Applications of 3D-Printed PEEK via Fused Filament Fabrication: A Systematic Review

Abstract

:1. Introduction

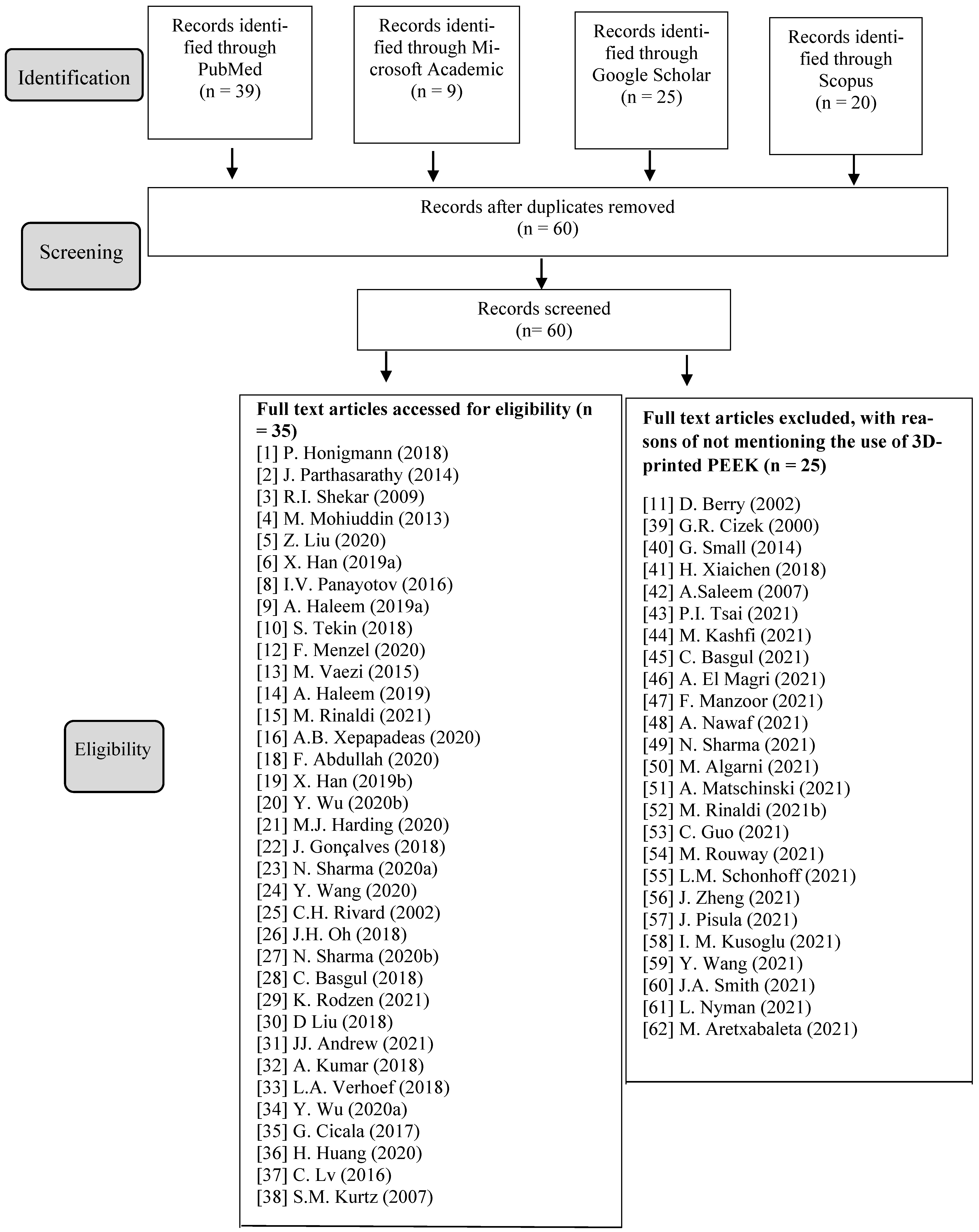

2. Materials and Methods

2.1. Inclusion Criteria

2.2. Exclusion Criteria

2.3. Search Strategy

3. Classification of Use of Additively Manufactured/3D-Printed PEEK in Different Fields

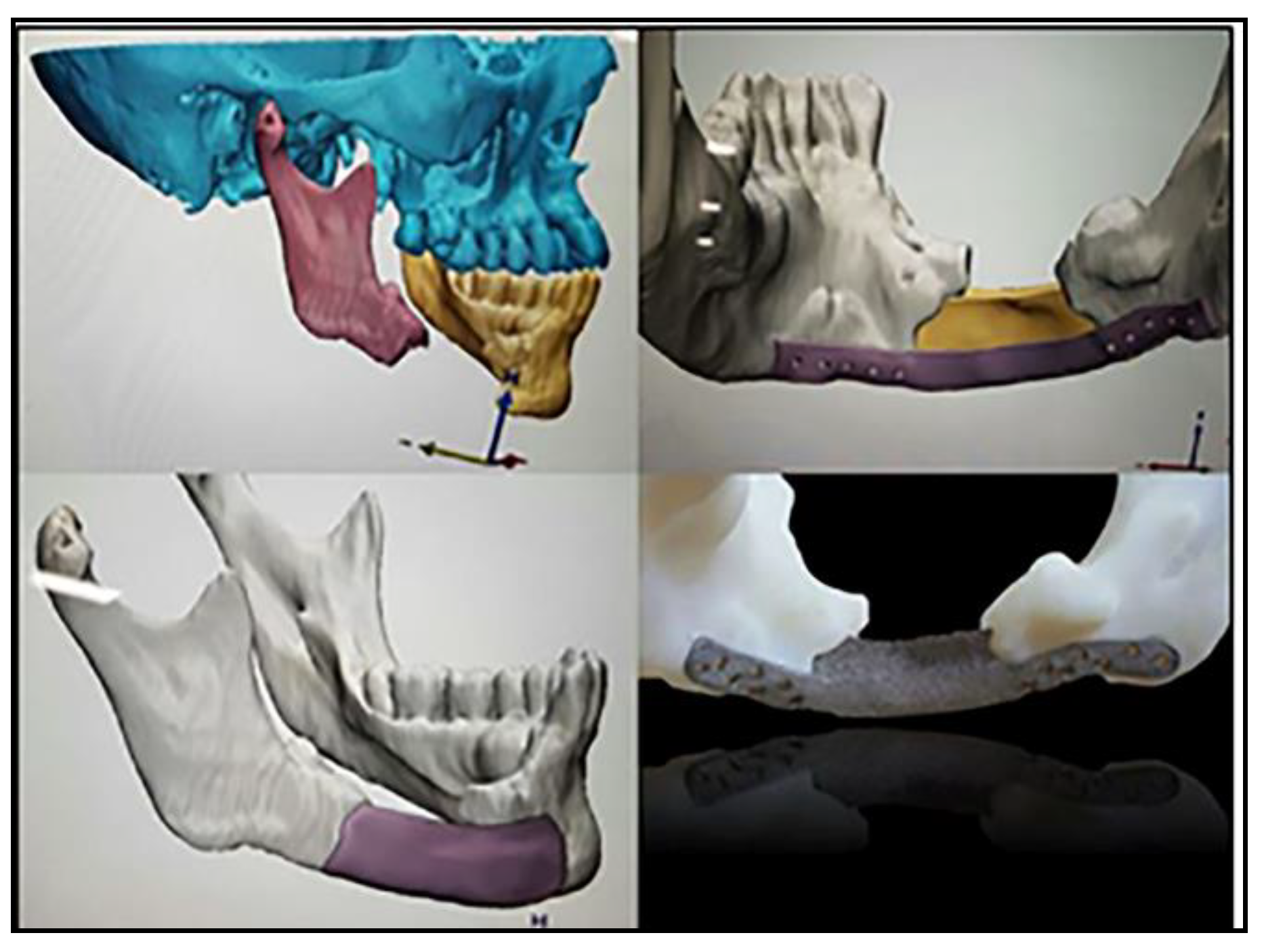

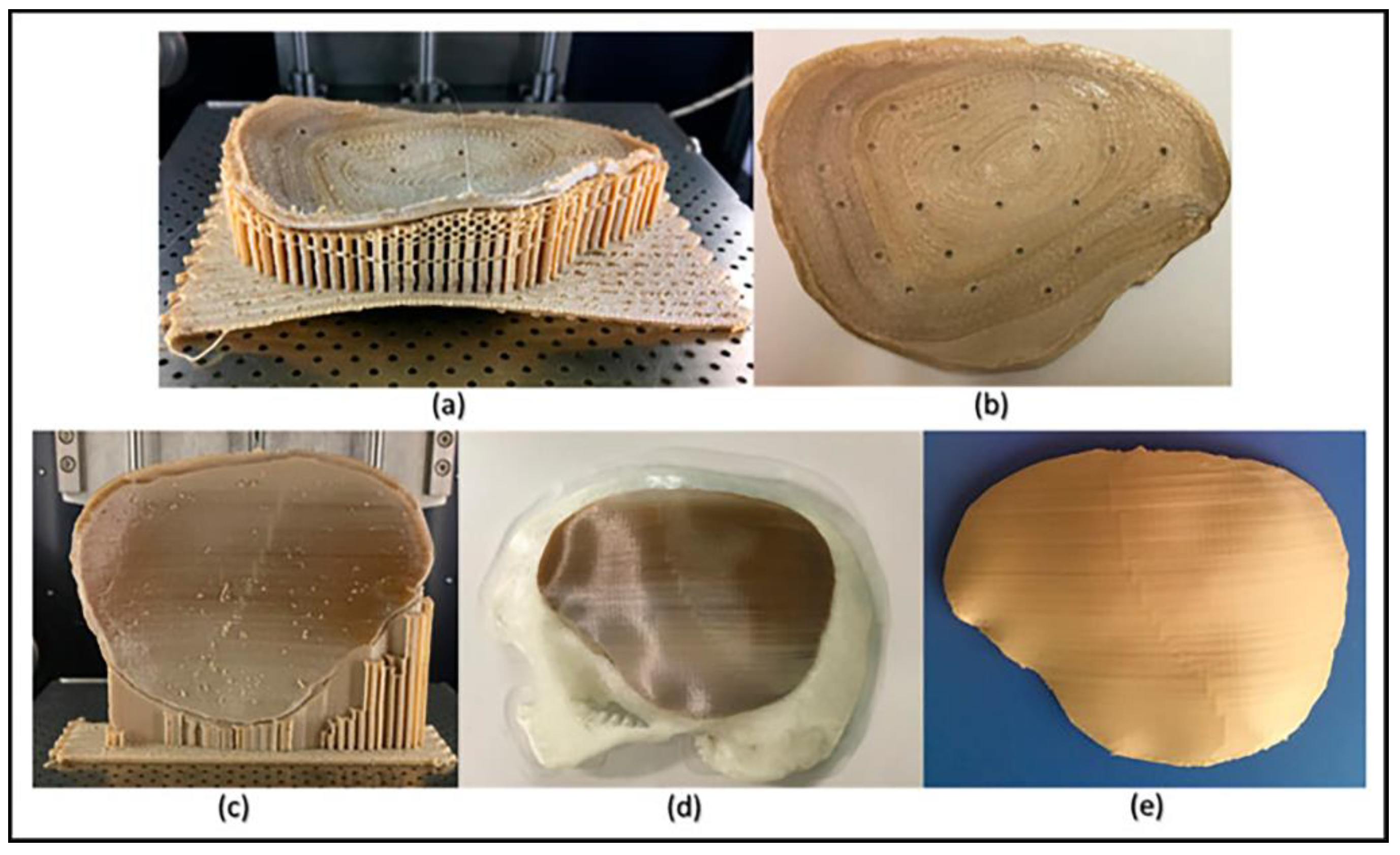

3.1. Use of 3D-Printed PEEK in the Medical Field

3.2. Use of 3D-Printed PEEK in the Aerospace Field

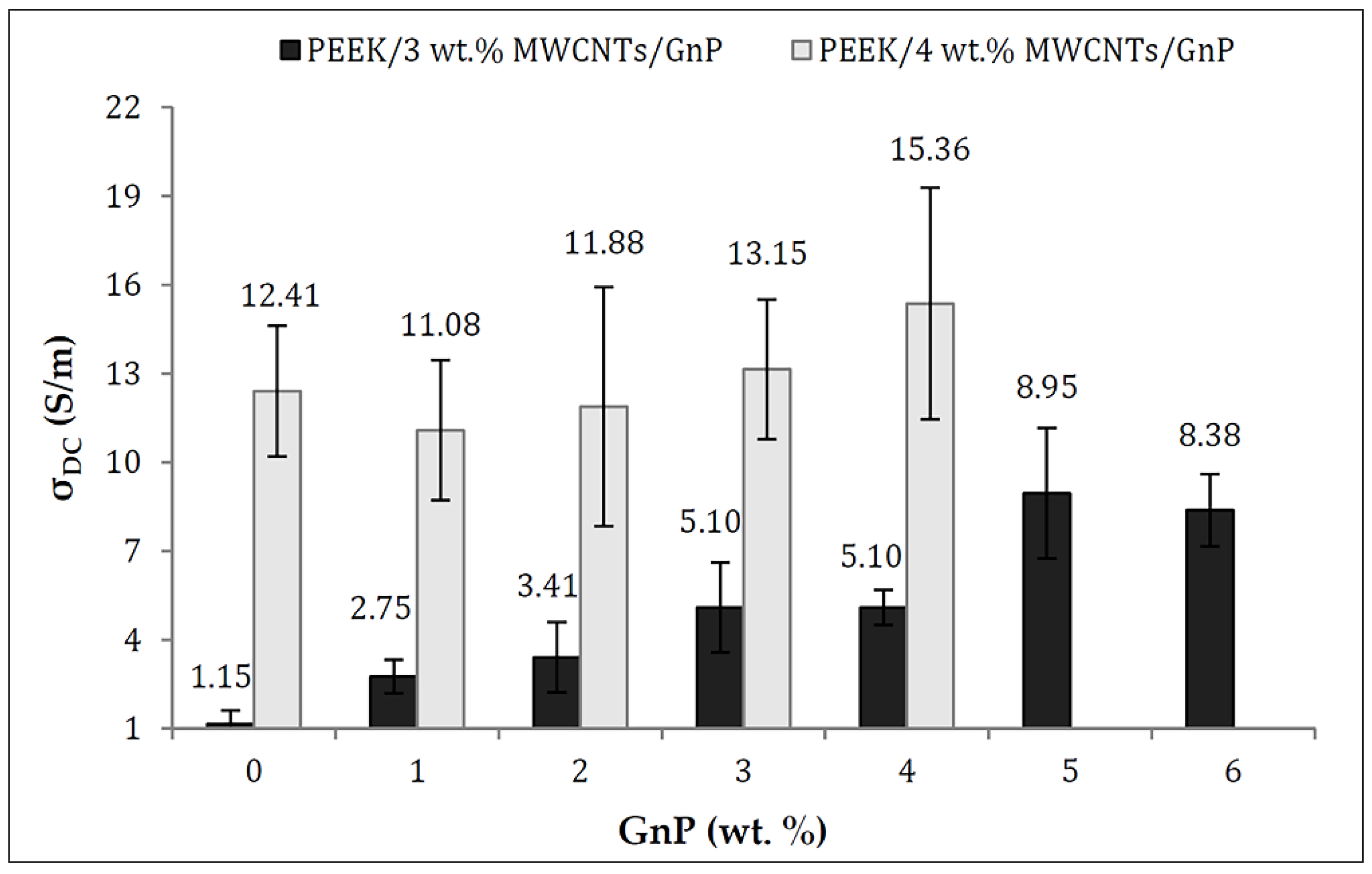

3.3. Use of 3D-Printed PEEK in the Electrical Field

3.4. Use of 3D-Printed PEEK in the Chemical Field

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Honigmann, P.; Sharma, N.; Okolo, B.; Popp, U.; Msallem, B.; Thieringer, F.M. Patient-specific surgical implants made of 3D printed PEEK: Material, technology, and scope of surgical application. Biomed Res. Int. 2018, 2018, 4520636. [Google Scholar] [CrossRef] [Green Version]

- Parthasarathy, J. 3D modeling, custom implants and its future perspectives in craniofacial surgery. Ann. Maxillofac. Surg. 2014, 4, 9. [Google Scholar] [CrossRef] [Green Version]

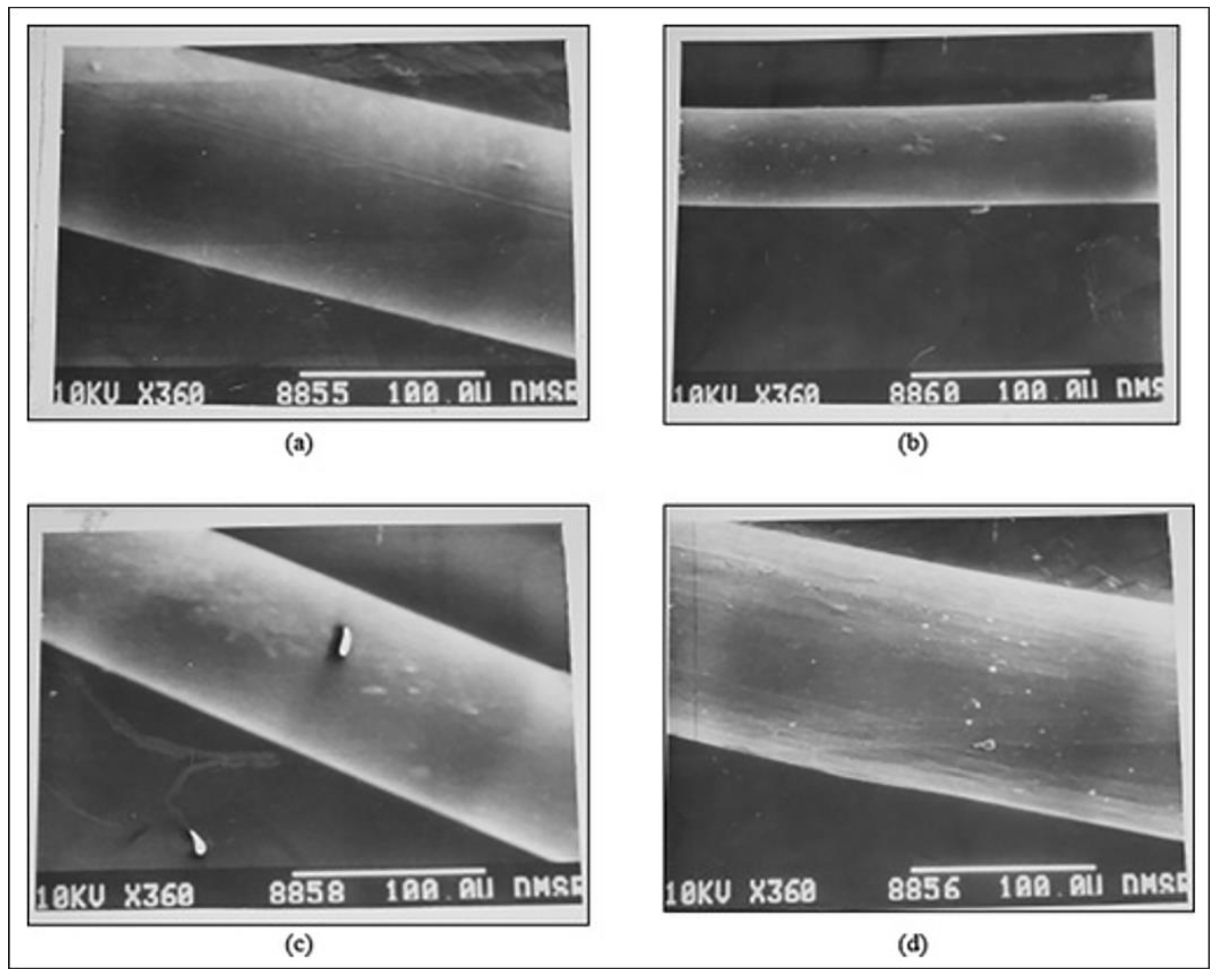

- Shekar, R.I.; Kotresh, T.M.; Rao, P.M.D.; Kumar, K. Properties of high modulus PEEK yarns for aerospace applications. J. Appl. Polym. Sci. 2009, 112, 2497–2510. [Google Scholar] [CrossRef]

- Mohiuddin, M.; Hoa, S.V. Estimation of contact resistance and its effect on electrical conductivity of CNT/PEEK composites. Compos. Sci. Technol. 2013, 79, 42–48. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, L.; Hou, X.; Wu, J. Investigation on dielectrical and space charge characteristics of peek insulation used in aerospace high-voltage system. IEEJ Trans. Electr. Electron. Eng. 2020, 15, 172–178. [Google Scholar] [CrossRef]

- Han, X.; Sharma, N.; Xu, Z.; Scheideler, L.; Geis-Gerstorfer, J.; Rupp, F.; Thieringer, F.M.; Spintzyk, S. An In Vitro Study of Osteoblast Response on Fused-Filament Fabrication 3D Printed PEEK for Dental and Cranio-Maxillofacial Implants. J. Clin. Med. 2019, 8, 771. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, F.; Roovers, J. Functionalization of poly (aryl ether ether ketone)(PEEK): Synthesis and properties of aldehyde and carboxylic acid substituted PEEK. Macromolecules 1993, 26, 5295–5302. [Google Scholar] [CrossRef]

- Panayotov, I.V.; Orti, V.; Cuisinier, F.; Yachouh, J. Polyetheretherketone (PEEK) for medical applications. J. Mater. Sci. Mater. Med. 2016, 27, 118. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M. Polyether ether ketone (PEEK) and its 3D printed implants applications in medical field: An overview. Clin. Epidemiol. Glob. Health 2019, 7, 571–577. [Google Scholar] [CrossRef] [Green Version]

- Tekin, S.; Cangül, S.; Adıgüzel, Ö.; Değer, Y. Areas for use of PEEK material in dentistry. Int. Dent. Res. 2018, 8, 84–92. [Google Scholar] [CrossRef]

- Berry, D. Use of Victrex® PEEK™ Thermoplastic to Drive New Designs, Processing Flexibility, and Cost Reduction in Aerospace Components. SAE Trans. 2002, 426–431. [Google Scholar]

- Menzel, F.; Klein, T.; Ziegler, T.; Neumaier, J.M. 3D-printed PEEK reactors and development of a complete continuous flow system for chemical synthesis. React. Chem. Eng. 2020, 5, 1300–1310. [Google Scholar] [CrossRef]

- Vaezi, M.; Yang, S. Extrusion-based additive manufacturing of PEEK for biomedical applications. Virtual Phys. Prototyp. 2015, 10, 123–135. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M. Polyether ether ketone (PEEK) and its manufacturing of customised 3D printed dentistry parts using additive manufacturing. Clin. Epidemiol. Glob. Health 2019, 7, 654–660. [Google Scholar] [CrossRef] [Green Version]

- Rinaldi, M.; Cecchini, F.; Pigliaru, L.; Ghidini, T.; Lumaca, F.; Nanni, F. Additive Manufacturing of Polyether Ether Ketone (PEEK) for Space Applications: A Nanosat Polymeric Structure. Polymers 2021, 13, 11. [Google Scholar] [CrossRef]

- Xepapadeas, A.B.; Weise, C.; Frank, K.; Spintzyk, S.; Poets, C.F.; Wiechers, C.; Arand, J.; Koos, B. Technical note on introducing a digital workflow for newborns with craniofacial anomalies based on intraoral scans—Part II: 3D printed Tubingen palatal plate prototype for newborns with Robin sequence. BMC Oral. Health 2020, 20, 171. [Google Scholar] [CrossRef] [PubMed]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Muülhaupt, R. Polymers for 3D printing and customized additive manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abdullah, F.; Okuyama, K.-i.; Morimitsu, A.; Yamagata, N. Effects of Thermal Cycle and Ultraviolet Radiation on 3D Printed Carbon Fiber/Polyether Ether Ketone Ablator. Aerospace 2020, 7, 95. [Google Scholar] [CrossRef]

- Han, X.; Yang, D.; Yang, C.; Spintzyk, S.; Scheideler, L.; Li, P.; Li, D.; Geis-Gerstorfer, J.; Rupp, F. Carbon fiber reinforced PEEK composites based on 3D-printing technology for orthopedic and dental applications. J. Clin. Med. 2019, 8, 240. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Cao, Y.; Wu, Y.; Li, D. Mechanical Properties and Gamma-Ray Shielding Performance of 3D-Printed Poly-Ether-Ether-Ketone/Tungsten Composites. Materials 2020, 13, 4475. [Google Scholar] [CrossRef]

- Harding, M.J.; Brady, S.; O’Connor, H.; Lopez-Rodriguez, R.; Edwards, M.D.; Tracy, S.; Dowling, D.; Gibson, G.; Girard, K.P.; Ferguson, S. 3D printing of PEEK reactors for flow chemistry and continuous chemical processing. React. Chem. Eng. 2020, 5, 728–735. [Google Scholar] [CrossRef]

- Gonçalves, J.; Lima, P.; Krause, B.; Pötschke, P.; Lafont, U.; Gomes, J.R.; Abreu, C.S.; Paiva, M.C.; Covas, J.A. Electrically conductive polyetheretherketone nanocomposite filaments: From production to fused deposition modeling. Polymers 2018, 10, 925. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharma, N.; Aghlmandi, S.; Cao, S.; Kunz, C.; Honigmann, P.; Thieringer, F.M. Quality characteristics and clinical relevance of in-house 3D-printed customized polyetheretherketone (PEEK) implants for craniofacial reconstruction. J. Clin. Med. 2020, 9, 2818. [Google Scholar] [CrossRef]

- Wang, Y.; Muller, W.D.; Rumjahn, A.; Schwitalla, A. Parameters influencing the outcome of additive manufacturing of tiny medical devices based on PEEK. Materials 2020, 13, 466. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rivard, C.H.; Rhalmi, S.; Coillard, C. In vivo biocompatibility testing of peek polymer for a spinal implant system: A study in rabbits. J. Biomed. Mater. Res. 2002, 62, 488–498. [Google Scholar] [CrossRef] [PubMed]

- Oh, J.H. Recent advances in the reconstruction of cranio-maxillofacial defects using computer-aided design/computer-aided manufacturing. Maxillofac. Plast. Reconstr. Surg. 2018, 40, 2. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharma, N.; Honigmann, P.; Cao, S.; Thieringer, F. Dimensional characteristics of FDM 3D printed PEEK implant for craniofacial reconstructions. Trans. Addit. Manuf. Meets Med. 2020, 2. [Google Scholar]

- Basgul, C.; Yu, T.; MacDonald, D.W.; Siskey, R.; Marcolongo, M.; Kurtz, S.M. Structure–property relationships for 3D-printed PEEK intervertebral lumbar cages produced using fused filament fabrication. J. Mater. Res. 2018, 33, 2040–2051. [Google Scholar] [CrossRef] [PubMed]

- Rodzen, K.; Sharma, P.K.; McIlhagger, A.; Mokhtari, M.; Dave, F.; Tormey, D.; Sherlock, R.; Meenan, B.J.; Boyd, A. The Direct 3D Printing of Functional PEEK/Hydroxyapatite Composites via a Fused Filament Fabrication Approach. Polymers 2021, 13, 545. [Google Scholar] [CrossRef]

- Liu, D.; Fu, J.; Fan, H.; Li, D.; Dong, E.; Xiao, X.; Wang, L.; Guo, Z. Application of 3D-printed PEEK scapula prosthesis in the treatment of scapular benign fibrous histiocytoma: A case report. J. Bone Oncol. 2018, 12, 78–82. [Google Scholar] [CrossRef] [PubMed]

- Andrew, J.J.; Alhashmi, H.; Schiffer, A.; Kumar, S.; Deshpande, V.S. Energy absorption and self-sensing performance of 3D printed CF/PEEK cellular composites. Mater. Des. 2021, 109863. [Google Scholar] [CrossRef]

- Kumar, A.; Yap, W.T.; Foo, S.L.; Lee, T.K. Effects of sterilization cycles on PEEK for medical device application. Bioengineering 2018, 5, 18. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Verhoef, L.A.; Budde, B.W.; Chockalingam, C.; Nodar, B.G.; van Wijk, A.J. The effect of additive manufacturing on global energy demand: An assessment using a bottom-up approach. Energy Policy 2018, 112, 349–360. [Google Scholar] [CrossRef]

- Wu, Y.; Cao, Y.; Wu, Y.; Li, D. Neutron shielding performance of 3D-printed boron carbide PEEK composites. Materials 2020, 13, 2314. [Google Scholar] [CrossRef]

- Cicala, G.; Latteri, A.; Del Curto, B.; Lo Russo, A.; Recca, G.; Fare, S. Engineering thermoplastics for additive manufacturing: A critical perspective with experimental evidence to support functional applications. J. Appl. Biomater. Funct. Mater. 2017, 15, 10–18. [Google Scholar] [CrossRef] [Green Version]

- Huang, H.; Liu, W.; Liu, Z. An additive manufacturing-based approach for carbon fiber reinforced polymer recycling. CIRP Ann. 2020, 69, 33–36. [Google Scholar] [CrossRef]

- Lv, C.; Heiter, J.; Haljasorg, T.; Leito, I. Covalent attachment of polymeric monolith to polyether ether ketone (PEEK) tubing. Anal. Chim. Acta 2016, 932, 114–123. [Google Scholar] [CrossRef] [PubMed]

- Kurtz, S.M.; Devine, J.N. PEEK biomaterials in trauma, orthopedic, and spinal implants. Biomaterials 2007, 28, 4845–4869. [Google Scholar] [CrossRef] [Green Version]

- Cizek, G.R.; Boyd, L.M. Imaging pitfalls of interbody spinal implants. Spine 2000, 25, 2633–2636. [Google Scholar] [CrossRef] [Green Version]

- Small, G. Outstanding physical properties make PEEK ideal for sealing applications. Seal. Technol. 2014, 2014, 9–12. [Google Scholar] [CrossRef]

- Hou, X.; Hu, Y.; Hu, X.; Jiang, D. Poly (ether ether ketone) composites reinforced by graphene oxide and silicon dioxide nanoparticles: Mechanical properties and sliding wear behavior. High Perform. Polym. 2018, 30, 406–417. [Google Scholar] [CrossRef]

- Saleem, A.; Frormann, L.; Iqbal, A. High performance thermoplastic composites: Study on the mechanical, thermal, and electrical resistivity properties of carbon fiber-reinforced polyetheretherketone and polyethersulphone. Polym. Compos. 2007, 28, 785–796. [Google Scholar] [CrossRef]

- Tsai, P.-I.; Wu, M.-H.; Li, Y.-Y.; Lin, T.-H.; Tsai, J.S.; Huang, H.-I.; Lai, H.-J.; Lee, M.-H.; Chen, C.-Y. Additive-manufactured Ti-6Al-4 V/Polyetheretherketone composite porous cage for Interbody fusion: Bone growth and biocompatibility evaluation in a porcine model. BMC Musculoskelet. Disord. 2021, 22, 171. [Google Scholar] [CrossRef]

- Kashfi, M.; Tehrani, M. Effects of void content on flexural properties of additively manufactured polymer composites. Compos. Part C Open Access 2021, 6, 100173. [Google Scholar] [CrossRef]

- Basgul, C.; Thieringer, F.M.; Kurtz, S.M. Heat transfer-based non-isothermal healing model for the interfacial bonding strength of fused filament fabricated polyetheretherketone. Addit. Manuf. 2021, 102097. [Google Scholar] [CrossRef]

- El Magri, A.; El Mabrouk, K.; Vaudreuil, S. Preparation and characterization of poly (ether ether ketone)/poly (ether imide) [PEEK/PEI] blends for fused filament fabrication. J. Mater. Sci. 2021, 1–20. [Google Scholar] [CrossRef]

- Manzoor, F.; Golbang, A.; Jindal, S.; Dixon, D.; McIlhagger, A.; Harkin-Jones, E.; Crawford, D.; Mancuso, E. 3D printed PEEK/HA composites for bone tissue engineering applications: Effect of material formulation on mechanical performance and bioactive potential. J. Mech. Behav. Biomed. Mater. 2021, 104601. [Google Scholar] [CrossRef] [PubMed]

- Alsinani, N.; Ghaedsharaf, M.; Lebel, L.L. Effect of cooling temperature on deconsolidation and pulling forces in a thermoplastic pultrusion process. Compos. B. Eng. 2021, 219, 108889. [Google Scholar] [CrossRef]

- Sharma, N.; Aghlmandi, S.; Dalcanale, F.; Seiler, D.; Zeilhofer, H.-F.; Honigmann, P.; Thieringer, F.M. Quantitative assessment of point-of-care 3D-printed patient-specific polyetheretherketone (PEEK) cranial implants. Int. J. Mol. Sci. 2021, 22, 8521. [Google Scholar] [CrossRef]

- Algarni, M.; Ghazali, S. Comparative study of the sensitivity of PLA, ABS, PEEK, and PETG’s mechanical properties to FDM printing process parameters. Crystals 2021, 11, 995. [Google Scholar] [CrossRef]

- Matschinski, A.; Ziegler, P.; Abstreiter, T.; Wolf, T.; Drechsler, K. Fiber formation of printed carbon Fiber/Poly (Ether Ether Ketone) with different nozzle shapes. Polym. Int. 2021. [Google Scholar] [CrossRef]

- Rinaldi, M.; Ghidini, T.; Nanni, F. Fused filament fabrication of polyetheretherketone/multiwalled carbon nanotube nanocomposites: The effect of thermally conductive nanometric filler on the printability and related properties. Polym. Int. 2021. [Google Scholar] [CrossRef]

- Guo, C.; Liu, X.; Liu, G. Surface finishing of FDM-fabricated amorphous polyetheretherketone and its carbon-fiber-reinforced composite by dry milling. Polymers 2021, 13, 2175. [Google Scholar] [CrossRef]

- Rouway, M.; Nachtane, M.; Tarfaoui, M.; Chakhchaoui, N.; Omari, L.E.H.; Fraija, F.; Cherkaoui, O. 3D printing: Rapid manufacturing of a new small-scale tidal turbine blade. Int. J. Adv. Manuf. Technol. 2021, 1–16. [Google Scholar] [CrossRef]

- Schönhoff, L.M.; Mayinger, F.; Eichberger, M.; Reznikova, E.; Stawarczyk, B. 3D printing of dental restorations: Mechanical properties of thermoplastic polymer materials. J. Mech. Behav. Biomed. Mater. 2021, 119, 104544. [Google Scholar] [CrossRef]

- Zheng, J.; Kang, J.; Sun, C.; Yang, C.; Wang, L.; Li, D. Effects of printing path and material components on mechanical properties of 3D-printed polyether-ether-ketone/hydroxyapatite composites. J. Mech. Behav. Biomed. Mater. 2021, 118, 104475. [Google Scholar] [CrossRef]

- Pisula, J.; Budzik, G.; Turek, P.; Cieplak, M. An analysis of polymer gear wear in a spur gear train made using FDM and FFF methods based on tooth surface topography assessment. Polymers 2021, 13, 1649. [Google Scholar] [CrossRef]

- Kusoglu, I.M.; Doñate-Buendía, C.; Barcikowski, S.; Gökce, B. Laser powder bed fusion of polymers: Quantitative esearch direction indices. Materials 2021, 14, 1169. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, J.; Yan, M.; Tian, X. Poly ether ether ketone and its composite powder prepared by thermally induced phase separation for high temperature selective laser sintering. Mater. Des. 2021, 201, 109510. [Google Scholar] [CrossRef]

- Smith, J.A.; Li, S.; Mele, E.; Goulas, A.; Engstrøm, D.; Silberschmidt, V.V. Printability and mechanical performance of biomedical PDMS-PEEK composites developed for material extrusion. J. Mech. Behav. Biomed. Mater. 2021, 115, 104291. [Google Scholar] [CrossRef]

- Nyman, L.; Kestilä, A.; Porri, P.; Pudas, M.; Salmi, M.; Silander, R.; Miikkulainen, V.; Kaipio, M.; Kallio, E.; Ritala, M. Constructing spacecraft components using additive manufacturing and atomic layer deposition: First steps for integrated electric circuitry. J. Aerosp. Eng. 2021, 34, 04021049. [Google Scholar] [CrossRef]

- Aretxabaleta, M.; Xepapadeas, A.B.; Poets, C.F.; Koos, B.; Spintzyk, S. Fracture load of an Orthodontic appliance for Robin Sequence Treatment in a digital workflow. Materials 2021, 14, 344. [Google Scholar] [CrossRef] [PubMed]

- Rahman, K.M.; Letcher, T.; Reese, R. Mechanical properties of additively manufactured PEEK components using fused filament fabrication. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 10–13 November 2015; p. V02AT02A009. [Google Scholar]

- Peng, W.; Bin, Z.O.; Shouling, D.; Lei, L.; Huang, C. Effects of FDM-3D printing parameters on mechanical properties and microstructure of CF/PEEK and GF/PEEK. Chin. J. Aeronaut. 2021, 34, 236–246. [Google Scholar]

- Golbang, A.; Mokhtari, M.; Harkin-Jones, E.; Archer, E.; Mcilhagger, A. Additive manufacturing and injection moulding of high-performance IF-WS 2/PEEK nanocomposites: A comparative study. Front. Mater. 2021, 8, 745088. [Google Scholar] [CrossRef]

| Field of Use of 3D-Printed PEEK | Properties of PEEK | Material | Applications | References |

|---|---|---|---|---|

| Medical |

|

|

| [6,14,16,19,23,24,27,28,29,30] |

| Aerospace |

|

|

| [3,15,18,20,34] |

| Electrical |

|

|

| [22,31,36] |

| Chemical |

|

|

| [12,21,37] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dua, R.; Rashad, Z.; Spears, J.; Dunn, G.; Maxwell, M. Applications of 3D-Printed PEEK via Fused Filament Fabrication: A Systematic Review. Polymers 2021, 13, 4046. https://doi.org/10.3390/polym13224046

Dua R, Rashad Z, Spears J, Dunn G, Maxwell M. Applications of 3D-Printed PEEK via Fused Filament Fabrication: A Systematic Review. Polymers. 2021; 13(22):4046. https://doi.org/10.3390/polym13224046

Chicago/Turabian StyleDua, Rupak, Zuri Rashad, Joy Spears, Grace Dunn, and Micaela Maxwell. 2021. "Applications of 3D-Printed PEEK via Fused Filament Fabrication: A Systematic Review" Polymers 13, no. 22: 4046. https://doi.org/10.3390/polym13224046

APA StyleDua, R., Rashad, Z., Spears, J., Dunn, G., & Maxwell, M. (2021). Applications of 3D-Printed PEEK via Fused Filament Fabrication: A Systematic Review. Polymers, 13(22), 4046. https://doi.org/10.3390/polym13224046