Characterization of Thermal Bio-Insulation Materials Based on Oil Palm Wood: The Effect of Hybridization and Particle Size

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Preparation

2.2. Treatment of Fiber

2.3. Manufacturing of Bio-Panels

2.4. Physical Measurements

2.5. Mechanical Measurements

2.6. Thermal Measurements

3. Results and Discussion

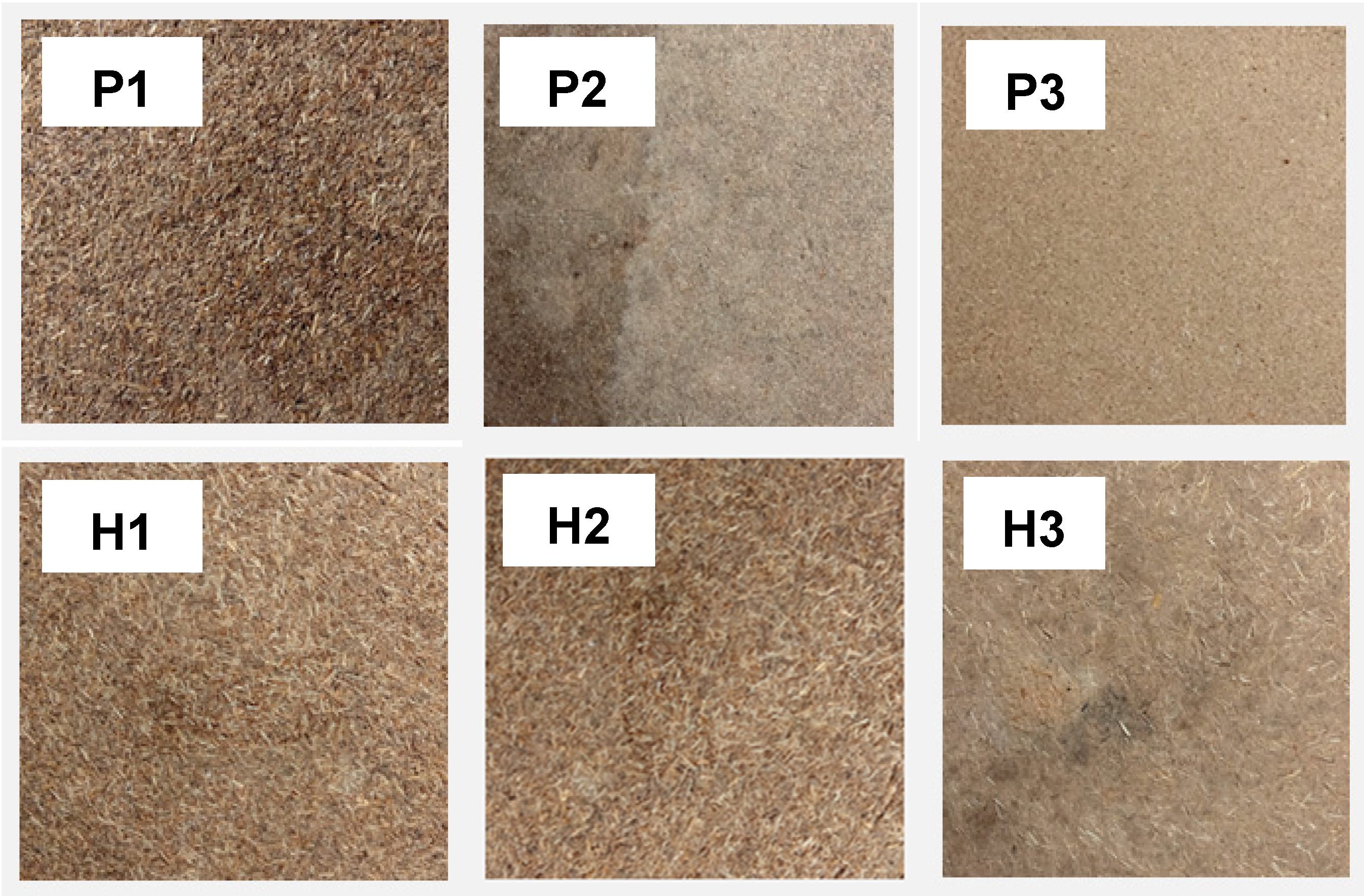

3.1. Physical Properties of the Bio-Panels

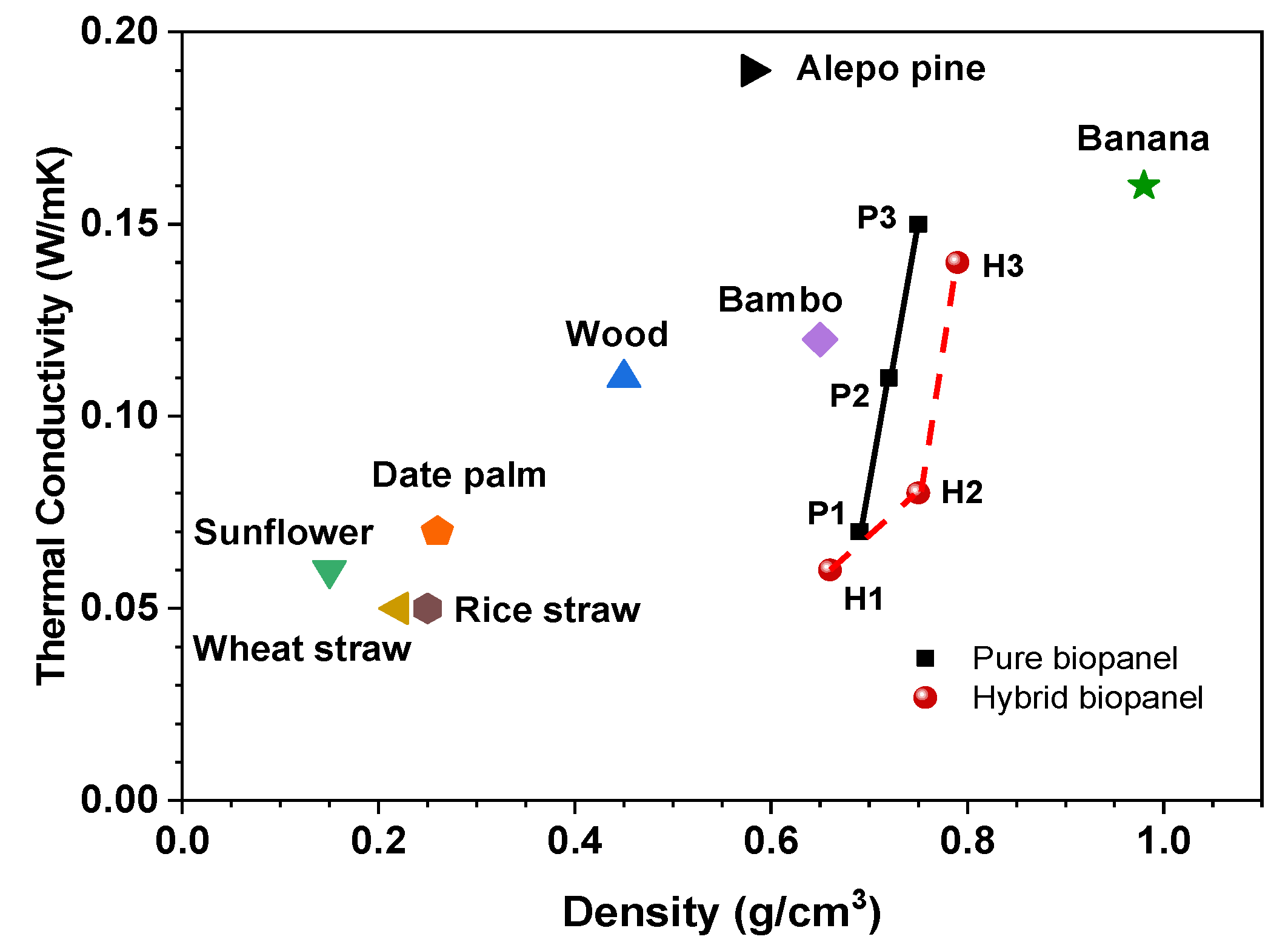

3.2. Correlation of Density with the Thermal Conductivity of Bio-Panels

3.3. Bending Strength and Thermal Conductivity

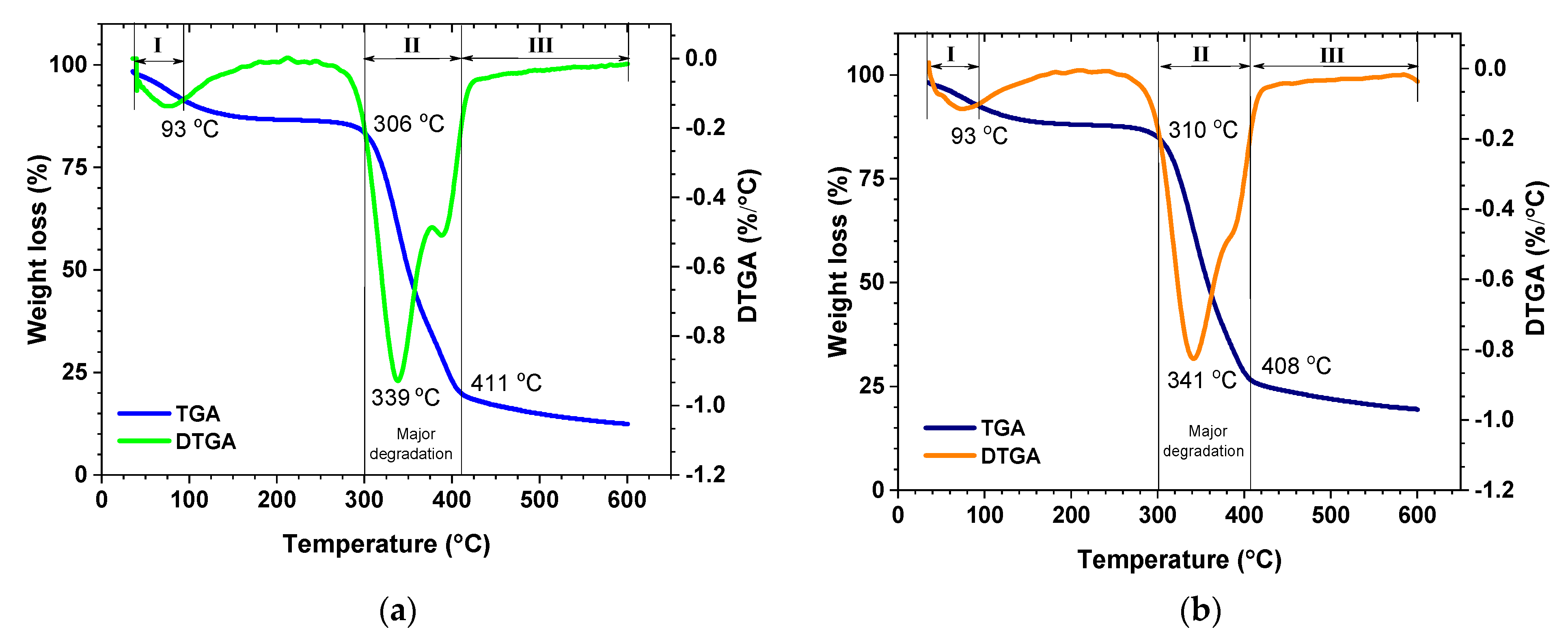

3.4. TGA and DTGA Spectra

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- BPS-Statistics Indonesia. Indonesian Oil Palm Statistic 2019; BPS-Statistics Indonesia: Jakarta, Indonesia, 2020. [Google Scholar]

- Lim Meng Hon, J. A case study on palm empty fruit bunch as energy feedstock. SEGi Rev. 2010, 3, 3–15. [Google Scholar]

- Abnisa, F.; Arami-Niya, A.; Daud, W.M.A.W.; Sahu, J.N.; Noor, I.M. Utilization of oil palm tree residues to produce bio-oil and bio-char via pyrolysis. Energy Convers. Manag. 2013, 76, 1073–1082. [Google Scholar] [CrossRef]

- Loh, S.K. The potential of the Malaysian oil palm biomass as a renewable energy source. Energy Convers. Manag. 2017, 141, 285–298. [Google Scholar] [CrossRef]

- Mokhtar, A.; Hassan, K.; Aziz, A.A.; Wahid, M. Plywood from oil palm trunks. J. Oil Palm Res. 2011, 23, 1159–1165. [Google Scholar]

- Abdullah, C.K.; Jawaid, M.; Khalil, H.P.S.A.; Zaidon, A.; Hadiyane, A. Oil palm trunk polymer composite: Morphology, water absorption, and thickness swelling behaviours. BioResources 2012, 7, 2948–2959. [Google Scholar]

- Aizat, A.G.; Zaidon, A.; Nabil, F.L.; Bakar, E.S.; Rasmina, H. Effects of diffusion process and compression on polymer loading of laminated compreg oil palm (Elaeis guineensis) wood and its relation to properties. J. Biobased Mater. Bioenergy 2014, 8, 519–525. [Google Scholar] [CrossRef]

- Baskaran, M.; Azmi, N.A.C.H.; Hashim, R.; Sulaiman, O. Properties of binderless particleboard and particleboard with addition of urea formaldehyde made from oil palm trunk waste. J. Phys. Sci. 2017, 28, 151–159. [Google Scholar] [CrossRef]

- Nuryawan, A.; Abdullah, C.K.; Hazwan, C.M.; Olaiya, N.G.; Yahya, E.B.; Risnasari, I.; Masruchin, N.; Baharudin, M.S.; Khalid, H.; Abdul Khalil, H.P.S. Enhancement of oil palm waste nanoparticles on the properties and characterization of hybrid plywood biocomposites. Polymers 2020, 12, 1007. [Google Scholar] [CrossRef] [PubMed]

- Chin, K. Mechanical and physical properties of oil palm trunk core particleboard bonded with different UF resins. J. Oil Palm Res. 2014, 26, 163–169. [Google Scholar]

- Kaynakli, O. A review of the economical and optimum thermal insulation thickness for building applications. Renew. Sustain. Energy Rev. 2012, 16, 415–425. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Demirhan, C. Mechanical, thermal and acoustical characterizations of an insulation composite made of bio-based materials. Sustain. Cities Soc. 2016, 20, 17–26. [Google Scholar] [CrossRef]

- Bakatovich, A.; Davydenko, N.; Gaspar, F. Thermal insulating plates produced on the basis of vegetable agricultural waste. Energy Build. 2018, 180, 72–82. [Google Scholar] [CrossRef]

- Manohar, K. Experimental investigation of building thermal insulation from agricultural by-products. Br. J. Appl. Sci. Technol. 2012, 2, 227. [Google Scholar] [CrossRef]

- Singh, K.; Saxena, N.S.; Sreekala, M.S.; Thomas, S. Temperature dependence of the thermal conductivity and thermal diffusivity of treated oil-palm-fiber-reinforced phenolformaldehyde composites. J. Appl. Polym. Sci. 2003, 89, 3458–3463. [Google Scholar] [CrossRef]

- Gößwald, J.; Barbu, M.-C.; Petutschnigg, A.; Tudor, E.M. Binderless Thermal Insulation Panels Made of Spruce Bark Fibres. Polymers 2021, 13, 1799. [Google Scholar] [CrossRef]

- Pásztory, Z.; Mohácsiné, I.R.; Börcsök, Z. Investigation of thermal insulation panels made of black locust tree bark. Constr. Build. Mater. 2017, 147, 733–735. [Google Scholar] [CrossRef]

- Tsalagkas, D.; Börcsök, Z.; Pásztory, Z. Thermal, physical and mechanical properties of surface overlaid bark-based insulation panels. Eur. J. Wood Wood Prod. 2019, 77, 721–730. [Google Scholar] [CrossRef]

- Tudor, E.M.; Scheriau, C.; Barbu, M.C.; Réh, R.; Krišťák, Ľ.; Schnabel, T. Enhanced resistance to fire of the bark-based panels bonded with clay. Appl. Sci. 2020, 10, 5594. [Google Scholar] [CrossRef]

- Busquets-Ferrer, M.; Czabany, I.; Vay, O.; Gindl-Altmutter, W.; Hansmann, C. Alkali-extracted tree bark for efficient bio-based thermal insulation. Constr. Build. Mater. 2021, 271, 121577. [Google Scholar] [CrossRef]

- Kristak, L.; Ruziak, I.; Tudor, E.M.; Barbu, M.C.; Kain, G.; Reh, R. Thermophysical Properties of Larch Bark Composite Panels. Polymers 2021, 13, 2287. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.-J.; Kuiper, P.; de Wit, H. Recycling of composite materials. Chem. Eng. Process. Process Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Nguyen, D.M.; Grillet, A.-C.; Bui, Q.-B.; Diep, T.M.H.; Woloszyn, M. Building bio-insulation materials based on bamboo powder and bio-binders. Constr. Build. Mater. 2018, 186, 686–698. [Google Scholar] [CrossRef]

- Edhirej, A.; Sapuan, S.M.; Jawaid, M.; Zahari, N.I. Preparation and characterization of cassava bagasse reinforced thermoplastic cassava starch. Fibers Polym. 2017, 18, 162–171. [Google Scholar] [CrossRef]

- Ali, M.E.; Alabdulkarem, A. On thermal characteristics and microstructure of a new insulation material extracted from date palm trees surface fibers. Constr. Build. Mater. 2017, 138, 276–284. [Google Scholar] [CrossRef]

- Ghahri, S.; Pizzi, A. Improving soy-based adhesives for wood particleboard by tannins addition. Wood Sci. Technol. 2018, 52, 261–279. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, F.; Wu, L.; Gao, Z.; Zhang, L. Assessment of soybean protein-based adhesive formulations, prepared by different liquefaction technologies for particleboard applications. Wood Sci. Technol. 2021, 55, 33–48. [Google Scholar] [CrossRef]

- Arias, A.; Feijoo, G.; Moreira, M.T. Evaluation of Starch as an Environmental-Friendly Bioresource for the Development of Wood Bioadhesives. Molecules 2021, 26, 4526. [Google Scholar] [CrossRef]

- Karthäuser, J.; Biziks, V.; Mai, C.; Militz, H. Lignin and Lignin-Derived Compounds for Wood Applications—A Review. Molecules 2021, 26, 2533. [Google Scholar] [CrossRef]

- Dunky, M. Wood Adhesives Based on Natural Resources: A Critical Review Part I. Protein-Based Adhesives. Rev. Adhes. Adhes. 2020, 8, 199–332. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Neykov, N. Sustainable bio-based adhesives for eco-friendly wood composites. A review. Wood Res 2020, 65, 51–62. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Trichkov, N.; Krišťák, Ľ.; Réh, R.; Papadopoulos, A.N.; Taghiyari, H.R.; Pizzi, A.; Kunecová, D.; Pachikova, M. Properties of High-Density Fiberboard Bonded with Urea–Formaldehyde Resin and Ammonium Lignosulfonate as a Bio-Based Additive. Polymers 2021, 13, 2775. [Google Scholar] [CrossRef] [PubMed]

- Antov, P.; L’uboš, K.; Réh, R.; Savov, V.; Papadopoulos, A.N. Eco-friendly fiberboard panels from recycled fibers bonded with calcium lignosulfonate. Polymers 2021, 13, 639. [Google Scholar] [CrossRef] [PubMed]

- Bekhta, P.; Noshchenko, G.; Réh, R.; Kristak, L.; Sedliačik, J.; Antov, P.; Mirski, R.; Savov, V. Properties of Eco-Friendly Particleboards Bonded with Lignosulfonate-Urea-Formaldehyde Adhesives and pMDI as a Crosslinker. Materials 2021, 14, 4875. [Google Scholar] [CrossRef] [PubMed]

- Syafri, E.; Kasim, A.; Abral, H.; Sulungbudi, G.T.; Sanjay, M.R.; Sari, N.H. Synthesis and characterization of cellulose nanofibers (CNF) ramie reinforced cassava starch hybrid composites. Int. J. Biol. Macromol. 2018, 120, 578–586. [Google Scholar] [CrossRef]

- Asrofi, M.; Syafri, E.; Sapuan, S.M.; Ilyas, R.A. Improvement of biocomposite properties based tapioca starch and sugarcane bagasse cellulose nanofibers. Key Eng. Mater. Trans. Tech. Publ. 2020, 849, 96–101. [Google Scholar] [CrossRef]

- Abral, H.; Dalimunthe, M.H.; Hartono, J.; Efendi, R.P.; Asrofi, M.; Sugiarti, E.; Sapuan, S.M.; Park, J.; Kim, H. Characterization of tapioca starch biopolymer composites reinforced with micro scale water hyacinth fibers. Starch-Stärke 2018, 70, 1700287. [Google Scholar] [CrossRef]

- Yusof, F.M.; Wahab, N.; Rahman, N.L.A.; Kalam, A.; Jumahat, A.; Taib, C.F.M. Properties of treated bamboo fiber reinforced tapioca starch biodegradable composite. Mater. Today Proc. 2019, 16, 2367–2373. [Google Scholar] [CrossRef]

- Abral, H.; Putra, G.J.; Asrofi, M.; Park, J.-W.; Kim, H.-J. Effect of vibration duration of high ultrasound applied to bio-composite while gelatinized on its properties. Ultrason. Sonochem. 2018, 40, 697–702. [Google Scholar] [CrossRef] [PubMed]

- Khalil, H.P.S.A.; Fazita, M.R.N.; Bhat, A.H.; Jawaid, M.; Fuad, N.A.N. Development and material properties of new hybrid plywood from oil palm biomass. Mater. Des. 2010, 31, 417–424. [Google Scholar] [CrossRef]

- Ramlee, N.A.; Jawaid, M.; Zainudin, E.S.; Yamani, S.A.K. Tensile, physical and morphological properties of oil palm empty fruit bunch/sugarcane bagasse fibre reinforced phenolic hybrid composites. J. Mater. Res. Technol. 2019, 8, 3466–3474. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.P.S.A.; Khanam, P.N.; Bakar, A.A. Hybrid composites made from oil palm empty fruit bunches/jute fibres: Water absorption, thickness swelling and density behaviours. J. Polym. Environ. 2011, 19, 106–109. [Google Scholar] [CrossRef]

- Swinkels, J.J.M. Composition and properties of commercial native starches. Starch-Stärke 1985, 37, 1–5. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Jumhuri, N.; Hashim, R.; Sulaiman, O.; Nadhari, W.N.A.W.; Salleh, K.M.; Khalid, I.; Saharudin, N.I.; Razali, M.Z. Effect of treated particles on the properties of particleboard made from oil palm trunk. Mater. Des. 2014, 64, 769–774. [Google Scholar] [CrossRef]

- Jaafar, J.; Siregar, J.P.; Oumer, A.N.; Hamdan, M.H.M.; Tezara, C.; Salit, M.S. Experimental investigation on performance of short pineapple leaf fiber reinforced tapioca biopolymer composites. BioResources 2018, 13, 6341–6355. [Google Scholar]

- Savov, V.; Antov, P. Engineering the Properties of Eco-Friendly Medium Density Fibreboards Bonded with Lignosulfonate Adhesive. Drv. Ind. Znan. Časopis Pitanja Drv. Tehnol. 2020, 71, 157–162. [Google Scholar] [CrossRef]

- Nguyen, D.M.; Grillet, A.-C.; Diep, T.M.H.; Bui, Q.B.; Woloszyn, M. Influence of thermo-pressing conditions on insulation materials from bamboo fibers and proteins based bone glue. Ind. Crops Prod. 2018, 111, 834–845. [Google Scholar] [CrossRef]

- SNI 03-2105-2006. Papan Partikel; Badan Standardisasi Nasional: Jakarta, Indonesia, 2006. [Google Scholar]

- ASTM D-03. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; American Society for Testing and Materials: West Conshohocken, PA, USA, 2003. [Google Scholar]

- ASTM C-97. Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus; American Society for Testing and Materials: West Conshohocken, PA, USA, 1997. [Google Scholar]

- Limam, A.; Zerizer, A.; Quenard, D.; Sallee, H.; Chenak, A. Experimental thermal characterization of bio-based materials (Aleppo Pine wood, cork and their composites) for building insulation. Energy Build. 2016, 116, 89–95. [Google Scholar] [CrossRef]

- Ferrandez-Garcia, M.T.; Ferrandez-Garcia, A.; Garcia-Ortuño, T.; Ferrandez-Garcia, C.E.; Ferrandez-Villena, M. Influence of Particle Size on the Properties of Boards Made from Washingtonia Palm Rachis with Citric Acid. Sustainability 2020, 12, 4841. [Google Scholar] [CrossRef]

- Ferrández-García, C.C.; Ferrández-García, C.E.; Ferrández-Villena, M.; Ferrandez-García, M.T.; García-Ortuño, T. Acoustic and Thermal Evaluation of Palm Panels as Building Material. BioResources 2017, 12, 8047–8057. [Google Scholar]

- Lamaming, J.; Hashim, R.; Sulaiman, O.; Sugimoto, T.; Sato, M.; Hiziroglu, S. Measurement of some properties of binderless particleboards made from young and old oil palm trunks. Measurement 2014, 47, 813–819. [Google Scholar] [CrossRef]

- Debeli, D.K.; Guo, J.; Li, Z.; Zhu, J.; Li, N. Treatment of ramie fiber with different techniques: The influence of diammonium phosphate on interfacial adhesion properties of ramie fiber-reinforced polylactic acid composite. Iran. Polym. J. 2017, 26, 341–354. [Google Scholar] [CrossRef]

- Pan, Z.; Zheng, Y.; Zhang, R.; Jenkins, B.M. Physical properties of thin particleboard made from saline eucalyptus. Ind. Crops Prod. 2007, 26, 185–194. [Google Scholar] [CrossRef]

- Tay, C.C.; Hamdan, S.; Osman, M.S.B. Properties of sago particleboards resinated with UF and PF resin. Adv. Mater. Sci. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Alabdulkarem, A.; Ali, M.; Iannace, G.; Sadek, S.; Almuzaiqer, R. Thermal analysis, microstructure and acoustic characteristics of some hybrid natural insulating materials. Constr. Build. Mater. 2018, 187, 185–196. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Dıncer, A.; Luga, E.; Eken, M.; Isikaltun, O. The possibility of vermiculite, sunflower stalk and wheat stalk using for thermal insulation material production. Therm. Sci. Eng. Prog. 2020, 18, 100567. [Google Scholar] [CrossRef]

- Thoemen, H.; Humphrey, P.E. Modeling the continuous pressing process for wood-based composites. Wood fiber Sci. 2007, 35, 456–468. [Google Scholar]

- Wei, K.; Lv, C.; Chen, M.; Zhou, X.; Dai, Z.; Shen, D. Development and performance evaluation of a new thermal insulation material from rice straw using high frequency hot-pressing. Energy Build. 2015, 87, 116–122. [Google Scholar] [CrossRef]

- Mati-Baouche, N.; De Baynast, H.; Lebert, A.; Sun, S.; Lopez-Mingo, C.J.S.; Leclaire, P.; Michaud, P. Mechanical, thermal and acoustical characterizations of an insulating bio-based composite made from sunflower stalks particles and chitosan. Ind. Crops Prod. 2014, 58, 244–250. [Google Scholar] [CrossRef]

- Muthuraj, R.; Lacoste, C.; Lacroix, P.; Bergeret, A. Sustainable thermal insulation biocomposites from rice husk, wheat husk, wood fibers and textile waste fibers: Elaboration and performances evaluation. Ind. Crops Prod. 2019, 135, 238–245. [Google Scholar] [CrossRef]

- Paul, S.A.; Boudenne, A.; Ibos, L.; Candau, Y.; Joseph, K.; Thomas, S. Effect of fiber loading and chemical treatments on thermophysical properties of banana fiber/polypropylene commingled composite materials. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1582–1588. [Google Scholar] [CrossRef]

- Hashim, R.; Saari, N.; Sulaiman, O.; Sugimoto, T.; Hiziroglu, S.; Sato, M.; Tanaka, R. Effect of particle geometry on the properties of binderless particleboard manufactured from oil palm trunk. Mater. Des. 2010, 31, 4251–4257. [Google Scholar] [CrossRef]

- Almusawi, A.; Lachat, R.; Atcholi, K.E.; Gomes, S. Proposal of manufacturing and characterization test of binderless hemp shive composite. Int. Biodeterior. Biodegradation 2016, 115, 302–307. [Google Scholar] [CrossRef]

- Lim, S.C.; Gan, K.S. Characteristics and utilization of oil palm stem. Timber Technol. Bull. 2005, 35, 1–7. [Google Scholar]

- Nasir, M.; Khali, D.P.; Jawaid, M.; Tahir, P.M.; Siakeng, R.; Asim, M.; Khan, T.A. Recent development in binderless fiber-board fabrication from agricultural residues: A review. Constr. Build. Mater. 2019, 211, 502–516. [Google Scholar] [CrossRef]

- Jawaid, M.; Saba, N.; Alothman, O.Y.; Khalil, H.P.S.A.; Mariatti, M. Thermal conductivity behavior of oil palm/jute fibre-reinforced hybrid composites. In Proceedings of the AIP Conference Proceedings; AIP Publishing LLC: Langkawi, Malaysia, 2016; Volume 1901, p. 30007. [Google Scholar]

- Lomelí-Ramírez, M.G.; Kestur, S.G.; Manríquez-González, R.; Iwakiri, S.; De Muniz, G.B.; Flores-Sahagun, T.S. Bio-composites of cassava starch-green coconut fiber: Part II—Structure and properties. Carbohydr. Polym. 2014, 102, 576–583. [Google Scholar] [CrossRef]

- Mawardi, I.; Rizal, S.; Aprilia, S.; Faisal, M. Thermal Characteristics of Oil Palm Wood and Ramie Fiber as Raw Materials for Thermal Insulation Bio Board. In Proceedings of the 2nd International Conference on Experimental and Computational Mechanics in Engineering, Banda Aceh, Indonesia, 13–14 October 2020; Springer: Banda Aceh, Indonesia, 2020; pp. 21–31. [Google Scholar]

- Baskaran, M.; Hashim, R.; Said, N.; Raffi, S.M.; Balakrishnan, K.; Sudesh, K.; Sulaiman, O.; Arai, T.; Kosugi, A.; Mori, Y. Properties of binderless particleboard from oil palm trunk with addition of polyhydroxyalkanoates. Compos. Part B Eng. 2012, 43, 1109–1116. [Google Scholar] [CrossRef]

- Jonoobi, M.; Khazaeian, A.; Tahir, P.M.; Azry, S.S.; Oksman, K. Characteristics of cellulose nanofibers isolated from rubberwood and empty fruit bunches of oil palm using chemo-mechanical process. Cellulose 2011, 18, 1085–1095. [Google Scholar] [CrossRef]

- Komariah, R.N.; Miyamoto, T.; Tanaka, S.; Prasetiyo, K.W.; Syamani, F.A.; Umezawa, T.; Kanayama, K.; Umemura, K. High-performance binderless particleboard from the inner part of oil palm trunk by addition of ammonium dihydrogen phosphate. Ind. Crops Prod. 2019, 141, 111761. [Google Scholar] [CrossRef]

- Al-Khanbashi, A.; Al-Kaabi, K.; Hammami, A. Date palm fibers as polymeric matrix reinforcement: Fiber characterization. Polym. Compos. 2005, 26, 486–497. [Google Scholar] [CrossRef]

| Description | OPW | Ramie Fiber | Tapioca Starch |

|---|---|---|---|

| Chemical constituents (%) | 29–37 | 68.6–76.2 | |

| Cellulose | 12–17 | 13.1–16.7 | |

| Hemi cellulose | 18–23 | 0.60–0.80 | - |

| Lignin | - | - | - |

| Amylose | - | - | - |

| Amylopectin | - | - | - |

| Physical and mechanical properties | - | - | 17 |

| Density (g/cm3) | 0.15–0.4 | 1.50 | 83 |

| Tensile strength (MPa) | 300–600 | 290–1060 | |

| Young’s modulus (GPa) | 15–32 | 5–128 |

| Type | Code | Particle Classification | OPW (%) | Ramie Fiber (%) | Tapioca Starch (%) |

|---|---|---|---|---|---|

| Pure bio-panels | P1 | coarse | 70 | 0 | 30 |

| P2 | medium | 70 | 0 | 30 | |

| P3 | fine | 70 | 0 | 30 | |

| Hybrid bio-panels | H1 | coarse | 50 | 20 | 30 |

| H2 | medium | 50 | 20 | 30 | |

| H3 | fine | 50 | 20 | 30 |

| Kode | Density (g/cm3) | MC (%) | WA (%) | DS (%) | BS (MPa) | MOE (MPa) | k (W/mK) |

|---|---|---|---|---|---|---|---|

| Pure bio-panels | |||||||

| P1 | 0.69 | 13 | 65.48 | 30.28 | 13.88 | 3093 | 0.071 |

| P2 | 0.72 | 13 | 58.72 | 29.70 | 13.73 | 2604 | 0.110 |

| P3 | 0.75 | 13 | 56.69 | 24.49 | 11.49 | 1864 | 0.154 |

| Hybrid bio-panels | |||||||

| H1 | 0.66 | 14 | 65.12 | 29.63 | 18.15 | 2605 | 0.067 |

| H2 | 0.75 | 13 | 55.59 | 25.00 | 17.83 | 2546 | 0.089 |

| H3 | 0.79 | 13 | 54.75 | 18.18 | 16.26 | 1984 | 0.148 |

| Bio-Panel | Weight Loss at Temp. Decomposition (°C) | Weight Residue at 600 °C | ||

|---|---|---|---|---|

| 25% | 50% | 75% | ||

| Pure | 321 | 349 | 394 | 12 |

| Hybrid | 327 | 358 | 421 | 19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mawardi, I.; Aprilia, S.; Faisal, M.; Rizal, S. Characterization of Thermal Bio-Insulation Materials Based on Oil Palm Wood: The Effect of Hybridization and Particle Size. Polymers 2021, 13, 3287. https://doi.org/10.3390/polym13193287

Mawardi I, Aprilia S, Faisal M, Rizal S. Characterization of Thermal Bio-Insulation Materials Based on Oil Palm Wood: The Effect of Hybridization and Particle Size. Polymers. 2021; 13(19):3287. https://doi.org/10.3390/polym13193287

Chicago/Turabian StyleMawardi, Indra, Sri Aprilia, Muhammad Faisal, and Samsul Rizal. 2021. "Characterization of Thermal Bio-Insulation Materials Based on Oil Palm Wood: The Effect of Hybridization and Particle Size" Polymers 13, no. 19: 3287. https://doi.org/10.3390/polym13193287

APA StyleMawardi, I., Aprilia, S., Faisal, M., & Rizal, S. (2021). Characterization of Thermal Bio-Insulation Materials Based on Oil Palm Wood: The Effect of Hybridization and Particle Size. Polymers, 13(19), 3287. https://doi.org/10.3390/polym13193287