Incorporating MXene into Boron Nitride/Poly(Vinyl Alcohol) Composite Films to Enhance Thermal and Mechanical Properties

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

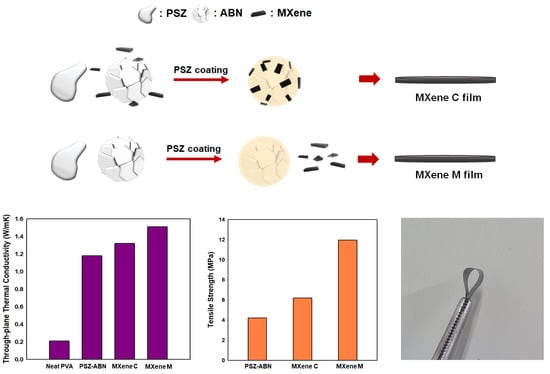

2.2. Preparation of the Composite Film

2.3. Characterization

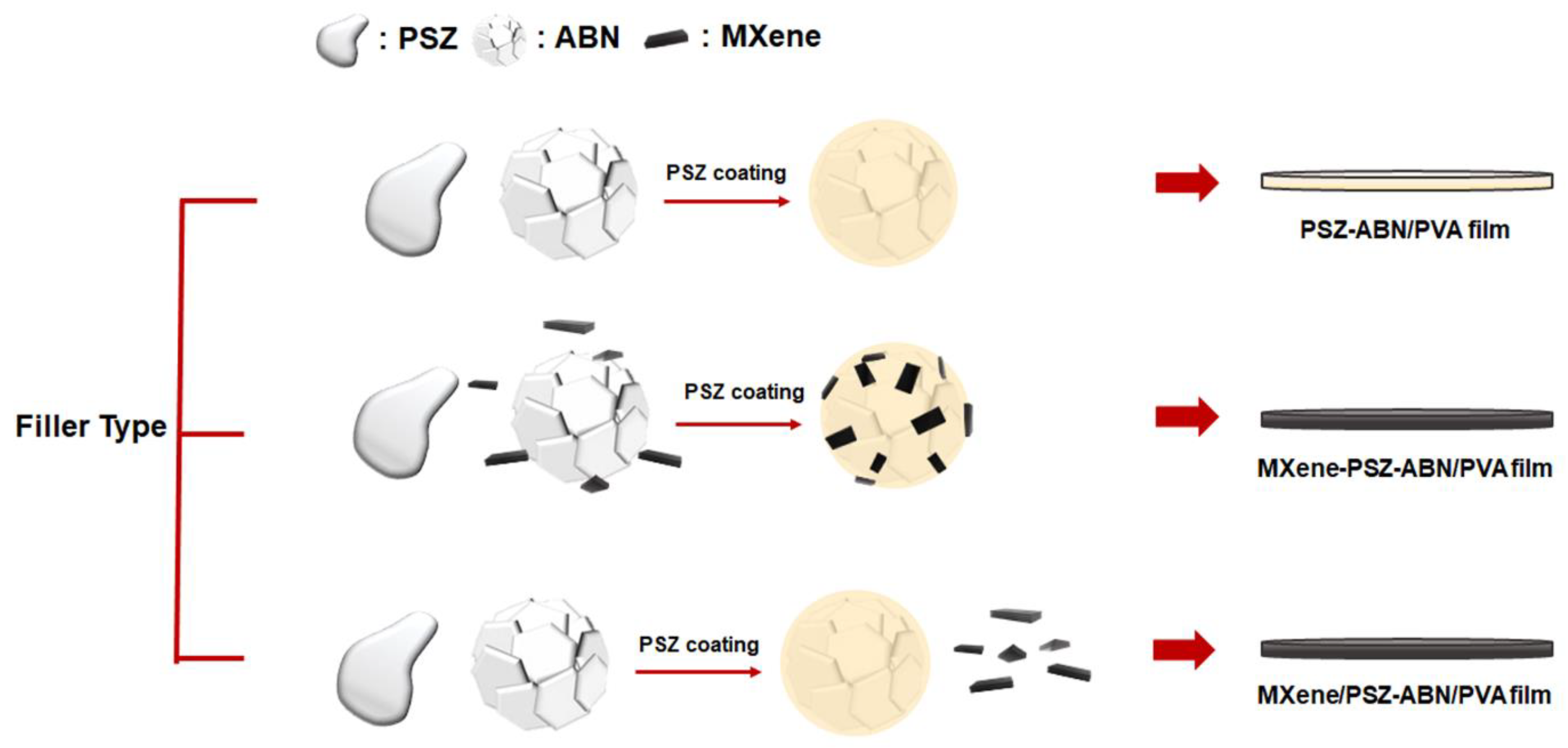

3. Results and Discussion

3.1. Synthesized Fillers Analysis

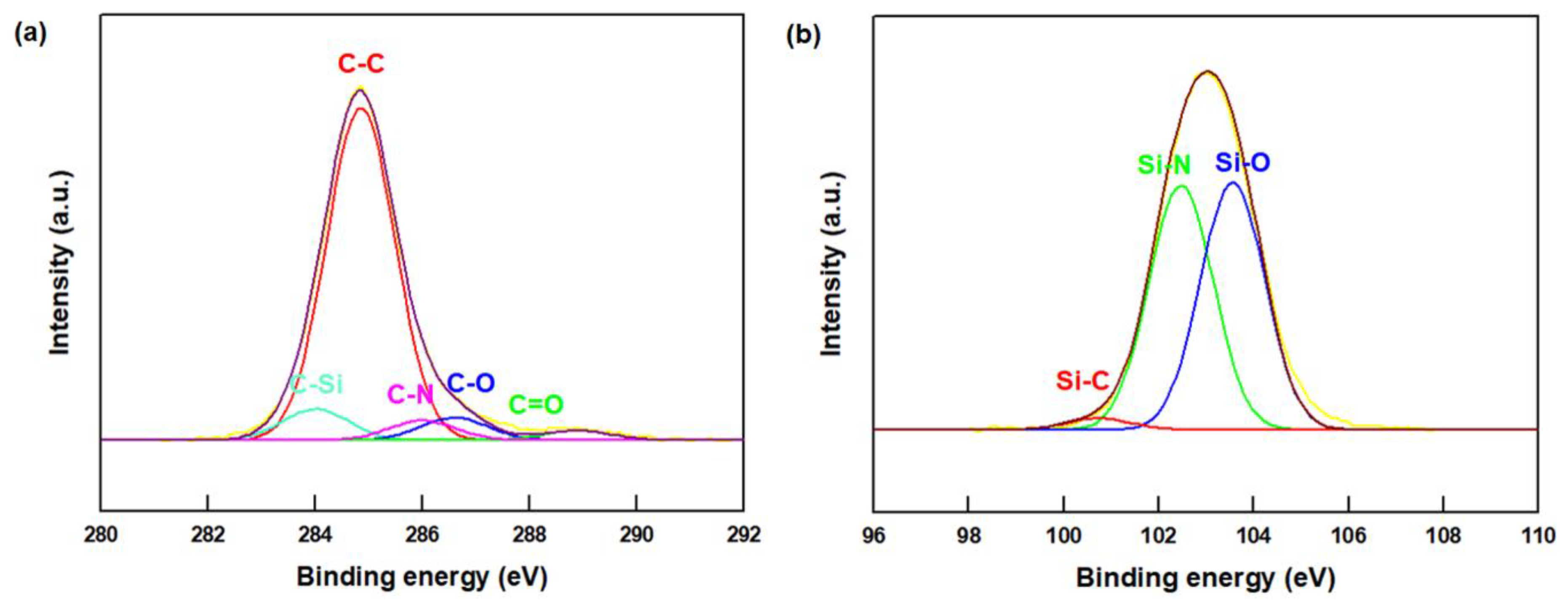

3.1.1. XPS

3.1.2. Morphology

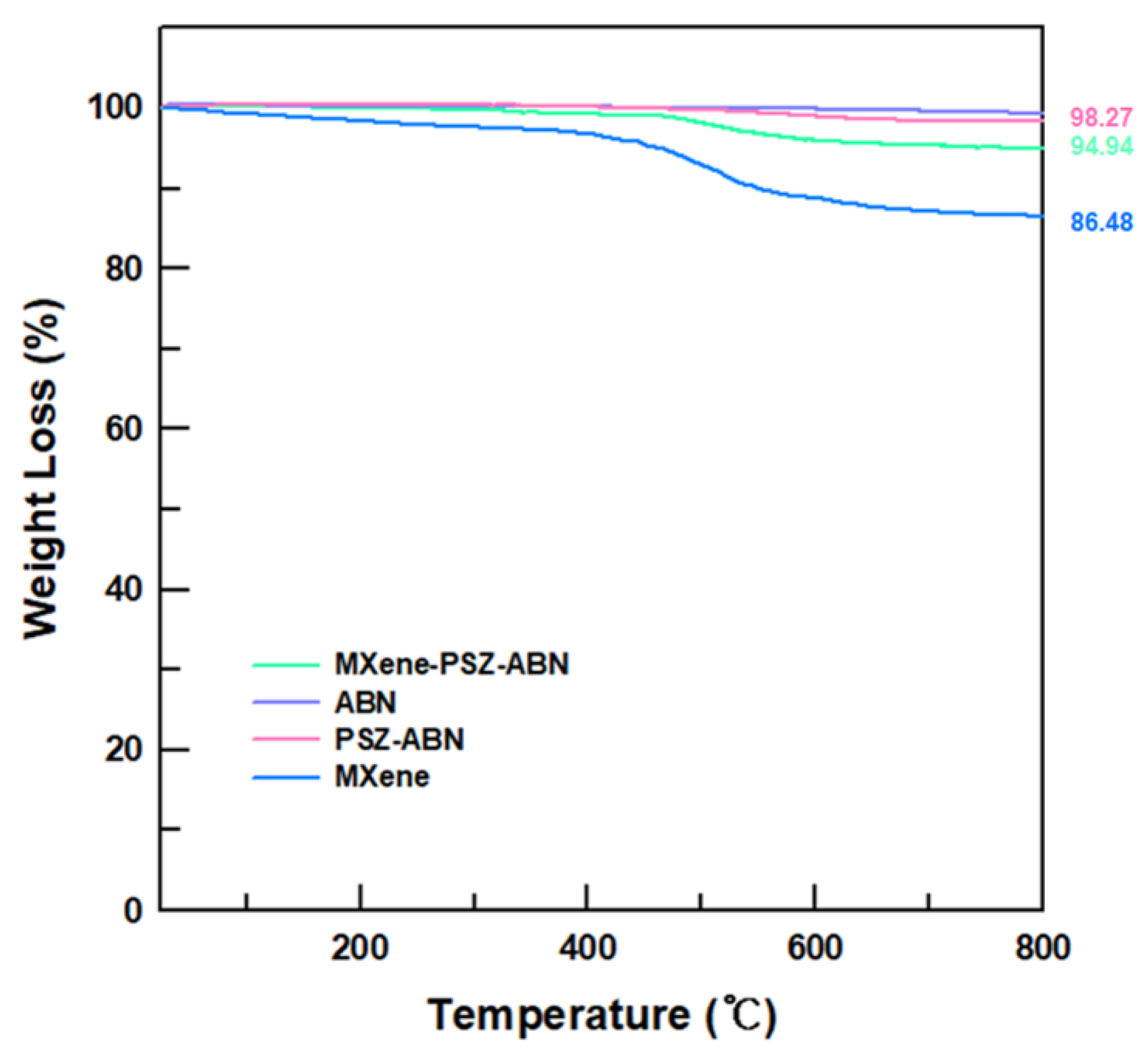

3.1.3. Thermogravimetry

3.2. Synthesized Composite Films Analysis

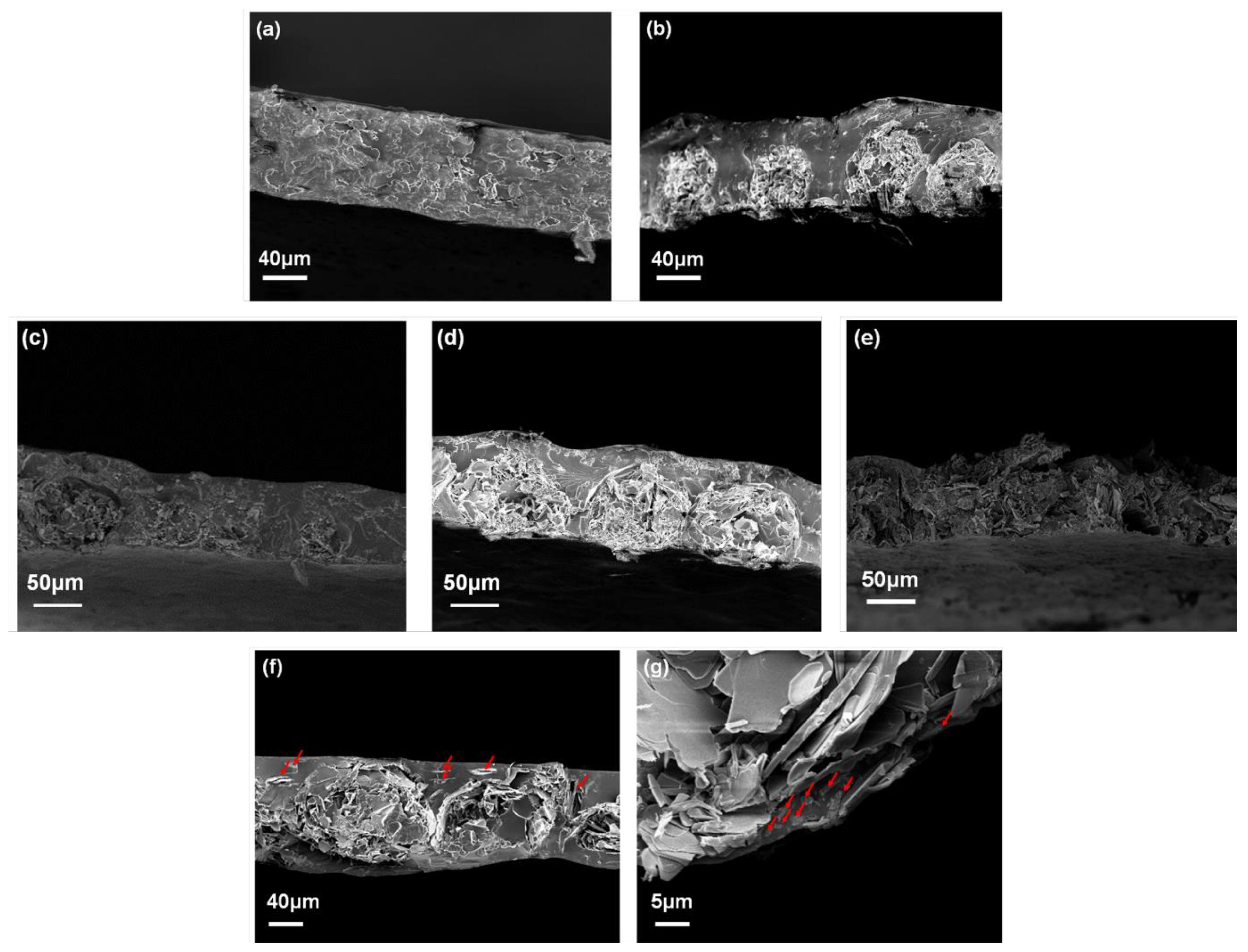

3.2.1. Morphology

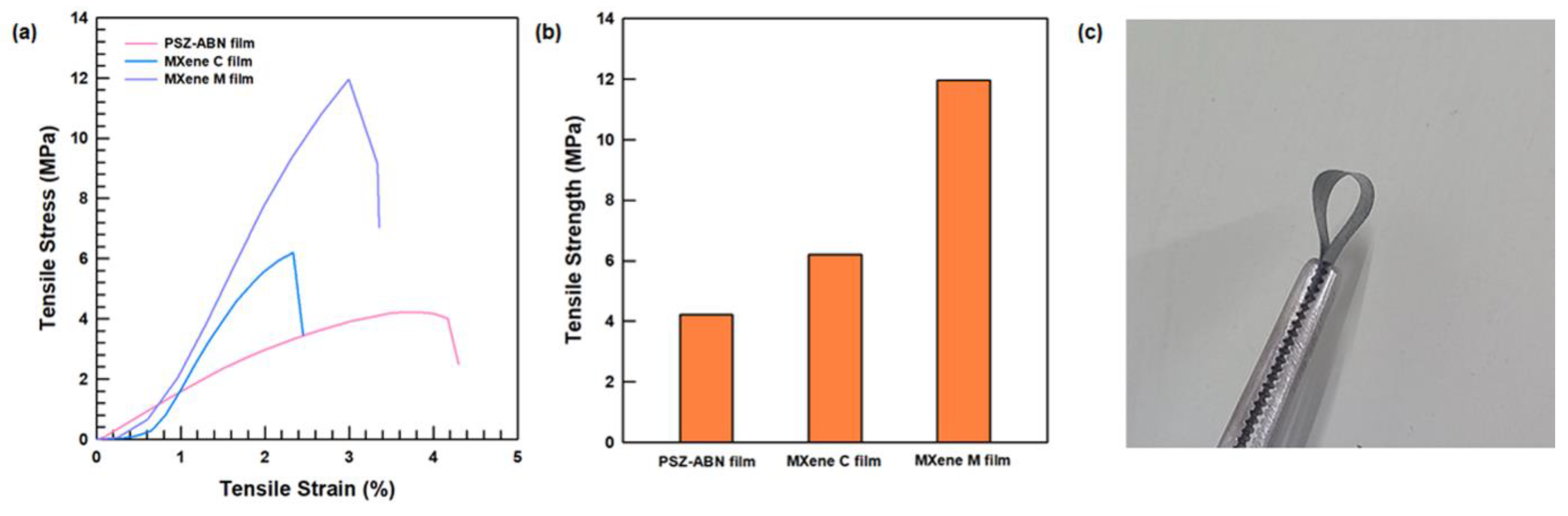

3.2.2. Mechanical Properties

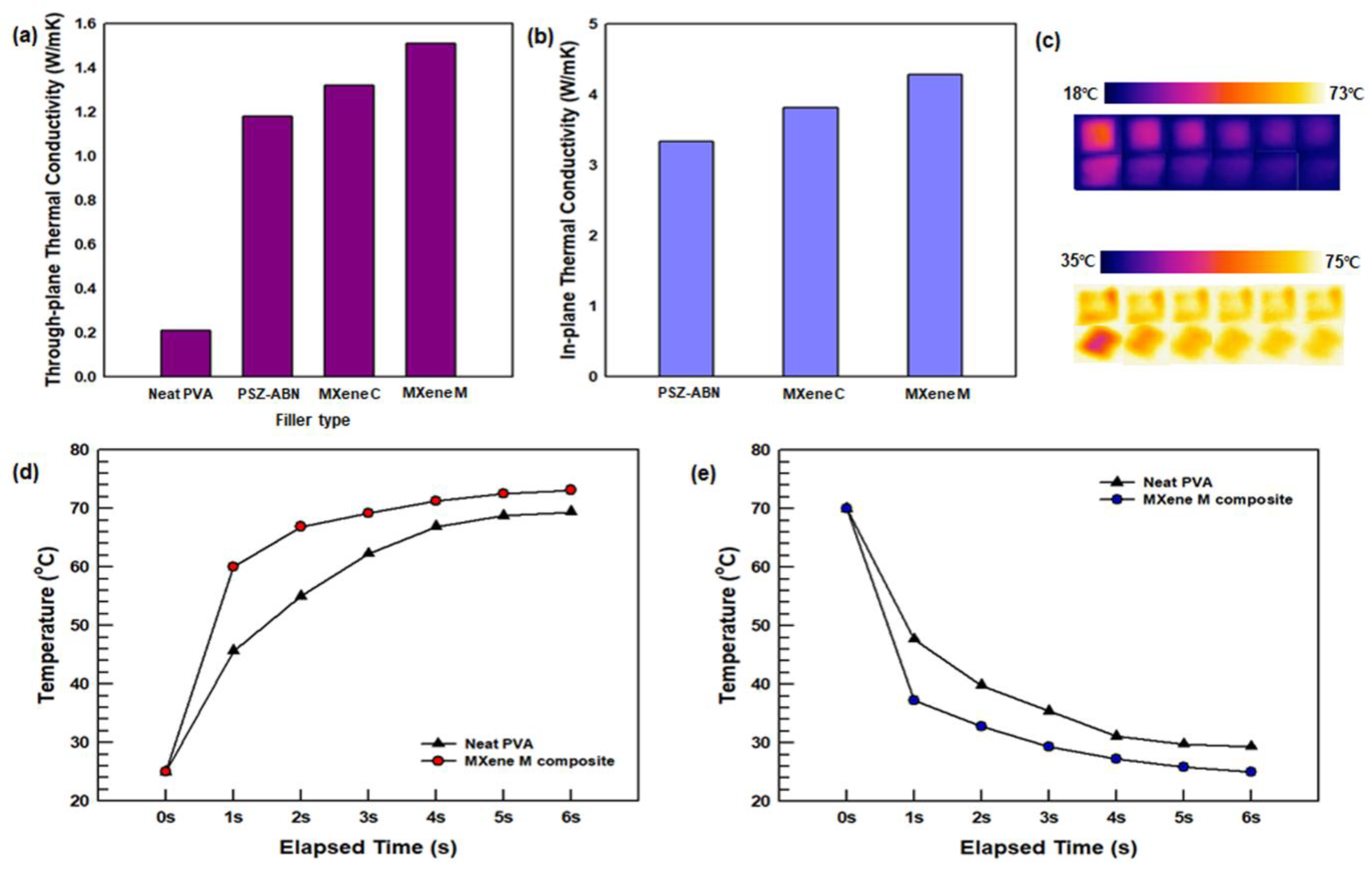

3.2.3. Thermal Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, W.; Chen, M.; Song, W.; Ge, C.; Zhang, X. Construction of hexagonal boron nitride@ polystyrene nanocomposite with high thermal conductivity for thermal management application. Ceram. Int. 2020, 46, 7595–7601. [Google Scholar] [CrossRef]

- Wang, X.; Feng, C.P.; Wang, M.; Lu, H.; Ni, H.Y.; Chen, J. Multilayered ultrahigh molecular weight polyethylene/natural graphite/boron nitride composites with enhanced thermal conductivity and electrical insulation by hot compression. J. Appl. Polym. Sci. 2020, 138, 49938. [Google Scholar] [CrossRef]

- Chen, Y.; Hou, X.; Liao, M.; Dai, W.; Wang, Z.; Yan, C.; Li, H.; Lin, C.T.; Jiang, N.; Yu, J. Constructing a “pea-pod-like” alumina-graphene binary architecture for enhancing thermal conductivity of epoxy composite. Chem. Eng. J. 2020, 381, 122690. [Google Scholar] [CrossRef]

- Lule, Z.C.; Kim, J. Properties of economical and eco-friendly polybutylene adipate terephthalate composites loaded with surface treated coffee husk. Compos. Part A Appl. Sci. Manuf. 2020, 140, 106154. [Google Scholar] [CrossRef]

- Kim, K.; Kang, T.; Kim, M.; Kim, J. Three-dimensional entangled and twisted structures of nitrogen doped poly-(1, 4-diethynylbenzene) chain combined with cobalt single atom as a highly efficient bifunctional electrocatalyst. Appl. Catal. B 2020, 275, 119107. [Google Scholar] [CrossRef]

- Han, X.; Wu, L.; Zhang, H.; He, A.; Nie, H. Inorganic–Organic Hybrid Janus Fillers for Improving the Thermal Conductivity of Polymer Composites. ACS Appl. Mater. Interfaces 2019, 11, 12190–12194. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Park, D.; Kim, J. Enhancement of Bi2O2Se thermoelectric power factor via Nb doping. J. Alloys Compd. 2021, 851, 156905. [Google Scholar] [CrossRef]

- He, X.; Huang, Y.; Wan, C.; Zheng, X.; Kormakov, S.; Gao, X.; Sun, J.; Zheng, X.; Wu, D. Enhancing thermal conductivity of polydimethylsiloxane composites through spatially confined network of hybrid fillers. Compos. Sci. Technol. 2019, 172, 163–171. [Google Scholar] [CrossRef]

- Kim, K.; Wie, J.; Kim, J. Synergistic interaction of P and N co-doping EDTA with controllable active EDTA-cobalt sites as efficient electrocatalyst for oxygen reduction reaction. J. Ind. Eng. Chem. 2020, 83, 252–259. [Google Scholar] [CrossRef]

- An, D.; Cheng, S.; Zhang, Z.; Jiang, C.; Fang, H.; Li, J.; Liu, Y.; Wong, C.P. A polymer-based thermal management material with enhanced thermal conductivity by introducing three-dimensional networks and covalent bond connections. Carbon 2019, 155, 258–267. [Google Scholar] [CrossRef]

- Li, M.; Wang, M.; Hou, X.; Zhan, Z.; Wang, H.; Fu, H.; Lin, C.T.; Fu, L.; Jiang, N.; Yu, J. Highly thermal conductive and electrical insulating polymer composites with boron nitride. Compos. B Eng. 2020, 184, 107746. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, W.; Drummer, D.; Liu, C.; Tomiak, F.; Schneider, K.; Huang, Z. Achieving a 3D Thermally Conductive while Electrically Insulating Network in Polybenzoxazine with a Novel Hybrid Filler Composed of Boron Nitride and Carbon Nanotubes. Polymers 2020, 12, 2331. [Google Scholar] [CrossRef] [PubMed]

- Wie, J.; Kim, J. Thermal Properties of Binary Filler Hybrid Composite with Graphene Oxide and Pyrolyzed Silicon-Coated Boron Nitride. Polymers 2020, 12, 2553. [Google Scholar] [CrossRef] [PubMed]

- Han, J.; Du, G.; Gao, W.; Bai, H. An anisotropically high thermal conductive boron nitride/epoxy composite based on nacre-mimetic 3D network. Adv. Funct. Mater. 2019, 29, 1900412. [Google Scholar] [CrossRef]

- Wie, J.; Kim, M.; Kim, J. Enhanced thermal conductivity of a polysilazane-coated A-BN/epoxy composite following surface treatment with silane coupling agents. Appl. Surf. Sci. 2020, 529, 147091. [Google Scholar] [CrossRef]

- Ahn, K.; Kim, K.; Kim, M.; Kim, J. Fabrication of silicon carbonitride-covered boron nitride/Nylon 6, 6 composite for enhanced thermal conductivity by melt process. Ceram. Int. 2015, 41, 2187–2195. [Google Scholar] [CrossRef]

- Kim, K.; Ryu, S.; Kim, J. Melt-processable aggregated boron nitride particle via polysilazane coating for thermal conductive composite. Ceram. Int. 2017, 43, 2441–2447. [Google Scholar] [CrossRef]

- Kim, K.; Ju, H.; Kim, J. Pyrolysis behavior of polysilazane and polysilazane-coated-boron nitride for high thermal conductive composite. Compos. Sci. Technol. 2017, 141, 1–7. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, D.; Yuan, Y.; Wang, Y.; Cheng, Z.; Liu, Y.; Xie, Z. A lightweight and conductive MXene/graphene hybrid foam for superior electromagnetic interference shielding. Chem. Eng. J. 2020, 381, 122696. [Google Scholar] [CrossRef]

- Ma, W.; Chen, H.; Hou, S.; Huang, Z.; Huang, Y.; Xu, S.; Fan, F.; Chen, Y. Compressible highly stable 3D porous MXene/GO foam with a tunable high-performance stealth property in the terahertz band. ACS Appl. Mater. Interfaces 2019, 11, 25369–25377. [Google Scholar] [CrossRef]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Hong, S.M.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef]

- Guo, J.; Zhao, Y.; Ma, T. Electrostatic self-assembly of 2D delaminated MXene (Ti3C2) onto Ni foam with superior electrochemical performance for supercapacitor. Electrochim. Acta 2019, 305, 164–174. [Google Scholar] [CrossRef]

- Jin, X.; Wang, J.; Dai, L.; Liu, X.; Li, L.; Yang, Y.; Cao, Y.; Wang, W.; Wu, H.; Guo, S. Flame-retardant poly (vinyl alcohol)/MXene multilayered films with outstanding electromagnetic interference shielding and thermal conductive performances. Chem. Eng. J. 2020, 380, 122475. [Google Scholar] [CrossRef]

- Liu, R.; Li, W. High-Thermal-Stability and High-Thermal-Conductivity Ti3C2T x MXene/Poly (vinyl alcohol)(PVA) Composites. ACS Omega 2018, 3, 2609–2617. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhang, H.B.; Sun, R.; Liu, Y.; Liu, Z.; Zhou, A.; Yu, Z.Z. Hydrophobic, flexible, and lightweight MXene foams for high-performance electromagnetic-interference shielding. Adv. Mater. 2017, 29, 1702367. [Google Scholar] [CrossRef]

- Lu, X.; Huang, H.; Zhang, X.; Lin, P.; Huang, J.; Sheng, X.; Zhang, L.; Qu, J.-P. Novel light-driven and electro-driven polyethylene glycol/two-dimensional MXene form-stable phase change material with enhanced thermal conductivity and electrical conductivity for thermal energy storage. Compos. B Eng. 2019, 177, 107372. [Google Scholar] [CrossRef]

- Li, X.; Yin, X.; Song, C.; Han, M.; Xu, H.; Duan, W.; Cheng, L.; Zhang, L. Self-Assembly Core–Shell Graphene-Bridged Hollow MXenes Spheres 3D Foam with Ultrahigh Specific EM Absorption Performance. Adv. Funct. Mater. 2018, 28, 1803938. [Google Scholar] [CrossRef]

- Xue, Y.; Feng, J.; Huo, S.; Song, P.; Yu, B.; Liu, L.; Wang, H. Polyphosphoramide-intercalated MXene for simultaneously enhancing thermal stability, flame retardancy and mechanical properties of polylactide. Chem. Eng. J. 2020, 397, 125336. [Google Scholar] [CrossRef]

- Feng, C.P.; Chen, L.B.; Tian, G.L.; Bai, L.; Bao, R.Y.; Liu, Z.Y.; Ke, K.; Yang, M.B.; Yang, W. Robust polymer-based paper-like thermal interface materials with a through-plane thermal conductivity over 9 Wm−1 K−1. Chem. Eng. J. 2020, 392, 123784. [Google Scholar] [CrossRef]

- Pan, Y.; Fu, L.; Zhou, Q.; Wen, Z.; Lin, C.T.; Yu, J.; Wang, W.; Zhao, H. Flammability, thermal stability and mechanical properties of polyvinyl alcohol nanocomposites reinforced with delaminated Ti3C2Tx (MXene). Polym. Compos. 2020, 41, 210–218. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Kim, J. Incorporating MXene into Boron Nitride/Poly(Vinyl Alcohol) Composite Films to Enhance Thermal and Mechanical Properties. Polymers 2021, 13, 379. https://doi.org/10.3390/polym13030379

Lee S, Kim J. Incorporating MXene into Boron Nitride/Poly(Vinyl Alcohol) Composite Films to Enhance Thermal and Mechanical Properties. Polymers. 2021; 13(3):379. https://doi.org/10.3390/polym13030379

Chicago/Turabian StyleLee, Seonmin, and Jooheon Kim. 2021. "Incorporating MXene into Boron Nitride/Poly(Vinyl Alcohol) Composite Films to Enhance Thermal and Mechanical Properties" Polymers 13, no. 3: 379. https://doi.org/10.3390/polym13030379

APA StyleLee, S., & Kim, J. (2021). Incorporating MXene into Boron Nitride/Poly(Vinyl Alcohol) Composite Films to Enhance Thermal and Mechanical Properties. Polymers, 13(3), 379. https://doi.org/10.3390/polym13030379