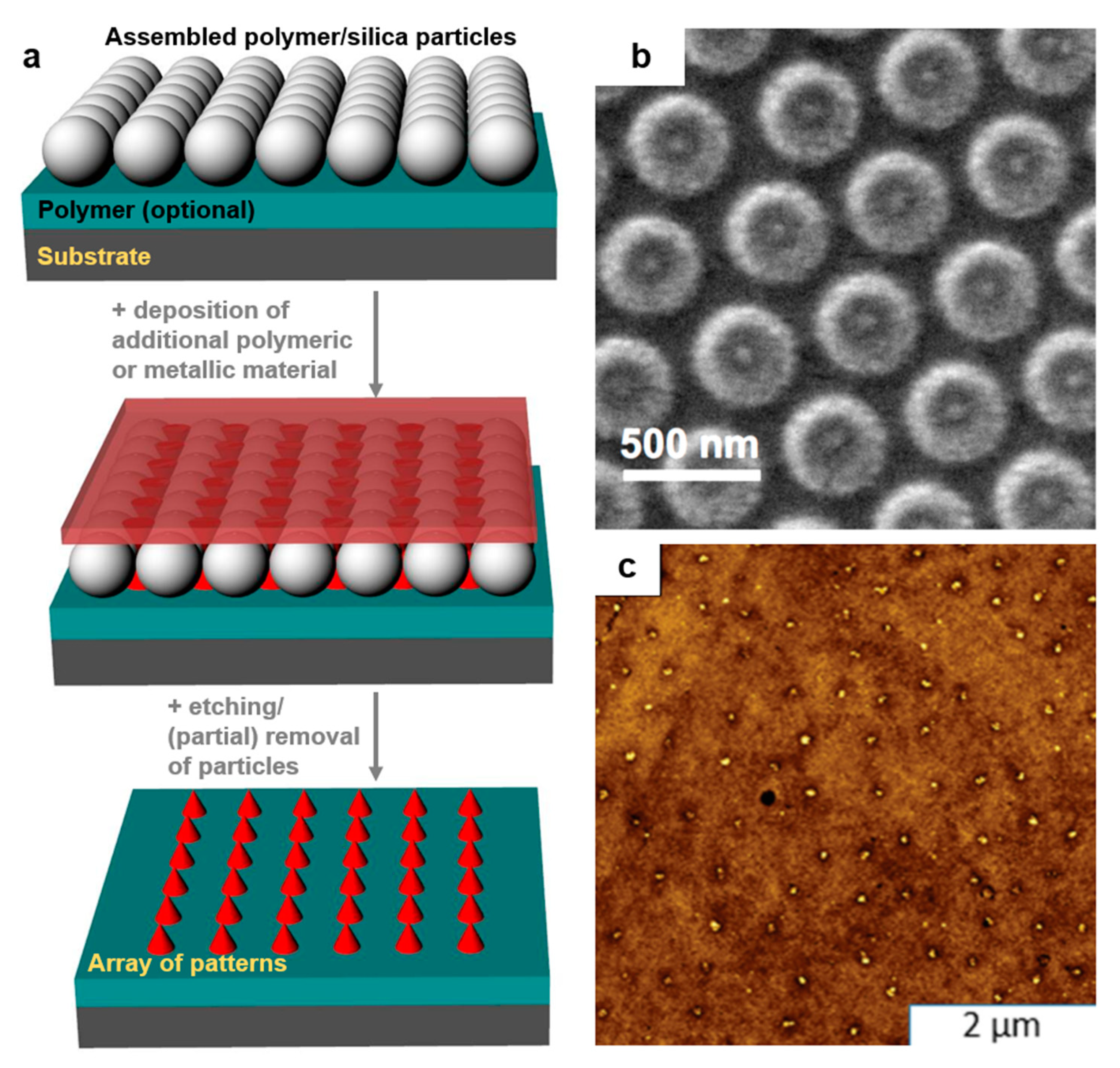

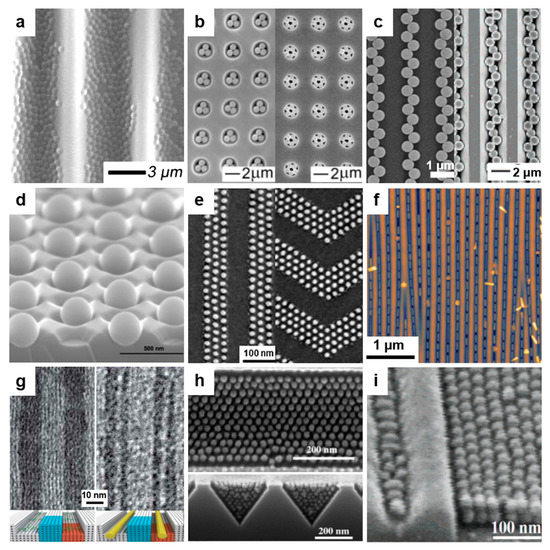

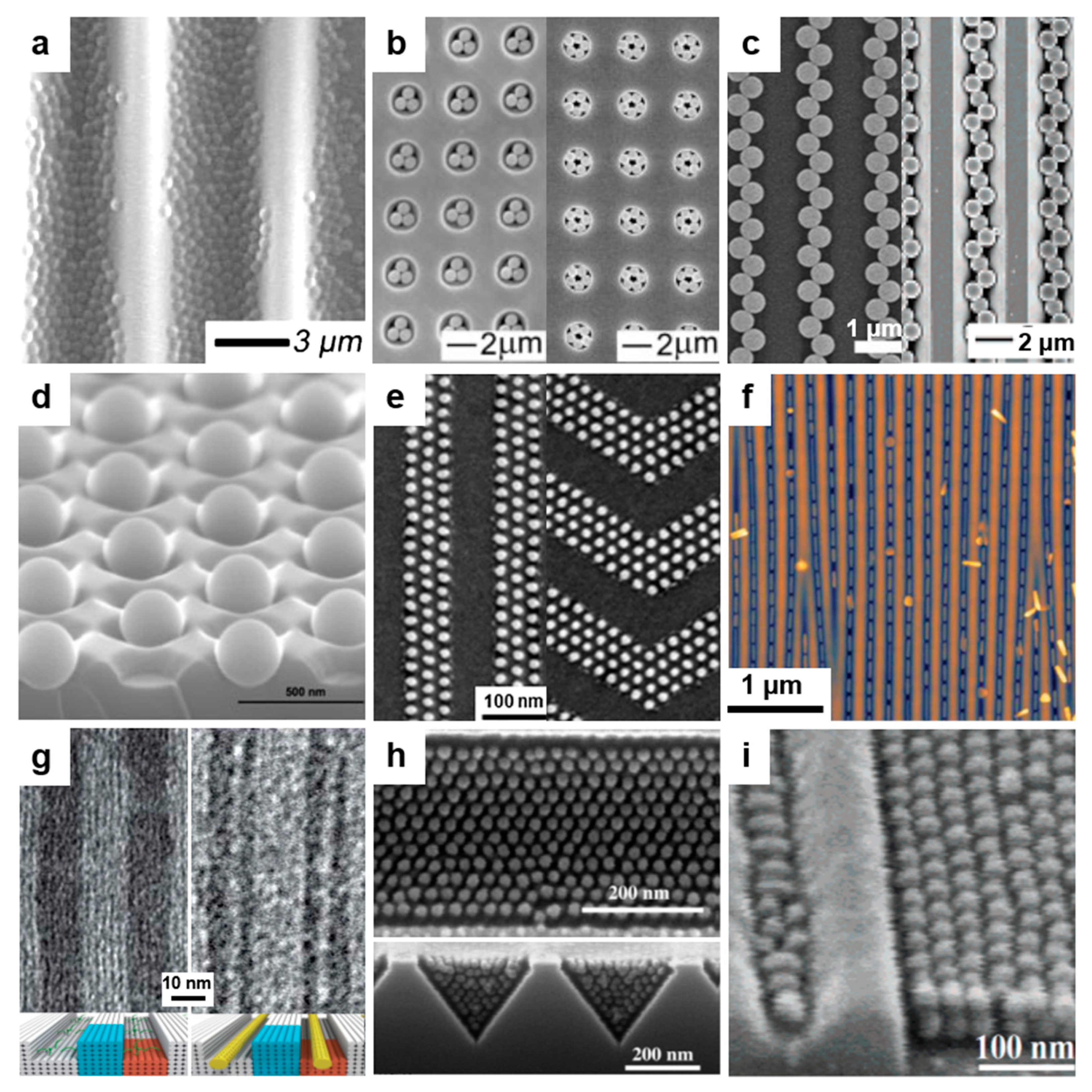

2.7. Particle Lithography

Particle lithography (PL) is a massively used patterning method that takes advantage of an evaporation mask made of (self-)assembled (colloidal) particles/spheres of silica or polymers (Figure 10a). It can constantly lead to sub-200 nm polymeric surface relief patterns of different geometrical shapes at low cost and on a large range of substrates [182]. Particles can get assembled using common techniques such as Langmuir–Blodgett, dip coating, spin coating, drop casting, doctor blade, etc. PL has the advantage of being able to develop hierarchical polymeric features in ambient conditions [183] without the need for expensive clean-room equipment. Often, this method is used along with various etching processes, including solvent [182] or (enhanced) plasma [184] etching. A typical example of patterns created by PL was given by Valsesia et al. By employing a colloidal PS mask, they have created nanocraters of PAA surrounded by poly(ethylene glycol) (PEG) (Figure 10b). Experimentally, this was done by depositing PS particles on PAA followed by the deposition of PEG on top of the PS mask, which in turn was followed by a plasma-enhanced etching process [184].

In recent examples reported in the literature (Table 3), PL has been used to create a variety of nanostructured patterns [185], including arrays of metallic nanobowls, nanoholes, nanocones, nanovolcanos, nanotriangles, etc. These patterns are obtained mostly by depositing thin metallic films on the polymeric particle mask assembled on non-confined substrates and followed by the partial removal of the mask. Nonetheless, in order to study, for example, cell recruitments or various arrangements and patterns of proteins in confined structures, microfluidic grooves can be fabricated, too. This was shown by Andersen et al. who have fabricated protein nanostructured circular domains of a diameter ranging down to 100 nm [186]. Other examples of PL being used in biomedical field applications include the realization of protein-covered circular patches of a diameter ranging from 15 to 200 nm (by using hole mask PL nanowells [187]) and the generation of circular patches of green fluorescent proteins bound to organosilane (Figure 10c). These patches have a diameter of ≈125 nm and were obtained by PL using 500 nm silica particles [188].

PL can be further applied to create masks [189] that then can be employed in other type of lithographic techniques in order to generate various patterns in polymeric materials. For instance, Friedl et al. have exploited a spin coating approach to prepare colloidal monolayers of PS particles of diameters ranging from few to several hundreds of nanometers on corresponding grating templates. Their studies revealed that smaller particles had a higher coverage capability [189], being better suitable for the mask fabrication. Moreover, Saracut et al. have created uniaxial colloidal arrays by the colloidal assembly of 500 nm PS spheres on a DVD substrate patterned with structures exhibiting a lateral periodicity of 750 nm [4]. The well-arranged, parallel, and periodic chains of particles were further covered with a thin layer of silver and employed as a lithographic mask to create metal half shells. Although in all the above cases polymer/silica particles were assembled into packed structures, there are examples in the literature where arrays of PS spheres adopting a non-close-packed structure are being used too, in order to fabricate cylindrical grooves in thick poly(4-vinylphenol) (PVP) layers [190].

Figure 10.

(a) Schematics of the particle lithography (PL) patterning technique. (b) Nanocraters of PAA surrounded by a matrix of poly(ethylene glycol) (PEG). (c) AFM topography image depicting circular patches of a protein bound to organosilane. Adapted with permission from ref. [184] (b) and ref. [188] (c). Copyright (2006) John Wiley and Sons and (2017) American Vacuum Society.

Figure 10.

(a) Schematics of the particle lithography (PL) patterning technique. (b) Nanocraters of PAA surrounded by a matrix of poly(ethylene glycol) (PEG). (c) AFM topography image depicting circular patches of a protein bound to organosilane. Adapted with permission from ref. [184] (b) and ref. [188] (c). Copyright (2006) John Wiley and Sons and (2017) American Vacuum Society.

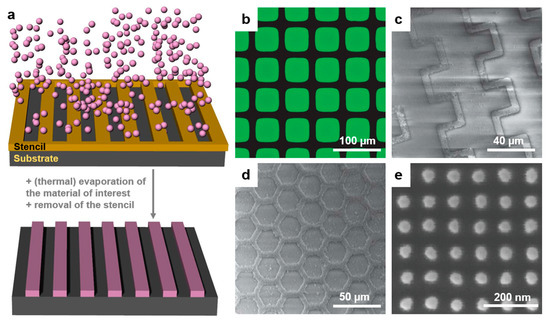

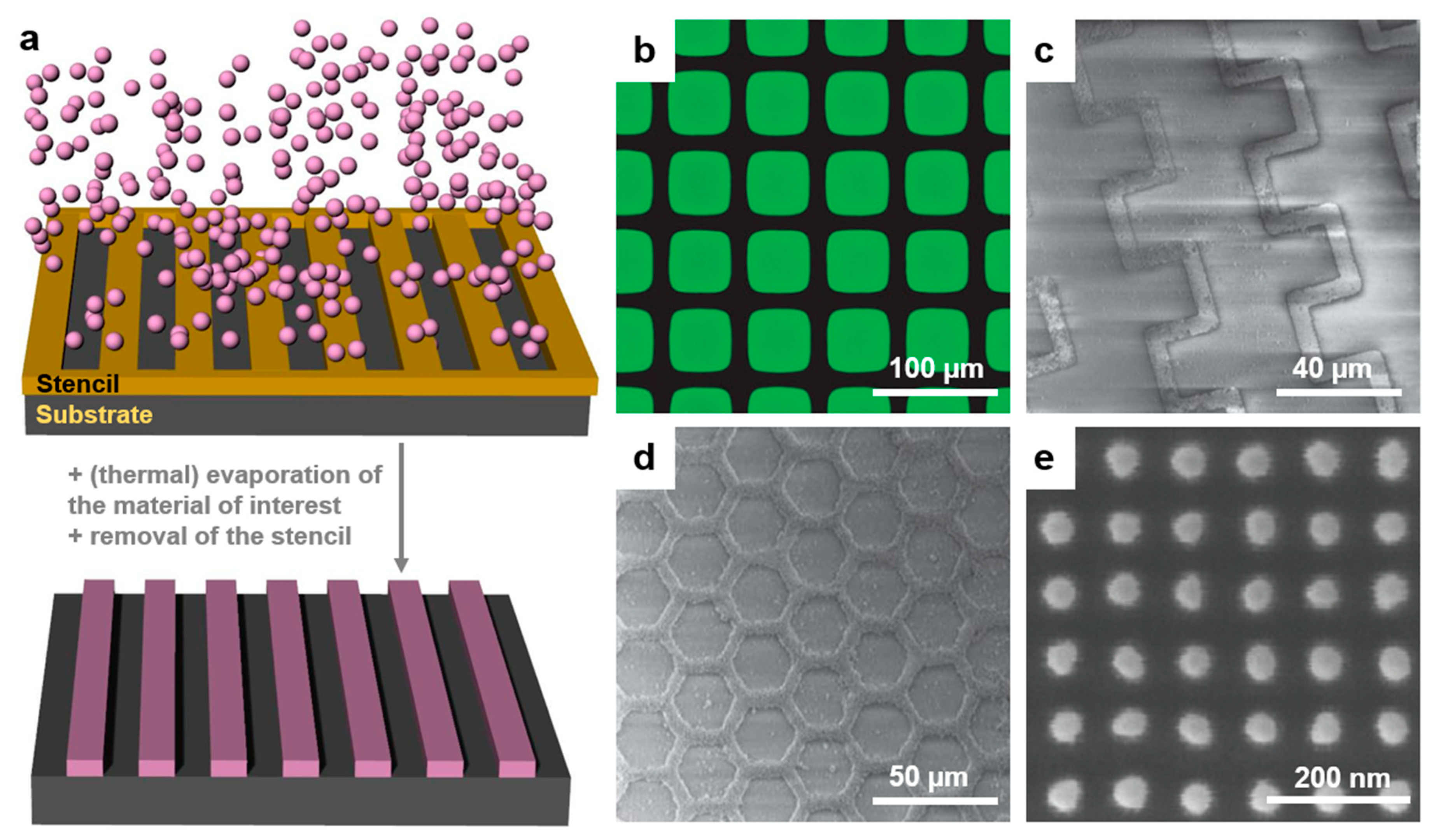

2.8. Stencil Lithography

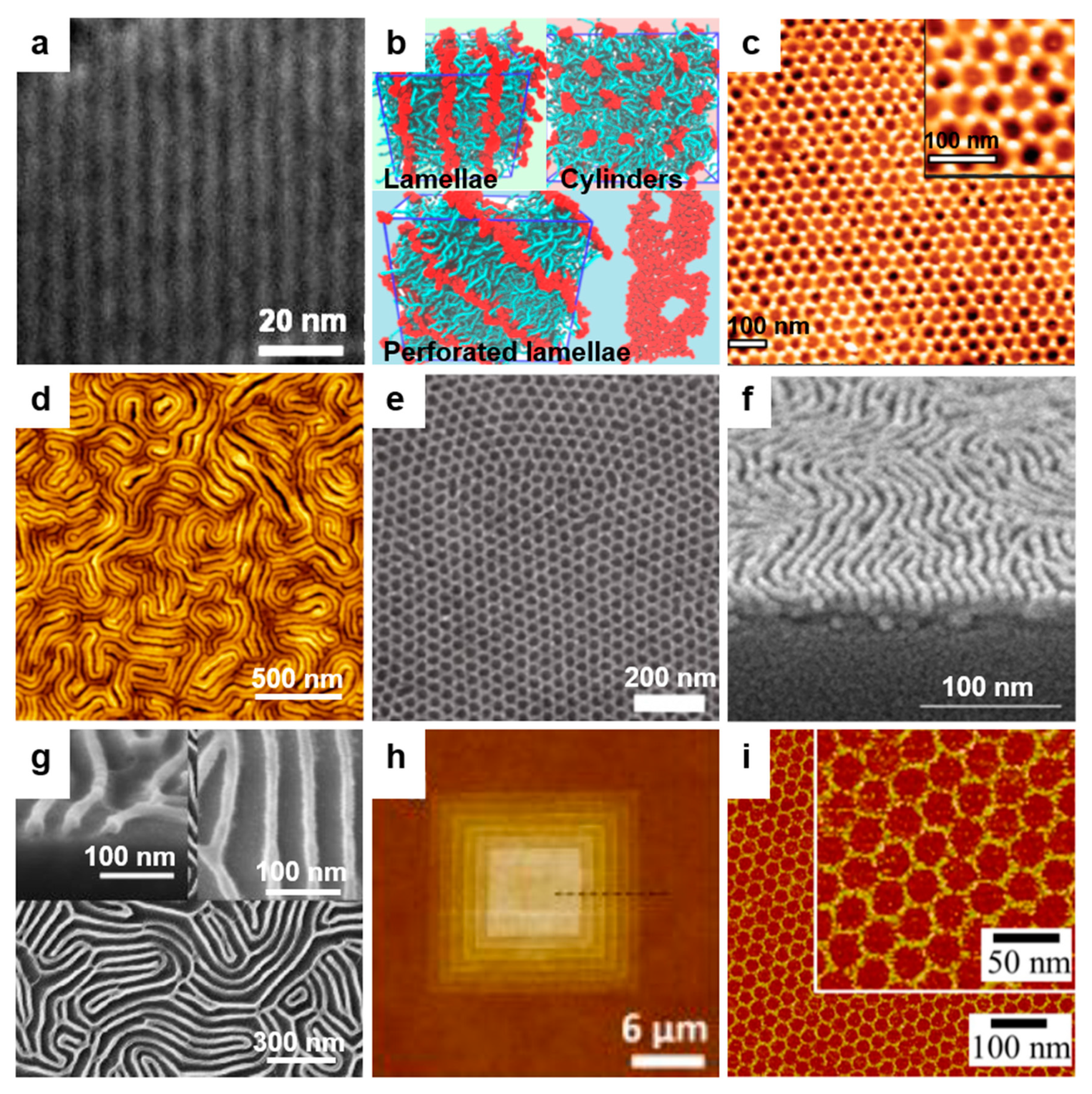

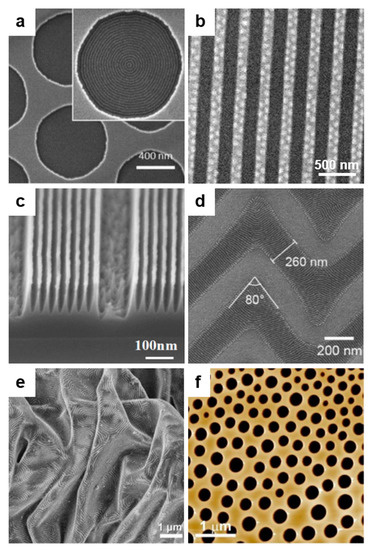

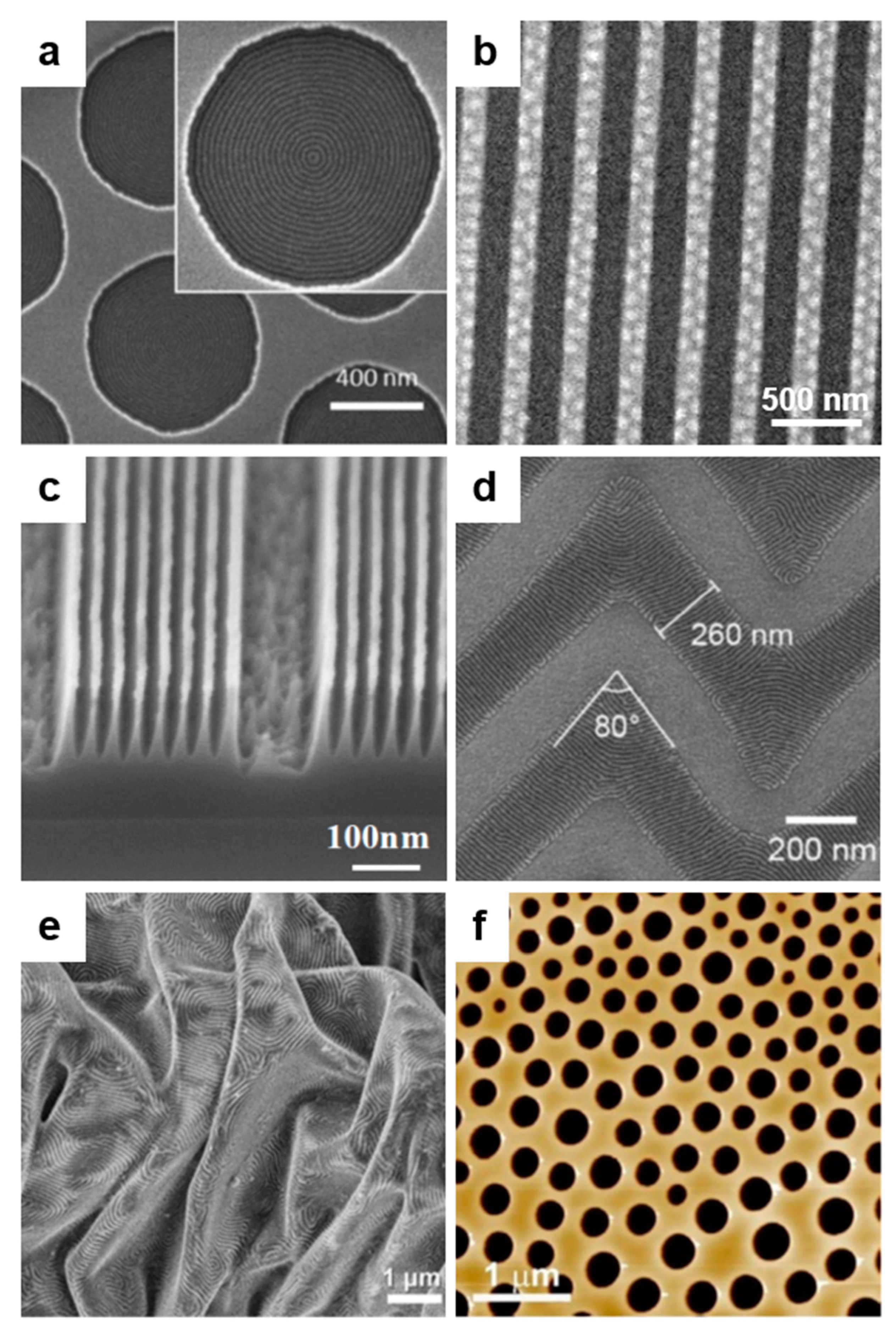

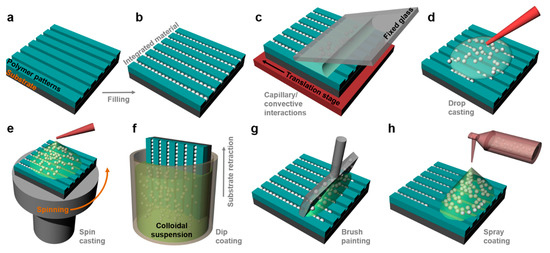

Stencil lithography (SL) is a patterning method based on the use of nanometer-sized apertures called shadow or stencil masks. SL is employed to create micro- or nanostructures for various applications, including plasmonics, transistors, gratings, magnetic structures, fabrication of NIL stamps, cell and protein patterning, or biosensing devices [191,192]. This method shows high versatility because it can rapidly pattern large areas, it is based on simple material deposition techniques such as thermal evaporation [193], and it can be applied on multiple materials without the need for a certain resist layer (Figure 11a). Moreover, the stencils can be reused many times, thus making SL a cost-effective patterning approach. This is especially valid when the fabrication of smaller-sized structures is targeted. Furthermore, special attention is needed when reusing the stencil, because it can become clogged, leading to lower fidelity of the initial proposed design. Additionally, the membrane stability has to be taken into consideration when the desired pattern needs a high aspect ratio (a fragile membrane of the stencil can create deformations on the pattern or it can break during the lithographic process [192]). Other advantages or disadvantages of SL were highlighted by Vasquez-Mena and collaborators and can be found in the literature [192].