Functional Properties of Kenaf Bast Fibre Anhydride Modification Enhancement with Bionanocarbon in Polymer Nanobiocomposites

Abstract

1. Introduction

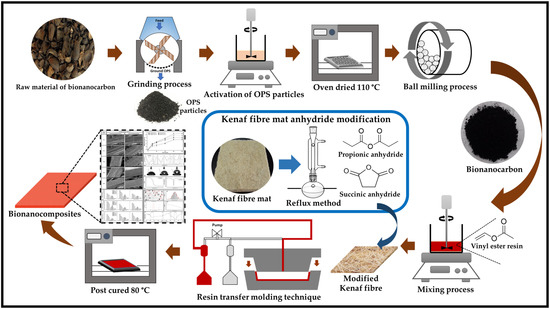

2. Materials and Method

2.1. Materials

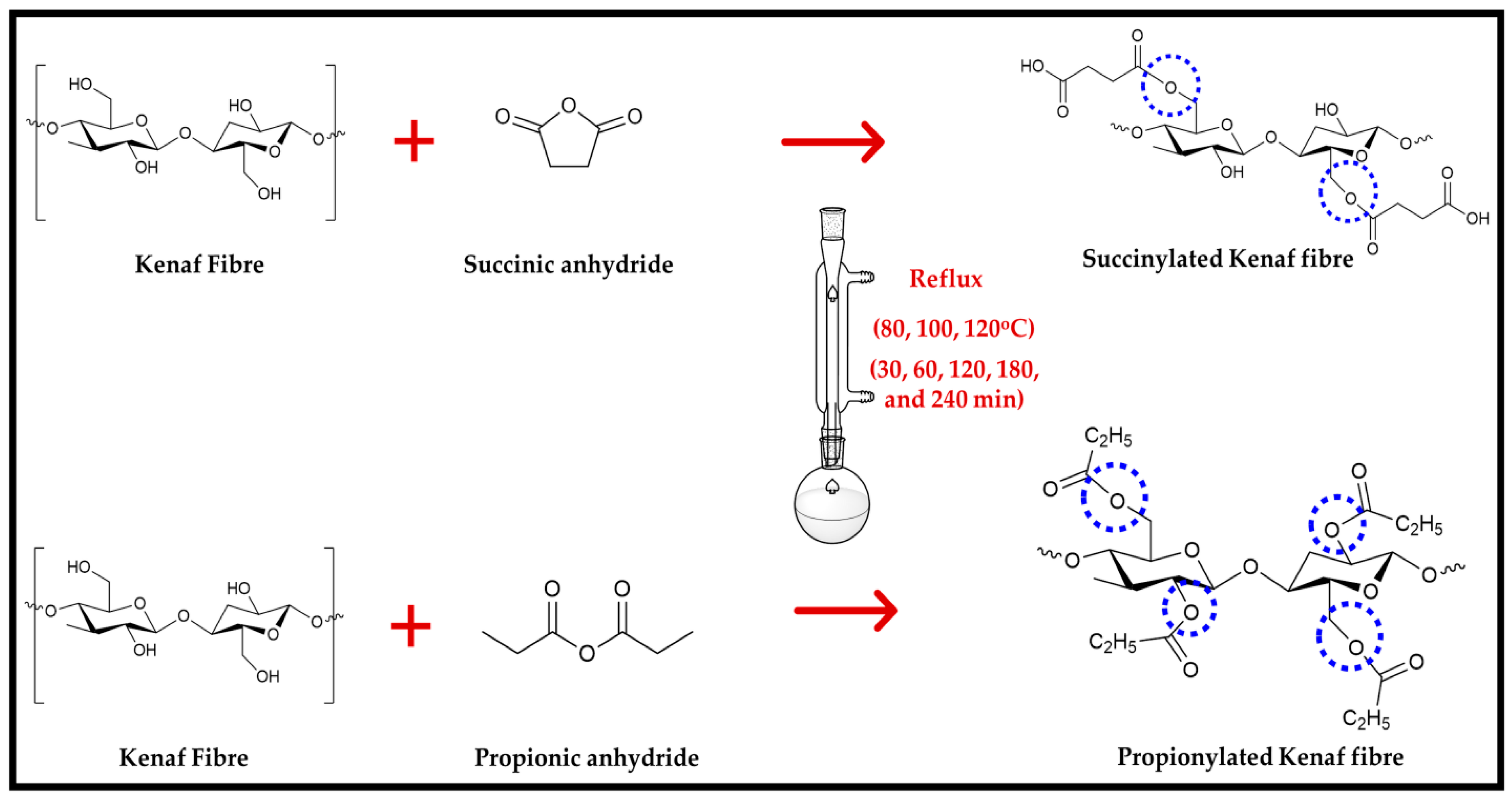

2.2. Anhydride Modification of Nonwoven Kenaf Fibre

2.3. Preparation of Bionanocarbon

2.4. Characterisation of Kenaf Fibre and Bionanocarbon

2.5. Preparation of Nanobiocomposites

2.6. Characterisation of Bionanocomposites

3. Results and Discussion

3.1. Characterisation of Nonwoven Kenaf Fibre

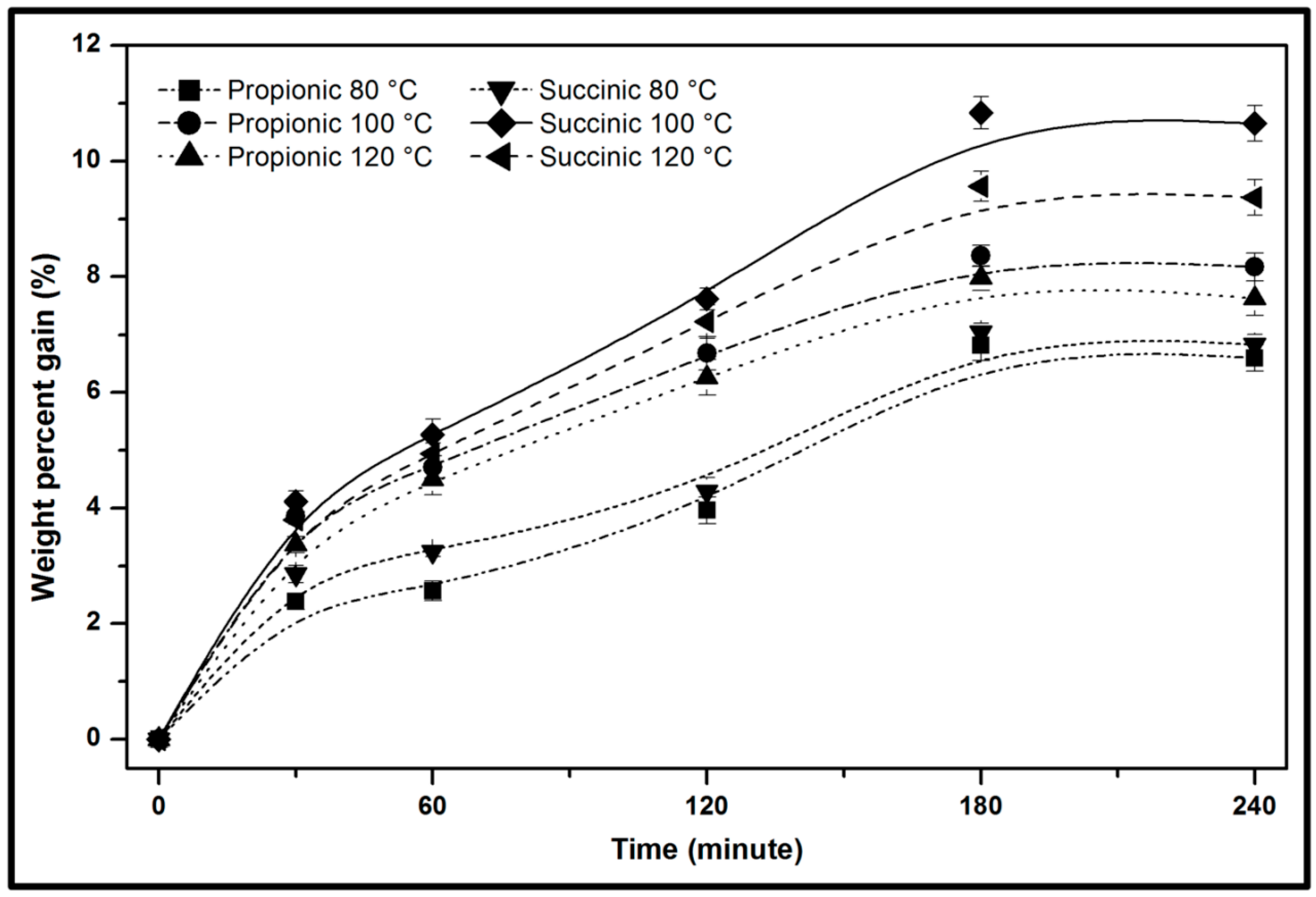

3.1.1. Weight Percent Gain Properties

3.1.2. Morphological Analysis

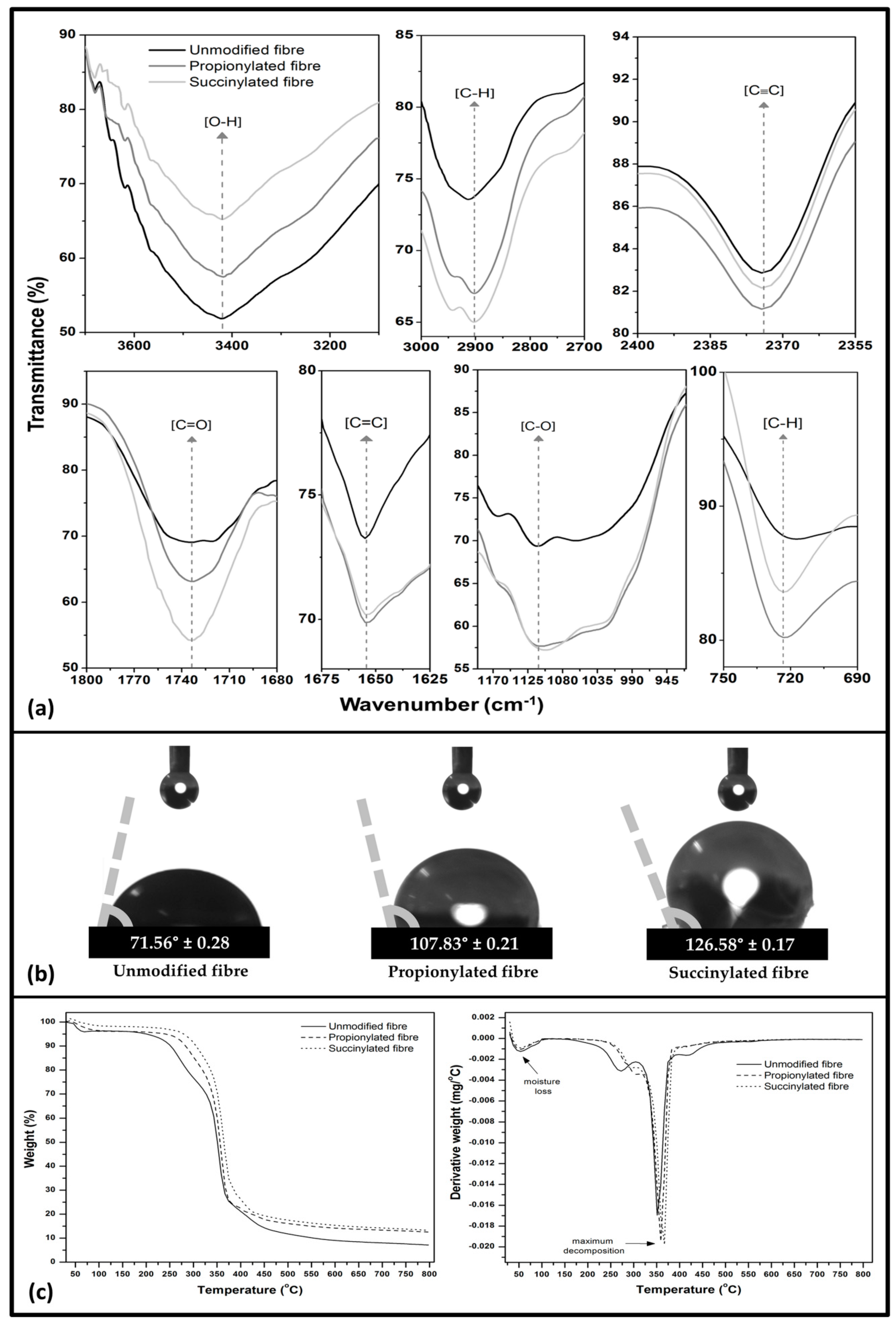

3.1.3. Structural, Wettability, and Thermal Properties

3.2. Characterisation of Bionanocarbon and Bionanocomposites

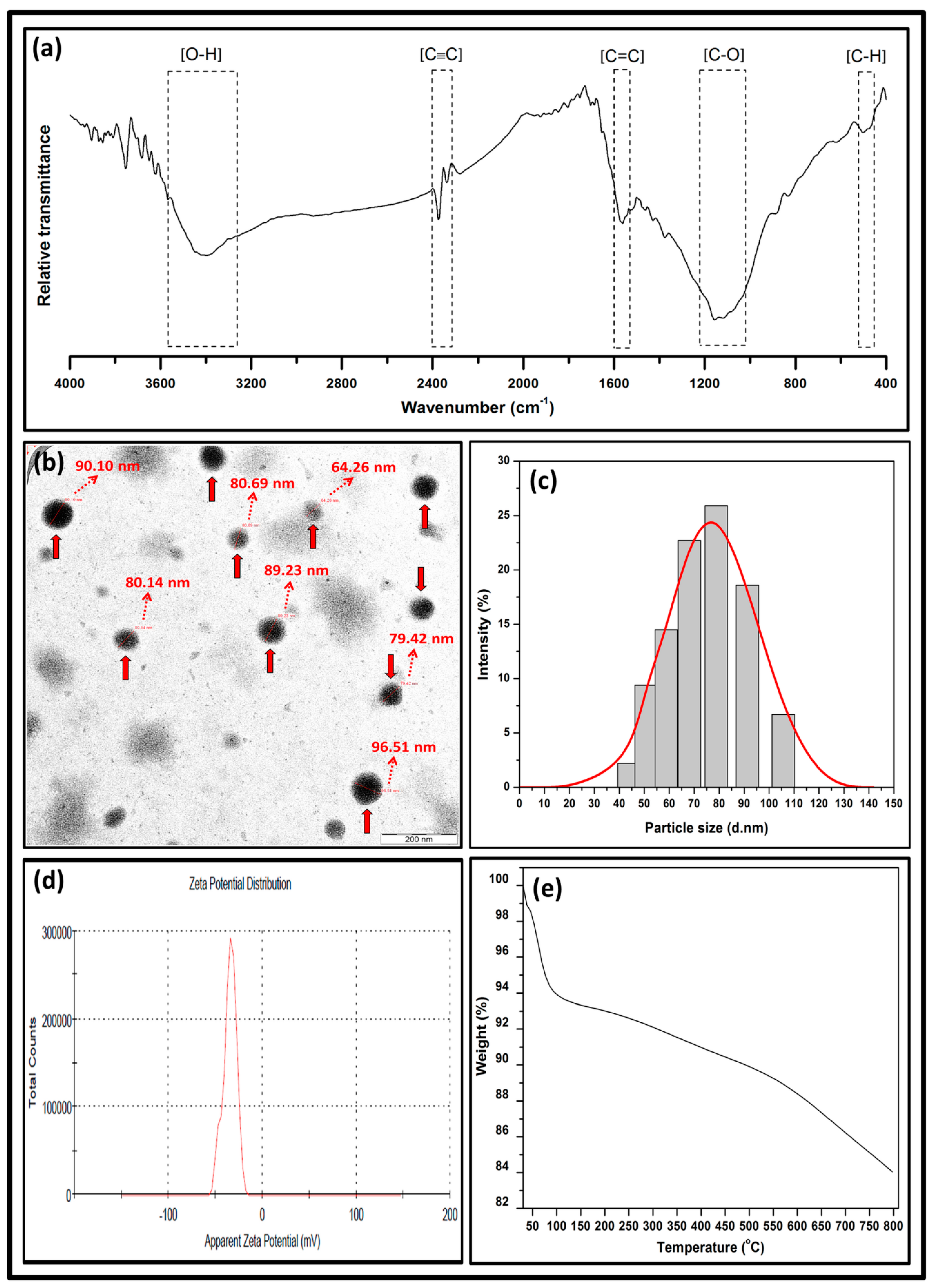

3.2.1. Characterisation of Bionanocarbon

3.2.2. Characterisation of Bionanocomposites

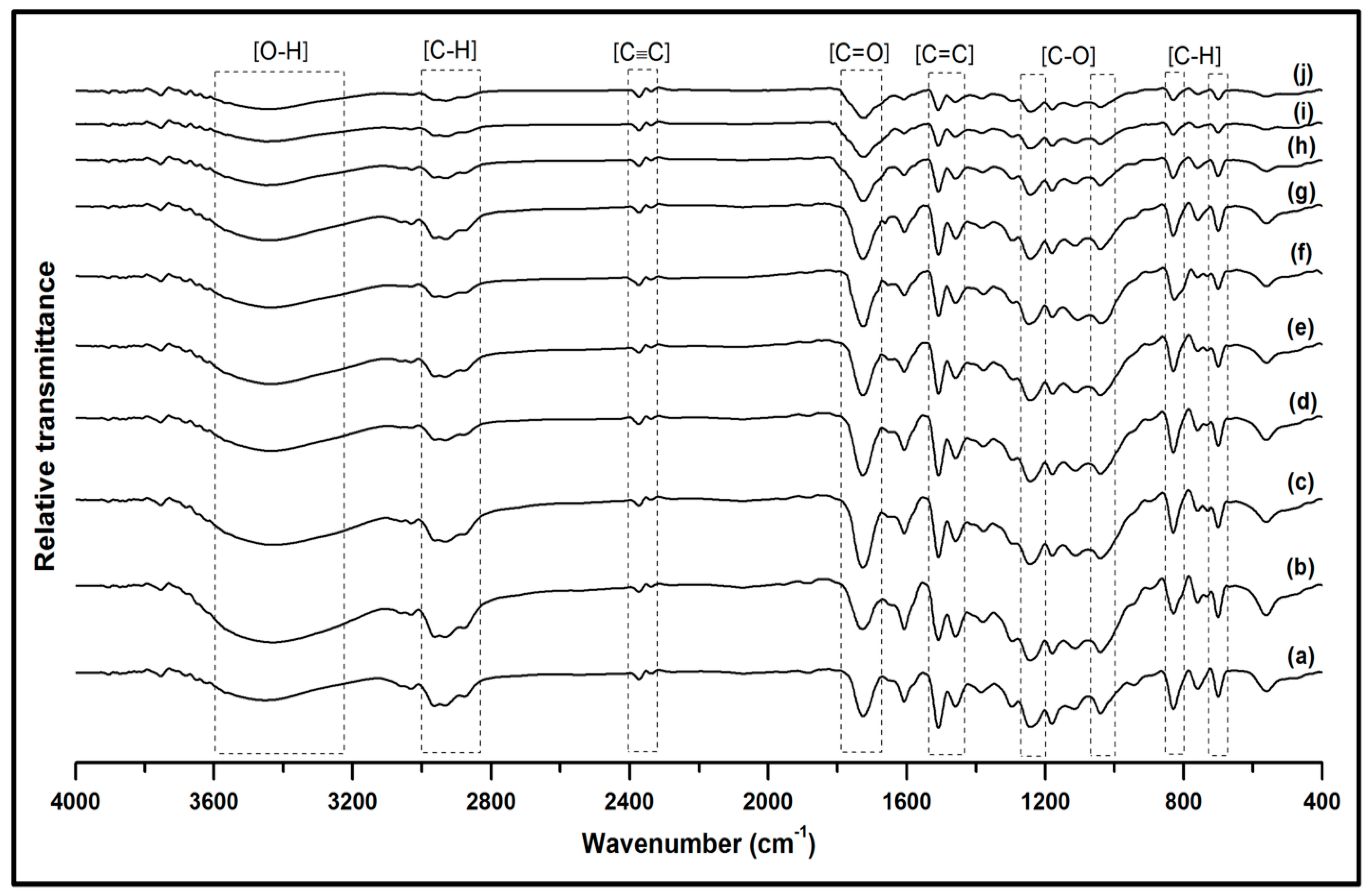

Chemical Structural Analysis

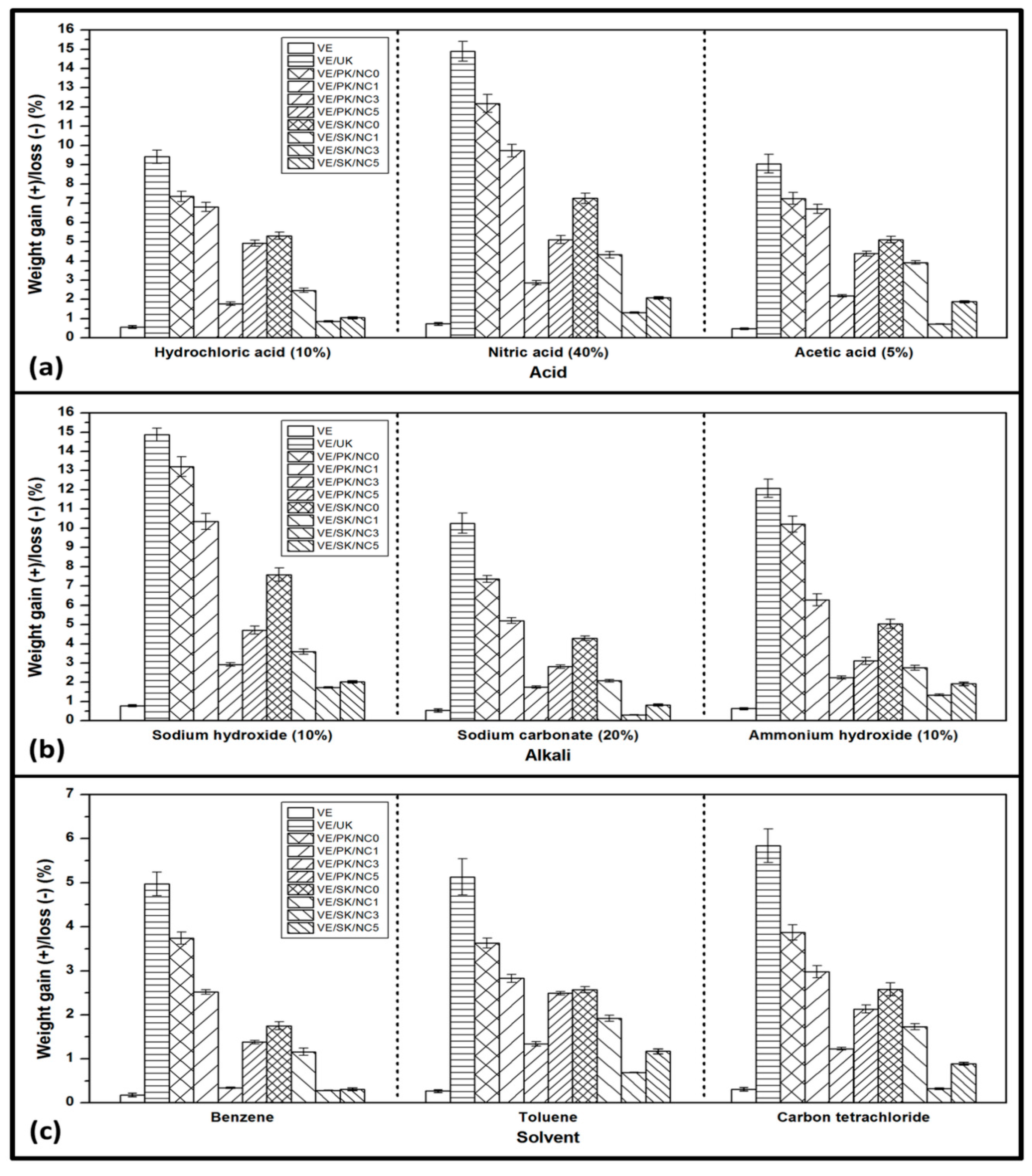

Physical Properties

Mechanical Properties

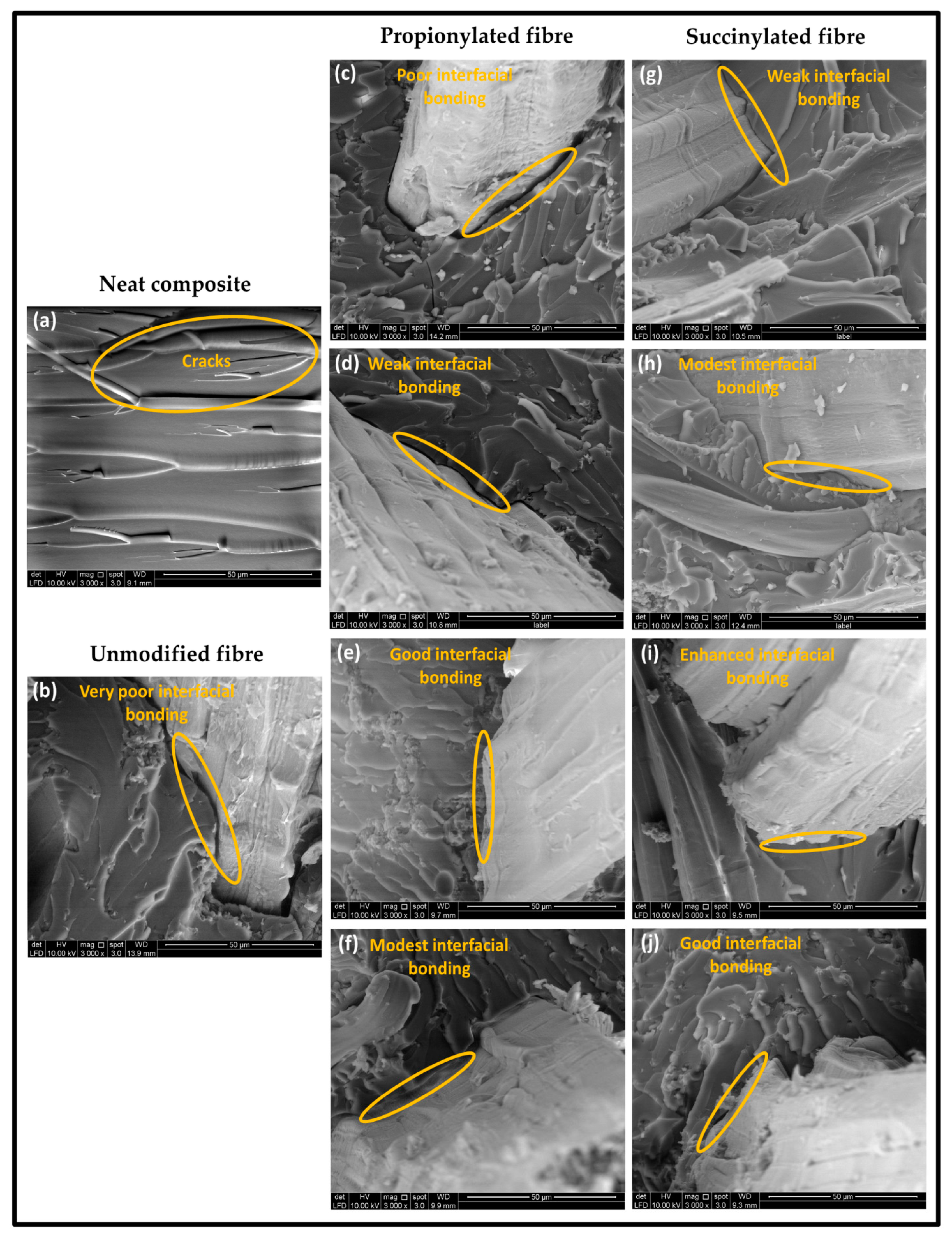

Morphological Analysis

Thermal Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bari, E.; Sistani, A.; Morrell, J.J.; Pizzi, A.; Akbari, M.R.; Ribera, J. Current Strategies for the Production of Sustainable Biopolymer Composites. Polymers 2021, 13, 2878. [Google Scholar] [CrossRef]

- Weiland, K.; Jones, M.P.; Zinsser, F.; Kontturi, E.; Mautner, A.; Bismarck, A. Grow it yourself composites: Delignification and hybridisation of lignocellulosic material using animals and fungi. Green Chem. 2021, 23, 7506–7514. [Google Scholar] [CrossRef]

- Merino, D.; Simonutti, R.; Perotto, G.; Athanassiou, A. Direct transformation of industrial vegetable waste into bioplastic composites intended for agricultural mulch films. Green Chem. 2021, 23, 5956–5971. [Google Scholar] [CrossRef]

- Le Phuong, H.A.; Ayob, N.A.I.; Blanford, C.F.; Rawi, N.F.M.; Szekely, G. Nonwoven Membrane Supports from Renewable Resources: Bamboo Fiber Reinforced Poly(Lactic Acid) Composites. ACS Sustain. Chem. Eng. 2019, 7, 11885–11893. [Google Scholar] [CrossRef]

- Sapiai, N.; Jumahat, A.; Jawaid, M.; Midani, M.; Khan, A. Tensile and Flexural Properties of Silica Nanoparticles Modified Unidirectional Kenaf and Hybrid Glass/Kenaf Epoxy Composites. Polymers 2020, 12, 2733. [Google Scholar] [CrossRef]

- Yusuff, I.; Sarifuddin, N.; Ali, A.M. A review on kenaf fiber hybrid composites: Mechanical properties, potentials, and challenges in engineering applications. Prog. Rubber Plast. Recycl. Technol. 2020, 37, 66–83. [Google Scholar] [CrossRef]

- Prakash, V.A.; Viswanthan, R. Fabrication and characterization of echinoidea spike particles and kenaf natural fibre-reinforced Azadirachta-Indica blended epoxy multi-hybrid bio composite. Compos. Part A Appl. Sci. Manuf. 2019, 118, 317–326. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Sultan, M.; Alothman, O.Y.; Abdullah, L.C. Effects of nanoclay on physical and dimensional stability of Bamboo/Kenaf/nanoclay reinforced epoxy hybrid nanocomposites. J. Mater. Res. Technol. 2020, 9, 5871–5880. [Google Scholar] [CrossRef]

- Venkatasudhahar, M.; Ravichandran, A.; Dilipraja, N. Effect of stacking sequence on mechanical and moisture absorption properties of abaca-kenaf-carbon fiber reinforced hybrid composites. J. Nat. Fibers 2021, 1–12. [Google Scholar] [CrossRef]

- Birnin-Yauri, A.U.; Ibrahim, N.A.; Zainuddin, N.; Abdan, K.; Then, Y.Y.; Chieng, B.W. Effect of Maleic Anhydride-Modified Poly(lactic acid) on the Properties of Its Hybrid Fiber Biocomposites. Polymers 2017, 9, 165. [Google Scholar] [CrossRef]

- Gallardo-Cervantes, M.; González-García, Y.; Pérez-Fonseca, A.A.; González-López, M.E.; Manríquez-González, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Biodegradability and improved mechanical performance of polyhydroxyalkanoates/agave fiber biocomposites compatibilized by different strategies. J. Appl. Polym. Sci. 2020, 138, 50182. [Google Scholar] [CrossRef]

- Ahmed, A.S.; Islam, S.; Hassan, A.; Haafiz, M.K.M.; Islam, K.N.; Arjmandi, R. Impact of succinic anhydride on the properties of jute fiber/polypropylene biocomposites. Fibers Polym. 2014, 15, 307–314. [Google Scholar] [CrossRef]

- Mikociak, D.; Rudawski, A.; Blazewicz, S. Mechanical and thermal properties of C/C composites modified with SiC nanofiller. Mater. Sci. Eng. A 2018, 716, 220–227. [Google Scholar] [CrossRef]

- Zhu, T.; Li, Y.; Sang, S. Heightening mechanical properties and thermal shock resistance of low–carbon magnesia–graphite refractories through the catalytic formation of nanocarbons and ceramic bonding phases. J. Alloys Compd. 2018, 783, 990–1000. [Google Scholar] [CrossRef]

- Nikolaeva, A.; Gofman, I.; Yakimansky, A.; Ivan’Kova, E.; Abalov, I.; Baranchikov, A.; Ivanov, V. Polyimide-Based Nanocomposites with Binary CeO2/Nanocarbon Fillers: Conjointly Enhanced Thermal and Mechanical Properties. Polymers 2020, 12, 1952. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, N.; He, C. The superior mechanical and physical properties of nanocarbon reinforced bulk composites achieved by architecture design—A review. Prog. Mater. Sci. 2020, 113, 100672. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Smith, R.L., Jr.; Liang, Y.; Qi, X. Direct one-pot synthesis of ordered mesoporous carbons from lignin with metal coordinated self-assembly. Green Chem. 2021. [Google Scholar] [CrossRef]

- Voros, V.; Drioli, E.; Fonte, C.; Szekely, G. Process Intensification via Continuous and Simultaneous Isolation of Antioxidants: An Upcycling Approach for Olive Leaf Waste. ACS Sustain. Chem. Eng. 2019, 7, 18444–18452. [Google Scholar] [CrossRef]

- Jiao, W.; Jiang, L.; Wang, R.; Liu, W.; Yang, F. Improving the interfacial property of carbon fiber/vinyl ester resin composite by grafting modification of sizing agent on carbon fiber surface. J. Mater. Sci. 2017, 52, 13812–13828. [Google Scholar] [CrossRef]

- Jahandideh, A.; Moini, N.; Bajgholi, S.; Zohuriaan-Mehr, M.J.; Kabiri, K. Making vinyl ester resin greener: Succinic acid–glycerol-derived reactive diluent as an alternative to styrene. J. Appl. Polym. Sci. 2020, 137, 49144. [Google Scholar] [CrossRef]

- Rizal, S.; Mistar, E.; Rahman, A.; Abdul Khalil, H.P.S.; Oyekanmi, A.; Olaiya, N.; Abdullah, C.; Alfatah, T. Bionanocarbon Functional Material Characterisation and Enhancement Properties in Nonwoven Kenaf Fibre Nanocomposites. Polymers 2021, 13, 2303. [Google Scholar] [CrossRef]

- Çavdar, A.D.; Mengeloglu, F.; Karakus, K.; Tomak, E.D. Effect of Chemical Modification with Maleic, Propionic, and Succinic Anhydrides on Some Properties of Wood Flour Filled HDPE Composites. BioResources 2014, 9, 6490–6503. [Google Scholar] [CrossRef][Green Version]

- Leszczyńska, A.; Radzik, P.; Szefer, E.; Mičušík, M.; Omastová, M.; Pielichowski, K. Surface Modification of Cellulose Nanocrystals with Succinic Anhydride. Polymers 2019, 11, 866. [Google Scholar] [CrossRef]

- Alfatah, T.; Mistar, E.M.; Supardan, M.D. Porous structure and adsorptive properties of activated carbon derived from Bambusa vulgaris striata by two-stage KOH/NaOH mixture activation for Hg2+ removal. J. Water Process. Eng. 2021, 43, 102294. [Google Scholar] [CrossRef]

- Mistar, E.M.; Ahmad, S.; Muslim, A.; Alfatah, T.; Supardan, M.D. Preparation and characterization of a high surface area of activated carbon fromBambusa vulgaris—Effect of NaOH activation and pyrolysis temperature. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 334, p. 012051. [Google Scholar] [CrossRef]

- Mistar, E.M.; Alfatah, T.; Supardan, M.D. Synthesis and characterization of activated carbon from Bambusa vulgaris striata using two-step KOH activation. J. Mater. Res. Technol. 2020, 9, 6278–6286. [Google Scholar] [CrossRef]

- Mistar, E.M.; Hasmita, I.; Alfatah, T.; Muslim, A.; Supardan, M.D. Adsorption of Mercury(II) using Activated Produced from Bambusa vulgaris var. striata in a Fixed Bed Column. Sains Malays. 2019, 48, 719–725. [Google Scholar] [CrossRef]

- Mahjoub, R.; Yatim, J.M.; Sam, A.R.M.; Raftari, M. Characteristics of continuous unidirectional kenaf fiber reinforced epoxy composites. Mater. Des. 2014, 64, 640–649. [Google Scholar] [CrossRef]

- Sumesh, K.; Kanthavel, K.; Kavimani, V. Peanut oil cake-derived cellulose fiber: Extraction, application of mechanical and thermal properties in pineapple/flax natural fiber composites. Int. J. Biol. Macromol. 2020, 150, 775–785. [Google Scholar] [CrossRef] [PubMed]

- Jawaid, M.; Abdul Khalil, H.P.S.; Hassan, A.; Abdallah, E. Bi-layer hybird biocomposites: Chemical resistant and physical propertites. BioResources 2012, 7, 2344–2355. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Suraya, N.L. Anhydride modification of cultivated kenaf bast fibers: Morphological, spectroscopic, and thermal studies. BioResources 2011, 6, 1122–1135. [Google Scholar] [CrossRef]

- Beck, G.; Strohbusch, S.; Larnøy, E.; Militz, H.; Hill, C. Accessibility of hydroxyl groups in anhydride modified wood as measured by deuterium exchange and saponification. Holzforschung 2017, 72, 17–23. [Google Scholar] [CrossRef]

- Mohammed, A.; Atiqah, M.N.; Gopakumar, D.A.; Fazita, M.; Rizal, S.; Hermawan, D.; Thomas, S.; Abdul Khalil, H.P.S. Influence of layering pattern of modified kenaf fiber on thermomechanical properties of epoxy composites. Prog. Rubber Plast. Recycl. Technol. 2019, 36, 47–62. [Google Scholar] [CrossRef]

- Silva, N.G.S.; Maia, T.F.; Mulinari, D.R. Effect of Acetylation with Perchloric Acid as Catalyst in Sugarcane Bagasse Waste. J. Nat. Fibers 2021, 1–15. [Google Scholar] [CrossRef]

- Wu, Y.; Zeng, J.; Huang, X.; Yuan, Z.; Liu, G.; Ding, J. Styrene-maleic anhydride/polyethersulfone blending membranes modified by PEI functionalized TiO2 to enhance separation and antifouling properties: Dye purification. J. Environ. Chem. Eng. 2021, 9, 106040. [Google Scholar] [CrossRef]

- Teacă, C.-A.; Tanasă, F. Wood Surface Modification—Classic and Modern Approaches in Wood Chemical Treatment by Esterification Reactions. Coatings 2020, 10, 629. [Google Scholar] [CrossRef]

- Rizal, S.; Saharudin, N.; Olaiya, N.; Abdul Khalil, H.P.S.; Haafiz, M.; Ikramullah, I.; Muksin, U.; Olaiya, F.; Abdullah, C.; Yahya, E. Functional Properties and Molecular Degradation of Schizostachyum Brachycladum Bamboo Cellulose Nanofibre in PLA-Chitosan Bionanocomposites. Molecules 2021, 26, 2008. [Google Scholar] [CrossRef] [PubMed]

- Abdul Khalil, H.P.S.; Suraya, N.; Atiqah, N.; Jawaid, M.; Hassan, A. Mechanical and thermal properties of chemical treated kenaf fibres reinforced polyester composites. J. Compos. Mater. 2012, 47, 3343–3350. [Google Scholar] [CrossRef]

- Jung, J.S.; Song, K.H.; Kim, S.H. Biodegradable Acetylated Kenaf Fiber Composites. Fibers Polym. 2021, 2021, 1–7. [Google Scholar] [CrossRef]

- Dehury, J.; Nayak, S.; Mohanty, J.R. Comprehensive characterization sea purslane (Sesuvium portulacastrum) fiber and the effect of surface modifications on physical, mechanical and thermal properties. J. Nat. Fibers 2021, 1–13. [Google Scholar] [CrossRef]

- Fan, W.-X.; Ding, Y.; Tu, Z.-D.; Huang, K.-S.; Huang, C.-M.; Yeh, J.-T. Enhancement on ultimate tensile properties of ultrahigh molecular weight polyethylene composite fibers filled with activated nanocarbon particles with varying specific surface areas. Polym. Eng. Sci. 2017, 58, 980–990. [Google Scholar] [CrossRef]

- Yang, P.; You, X.; Yi, J.; Fang, D.; Bao, R.; Shen, T.; Liu, Y.; Tao, J.; Li, C. Influence of dispersion state of carbon nanotubes on electrical conductivity of copper matrix composites. J. Alloys Compd. 2018, 752, 376–380. [Google Scholar] [CrossRef]

- Ali, S.; Rehman, S.A.U.; Shah, I.A.; Farid, M.U.; An, A.K.; Huang, H. Efficient removal of zinc from water and wastewater effluents by hydroxylated and carboxylated carbon nanotube membranes: Behaviors and mechanisms of dynamic filtration. J. Hazard. Mater. 2018, 365, 64–73. [Google Scholar] [CrossRef] [PubMed]

- Bai, L.; Li, Z.; Zhao, S.; Zheng, J. Covalent functionalization of carbon nanotubes with hydroxyl-terminated polydimethylsiloxane to enhance filler dispersion, interfacial adhesion and performance of poly(methylphenylsiloxane) composites. Compos. Sci. Technol. 2018, 165, 274–281. [Google Scholar] [CrossRef]

- Rizal, S.; Alfatah, T.; Abdul Khalil, H.P.S.; Mistar, E.; Abdullah, C.; Olaiya, F.; Sabaruddin, F.; Ikramullah; Muksin, U. Properties and Characterization of Lignin Nanoparticles Functionalized in Macroalgae Biopolymer Films. Nanomaterials 2021, 11, 637. [Google Scholar] [CrossRef] [PubMed]

- Cacua, K.; Ordoñez, F.; Zapata, J.C.; Herrera, B.; Pabón, E.; Buitrago-Sierra, R. Surfactant concentration and pH effects on the zeta potential values of alumina nanofluids to inspect stability. Colloids Surf. A Physicochem. Eng. Asp. 2019, 583, 123960. [Google Scholar] [CrossRef]

- Oveisi, M.; Asli, M.A.; Mahmoodi, N.M. Carbon nanotube based metal-organic framework nanocomposites: Synthesis and their photocatalytic activity for decolorization of colored wastewater. Inorg. Chim. Acta 2018, 487, 169–176. [Google Scholar] [CrossRef]

- Kumar, U.S.U.; Abdulmadjid, S.N.; Olaiya, N.G.; Amirul, A.A.; Rizal, S.; Rahman, A.A.; Alfatah, T.; Mistar, E.M.; Abdul Khalil, H.P.S. Extracted Compounds from Neem Leaves as Antimicrobial Agent on the Physico-Chemical Properties of Seaweed-Based Biopolymer Films. Polymers 2020, 12, 1119. [Google Scholar] [CrossRef]

- Li, N.; Ma, X.; Zha, Q.; Kim, K.; Chen, Y.; Song, C. Maximizing the number of oxygen-containing functional groups on activated carbon by using ammonium persulfate and improving the temperature-programmed desorption characterization of carbon surface chemistry. Carbon 2011, 49, 5002–5013. [Google Scholar] [CrossRef]

- Haske-Cornelius, O.; Bischof, S.; Beer, B.; Bartolome, M.J.; Olakanmi, E.O.; Mokoba, M.; Guebitz, G.; Nyanhongo, G. Enzymatic synthesis of highly flexible lignin cross-linked succinyl-chitosan hydrogels reinforced with reed cellulose fibres. Eur. Polym. J. 2019, 120, 109201. [Google Scholar] [CrossRef]

- Shu, R.; Jiang, X.; Li, J.; Shao, Z.; Zhu, D.; Song, T.; Luo, Z. Microstructures and mechanical properties of Al-Si alloy nanocomposites hybrid reinforced with nano-carbon and in-situ Al2O3. J. Alloys Compd. 2019, 800, 150–162. [Google Scholar] [CrossRef]

- Herrera-Ramírez, L.C.; Cano, M.; de Villoria, R.G. Low thermal and high electrical conductivity in hollow glass microspheres covered with carbon nanofiber–polymer composites. Compos. Sci. Technol. 2017, 151, 211–218. [Google Scholar] [CrossRef]

- Paszkiewicz, S.; Szymczyk, A.; Zubkiewicz, A.; Subocz, J.; Stanik, R.; Szczepaniak, J. Enhanced Functional Properties of Low-Density Polyethylene Nanocomposites Containing Hybrid Fillers of Multi-Walled Carbon Nanotubes and Nano Carbon Black. Polymers 2020, 12, 1356. [Google Scholar] [CrossRef] [PubMed]

- Jawaid, M.; Abdul Khalil, H.P.S.; Abu Bakar, A.; Khanam, P.N. Chemical resistance, void content and tensile properties of oil palm/jute fibre reinforced polymer hybrid composites. Mater. Des. 2011, 32, 1014–1019. [Google Scholar] [CrossRef]

- Emam, H.E.; Shaheen, T.I. Investigation into the Role of Surface Modification of Cellulose Nanocrystals with Succinic Anhydride in Dye Removal. J. Polym. Environ. 2019, 27, 2419–2427. [Google Scholar] [CrossRef]

- Oushabi, A.; Sair, S.; Hassani, F.O.; Abboud, Y.; Tanane, O.; El Bouari, A. The effect of alkali treatment on mechanical, morphological and thermal properties of date palm fibers (DPFs): Study of the interface of DPF-Polyurethane composite. S. Afr. J. Chem. Eng. 2017, 23, 116–123. [Google Scholar] [CrossRef]

- Khan, A.; Asiri, A.M.; Jawaid, M.; Saba, N. Inamuddin Effect of cellulose nano fibers and nano clays on the mechanical, morphological, thermal and dynamic mechanical performance of kenaf/epoxy composites. Carbohydr. Polym. 2020, 239, 116248. [Google Scholar] [CrossRef]

- Behnam, R.; Roghani-Mamaqani, H.; Salami-Kalajahi, M. Preparation of carbon nanotube and polyurethane-imide hybrid composites by sol-gel reaction. Polym. Compos. 2018, 40, E1903–E1909. [Google Scholar] [CrossRef]

- Li, B.; Dong, S.; Wu, X.; Wang, C.; Wang, X.; Fang, J. Anisotropic thermal property of magnetically oriented carbon nanotube/graphene polymer composites. Compos. Sci. Technol. 2017, 147, 52–61. [Google Scholar] [CrossRef]

- Kumar, U.S.; Paridah, M.T.; Owolabi, F.A.T.; Gopakumar, D.A.; Rizal, S.; Amirul, A.A.; Rahman, A.A.; Alfatah, T.; Mistar, E.M.; Aprilia, N.A.S.; et al. Neem leaves extract based seaweed bio-degradable composite films with excellent antimicrobial activity for sustainable packaging material. BioResources 2019, 14, 700–713. [Google Scholar] [CrossRef]

| Composites | Tensile Strength (MPa) | Tensile Modulus (GPa) | Elongation at Break (%) | Tensile Toughness (MPa) | Flexural Strength (MPa) | Flexural Modulus (GPa) | Flexural Toughness (GPa) | Impact Strength (kJ·m−2) |

|---|---|---|---|---|---|---|---|---|

| VE | 31.64 ± 0.82 | 0.74 ± 0.03 | 8.82 ± 0.41 | 42.15 ± 0.36 | 36.04 ± 1.27 | 2.63 ± 0.14 | 42.56 ± 1.70 | 2.15 ± 0.08 |

| VE/UK | 42.79 ± 1.40 | 1.27 ± 0.06 | 7.83 ± 0.25 | 72.21 ± 1.53 | 51.84 ± 1.26 | 3.62 ± 0.11 | 53.09 ± 0.85 | 3.61 ± 0.18 |

| VE/PK/NC0 | 54.28 ± 1.27 | 2.31 ± 0.11 | 6.80 ± 0.19 | 82.29 ± 1.06 | 75.83 ± 1.14 | 6.13 ± 0.05 | 64.20 ± 1.39 | 5.02 ± 0.17 |

| VE/PK/NC1 | 63.87 ± 1.34 | 2.44 ± 0.09 | 5.48 ± 0.16 | 87.04 ± 0.98 | 81.95 ± 1.62 | 7.18 ± 0.11 | 72.36 ± 0.89 | 5.37 ± 0.15 |

| VE/PK/NC3 | 75.28 ± 1.28 | 2.63 ± 0.08 | 5.10 ± 0.19 | 92.49 ± 1.63 | 94.73 ± 1.32 | 8.27 ± 0.26 | 82.75 ± 0.81 | 6.59 ± 0.14 |

| VE/PK/NC5 | 71.38 ± 1.43 | 2.52 ± 0.05 | 5.27 ± 0.12 | 90.38 ± 0.94 | 89.70 ± 1.26 | 7.93 ± 0.18 | 78.61 ± 1.77 | 6.12 ± 0.18 |

| VE/SK/NC0 | 65.91 ± 1.16 | 2.57 ± 0.19 | 5.38 ± 0.11 | 88.72 ± 0.85 | 82.35 ± 1.60 | 7.42 ± 0.16 | 74.29 ± 1.38 | 5.51 ± 0.16 |

| VE/SK/NC1 | 81.72 ± 1.26 | 2.81 ± 0.09 | 5.06 ± 0.17 | 95.81 ± 1.24 | 96.36 ± 1.62 | 8.39 ± 0.06 | 84.03 ± 0.75 | 6.90 ± 0.12 |

| VE/SK/NC3 | 92.47 ± 1.19 | 3.16 ± 0.08 | 4.82 ± 0.12 | 106.71 ± 1.79 | 108.34 ± 1.40 | 9.56 ± 0.08 | 93.49 ± 0.97 | 8.94 ± 0.12 |

| VE/SK/NC5 | 87.40 ± 1.82 | 2.93 ± 0.05 | 4.95 ± 0.16 | 102.48 ± 0.76 | 104.59 ± 1.07 | 9.14 ± 0.11 | 88.29 ± 1.37 | 8.35 ± 0.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rizal, S.; H.P.S., A.K.; Mistar, E.M.; Olaiya, N.G.; Muksin, U.; Marwan, M.; Ikramullah; Suriani, A.B.; Abdullah, C.K.; Alfatah, T. Functional Properties of Kenaf Bast Fibre Anhydride Modification Enhancement with Bionanocarbon in Polymer Nanobiocomposites. Polymers 2021, 13, 4211. https://doi.org/10.3390/polym13234211

Rizal S, H.P.S. AK, Mistar EM, Olaiya NG, Muksin U, Marwan M, Ikramullah, Suriani AB, Abdullah CK, Alfatah T. Functional Properties of Kenaf Bast Fibre Anhydride Modification Enhancement with Bionanocarbon in Polymer Nanobiocomposites. Polymers. 2021; 13(23):4211. https://doi.org/10.3390/polym13234211

Chicago/Turabian StyleRizal, Samsul, Abdul Khalil H.P.S., E. M. Mistar, Niyi Gideon Olaiya, Umar Muksin, Marwan Marwan, Ikramullah, A. B. Suriani, C. K. Abdullah, and Tata Alfatah. 2021. "Functional Properties of Kenaf Bast Fibre Anhydride Modification Enhancement with Bionanocarbon in Polymer Nanobiocomposites" Polymers 13, no. 23: 4211. https://doi.org/10.3390/polym13234211

APA StyleRizal, S., H.P.S., A. K., Mistar, E. M., Olaiya, N. G., Muksin, U., Marwan, M., Ikramullah, Suriani, A. B., Abdullah, C. K., & Alfatah, T. (2021). Functional Properties of Kenaf Bast Fibre Anhydride Modification Enhancement with Bionanocarbon in Polymer Nanobiocomposites. Polymers, 13(23), 4211. https://doi.org/10.3390/polym13234211