Synthesis and Characterization of Hybrid Fiber-Reinforced Polymer by Adding Ceramic Nanoparticles for Aeronautical Structural Applications

Abstract

1. Introduction

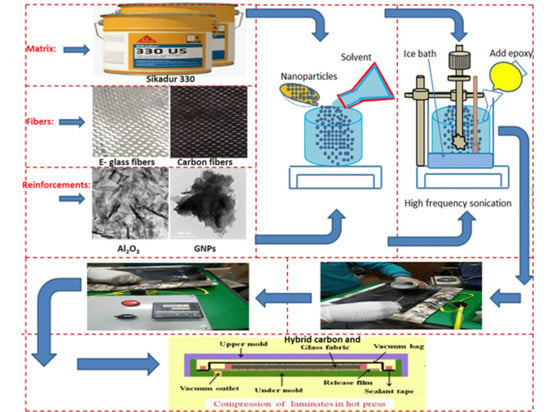

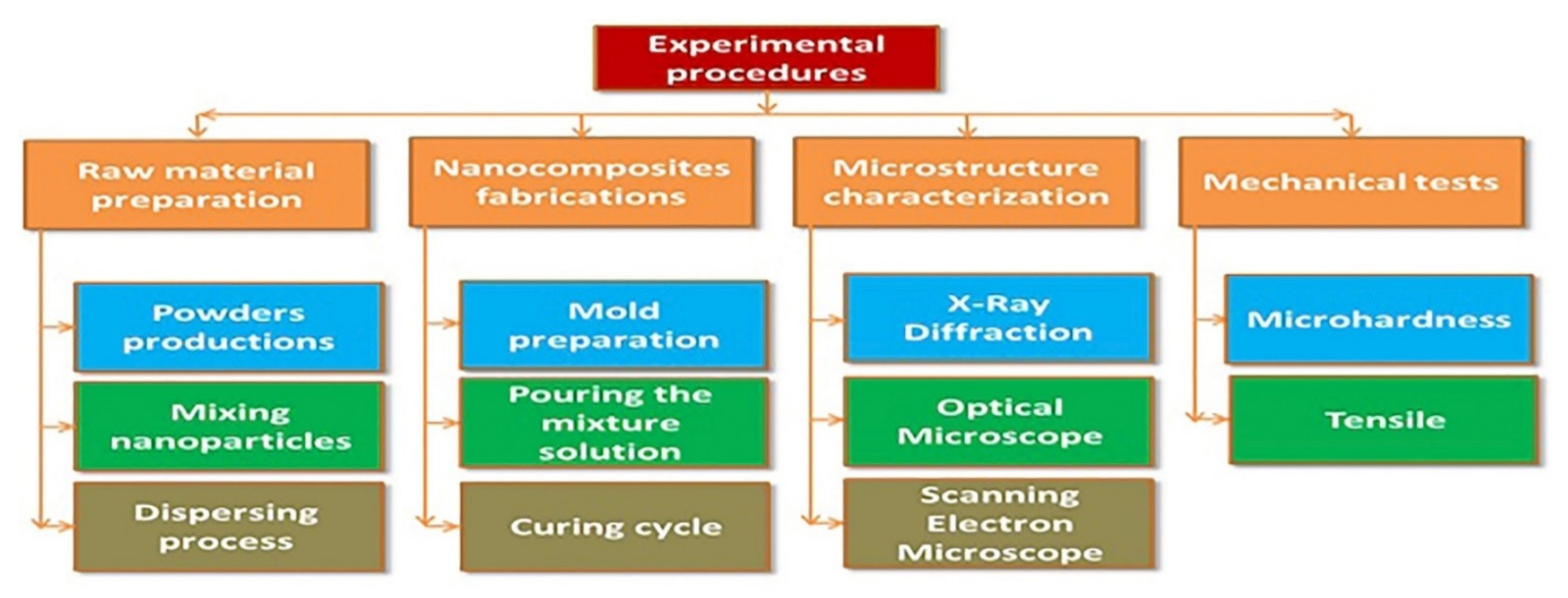

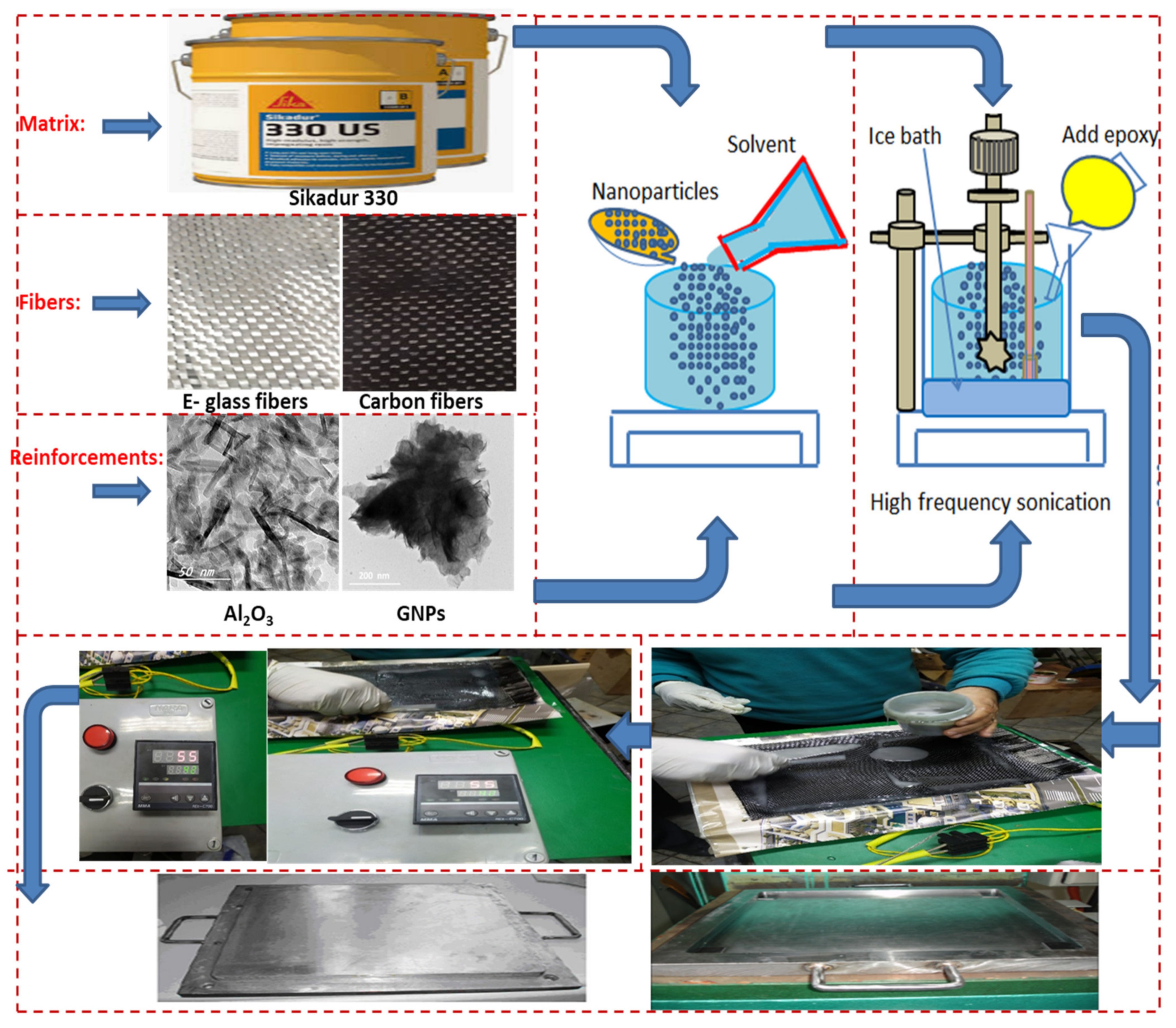

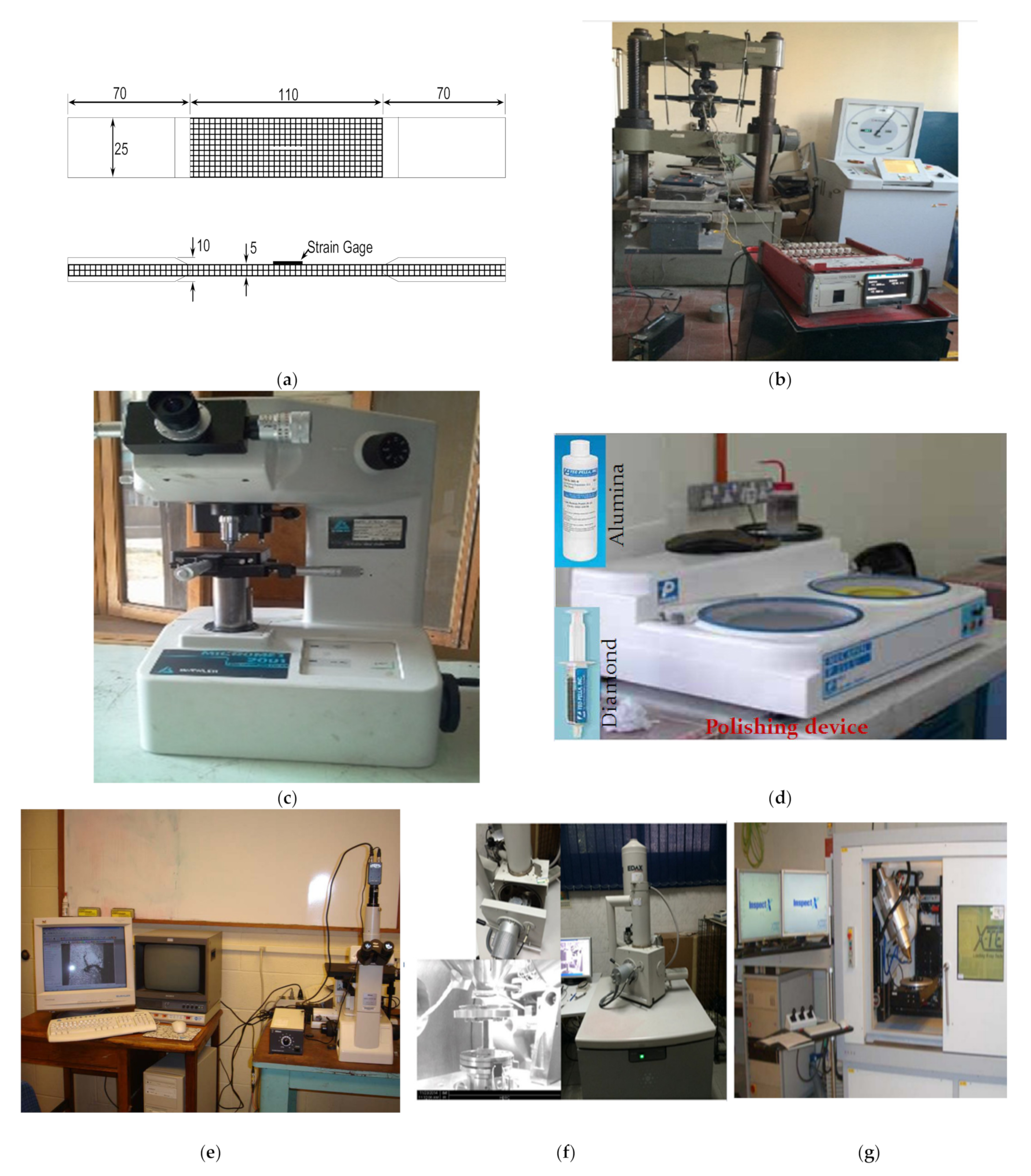

2. Materials and Methods

3. Results

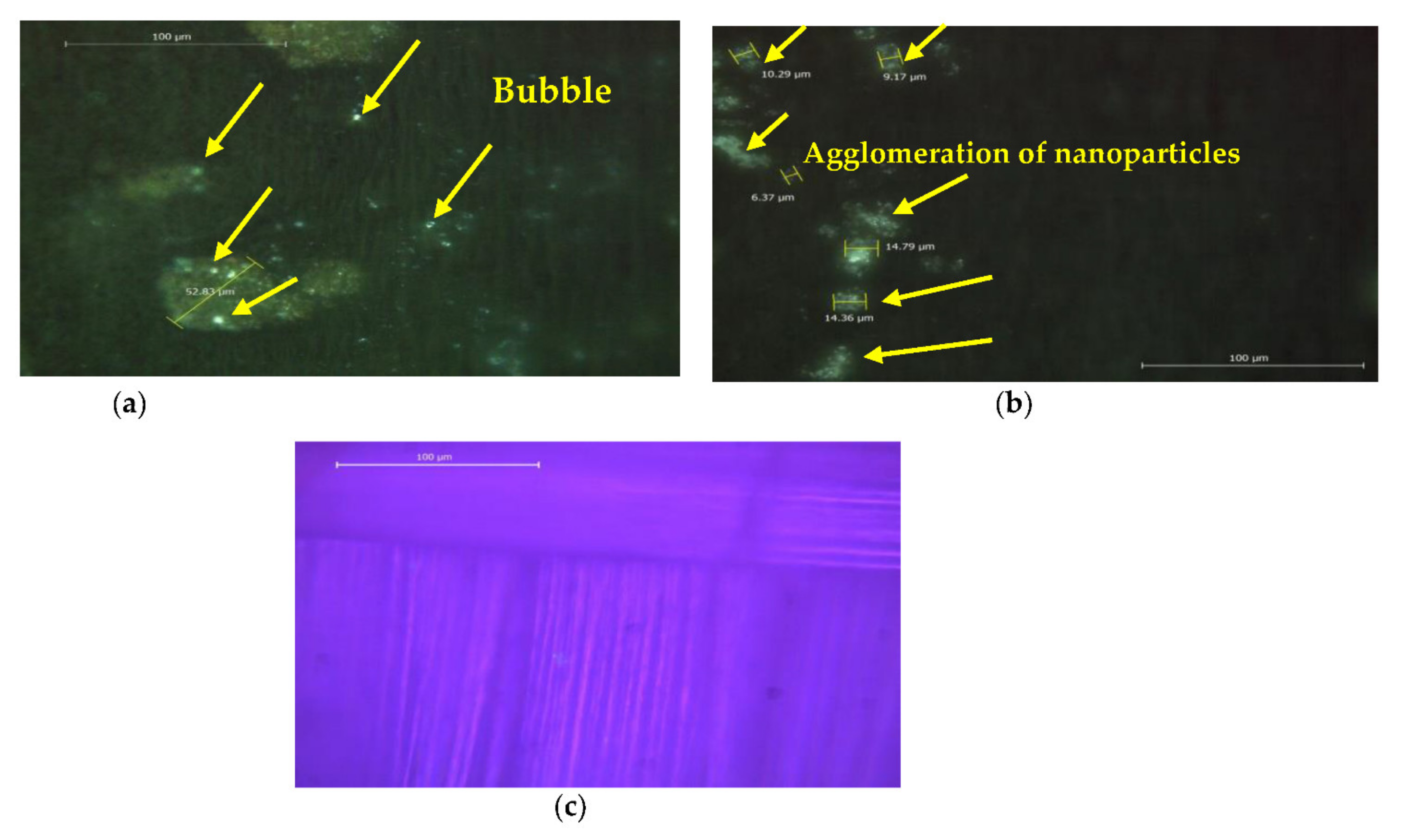

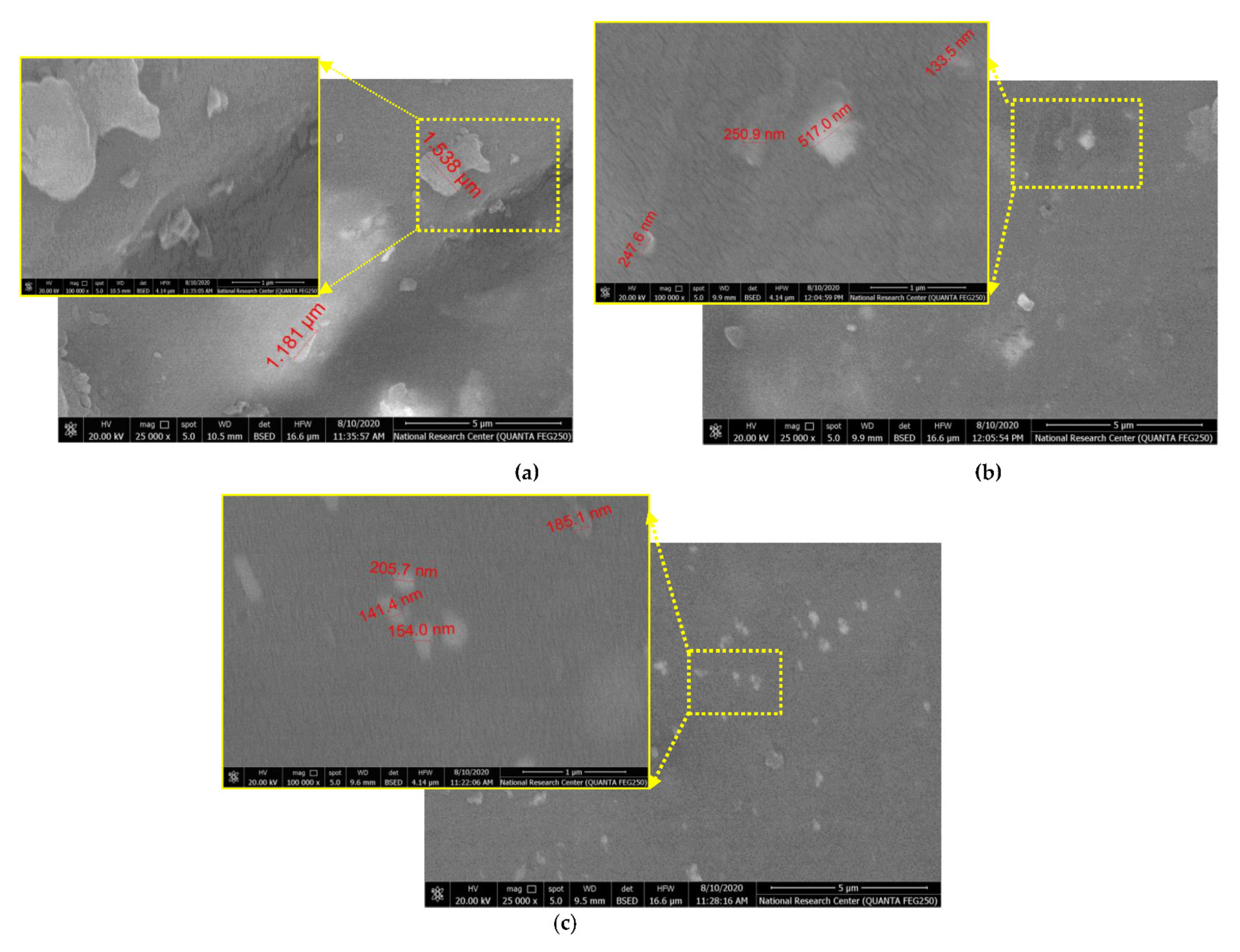

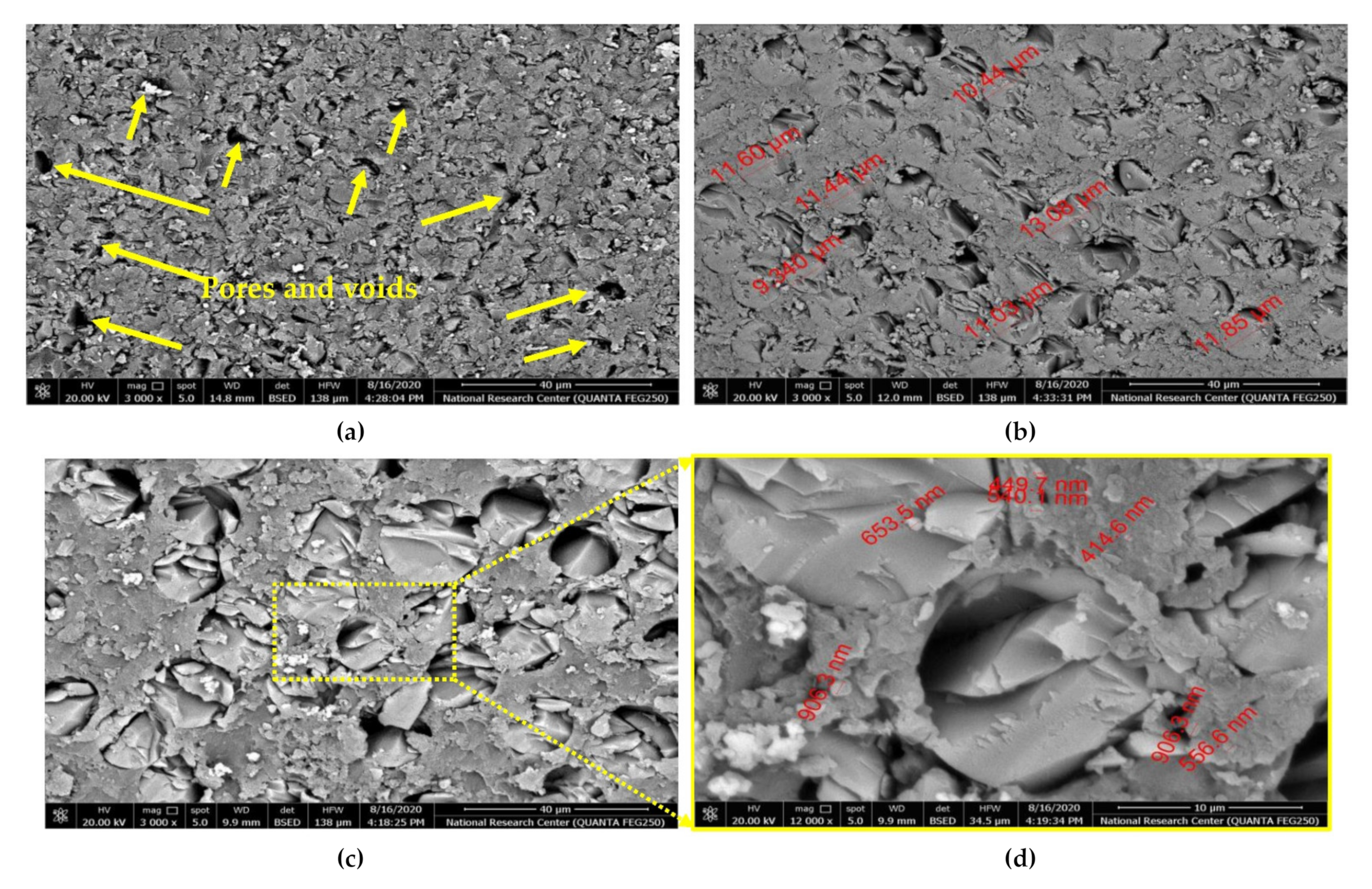

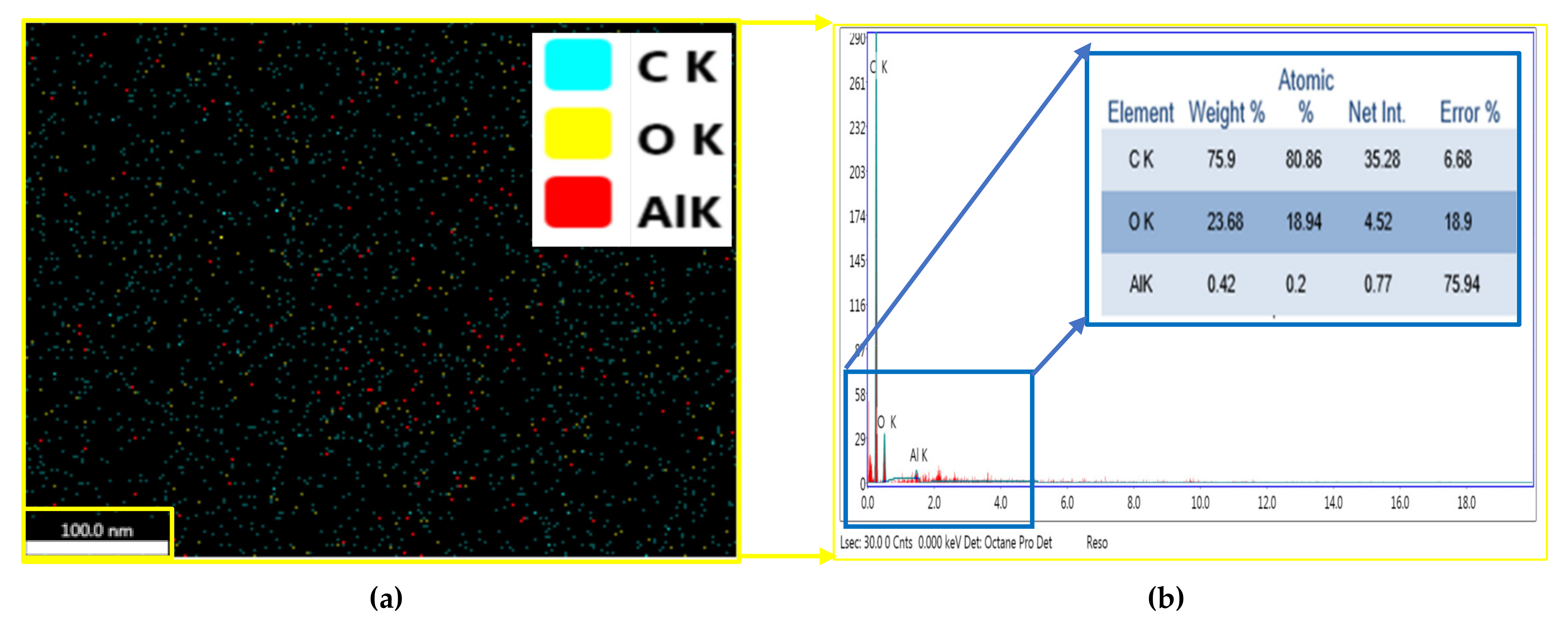

3.1. Microstructral Observations

3.2. Mechanical Properties

4. Discussion

4.1. Microstructral Investigations

4.2. Mechanical Response

5. Conclusions

- Uniform distribution of GNPs and Al2O3 with weight fraction of 1.5% of both nanoparticles was achieved in the hybrid FRPs matrix, and the spherical bubbles disappeared with the addition of ceramic nanoparticles to glass fiber and carbon fiber.

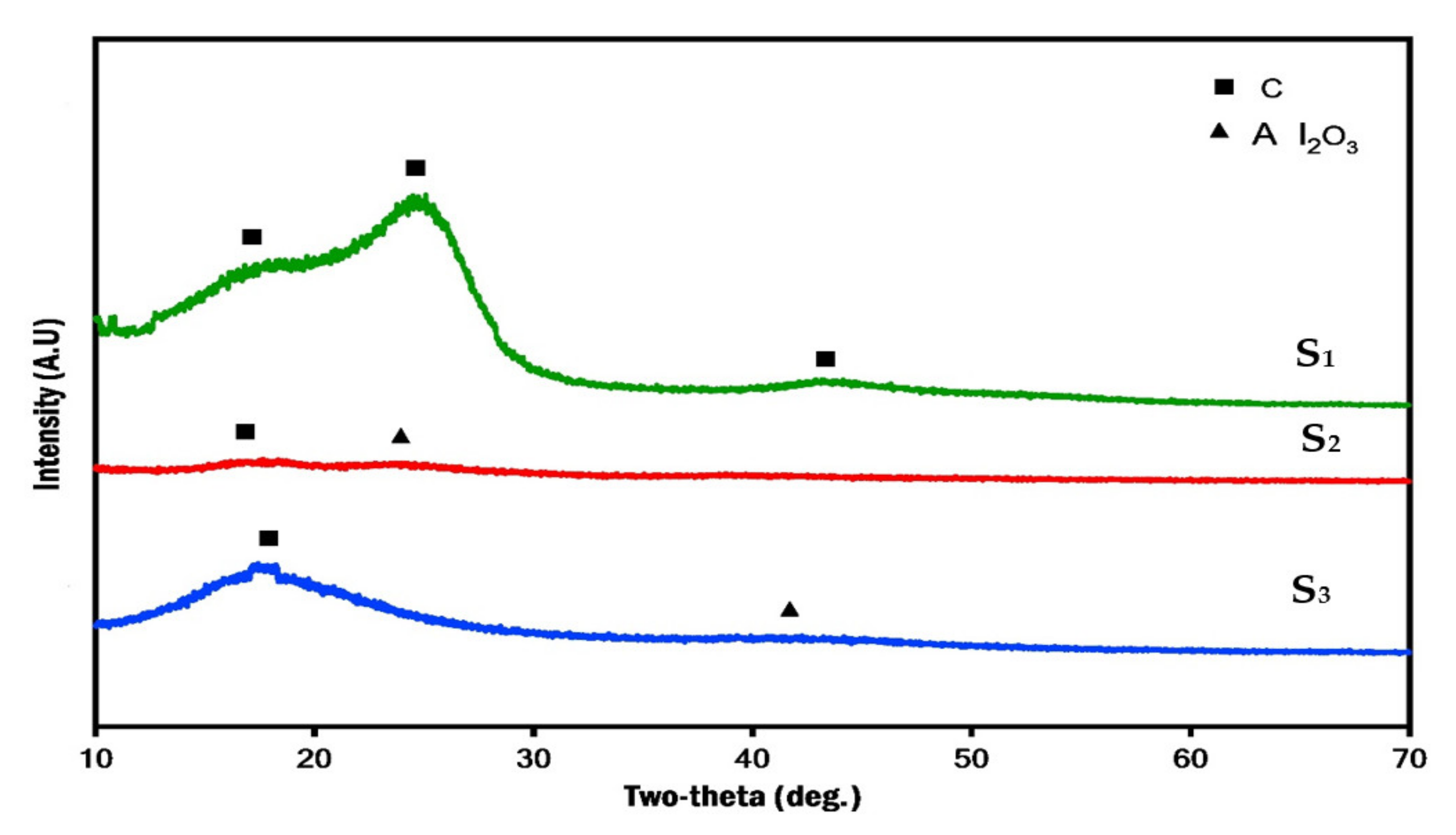

- According to XRD results, the diffraction patterns represent two peaks, i.e., higher-intensity peaks of amorphous carbon, due to the similarities between additive nanoparticles such as GNPs and glass and carbon fiber in all the composite samples, and weak peaks of the Al2O3 phase in samples S2 and S3 due to its low weight percentage in the resin matrix.

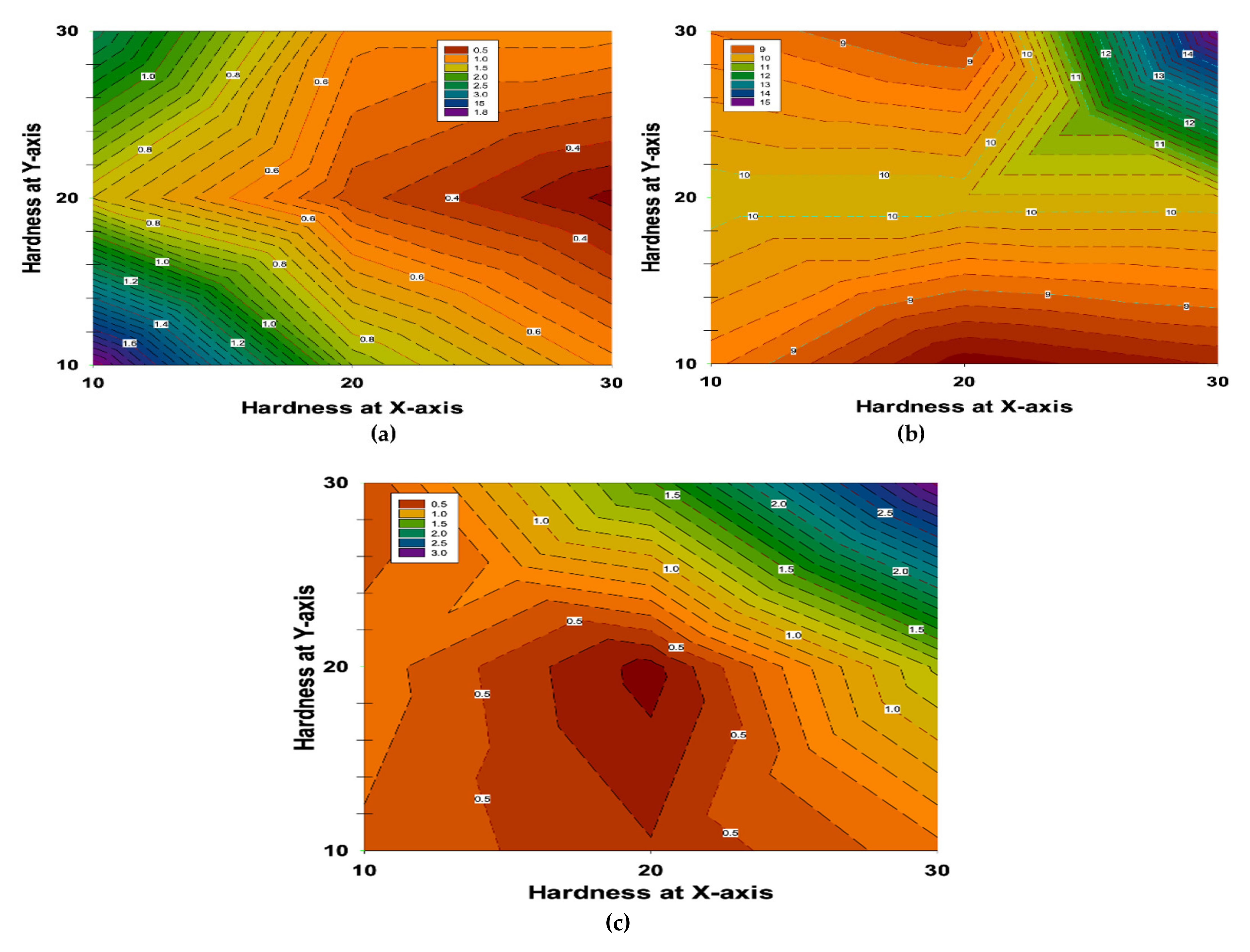

- The addition reinforcements of GNPs and Al2O3 with weight fractions of both nanoparticles at 1.5% to the resin matrix affords significant improvements in the hardness, which can be ascribed to the hard nature of these ceramic nanoparticles, which displayed a uniform distribution within the resin matrix.

- Additionally, the tensile properties were improved with the addition of GNPs and Al2O3 particles. The highest value of tensile strength (230 MPa) belonged to the hybrid glass and carbon fibers with 3 wt.% Al2O3, while the strength value of composite S1 with no reinforcements was 133 MPa.

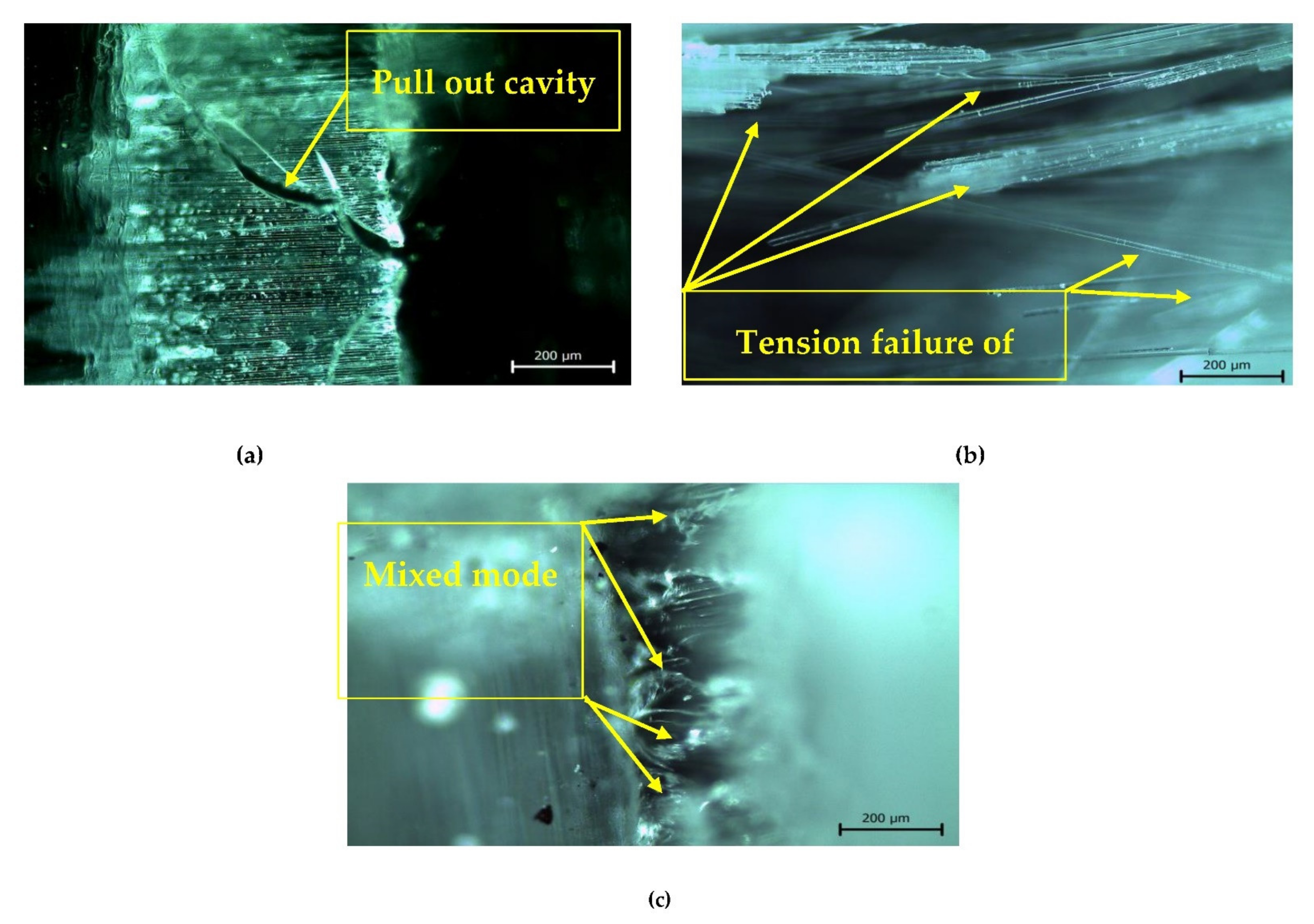

- The type of layer structure of fibers, matrix, and fillers (nanoparticles) plays a critical role in scattering, distribution, and also adhesion.

- Finally, according to the previous findings and conclusions, it can be concluded that the properties of the combination of nanomaterials depend on several factors, such as type of nanoparticles, surface treatments, polymer matrix, synthesis methods, and polymer nanocomposite morphology. These factors will a research area of interest in the future.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ata, M.H.; Abu-Okail, M.; Essa, G.M.F.; Mahmoud, T.S.; Hassab-Allah, I. Failure mode and failure load of adhesively bonded composite joints made by glass fiber-reinforced polymer. J. Fail. Anal. Preven. 2019, 19, 950–957. [Google Scholar] [CrossRef]

- Abu-Okail, M.; Nafea, M.; Ghanem, M.A.; El-Sheikh, M.N.; El-Nikhaily, A.E.; Abu-Oqail, A. Damage Mechanism Evaluation of Polymer Matrix Composite Reinforced with Glass Fiber via Modified Arcan Test Specimens. J. Fail. Anal. Prev. 2021, 21, 451–461. [Google Scholar] [CrossRef]

- Abdelfatah, A. Corrosion behavior of the pre-heated friction stir welded AA2024 alloy reinforced with AA7075 in 3.5% NaCl solution. Int. J. Electrochem. Sci. 2021, 16, 151001. [Google Scholar] [CrossRef]

- Sabry, I.; Gadallah, N.; Abu-Okail, M. Optimization of friction stir welding parameters using response surface methodology. IOP Conf. Ser.: Mater. Sci. Eng. 2020, 973, 12017. [Google Scholar] [CrossRef]

- Abu–Okail, M.; Ata, M.H.; Abuoqail, A.; Essa, G.M.F.; Mahmoud, T.S.; Hassab–Allah, I. Production of tailor-welded blanks by vertical compensation friction stir welding technique. J. Mater. Sci. Technol. 2018, 34, 2030–2041. [Google Scholar] [CrossRef]

- Abu-Okail, M.; Ata, M.H.; Abu-Oqail, A. Effect of friction stir welding process parameters with interlayer strip on microstructural characterization and mechanical properties. J. Fail. Anal. Prev. 2019, 20, 173–183. [Google Scholar] [CrossRef]

- Abu-Okail, M.; Mahmoud, T.S.; Abu-Oqail, A. Improving microstructural and mechanical properties of AA2024 base metal by adding reinforced strip width of AA7075 via vertical compensation friction stir welding technique. J. Fail. Anal. Prev. 2019, 20, 184–196. [Google Scholar] [CrossRef]

- Abu-Okail, M.; Ata, M.H. Enhancement ductility of friction stir welded aluminum blanks AA2024 via adding interlayer strip width of AA7075. Mater. Res. Express 2019, 6, 116510. [Google Scholar] [CrossRef]

- Abu-Okail, M.; Sabry, I.; Abu-Oqail, A.; Shewakh, W. Effect of changing heat treatment conditions on microstructural and mechanical properties of friction stir welded sheets of AA2024 with interlayer strip width AA7075. J. Fail. Anal. Prev. 2020, 20, 701–722. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, L.; Wu, Z.; Du, B.; Chen, L.; Li, W.; Fang, D. Lateral crushing behavior of novel carbon fiber/epoxy composite bidirectional self-locked thin-walled tubular structure and system. Thin-Walled Struct. 2020, 157, 107063. [Google Scholar] [CrossRef]

- Zheng, J.; Zhao, L.; Fan, H. Energy absorption mechanisms of hierarchical woven lattice composites. Compos. Part B Eng. 2012, 43, 1516–1522. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, S.; Wu, K.; Dong, Z. Multi-response optimization design of tailor-welded blank (TWB) thin-walled structures using Taguchi-based gray relational analysis. Thin-Walled Struct. 2018, 131, 286–296. [Google Scholar] [CrossRef]

- Yan, B.; Zhu, S.; Tong, M.; Pan, S. Experimental study on the mechanical properties of laminates made of thin carbon fiber plies. Compos. Struct. 2020, 245, 112336. [Google Scholar] [CrossRef]

- Arteiro, A.; Catalanotti, G.; Xavier, J.; Linde, P.; Camanho, P.P. Effect of tow thickness on the structural response of aerospace-grade spread-tow fabrics. Compos. Struct. 2017, 179, 208–223. [Google Scholar] [CrossRef]

- Nishikawa, Y.; Okubo, K.; Fujii, T.; Kawabe, K. Fatigue crack constraint in plain-woven CFRP using newly-developed spread tows. Int. J. Fatigue 2006, 28, 1248–1253. [Google Scholar] [CrossRef]

- Herwig, A.; Schmidt, C.; Horst, P. Numerical Investigation of a Layered Hybrid Load Introduction Element for Thin-Walled CFRP Structures. In Proceedings of the 18th European Conference on Composite Materials, Athens, Greece, 25–28 June 2018. [Google Scholar]

- Bałon, P.; Rejman, E.; Świątoniowski, A.; Kiełbasa, B.; Smusz, R.; Szostak, J.; Kowalski, Ł. Thin-walled Integral Constructions in Aircraft Industry. Procedia Manuf. 2020, 47, 498–504. [Google Scholar] [CrossRef]

- Bałon, P.; Świątoniowski, A.; Kiełbasa, B.; Rejman, E.; Szostak, J.; Smusz, R.; Kowalski, Ł. The application of thin-walled integral constructions in aviation as exemplified by the SAT-AM project. MATEC Web Conf. 2019, 304, 1026. [Google Scholar] [CrossRef]

- Soutis, C. Carbon fiber reinforced plastics in aircraft construction. J. Mater. Sci. Eng. A 2005, 412, 171–176. [Google Scholar] [CrossRef]

- Takahashi, T. Aircraft Performance and Sizing, Volume II, Applied Aerodynamic Design; Aerospace Engineering Collection; IOS Press: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Roskam, J. Aircraft Design Part VIII: Airplane Cost Estimation: Design, Development, Manufacturing and Operating; DARcorporation: Lawrence, KS, USA, 2002. [Google Scholar]

- Roskam, J. Aircraft Design Part V: Component Weight Estimation; DARcorporation: Lawrence, KS, USA, 1999. [Google Scholar]

- Kirby, M.R. TIES for Dummies (Technology Identification, Evaluation, and Selection), Basic how to’s to Implement the TIES Method, 3rd ed.; Aerospace Systems Design Laboratory, Georgia Institute of Technology: Atlanta, GA, USA, 2002. [Google Scholar]

- Roskam, J. Aircraft Design Part III: Layout Design of Cockpit, Fuselage, Wing and Empennage: Cutaways and Inboard Profiles; DARcorporation: Lawrence, KS, USA, 2002. [Google Scholar]

- Cristofaro, M. Elements of Computational Flight Dynamics for Complete Aircraft. Ph.D. Thesis, Politecnico di Torino, Turin, Italy, 2014. [Google Scholar]

- Lyu, Z.; Martins, J.R.R.A. Aerodynamic Design Optimization Studies of a Blended Wing Body Aircraft. J. Aircr. 2014, 51, 1604–1617. [Google Scholar] [CrossRef]

- Reis, J.M.L.d. Displacement rate effect on the flexural properties of glass fiber reinforced polyurethane. Mater. Res. 2016, 19, 183–186. [Google Scholar] [CrossRef][Green Version]

- Dong, C. Flexural Properties of Symmetric Carbon and Glass Fibre Reinforced Hybrid Composite Laminates. Compos. Part C Open Access 2020, 3, 100047. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C.; Hong, B. Effects of rod size and fiber hybrid mode on the interface shear strength of carbon/glass fiber composite rods exposed to freezing-thawing and outdoor environments. JMR&T 2021, 14, 2812–2831. [Google Scholar]

- Tsai, Y.; Bosze, J.; Barjasteh, E.; Nutt, S. Influence of hygrothermal environment on thermal and mechanical properties of carbon fiber/fiberglass hybrid composites. Compos. Sci. Technol. 2009, 69, 432–437. [Google Scholar] [CrossRef]

- Li, C.; Yin, X.; Wang, Y.; Zhang, L.; Zhang, Z.; Liu, Y.; Xian, G. Mechanical property evolution and service life prediction of pultruded carbon/glass hybrid rod exposed in harsh oil-well condition. Compos. Struct. 2020, 246, 112418. [Google Scholar] [CrossRef]

- Bragg, M.B.; Gregorek, G.M.; Lee, J.D. Airfoil aerodynamics in icing conditions. J. Aircr. 1986, 23, 76–81. [Google Scholar] [CrossRef]

- Khamaj, A.W.M.; Farouk, W.M.; Shewakh, A.M.I.; Abu-Oqail, A.; Wagih, M.; Abu–Okail, M. Effect of lattice structure evolution on the thermal and mechanical properties of Cu–Al2O3/GNPs nanocomposites. J. Ceram. Int. 2021, 47, 16511–16520. [Google Scholar]

- Karnati, S.R.; Agbo, P.; Zhang, L. Applications of Silica Nanoparticles in Glass/Carbon Fiber-Reinforced Epoxy Nanocomposite. Compos. Commun. 2019, 17, 32–41. [Google Scholar] [CrossRef]

- Domun, N.; Hadavinia, H.; Zhang, T.; Sainsbury, T.; Liaghat, G.; Vahid, S. Improving the fracture toughness and the strength of epoxy using nanomaterials—A review of the current status. Nanoscale 2015, 7, 10294–10329. [Google Scholar] [CrossRef] [PubMed]

- Seretis, G.V.; Manolakos, D.E.; Provatidis, C.G. On the stainless steel flakes reinforcement of polymer matrix particulate composites. Compos. Part B Eng. 2019, 162, 80–88. [Google Scholar] [CrossRef]

- Hao, X.; Nie, H.; Ye, Z.; Luo, Y.; Zheng, L.; Liang, W. Mechanical properties of a novel fiber metal laminate based on a carbon fiber reinforced Zn-Al alloy composite. J. Mater. Sci. Eng. A 2018, 740–741, 218–225. [Google Scholar] [CrossRef]

- Quan, D.; Urdániz, J.L.; Rouge, C.; Ivanković, A. The enhancement of adhesively-bonded aerospace-grade composite joints using steel fibres. Compos. Struct. 2018, 198, 11–18. [Google Scholar] [CrossRef]

- Loos, M.R.; Yang, J.; Feke, D.L.; Manas-Zloczower, I.; Unal, S.; Younes, U. Enhancement of fatigue life of polyurethane composites containing carbon nanotubes. Compos. Part B Eng. 2013, 44, 740–744. [Google Scholar] [CrossRef]

- Abu–Okail, M.; Shewakh, W.M.; Brisha, A.M.; Abdelraouf, Y.A.; Abu-Oqail, A. Effect of GNPs content at various compaction pressures and sintering temperatures on the mechanical and electrical properties of hybrid Cu/Al2O3/xGNPs nanocomposites synthesized by high energy ball milling. Ceram. Int. 2020, 46, 18037–18045. [Google Scholar] [CrossRef]

- Kaybal, H.B.; Ulus, H.; Demir, O.; Şahin, S.; Avcı, A. Effects of alumina nanoparticles on dynamic impact responses of carbon fiber reinforced epoxy matrix nanocomposites. Eng. Sci. Technol. Int. J. 2018, 21, 399–407. [Google Scholar] [CrossRef]

- Mohanty, A.; Srivastava, V.K. Effect of alumina nanoparticles on the enhancement of impact and flexural properties of the short glass/carbon fiber reinforced epoxy based composites. Fibers Polym. 2015, 16, 188–195. [Google Scholar] [CrossRef]

- Abu–Okail, M.; Alsaleh, N.; Farouk, W.; Elsheikh, A.; Abu-Oqail, A.; Abdelraouf, Y.; Abdel Ghafaar, M. Effect of dispersion of alumina nanoparticles and graphene nanoplatelets on microstructural and mechanical characteristics of hybrid carbon/glass fibers reinforced polymer composite. JMR&T 2021, 14, 2624–2637. [Google Scholar]

- Li, W.; Dichiara, A.; Zha, J.; Su, Z.; Bai, J. On improvement of mechanical and thermo-mechanical properties of glass fabric/epoxy composites by incorporating CNT–Al2O3 hybrids. Compos. Sci. Technol. 2014, 103, 36–43. [Google Scholar] [CrossRef]

- Kickelbick, G. Concepts for the incorporation of inorganic building blocks into organic polymers on a nanoscale. Prog. Polym. Sci. 2003, 28, 83–114. [Google Scholar] [CrossRef]

- Liu, T.X.; Phang, I.Y.; Shen, L.; Chow, S.Y.; Zhange, W.D. Morphology and mechanical properties of multiwalled carbon nanotubes reinforced nylon-6 composites. Macromolecules 2004, 37, 7214–7222. [Google Scholar] [CrossRef]

- Okamoto, M.; Morita, S.; Kotaka, T. Dispersed structure and ionic conductivity of smectic clay/polymer nanocomposites. Polymer 2001, 42, 2685–2688. [Google Scholar] [CrossRef]

- Shibata, S.; Cao, Y.; Fukumoto, I. Press forming of short natural fiber-reinforced biodegradable resin: Effects of fiber volume and length on flexural properties. Polym. Test. 2005, 24, 1005–1011. [Google Scholar] [CrossRef]

- Gowda, T.M.; Naidu, A.; Chhaya, R. Some mechanical properties of untreated jute fabric-reinforced polyester composites. Compos. Part A Appl. Sci. Manuf. 1999, 30, 277–284. [Google Scholar] [CrossRef]

- Mahan, H.M.; Mahjoob, D.; Rashid, N.A. Influence of Silica and Nano Alumina on Mechanical Properties of Glass Fiber Reinforced Epoxy Composite Systems. J. Adv. Res. Dyn. Control Syst. 2018, 10, 888–895. [Google Scholar]

| Properties | Epoxy | E-Glass Fiber | Carbon Fiber | Al2O3 | GNPs |

|---|---|---|---|---|---|

| Density (gram/cm3) | 1.16 | 2.56 | 1.6 | 3.78 | 2.267 |

| Tensile strength (MPa) | 30 | 1400 | 2400 | 665 | 167 |

| Tensile modulus (GPa) | 4.1 | 72.3 | 228 | 210 | 2.4 × 103 |

| Poisson’s ratio | 0.35 | 0.22 | 0.30 | 0.24 | 0.012 |

| Series | Specimen Name | Specimen Code | Reinforcement Type | Matrix Type | Ceramic Reinforcements |

|---|---|---|---|---|---|

| I | Hybrid glass and carbon fibers | S1 | Carbon fibers + Glass fibers | Sikadur 330 epoxy | without |

| II | Hybrid glass and carbon fibers at (1.5% wt. GNPs + 1.5% wt. Al2O3) | S2 | Carbon fibers + Glass fibers | Sikadur 330 epoxy | 1.5% wt. GNPs + 1.5% wt. Al2O3 |

| III | Hybrid glass and carbon fibers at 3% wt. Al2O3 | S3 | Carbon fibers + Glass fibers | Sikadur 330 epoxy | 3%wt. Al2O3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bafakeeh, O.T.; Shewakh, W.M.; Abu-Oqail, A.; Abd-Elaziem, W.; Abdel Ghafaar, M.; Abu-Okail, M. Synthesis and Characterization of Hybrid Fiber-Reinforced Polymer by Adding Ceramic Nanoparticles for Aeronautical Structural Applications. Polymers 2021, 13, 4116. https://doi.org/10.3390/polym13234116

Bafakeeh OT, Shewakh WM, Abu-Oqail A, Abd-Elaziem W, Abdel Ghafaar M, Abu-Okail M. Synthesis and Characterization of Hybrid Fiber-Reinforced Polymer by Adding Ceramic Nanoparticles for Aeronautical Structural Applications. Polymers. 2021; 13(23):4116. https://doi.org/10.3390/polym13234116

Chicago/Turabian StyleBafakeeh, Omar Talal, Walid Mahmoud Shewakh, Ahmed Abu-Oqail, Walaa Abd-Elaziem, Metwally Abdel Ghafaar, and Mohamed Abu-Okail. 2021. "Synthesis and Characterization of Hybrid Fiber-Reinforced Polymer by Adding Ceramic Nanoparticles for Aeronautical Structural Applications" Polymers 13, no. 23: 4116. https://doi.org/10.3390/polym13234116

APA StyleBafakeeh, O. T., Shewakh, W. M., Abu-Oqail, A., Abd-Elaziem, W., Abdel Ghafaar, M., & Abu-Okail, M. (2021). Synthesis and Characterization of Hybrid Fiber-Reinforced Polymer by Adding Ceramic Nanoparticles for Aeronautical Structural Applications. Polymers, 13(23), 4116. https://doi.org/10.3390/polym13234116